Assessing Cross Laminated Timber (CLT) as an Alternative Material for Mid-Rise Residential Buildings in Cold Regions in China—A Life-Cycle Assessment Approach

Abstract

:1. Introduction

2. Description of the Case Studies Buildings and Environment

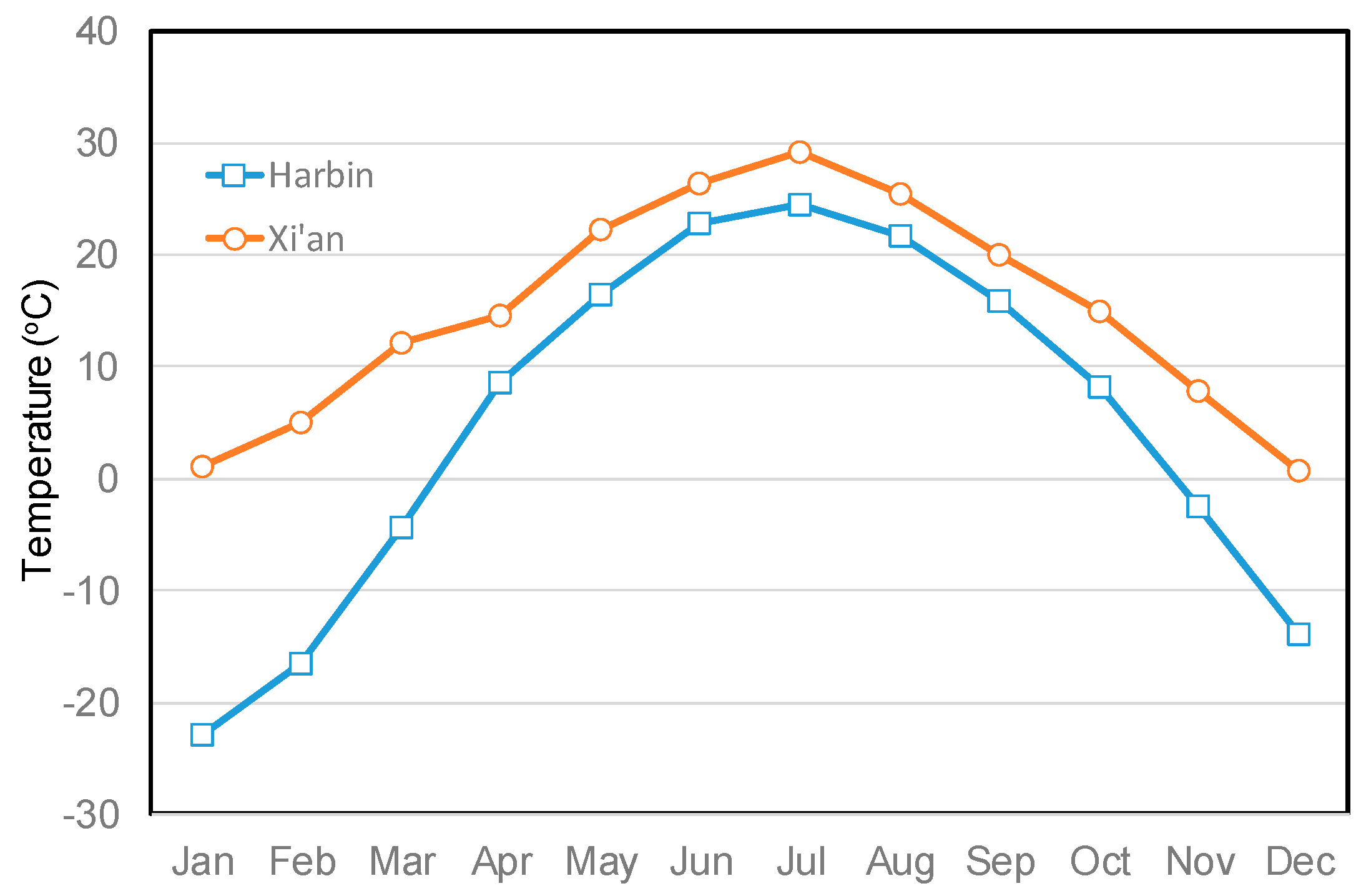

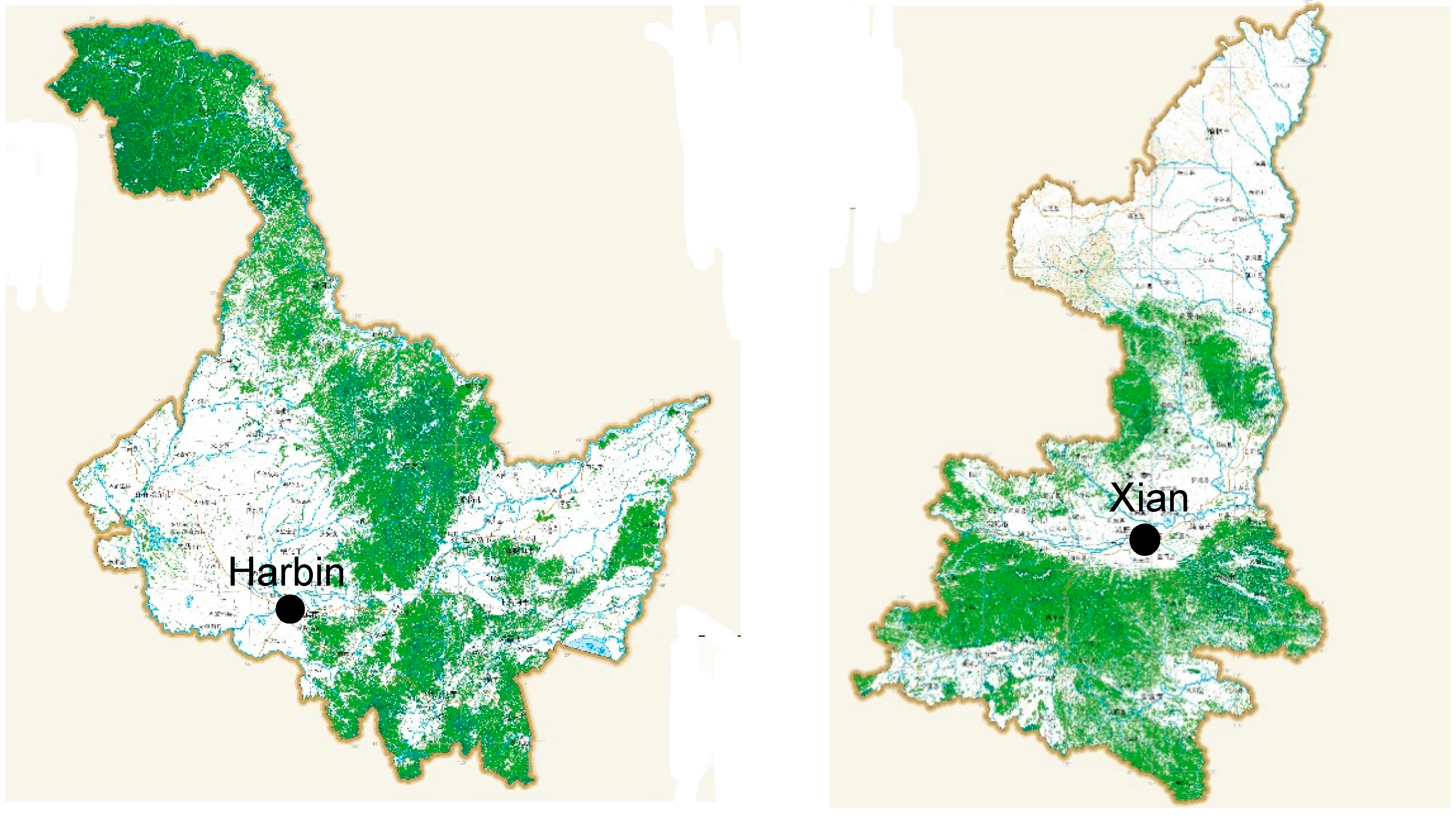

2.1. Weather Regions of Harbin and Xi’an

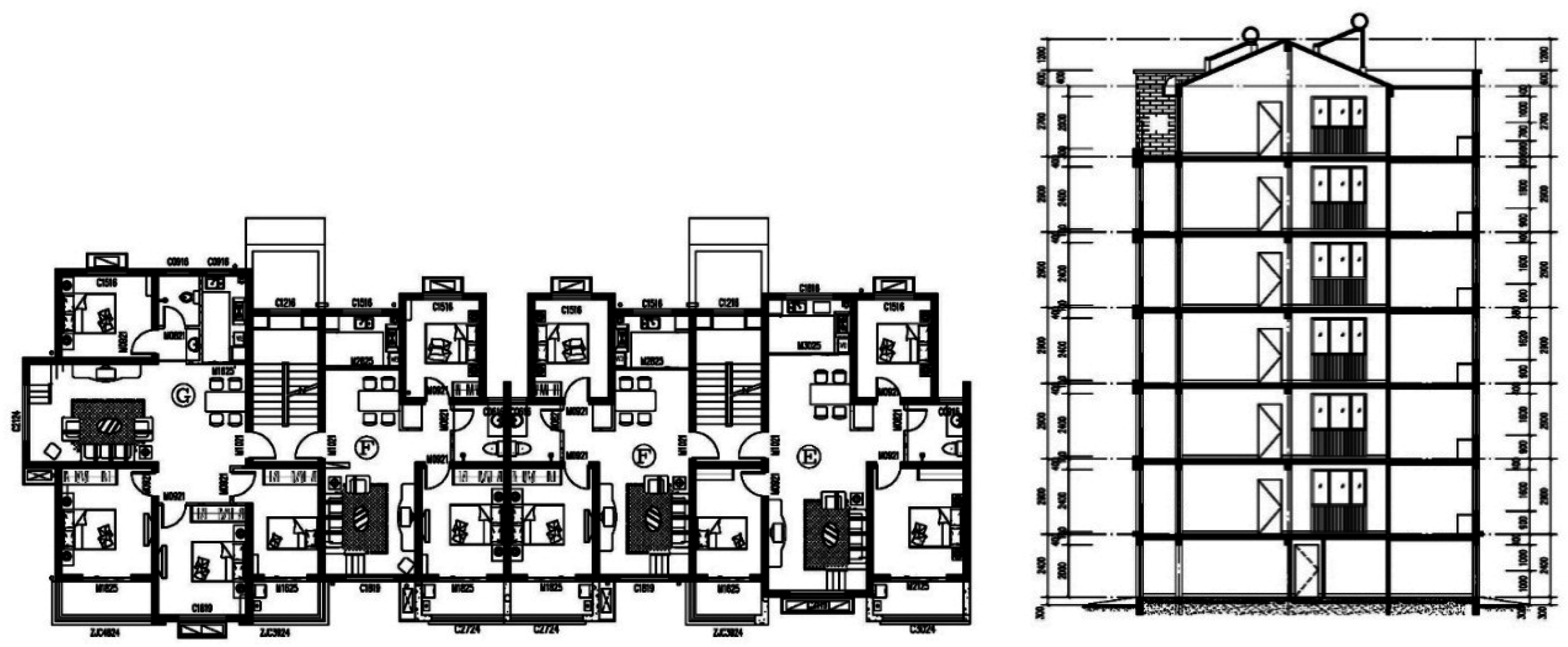

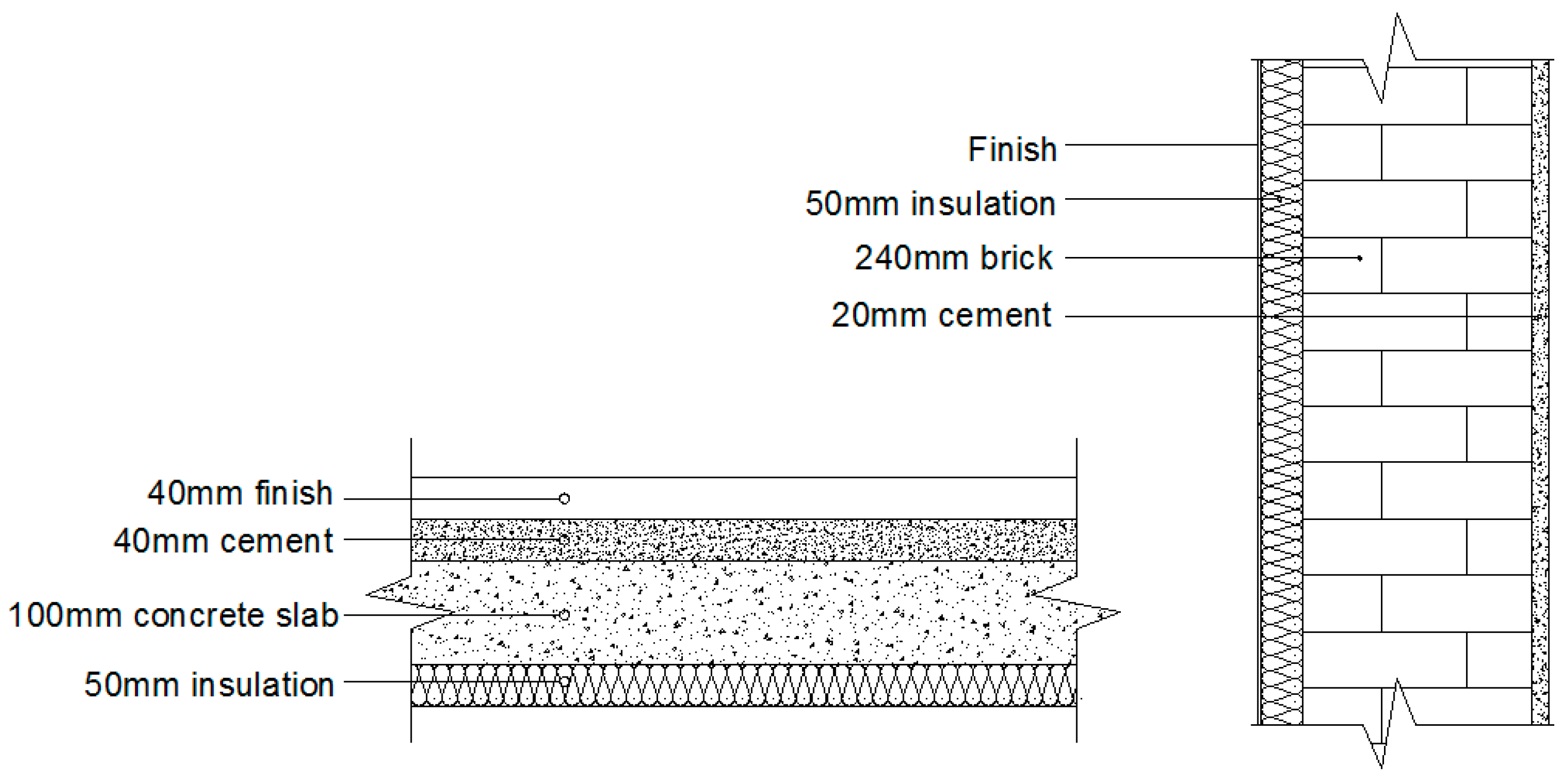

2.2. Concrete Structures

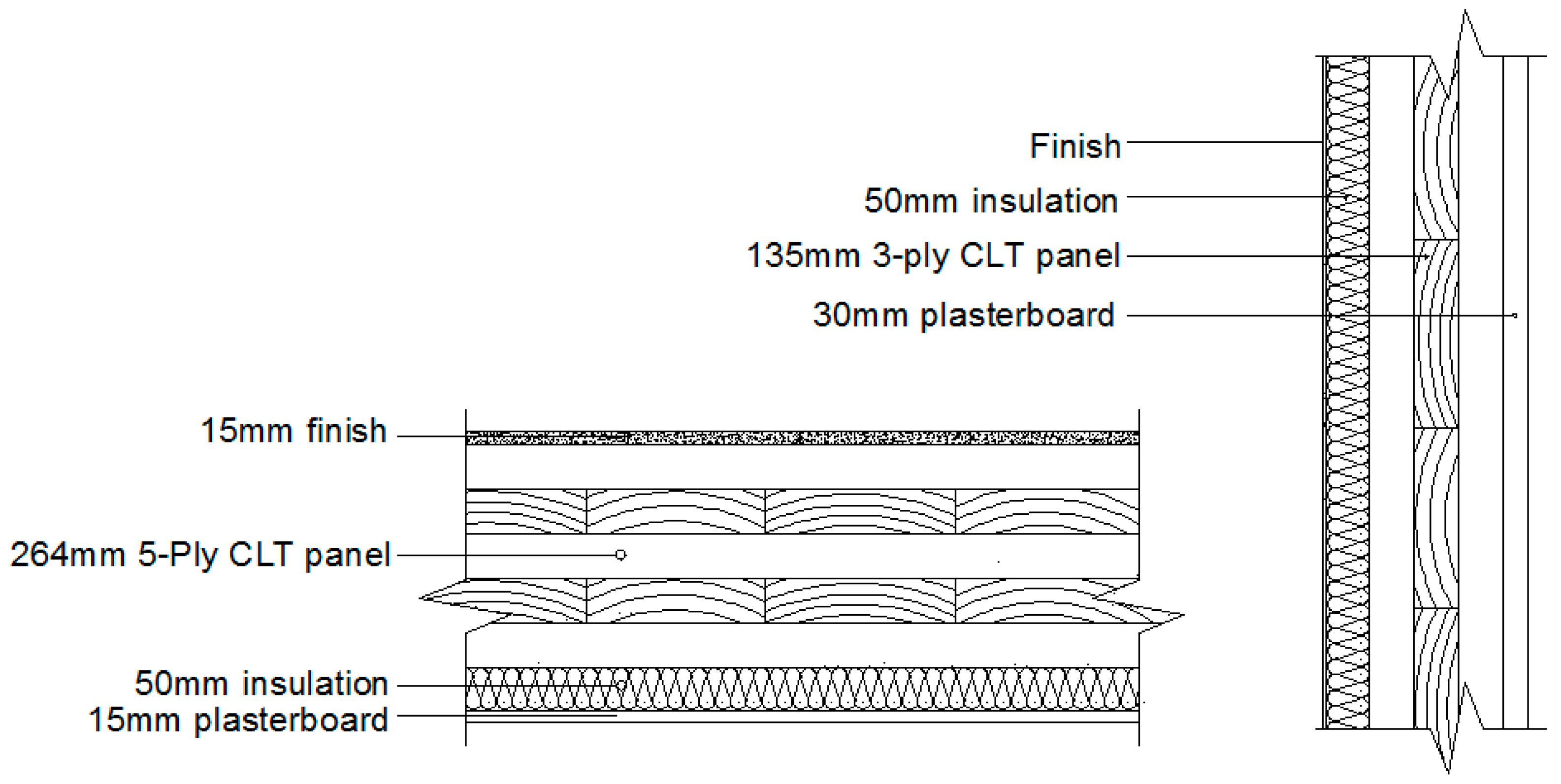

2.3. CLT Substitution Design

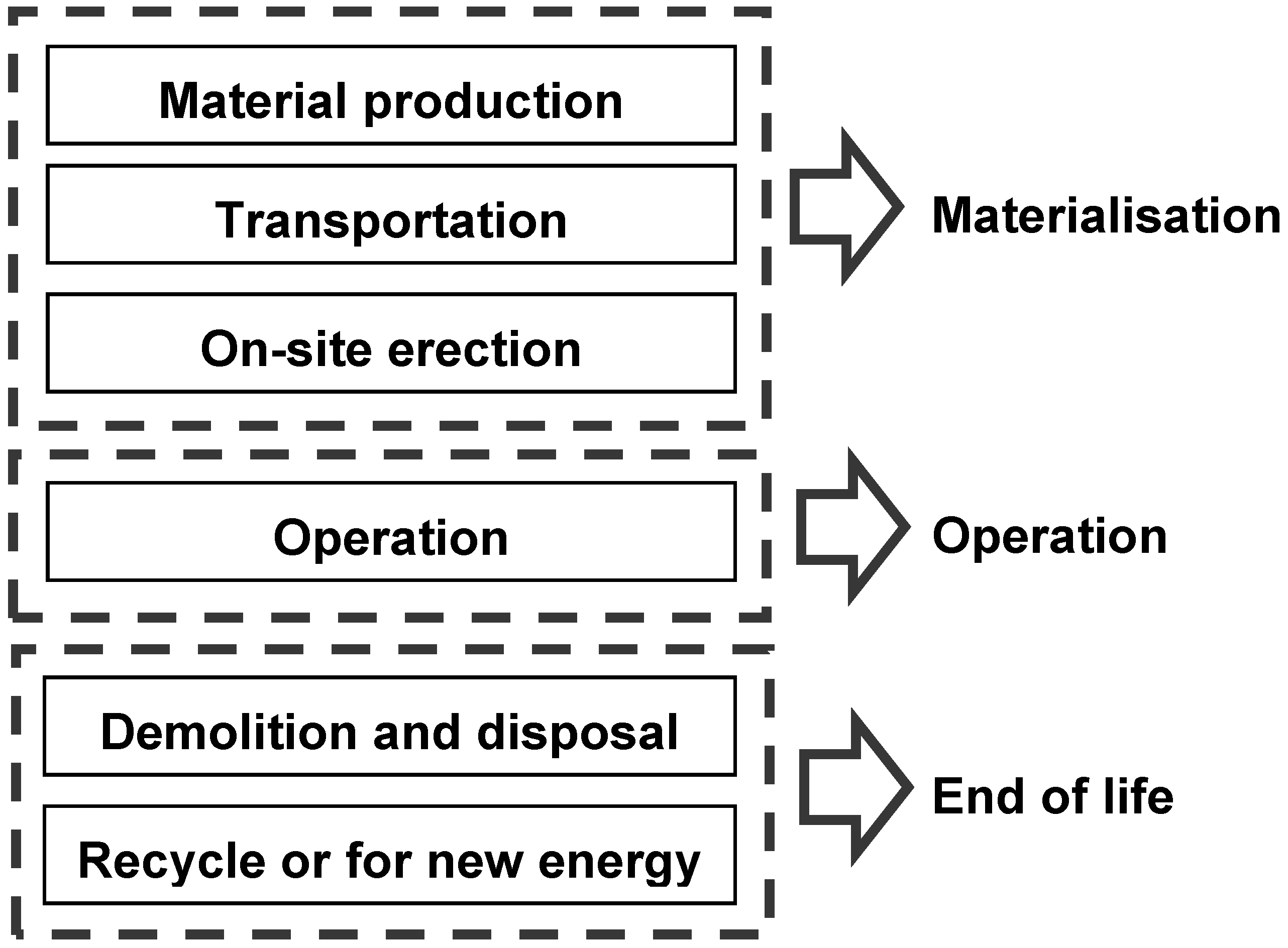

3. Life-Cycle Assessment Framework

3.1. The Framework

3.2. Materialisation Stage

- (1)

- Energy consumed and carbon emission produced by decoration of concrete structures were neglected.

- (2)

- Fasteners for construction of CLT were not considered due to the small amount of volume when compare with CLT panels.

- (3)

- The carbon sequestration of CLT is considered in the assessment with the assumption that 1 cubic metre of timber would store 800 kg of CO2.

- (4)

- Erection of CLT buildings is set to be 20 MJ/m2 [8].

- (5)

- The boundary of the materials including concrete, sand, cement, steel and brick start from the extraction of the raw materials, whereas that for CLT starts from harvesting the tree.

3.3. Operation Stage (Modelling Approach and Its Assumptions)

- (1)

- Only energy used for heating, cooling and lighting is simulated.

- (2)

- The locations of windows are not changed when altering CLT from concrete and therefore the lighting requirements are not changed.

- (3)

- The indoor temperature is controlled between 18 °C and 26 °C in all rooms except for balconies. The lights were assumed to be switched on in bedrooms between 21:00–24:00 and in living rooms between 18:00 to 21:00.

- (4)

- Internal heat gain was assumed to be 90 W per person

- (5)

- Areas for staircases are not heated or cooled.

- (6)

- The ventilation rate is assumed to be 30 m3 per hour per person.

- (7)

- Electricity is used for cooling and lighting whereas coal is used for heating. This is the current practice in China.

3.4. End-of-Life Stage

4. Results and Discussion

4.1. Quality of Data and Uncertainties of the Assessment

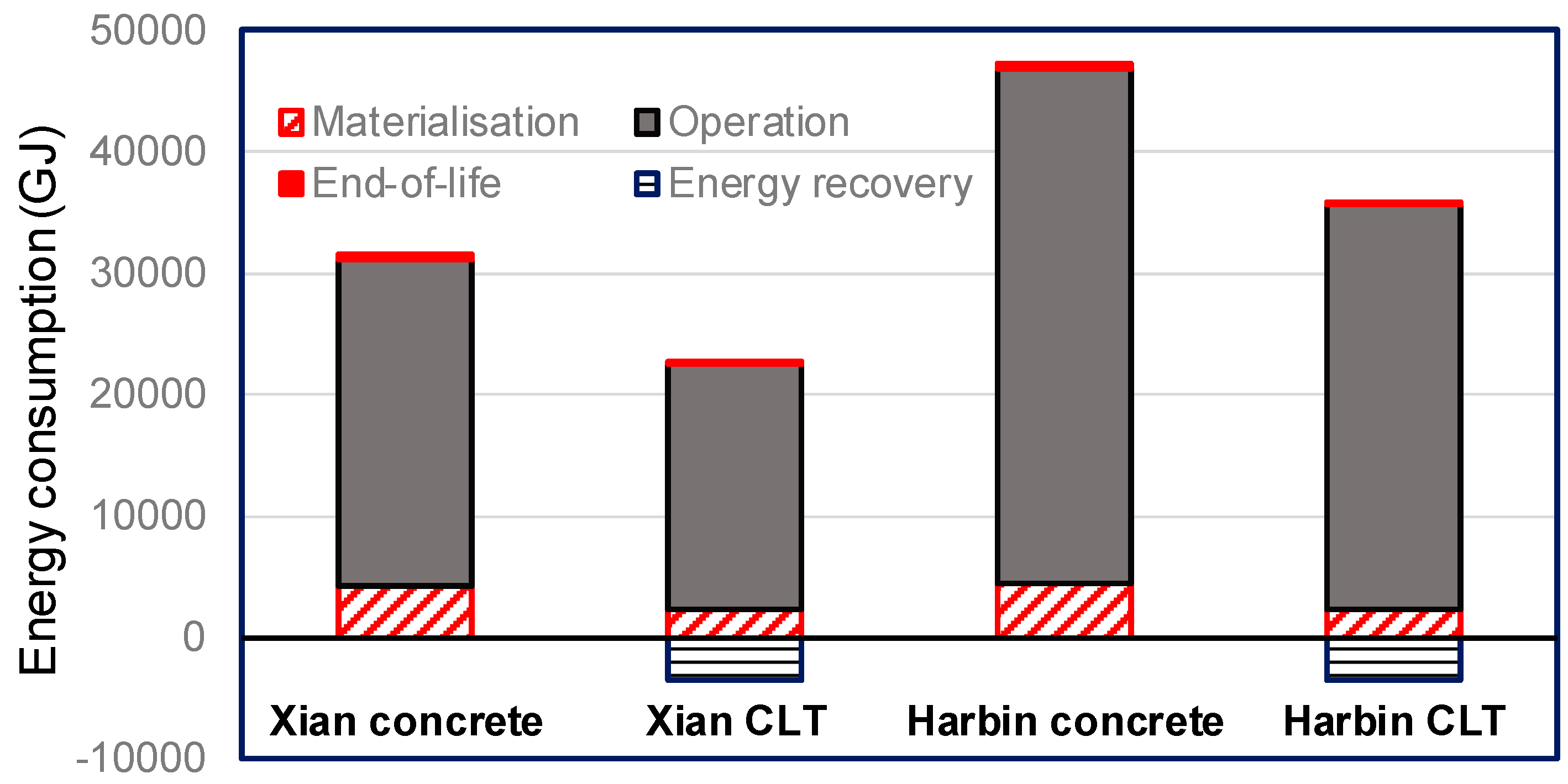

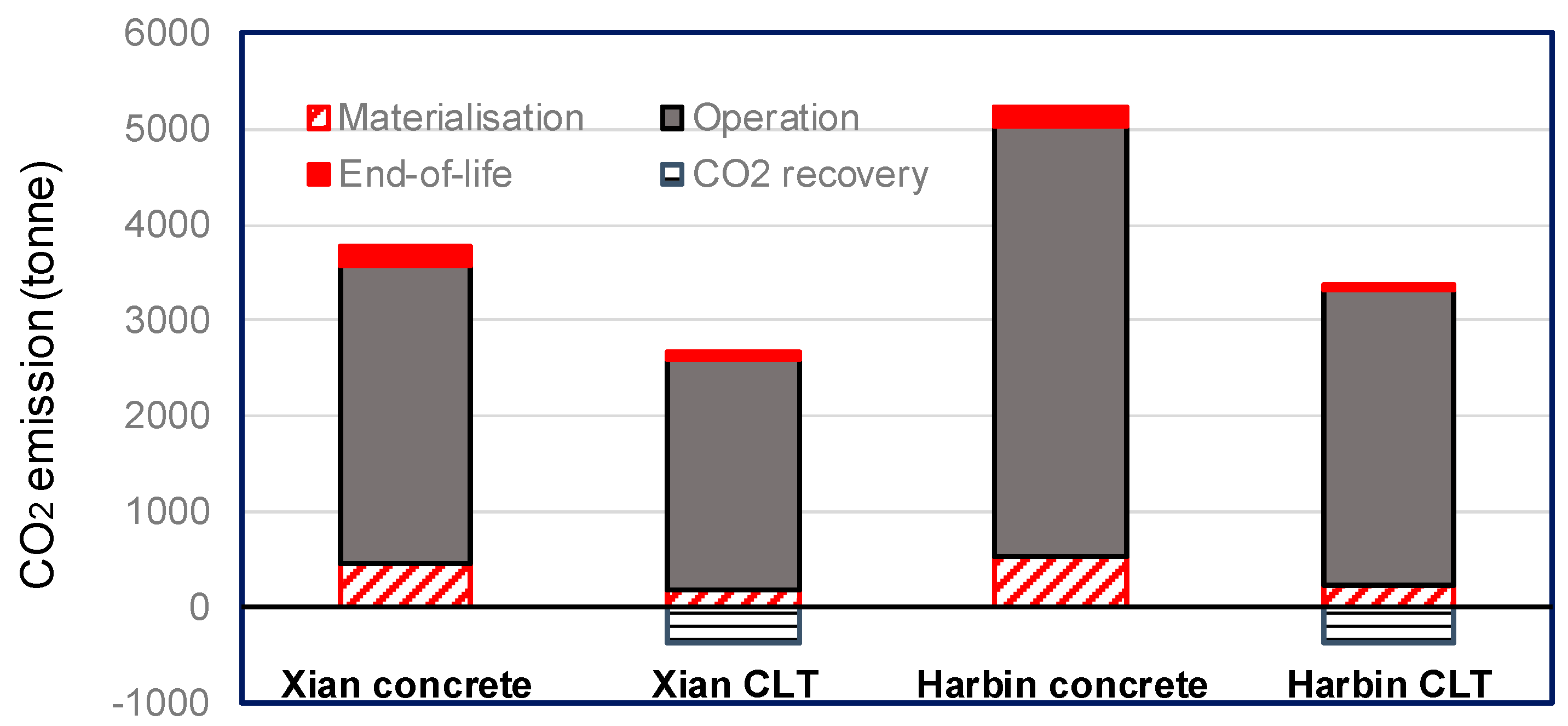

4.2. Energy Consumptions and CO2 Emissions

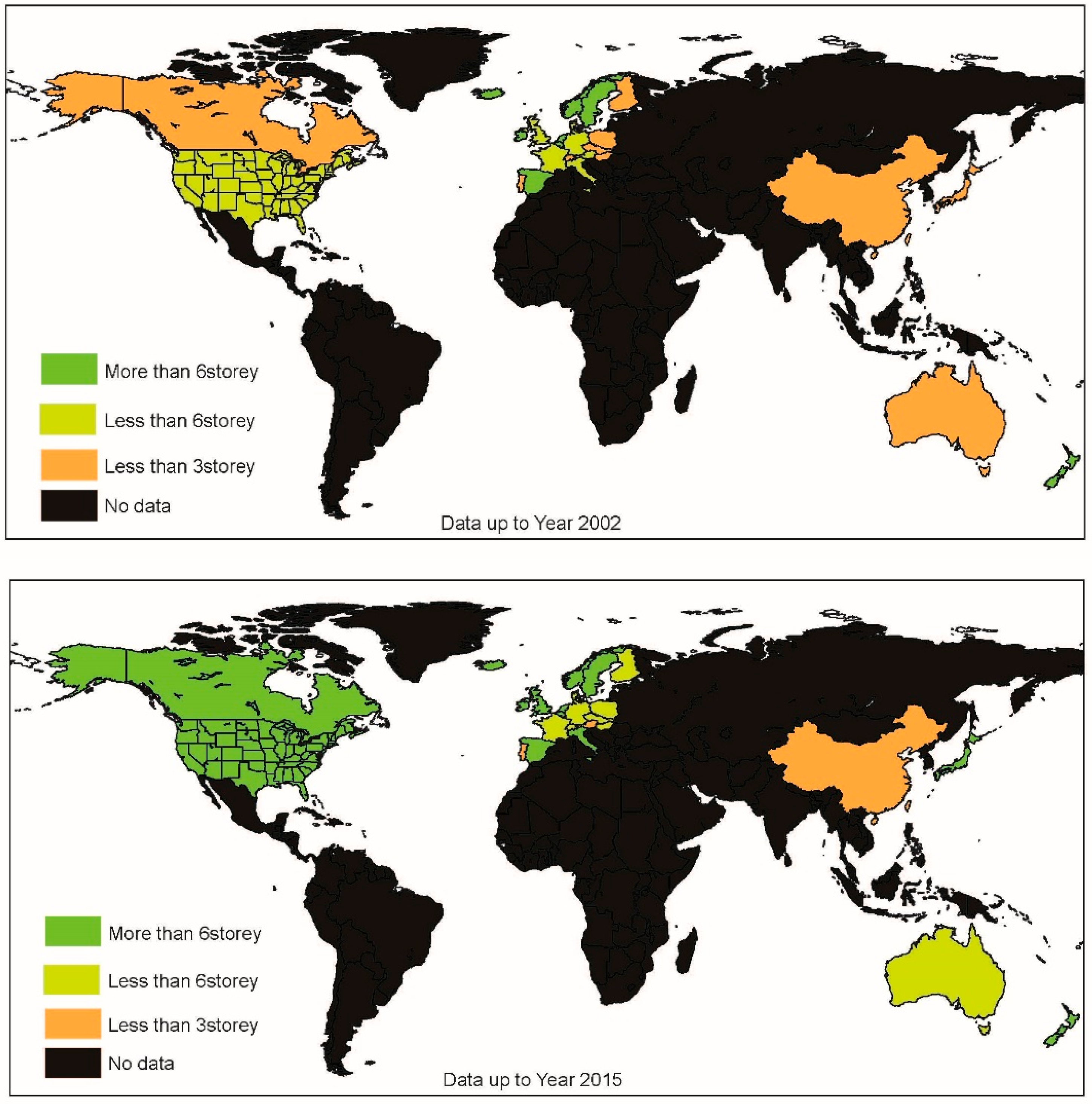

4.3. Forest Resource Distribution in China

4.4. Legal Implementations

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chau, C.K.; Hui, W.K.; Ng, W.Y.; Powell, G. Assessment of CO2 emissions reduction in high-rise concrete office buildings using different material use options. Resour. Conserv. Recycl. 2012, 61, 22–34. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, R.; Liu, M.; Bi, J. The carbon emissions of Chinese cities. Atmos. Chem. Phys. 2012, 12, 6197–6206. [Google Scholar] [CrossRef]

- Yu, X.; Qu, H. The role of China’s renewable powers against climate change during the 12th Five-Year and until 2020. Renew. Sustain. Energy Rev. 2013, 22, 401–409. [Google Scholar] [CrossRef]

- Zhang, Z. Assessing China’s carbon intensity pledge for 2020: Stringency and credibility issues and their implications. Environ. Econ. Policy Stud. 2011, 13, 219–235. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development. Action Plan to Promote Green Building Materials Production and Building Applications; China Construction Industry Publishing House: Beijing, China, 2015. (In Chinese) [Google Scholar]

- Lo, K. China’s low-carbon city initiatives: The implementation gap and the limits of the target responsibility system. Habitat Int. 2014, 42, 236–244. [Google Scholar] [CrossRef]

- Dijk, M.; Blom, I.; Salet, T.; Marinus, P. Environmental impact as a parameter in concrete structure parametric associative models. Constr. Build. Mater. 2014, 67, 360–365. [Google Scholar] [CrossRef]

- Gong, X.; Nie, Z.; Wang, Z.; Cui, S.; Gao, F.; Zuo, T. Life cycle energy consumption and carbon dioxide emission of residential building designs in Beijing. J. Ind. Ecol. 2012, 16, 576–587. [Google Scholar] [CrossRef]

- Eriksson, P.E. Comparative LCAs for wood and other construction methods. In Proceedings of the World Conference on Timber Engineering, Lahti, Finland, 14–17 June 2004.

- Gustavsson, L.; Sathre, R. Variability in energy and carbon dioxide balances of wood and concrete building materials. Build. Environ. 2006, 41, 940–951. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Cabeza, L.; Labrincha, J.; De Magalhaes, A. Comparing the environmental impact of reinforced concrete and wooden structures. In Eco-Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Guardigli, L., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2014; pp. 407–433. [Google Scholar]

- Mallo, M.F.L.; Espinoza, O.A. Outlook for cross-laminated timber in the United States. BioResources 2014, 9, 7427–7443. [Google Scholar]

- Crespell, P.; Gagnon, S. Cross Laminated Timber: A primer; Fpinnovations: Vancouver, QC, Canada, 2010. [Google Scholar]

- Stanić, A.; Hudobivnik, B.; Brank, B. Economic-design optimization of cross laminated timber plates with ribs. Compos. Struct. 2016, 154, 527–537. [Google Scholar] [CrossRef]

- Lineham, S.A.; Thomson, D.; Bartlett, A.I.; Bisby, L.A.; Hadden, R.M. Structural response of fire-exposed cross-laminated timber beams under sustained loads. Fire Saf. J. 2016, 85, 23–34. [Google Scholar] [CrossRef]

- Sikora, K.S.; McPolin, D.O.; Harte, A.M. Effects of the thickness of cross-laminated timber (CLT) panels made from Irish Sitka spruce on mechanical performance in bending and shear. Constr. Build. Mater. 2016, 116, 141–150. [Google Scholar] [CrossRef]

- Aicher, S.; Hirsch, M.; Christian, Z. Hybrid cross-laminated timber plates with beech wood cross-layers. Constr. Build. Mater. 2016, 124, 1007–1018. [Google Scholar] [CrossRef]

- Khavari, A.M.; Pei, S.; Tabares-Velasco, P.C. Energy Consumption Analysis of Multistory Cross-Laminated Timber Residential Buildings: A Comparative Study. J. Archit. Eng. 2016, 22, 04016002. [Google Scholar] [CrossRef]

- Harley, T.; White, G.; Dowdall, A.; Bawcombe, J.; McRobie, A.; Steinke, R. Dalston Lane—The world’s tallest CLT building. In Proceedings of the World Conference on Timber Engineering (WCTE 2016), Vienna, Austria, 22–25 August 2016.

- Ministry of Housing and Urban-Rural Development. Code for Design of Civil Buildings (GB 50352-2005); China Construction Industry Publishing House: Beijing, China, 2005. (In Chinese) [Google Scholar]

- Ministry of Housing and Urban-Rural Development. Energy Conservation Design Standard for New Heating Residential Buildings (JGJ26-2010); China Construction Industry Publishing House: Beijing, China, 2010. (In Chinese) [Google Scholar]

- European Committee for Standardization (CEN). Eurocode 5 Design of Timber Structures—Part 1–1: General Rules and Rules for Buildings; European Committee for Standardization: Bruxelles, Belgium, 2003. [Google Scholar]

- Timber Research and Development Association (TRADA). Cross-Laminated Timber (Eurocode 5) Design Guide for Project Feasibility; TRADA Technology: London, UK, 2009. [Google Scholar]

- British Standard Insitute. Structural Timber, Strength Classes; British Standards Institute: London, UK, 2009. [Google Scholar]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Hollberg, A.; Ruth, J. LCA in architectural design—A parametric approach. Int. J. Life Cycle Assess. 2016. [Google Scholar] [CrossRef]

- Robertson, A.B.; Lam, F.C.; Cole, R.J. A comparative cradle-to-gate life cycle assessment of mid-rise office building construction alternatives: Laminated timber or reinforced concrete. Buildings 2012, 2, 245–270. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Peng, Y.; Mao, C. Uncertainty analysis for measuring greenhouse gas emissions in the building construction phase: A case study in China. J. Clean. Prod. 2016, 129, 183–195. [Google Scholar] [CrossRef]

- Zhou, X.X.; Song, Z.L. The life cycle assessment of two kinds of concretes. Environ. Eng. 2009, S1, 472–475. (In Chinese) [Google Scholar]

- IKE. Chinese Life Cycle Database—CLCD (2016). Available online: http://www.ike-global.com/products-2/chinese-lca-database-clcd (accessed on 9 June 2016).

- Sui, X. Exergetic Life-Cycle Assessment of Cement Production Processes. Master’s Thesis, Dalian University of Technology, Dalian, China, 2014. [Google Scholar]

- Wang, L.S.; Zhang, L.F. Life Cycle assessment of environmental impacts for the whole steel production process. China Popul. Resour. Environ. 2012, 22, 239–244. [Google Scholar]

- Li, Q.J.; Liu, J. Lifecycle energy consumption and carbon emissions of aerated concrete block and sintered shale hollow brick. J. Chongqing Coll. Electron. Eng. 2015, 24, 148–151. (In Chinese) [Google Scholar]

- Athena Sustainable Materials Institute (ASMI). A Life Cycle Assessment of Cross-Laminated Timber Produced in Canada; Athena Sustainable Materials Institute: Ottawa, ON, Canada, 2013. [Google Scholar]

- Li, Z.; Gong, X.Z.; Wang, Z.H.; Liu, Y.; Ma, L.P.; Wang, S.P.; Guo, J. Life cycle assessment of rock wool board and EPS board. Mater. Sci. Forum 2014. [Google Scholar] [CrossRef]

- Spielmann, M.; Scholz, R. Life cycle inventories of transport services: Background data for freight transport. Int. J. Life Cycle Assess. 2005, 10, 85–94. [Google Scholar] [CrossRef]

- Zhang, X. Carbon Emissions Measurement Methods and Comparative Studies on Green Building Structural System. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2014. [Google Scholar]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

| Products | Function Units | Value | Reference |

|---|---|---|---|

| Concrete | GJ/t | 0.764 | [29] |

| Sand | GJ/t | 0.029 | [30] |

| Cement | GJ/t | 3.186 | [31] |

| Steel | GJ/t | 19.52 | [32] |

| Brick | GJ/t | 0.218 | [33] |

| CLT | GJ/m3 | 0.545 | [34] |

| Gypsum board | GJ/m3 | 2.400 | [30] |

| Expanded polystyrene | GJ/t | 94.00 | [35] |

| Transportation (train) | MJ/t∙km | 0.220 | [36] |

| Transportation (lorries) | MJ/t∙km | 2.300 | [36] |

| Xi’an (GJ/m2) | Harbin (GJ/m2) | |

|---|---|---|

| Concrete | 11.29 | 16.90 |

| CLT | 6.84 | 11.56 |

| CLT Recycling Ratio | Material | Xi’an (t/m2) | Harbin (t/m2) |

|---|---|---|---|

| NA | Concrete | 1.35 | 1.87 |

| 55% | CLT | 0.82 | 1.07 |

| 90% | CLT | 0.73 | 0.99 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Guo, H.; Sun, C.; Chang, W.-S. Assessing Cross Laminated Timber (CLT) as an Alternative Material for Mid-Rise Residential Buildings in Cold Regions in China—A Life-Cycle Assessment Approach. Sustainability 2016, 8, 1047. https://doi.org/10.3390/su8101047

Liu Y, Guo H, Sun C, Chang W-S. Assessing Cross Laminated Timber (CLT) as an Alternative Material for Mid-Rise Residential Buildings in Cold Regions in China—A Life-Cycle Assessment Approach. Sustainability. 2016; 8(10):1047. https://doi.org/10.3390/su8101047

Chicago/Turabian StyleLiu, Ying, Haibo Guo, Cheng Sun, and Wen-Shao Chang. 2016. "Assessing Cross Laminated Timber (CLT) as an Alternative Material for Mid-Rise Residential Buildings in Cold Regions in China—A Life-Cycle Assessment Approach" Sustainability 8, no. 10: 1047. https://doi.org/10.3390/su8101047

APA StyleLiu, Y., Guo, H., Sun, C., & Chang, W.-S. (2016). Assessing Cross Laminated Timber (CLT) as an Alternative Material for Mid-Rise Residential Buildings in Cold Regions in China—A Life-Cycle Assessment Approach. Sustainability, 8(10), 1047. https://doi.org/10.3390/su8101047