Author Contributions

Conceptualization, A.K.K., I.-H.S. and I.-S.K.; methodology, A.K.K. and I.-S.K.; software, A.K.K.; validation, A.K.K., I.-H.S. and I.-S.K.; formal analysis, A.K.K.; investigation, A.K.K.; resources, I.-H.S. and I.-S.K.; data curation, I.-S.K.; writing—original draft preparation, A.K.K.; writing—review and editing, A.K.K.; visualization I.-S.K.; supervision I.-H.S. and I.-S.K.; project administration, I.-S.K.; funding acquisition, I.-H.S. and I.-S.K. All authors have read and agreed to the published version of the manuscript.

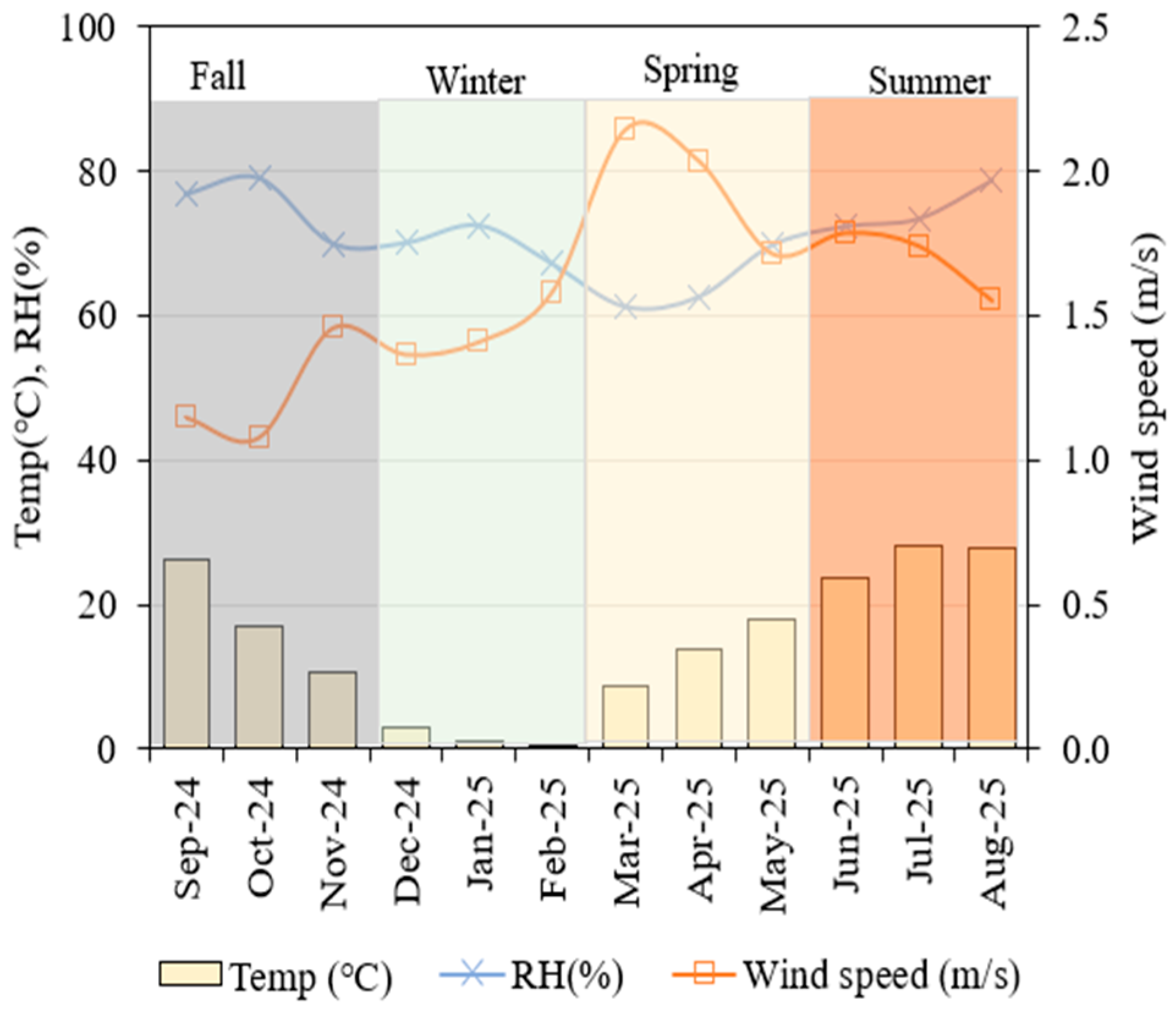

Figure 1.

Seasonal variations in ambient environmental conditions (temperature, relative humidity, and wind speed) obtained from the nearest Korea Meteorological Administration (KMA) station during the measurement period. Wind speed corresponds to the standard 10 m measurement height.

Figure 1.

Seasonal variations in ambient environmental conditions (temperature, relative humidity, and wind speed) obtained from the nearest Korea Meteorological Administration (KMA) station during the measurement period. Wind speed corresponds to the standard 10 m measurement height.

Figure 2.

Experimental site location and layout of the wastewater treatment system used for GHG monitoring. (A) Geographical location of the study site in Korea. (B) Aerial view of the farm and waste treatment facility showing sampling points (1 to10) and key units (a to d). (C) Illustration of the treatment sequence, tank dimensions, and sampling stages.

Figure 2.

Experimental site location and layout of the wastewater treatment system used for GHG monitoring. (A) Geographical location of the study site in Korea. (B) Aerial view of the farm and waste treatment facility showing sampling points (1 to10) and key units (a to d). (C) Illustration of the treatment sequence, tank dimensions, and sampling stages.

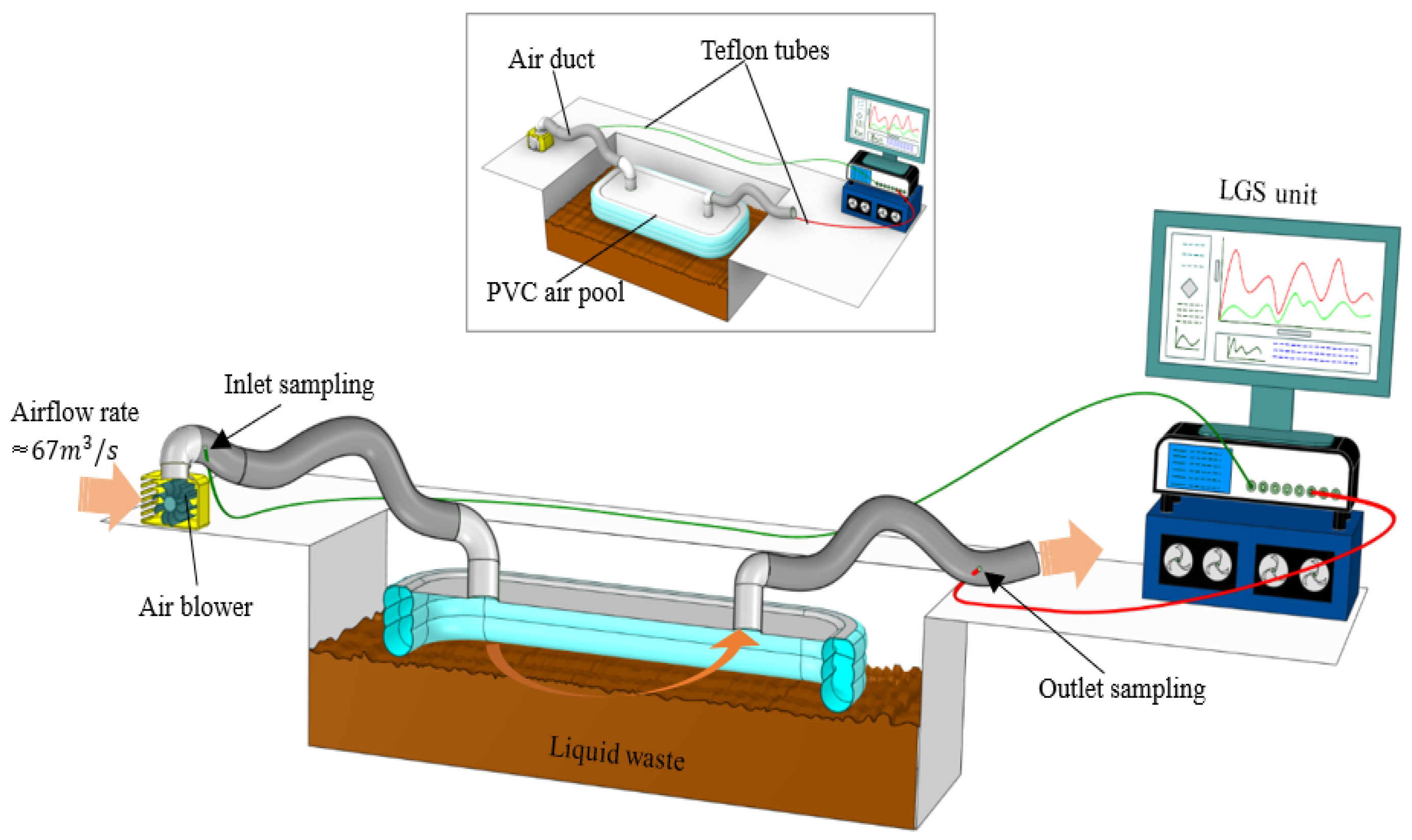

Figure 3.

Schematic illustration of gas collection and monitoring setup, showing the isometric and cross-sectional views of the PVC air pool system. The setup includes an air blower airflow, Teflon sampling tubes for inlet and outlet gas collection, and a laser gas spectrometer (LGS) unit for real-time CH4 and N2O measurement.

Figure 3.

Schematic illustration of gas collection and monitoring setup, showing the isometric and cross-sectional views of the PVC air pool system. The setup includes an air blower airflow, Teflon sampling tubes for inlet and outlet gas collection, and a laser gas spectrometer (LGS) unit for real-time CH4 and N2O measurement.

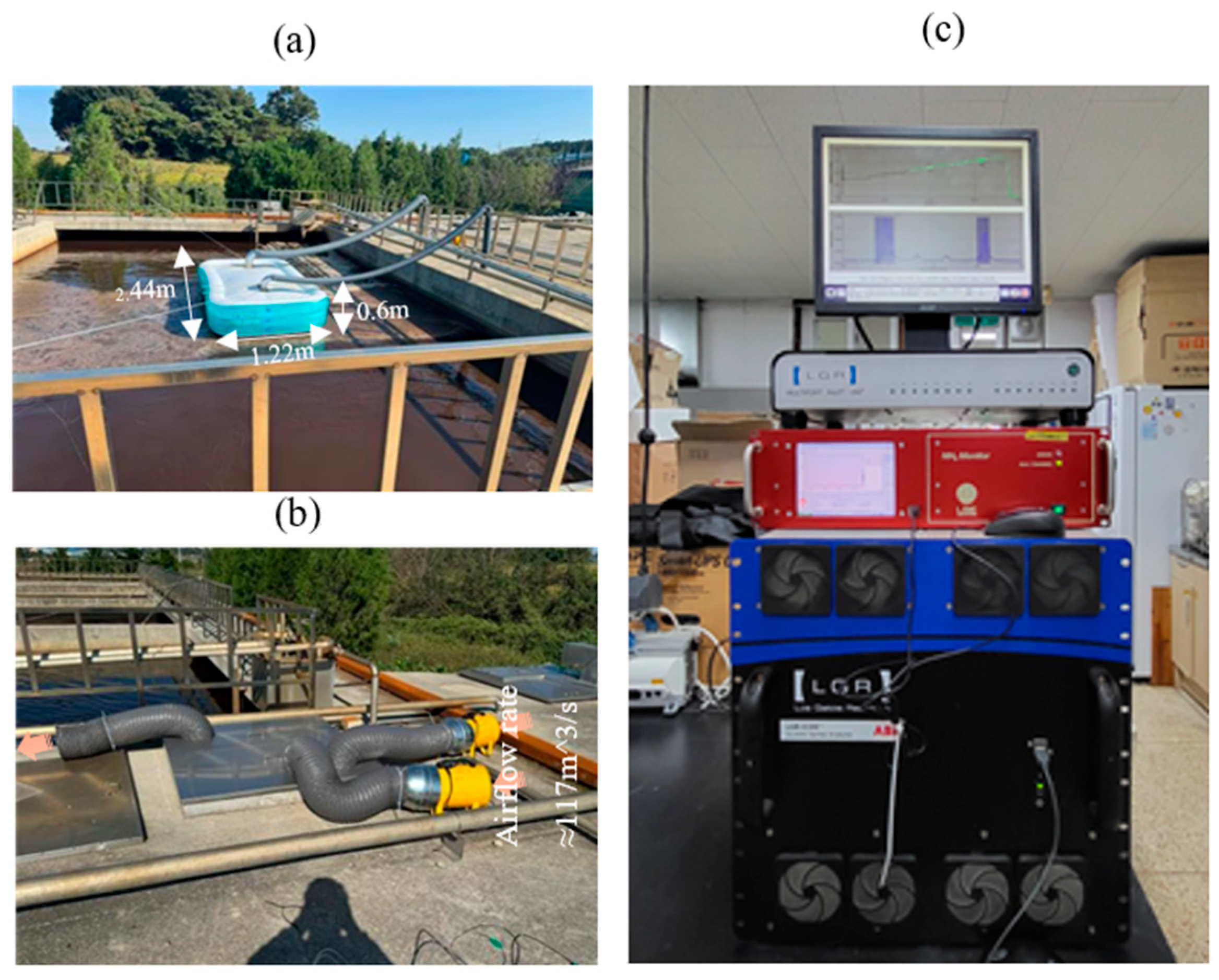

Figure 4.

Field installation and analytical system used for GHG flux monitoring. (a) Floating PVC air pool chamber deployed at monitoring stages 2, 3, 8, and 9; (b) gas collection and transfer setup at the raw-water storage tank (stage 1) and (c) Laser Gas Analyzer (LGR) unit.

Figure 4.

Field installation and analytical system used for GHG flux monitoring. (a) Floating PVC air pool chamber deployed at monitoring stages 2, 3, 8, and 9; (b) gas collection and transfer setup at the raw-water storage tank (stage 1) and (c) Laser Gas Analyzer (LGR) unit.

Figure 5.

(Top) CH4 and (Bottom) N2O diurnal flux distributions for Morning, Afternoon, Evening, and Night periods.

Figure 5.

(Top) CH4 and (Bottom) N2O diurnal flux distributions for Morning, Afternoon, Evening, and Night periods.

Figure 6.

Treatment stage variability in CH4 and N2O fluxes measured across the swine wastewater process.

Figure 6.

Treatment stage variability in CH4 and N2O fluxes measured across the swine wastewater process.

Figure 7.

Seasonal variations in CH4 (top) and N2O (bottom) fluxes across the monitoring period.

Figure 7.

Seasonal variations in CH4 (top) and N2O (bottom) fluxes across the monitoring period.

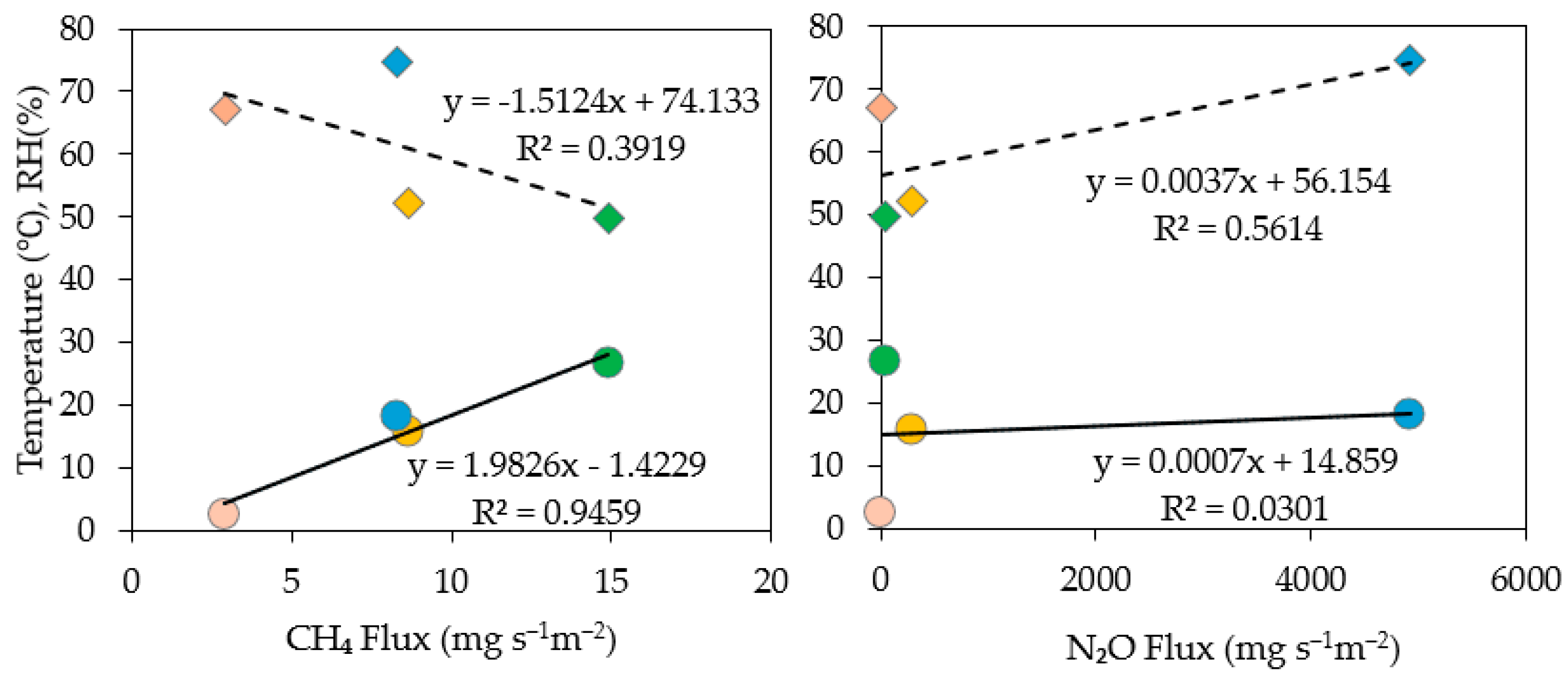

Figure 8.

Seasonal scale linear regressions between GHG flux and temperature (○), and relative humidity (◇). Each color represents a seasonal mean: Spring, Summer, Fall, and Winter. Each point represents a seasonal mean (n = 4: Spring, Summer, Fall, Winter). Regression equations and R2 values are shown for each relationship.

Figure 8.

Seasonal scale linear regressions between GHG flux and temperature (○), and relative humidity (◇). Each color represents a seasonal mean: Spring, Summer, Fall, and Winter. Each point represents a seasonal mean (n = 4: Spring, Summer, Fall, Winter). Regression equations and R2 values are shown for each relationship.

Table 1.

Average annual weather conditions of the study area during the experiment period.

Table 1.

Average annual weather conditions of the study area during the experiment period.

| Index | Fall | Winter | Spring | Summer |

|---|

| Wind speed (m/s) | 1.2 | 1.5 | 2.0 | 1.7 |

| Temperature (°C) | 18.0 | 1.5 | 13.4 | 26.5 |

| Relative humidity (%) | 75.3 | 69.9 | 64.5 | 74.9 |

Table 2.

Measurement range, interval, and method of the gas sensors.

Table 2.

Measurement range, interval, and method of the gas sensors.

| Sensor Type | Measurement Range | Measurement Cycle | Measurement Method |

|---|

| Methane (CH4) | 0–1000 ppm | 1 s | Laser analysis |

| Nitrous oxide (N2O) | 0–40 ppm | 1 s | Laser analysis |

Table 3.

Monitoring period and seasonal coverage.

Table 3.

Monitoring period and seasonal coverage.

| Item | Description |

|---|

| Monitoring period | 6 September 2024–30 August 2025 |

| Seasons covered | Autumn (Sep–Nov), Winter (Dec–Feb), Spring (Mar–May), Summer (Jun–Aug) |

| Monitoring days | 6 Sep 2024; 24 Sep 2024; 24 Oct 2024; 9 Nov 2024; 17 Dec 2024; 13 Feb 2025; 13 Mar 2025; 29 May 2025; 30 Jun 2025; 30 Aug 2025 |

Table 4.

Summary of diurnal CH4 and N2O flux statistics from pig wastewater treatment system. Values represent the Mean, standard deviation (SD), standard error (SE), coefficient of variation (CV), and maximum observed flux (n =35 per period).

Table 4.

Summary of diurnal CH4 and N2O flux statistics from pig wastewater treatment system. Values represent the Mean, standard deviation (SD), standard error (SE), coefficient of variation (CV), and maximum observed flux (n =35 per period).

| Period | GHG | Mean | SD | SE of Mean | CV | Max |

|---|

| Morning | CH4 | 5.8 | 19.8 | 3.3 | 3.4 | 116.8 |

| N2O | 3174.6 | 15,199.2 | 2569.1 | 4.8 | 90,162.9 |

| Afternoon | CH4 | 3.2 | 7.5 | 1.3 | 2.3 | 36.5 |

| N2O | 439.9 | 1501.4 | 253.8 | 3.4 | 8671.8 |

| Evening | CH4 | 7.0 | 14.1 | 2.4 | 2.0 | 79.1 |

| N2O | 543.6 | 1434.7 | 242.5 | 2.6 | 7900.4 |

| Night | CH4 | 7.2 | 12.4 | 2.1 | 1.7 | 60.5 |

| N2O | 2056.5 | 8650.5 | 1462.2 | 4.2 | 49,913.1 |

Table 5.

Summary of treatment stage specific CH4 and N2O flux statistics from pig wastewater treatment system. Values represent the Mean, standard deviation (SD), standard error (SE), coefficient of variation (CV), and maximum observed flux (n = 35 per stage).

Table 5.

Summary of treatment stage specific CH4 and N2O flux statistics from pig wastewater treatment system. Values represent the Mean, standard deviation (SD), standard error (SE), coefficient of variation (CV), and maximum observed flux (n = 35 per stage).

| Period | GHG | Mean | SD | SE of Mean | CV | Max |

|---|

| Aeration tank I | CH4 | 4.3 | 8.3 | 1.6 | 1.9 | 36.5 |

| N2O | 2108.4 | 3297.3 | 623.1 | 1.6 | 13,803.1 |

| Aeration tank II | CH4 | 14.5 | 27.8 | 5.3 | 1.9 | 116.8 |

| N2O | 202.9 | 323.2 | 61.1 | 1.6 | 1039.3 |

| Anaerobic tank II | CH4 | 2.0 | 2.8 | 0.5 | 1.4 | 10.8 |

| N2O | 279.5 | 666.0 | 125.9 | 2.4 | 3522.4 |

| Anaerobic Tank I | CH4 | 5.5 | 7.2 | 1.4 | 1.3 | 20.8 |

| N2O | 5163.9 | 19,129.6 | 3615.2 | 3.7 | 90,162.9 |

| Raw water storage tank | CH4 | 2.7 | 3.7 | 0.7 | 1.4 | 13.3 |

| N2O | 13.5 | 39.9 | 7.5 | 2.9 | 181.8 |

Table 7.

Annual CH4 and N2O emissions by treatment stage, percentage contributions, and system-level emission factors.

Table 7.

Annual CH4 and N2O emissions by treatment stage, percentage contributions, and system-level emission factors.

| Treatment Stage | CH4 Emission (kg yr−1) | CH4 Share (%) | N2O Emission (kg yr−1) | N2O Share (%) |

|---|

| Aeration Tank I | 252.8 | 25.0 | 115,434.3 | 28.3 |

| Aeration Tank II | 315.3 | 31.2 | 4258.6 | 1.0 |

| Anaerobic Tank II | 42.0 | 4.1 | 4906.8 | 1.2 |

| Anaerobic Tank I | 316.1 | 31.3 | 281,934.7 | 69.4 |

| Raw Water Storage Tank | 87.7 | 8.7 | 426.7 | 0.1 |

| Total Annual Emissions | 1014.0 | 100 | 406,961.0 | 100 |

| Per-Head EF (9000 pigs) | 0.11 kg CH4 head−1 yr−1 | – | 45.2 kg N2O head−1 yr−1 | – |

| CO2-eq EF (IPCC AR6 GWP) | 3.1 kg CO2-eq head−1 yr−1 | – | 1.23 × 104 kg CO2-eq head−1 yr−1 | – |