From Waste to Sustainable Pavements: A Systematic and Scientometric Assessment of E-Waste-Derived Materials in the Asphalt Industry

Abstract

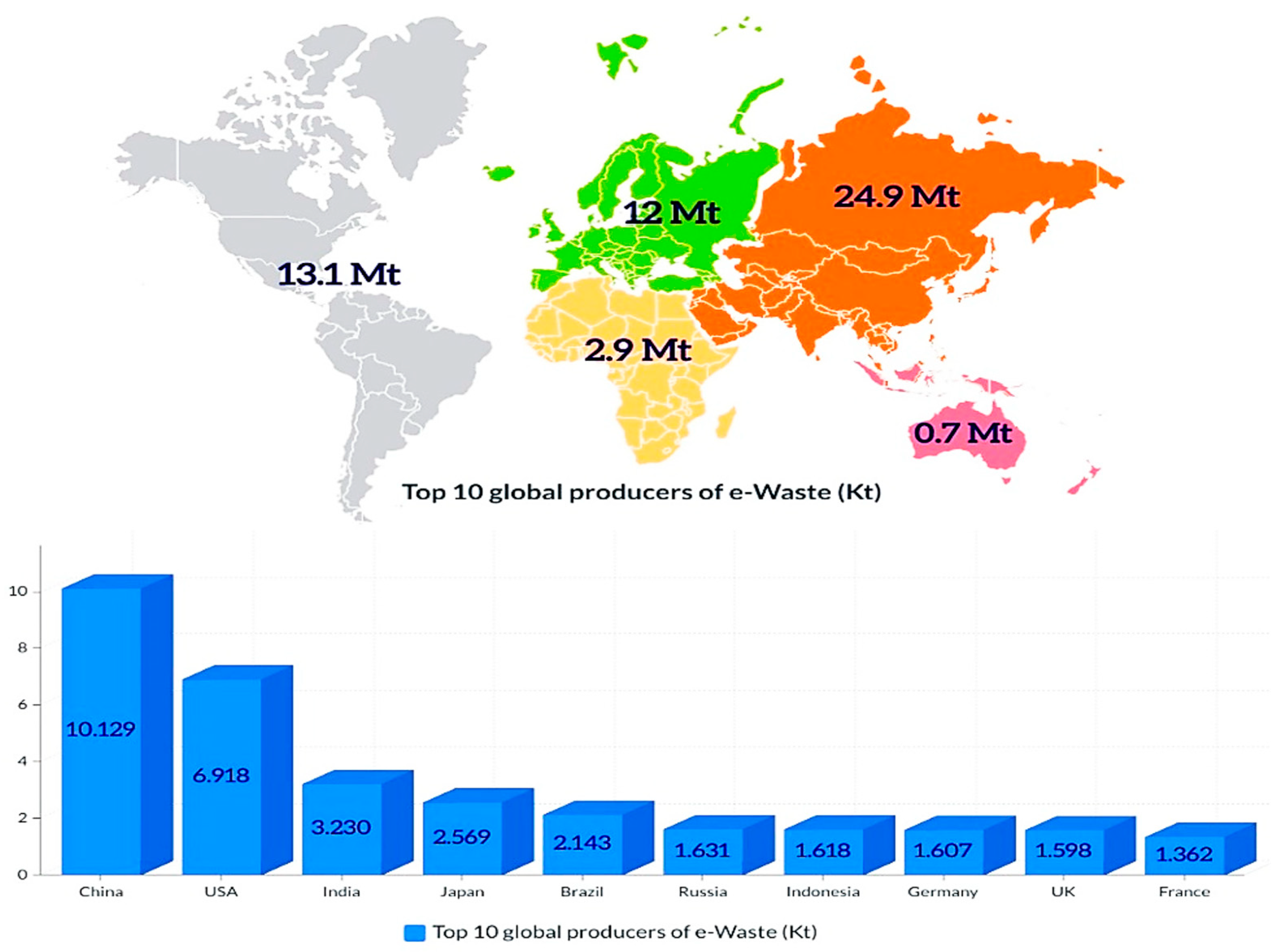

1. Introduction

2. Theoretical Background

2.1. Waste Generation and Application in Pavement Engineering

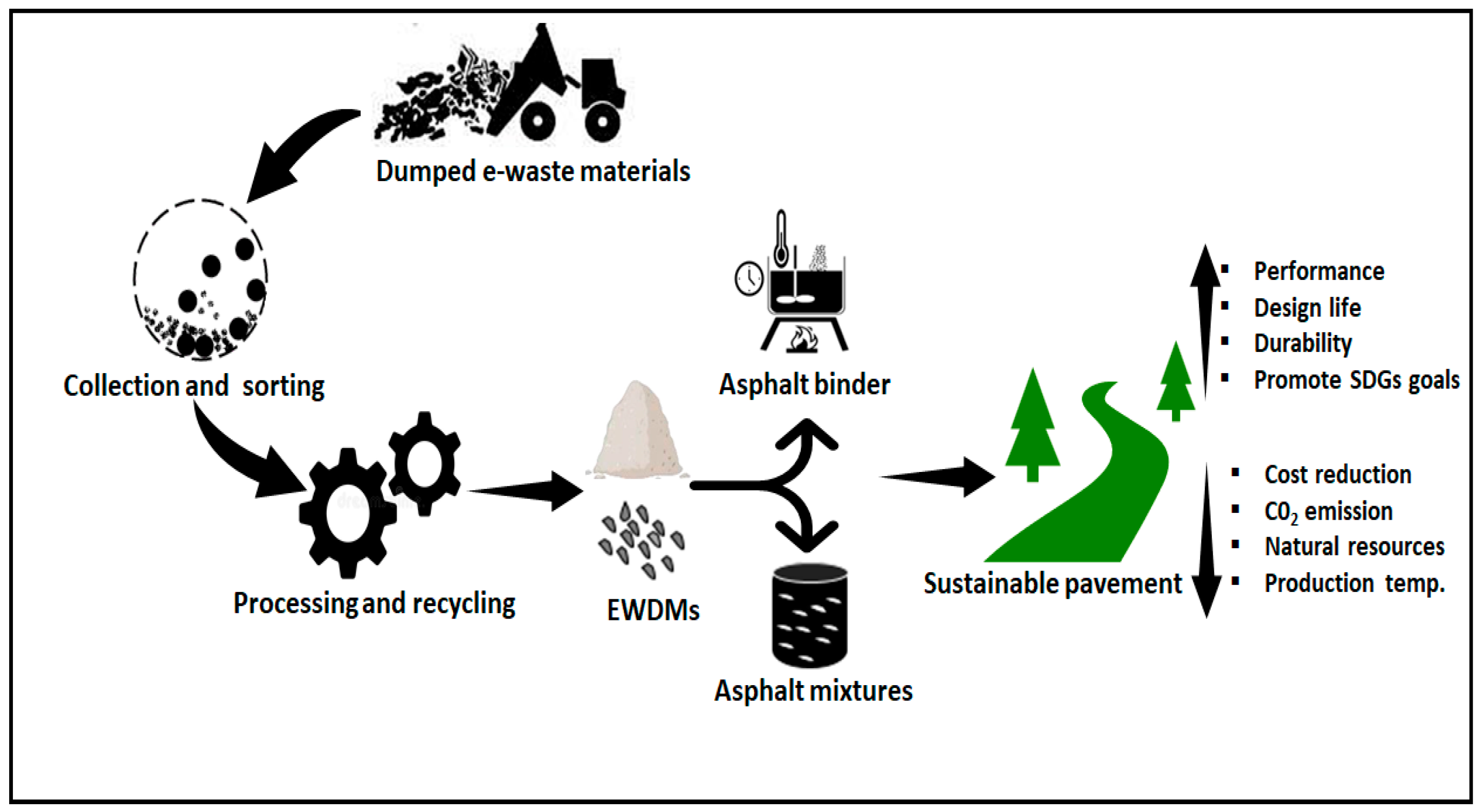

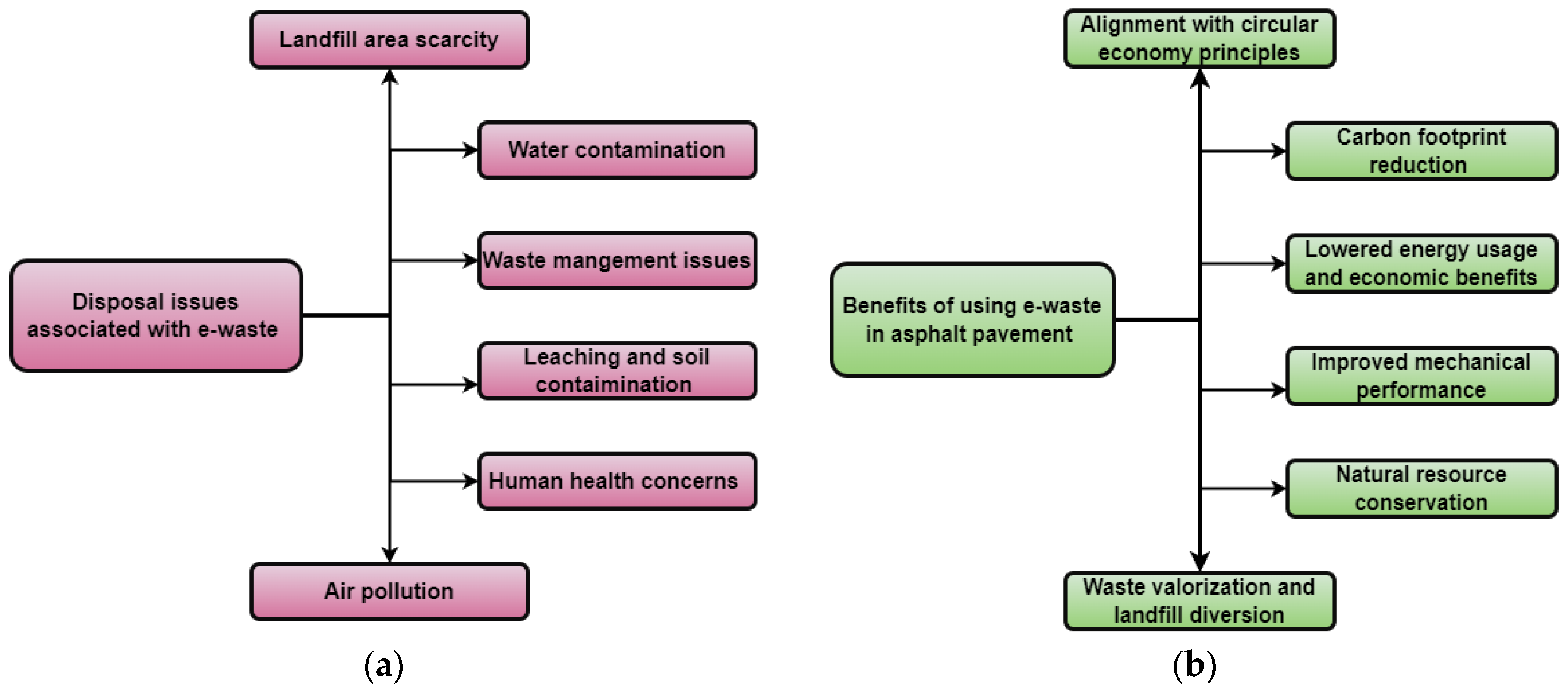

2.2. EWDM Application in Asphalt Pavement

2.3. Classification of EWDMs for Use in Asphalt Pavement

3. Methodology

3.1. Comprehensive Research Approach

3.2. Study Motivation, Research Objectives, and Questions

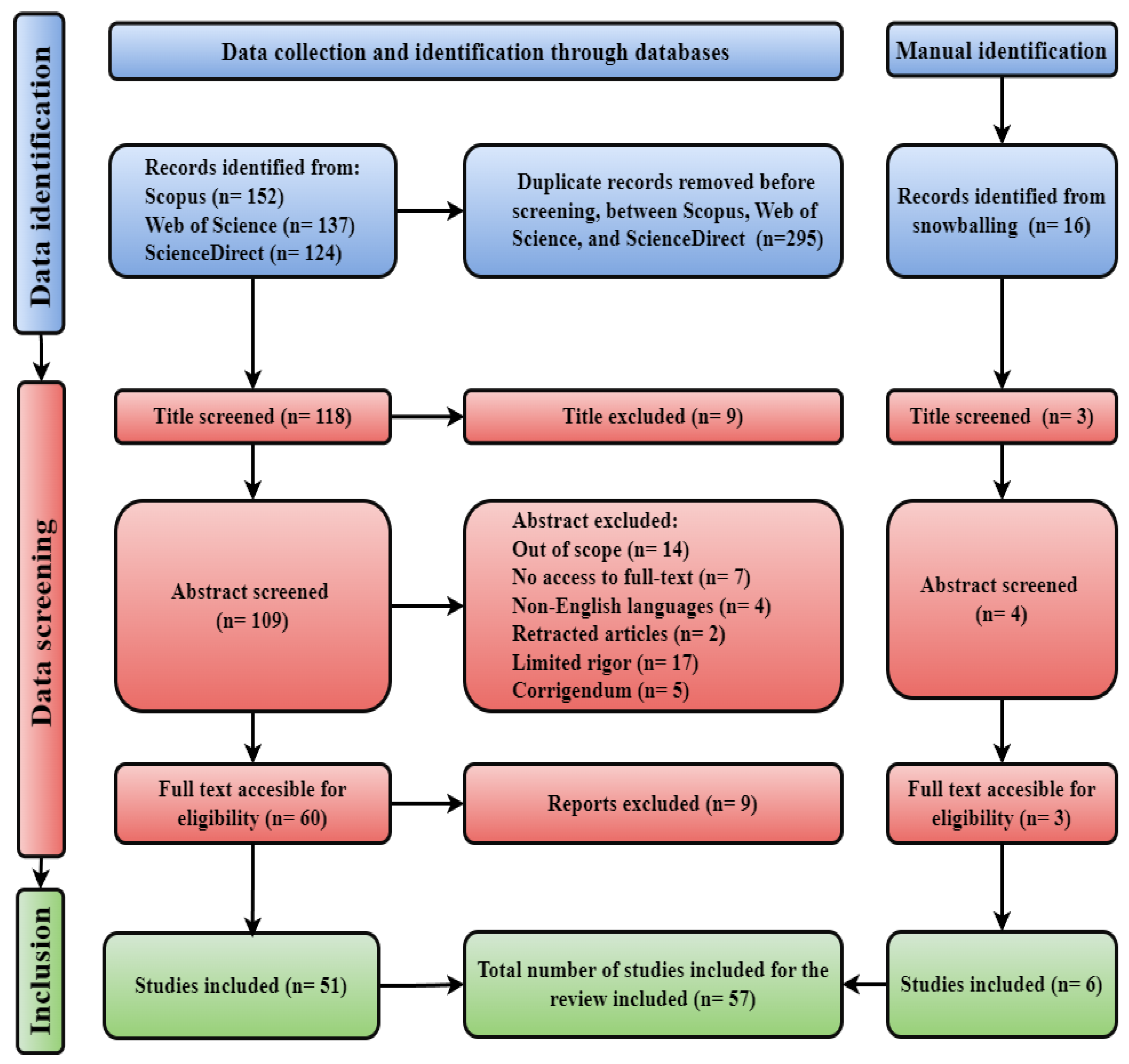

3.3. Literature Data Retrieval Approach

3.4. Bibliometric Data Sources and Search Phrases

3.5. The Screening Procedure and Eligibility Conditions

3.5.1. Inclusion Requirements

3.5.2. Criteria for Exclusion

3.5.3. Screening Process

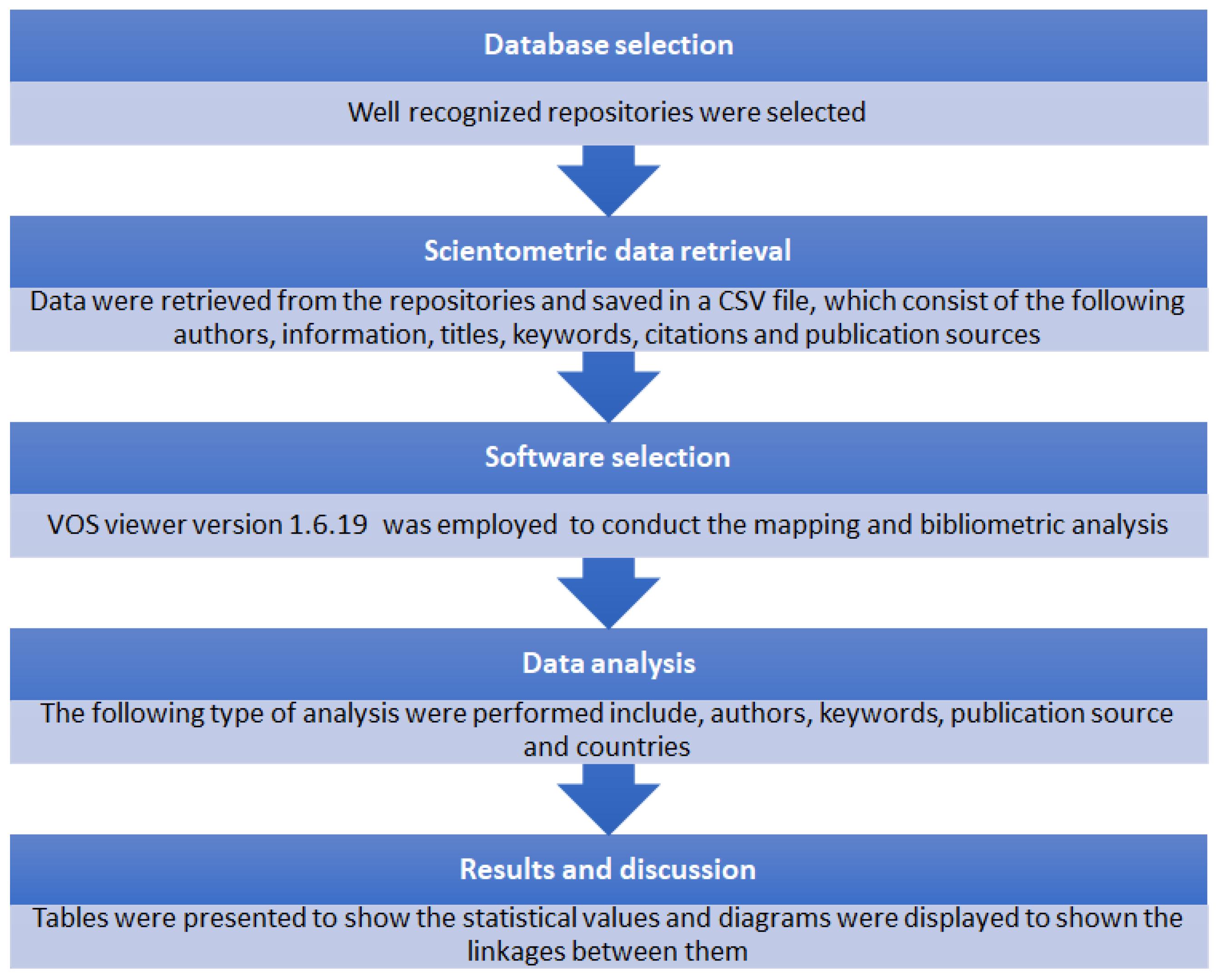

3.6. Scientometric Analysis

3.7. Systematic Analyses

3.8. Environmental Assessment

4. Results and Discussion

4.1. Bibliometric Analysis

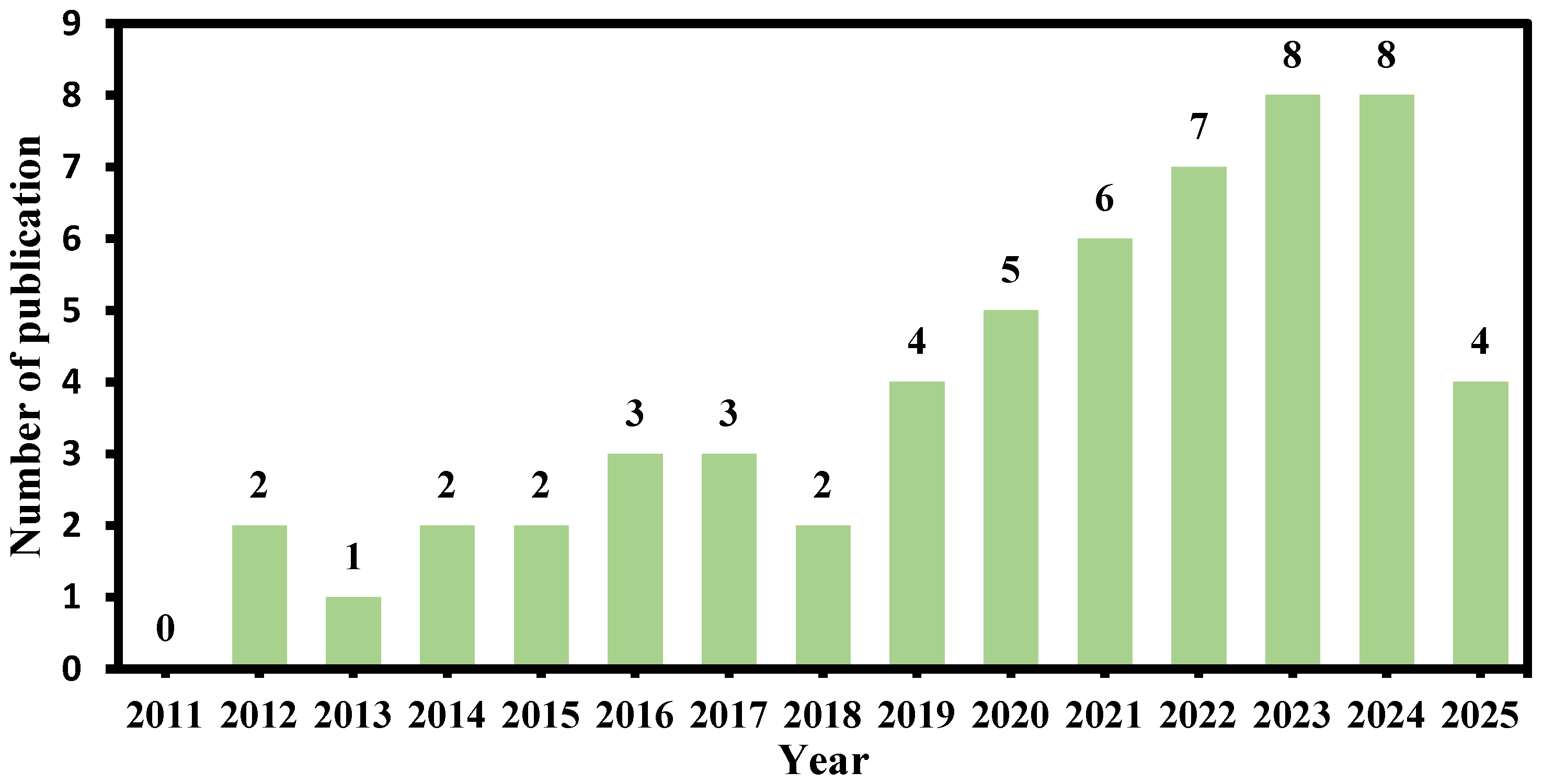

4.1.1. Publication Trends

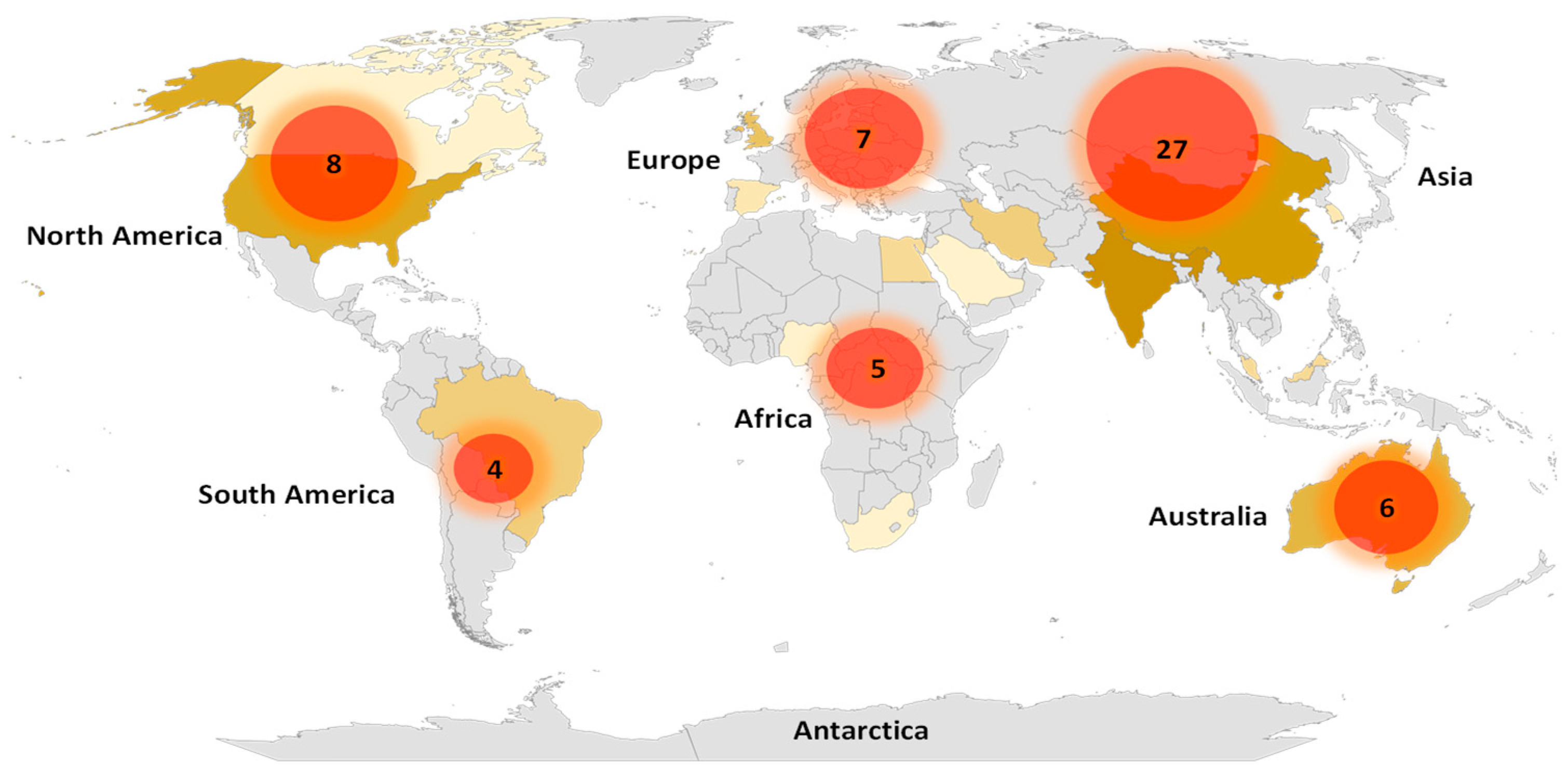

4.1.2. Research Contributions by Country

4.1.3. Continental Research Contributions

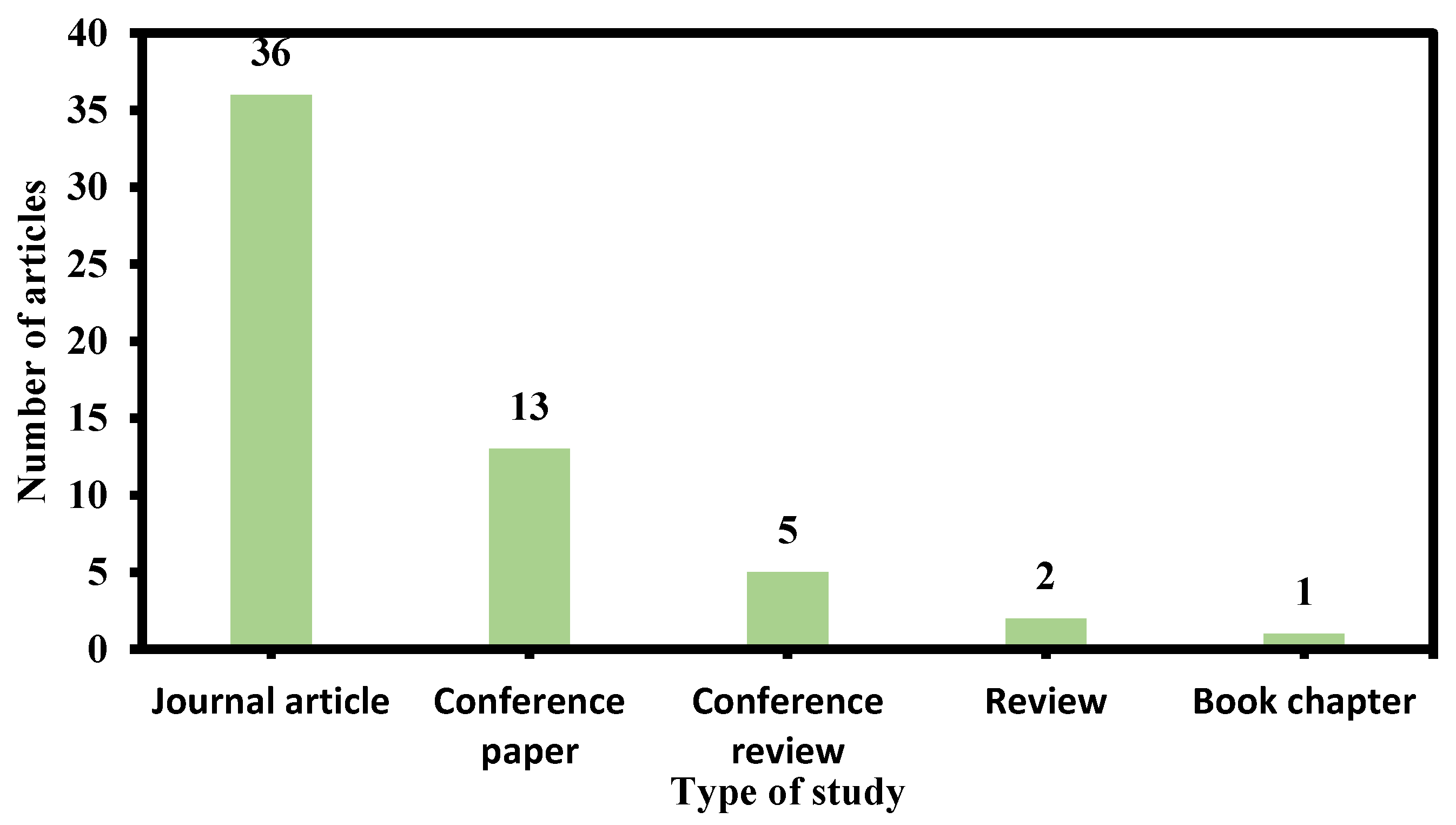

4.1.4. Type of Publication

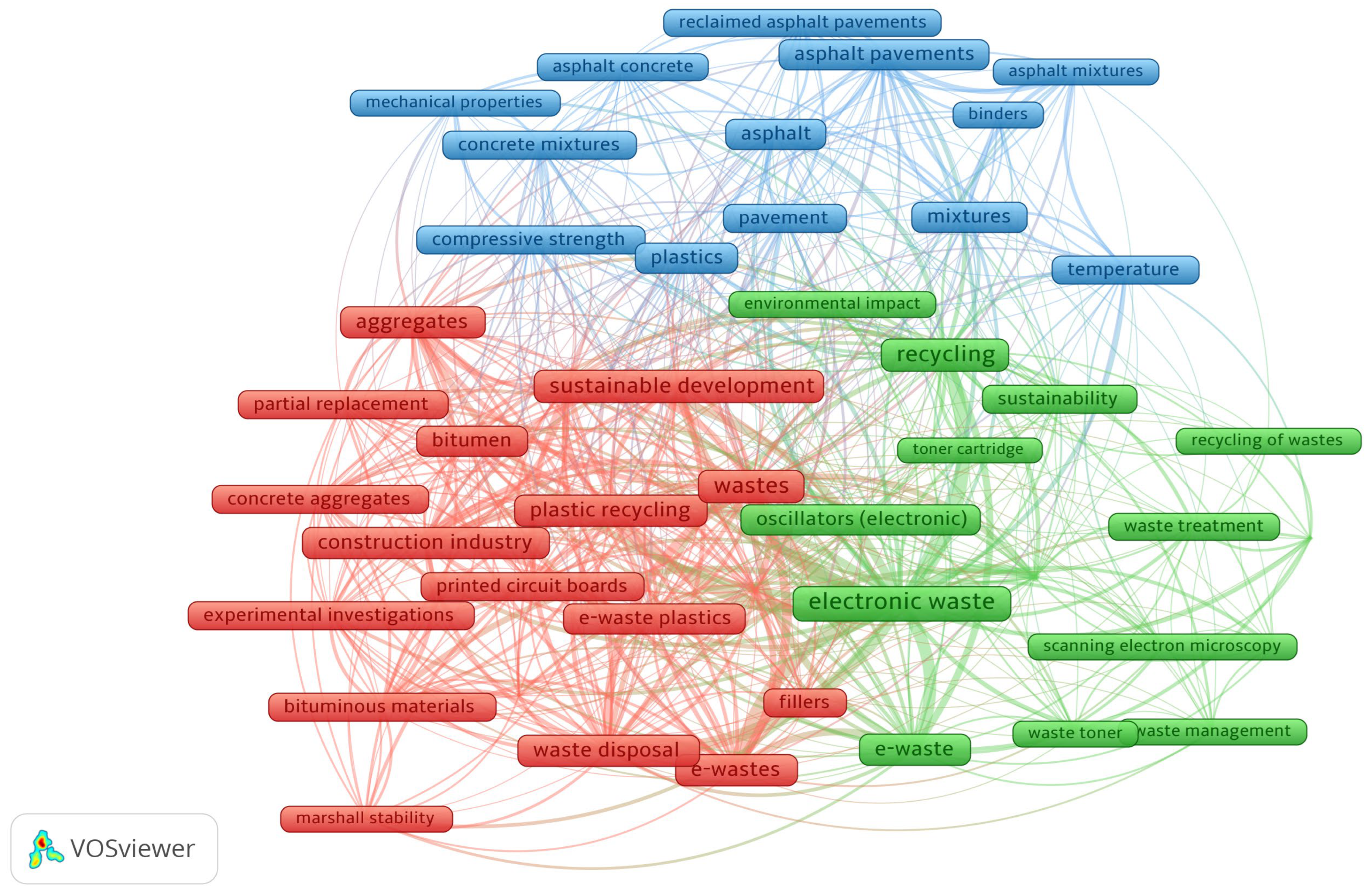

4.1.5. Keywords Co-Occurrence

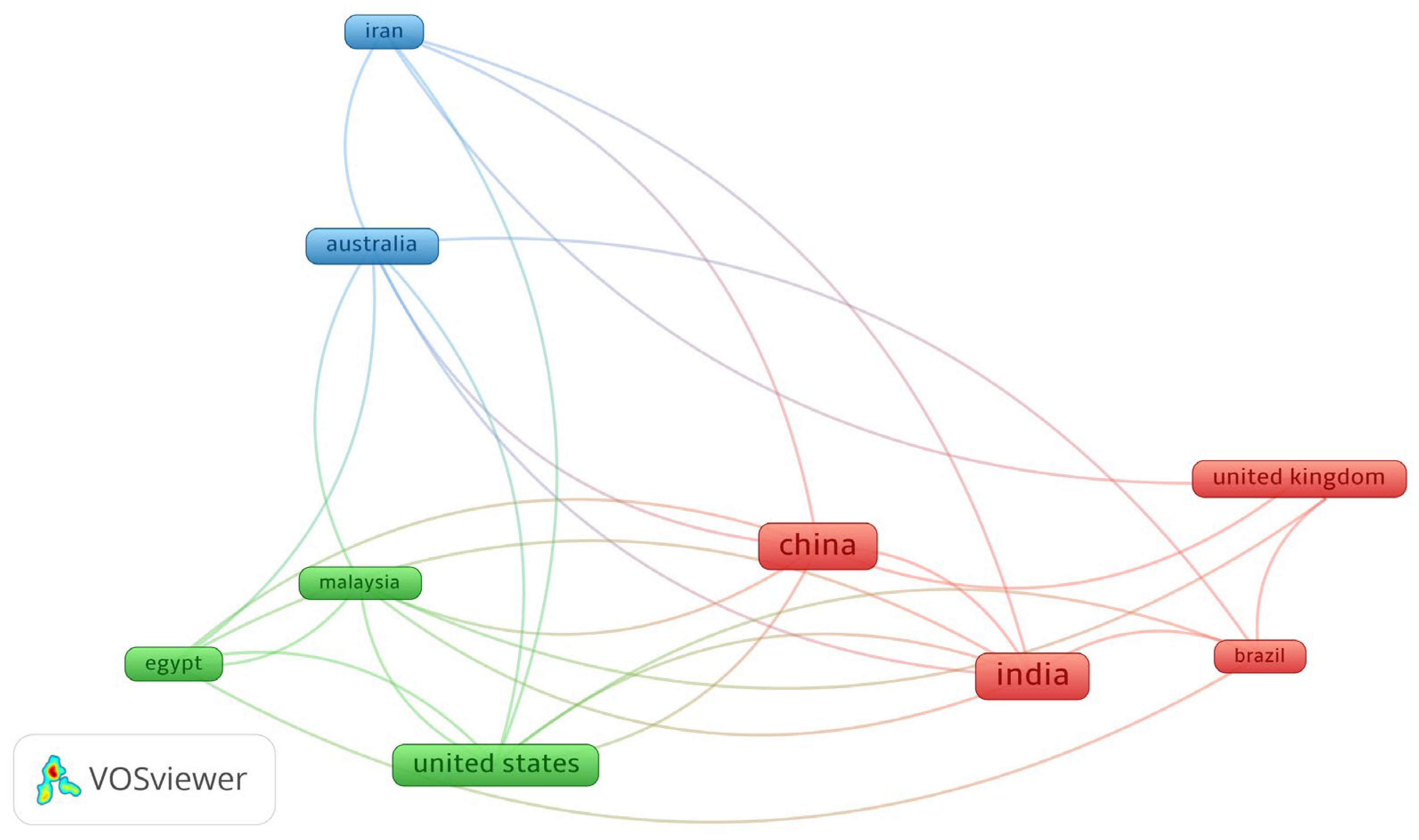

4.1.6. Country Network Visualisation

4.1.7. Visualisation of the Publication Source Network

5. Upcycling and Application of EWDMs in Asphalt Pavement

5.1. Application of E-Waste Plastics

5.2. Non-Metallic Fractions

5.3. Waste Toner

| Type of E-Waste | Material Form | Application and Content | Modification Type and Level | Tests | Findings | Comments |

|---|---|---|---|---|---|---|

| PCB [89] | Powdered | Mineral filler replacement (100% lime filler) | Asphalt mixture | Marshall stability and flow, rutting, and cyclic compression-dynamic flow | PCB-modified mixtures showed less stiffness than the control; recycling e-waste in asphalt was shown to be technically feasible. | More optimisation is necessary for long-term durability and mechanical performance. |

| HIPS and ABS [79] | Powdered for (both untreated and chemically modified using initiators of free radicals) | Bitumen modifier by binder weight (2.5 and 5%). | Hot mix asphalt | Analysis of the Mechanistic-Empirical Pavement Design Guide (M-EPDG) | Modification of e-waste decreased pavement design thickness; the greatest reduction was obtained with chemically treated ABS at 2.5%. | Limited to simulation results; long-term field performance and durability not evaluated. |

| Computers, plastics [81] | Powdered | Bitumen modifier by binder weight (2.5%, 5%, and 15%) | Bitumen binder modification | Rotational viscosity and rheological analysis using BBR and DSR | The modified bitumen had a lower susceptibility to rutting, improved blending temperature and bitumen viscosity, and sustained low-temperature performance at a lower content. | No performance and field validation is done, and high modifier content may cause workability problems. |

| ABS and HIPS [80] | Pulverised powder (both chemically and untreated) | Asphalt binder and mixture modifier | Superpave asphalt mixtures with modified binder | Tensile strength ratio (TSR), dynamic modulus, MEPDG rutting analysis, SimaPro emissions analysis, and superpave binder tests | Compared to standard asphalt, chemically treated e-waste reduced CO2 emissions, improved low-temperature dynamic modulus, delayed tertiary flow, and increased TSR. | Long-term field performance is not assessed, and specific ideal content is not well established. |

| PCB and PVC [86] | Plastic fragments as coarse aggregate and Marble dust as a filler | Coarse aggregate alternative (0%, 4%, 8%, or 12%) and filler substitute with 100% marble dust. | Modified asphalt concrete | Unit weight, VMA, VFB, Marshall Stability, and Flow | Marshall properties were improved up to a 12% plastic content, a higher percentage than that diminished stability | No mechanical evaluation of long-term performance or environmental impact. |

| N/A [82] | Powdered plastic | Bitumen substitute by (5%, 10%, 15%, and 20%) by weight | Bitumen of VG30 grade | Tests of strength (according to Indian standards) | Binder strength was increased up to 15% substitution; after that, performance declined. | Limited tests on durability and long-term field performance data are absent. |

| PE [83] | Powdered | Binder additive (5%) by weight of binder | Bitumen blends with various levels of bitumen | Marshall flow and stability | Both Marshall stability and flow parameters were improved as strength was enhanced by 10% compared to conventional bitumen. | Limited studies on mechanical performance tests and field evaluation tests |

| ABS, ABS-PC, and HIPS [24] | Powdered (less than 300 μm) | Asphalt binder modifier (5 and 15%) | PG58-28 asphalt binder | Work Dissipation, Rheology, and Chemical Treatment Analysis | The covalent bonding in chemically treated modifiers resulted in dramatically increased stiffness, elasticity, and resistance to rutting; untreated modifiers likewise outperformed the control. | Future research should focus on the mixture’s long-term performance and mechanical performance tests. |

| HIPS and PCB [94] | HIPS is a coarse aggregate form, while PCB chips are in powder form | Coarse aggregate substitution (<20 mm) and binder substitution by (5%, 10%, 15%, and 20%) weight of binder | Binder and mixture blends of VG30 | Viscosity, ductility, penetration, flash/fire point, softening point, and Marshall Stability | The binder and Marshall properties were enhanced by increasing the amount of e-waste and HIPS. | Long-term permanence and further research may be required for durability under varied situations. |

| PCB [95] | Non-metallic chips (coarse aggregate modifier); powder (binder modifier) | Aggregate replacement: 5%, 10%, 15% (optimal 10% by aggregate weight); binder substitute: 6%, 12%, and 18% (optimal 12% by binder weight). | Asphalt mixtures with aggregates and a modified VG30 binder | Viscosity, ductility, penetration, softening point, flash/fire point, and Marshall stability, | The optimum stability and binder performance were achieved using 12% E-PCB powder and 10% E-PCB chips. | The mechanical performance of mixes and environmental evaluations are not conducted. |

| E-waste plastic [92] | Chopped granules | Aggregate substitution: 2.36 mm for 9% fine aggregate and 13.2 mm for 3.5% coarse aggregate. | Asphalt concrete mixes with a varied bitumen proportion (4–7%) | Marshall Stability and permanent deformation test | Improved Marshall stability and reduced rutting by 21.30% (13.2 mm) and 30.62% (2.36 mm) compared to the unmodified mixture | Limited to laboratory scale; environmental durability and long-term field performance are not evaluated. |

| PCB and HIPS [37] | Liquid and granules | Melted HIPS is used as a binder modifier, while crushed PCBs (≤20 mm) are used as coarse material. | Asphalt mixture with modified aggregate and binder (replacement levels not specified) | Marshall stability | Marshall stability was enhanced by the use of HIPS and e-waste. | Limited Mechanical performance and inadequate evaluation of long-term performance |

| N/A [84] | Crushed plastic | Bitumen replacement (5% to 10%) by binder weight | PEN 80/100 bitumen | Softening point, ductility, and penetration | With an increase in plastic content, ductility decreases, and penetration and softening point increase. | The performance of entire asphalt mixtures was not investigated; only basic binder properties were assessed. |

| N/A [87] | Powdered | Bitumen modifier 5% by binder weight | Asphalt mixtures with VG-30 binder | Marshall Stability, DSR, and Cyclic Triaxial Tests (Fatigue, Rutting, Phase Angle, and Dynamic Modulus) | Dynamic modulus increased by 10% at 40 °C, fatigue resistance improved by 19% at 10 °C, and rutting resistance increased by 28% at 40 °C. | Further studies into the surface energy, adhesion characteristics, and morphology of the e-waste modified binder are recommended. |

| e-waste and waste plastic [116] | Waste plastic (semi-solid), e-waste (fine particles) | Bitumen and filler are partially replaced (precise dosages not provided). | Hot mix asphalt | Bulk Density, VMA, Air Voids, Marshall Stability, and Flow | increased strength, stability, and cost-effectiveness, and verified the applicability of plastic and e-waste in asphalt pavement | Dosage optimisation and long-term field performance require further study |

| Mixed e-waste [93] | Crushed artificial aggregate | Aggregate replacement (15%) by volume | Hot mix asphalt | Wheel tracking and semicircular bend test | Enhanced resistance to rutting and cracking, with environmental and economic benefits. | Additional performance research and field assessments are needed. |

| N/A [91] | Powdered | Mineral filler substitute (5%, 10%, and 15%) by filler mass | Hot mix asphalt | Marshall flow and stability | The study shows that 10% e-waste increased stability by 11%, whereas fly ash added little strength. | Further mechanical testing and analysis of the mixture are lacking. |

| ABS [85] | Powdered | Asphalt binder modifier (1–5%) by weight of binder | Asphalt binder and mixtures | Penetration, Softening Point, Viscosity, Rheological Properties, and Marshall Stability | Optimal ABS percentage of 4% improves softening point, viscosity, rutting resistance, elasticity, Marshall stability, and stripping. | More studies are recommended on the mixture’s long-term ageing and mechanical performance tests. |

| PCB [36] | Powdered | Asphalt binder modifier (2 and 5%) by weight of binder | Dense Bituminous Macadam mixtures | Specific gravity, Softening Point, Penetration, and Marshall Stability, | When compared to ordinary bitumen, modified binders containing 2% and 5% e-waste demonstrated better stability and performance | It is recommended that the surface energy and morphological characteristics of the modified binders be examined. |

| N/A [90] | Chunks | Alternative aggregate at (20%, 25%, and 30%)of mix and flyash as filler | Dense bituminous mixtures | Marshall Stability, Flow, VMA, Air Voids | Optimal Marshall Stability and flow were noted at a 25% e-waste replacement. Additionally, the fly ash filler’s properties remained similar to those of the control mix. | More field and experimental testing is needed to fill a research gap. Additionally, life cost analyses in needed. |

| N/A [88] | Powdered | Asphalt binder modifier (5–20%) by weight and Fly ash as mineral filler. | Asphalt mixtures | Asphalt binder conventional properties, Marshall stability, and flow | Optimal performance was noted at 10–15% e-waste replacement; binder consumption was decreased. | More mechanical performance, leachability tests, and long-term performance are needed. |

| NMF [96] | Powdered (0.07–0.09 mm) | Asphalt binder modifier (25%) | Asphalt binder | Softening Point, Ductility, Viscosity, Penetration, DSR (G*/sin δ), and Upper Limit Temperature | Improved rheological properties, load resistance, and high-temperature performance (viscosity: 1225 cP, softening point: 54 °C, and G*/sin δ: 3995.27 Pa). | The study concentrated on binder-level performance; long-term durability and full-scale mixing were not assessed. |

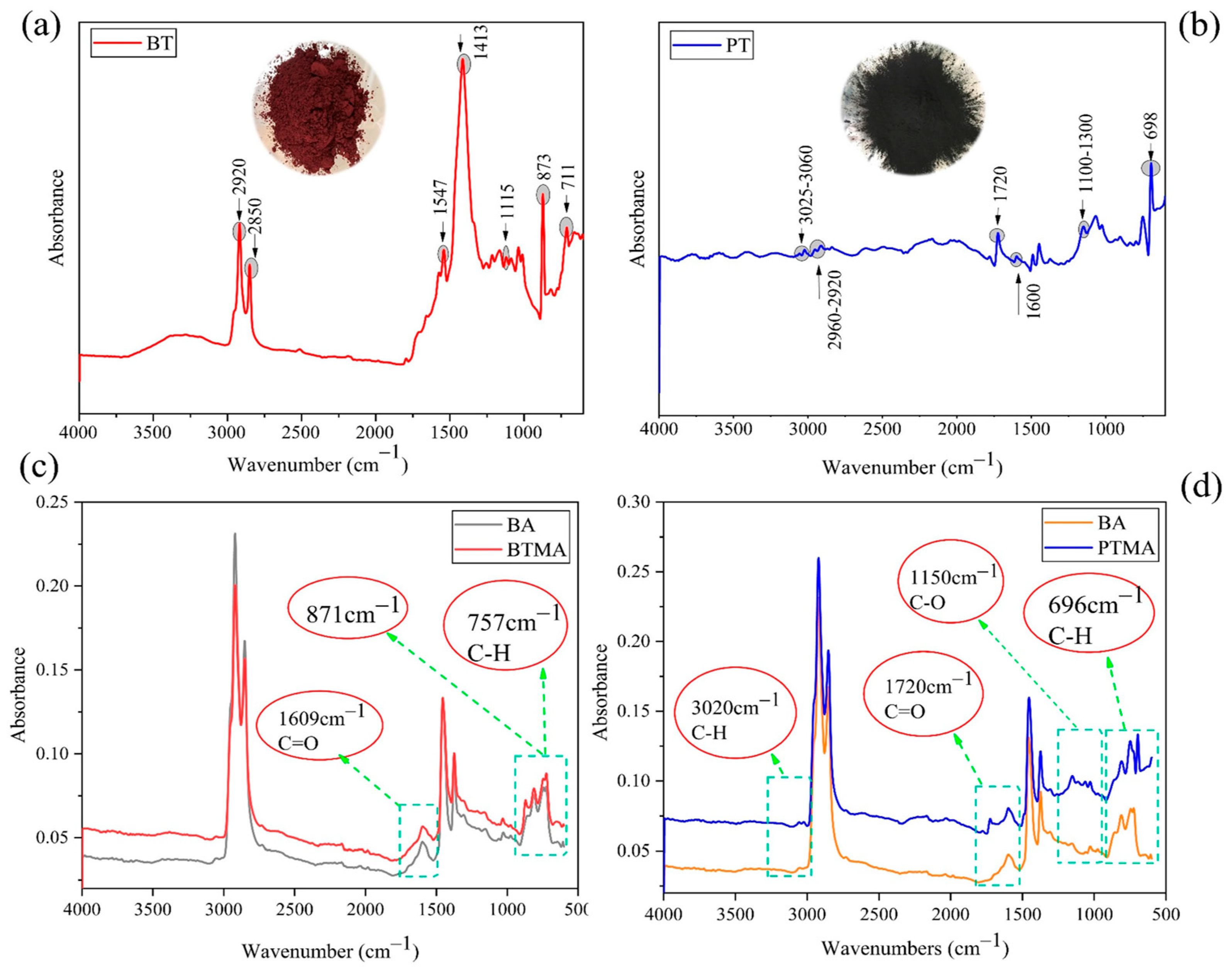

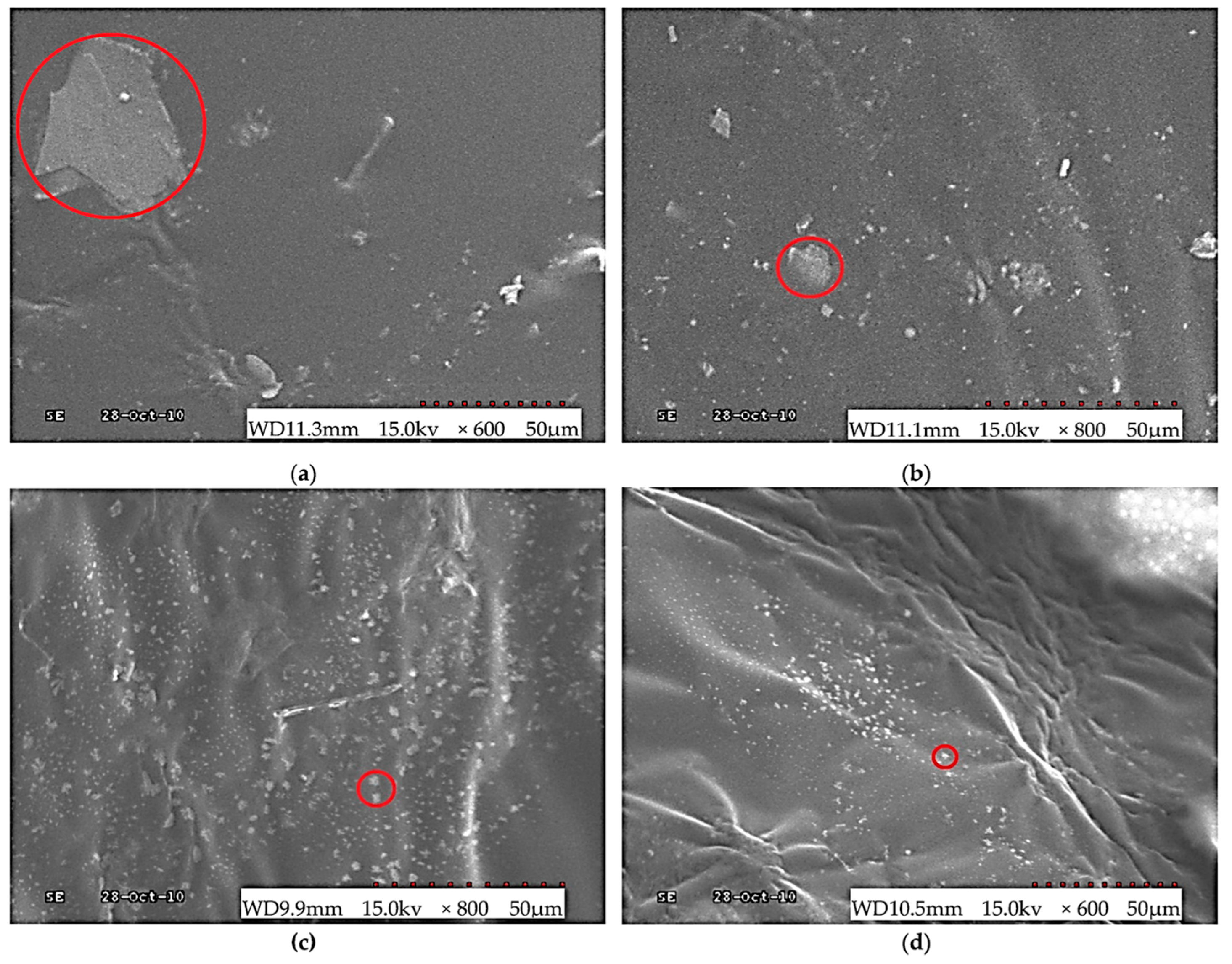

| NMF [57] | Powdered | Asphalt binder modifier with 30% NMF by weight of asphalt and 8% tung oil–glycerol compatibilizer | Asphalt binder modification and dispersion improvement using biobased compatibilizer | Penetration, Ductility, Softening Point, SPD, DSR, BBR, FTIR, SEM, and | Reduced temperature sensitivity, increased stiffness, rutting resistance, and high-temperature stability; increased dispersion-based compatibility; no observable chemical reaction. | There are currently insufficient evaluations of mechanical performance, long-term durability, and large-scale use. |

| NMF [11] | Powdered | Fine aggregate replacement by (1%, 2%, and 3%) of the total aggregate weight | Superpave asphalt mixtures | Moisture damage, fatigue, permanent deformation, and the flexibility index | Modified mixtures show predicted distresses below failure thresholds, acceptable rutting and fatigue performance, and excellent moisture resistance. | Further investigation should look at the effects of NMF on the modified mixtures’ chemical and microstructural characteristics. |

| NMF [53] | Powder and slurry | Bitumen modifier at 2.5% optimal | Base bitumen 80/100 (target VG40 equivalent) | Softening Point, Penetration, and Rheology (G*, δ) | 2.5% e-waste slurry raised the softening point from 47 °C to 50 °C, decreased penetration from 100 dmm to 40 dmm, and improved rheological properties; it also satisfied VG40 requirements. | Further studies should examine the impact of the e-waste on the mechanical, chemical, and microstructural properties of the modified asphalt binder. |

| Fluorescent lamps [98] | Powdered | Mineral filler replacement (N/A) | Mixtures of asphalt wearing and binder courses | Wheel tracking, dynamic creep, Marshall stability, indirect tensile stiffness modulus, and indirect tensile fatigue | Modified mix shows enhanced mechanical performance; practical for pavements with light to moderate traffic. | Lack of techno-economic analysis, leachability testing, and field research |

| Type of E-Waste | Material Form | Application and Content | Modification Type and Level | Tests | Findings | Comments |

|---|---|---|---|---|---|---|

| WT [25] | Powdered | Asphalt binder modifier by (4%, 8%, 12%, and 16%) by binder weight | Modified asphalt binder and mixtures | Viscosity, Wheel Tracking, Modified Lottman, Multiple Stress Creep Recovery, Densification Indices (Locking Point), and Bitumen Bond Strength | Enhanced rutting resistance, decreased susceptibility to moisture, improved pumping ability, and increased binder stiffness; nevertheless, with greater toner levels, there is a decrease in workability and resistance to moisture-induced damage. | Appropriate mix ratios, performance in a range of environmental circumstances, and further long-term performance and toxicity tests are needed. |

| WT [56] | Powdered | Asphalt binder modifier (0%, 5%, 10%, 15%, and 20%) by binder volume. | Asphalt binder | Viscosity, softening point, penetration, and ductility | As the toner content increases, it improves the softening point and viscosity while decreasing penetration and ductility. | The impact of WT on the mechanical and microstructural traits of the modified asphalt binder should be investigated. |

| WT [99] | Powdered | Filler replacement in asphalt mixtures (4–8%) | Asphalt mixtures | Life cycle assessment, adhesion testing, mechanical properties, microscopy morphology, and molecular dynamics simulation | WTP with >30% nano-SiO2 and FeO4 demonstrated superior bonding; optimal performance was achieved at 8% WTP content; enhanced adhesion, bonding energy, storage stability, and environmental advantages | Detailed long-term durability and leachability under varying conditions are not assessed. |

| WT [66] | Powdered at different gradations | Asphalt binder modifier (0 to 8%) by binder weight | Modified PG70-22 base asphalt binder | Fluorescence Microscopy, ATR-FTIR, SEM-EDS, XRF, MSCR, Oscillation Tests, and BBR | 8% WT improved resistance to rutting, increased elasticity, confirmed chemical contact, and better high and low temperature capabilities (PG70-22 to PG76-22). | More research is needed on performance variability about e-waste source and content, and variability in properties and composition. |

| WT [67] | Powdered | Asphalt binder modifer: (0%, 5%, 10%, 15%, and 20%) by binder volume | Asphalt binder and mixtures | Specific gravity, ductility, softening point, flash/fire point, RV, RTFO, PAV, DSR, BBR, Marshall stability, dynamic creep, and fatigue (indirect tensile modulus) | Increasing WT content enhanced fatigue life, improved modulus, rutting resistance, softening point, and viscosity; decreased penetration and ductility. PG advanced to PG 82-16 (15–20% WT) and PG 82-22 (5–10% WT). | Long-term durability and leachability potential under various environmental conditions have not yet been evaluated. |

| WT1 and WT2 [100] | Powdered | Asphalt binder modifier (8% by wt. of binder) | Asphalt binder and mixtures | Ductility, softening point, penetration, G* sinδ, IDEAL-CT, IDEAL-RT, and G*/sinδ | The viscosity of WT2-modified binders was higher than that of WT1, and both enhanced rutting resistance (IDEAL-RT); there was no discernible difference in CT index values. | Only short-term performance is assessed; higher viscosity for WT2 raises the energy need for mixing and compaction. |

| WT (A, B, C, and D) [101] | Powdered | Asphalt binder modifier (5% and 20%) of each toner type by weight of binder | Trinidad Petroleum Bitumen (TPB) and Trinidad Lake Asphalt (TLA) | Rheological properties | All the WT shows Improved stiffness, elasticity, viscosity, and temperature susceptibility; 5% Toner C and 20% Toner D showed superior elasticity at 90 °C compared to unmodified TLA. | Only rheological examination was conducted. Thus, more field validation and long-term performance are recommended. |

| WT [102] | Powdered | Asphalt binder modifier (0 to 12%) by weight of binder | Asphalt binder | Rheological Ageing Index (RAI), Viscosity Aging Index (VAI), FTIR, DSR, Viscometer, TSR | Low dosages of toner enhanced resistance to short-term ageing; Binders and mixes’ resistance to moisture was improved by 12% WT. | Assessments of mechanical performance, long-term durability, and large-scale application are still lacking. |

| WT [103] | Powdered | Asphalt binder modifier (0 to 30%) by weight of binder | Asphalt binder and mixtures | Marshall Flow, Stability (MS), stiffness, ITS, and RSM optimisation | Modified mixtures show improved mechanical properties and an RSM model with R2 > 0.86. Additionally, optimal performance was attained at a BT ratio of 0.249 and a MER ratio of 1.63. | Further investigation into the surface energy, adhesion characteristics, and morphology of asphalt binders and mixtures modified with WT. |

| WT [104] | Powdered | Asphalt binder modifier WT (0% and 8%) by binder weight and CCPO (0.5, 1.5%, and 2.5%) by weight of WT-modified binder. | WT-modified asphalt binder combined with biobased CCPO | Storage stability, self-healing, DSR, BBR, FM, FTIR, and ageing index, | WT improved self-healing; CCPO decreased viscosity, increased fatigue and low-temperature cracking resistance, and improved phase stability and compatibility; maximum efficiency with 8% WT and 2.5% CCPO | Rutting performance was decreased by increasing CCPO content (lower G*/sinδ, %R, and higher Jnr); at lower CCPO dosages, self-healing was initially lowered. |

| WT [105] | Powdered | Asphalt binder modifier at (0%, 5%, 10%, 15%, and 20%) by binder volume | Asphalt binder and mixtures | Accumulated strain, Dynamic creep test, Creep stiffness, and resilient modulus | With higher WT content, resilient modulus and creep stiffness first increased before decreasing; accumulated strain also decreased, suggesting better resistance to rutting at the optimal content. | At higher content, excessive WT may reduce stiffness, as it was observed that the performance is sensitive to the incorporated content. |

| WT [106] | Powdered | Asphalt binder modifier at (3%, 6%, 9% and 12%) by binder weight | Asphalt binder | Ductility, penetration, softening point, flash point, MSCR, and BBR | All the modified binders show improved resistance, with 12% showing more resistance to fracture, bonding, and moisture; improved rheological properties at both low and high temperatures. | More comprehensive rheological and performance evaluation is required to have a complete understanding of the modified asphalt binder’s microscopic and thixotropic behaviour. |

| WT ink [107] | Powdered | Asphalt binder modifier at (2%, 4%, 6% 8% and 10%) by binder weight | Asphalt mixture | Specific Gravity, volumetric properties, Marshall flow and Stability, and Cantabro Loss | An increase in the content of the modifier increased load-bearing capacity with maximum Marshall stability at 6%. Additionally, it decreased the optimal binder content. | Various mechanical performance tests have not been assessed. Additionally, more validation of the optimal content under long-term field conditions is needed. |

| WT [108] | Powdered | Asphalt binder modifier at (7%, 14% and 21%) by binder weight | Asphalt binder | PG grading, frequency sweep, temperature sweep, and MSCR | WT slightly raised the mixing and compaction temperatures; lowered δ at low frequencies, improved G*, and improved high-temperature PG; enhanced resistance to rutting. Additionally, the higher the WT concentration, the lower the fatigue resistance. | Additional optimisation is required to mitigate the adverse impacts of WT on asphalt binder performance. More performance tests are recommended. |

| WT [109] | Powdered | Asphalt binder modifier at (4%, 8%, 12% and 16%) by binder weight. | Asphalt binder and mixtures | MSCR, Superpave G*/sinδ, and Wheel Tracking Test | WT improved the rutting resistance of both the asphalt binder and mixture, and the optimal improvement was observed at 12% WT content. | Limited assessment of fatigue, moisture damage, performance, and long-term durability. |

| WT [110] | Burnt powder | Asphalt binder modifier at (0% to 8%) by binder weight | Asphalt binder | Rheological, FTIR, and XRD, | WT increased enhanced high-temperature performance and binder flexibility; 8% WT improved self-healing via improved molecular diffusion and wetting. | Lack of thorough mechanical performance and leachability tests |

| WT [111] | Powdereded | Asphalt binder modifier at (0% to 8%) by binder weight | Asphalt binder | Dissipated energy ratio, fatigue parameters, XRD, and DSR (LAS test) | Modified binder shows improved fatigue resistance, which shows higher load cycles, less crack propagation, and less lost energy. | Lack of leachability testing, techno-economic analysis, and field research |

| WT [112] | Nano powdered | Asphalt binder modifier at (0% to 8%) by binder weight | Asphalt binder | BBR, DER, DCC, DSC, Burgers model (viscoelastic modelling), | WT was observed to decrease creep stiffness, increase stress relaxation, improve glass transition temperature, and DCC’s ability to accurately reflect changes in microstructure | Additional laboratory testing, large-scale design, and life cycle assessment are needed for proper comprehension of the WT effect on asphalt binder and mixtures. |

| WT [113] | Powdered | Asphalt binder modifier at (0%, 10% and 20%) by binder weight | Asphalt binder | Phase separation, Superpave PG, frequency sweep, and MSCR | Improved rutting resistance, increased stiffness and viscosity, and optimal performance at 10% MPCP without affecting low-temperature performance. | Phase separation and a decline in low-temperature performance at 20% MPCP are notable, and more mechanical tests are recommended. |

| WT (with other wastes) [114] | Powdered | Filler alternative | Asphalt mixture | The Marshall test, fatigue testing, and UTM (dynamic and static creep) | Waste toner was the best filler among the wastes studied, with the highest resilient modulus, creep stiffness, decreased cumulative strain, and longest fatigue life. | No leachability test or comprehensive field validation has been carried out. |

| WT [115] | Powdered | Asphalt binder modifier at (2%, 8% and 12%) by binder weight | Binder with toner and stearic acid, synergist with aluminate coupling agent. | Softening point, PG, Marshall stability, and Rutting test, | Modified asphalt binder maintained low-temperature cracking resistance while increasing high-temperature stability and rutting resistance, and it increased the softening point by 3–8 °C. | Long-term performance, leaching, and environmental impact were not assessed. |

5.4. EWDM Interaction with the Asphalt Binder

6. Environmental Implications for Upcycling EWDMs in Asphalt Pavement

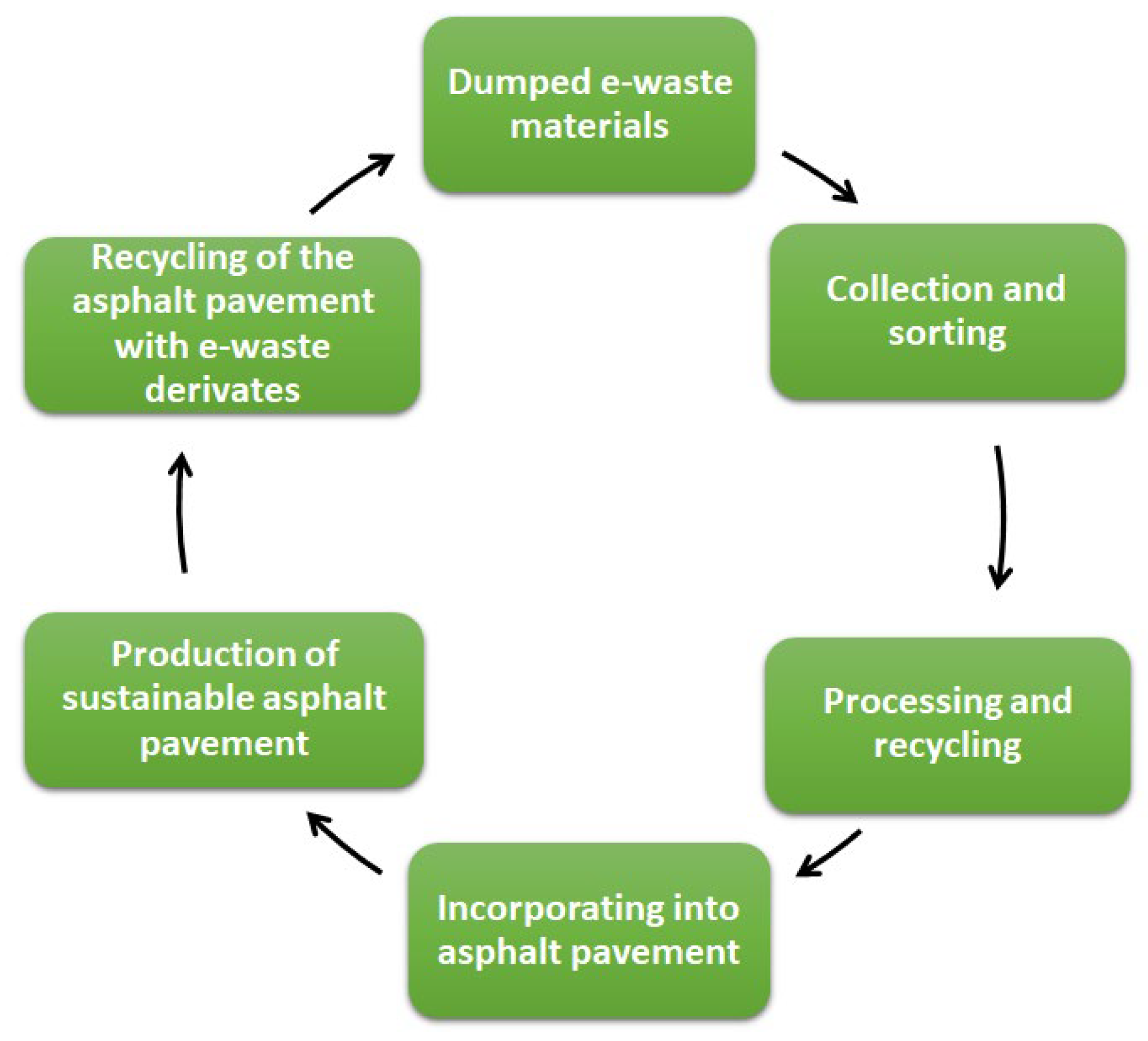

7. Circular Economy Potential of EWDMs in Asphalt Pavement

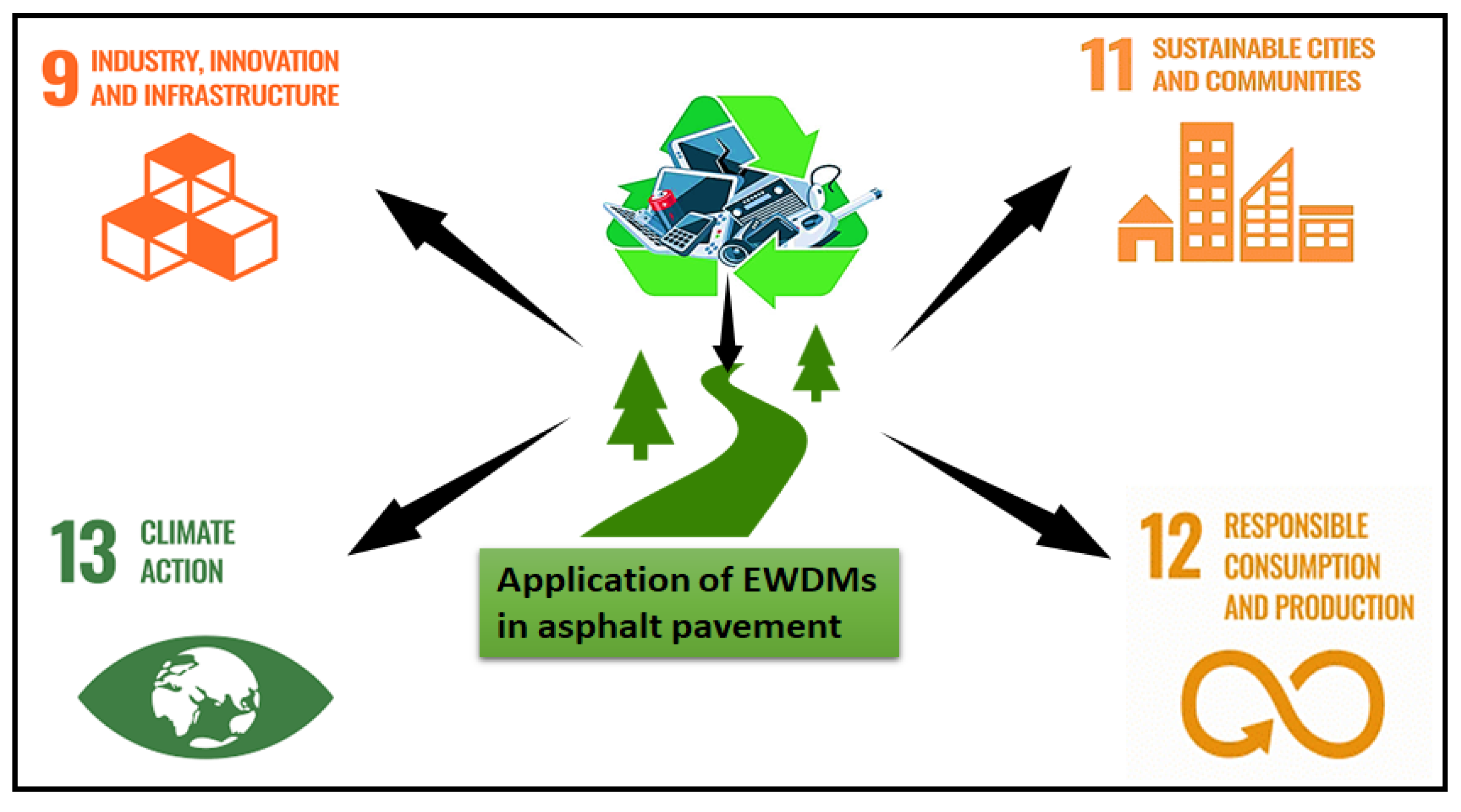

7.1. EWDMs’ Contribution to Sustainable Development Goals

7.2. Implications for the Application of E-Waste in Asphalt Pavement

8. Future Research Directions and Gaps

- ➢

- More microstructural and performance tests: To gain a better understanding of the microstructural interactions between e-waste polymers, toner residues, PCB non-metallic fractions, and asphalt binders, advanced characterisation techniques such as nanoindentation, atomic force microscopy (AFM), SEM, transmission electron microscopy (TEM), or molecular dynamics (MD) simulations should be used more frequently. Under various loading and environmental circumstances, these techniques can clarify the physical, chemical, and interfacial behaviours that control the rheological, mechanical, and durability characteristics of asphalt mixtures treated with EWDM.

- ➢

- E-waste incorporation technoeconomic analysis: Evaluate the financial effects of incorporating materials obtained from EWDMs into flexible pavement applications. Assessing lifespan cost reductions, reducing reliance on landfills, creating jobs in the material recovery and processing industries, and assessing the long-term value proposition for public infrastructure projects are all included in this.

- ➢

- Impact on the environment and life cycle assessment (LCA): Perform thorough LCA studies on asphalt mixtures modified with EWDM to measure their environmental advantages and trade-offs, such as carbon emissions, residual toxin leachability, and energy consumption during the manufacturing, application, and end-of-life phases.

- ➢

- Strengthening policy and institutional processes: Enhancing the institutional and legislative frameworks that control the reuse and management of e-waste in the building industry. The 4Rs, reduce, reuse, recycle, and recover, should be applied in infrastructure development projects by policy. To promote the responsible disposal and industrial adoption of EWDMs, incentive-based mechanisms (such as tax breaks or fines) should be combined with clear regulations on e-waste segregation, material handling, and environmental compliance.

- ➢

- Promote comprehensive waste management systems: Encourage the use of comprehensive waste management systems that emphasise resource recovery at the source, waste prevention, and material minimisation. The use of intelligent technology for automated sorting, effective recycling of non-metallic and polymeric e-waste fractions, and energy recovery through waste-to-energy (WtE) programmes can promote energy-neutral paving solutions and drastically reduce reliance on landfills.

- ➢

- Establishment of Circular Economy Frameworks: Finally, incorporating e-waste valuation into frameworks for the circular economy necessitates interdisciplinary research that addresses policy incentives, public acceptance, quality control procedures, and regulatory standards. These initiatives support the shift to low-carbon, climate-resilient, and resource-efficient transportation infrastructure.

- ➢

- Encouraging Private Sector Participation through PPPs (Public-Private Partnerships): By creating PPP frameworks, the private sector may be encouraged to actively participate in the development of circular waste infrastructure. This entails making investments in material recovery facilities, specialising in recycling factories for electronic waste, and constructing regional processing facilities for the production of EWDM. These types of partnerships have the potential to increase jobs, the economy, and the effectiveness of asphalt-modified material supply chains.

- ➢

- The process for processing e-waste can be optimised by looking at scalable and sophisticated methods for processing it, especially for removing non-metallic and polymeric fractions that work well with bituminous binders. To improve material quality and environmental safety, a focus should be placed on enhancing mechanical and thermal treatment techniques.

- ➢

- Evaluation of the Policy and Regulatory Framework: Looking at how well current waste management regulations encourage the reuse of e-waste in buildings. Strategic avenues for mainstreaming the use of EWDM in asphalt technologies can be found in comparative policy studies with nations that have effectively adopted circular practices.

9. Conclusions

9.1. Key Findings

9.2. Implications for Industry and Policy

9.3. Gaps

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ajirotutu, R.O.; Adeyemi, A.B.; Ifechukwu, G.-O.; Iwuanyanwu, O.; Ohakawa, T.C.; Garba, B.M.P. Future cities and sustainable development: Integrating renewable energy, advanced materials, and civil engineering for urban resilience. Int. J. Sustain. Urban Dev. 2024, 12, 235–250. [Google Scholar]

- Tafida, A.; Alaloul, W.S.; Zawawi, N.A.B.W.; Musarat, M.A.; Abubakar, A.S. A Review of Eco-Friendly Road Infrastructure Innovations for Sustainable Transportation. Infrastructures 2024, 9, 216. [Google Scholar] [CrossRef]

- Salehi, S.; Arashpour, M.; Kodikara, J.; Guppy, R. Sustainable pavement construction: A systematic literature review of environmental and economic analysis of recycled materials. J. Clean. Prod. 2021, 313, 127936. [Google Scholar] [CrossRef]

- Liu, Z.; Kringos, N. Transition from linear to circular economy in pavement engineering: A historical review. J. Clean. Prod. 2024, 449, 141809. [Google Scholar] [CrossRef]

- Chen, L.; Yang, M.; Chen, Z.; Xie, Z.; Huang, L.; Osman, A.I.; Farghali, M.; Sandanayake, M.; Liu, E.; Ahn, Y.H. Conversion of waste into sustainable construction materials: A review of recent developments and prospects. Mater. Today Sustain. 2024, 27, 100930. [Google Scholar] [CrossRef]

- Ouro-Salim, O. Urban mining of e-waste management globally: Literature review. Clean. Waste Syst. 2024, 9, 100162. [Google Scholar] [CrossRef]

- Ali, W. Optimizing the e-waste management in India: A sustainable mathematical modeling approach to circular economy. Qual. Quant. 2025, 59, 4647–4678. [Google Scholar] [CrossRef]

- Sachdeva, A.; Sharma, U. An overview of utilization of e-waste plastic in road construction. In Sustainable Civil Engineering Practices: Select Proceedings of ICSCEP 2019; Springer: Singapore, 2020; pp. 101–109. [Google Scholar]

- Vishwakarma, A.; Kanaujia, K.; Hait, S. Global scenario of E-waste generation: Trends and future predictions. In Global E-Waste Management Strategies and Future Implications; Elsevier: Amsterdam, The Netherlands, 2023; pp. 13–30. [Google Scholar]

- Wäger, P.; Böni, H.; Buser, A.; Morf, L.; Schluep, M.; Streicher, M. Recycling of Plastics from waste electrical and electronic equipment (WEEE)–tentative results of a Swiss study. Proc. R 2009, 9. [Google Scholar]

- Shafiee, M.; Fattahi, M. Performance Evaluation of an Asphalt Mix Containing Non-Metallic Fractions of Recycled Printed Circuit Boards. J. Civ. Eng. Constr. 2024, 13, 59–66. [Google Scholar] [CrossRef]

- Coalition, E.-W. A New Circular Vision for Electronics: Time for a Global Reboot; World Economic Forum: Geneva, Switzerland, 2019. [Google Scholar]

- Khan, S.A. E-products, E-waste and the Basel Convention: Regulatory challenges and impossibilities of international environmental law. Rev. Eur. Comp. Int. Environ. Law 2016, 25, 248–260. [Google Scholar] [CrossRef]

- Baldé, C.P.; Kuehr, R.; Yamamoto, T.; McDonald, R.; D’Angelo, E.; Althaf, S.; Bel, G.; Deubzer, O.; Fernandez-Cubillo, E.; Forti, V. The Global E-Waste Monitor; International Telecommunication Union (ITU): Geneva, Switzerland; International Solid Waste Association (ISWA): Bonn, Germany, 2024; pp. 1–147. [Google Scholar]

- Fawole, A.A.; Orikpete, O.F.; Ehiobu, N.N.; Ewim, D.R.E. Climate change implications of electronic waste: Strategies for sustainable management. Bull. Natl. Res. Cent. 2023, 47, 147. [Google Scholar] [CrossRef]

- Grandhi, S.P.; Dagwar, P.P.; Dutta, D. Policy pathways to sustainable E-waste management: A global review. J. Hazard. Mater. Adv. 2024, 16, 100473. [Google Scholar] [CrossRef]

- Ajekwene, K.K.; Aigbokhan, E.; Akindele, O.; Yibowei, M.; Momoh, F.; Ugonna, U. Electronic waste (e-waste): Sources, proliferation, effects & management in developing nations. IOSR J. Eng. 2022, 12, 12–27. [Google Scholar]

- Sarkhoshkalat, M.M.; Afkham, A.; Bonyadi Manesh, M.; Sarkhosh, M. Circular Economy and the Recycling of E-Waste. In New Technologies for Energy Transition Based on Sustainable Development Goals: Factors Contributing to Global Warming; Springer: Berlin/Heidelberg, Germany, 2024; pp. 319–354. [Google Scholar]

- Le, M.-H.; Lu, W.-M.; Chang, J.-C. Recycling e-waste and the sustainable economy: A bibliometric exploration. Sustainability 2023, 15, 16108. [Google Scholar] [CrossRef]

- Kumar, G.; Bansal, T.; Haq, M.; Sharma, U.; Kumar, A.; Jha, P.; Sharma, D.; Kamyab, H.; Valencia, E.A.V. Utilizing E-Waste as a Sustainable Aggregate in Concrete Production: A Review. Buildings 2024, 14, 2495. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Effiong, J.U.; Ede, A.N.; Olukanni, D.O.; Okoro, C.W.; Adebesin, J.A. Review of the use of E-waste in concrete production: Challenges and prospects. Emergent Mater. 2024, 7, 821–845. [Google Scholar] [CrossRef]

- Mohammadi, S.; Jin, D.; Liu, Z.; You, Z. Incorporation of E-Waste plastics into asphalt: A review of the materials, methods, and impacts. Encyclopedia 2025, 5, 112. [Google Scholar] [CrossRef]

- de Abreu, V.H.S. Implementing Circular Economy Principles in Road Transport: Enhancing Efficiency to Mitigate Resource Depletion and Carbon Footprint. In Carbon Footprint Assessments: Case Studies & Best Practices; Springer: Berlin/Heidelberg, Germany, 2024; pp. 289–312. [Google Scholar]

- Hasan, M.R.M.; Colbert, B.; You, Z.; Jamshidi, A.; Heiden, P.A.; Hamzah, M.O. A simple treatment of electronic-waste plastics to produce asphalt binder additives with improved properties. Constr. Build. Mater. 2016, 110, 79–88. [Google Scholar] [CrossRef]

- Huang, J.; Kumar, G.S.; Sun, Y. Evaluation of workability and mechanical properties of asphalt binder and mixture modified with waste toner. Constr. Build. Mater. 2021, 276, 122230. [Google Scholar] [CrossRef]

- Parthasarathy, M. Challenges and emerging trends in toner waste recycling: A review. Recycling 2021, 6, 57. [Google Scholar] [CrossRef]

- Westerdahl, J.; Belhaj, M.; Rydberg, T.; Munthe, J.; Darbra, R.M.; Àgueda, A.; Heise, S.; Ziyang, L. Additives and other hazardous compounds in electronic products and their waste. In Global Risk-Based Management of Chemical Additives I: Production, Usage and Environmental Occurrence; Springer: Berlin/Heidelberg, Germany, 2012; pp. 57–81. [Google Scholar]

- Ren, J.; Huang, X.; Liu, J.; Mao, J.; Liang, C.; Cheng, Z.; Zhu, H.; Xu, J.; Dong, Z.; Newlands, M. Reusing Waste Toner Powder as Functional Additives for Alkali-Activated Slag. Case Stud. Constr. Mater. 2025, 22, e04783. [Google Scholar] [CrossRef]

- Gaikwad, V.; Kumar, U.; Pahlevani, F.; Piadasa, A.; Sahajwalla, V. Thermal transformation of waste toner powder into a value-added ferrous resource. ACS Sustain. Chem. Eng. 2017, 5, 11543–11550. [Google Scholar] [CrossRef]

- Ruan, J.; Dong, L.; Huang, J.; Huang, Z.; Huang, K.; Dong, H.; Zhang, T.; Qiu, R. Vacuum-gasification-condensation of waste toner to produce industrial chemicals and nanomaterials. ACS Sustain. Chem. Eng. 2017, 5, 4923–4929. [Google Scholar] [CrossRef]

- Shahib, M.I.; Dsouza, G.C.; Vijayakumar, R. A review on end-of-life waste toner powder: Recovery, utilization and upcycling. Waste Manag. 2025, 204, 114911. [Google Scholar] [CrossRef] [PubMed]

- Naseri, H.; Hosseini, P.; Jahanbakhsh, H.; Hosseini, P.; Gandomi, A.H. A novel evolutionary learning to prepare sustainable concrete mixtures with supplementary cementitious materials. Environ. Dev. Sustain. 2023, 25, 5831–5865. [Google Scholar] [CrossRef]

- Ádám, B.; Göen, T.; Scheepers, P.T.; Adliene, D.; Batinic, B.; Budnik, L.T.; Duca, R.-C.; Ghosh, M.; Giurgiu, D.I.; Godderis, L. From inequitable to sustainable e-waste processing for reduction of impact on human health and the environment. Environ. Res. 2021, 194, 110728. [Google Scholar] [CrossRef]

- Hu, W.; Shu, X.; Huang, B. Sustainability innovations in transportation infrastructure: An overview of the special volume on sustainable road paving. J. Clean. Prod. 2019, 235, 369–377. [Google Scholar] [CrossRef]

- Sharma, S.; Boora, A. Application of E-Waste in the Construction of Concrete Pavements: A Comprehensive Review. In E3S Web of Conferences; EDP Sciences: Evry, France, 2024; Volume 194, p. 01031. [Google Scholar]

- Suganthi, S.; Arunkumar, R.; Premkumar, R.; Suthahar, P.; Venkatasubramanian, R. E-waste infused bituminous mix for flexible pavements. Mater. Today Proc. 2023, in press. [Google Scholar]

- Muthukumar, S.; Bavithran, O.; Nandhagopal, A.; Snehasree, T. Stability study on eco-friendly Flexible pavement using E-waste and Hips. Int. J. Civ. Eng. Technol. 2017, 8, 956–965. [Google Scholar]

- Wirtu, Y.D.; Godana, U.A.; Tucho, G.T. A Review of public perception and awareness of e-waste management in developing countries: Challenges and opportunities for sustainable solutions. Environ. Rev. 2025, 33, 1–12. [Google Scholar] [CrossRef]

- Serpe, A.; Purchase, D.; Bisschop, L.; Chatterjee, D.; De Gioannis, G.; Garelick, H.; Kumar, A.; Peijnenburg, W.J.G.M.; Piro, V.M.I.; Cera, M.; et al. 2002–2022: 20 years of e-waste regulation in the European Union and the worldwide trends in legislation and innovation technologies for a circular economy. RSC Sustain. 2025, 3, 1039–1083. [Google Scholar] [CrossRef]

- Saha, L.; Kumar, V.; Tiwari, J.; Rawat, S.; Singh, J.; Bauddh, K. Electronic waste and their leachates impact on human health and environment: Global ecological threat and management. Environ. Technol. Innov. 2021, 24, 102049. [Google Scholar] [CrossRef]

- Chan, J. The Largest Global Producers of E-Waste and the Need for Change. Brook. J. Int’l L. 2022, 48, 215. [Google Scholar]

- Murthy, V.; Ramakrishna, S. A review on global E-waste management: Urban mining towards a sustainable future and circular economy. Sustainability 2022, 14, 647. [Google Scholar] [CrossRef]

- Mir, M.A.; Chang, S.K. Saudi Arabia E-waste management strategies, challenges and opportunities, effect on health and environment: A strategic review. Emerg. Contam. 2024, 10, 100357. [Google Scholar] [CrossRef]

- Perkins, D.N.; Drisse, M.-N.B.; Nxele, T.; Sly, P.D. E-waste: A global hazard. Ann. Glob. Health 2014, 80, 286–295. [Google Scholar] [CrossRef]

- Lepawsky, J. Mapping chemical discardscapes of electronics production. Geoforum 2022, 132, 113–124. [Google Scholar] [CrossRef]

- Forti, V.; Balde, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential; United Nations University/United Nations Institute for Training and Research: Geneva, Switzerland; International Telecommunication Union: Geneva, Switzerland; International Solid Waste Association: Wien, Austria, 2020. [Google Scholar]

- Mihai, F.-C.; Gnoni, M.G.; Meidiana, C.; Schneider, P.; Ezeah, C.; Elia, V. A global outlook on the implementation of the Basel Convention and the Transboundary Movement of E-waste. In Paradigm Shift in E-Waste Management; CRC Press: Boca Raton, FL, USA, 2022; pp. 49–75. [Google Scholar]

- Selvakumar, S.; Adithe, S.; Isaac, J.S.; Pradhan, R.; Venkatesh, V. A study of the printed circuit board (PCB) e-waste recycling process. In Sustainable Approaches and Strategies for E-Waste Management and Utilization; IGI Global: Hershey, PA, USA, 2023; pp. 159–184. [Google Scholar]

- Chel, A.L.; Wani, A.; Shetty, N.C.; Kaushik, G. Utilization of Micro-Nano Plastics Derived from Electronic Waste into Bitumen for Sustainable Environment. In Micro-Nano Plastics Exposure, Environmental Degradation and Public Health Crisis; Springer: Berlin/Heidelberg, Germany, 2025; pp. 269–279. [Google Scholar]

- Bayagoob, A.A.; Péter, F. The utilization of e-waste in asphalt pavement: A review. J. Adv. Ind. Technol. Appl. 2022, 3, 62–72. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Sutanto, M.H.; Baloo, L.; Habib, N.Z.; Usman, A.; Yousafzai, A.K.; Ahmad, A.; Birniwa, A.H.; Jagaba, A.H.; Noor, A. A comprehensive overview of the utilization of recycled waste materials and technologies in asphalt pavements: Towards environmental and sustainable low-carbon roads. Processes 2023, 11, 2095. [Google Scholar] [CrossRef]

- Tetley, S.; Lewis, T.; Nortje, W.; Koekemoer, D.; Visser, H. Asphalt Modified with Recycled Waste Plastic in South Africa Encouraging Results of Trial Section Performance. In International Road Federation World Meeting & Exhibition; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1125–1135. [Google Scholar]

- Kumar, K.; Kumar, A.; Srivastava, M.; Chandra, H.; Singh, R.K. Study of physical and rheological properties of modified bitumen prepared by blending non-metallicpart of e-waste. Int. J. Adhes. Adhes. 2023, 127, 103516. [Google Scholar] [CrossRef]

- Asteray, D.B.; Elsaigh, W.A. Waste Plastic to Roads–HDPE-modified Bitumen and PET Plastic Fibres for Road Maintenance in South Africa: A Review. Waste Manag. Res. 2024, 42, 932–946. [Google Scholar] [CrossRef] [PubMed]

- Needhidasan, S.; Agarwal, S.G. A review on properties evaluation of bituminous addition with E-waste plastic powder. Mater. Today Proc. 2020, 22, 1218–1222. [Google Scholar] [CrossRef]

- Khedaywi, T.S. Study on utilising waste toner in asphalt cement. Road Mater. Pavement Des. 2014, 15, 446–454. [Google Scholar] [CrossRef]

- Li, S.; Sun, Y.; Fang, S.; Huang, Y.; Yu, H.; Ye, J. Recycling non-metallic powder of waste printed circuit boards to improve the performance of asphalt material. Materials 2022, 15, 4172. [Google Scholar] [CrossRef]

- Premur, V.; Vučinić, A.A.; Melnjak, I.; Radetić, L. Reuse of the recycled nonmetallic fraction from waste printed circuit boards in pavement industry. Environ. Eng. Manag. J. 2018, 17, 2719–2729. [Google Scholar] [CrossRef]

- Huang, W.; Hu, J.; Luo, S. The technological innovation pathway for green, low-carbon, and durable pavement construction and maintenance. Sci. China Technol. Sci. 2024, 67, 3959–3961. [Google Scholar] [CrossRef]

- Krithiga, P.; Preethi, M.V.; Samritha, K.; Mena, K.S.K. Review on Utilizing E-Waste Plastic in Bitumen for Better Strength and Sustainable Environment. In Sustainable Materials and Smart Practices: NCSMSP-2021; Materials Research Forum LLC.: Millersville, PA, USA, 2022; Volume 23, p. 381. [Google Scholar]

- Luhar, S.; Luhar, I. Potential application of E-wastes in construction industry: A review. Constr. Build. Mater. 2019, 203, 222–240. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Uddin, M.N.; Chowdhury, J.; Ahmed, S.; Uddin, M.; Mofijur, M.; Uddin, M. A review of the recent development, challenges, and opportunities of electronic waste (e-waste). Int. J. Environ. Sci. Technol. 2023, 20, 4513–4520. [Google Scholar] [CrossRef]

- Guo, J.; Guo, J.; Xu, Z. Recycling of non-metallic fractions from waste printed circuit boards: A review. J. Hazard. Mater. 2009, 168, 567–590. [Google Scholar] [CrossRef]

- Choudhary, D.; Kaithwas, S.; Sharma, R.; Mishra, A.; Singhai, S.; Powar, S.; Singh, A. Recycling of waste toner derived from exhausted printer cartridges as adsorbent for defluoridation of water. Environ. Technol. Innov. 2024, 34, 103572. [Google Scholar] [CrossRef]

- Yordanova, D.; Angelova, S.; Dombalov, I. Utilisation options for waste toner powder. J. Environ. Sci 2014, 3, 140–144. [Google Scholar]

- Itoua, P.I.; Sun, D.; Li, P.; Shen, S. Influence of waste toner on asphalt binder: Chemical and rheological characterization. Molecules 2023, 28, 2794. [Google Scholar] [CrossRef] [PubMed]

- Khedaywi, T.; Haddad, M.; Al-Masaeid, H.; Mharib, I.A.; Hawari, S. Characterization of binder and asphalt mixture modified with waste toner. Int. J. Transp. Sci. Technol. 2025, in press. [Google Scholar] [CrossRef]

- Dankwah, J.; Anderson, M.; Owusu-Ansah, Y. Waste Toner Powder, a Potential Resource for Iron and Steelmaking Technologies. In Proceedings of the 7th UMaT Biennial International Mining and Mineral Conference, Tarkwa, Ghana, August 2022; Available online: https://conference.umat.edu.gh/wp-content/uploads/2022/10/Darkwah-et-al-.-2022.pdf (accessed on 1 October 2025).

- Hossain, R.; Sahajwalla, V. Material microsurgery: Selective synthesis of materials via high-temperature chemistry for microrecycling of electronic waste. ACS Omega 2020, 5, 17062–17070. [Google Scholar] [CrossRef]

- Otsuki, A.; Dodbiba, G.; Fujita, T. Two-liquid flotation: Heterocoagulation of fine particles in polar organic solvent. Mater. Trans. 2007, 48, 1095–1104. [Google Scholar] [CrossRef]

- Sohaili, J.; Muniyandi, S.K.; Mohamad, S.S.; Ariffin, A. Effect of particle size and amount of nonmetallic PCB materials on the mechanical properties of rHDPE/PCB composites. Mal. J. Fundam. Appl. Sci 2019, 15, 260–267. [Google Scholar] [CrossRef]

- Dickson, K.; Yeung, C.A. PRISMA 2020 updated guideline. Br. Dent. J. 2022, 232, 760–761. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Sutanto, M.H.; Hainin, M.R.; Habib, N.Z.; Usman, A.; Bello, M.S.; Wada, S.A.; Adebanjo, A.U.; Jagaba, A.H. Soft computing applications in asphalt pavement: A comprehensive review of data-driven techniques using response surface methodology and machine learning. J. Road Eng. 2025, 5, 129–163. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Zhu, Y.; Zhang, H. A Review of Sustainability in Hot Asphalt Production: Greenhouse Gas Emissions and Energy Consumption. Appl. Sci. 2024, 14, 10246. [Google Scholar] [CrossRef]

- Styer, J.; Tunstall, L.; Landis, A.; Grenfell, J. Innovations in pavement design and engineering: A 2023 sustainability review. Heliyon 2024, 10, e33602. [Google Scholar] [CrossRef] [PubMed]

- Buekens, A.; Yang, J. Recycling of WEEE plastics: A review. J. Mater. Cycles Waste Manag. 2014, 16, 415–434. [Google Scholar] [CrossRef]

- Deshmukh, D.; Kulkarni, H.; Srivats, D.S.; Bhanushali, S.; More, A.P. Recycling of acrylonitrile butadiene styrene (ABS): A review. Polym. Bull. 2024, 81, 1–38. [Google Scholar] [CrossRef]

- Colbert, B.W.; Diab, A.; You, Z. Using ME PDG to study the effectiveness of electronic waste materials modification on asphalt pavements design thickness. Int. J. Pavement Res. Technol. 2013, 6, 319. [Google Scholar]

- Colbert, B.W. The Performance and Modification of Recycled Electronic Waste Plastics for the Improvement of Asphalt Pavement Materials. Ph.D. Thesis, Michigan Technological University, Houghton, MI, USA, 2012. [Google Scholar]

- Colbert, B.W.; You, Z. Properties of modified asphalt binders blended with electronic waste powders. J. Mater. Civ. Eng. 2012, 24, 1261–1267. [Google Scholar] [CrossRef]

- Santhanam, N.; Ramesh, B.; Agarwal, S.G. Experimental investigation of bituminous pavement (VG30) using E-waste plastics for better strength and sustainable environment. Mater. Today Proc. 2020, 22, 1175–1180. [Google Scholar] [CrossRef]

- Krithiga, P.; Preethi, M.V.; Samritha, K.; Mena, K.S.K. Experimental Investigation of Bitumen by Using E-Waste Plastic as Filler. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; Volume 1125, p. 012003. [Google Scholar]

- Patel, V.J.; Kumavat, H.R.; Tapkire, G.V. An Experimental Study of Bituminous Pavement adding Electronic-Waste to Increase the Strength Economically. Int. J. Innov. Res. Sci. Eng. Technol. 2007, 6. [Google Scholar] [CrossRef]

- Singh, P.K.; Suman, S.; Kumar, M. Influence of recycled acrylonitrile butadiene styrene (ABS) on the physical, rheological and mechanical properties of bitumen binder. Transp. Res. Procedia 2020, 48, 3668–3677. [Google Scholar] [CrossRef]

- Sinha, R.; Kumar, S.; Garg, S.; Prasad, N.M. Use of electronic waste plastic in asphalt mix with marble dust as filler. Indian J. Eng. Mater. Sci. 2021, 28, 36–45. [Google Scholar] [CrossRef]

- Shahane, H.A.; Bhosale, S.S. E-Waste plastic powder modified bitumen: Rheological properties and performance study of bituminous concrete. Road Mater. Pavement Des. 2021, 22, 682–702. [Google Scholar] [CrossRef]

- Mani, S.S.; Mohamed, I.S.; Prabu, P.N.; Rajkumar, M.; Suresh, M. Experimental study on bituminous pavement by using e-waste and fly-ash. J. Environ. Res. Dev. 2015, 9. [Google Scholar]

- Dragomir, M.; Cadar, R.; Boitor, R. Using E-waste in asphalt mixtures–A laboratory investigation. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1138, p. 012022. [Google Scholar]

- Vaidevi, C.; Sahana, D.; Sripriya, E.; Tamilselvi, T.; Vijayan, D. Utilization of e-waste in flexible pavement. In AIP Conference Proceedings; AIP Publishing: New York, NY, USA, 2020; Volume 2271. [Google Scholar]

- Ranadive, M.; Shinde, M.K. Performance evaluation of E-waste in flexible pavement-an experimental approach. Int. J. Civ. Struct. Environ. Infrastruct. Eng. Res. Dev. 2012, 2, 1–11. [Google Scholar]

- Sachdeva, A.; Sharma, U. Utilization of E-waste Plastic as Aggregate Replacement in Bituminous Concrete Mixes. In Proceedings of the Fifth International Conference of Transportation Research Group of India. Lecture Notes in Civil Engineering; Singh, D., Vanajakshi, L., Verma, A., Das, A., Eds.; Springer: Singapore, 2022; Volume 218. [Google Scholar] [CrossRef]

- Ghabchi, R.; Mihandoust, M.; Datta, D. Electronic Waste (E-Waste) as Synthetic Aggregate for Hot-Mix Asphalt. In Proceedings of the International Airfield and Highway Pavements Conference 2023, Austin, TX, USA, 14–17 June 2023; pp. 83–91. [Google Scholar]

- Bharani, S.; Rajesh, M.; Sivaprashad, R. Experimental investigation of modified bitumen in flexible pavements by using electronic waste and high impact polystyrene. Mater. Today Proc. 2023, in press. [Google Scholar]

- Kumar, G.R.; Santhosh, K.; Bharani, S. Influence of E-waste on properties of bituminous mixes. Mater. Today Proc. 2021, 37, 2719–2724. [Google Scholar] [CrossRef]

- Guo, J.; Guo, J.; Wang, S.; Xu, Z. Asphalt modified with nonmetals separated from pulverized waste printed circuit boards. Environ. Sci. Technol. 2009, 43, 503–508. [Google Scholar] [CrossRef] [PubMed]

- Reashma, P.S.; Nivitha, M.R.; Veeraragavan, A.; Sikdar, P.K.; Krishnan, J.M. Development of unmodified binder specifications for India. Transp. Dev. Econ. 2017, 3, 12. [Google Scholar] [CrossRef]

- Gedik, A.; Selcuk, S.; Lav, A.H. Investigation of recycled fluorescent lamps waste as mineral filler in highway construction: A case of asphaltic pavement layers. Resour. Conserv. Recycl. 2021, 168, 105290. [Google Scholar] [CrossRef]

- Du, X.; Hu, K.; Zhang, F.; Liu, J.; Gillani, S.T.A. Characteristics of waste toner powder and its interaction effect on the physicochemical properties of asphalt binder. Constr. Build. Mater. 2025, 458, 139484. [Google Scholar] [CrossRef]

- Itoua, P.; Sun, D.; Shen, S. Investigating the Properties of Asphalt and Asphalt Mixture Based on the Effect of Waste Toner. Carbon 2024, 59, 55+88. [Google Scholar]

- Rambarran, S.; Maharaj, R.; Mohammed, S.; Sangster, N. The utilization of waste toner as a modifier in trinidad asphalts. Recycling 2022, 7, 74. [Google Scholar] [CrossRef]

- Notani, M.A.; Hajikarimi, P.; Moghadas Nejad, F.; Khodaii, A. Performance evaluation of using waste toner in bituminous material by focusing on aging and moisture susceptibility. J. Mater. Civ. Eng. 2021, 33, 04020405. [Google Scholar] [CrossRef]

- Shah, S.A.R.; Hussan, S.; Kahla, N.B.; Anwar, M.K.; Baluch, M.A.; Nawaz, A. Performance Evaluation and Optimization of Binder-Toner and Mixing Efficiency Ratios in an E-Waste Toner-Modified Composite Mixture Using Response Surface Methodology. Infrastructures 2024, 9, 200. [Google Scholar] [CrossRef]

- Itoua, P.I.; Sun, D. Evaluation of waste toner asphalt containing crude palm oil from Congo: Rheological properties, compatibility, self-healing and aging characteristic. Case Stud. Constr. Mater. 2024, 20, e03082. [Google Scholar] [CrossRef]

- Khedaywi, T.S. Laboratory study to evaluate the effect of waste toner on dynamic creep of asphalt concrete mixtures. In Proceedings of Fifth International Conference on Sustainable Construction Materials and Technologies (SCMT5), London, UK, 14–17 July 2019; Kingston University: London, UK, 2019; pp. 14–17. [Google Scholar]

- Huang, J.; Li, X.; Kumar, G.S.; Deng, Y.; Gong, M.; Dong, N. Rheological properties of bituminous binder modified with recycled waste toner. J. Clean. Prod. 2021, 317, 128415. [Google Scholar] [CrossRef]

- Tailat, O.Y.; Oluwasola, E.A.; Afolayan, A. Volumetric and Abrasion Loss Properties of Asphalt Mix Modified with Used Toner Ink. Int. J. Innov. Res. Dev. 2021, 10. [Google Scholar] [CrossRef]

- Showkat, B.; Suresha, S.; Akhandappagol, N. Study of rheological and creep recovery properties of asphalt binder modified with waste toner. J. Mater. Civ. Eng. 2020, 32, 04020331. [Google Scholar] [CrossRef]

- Notani, M.A.; Hajikarimi, P.; Nejad, F.M.; Khodaii, A. Rutting resistance of toner-modified asphalt binder and mixture. Int. J. Pavement Res. Technol. 2020, 13, 1–9. [Google Scholar] [CrossRef]

- Notani, M.A.; Mokhtarnejad, M. Investigating the rheological and self-healing capability of toner-modified asphalt binder. Proc. Inst. Civ. Eng. Constr. Mater. 2020, 173, 123–131. [Google Scholar] [CrossRef]

- Notani, M.A.; Moghadas Nejad, F.; Khodaii, A.; Hajikarimi, P. Evaluating fatigue resistance of toner-modified asphalt binders using the linear amplitude sweep test. Road Mater. Pavement Des. 2019, 20, 1927–1940. [Google Scholar] [CrossRef]

- Notani, M.A.; Moghadas Nejad, F.; Fini, E.H.; Hajikarimi, P. Low-temperature performance of toner-modified asphalt binder. J. Transp. Eng. Part B Pavements 2019, 145, 04019022. [Google Scholar] [CrossRef]

- Larios Rodriguez, J.; Sebaaly, P.; Hitti, E.; Hajj, E.; Hand, A. Impact of modified post-consumer plastic (MPCP) toner on asphalt binder properties. Transp. Res. Rec. 2025, 2679, 953–962. [Google Scholar] [CrossRef]

- Al-Mistarehi, B.W.; Khadaywi, T.S.; Hussein, A.K. Investigating the effects on creep and fatigue behavior of asphalt mixtures with recycled materials as fillers. J. King Saud Univ. Eng. Sci. 2021, 33, 355–363. [Google Scholar] [CrossRef]

- Lin, C.; Chen, C.; Lian, J. Properties of printer waste toner modified bitumen. In Proceedings of the 2016 2nd International Conference on Sustainable Energy and Environmental Engineering (SEEE 2016), Xiamen, China, 18–19 December 2016. [Google Scholar]

- Dombe, S.; Tapase, A.B.; Ghugal, Y.; Konnur, B.; Akshay, P. Investigation on the use of E-waste and waste plastic in road construction. In Recent Developments in Pavement Engineering: Proceedings of the 3rd GeoMEast International Congress and Exhibition, Egypt 2019 on Sustainable Civil Infrastructures–The Official International Congress of the Soil-Structure Interaction Group in Egypt (SSIGE); Springer: Berlin/Heidelberg, Germany, 2020; pp. 85–99. [Google Scholar]

- Yang, Q.; Lin, J.; Wang, X.; Wang, D.; Xie, N.; Shi, X. A review of polymer-modified asphalt binder: Modification mechanisms and mechanical properties. Clean. Mater. 2024, 12, 100255. [Google Scholar] [CrossRef]

- Hameed, R.; Divyabharathi, R.; Yadav, K.K.; Debbarma, P.; Singh, S.V.; Arabi, A.I.A.; Abbas, A.; Durgude, S.A.; Alam, M.W.; Wang, C. A review on sustainable management strategies for navigating the piling e-waste crisis and associated environmental threats. Toxicology 2024, 511, 154019. [Google Scholar] [CrossRef]

- Mohammed, S.; Kaida, N. Opportunities and challenges for circular economy in the Maldives: A stakeholder analysis of informal E-waste management in the Greater Malé Region. J. Environ. Manag. 2024, 358, 120944. [Google Scholar] [CrossRef]

- Srivastava, A.N.; Sikarwar, V.S.; Bisen, D.; Fathi, J.; Maslani, A.; Lopez Nino, B.N.; Barmavatu, P.; Kaviti, A.K.; Pohořelý, M.; Buryi, M. E-Waste Unplugged: Reviewing Impacts, Valorization Strategies and Regulatory Frontiers for Efficient E-Waste Management. Processes 2025, 13, 2014. [Google Scholar] [CrossRef]

- Munni, M.N.; Karim, M.R.; Haque, M.; Khan, S.; Khan, M.A.S.; Hossain, I. Awareness, Safety Practices and Associated Factors Among E-Waste Recycling Workers in Bangladesh. Environ. Health Insights 2024, 18, 11786302241271555. [Google Scholar] [CrossRef]

- Farjana, S.H.; Mungombe, T.M.; Gamage, H.M.K.; Rajwani, A.S.; Tokede, O.; Ashraf, M. Circulating the E-Waste Recovery from the Construction and Demolition Industries: A Review. Sustainability 2023, 15, 12435. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Sutanto, M.H.; Habib, N.Z.; Napiah, M.; Usman, A.; Jagaba, A.H.; Al-Sabaeei, A.M. Application and circular economy prospects of palm oil waste for eco-friendly asphalt pavement industry: A review. J. Road Eng. 2022, 2, 309–331. [Google Scholar] [CrossRef]

- Hobson, K. The limits of the loops: Critical environmental politics and the Circular Economy. In Trajectories in Environmental Politics; Routledge: London, UK, 2022; pp. 158–176. [Google Scholar]

- Parajuly, K.; Fitzpatrick, C.; Muldoon, O.; Kuehr, R. Behavioral change for the circular economy: A review with focus on electronic waste management in the EU. Resour. Conserv. Recycl. X 2020, 6, 100035. [Google Scholar] [CrossRef]

- Sauvé, S.; Bernard, S.; Sloan, P. Environmental sciences, sustainable development and circular economy: Alternative concepts for trans-disciplinary research. Environ. Dev. 2016, 17, 48–56. [Google Scholar] [CrossRef]

- Ogunmakinde, O.E.; Egbelakin, T.; Sher, W. Contributions of the circular economy to the UN sustainable development goals through sustainable construction. Resour. Conserv. Recycl. 2022, 178, 106023. [Google Scholar] [CrossRef]

- Bucknall, D.G. Plastics as a materials system in a circular economy. Philos. Trans. R. Soc. A 2020, 378, 20190268. [Google Scholar] [CrossRef]

- Srivastav, A.L.; Markandeya; Patel, N.; Pandey, M.; Pandey, A.K.; Dubey, A.K.; Kumar, A.; Bhardwaj, A.K.; Chaudhary, V.K. Concepts of circular economy for sustainable management of electronic wastes: Challenges and management options. Environ. Sci. Pollut. Res. 2023, 30, 48654–48675. [Google Scholar] [CrossRef]

- Peralta Ring, R.; Cordoba, G.; Delbianco, N.; Priano, C.; Rahhal, V. Circular Economy Approach: Recycling Toner Waste in Cement-Based Construction Materials. Sustainability 2024, 16, 4707. [Google Scholar] [CrossRef]

- Oad, P.K. Innovation in the Road Construction Sector and Its Benefits to the Industry. Master’s Thesis, Queensland University of Technology, Brisbane, Australia, 2016. [Google Scholar]

- Coopland, P.; Winter, M. The Use of Waste-Derived Materials in Road Construction; Briefing Report; Coopland Consultancy Ltd.: Dumfries, UK, 2021. [Google Scholar]

- Anuardo, R.G.; Espuny, M.; Costa, A.C.F.; Espuny, A.L.G.; Kazançoğlu, Y.; Kandsamy, J.; de Oliveira, O.J. Transforming E-waste into opportunities: Driving organizational actions to achieve sustainable development goals. Sustainability 2023, 15, 14150. [Google Scholar] [CrossRef]

- Ghosh, B.K.; Mekhilef, S.; Ahmad, S.; Ghosh, S.K. A review on global emissions by E-products based waste: Technical management for reduced effects and achieving sustainable development goals. Sustainability 2022, 14, 4036. [Google Scholar] [CrossRef]

- Haba, B.; Djellali, S.; Abdelouahed, Y.; Boudjelida, S.; Faleschini, F.; Carraro, M. Transforming plastic waste into value: A review of management strategies and innovative applications in sustainable construction. Polymers 2025, 17, 881. [Google Scholar] [CrossRef]

- He, Y.; Kiehbadroudinezhad, M.; Hosseinzadeh-Bandbafha, H.; Gupta, V.K.; Peng, W.; Lam, S.S.; Tabatabaei, M.; Aghbashlo, M. Driving sustainable circular economy in electronics: A comprehensive review on environmental life cycle assessment of e-waste recycling. Environ. Pollut. 2024, 342, 123081. [Google Scholar] [CrossRef]

- Phogat, P.; Kumar, S.; Wan, M. A scientometrics study of advancing sustainable metal recovery from e-waste: Processes, challenges, and future directions. RSC Sustain. 2025, 3, 2434–2454. [Google Scholar] [CrossRef]

- Abogunrin-Olafisoye, O.B.; Adeyi, O.; Adeyi, A.J.; Oke, E.O.; Ojediran, G.O. Sustainable Waste Electrical and Electronics Equipment Recycling in Nigeria, Policies and Emerging Technologies. Environ. Qual. Manag. 2025, 34, e70020. [Google Scholar] [CrossRef]

- Kaliyavaradhan, S.K.; Prem, P.R.; Ambily, P.; Mo, K.H. Effective utilization of e-waste plastics and glasses in construction products-a review and future research directions. Resour. Conserv. Recycl. 2022, 176, 105936. [Google Scholar] [CrossRef]

- Assaad, R.H. Examining low-carbon material initiatives: Existing policies, impacts on the procurement of projects, current challenges, and potential solutions to reduce embodied carbon in the construction industry. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2024, 16, 04523060. [Google Scholar] [CrossRef]

- Lee, E.; Tan, E.; Tingey, J. Disclosures of Carbon Credits in Australia. Available at SSRN 5134021. 2025. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5134021 (accessed on 7 October 2025).

- Sajid, Z.W.; Aftab, U.; Ullah, F. Barriers to adopting circular procurement in the construction industry: The way forward. Sustain. Futures 2024, 8, 100244. [Google Scholar] [CrossRef]

- Liu, K.; Tan, Q.; Yu, J.; Wang, M. A global perspective on e-waste recycling. Circ. Econ. 2023, 2, 100028. [Google Scholar] [CrossRef]

| Category | Source | Material Properties | Application |

|---|---|---|---|

| E-waste Plastics (Polycarbonate, ABS-PC, HIPS, and ABS) | Plastic parts found in electronics, appliances, and casings | improved viscoelasticity, thermoplastic behaviour, and high bitumen compatibility | Binder modification, improved fatigue life, and increased flexibility |

| Waste toner powder | Wasted toner cartridges for printers | Iron oxide, carbon black, fine powder, and thermoplastic polymers | Asphalt binder modifier and filler replacement |

| P-CB, or pyrolysis-derived carbon black | Pyrolysis of rubber and plastics from e-waste | Strong adsorption capabilities, large surface area, and carbon-rich powder | Asphalt binder modifier and filler material |

| Non-metallic Fractions (NMF) of PCBs | Processing material from printed circuit boards | Glass fibre, thermoset polymers, epoxy resin, and fibrous | Asphalt binder modifier, filler material, and additive |

| Fluorescent Powder and Components of Rare Earth | fluorescent bulbs and Specialised electronic trash | Phosphorus, luminous qualities, and trace metals | Pigment or experimental filler (limited study) |

| Reference | Type of E-Waste | Oxide Composition (%) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO3 | Fe2O3 | Al2O3 | P2O5 | MnO | SO3 | CO2 | TiO2 | Cr2O3 | ZrO2 | V2O3 | ZnO | CaO | ||

| [64] | Waste toner | 10.25 | - | 0.45 | - | 0.2 | 0.5 | - | - | - | - | - | 0.3 | 0.4 |

| [65] | Waste toner powder | 32.2 | 0.35 | 0.73 | - | - | - | 0.95 | - | - | - | 2.65 | 0.33 | |

| [65] | Waste toner powder | 41.05 | 0.35 | 0.75 | - | - | - | 0.01 | 1.45 | - | - | - | 0.95 | 0.82 |

| [66] | Bank note toner | 1.48 | 4.45 | - | 0.05 | - | 2.76 | 32.16 | 6.79 | 2.22 | - | - | 44.15 | |

| [67] | Waste toner | 25.1 | 42.2 | - | - | 0.22 | 2.47 | - | 2.46 | 0.96 | 0.89 | - | 5.91 | 9.03 |

| [66] | Printer toner | 4.93 | 92.09 | - | - | 0.42 | 0.62 | - | 0.55 | 0.08 | - | |||

| [68] | Waste toner ash | 4.47 | 80.08 | 3.85 | 0.16 | 0.31 | 0.94 | - | 4.62 | 0.18 | 0.01 | 0.01 | - | 1.98 |

| [69] | PCB plastic | 36.80 | - | 11.44 | 0.20 | - | - | - | - | - | - | - | - | 12.7 |

| [68] | Waste toner ash | 3.00 | 83.57 | 3.91 | 0.12 | 0.42 | 0.77 | - | 1.74 | 0.13 | - | 0.01 | - | 1.09 |

| [69] | Computer screen glass chips | 68.3 | 0.1 | 2.8 | - | - | 3.9 | - | - | - | - | - | - | 7.8 |

| [70] | Fluorescent powder | - | 0.01 | 1.3 | 25.00 | - | - | - | - | - | - | - | - | 1.8 |

| [71] | PCB | 43.24 | 0.77 | 9.17 | 0.06 | - | 0.33 | - | 0.44 | - | 0.02 | - | 0.02 | 18.98 |

| [65] | Waste toner powder | 40.83 | 1.1 | 1.52 | - | - | - | 0.02 | 5.39 | - | - | - | 0.2 | 0.42 |

| [68] | Waste toner ash | 1.55 | 84.44 | 3.13 | 0.12 | 0.13 | 2.73 | - | 3.32 | 0.03 | - | 0.10 | - | 1.37 |

| Objectives | Questions | |

|---|---|---|

| 1 | To use scientometric analysis to map the research landscape on the use of e-waste–derived materials, such as waste plastics and waste toner, in the asphalt pavement industry. | RQ1: What are the main publication trends, key terms, nations that contribute, patterns of collaboration, and new themes that have emerged in the literature on the integration of e-waste into asphalt pavements? |

| 2 | To conduct a systematic assessment of the modification mechanisms, performance, and environmental benefits of incorporating e-waste-derived materials into asphalt binders and mixtures. | RQ2: How are e-waste materials handled and mixed into asphalt pavements, and what effects do they have on binder modification, mixture performance, and durability? |

| 3 | Conduct an environmental implication analysis to evaluate the strategic benefits, opportunities, and circular economy potential of incorporating e-waste in asphalt pavement engineering. | RQ3: What are the primary benefits and issues influencing the use of e-waste materials in asphalt pavement, and how can these findings be used to guide future research and policy frameworks? |

| Data Source | Search Syntax Formulation | Articles |

|---|---|---|

| Scopus | (TITLE-ABS-KEY (“e-waste” OR “electronic waste” OR “waste toner” OR “PCB waste” OR “NMF” OR “waste plastic” OR “ABS” OR “HIPS”)) AND (TITLE-ABS-KEY (“asphalt” OR “bitumen” OR “pavement” OR “asphalt concrete” OR “road construction” OR “asphalt modifier”)) | 152 |

| Web of Science | TS = (“e-waste” OR “electronic waste” OR “waste toner” OR “PCB waste” OR “NMF” OR “waste plastic” OR “ABS” OR “HIPS”) AND TS = (“asphalt” OR “bitumen” OR “pavement” OR “asphalt concrete” OR “road construction” OR “asphalt modifier”) | 137 |

| ScienceDirect | (“e-waste” OR “electronic waste” OR “waste toner” OR “PCB waste” OR “non-metallic fraction” OR “NMF” OR “waste plastic” OR “ABS” OR “HIPS”) AND (“asphalt” OR “bitumen” OR “pavement” OR “asphalt concrete” OR “road construction” OR “asphalt modifier”) | 124 |

| Research Areas | Searched Keyword |

|---|---|

| E-waste source | “e-waste,” “electronic waste,” “electronic waste,” “waste electrical and electronic equipment (WEEE),” “waste toner,” “waste printer cartridge,” “printed circuit board (PCB) waste,” “non-metallic fraction (NMF),” “pyrolysis carbon black,” “waste plastic,” “acrylonitrile butadiene styrene (ABS)”, “ABS-PC,” “High Impact Polystyrene (HIPS)” |

| Application | “Asphalt,” “bitumen,” “asphalt pavement,” “asphalt mixture,” “asphalt concrete,” “hot mix asphalt,” “warm mix asphalt,” “binder modification,” “cold mix asphalt,” “asphalt modifier” |

| Performance | “Mechanical performance,” “durability,” “rutting resistance,” “moisture susceptibility,” “fatigue life,” “binder properties,” “rheological properties,” “viscoelastic behaviour,” “stiffness modulus,” complex modulus (G)”, “phase angle (δ)”, “low-temperature cracking,” “ageing resistance,” and “thermal susceptibility.” |

| Sustainability and environmental aspects | “Landfill diversion,” “life cycle assessment (LCA),” “carbon reduction,” “CO2 emissions,” “hazardous waste management,” “ environmental analysis,” and “circular economy” |

| S/N | Keywords | Occurrence | Total Strength |

|---|---|---|---|

| 1 | Electronic waste | 82 | 419 |

| 2 | Wastes | 78 | 403 |

| 3 | Recycling | 75 | 396 |

| 4 | E-waste plastic | 70 | 389 |

| 5 | Waste disposal | 68 | 371 |

| 6 | Asphalt | 64 | 358 |

| 7 | Bitumen | 63 | 345 |

| 8 | Sustainable development | 61 | 324 |

| 9 | Waste toner | 57 | 311 |

| 10 | E-waste | 55 | 305 |

| 11 | Mixtures | 51 | 293 |

| 12 | Plastic recycling | 48 | 267 |

| 13 | Waste treatment | 45 | 259 |

| 14 | Aggregates | 43 | 251 |

| 15 | Partial replacement | 40 | 248 |

| 16 | Construction industry | 39 | 231 |

| 17 | Asphalt concrete | 38 | 225 |

| 18 | Asphalt pavements | 36 | 217 |

| 19 | Pavement | 34 | 198 |

| 20 | Plastics | 33 | 192 |

| 21 | Printed circuit board | 31 | 184 |

| 22 | Waste management | 29 | 178 |

| 23 | Mechanical properties | 28 | 169 |

| 24 | Reclaimed asphalt pavement | 25 | 164 |

| 25 | Bituminous materials | 23 | 152 |

| 26 | E-wastes | 22 | 145 |

| 27 | Toner cartridge | 21 | 137 |

| 28 | Temperatures | 19 | 129 |

| 29 | Asphalt mixtures | 18 | 115 |

| 30 | Concrete aggregate | 17 | 99 |

| 31 | Oscillator electronic | 15 | 97 |

| 32 | Marshall stability | 13 | 83 |

| 33 | Sustainability | 12 | 72 |

| 34 | Experimental investigations | 10 | 69 |

| 35 | Concrete mixtures | 9 | 63 |

| 36 | Environmental impact | 9 | 53 |

| 37 | Binders | 8 | 47 |

| 38 | Fillers | 7 | 39 |

| 39 | Recycling wastes | 6 | 35 |

| 40 | Compressive strength | 5 | 27 |

| 41 | Scanning electron microscope | 4 | 20 |

| S/N | Country | Documents | Citations | Total Link Strength |

|---|---|---|---|---|

| 1 | India | 9 | 49 | 190 |

| 2 | China | 8 | 41 | 182 |

| 3 | USA | 7 | 36 | 131 |

| 4 | Australia | 6 | 24 | 110 |

| 5 | UK | 5 | 18 | 101 |

| 6 | Brazil | 4 | 15 | 89 |

| 7 | Iran | 4 | 11 | 75 |

| 8 | Malaysia | 3 | 9 | 52 |

| 9 | Egypt | 3 | 5 | 45 |

| S/N | Sources | Documents | Citations |

|---|---|---|---|

| 1 | Journal of Cleaner Production | 5 | 108 |

| 2 | Lecturer Notes in Civil Engineering | 4 | 98 |

| 3 | Construction and Building Materials | 4 | 83 |

| 4 | Materials today: proceeding | 4 | 79 |

| 5 | Recycling | 3 | 64 |

| 6 | AIP Conference Proceedings | 3 | 51 |

| 7 | Environmental Science and Technology | 2 | 48 |

| 8 | IOP Conference Series: Earth and Environmental Science | 2 | 31 |

| Area | Influence of E-Waste Application in Asphalt Pavement |

|---|---|

| Effect on asphalt binder and mixtures |

|

| Environment |

|

| Limitations |

|

| Application | Material Replaced | Economic Impact | Environmental Impact |

|---|---|---|---|

| Production of cement mortar | OPC replacement with WT up to 15% | Lower cost advantages due to the use of WT compared to cement | Embedded CO2 decreased by 14.3% as a result of the high OPC carbon footprint (95% of total emissions). |

| WT modified binder blended with recycled asphalt pavement | Conventional binder and mineral aggregates | Lower cost advantages due to higher RAP content and reduced virgin aggregate demand. | Incorporating RAP by 15–30% results in additional annual emission savings of approximately 23,000 kg CO2. |

| Warm mix asphalt modified with WT (Australian TonerPave Case) | Partially substituting petroleum-based asphalt binder and polymers. | About $150 per tonne (equivalent to regular asphalt) | Decrease of 270 kg CO2 per tonne, lowering of production temperature by 20 to 50 °C, and annual savings of approximately 24,000 kg CO2 |

| Comparing the use of WTP as an asphalt modifier (A-WTP) to regeneration (N-WTP) and incineration (I-WTP) | Additives for virgin binder and base asphalt modification | The life cycle costs of A-WTP were the lowest, whereas those of I-WTP and N-WTP were 0.71 and 0.92 CNY/kg, respectively. | GWP was approximately 7.385 kg CO2-eq/kg-WTP for I-WTP, while A-WTP had the lowest emissions. 91.7% of GHG was attributed to CO2 emissions from I-WTP. N-WTP and A-WTP had lower environmental externality costs, whereas I-WTP had 2.85× and 1.69× higher costs, respectively. |

| e-waste management | Minimising landfills and incineration | Potential revenue from the use of the circular economy and reductions in disposal costs | Prevents CO2 from burning and reduces leachate pollution. Promotes SDGs 9, 11, 12, and 13 through sustainable waste valorisation. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Yaro, N.S.A.; Jele, L.N.; Adedeji, J.A.; Ngubane, Z.; Ikotun, J.O. From Waste to Sustainable Pavements: A Systematic and Scientometric Assessment of E-Waste-Derived Materials in the Asphalt Industry. Sustainability 2026, 18, 12. https://doi.org/10.3390/su18010012

Yaro NSA, Jele LN, Adedeji JA, Ngubane Z, Ikotun JO. From Waste to Sustainable Pavements: A Systematic and Scientometric Assessment of E-Waste-Derived Materials in the Asphalt Industry. Sustainability. 2026; 18(1):12. https://doi.org/10.3390/su18010012

Chicago/Turabian StyleYaro, Nura Shehu Aliyu, Luvuno Nkosinathi Jele, Jacob Adedayo Adedeji, Zesizwe Ngubane, and Jacob Olumuyiwa Ikotun. 2026. "From Waste to Sustainable Pavements: A Systematic and Scientometric Assessment of E-Waste-Derived Materials in the Asphalt Industry" Sustainability 18, no. 1: 12. https://doi.org/10.3390/su18010012

APA StyleYaro, N. S. A., Jele, L. N., Adedeji, J. A., Ngubane, Z., & Ikotun, J. O. (2026). From Waste to Sustainable Pavements: A Systematic and Scientometric Assessment of E-Waste-Derived Materials in the Asphalt Industry. Sustainability, 18(1), 12. https://doi.org/10.3390/su18010012