Abstract

With the aim of reducing the environmental impact of buildings, the appropriate selection of building materials is essential, as a building is a complex system composed of various materials. With this background, a multi-criteria decision-making approach has recently gained traction. This study demonstrated the effect of building material selection on both environmental and economic parameters of a building in the context of Japan. A comparative analysis of five structural frame options was conducted utilizing a reference building model to assess the implication of material choices. The findings indicated that wooden frame options are advantageous in environmental aspects compared to non-wooden frames, provided that sustainable forestry practices and appropriate recycling scenarios are implemented. Conversely, it was found that a Cross Laminated Timber (CLT) frame is the most expensive option. This suggests that a hybrid approach, which combines various frame materials, could yield a more effective solution in terms of both environmental and economic sustainability. In addition, it was highlighted that building envelopes, such as foundation, exterior wall, and roof, should be prioritized to enhance the sustainability of a building from a material perspective. Furthermore, gypsum board, commonly used for sheathing building elements, should be selected with careful consideration of its environmental impact.

1. Introduction

The building sector plays a substantial role in contributing to global environmental challenges [1]. Therefore, minimizing the environmental impact of buildings throughout their life cycle is a crucial objective in the pursuit of sustainable development. In this context, considerable research efforts have been dedicated over the past few decades to investigate the life cycle impacts associated with buildings. In an effort to reduce the environmental impact of buildings, most of the attention has thus far been focused on operational energy use. As a result of advancements in this area, such as enhancements in the thermal insulation performance of the building envelope [2,3], the environmental impact during the operation phase has been effectively reduced and the significance of other life cycle stages (embodied impacts) has increased [4].

To mitigate the embodied impacts of buildings, the careful selection of building materials is essential since a building is a complex system composed of various materials. However, a dilemma arises in a building life cycle assessment (LCA). During the design phase, there is a discrepancy between the flexibility in selecting design parameters and the quality and quantity of information available for the LCA [5]. Although the life cycle impacts of a building can vary considerably based on decisions made in the early design phase [6,7], designers are often forced to make significant decisions at this initial design stage with insufficient information.

In this context, numerous researchers have explored indices of building materials to assist designers in achieving optimal design solutions for a sustainable building. For instance, Kerr et al. [8] compared Environmental Products Declarations (EPDs) of structural stone, concrete products, and steel products focusing on their Global Warming Potential (GWP). The findings indicated that utilizing structural stone can significantly reduce the embodied CO2 emissions of a building, being 45–75% lower than those of concrete products and over 99% lower than those of steel products. Thormark [9] investigated the effects of material selection on both the embodied energy and recycling potential within an energy efficient apartment block in Sweden. He noted that a simple alternation in material choice could lead to a reduction in embodied energy by approximately 17% or an increase of about 6%. Tavares et al. [10] studied the embodied energy and greenhouse gas (GHG) emissions of a prefabricated house with alternative structural materials (steel, concrete, timber, and light steel framing (LSF)). The result indicated that the material production phase is dominant and LSF or timber yield the lowest impacts, resulting in a reduction of approximately 10–20% in embodied energy and 20–40% in GHG emissions compared to steel and concrete. Takano et al. [11] studied the impact of material choice on the life cycle energy balance of a building in Finland. It was revealed that differences in material selection are quite visible at the production stage. For example, substituting gypsum board with plywood as the sheathing material increased the renewable primary energy in the production stage by nearly 50% compared to the original configuration. Whereas changing the gypsum board to MDF only increased the renewable primary energy by a few percent. These studies provided valuable insights into proper building material selection mainly from the aspects of energy performance and GWP, which are the most influential impact categories.

Meanwhile, there is a growing interest in a multi-criteria decision-making approach [7,12,13]. Chen et al. [14] conducted a cradle-to-gate LCA on an eight-story residential building in China, focusing on the environmental impacts associated with two structural frame options, Cross Laminated Timber (CLT) and concrete, across 13 categories. It was reported that the environmental performance of the two frame options varies depending on the categories. For instance, the timber frame shows about 25% less GWP than the concrete frame; however, on the other hand, it also leads to about 70% higher acidification potential of soil and water sources (AP) and formation potential of tropospheric ozone (SFP). Vasishta et al. [15] examined the life cycle environmental impacts and costs associated with precast and cast-in-place (CIP) concrete building systems in the United States (US). The two systems were compared based on nine environmental impact indicators and life cycle costs (LCC). This study emphasized that the precast building system can be a more sustainable and efficient construction methodology compared to the conventional CIP system, which demonstrated superior results across all environmental impact indicators and LCC. Pierobon et al. [16] performed a cradle-to-gate environmental impact assessment, incorporating nine indicators, for a hybrid (CLT + Concrete) mid-rise commercial building in comparison to that of a traditional reinforced concrete building in the US. The findings indicated that substituting concrete and steel with CLT in the structural frame has significant potential to reduce environmental impacts, including approximately a 25% reduction in GWP and a 30% reduction in eutrophication potential. Geß et al. [17] analyzed environmental impacts of insulation materials derived from four renewable resources (pasture grass, seaweed, reed, and recycled jute fibers) on eight indicators in comparison with conventional non-renewable insulation materials such as mineral wool. The results demonstrated that the renewable insulation materials had lower environmental impacts in all indicators than their conventional counterparts and advantages regarding GWP were particularly highlighted. Takano et al. [18] illustrated the impact of building material selection on both the environmental and economic parameters of a building in the context of Finland, revealing that the choice of frame material had the most substantial impact. In addition, it was noted that inner components, such as insulation and sheathing, also exert certain influences and should be carefully considered, even though they are not visible at the end. Balasbaneh et al. [19] studied the sustainability performance of four different flooring systems using a multi-criteria assessment method. It was revealed that, for instance, concrete flooring is the best option in terms of economic aspect, whilst wood flooring shows the lowest environmental impacts because of fewer CO2 emissions than the others. Balasbaneh et al. [20] evaluated the GWP, ozone layer depletion (OLD), life cycle cost (LCC), and social life cycle assessment (S-LCA) of five retaining wall materials used in a typical Malaysian residence. The results showed that stone walls are about one-third lower than concrete walls in terms of GWP and OLD. However, in terms of LCC, the cantilever reinforced concrete wall is the best option, which is about 14% less than the second-best option. In terms of S-LCA, the rubble masonry wall is the best option, showing a 10% cost advantage over the second option. These studies underlined the significance of a multi-criteria approach for decision-making in building design, as a comprehensive perspective is essential in determining optimal solutions. However, in Japan, most research conducted thus far has focused on a single indicator, either energy consumption or CO2 emission, in the assessment and, therefore, an importance of multi-criteria approach has increased recently [21,22].

In such background, the objective of this study was to demonstrate the impact of material selection on various indicators in the material production phase of a building in a Japanese context. The indicators examined include the following:

- Greenhouse gas emissions (GHG);

- Embodied energy (EE);

- Resource use (RU);

- Ozone depletion potential (ODP);

- Acidification potential (AP);

- Carbon storage (CS);

- Energy content (EC);

- Material cost (MC).

The analysis focused on the effects of five different structural frame alternatives on these indicators and the dominance of each building element (e.g., exterior wall) and material (e.g., concrete) depending on the options, which were investigated comparatively on a reference building. Secondly, the effects of an alternative building element use were quantified in order to observe the contribution of partial changes in the building constitution to the end results. Given the scarcity of similar research in Japan, this study aims to facilitate informed decision-making among professionals in the construction sector, thereby promoting enhanced sustainability in building design.

2. Materials and Methods

2.1. Reference Building Model and Building Materials Compared

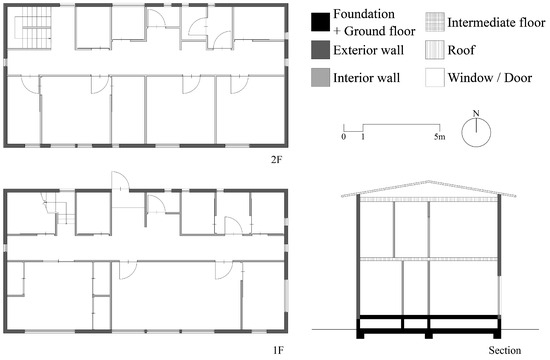

The reference building was a hypothetical two-story building model, as exemplified in reference [23]. Figure 1 presents the basic plan and section of the building, indicating each building element, whilst Table 1 shows the floor area of the building and the surface area of each building element used in the calculation. The reasons for employing this hypothetical model in this study are (1) the building composition is typical in Japan, regardless of the structural frame, (2) to ensure that the assessment conditions are as comparable as possible between the alternatives and, consequently, (3) to maximize the generality of the results.

Figure 1.

Basic plan and section of reference building with indication of building elements.

Table 1.

Floor area of reference building and surface area of each building element used in calculation (m2).

This study employs a comparative analysis of five alternative structural frames, wooden post and beam frame (P&B), Cross Laminated Timber frame (CLT), Massive Holz frame (MH), reinforced concrete frame (RC) and steel frame (Steel), based on the building materials commonly used in Japan [23]. Table 2 outlines the selected structures for each building element corresponding to the five frame options. To observe the differences resulting from the selection of the frame materials, other building components, such as thermal insulation and finishing, were kept as consistent as possible, based on a typical combination with the structural frame. In addition, irrespective of the frame materials, all building elements adhered to identical specifications across all cases (e.g., U-value; exterior wall = 0.53 W/m2 K, floor = 0.34 W/m2 K, roof = 0.24 W/m2 K) in accordance with the Building Energy Efficiency Act [24]. The building was assumed to be of the lowest fire protection class as per the Japanese building code. Thus, structural fire protection was not considered.

Table 2.

Structure of each building element with five frame materials (t = mm).

In addition to examining the structural frame materials, alternative frame combinations were also studied. In general, the structural frame tends to consist of a single material due to, for instance, construction and cost efficiency. Here, however, the aim was also to demonstrate how the sustainability performance changes when different structural frame materials are combined in a building. The reference building with the CLT frame served as the case study model. In this analysis, it was assumed that the interior wall, floor (both ground and intermediate), and roof elements of the CLT frame would be substituted with the elements from the P&B frame. The original specifications of the CLT described in Table 2 were utilized as a benchmark, and the impact of the alternative elements was assessed in relation to this reference. The comparative study was conducted for each category of building elements, and the contribution of these elements to the end results was examined. The performance of the building (e.g., U-value) remained constant in all cases.

2.2. Indicators

2.2.1. Greenhouse Gas Emissions (GHG; Unit: kgCO2eq)

Greenhouse gas (GHG) emissions associated with the material production phase of the building, from the extraction of raw materials through to the completion of a product ready for delivery at the factory gate, were evaluated as embodied GHG using the IDEA database [25]. Emissions from the combustion of biogenic fuels were considered to be zero, in accordance with the principle of biogenic carbon neutrality [26]. Thus, in this study, GHG refers to only emissions arising from the combustion of fossil fuels.

2.2.2. Embodied Energy (EE; Unit: MJ)

Primary energy consumed in the material production phase of the building was calculated as embodied energy with IDEA. Embodied energy originating from renewable (EE-R) and non-renewable resources (EE-NR) are presented separately.

2.2.3. Resource Use (RU; Unit: kg)

The mass of the renewable and non-renewable resources utilized as the raw materials in the production of building components was quantified as an index of resource use (RU-R and RU-NR).

2.2.4. Ozone Depletion Potential (ODP; Unit: kgCFC11eq)

Ozone-depleting substances (chlorofluorocarbons, halon, and methyl bromide) emitted in the material production phase of the building were assessed with IDEA.

2.2.5. Acidification Potential (AP; Unit: kgSO2eq)

Anthropogenic air pollutants (SO2 and NOx) emitted in the material production phase were assessed with IDEA.

2.2.6. Carbon Storage (CS; Unit: kgCO2eq)

As previously noted, biogenic GHG is considered to have a net-zero impact throughout the life cycle of wood products. In this context, the carbon storage in wood products may be perceived as a virtual value. However, it is advantageous to sequester carbon in a product that postpones the release of CO2 for a defined duration. Therefore, the temporal carbon storage in utilized wood products is recognized as an environmental benefit of the building, in accordance with EN16449 [27].

2.2.7. Energy Content (EC; Unit: MJ)

According to the specifications outlined in EN 16485 [26], the energy content of the materials used in the building is considered as an inherent property and is factored into the building’s potential for energy recovery. This value was quantified with IDEA and the literature [28].

2.2.8. Material Cost (MC; Unit: JPY)

Cost constitutes a primary criterion for material selection in practice; therefore, it should be taken into account in conjunction with the environmental attributes of products. Initial material cost was determined based on the data provided in reference [29].

2.3. Calculation

Based on the specifications of each building element (Table 2), the quantities of building materials used were calculated, and the unit values, which are the values derived from one square meter of the building elements, were quantified with the IDEA database and the Japanese literature according to the indicators (kg-CO2eq-, MJ-, kg-, kg-CFC-11eq-, kg-SO2eq-, JPY/m2). Then, the reference building was assessed by multiplying the unit values and the surface area of each building element (m2; shown in Table 1). All calculations were conducted using Microsoft Excel. Although the results shown are Japanese-specific information, they are also discussed in comparison with previous studies so that the trend of the results can be understood in different contexts.

2.4. Analysis Techniques

The results were presented and analyzed in a relative manner due to the application of a simplified calculation method. The differences among the frame materials were quantified in relation to the average of all alternatives, utilizing a metric referred to as “difference index (DI)”, as established by Takano et al. [18]. A DI value of 3, 2, and 1 indicates that the result associated with a particular frame material is 3 times, 2 times, and equal to the average, respectively. When a DI value is expressed as a decimal, such as 0.5, the result from the frame material is one-half of the average. Furthermore, a DI of 0 denotes that the frame material holds no value concerning that specific indicator.

For the comparative study of alternative frame material combinations, the percentage relative differences (PRDs) were used. The original specification of the CLT frame (Table 2) was set as the reference value and PRD in the result of the alternative frame combinations, which were determined using Equation (1).

where PRD is the percentage of relative differences (%). Valuex is the value calculated with element x (kg-CO2eq, MJ, kg-CFC11eq, or kg-SO2eq). Valueref is the value calculated with the original specification (kg-CO2eq, MJ, kg-CFC11eq, or kg-SO2eq).

PRD = (Valuex − Valueref)/Valueref × 100

This method allows for the identification of both positive and negative deviations in relation to the reference case, thereby enabling a comparative analysis of an index. For instance, PRDs of 100%, 50%, and 0% indicate that the results from the alternative building element are 2 times, 1.5 times, and equivalent to those of the reference case, respectively. PRDs with negative values, such as −66.6% and −50%, indicate that the results from the alternative element are, respectively, one-third and one-half of the results from the reference case.

3. Results

3.1. Comparison of Structural Frames

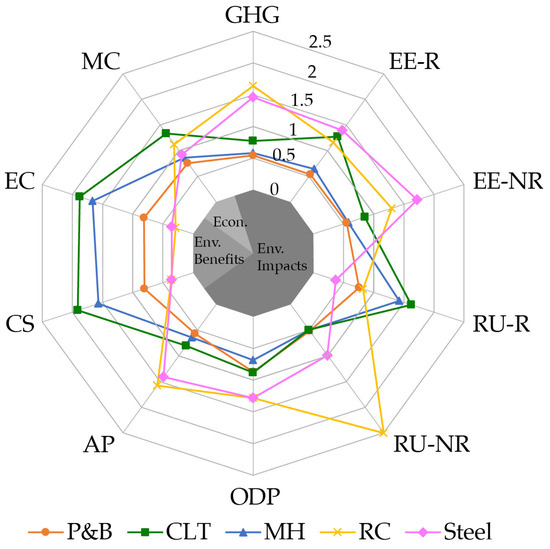

Table 3 presents the assessment results of the reference building with the five structural frame alternatives. This table shows the correlation among the frame options and highlights the predominance of each building element in accordance with the indicators. Additionally, Figure 2 illustrates the relative relationship between the frame options as the difference index (DI).

Table 3.

The assessment results of the reference building according to the five alternative frame materials: categorized by the building elements (functional unit is gross floor area).

Figure 2.

The difference index of the reference building with the five frame options on the indicators.

First of all, it is important to note that there is a considerable variation in the results. The magnitude of differences among the frame options varies depending on the indicators. But at the same time, a general tendency can also be seen in the results. For instance, the wooden frame options (P&B, CLT, and MH) are below average in the impacts, except EE-R and RU-R of the CLT frame and RU-R of the MH frame. Since RU-R indicates the mass of renewable resources used in the building, it is in proportion to CS and EC. Thus, CLT and MH show the largest CS and EC, which are higher than GHG and EE. On the other hand, the CLT frame is identified as the least favorable option concerning MC. This indicates that while the CLT frame may entail a higher initial cost, it may yield the greatest environmental benefits in the end, contingent upon the end of life (EoL) scenario for the material, such as energy recovery through thermal recycling. The P&B frame appears to represent a well balanced option, exhibiting the lowest values for nearly all the indicators while maintaining an adequate amount of CS and EC. The MH frame may also be considered a favorable option, as it is practically equivalent to the P&B frame in terms of environmental impacts and MC, but it has higher CS and EC.

The non-wooden frames (RC and steel) are notable in their environmental impacts. The RC frame exhibits the worst option regarding GHG, RU-NR, ODP, and AP, particularly, RU-NR has about a 2.5 times greater value than the average of all options. Conversely, the steel frame is the worst option in terms of EE (both R and NR); however, the differences between RC and steel are relatively minor across many indicators. In short, the large quantity of non-renewable resource use (for both energy and material) would be a clear weakness of the non-wooden frames. In terms of MC, the RC and steel frames are almost the average as they are a common frame option.

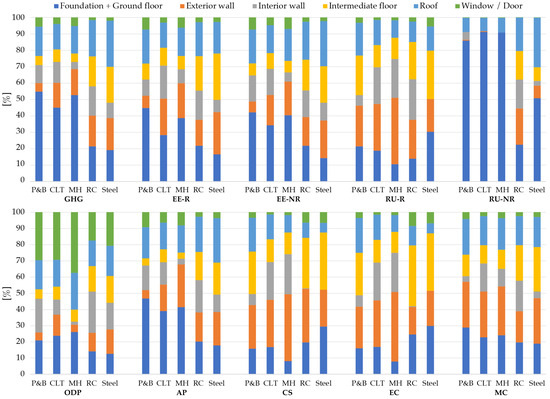

3.1.1. Dominance of Building Elements

Figure 3 highlights the predominance of each building element as determined by the indicators. The results depend on the indicators, but there is a clear trend. In terms of the environmental impact indicators except ODP, the foundation is significantly the most influential element in the wooden frame options (P&B, CLT, and MH), whilst the exterior wall, intermediate floor, and roof exhibit substantial contributions in the case of non-wooden frames (RC and steel). In terms of ODP, the interior wall and window/door emerge as the predominant elements in many cases due to the amount of glass and gypsum used as the surface material. In terms of CS and EC, the exterior wall and interior wall are the primary elements in the massive wooden frames (CLT and MH) because of the large surface area of the elements and the volume of wood product used. In the P&B frame, the exterior wall, intermediate floor, and roof share equivalent contributions. In terms of MC, the foundation, exterior wall, and roof correctively represent approximately 60–80% of the total. These assessment results indicate that the building envelope (foundation, exterior wall, and roof) has prominence across several aspects.

Figure 3.

The dominance of the building elements with the five frame options on the indicators.

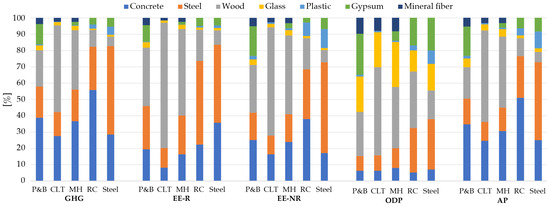

3.1.2. Dominance of Building Materials

Figure 4 and Table 4 present the assessment results of the reference building concerning the structural frame options in terms of GHG, EE-R/NR, ODP, and AP, indicating the dominance of each building material according to the indicators. The environmental indicators where a single material becomes dominant (RU-R/NR, CS, EC) and MC are excluded in this case. Naturally, the materials used as the structural components have a significant share, and concrete and steel are major materials in many cases. However, wood bears high share in the case of the massive wooden frames (CLT and MH). As discussed before, the use of large amount of wood may have environmental benefits (CS and EC), but at the same time, it would cause higher impacts in terms of EE-R and RU-R. These impacts may not be critical as long as renewable resources are available. However, for instance, they can become significant when sustainable forest management is not implemented. In fact, sustainable forestry practices have not been executed globally [30]. Although this indicates that, at present, wood may not be regarded as a renewable resource in a global context, it remains essential to utilize wood from sustainable forests whenever possible in a local context. Therefore, the impacts and benefits caused by using wood should be considered concurrently in relation to its source. Gypsum also shows a relevant share especially in the case of the lightweight frames (P&B and steel). The lightweight frame requires sheathing materials, and gypsum board is often used because of its reasonable function and cost. But the result would indicate that the environmental parameter should be considered more in the selection of sheathing materials. Glass, plastic, and mineral fiber used as the surface and inner components are minor materials in general, but their impacts are notable in terms of ODP.

Figure 4.

The dominance of the building materials with the five frame options on the indicators.

Table 4.

The assessment results of the reference building according to the five alternative frame materials: categorized by the materials (functional unit is gross floor area).

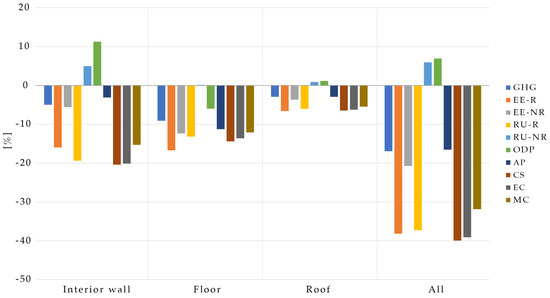

3.2. Comparison of Alternative Frame Material Combinations

Figure 5 illustrates the PRD in the assessment results of the reference building, which incorporates three alternative building elements in comparison to the original CLT frame elements. The objective of this analysis was to examine the differences among the individual building elements while simultaneously assessing their contributions to the overall results. Overall, MC and the environmental impacts except RU-NR and ODP decrease by about 15–40%, but at the same time, the environmental benefits (CS and EC) decline by about 40%, too. The greater influence can be seen in the interior wall and floor because of the substantial surface area (quantity) used. In the case of interior wall, RU-NR and ODP increase by about 5% and 11%, respectively, whilst the other indicators decrease by about 5–20%. In the case of floor, every indicator decreases by about 5–15%, except RU-NR, which was equivalent to the reference. These results mainly arise from the replacement of the large amount of massive wood (CLT) used in the elements with smaller wood components, such as timber post and joist, along with sheathing materials. The sheathing material has great influence because of the large quantity of material used. In this case, gypsum board used as the sheathing material had significant impacts in terms of RU-NR and ODP. Although this study acknowledges certain limitations, such as the number of combinations analyzed, it effectively demonstrates that the combination of different structural frames significantly influences the overall assessment results. As also demonstrated in the previous study [16], a hybrid structural frame solution is a valuable topic for the development from both environmental and economic perspectives.

Figure 5.

Percentage relative differences in assessment results of reference building caused by alternative frame material combinations (reference is CLT frame).

4. Discussion

The results of the structural frame comparison align with trends reported in previous studies [18,31]. Generally, lightweight wooden frames, such as the P&B and timber panel structures, are the most environmentally friendly options due to the minimal amount of materials used and their light weight. In contrast, the massive wooden frames (CLT and MH) offer distinct advantages in terms of environmental benefits, but also present disadvantages related to the other life cycle stages, as described above. The non-wooden frames (RC and steel) are less favorable regarding their environmental impact. Furthermore, the findings suggest that environmental considerations should take precedence over economic factors in decision-making, since MC did not exhibit significant variation among the alternative frame options analyzed. The comparison with the previous study [18] also revealed that the trends do not substantially change when the specifications of building elements differ. For instance, the U-value set in the previous study was much higher than that in this study (exterior wall and floor = 0.16 W/m2 K, roof = 0.09 W/m2 K). This information is valuable for decision-making focused on environmental aspects and is applicable regardless of geographical conditions.

On the other hand, the non-wooden frames represent generic construction systems, particularly suited for large-scale and high-rise buildings. For example, constructing a high-rise building solely with P&B can be challenging. Therefore, to encourage sustainable material selection for frames, greater emphasis should be placed on hybrid frame solutions. From the comparison of frame material combinations, at least two insights can be found. First, the combination of building elements should be carefully designed rather than constructing a building with a single structural frame material, which is common in reality though. For instance, it is advisable to utilize non-wooden frames for primary components that support vertical loads (e.g., posts and beams) while employing wooden frames for secondary components that resist horizontal forces (e.g., load-bearing walls and bracing). In fact, the Japanese building code allows a lower fire protection class for secondary structural frames. Second, the selection of building elements and materials should be carried out in such a way as to minimize weaknesses (impacts) and maximize strength (benefits) of a building in terms of sustainability. For instance, as shown in this study, it would be reasonable to use CLT in the building envelope by utilizing its structural stiffness and low thermal conductivity. On the other hand, the lightweight frame (e.g., P&B, steel), which makes a building lighter and gives flexibility for room arrangement, may be better for inner elements such as interior wall and floor. The implications of different frame material combinations warrant further investigation from multiple perspectives, including constructability, esthetic quality, and psychological perception throughout the building’s life cycle.

In terms of the building elements, in principle, the envelope (foundation, exterior wall, and roof) would have higher environmental and economic impacts due to its complex composition in response to the functions required. To mitigate these impacts, simplification of the composition of the element would be a solution. For instance, the use of a massive wooden frame like CLT as a structural component can effectively take advantage of the physical properties of wood (e.g., structural strength, low thermal conductivity, thermal/moisture buffering property, fire retardancy). By optimizing these properties, massive wood may have the potential to rationalize the composition of a building by integrating multiple functions into a single component. If advancements are made to ensure that massive wood meets relevant building regulations, such as fire safety and thermal performance, it could serve as a unitary and multi-functional component for the exterior wall. Such developments would contribute to enhancing the environmental and economic sustainability of buildings. In addition, the foundation is typically constructed from reinforced concrete, which significantly contributes to the high environmental impact associated with wood frame options (P&B, RC, and MH), particularly regarding GHG, EE (R and NR), RU-NR, and AP. Given that wooden buildings are relatively lightweight, alternative foundation types, such as screw piles and traditional wooden or stone foundations, should be considered feasible and reasonable options. Additionally, innovative products like spike foundations have also been developed to minimize environmental impacts [32]. Since small-scale wooden buildings (approx. 100 m2, one or two story) continue to be constructed annually in quantity in Japan [33], selecting low-impact foundations could effectively mitigate the environmental impact of buildings on a mass scale.

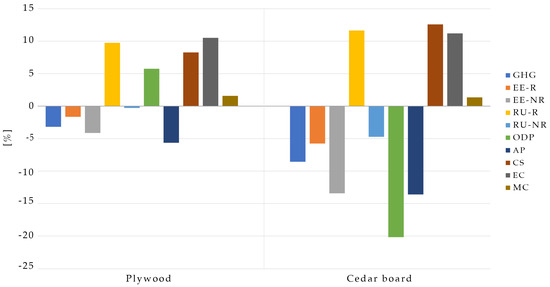

The dominance analysis of each building material revealed the importance of surface components in multi-criteria decision-making. In particular, gypsum board, commonly used for sheathing building elements, should be carefully evaluated from an environmental perspective. Due to its cost-effectiveness and excellent functional properties, such as fireproofing, soundproofing, dimensional stability, and constructability, the utilization rate of gypsum board is significantly higher than that of other sheathing materials, and it is projected to continue increasing in the coming years [34]. As a case study, Figure 6 illustrates the PRD in the assessment results of the reference building with the P&B frame, utilizing two alternative sheathing materials, plywood and cedar board, for the interior wall compared to gypsum board. In the case of plywood, although RU-R and ODP increase by about 5–10%, the other environmental impacts decrease by about 5%, resulting in an overall environmental benefit increase of about 10% compared to the reference case. For cedar board, the trend mirrors that of plywood, but it offers a more significant reduction in the environmental impacts; specifically, ODP decreases by 20%, and the benefits increases by more than 10%. Although MC increases slightly, the environmental effects arising from the replacement of gypsum board with wood materials are notable. This finding is comparable to results from the previous study [18], which also indicated that cement board for sheathing would not yield the same benefits, and that material selection for other surface materials, such as exterior cladding and flooring, has a minor influence on the environmental impacts during the material production phase. As discussed above, the construction of small-scale wooden buildings remains active in Japan, with several large housing manufacturers playing a significant role in this sector. This would suggest that if a few of these manufacturers were to choose plywood or cedar boards instead of gypsum board for sheathing materials, sustainability within the building industry could improve dramatically. In the context of small-scale construction, fire regulations are unlikely to hinder this shift in material selection. In addition, the use of wood necessitates a critical focus on recycling to mitigate the environmental impacts of buildings [35,36]. For instance, the repurposing of wood as secondary products and its recycling for thermal energy generation will lead to different impacts and benefits. This underlines the necessity of effective design methods, such as ensuring disassemblability and reversibility of the materials, as well as developing scenarios for the EoL management of these materials. Although this study only dealt with the material production phase of the building, the influence of the EoL of the materials on the environmental and economic performance of buildings is an important topic that should be investigated further.

Figure 6.

The percentage relative differences in the assessment results of the reference building caused by the different sheathing materials for the interior wall (reference is gypsum board).

As noted above, the material costs (MC) exhibit minor variations compared to the environmental indicators. Nevertheless, it is often observed that cost considerations take precedence over the other factors. Currently, it remains challenging to weigh the environmental impacts on par with material costs during the selection process. Therefore, it is crucial to establish a framework that integrates economic factors with other relevant aspects, allowing for a more balanced decision-making process. For instance, implementing a discount system that correlates with the environmental impacts of products available in the market could expand the range of choice. Additionally, initiatives such as green procurement and a tax system for building materials, including a carbon tax, may serve as effective measures. Furthermore, adopting a post-use material purchasing strategy could enhance recycling efforts, as evidenced by practices in the automotive industry.

5. Conclusions

This study demonstrated the effect of building material selection on the embodied environmental impacts, environmental benefits, and material cost associated with a building in a Japanese context. The influences of the selection were studied on the five structural frame options in a comparative manner using a reference building model. Even though the results relating to the material costs are specific to Japanese buildings, the other results can also be used and extrapolated in wider contexts, in conjunction with previous studies. The findings of this study are summarized as follows:

- The P&B frame is the preferred option in both environmental and economic aspects.

- The massive wooden frames (CLT and MH) can be the most environmentally friendly option, provided that sustainable forestry practices and appropriate EoL scenarios are implemented. However, CLT is the most expensive option.

- The RC and steel frames present certain disadvantages compared to wooden frames from an environmental perspective. While the standardized manufacturing and construction systems associated with RC and steel are advantageous, a hybrid approach that combines these materials with wooden frames could provide a solution that promotes both environmental and economic sustainability.

- Environmental indicators should take precedence over economic factors in the selection of a structural frame, as the impact of material selection among the considered options considered is minor in terms of MC.

- In the wooden frame options, the foundation is the predominant building element concerning GHG, EE (both R and NR), RU-NR, and AP. Given that small-scale wooden buildings continue to represent a significant portion of the current construction market in Japan, exploring alternative solutions for low-impact foundations could effectively reduce the environmental impacts of the construction industry.

- Referring to the concept of “two birds with one stone”, a single material that fulfills multiple functions in a building element, such as massive wood, can be an effective strategy for minimizing environmental impacts and costs while enhancing ecological benefits. This approach is particularly relevant for building elements that have diverse functional requirements, such as the building envelope.

- Greater attention should be paid to gypsum board, which is one of the most frequently used materials in Japan. There is significant potential to reduce the environmental impact of buildings by replacing it with alternative materials, such as wooden boards.

The goal of this research is to enhance multi-criteria decision-making processes for stakeholders in Japan’s construction sector. To achieve this goal, this study provides essential support for the rational selection of building materials as a fundamental step. The findings can be beneficial for decision-making in the building design process, as such information has been limited in Japan. However, this study has certain limitations that will be addressed in future research. Additional case studies will be conducted to incorporate other building life cycle phases, different building types, scales, geometries, a broader range of materials, diverse material combinations, and additional sustainable indicators. This approach aims to generalize the findings and promote a more comprehensive understanding of the relationship between material selection and sustainable building design.

Author Contributions

Conceptualization, A.T.; methodology, A.T.; software, A.T. and M.A.; validation, A.T. and M.A.; formal analysis, A.T. and M.A.; investigation, A.T. and M.A.; resources, A.T. and M.A.; data curation, A.T.; writing—original draft preparation, A.T. and M.A.; writing—review and editing, A.T.; visualization, A.T. and M.A.; supervision, A.T.; project administration, A.T.; funding acquisition, A.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Masashi Aiki was employed by the company Kajima Corporation. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- AR6 Synthesis Report: Climate Change 2023: IPCC. 2023. Available online: https://www.ipcc.ch/report/ar6/syr/ (accessed on 1 April 2025).

- Llantoy, N.; Chàfer, M.; Cabeza, F.L. A comparative life cycle assessment (LCA) of different insulation materials for buildings in the continental Mediterranean climate. Energy Build. 2020, 225, 110323. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Nwodo, M.N.; Anumba, C.J. A review of life cycle assessment of buildings using a systematic approach. Build. Environ. 2019, 162, 106290. [Google Scholar] [CrossRef]

- König, H.; Kohler, N.; Kreißig, J.; Lützkendorf, T. A Life Cycle Approach to Buildings: Principles, Calculations, Design Tools; Institut für Internationale Architektur-Dokumentation GmbH & Co. KG: Munich, Germany, 2010. [Google Scholar]

- Kotaji, S.; Schuurmans, A.; Edwards, S. Life-Cycle Assessment in Building and Construction: A State-of-The-Art Report of SETAC-Europe; Society of Environmental Toxicology & Chemist (SETAC): Brussels, Belgium, 2003. [Google Scholar]

- Hu, M. Building impact assessment-A combined life cycle assessment and multi-criteria decision analysis framework. Resour. Conserv. Recycl. 2019, 150, 104410. [Google Scholar] [CrossRef]

- Kerr, J.; Rayburg, S.; Neave, M.; Rodwell, J. Comparative Analysis of the Global Warming Potential (GWP) of Structural Stone, Concrete and Steel Construction Materials. Sustainability 2022, 14, 9019. [Google Scholar] [CrossRef]

- Thormark, C. The effect of material choice on the total energy need and recycling potential of a building. Build. Environ. 2006, 41, 1019–1026. [Google Scholar] [CrossRef]

- Tavares, V.; Lacerda, N.; Freire, F. Embodied energy and greenhouse gas emissions analysis of a prefabricated modular house: The “Moby” case study. J. Clean. Prod. 2021, 212, 1044–1053. [Google Scholar] [CrossRef]

- Takano, A.; Pal, S.K.; Kuittinen, M.; Alanne, K.; Hughes, M.; Winter, S. The effect of material selection on life cycle energy balance: A case study on a hypothetical building model in Finland. Build. Environ. 2015, 89, 192–202. [Google Scholar] [CrossRef]

- Feng, H.; Zhao, J.; Hollberg, A.; Habert, G. Where to focus? Developing a LCA impact category selection tool for manufactures of building materials. J. Clean. Prod. 2023, 405, 136936. [Google Scholar] [CrossRef]

- Invidiata, A.; Lavagnab, M.; Ghisi, E. Selecting design strategies using multi-criteria decision making to improve the sustainability of buildings. Build. Environ. 2018, 139, 58–68. [Google Scholar] [CrossRef]

- Chen, C.X.; Pierobon, E.; Jones, S.; Maples, L.; Gong, Y.; Ganguly, I. Comparative Life Cycle Assessment of Mass Timber and Concrete Residential Buildings: A case study in China. Sustainability 2022, 14, 144. [Google Scholar] [CrossRef]

- Vasishta, T.; Mehany, M.H.; Killingsworth, J. Comparative life cycle assessment (LCA) and life cycle cost analysis (LCCA) of precast and cast-in-place buildings in United States. J. Build. Eng. 2023, 67, 105921. [Google Scholar] [CrossRef]

- Pierobon, F.; Huang, M.; Simonen, K.; Ganguly, I. Environmental benefits of using hybrid CLT structure in midrise non-residential construction: An LCA based comparative case study in the U.S. J. Build. Eng. 2019, 26, 100862. [Google Scholar] [CrossRef]

- Geß, A.; Lorenz, M.; Tolsdorf, A.; Albrecht, S. Environmental impacts of Renewable Insulation Materials. Sustainability 2021, 13, 8505. [Google Scholar] [CrossRef]

- Takano, A.; Hughes, M.; Winter, S. A multidisciplinary approach to sustainable building material selection: A case study in a Finnish context. Build. Environ. 2014, 84, 526–535. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Yeoh, D.; Juki, M.I.; Gohari, A.; Abidin, A.R.Z.; Marsono, A.K.B. Applying three pillar indicator assessments on alternative floor systems: Life cycle study. Int. J. Life Cycle Assess. 2021, 26, 1439–1455. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Marsono, A.K.B. Applying multi-criteria decision-making on alternatives for earth-retaining walls: LCA, LCC, and S-LCA. Int. J. Life Cycle Assess. 2020, 25, 2140–2153. [Google Scholar] [CrossRef]

- Kobayashi, K.; Shimokawa, K.; Matsuzaki, R.; Suzuki, Y.; Isobe, T. Development of a background database for building LCA. J. Environ. Eng. 2021, 86, 388–398. [Google Scholar] [CrossRef]

- Kobayashi, K.; Isobe, T. LCA utilization for buildings: Current situation and future issues. AIJ J. Technol. Des. 2018, 24, 1129–1134. [Google Scholar] [CrossRef]

- Iwashita, Y.; Hurumoto, K.; Okuya, K.; Isono, S. Architectural Structure and Construction Method; Inoue Shoin: Tokyo, Japan, 2016. [Google Scholar]

- Overview of the Act on the Improvement of Energy Consumption Performance of Buildings. Institute for Building Environment and Energy Conservation (IBEC). 2016. Available online: https://www.mlit.go.jp/common/001134876.pdf (accessed on 26 September 2023).

- The National Institute of Advanced Industrial Science and Technology. Inventory Database for Environmental Analysis (IDEA), v3.3; National Institute of Advanced Industrial Science and Technology: Tokyo, Japan, 2024. [Google Scholar]

- EN 16485:2014; Round and Sawn Timber—Environmental Product Declarations—Product Category Rules for Wood and Wood-Based Products for Use in Construction. European Committee for Standardization: Brussels, Belgium, 2014.

- EN 16449:2014; Wood and Wood-Based Products—Calculation of the Biogenic Carbon Content of Wood and Conversion to Carbon Dioxide. European Committee for Standardization: Brussels, Belgium, 2014.

- Suzuki, Y. Material and energy utilization of forest resource. J. Jpn. Forest Eng. Soc. 2012, 27, 69–80. [Google Scholar]

- Economic Research Association. Price Data for Construction Cost Estimating; Economic Research Association: Tokyo, Japan, 2021. [Google Scholar]

- FAO. The State of the World’s Forests 2024—Forest Sector Innovations Towards a More Sustainable Future; FAO: Rome, Italy, 2024. [Google Scholar] [CrossRef]

- Yasantha, A.U.G.; Babel, S.; Gheewala, S. A matrix in life cycle perspective for selecting sustainable materials for buildings in Sri Lanka. Build. Environ. 2009, 44, 997–1004. [Google Scholar] [CrossRef]

- Spike Base/Frame Foundation System. Lasco Japan Co., Ltd. Available online: https://lasco.jp/technology/tec02/ (accessed on 1 April 2025).

- Construction Statistics in Japan. Ministry of Land, Infrastructure, Transport and Tourism. 2024. Available online: https://www.e-stat.go.jp/en/stat-search/files?page=1&toukei=00600120&tstat=000001016966 (accessed on 1 April 2025).

- Gypsum Board Association of Japan. 2025. Available online: https://www.gypsumboard-a.or.jp (accessed on 5 April 2025).

- Blay-Armah, A.; Mohebbi, G.; Bahadori-Jahromi, A.; Fu, C.; Amoako-Attah, J.; Barthorpe, M. Evaluation of Embodied Carbon Emission in UK Supermarket Constructions: A Study on Steel, Brick, and Timber Frameworks with consideration of End-of-Life Processes. Sustainability 2023, 15, 14978. [Google Scholar] [CrossRef]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Effect of thermal mass on life cycle primary energy balances of a concrete- and a wood-frame building. Appl. Energy 2012, 92, 462–472. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).