Abstract

Today’s world is characterized by rapid technological advancements and escalating ecological concerns including soil and water contamination, acidification, biodiversity loss, excessive waste, etc.; a need is continuously increasing to mitigate these issues and promote sustainability. This study investigated the impact of digitalization on resource use, energy use, waste reduction, and the moderating role of environmental awareness towards sustainability in the manufacturing sector of Pakistan. A quantitative-based approach was used and primary data were collected from the 650 managerial-level manufacturing sector employees from Pakistan by using a closed-ended questionnaire and purposive sampling. Structural equation modeling (SEM) using SmartPLS-4 was employed to analyze the data. Digitalization showed positive and significant effects on energy efficiency, waste reduction, and optimal resource utilization—all of which were significantly associated with sustainability. In addition, the results also showed that environmental awareness functions as a moderator, influencing the impact of digital technologies on resource use, energy use, and waste reduction. The study highlights the potential of digitalization for promoting sustainability by enhancing resource consumption efficiency in the manufacturing industry. It also underscores the importance and need for environmental awareness in adopting digital transformation. The study has major implications for governments, engineers, policymakers, and researchers to promote digital transformation in the manufacturing sector and provide support in accomplishing the Sustainable Development Goals, i.e., SGD-7, SDG-9, SDG-11, and SDG-12.

1. Introduction

Technology is transforming today’s society [1]. As economic development increases, it brings happiness accompanied by many serious challenges; sustainability is the most important among them [2]. There are always efforts in every field to obtain economic development such that they have the least possible negative environmental impact [3]. Concerns about the degradation of the environment, resource depletion, and global warming are increasing, necessitating the urgent need for novel solutions [4]. With each passing day, concerns regarding sustainability increase globally in the form of resource depletion, climate change, etc. [5]. The relentless consumption of resources and increase in greenhouse emissions have produced a risky imbalance in the ecosystems [6]. Some of the developing countries seek more economic benefits at the cost of huge global environmental sacrifices [7]. The world urgently needs to adopt sustainable practices, as the consequences of environmental damage impact beyond borders [8]. Luckily, nations across the globe also have recognized the necessity of sustainable practices [9] and have taken initiatives to transform their industrial operations towards sustainability [10]. For example, to ensure sustainability, the international community now focuses on encouraging responsible resource consumption and innovative approaches [11]. Pakistan is one of the most vulnerable countries in the world [12]. It is facing serious sustainability challenges like deforestation, natural resource depletion, soil erosion, and water scarcity [13]. Its reliance on outdated technologies and non-renewable sources of energy further increases carbon emissions and environmental damage [14]. Pakistan faces a difficult challenge in balancing environmental preservation with economic growth and struggles to adopt sustainable practices and ensure sustainability.

The confluence of the two issues calls for more in-depth knowledge regarding how digital transformation (DT) might reduce its environmental impact and accelerate sustainable development [15]. The rise of digitization has resulted in significant developments across sectors, driving a new era in monitoring and controlling resources [16]. It is a fact that the convergence of technological advancements and sustainability is now recognized as a critical driving factor for harmonious living with our environment [17]. The SDGs of the United Nations point to the need to combine technology and sustainability to build an equitable and environmentally balanced society [18], and this research gives useful insights for integrating digitalization into Pakistan’s manufacturing sector and facilitating the growth of a more environmentally responsible industry that supports the country’s economic development and sustainability in accordance to these goals.

In countries like China [19], Japan [20], and India [21], developing green infrastructure and incorporating environmental policy into various processes of manufacturing industries have been major areas of scientific interest. Similarly, efforts have been made for making manufacturing practices environmentally friendly by introducing green technologies, green resources, increasing efficiency, etc. Furthermore, environmental regulatory frameworks, public awareness and participation, etc., are also considered by European countries [22]. These regions typically benefit from substantial investment, established governance systems, and widespread public environmental awareness. The manufacturing industry diverges significantly due to limited funding, weak environmental regulations, old and traditional technology, and limited environmental awareness. These are some of the factors which need to be addressed for promoting environmental performance in the industry. Furthermore, Pakistan’s extreme vulnerability to impacts of climate change, including droughts, floods, and rapid loss of biodiversity, increases the urgency of environmental issues and necessitates more immediate and specific responses.

The digitalization of the manufacturing sector has been thoroughly studied globally, especially in developed nations, in an effort to make it environmentally friendly and to increase its productivity. Unfortunately, sustainability in the Pakistan’s manufacturing sector remains a challenge and despite attracting researchers, it still requires much deeper exploration to fully understand its challenges and solutions [23,24,25]. This study tries to fill the gap by using data collected from the employees of the industry, by considering context-relevant variables, and by using four theories for the understanding the interconnection among the study variables. The study aligns with Pakistan’s manufacturing industry like energy shortage, waste production, and resource scarcity. This approach differentiates the study from previous research and promises a more suitable solution by the digitalization of the manufacturing industry for sustainability.

Digitalization has the potential to minimize the issues of waste production, excessive energy usage, and resource inefficiencies in the manufacturing sector of Pakistan, which is essential for the economic growth of the nation [26]. However, there is a considerable knowledge gap about the significance of digitalization on resource use (RU), energy consumption, and waste reduction (WR) within this industry, especially with environmental consciousness as the moderating variable. Moreover, the manufacturing sector of Pakistan is under increasing pressure to improve its sustainability due to the recent incidents of climate change [27]. Still, there is not enough empirical information regarding digitalization initiatives, their impact on waste production, energy usage, RU, and environmental awareness (EA), and whether these relationships lead to sustainability [28]. Therefore, a thorough investigation is required to determine how the digitalization of the manufacturing industry influences resource and energy use (EU), WR, and how EA affects these impacts [29,30].

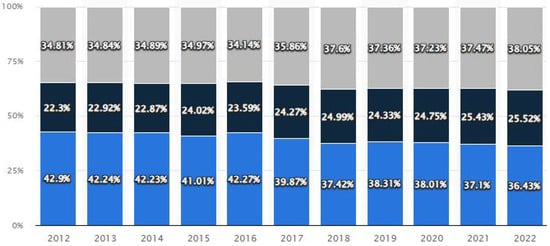

Manufacturing Sector of Pakistan: Pakistan’s manufacturing sector includes automobiles, textiles, metal, cotton processing, petroleum, fertilizers, cement, leather, pharmaceuticals, medical tools, etc. The automobile sector has been growing fast in the last decade, even though cotton processing, textiles, metal, petroleum, cement, and fertilizers continue to be the basic contributors to manufacturing. With Karachi dominating in textiles and automobiles, Faisalabad in textiles, furniture, and starch, Sialkot in sports goods and fabrics, and Lahore in automobiles, motorbikes, electronics, chemicals, and textiles, among other sectors, different locations in Pakistan have their specialties [31]. About 25% of Pakistan’s workforce is employed in this sector, as shown in Figure 1.

Figure 1.

Sector-wise share in employment [32].

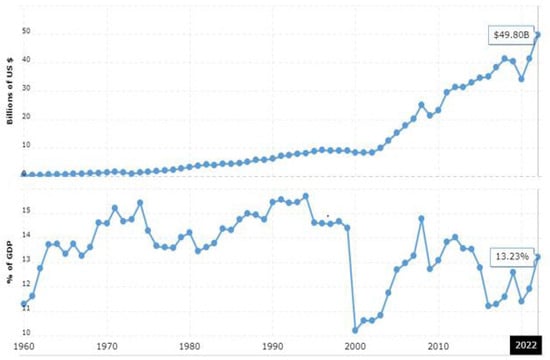

In addition, according to the 2021 statistics, the sector accounted for around 13% of the country’s GDP, which makes it a substantial economic contributor [33]. The total manufacturing output of Pakistan during 2022 was $49.80 billion, 20.05% higher than in 2021; in 2021, it increased by 20.96% to $41.49 billion, 20.96% higher than in 2020; in 2020, it was $34.30 billion, 15.09% lower than 2019; and in 2019, it was $40.39 billion, about 2.5% lower than 2018 [33]. Figure 2 shows the history of total manufacturing output and its percentage in GDP from 1960 to 2022.

Figure 2.

Pakistan’s manufacturing output versus its percentage in GDP [33].

The following are the objectives of the study:

- To examine the impact of DT on WR and its influence on sustainability.

- To examine the impact of DT on EU and its influence on sustainability.

- To examine the impact of DT on RU and its influence on sustainability.

- To examine the moderating impact of EA on the relationship of DT with WR, EU, and RU.

Significance: The study has significant and broad implications for academia, governments, companies, and society. It provides essential insights to assist decision-making by understanding the complex relationships between DT and sustainability. In addition, identifying mediators like WR, EU, and RU paves avenues for developing tailored initiatives to leverage digital breakthroughs for sustainability. Following the theme of the Global Enabling Sustainability Initiative (GeSI) [34], this study seeks to contribute to the continuing discussion about creating a sustainable future via a balanced combination of digital technology and sustainability. The study is important for the nation’s sustainable development because it addresses the critical challenges, stimulates sustainable economic growth, and contributes to achieving SDGs. It is specifically needed for the following reasons.

- Economic growth and resource shortage: Pakistan is dealing with resource shortages, such as energy, water, and other input resources. Optimizing RU through digitalization can increase economic efficiency and promote sustainable growth [35]. Policies that support appropriate resource management can benefit from recognizing EA’s role in this regard.

- Energy shortage and high prices: The shortage of energy in Pakistan has resulted in regular blackouts and rising energy prices. Digitalization promotes integrating green energy sources, improving energy efficiency [36]. The research will discover how digitalization might help resolve this problem, particularly when combined with the desire for sustainable energy solutions from an environmentally conscious society.

- Climate change vulnerability: Pakistan is potentially vulnerable and exposed to the adverse impacts of climate change, such as severe weather, floods, a lack of water, forest loss, and crop failures. Digitalization-driven sustainable practices can reduce risks and improve resilience. EA may drive the use of digital tools for climate adaptation while creating climate consciousness [37].

- Waste management issue: In Pakistan, one of the most prominent issues of all big cities is poor waste collection and disposal methods. Trash reduction, recycling, and waste-to-energy processes can be improved using digital solutions. Sustainable urbanization depends on exploring how EA affects digital waste management systems [38].

- Policy guidelines: Policymakers can benefit from the findings of this research on how well digitalization works to address sustainability issues. This might result in the creation of evidence-based laws and policies that support EA and digital innovation as major forces behind sustainable development.

- Public health: In Pakistan, pollution directly affects public health. Improved air and water quality can lower health risks by decreasing waste and managing resources sustainably.

- International pledges: Pakistan agreed to ratify international accords, including the Paris Climate Agreement and the United Nation’s SDGs. Pakistan can elevate its international status by fulfilling its promises by researching the role of digitalization towards sustainability.

2. Development of Theoretical Framework

2.1. Theories

The study bases itself on a broad theoretical structure incorporating four interrelated theories: innovation diffusion theory, resource-based view, institutional theory, and sustainability transition theory. This research attempts to thoroughly explain how innovations, institutions, resources, and sustainability transformations interact and impact each other in existing corporate and social contexts by combining these theories.

- Innovation Diffusion Theory (IDT)

The IDT was introduced in 1962 by Everett Rogers, which provides a thorough framework to understand how new concepts, innovations, and technologies spread across societies [39]. According to this theory, several factors, such as the invention’s characteristics, the communication channel, and the social system, affect the adoption process. It sets a five-stage process for adoption that individuals typically follow. These stages are awareness, interest, evaluation, trial, and adoption [40]. In the context of this study, this theory investigates the adoption and diffusion of new technologies inside a society, such as digitalization. It can be used to examine the adoption of digital technology, its impacts on resource usage, EU, and WR, and how ecological awareness can impact those relationships.

- 2.

- Resource-Based View (RBV)

RBV, developed by Birger Wernerfelt and Jay Barney, believes that a firm achieves a long-term competitive advantage when it has unique and valuable resources that are difficult for rivals to replicate. It recognizes the value of dynamic capabilities that enable firms to evolve and develop continuously. To beat competitors and grow in the market, RBV stresses the constant need to make investments and optimize its resources [41]. RBV may be used in this study to comprehend how digitalization can be a tactical tool for businesses looking to use resources efficiently and lessen their environmental impact to get a competitive advantage.

- 3.

- Institutional Theory

Institutional theory includes laws, regulations, social norms, etc., that shape human, organizational, and societal behaviors [42]. It believes institutions significantly impact individuals’ legitimacy, decision-making, and organizational practices in a particular setting [43]. Policymakers, agencies, and researchers can use its diverse insights to understand the complicated societal and organizational factors and how these factors promote stability and affect change and behaviors [44]. This study can be used to investigate how institutional constraints and norms, influenced by EA and legislative changes, alter an organization’s actions toward digitization and sustainability practices.

- 4.

- Sustainability Transition

It provides a framework to understand and guide the shift to sustainable practices from unsustainable ones. It includes a multi-level perspective that considers niche, landscape, and regime changes and underlines the vital functions that innovation, governance, and various changes that agents play [45]. This theory guides lawmakers, companies, and the public to navigate the complex dynamics of sustainability by fostering resilience, innovative solutions, and learning that balance the preservation of the environment, social welfare, and global economic development [46]. In the context of this research, it can be used to understand how digitization helps sustainability transitions and what function environmental consciousness can play.

These theories complement and interact with each other by addressing different but interconnected dimensions of the digitalization of manufacturing processes toward sustainability. IDT offers an understanding of how digital technologies spread within industries at a micro level and focuses on the characteristics of innovation and the behavior of adopters. RBV complements this and emphasizes the strategic value of digital assets and capabilities in achieving sustainability within the organizations. A macro-level insight is provided by institutional theory, which emphasizes how external forces, such as laws, industry standards, and public expectations influence organizational behaviors toward the adoption of digitalization for manufacturing for sustainability. STT integrates these perspectives by presenting the adoption of digital technologies as an integral part of a multi-level, long-term process of systemic transformation. Collectively, these theories provide a comprehensive picture of how digitalization supports sustainability in the manufacturing industry.

2.2. Digital Transformation

DT is a comprehensive process businesses use to enhance their operations by exploiting digital technology and approaches [47]. Businesses may innovate their present processes, models, and consumer interactions by adopting digital technologies such as artificial intelligence, automation, cloud computing, and big data analytics [48,49,50,51]. Its influence goes beyond merely enhancing productivity and efficiency. It supports sustainability and lowers negative environmental effects [52]. By adopting new technology, firms can improve RU, lower energy usage, and reduce waste [53]. This shift can restructure sectors and pave the way for greater sustainability for subsequent generations [54]. DT improves electricity management, a vital part of sustainability [55]. Smart energy management systems use live information from the Internet of Things devices to optimize the EU, from manufacturing facilities and buildings to a whole supply chain [56]. Determining consumption and surrounding circumstances, these systems employ smart controls that regulate heating, cooling, lighting, and various other consuming energy operations [57]. This constantly changing optimization not only cuts energy usage but also helps to save money [58]. DT provides a new degree of visibility and control in the supply chain. Firms may use digital platforms to track assets, inventory, and products instantly across their entire supply chain [59]. This increased visibility benefits minimizing overproduction, reducing extra inventory, preventing waste, and facilitating collaboration for innovative solutions and RU [60]. Through remote control and monitoring capabilities, DT contributes significantly to sustainable practices and enables firms to monitor operations remotely, reducing the requirement for transport and EU [61]. By simplifying the monitoring, reconditioning, and reusing of items and resources, digital technology is essential in supporting the circular economy, which minimizes waste and promotes long-term economic sustainability [62]. It also ensures resources are utilized efficiently and optimizes operations [63]. These tools let firms produce digital copies of actual processes, products, and systems, enabling them to evaluate multiple scenarios and optimize resource utilization without conducting real-world experiments [64].

In scientific research and popular discourse, digitalization is seen as a facilitator and driver for the transformation towards a circular economy [65], which is characterized by minimal resource use, reduction of waste, increase in energy efficiency, enhanced monitoring and controlling, etc. [66]. DT, such as big data, the Internet of Things (IoT), advanced analytics [67], additive manufacturing [68], 3D printing [69], and the blockchain, [70] have enhanced production processes. Research also shows that the digital economy reduces carbon footprints when the coagglomeration of industries increases [71]. Furthermore, DT enhances the function of consumers and citizens by educating and enabling them to participate in a leading part in the transition to a circular economy [72]. To summarize our discussion, DT is beneficial for obtaining sustainability as it optimizes resource and energy consumption and reduces waste production. With the adoption of DT, firms can improve their business activities by using data-driven decision-making, smart energy management, predictive maintenance, circular economy practices, etc. Simulation and remote monitoring enable firms to optimize processes and manage operations more efficiently. Industries embracing DT improve their productivity and competitiveness and contribute to an environmentally friendly and sustainable future.

2.3. Digital Transformation and Resource Usage

DT significantly influences RU, increasing efficiency, decreasing waste, and improving sustainability [73]. The transition to paperless processes is one of its essential benefits. Firms may reduce paper consumption by digitizing traditional tasks, which leads to cost reductions and green benefits [74]. Digital documents, electronic forms, and electronic processes make it possible to share information in real-time [75], reduces the consumption of resources, while also streamlining processes and increasing productivity [76]. In addition, it also reduces the challenge of human resource availability by digitalizing operations and minimizes the dependency on humans [77]. With the help of advanced digital technologies, many technical tasks can be performed [78]. It also allows people to work and collaborate distantly, which minimizes the need for transportation resources and reduces carbon footprints [79]. It also reduces the EU. For example, firms can improve resource allocation by switching to cloud-based systems and virtual servers, lowering energy consumption and carbon footprints [56]. Furthermore, energy-efficient and smart technology for power management facilitates organizations to reduce EU while maintaining performance [80]. Furthermore, data-driven decision-making improves the RU [81]. Firms can obtain helpful knowledge about RU trends by employing machine learning algorithms and analytics, which enable them to detect inefficiencies and use targeted measures to optimize the utilization of resources [82]. Analyzing energy usage data can indicate options for energy-saving measures and efficiency improvements [83].

Through various methods, DT considerably improves resource efficiency in manufacturing processes [84]. Through identifying technical issues, predictive maintenance with IoT sensors minimizes downtime avoids resource waste and promotes the efficient use of resources [85]. Process optimization and resource-efficient RU are ensured by digital technologies like automation and intelligent manufacturing [86]. Inefficiencies are found and fixed through machine learning and data analytics, which enhance RU efficiency [87]. DT drives resource-efficient techniques throughout the manufacturing process. The DT has a positive impact on RU. It reduces paper consumption, enables humans to work remotely, and optimizes resource usage. However, firms need to assess the whole impact of DT and implement responsible practices to mitigate any negative environmental impact.

2.4. Digital Transformation and Energy Usage

DT and EU are also closely linked [88] and can reduce and increase energy consumption. It is a fact the DT opens up numerous opportunities for energy conservation [89]. For example, virtualization technologies allow firms to combine their hardware, lowering the EU of IT systems. Virtualization assists in achieving better levels of energy efficiency by optimizing RU and minimizing unused power [90]. Similarly, using powerful data analytics and monitoring systems, DT empowers firms to continuously monitor and optimize the EU [91]. Firms can adopt energy-saving practices and optimize their efficiency by analyzing energy consumption trends and finding energy-intensive destinations in operations [92]. Smart systems control the EU by monitoring ventilation, air conditioning, and lighting depending on occupancy levels. Remote collaboration and work are also encouraged by DT [93]. Firms can decrease the staff requirement to go to the workplace by exploiting electronic means of communication, leading to reduced energy usage related to transport and hence, contributing to sustainability [94].

Similarly, a major role can also be played by expert and intelligent systems in digitalization for energy efficiency [95]. There are numerous ways in which expert and intelligent systems may be used to increase energy efficiency, reduce emissions, and promote sustainability [96]. For example, to monitor and improve energy use, obtain information on energy consumption via smart meters and grids, and determine areas for improvement. However, advanced digital technologies further improve expert and intelligent systems and help to develop more novel energy technologies for energy efficiency [97]. They also increase the economic growth [6].

It is crucial to highlight that while DT provides an opportunity for energy savings, it also poses challenges [98]. The rising need for information storage and processing contributes to increased energy usage. Therefore, when adopting DT, firms must emphasize energy efficiency, sustainable practices, and environmental effects. DT has a considerable impact on the EU [99]. While it increases energy consumption issues, it also increases energy efficiency options through practices such as advanced energy monitoring, virtualization, remote work, and the use of sources of clean energy [100].

2.5. Digital Transformation and Waste Reduction

There is a significant impact of the DT on WR in industries. By adopting digital technology, industries may enhance their processes, minimize waste output, and increase sustainability [101]. Shifting to electronic workflows is among the primary ways DT helps minimize waste [102]. Organizations through the adoption of DT dramatically reduce their dependency on paper by digitizing documents, implementing electronic processes, and employing electronic forms. It minimizes the necessity for printing and paper-based expenditures [103].

Another area of digitization that decreases waste is the management of documents digitally. Businesses can use electronic retrieval and storage tools to eliminate physical filing and storage requirements and reduce physical waste [74]. Electronic management of documents also makes tracking, editing, and archiving easier, leading to less operational waste [104]. It is also greatly helpful in production as analyzing data through advanced analytics about production can find inefficiencies, facilitating decreasing waste and process improvements [105].

In addition, DT enables supply chain optimization, reducing waste at various levels [106]. Data analytics allows firms to obtain information about demand trends, optimize inventory management, and decrease stocking-related supply issues [107]. That helps reduce waste caused by product obsolescence, surplus inventory, and wasteful transportation [108]. Another key impact of DT in waste control is process optimization. Firms may use automation and digital tools to improve operations, remove extra stages, and decrease human mistakes [109]. This increases efficiency in operations by decreasing the amount of waste caused by rework, inefficiencies, etc. [110]. Furthermore, DT can assist with the circular economy. Businesses may monitor and locate goods across the whole cycle by employing technology like blockchain and IoT sensors, which improve waste management and recycling and encourage adopting sustainable methods [111].

By using a variety of cutting-edge techniques, digitization significantly contributes to the WR in production [112]. Manufacturers can minimize the requirement for regular upgrades and reduce unplanned downtime by identifying and addressing equipment issues promptly through the use of predictive maintenance systems that use the Internet of Things devices [113]. Digital systems-driven automation streamlines manufacturing processes, improving accuracy reducing errors, and eventually lowering waste from defective goods [114]. Through the real-time identification of inefficiencies, data analytics promote process optimization and reduce waste [115]. Digitization has made 3D printing possible, which enables more precision in production with less material waste than traditional techniques [116]. In addition, DT improves quality control, and monitoring of energy consumption, also reduces waste via enhancing overall industrial efficiency and hence ensures sustainability [117]. In short, DT has a key role in WR. Firms can decrease waste, enhance efficiency, and encourage sustainability by implementing electronic operations, electronic document management, process and supply chain optimization, data analytics, and a circular economy. Firms need to adopt digital technologies to ensure WR and sustainability.

2.6. Moderating Relationship of Environmental Awareness

ENA refers to the understanding and recognition of environmental issues, along with the knowledge of how individual and collective actions impact the environment [118]. Additionally, it entails recognizing the significance of eliminating waste, adopting renewable energy, adhering to environmental regulations, making environmentally friendly consumer decisions, and promoting the conservation of the environment [119]. People aware of these aspects may make better decisions and take steps that lead to a happier, more sustainable world for generations to come [120].

ENA has a significant role in selecting new technology and human activities and ensuring sustainability [121]. Individuals, corporations, and communities who are ecologically conscious are more inclined to focus on the environmental consequences of their activities [122]. When adopting digital technology, they consider resource utilization, energy consumption, and waste creation [123]. The new technology may have many significant advantages, such as enhanced operation efficiency, real-time communication, better RU, EU, and better information access for better decisions [124]. However, it also possesses a chance to harm the environment. A variety of negative impacts and positive aspects stemming from DT cannot be properly recognized or evaluated without ENA [125]. This might have unexpected repercussions like more energy consumption caused by inefficient technology, increased electronic waste because of fast technology turnover, and an inability to deal with the ecological challenges accompanying the DT [126]. Therefore, the role of ENA is essential for DT for RU, EU, and WR towards sustainability.

Individuals who are more environmentally conscious make better decisions regarding new digital technology and consider its environmental impact [127]. This knowledge also supports the advancement and implementation of environmentally friendly technology that reduces or has a less negative environmental impact and leads to reducing and optimizing resources and their better use [128]. To conclude our argument, ENA is necessary to find and navigate the complicated DT process and make it consistent with sustainability [129]. It encourages people to make more suitable and environmentally friendly decisions and select the suitable technology that reduces adverse effects. It also encourages regulations that guarantee DT to ensure sustainability [130].

2.7. Sustainability

Sustainability is an essential concept involving the appropriate and rational consumption of resources that satisfy current demands without jeopardizing future generations’ ability to satisfy their needs [131]. Numerous strategies and efforts, from individual activities to international accords and legislation, are being created to promote sustainability [132]. SDGs established in the agenda for 2030 for sustainable development offer a framework for solving global issues and attaining a sustainable future for everyone [133].

Digitalization for sustainability involves a significant paradigm shift that utilizes technology to ensure sustainability in the manufacturing industry [65]. The primary benefit of DT for sustainability involves the improved use of resources [134]. In manufacturing industries, data analytics and smart technologies optimize processes, lowering waste, and energy use, and ensuring sustainability [11]. It improves visibility in operations supply chains, allowing firms to track and control their resources. Smart systems for energy management are aided by IoT, and digital platforms promote resource sharing and circular economy principles. Digitization drives sustainable growth, encouraging RU efficiency, promoting energy management, and reducing waste. All these factors address the multifaceted challenges of sustainability and assist in the attainment of SDGs [135]. This research tries to investigate the impact of DT on sustainability through WR, EU, and RU and adds implications for achieving SDGs.

2.8. Hypothesis and Theoretical Framework

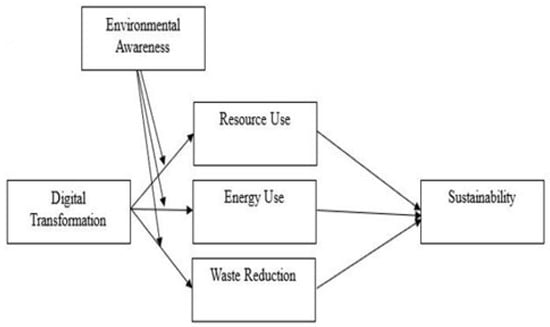

The research on how digitalization affects resource usage, energy consumption, and WR for sustainability, with a moderating effect on EA, can be conducted under the theoretical lenses of various theories. These ideas provide insight into the complicated connections between digitization, sustainability, and EA, highlighting the processes by which sustainable development can be achieved. After looking at these connections separately, it can be seen how each theory offers a distinctive viewpoint for the implementation and effects of DT at firms for the achievement of sustainability. Figure 3 shows the theoretical framework.

Figure 3.

Theoretical framework.

- Innovation diffusion theory: IDT describes the factors influencing an organization’s decisions to use digital technology for WR, resource efficiency, and energy efficiency [136]. For example, the relative benefits of using digital technologies in conserving resources, WR, and EU. This theory supports the following hypotheses:

H1.

DT has a significant positive impact on RU.

H2.

DT has a significant positive impact on the EU.

H3.

DT has a significant positive impact on WR.

- 2.

- Resource-based view: According to this concept, technological capabilities like IoT technology can be regarded as essential resources that provide organizations with the potential to measure energy efficiency, optimize RU, cut waste, and enhance sustainability performance [137]. This theory supports the following hypotheses:

H1.

DT has a significant positive impact on RU.

H2.

DT has a significant positive impact on the EU.

H3.

DT has a significant positive impact on WR.

- 3.

- Sustainability transition theory: DT is the technological transformation that hastens the transition to sustainable practices. It aids business and society’s transition from inefficient and resource-demanding processes towards sustainable ones, like clean energy sources, circular economy models, and effective WR practices [46]. This theory supports the following hypotheses:

H4.

RU has a significant positive impact on sustainability.

H5.

The EU has a significant positive impact on sustainability.

H6.

WR has a significant positive impact on sustainability.

- 4.

- Institutional theory: This theory describes how societal demands and governmental initiatives drive businesses to undergo DT for sustainability. Firms can use digital tools to adhere to rules and societal demands and keep their reputations [44]. The research uses EA as a moderator with the intention to assess its influence on the strength of relationships between DT and WR, EU and RU, not the process. According to institutional theory, organizations are a part of a social environment that is influenced by changing laws, customs, and behaviors [42]. EA reflects the extent to which individuals are agreed to these institutional changes, and alters their responsiveness to environmental pressures, thereby moderating the relationship between DT and WR, EU, and RU.

This theory supports the following hypotheses:

H7.

EA moderates the effect of DT on RU.

H8.

EA moderates the effect of DT on the EU.

H9.

EA moderates the effect of DT on WR.

3. Methodology

The philosophical foundation of this study is rooted in the positivism paradigm. The positivism paradigm is based on absolute scientific beliefs that rely on a single measurable reality [138]. Due to the measurable reality, a quantitative methodology addresses the issue in question [139]. Further, the problem of the study is addressed by using a deductive approach where the researchers have used several hypothesized relationships based on different general theories and testing these in the context of this research.

3.1. Sampling Technique and Data Collection

A quantitative method used survey-based data collection from the research respondents by a closed-ended questionnaire. A non-probability-based sampling technique named purposive sampling was adopted. The rationale for the non-probability sampling was used due to the accessibility constraint of the whole population [140]. Among the several types of non-probability sampling, purposive better identifies the research respondents. Using a purposive sampling technique, a closed-ended questionnaire was used to collect the data from the 650 respondents from managerial level employees of the manufacturing sector of Pakistan, including the textile, cement, food, automobile, and sports industries. Before conducting the final survey, a pilot study was conducted to check the suitability and refinement of the questionnaires. There is no consensus among the scholars about the research sample size. Different research scholars propose different sample sizes for the research. Rao soft, a major software used for sample calculations, shows a minimum sample size of 384 for primary data research. The sample calculation software also shows a close sample size of about a minimum of 385. However, this study’s research sample is based on 650 respondents, higher than the minimum threshold level.

3.2. Statistical Tools

The gathered data were analyzed with structural equation-based modeling via SmartPLS. The rationale for the use of structural equation modeling rather than an ordinary regression is that when the model of a study is based on a complex relationship, it requires more than one regression simultaneously to regress the model [141]. As this study is also based on complex relationships, it is better to adopt a structural equation modeling to better regress the model. Two main tools used in the social sciences for structural equation modeling are the variance-based approach and the co-variance-based approach [142]. There are assumptions for both tools as the co-variance-based approach is used for theory development while the variance-based approach is used for theory testing [143]. This study is based on the several prior theories the researcher will test. So, the variance-based approach is better suited, and the major software used for variance is based on SmartPLS, which the study uses.

3.3. Measurement Instrument

The research survey instrument of this study was based on seven constructs. All seven construct items were adopted from former studies, considering the reliability and validity of the scales. For DT, the items were taken from [144], for EA from [145], for RU and EU from [146], for WR from [147], and for sustainability from [148]. All the constructs’ items were measured with a five-point Likert scale, where 1 represents the lowest level of the agreement while 5 represents the highest level. Appendix A lists all the constructs with their corresponding items and sources of adoption.

3.4. Sample Characteristics

This study population was based on the managerial-level employees of the manufacturing sector of Pakistan. There are a total of 650 respondents. Table 1 of the sample characteristics shows the demography of the respondents. The first section of the table shows the gender-wise distribution of the respondents, which shows that 526 were males and 124 were females. The second section of the table shows the age-wise distribution of the respondents, which shows that the majority of respondents, 36%, belong to the age group of 31 to 40 years, and the minor age group is 51 and above years with 13%. The third section of the table denotes the industry experience of the respondents. This shows that the majority of the respondents, 40%, have experience the duration of 1 year to 5 years, while those with less than one-year experience make up the least with a percentage of 11.

Table 1.

Sample characteristics.

3.5. Reliability of the Scales

For the data analysis based on the primary data, it is necessary to validate the reliability and validity of the scales before the model estimation [149]. Using primary data based on the previously established measure, it is necessary to validate its reliability and validity by confirmatory factor analysis [150]. When using SEM based on a variance-based approach like SmartPLS, there are two types of reliability for the scales: item and construct reliability. The measure used for the item’s reliability is the outer loading values, while the measures used for the construct reliability are Cronbach alpha and composite reliability. The threshold value for all three measures is 0.7, but a value of 0.6 is also acceptable if the initial criteria for the validity are established [151].

DT3, RU2, RU5, SB3, SB4, WR5, and WR6 were removed due to low factor loading values, indicating a weak representation of their respective constructs. Their exclusion was necessary to improve model reliability, validity, and overall fit.

Table 2 shows that all the items and constructs have reliability values greater than the threshold value, indicating that the items and constructs are reliable for further analysis.

Table 2.

Reliability.

3.6. Convergent Validity of the Scales

Convergent validity refers to how much a construct’s items are related to the construct [152]. Average variance extracted (AVE) is the most common measure used for convergent validity. The threshold value for the AVE is 0.5 or greater, but a value of 0.4 is also acceptable if the initial criteria for scale reliability are established [153]. Table 3 shows that all the AVE values are more significant than the threshold value, indicating that all the constructs are convergently valid.

Table 3.

Convergent validity.

3.7. Discriminant Validity of the Scales

Discriminant validity refers to how much one construct of a model is theoretically different from another [154]. Various measures can be used for discriminant validity, while SmartPLS includes Fornell Larcker criteria, HTMT, and cross-loading [155]. Most researchers and statisticians suggest Fornell Larcker criteria and HTMT values for discriminant validity [156]. Regarding Fornell Larcker criteria, the measure used for this is the diagonal values of the AVEs. The threshold value for this is that the diagonal values of the table must be greater than the respective values of its columns and rows [151]. Table 4 shows that all the diagonal values are greater than the value of their respective columns and rows, indicating that all the constructs are discriminately valid.

Table 4.

Discriminant validity.

Another measure for testing the discriminant validity is the HTMT values. The threshold value for the HTMT values is 0.85 or less [157]. Table 5 shows that all the constructs’ HTMT values are below the threshold value, indicating that all the study constructs are discriminately valid.

Table 5.

HTMT Values.

3.8. Common Method Bias

Common method bias is a usual issue faced by the primary data when the independent and the dependent variables are calculated in the same survey and have the same response method as the ordinal scale [158]. Different measures are used for the common method bias. However, researchers and statisticians, using a partial least square structural equation modeling VIF values is the most robust technique to identify this issue [159]. If the VIF values are smaller than 3.3, the model is considered free from common method bias issues [160]. Table 6 represents the VIF values of each item, which are smaller than the threshold value, demonstrating that the model is free from the common method bias.

Table 6.

Multicollinearity.

3.9. Model Fitness

Once a model’s reliability, validity, and common method bias are addressed, it is necessary to confirm its fitness before estimating the model for the regression analysis [161]. Using a structural equation model based on variance, different measures like SRMR, Chi-Square, NFI, etc. exist. However, statisticians and researchers suggest that SRMR is the most robust technique to assess model fitness. The threshold value for the SRMR is 0.08 or less [162]. Table 7 of the model fitness shows that the SRMR value for this model is 0.066, smaller than the threshold value, indicating that model fitness is achieved.

Table 7.

Model fitness.

4. Results

4.1. Structural Model

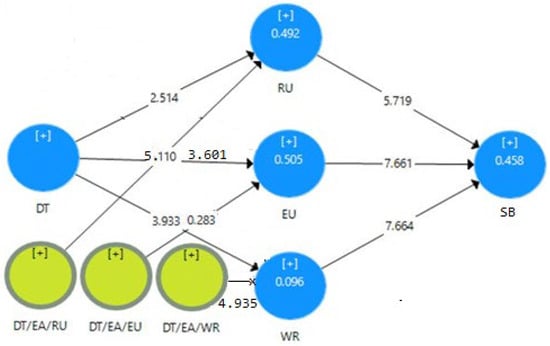

Figure 4 shows the study’s structural model, which elaborates on the relationship between the study’s variables.

Figure 4.

Tested theoretical model.

4.2. Hypothesis Testing on Direct Relationships

Table 8 shows the summary of the hypotheses. There are two common measures named t-value and p-value to identify the statistical significance of a hypothesized relationship. The threshold value for the t-value is 1.96 or above, while the threshold value for the p-value is 0.05 or less [163]. All six hypotheses are statistically significant based on direct relationships because they have a t-value greater than 1.96 and a p-value smaller than 0.05. while the beta value for each relationship denotes the strength of each relationship. The details of the direct relationships are given below.

Table 8.

Hypothesis testing.

H1.

DT has a significant positive impact on RU.

The results show that there is a statistically significant relationship between DT and RU having a β-value of 0.072 and a t-statistic of 2.514, with a level of significance of 0.012. This indicates that the hypothesis is supported by data, and shows a significant and positive relationship between DT and RU. According to the results, variations regarding DT have a significant impact on RU, indicating DT’s significance in influencing RU in manufacturing processes.

H2.

DT has a significant positive impact on the EU.

The findings of the study show that there is a statistically significant relationship between DT and EU having a β-value of 1.06 and a t-statistic of 3.601, with a significant 0.000. This indicates that the hypothesis is supported by data, and shows a significant and positive relationship between DT and EU. According to the results, variations regarding DT have a significant impact on the EU, indicating DT’s significance in influencing the EU in manufacturing processes.

H3.

DT has a significant positive impact on WR.

Similarly, according to the results, there is a statistically significant relationship between DT and WR having a β-value of 0.147 and a t-statistic of 3.933, with a level of significance of 0.000. This indicates that the hypothesis is supported by data, and shows a significant and positive relationship between DT and WR. According to the results, variations regarding DT possess a significant impact on WR, indicating DT’s significance in influencing WR in manufacturing processes.

H4.

RU has a significant positive impact on sustainability.

The statistics show that there is a statistically significant relationship between RU and SB having a β-value of 0.24 and a t-statistic of 5.719, with the level of significance 0.000. This indicates that the alternative hypothesis is supported by data, and shows a significant and positive relationship between RU and SB. According to the results, variations regarding RU possess a significant impact on SB, indicating RU’s significance in influencing SB in manufacturing processes.

H5.

EU has a significant positive impact on sustainability.

The findings show that there is a statistically significant relationship between EU and SB having a β-value of 0.289 and a t-statistic of 7.661, with the level of significance 0.000. This indicates that the alternative hypothesis is supported by data, and shows a significant and positive relationship between EU and SB. According to the results, variations regarding the EU possess a significant impact on SB, indicating the EU’s significance in influencing SB in manufacturing processes.

H6.

WR has a significant positive impact on sustainability.

The results show that there is a statistically significant relationship between WR and SB having a β-value of 0.257 and a t-statistic of 7.664, with the level of significance 0.000. This indicates that the alternative hypothesis is supported by data, and shows a significant and positive relationship between WR and SB. According to the results, variations regarding WR possess a significant impact on SB, indicating WR’s significance in influencing SB in manufacturing processes.

4.3. Hypothesis Testing on Moderating Relationships

Table 8 shows the summary of the three moderating relationships. There are two common measures named t-value and p-value to identify the statistical significance of a hypothesized relationship. The threshold value for the t-value is 1.96 or above, while the threshold value for the p-value is 0.05 or less [163]. All three hypotheses are statistically significant based on moderating relationships because they have a t-value greater than 1.96 and a p-value smaller than 0.05,while the beta value for each relationship denotes the strength of each relationship. The details of the moderating relationships are given below.

H7.

EA moderates the effect of DT on RU.

The statistics show that the hypothesis is supported with a β-value of 0.204, t-statistic 5.11, and a significance level of 0.000. This indicates the moderating role of EA on the relationship of DT towards RU is statistically significant. Moderation indicates that EA modifies the strength of the relationship between DT and RU. It means that the connection between DT and RU is dependent on the level of EA.

H8.

EA moderates the effect of DT on the EU.

The findings show that the hypothesis is supported by a β-value of 0.107, a t-statistic of 0.283, and a significance level of 0.000. This indicates the moderating role of EA on the relationship of DT towards the EU is statistically significant. Moderation indicates that EA modifies the strength of the relationship between DT and EU. It means that the connection between DT and EU is dependent on the level of EA.

H9.

EA moderates the effect of DT on WR.

The results show that the hypothesis is supported by a β-value of 0.234, a t-statistic of 4.935, and a significance level of 0.000. This indicates the moderating role of EA on the relationship of DT towards WR is statistically significant. Moderation indicates that EA modifies the strength of the relationship between DT and WR. It means that the connection between DT and WR is dependent on the level of EA.

4.4. Coefficient of Determination

The coefficient of determination gauges how effectively the model reflects observed results. This explains the overall variation in outcomes the model explains [164]. The measure used for the coefficient of determination is R square. Table 9 shows a value of 0.458, indicating that the model’s variables explain the 45.8% variation in the dependent variable explained by the model’s independent variables.

Table 9.

R-Square.

4.5. IPMA Analysis

IPMA stands for the importance and performance matrix analysis. It is an advanced technique used in SmartPLS to estimate the importance and the performance of the individual independent variable for the dependent variable [165]. Table 10 shows the importance and the performance of the variables for the dependent variable. According to the table, EA has the highest level of importance value, with a value of 0.409, while environmental regulation has the highest performance value, with a value of 70.293. On the other side, DT has the lowest level of importance value, with a value of 0.055, and the same variable also has the lowest performance value, with a value of 37.468.

Table 10.

IPMA Analysis.

4.6. Predictive Relevance of the Model

It is an advanced technique used in the SmartPLS to estimate the prediction power of the model. The measure used for the predictive relevance of a model is known as the Q square. According to the researchers, a value greater than zero Q square is considered a good model prediction [166]. Table 11 shows a Q-Square value of 0.223 for sustainability, which denotes a power of 22.3% when the model is tested in a context other than the researcher.

Table 11.

Predictive relevance of the model.

4.7. Model Robustness

A model must confirm the model robustness for the models based on the structural equation modeling. Two common measures and tests used for the SmartPLS to confirm the model robustness are non-linear effects and unobserved heterogeneity [167].

4.7.1. Non-Linear Effect

It is always believed that the relationships among the variables of the model, whenever we were regressing that model based on the linear regression model, are linear among them [168]. If the relationships among them are non-linear, it will result in spurious regression outcomes when regressed based on linear regression [169]. The test used for the linear effect is the Ramsey Regression Equation Specification Error Test (RESET). The measures used for the Ramsey test are the t-statistics and F-statistics. The threshold value for the t-statistics and f-statistics is the p-value of 0.05 or less for the non-linear detection among the variables. Table 12 of the Ramsey test shows that both the p values for the t and f statistics are greater than the threshold value. This indicates a linear relationship among the variables of this study’s model, which confirms that the model’s robustness is achieved.

Table 12.

Ramsey RESET test.

4.7.2. Unobserved Heterogeneity

Unmeasured (unobserved) differences between study subjects or samples connected to the (observed) variables of interest are referred to as unobserved heterogeneity [170]. When there is any hidden variable in the model but not included in the model, it will create a misleading conclusion from the regression of the model [171]. The measure used for unobserved heterogeneity is the FIMIX test in the SmartPLS. Table 13 of the FIMIX shows that all the values for the four variables named RU, EU, WR, and sustainability are declining from segment 1 to segment 5. This shows that there is no evidence for the unobserved heterogeneity in the model of this study, which also confirms the robustness of the model.

Table 13.

FIMIX residual variance.

5. Discussion

This study aims to examine the impact of DT on the sustainable practices of the manufacturing industry of Pakistan. This study further explores how this impact is mediated by different channels like EU, RU, and WR while how EA moderates it. The literature based on past studies claims that DT significantly impacts sustainable practices by mediating EU, RU, and WR [172]. According to the literature, increasing EA will also enhance sustainable practices. The first hypothesis claimed by this study argues that DT will lead to better use of resources in the manufacturing sector of Pakistan. The findings of this study also support the said arguments that DT will lead toward sustainable practices with β = 0.072 and p = 0.012. The past literature based on the arguments also supports the same arguments; however, these studies were conducted in different contexts other than researchers but support this argument [173,174]. There is an agreement among researchers that DT has exponentially enhanced the utilization of resources by streamlining the operations, workflows, and allocations [175]. As the manufacturing industries embrace advanced DT, it will become more productive and will more efficiently use its resources [176]. The findings of this study highlight and validate the role of DT in improving resource use. As the manufacturing industries implement more advanced technologies like automation, artificial intelligence, and data analytics, they will use their resources more efficiently [177].

The second hypothesis based on this study argues that DT will lead to better and more efficient energy usage in the manufacturing sector of Pakistan. The results of this study also support the said arguments claimed by the survey with a β = 0.106 and p = 0.000. However, different researchers from the past literature have also found the same results, but those studies have been conducted in different contexts and sectors other than the researchers [178,179]. DT has substantially enhanced energy efficiency which has been one of the most important challenges of the manufacturing industry [180]. Latest studies show the revolutionary potential of DT for energy consumption. Energy systems may now be precisely adjusted to match demand by real-time monitoring and control systems like smart grids, sensors, etc. [181]. While earlier studies mostly explored the negative effects of energy-intensive activities on the environment [182,183], contemporary research stresses how digitization can be used for energy-efficient processes [184]. This study validates an increasing consensus regarding the vital importance of digitalization for enhancing energy infrastructures.

The third hypothesis based on the model of this study argues that DT will lead to better deals with WR. However, the findings of this study also support the hypothesis that DT will lead to a better deal with WR with a β = 0.147 and p = 0.000. Different researchers from different world contexts have the same findings with the same study. However, these studies have been conducted in different contexts but have the same findings as the study [55,185]. The importance of DT in reducing waste throughout the manufacturing process has been highlighted by the current study. DT like predictive maintenance, real-time monitoring, the Internet of Things, etc., have made optimal resource utilization possible [85]. This enhances the efficient utilization of resources and reduces faults and overproduction [186]. Manufacturers can implement the circular economy principles easily due to DT [187]. Consequently, this study indicates an end to the resource-intensive methods of traditional processes while recognizing DT as an effective tool to decrease waste in the manufacturing industry.

The fourth hypothesis argues that efficient RU will lead to sustainable practices in the manufacturing sector of Pakistan. However, the results of this study also claimed the same results aligned with the argued hypothesis with a β = 0.240 and p = 0.000. Researchers from different contexts have surveyed the relationship in different contexts and found the same findings, aligning with this study’s findings [105,188]. Recent studies investigated the role of DT in using resources efficiently which is an essential component of manufacturing sustainability [189]. DT has improved the process of manufacturing and facilitated exact resource allocation [190]. A commitment to reduce the environmental impact of manufacturing operations is apparent in recent studies that emphasize production maximization and resource efficiency optimization [84,191]. Intending to build a more sustainable manufacturing landscape, this study stresses increasing RU efficiency through DT. Contrary to earlier periods, when resource-intensive methods were common, this study highlights how effectively RU can move the manufacturing sector towards sustainability.

The fifth hypothesis of this study claims that the EU significantly impacts sustainable practices in Pakistan’s manufacturing sector. However, this study has also found a significant impact on the EU of the sustainable practices of the manufacturing industry of Pakistan with a β = 0.289, p = 0.000. Researchers from different contexts also found the same findings that align with this study’s findings [192,193]. The studies examining the relationship between sustainable manufacturing practices and energy efficiency have attracted many researchers. Recent studies show the revolutionary effects of energy efficiency as a critical component of manufacturing sustainability [95]. DT has become an essential instruments for reducing the environmental impact of manufacturing processes [194]. In order to lower carbon dioxide emissions and reduce the general effect on the environment, the present study puts a strong emphasis on the need to implement energy-efficient practices. It is also evidenced by other studies that the incorporation of energy-efficient technologies in the manufacturing process will result in more sustainable manufacturing processes [195].

The study’s sixth hypothesis argues that WR will lead to sustainable practices. This study also found that WR will lead to sustainable practices in the manufacturing sector of Pakistan with a β = 0.257 and p = 0.000. Researchers from different geographical contexts have also found the same findings, which align with this study’s findings [196,197]. Although WR is one of the crucial aspects of the manufacturing process, it is considered as an inherent factor of industry [198]. Recent studies illustrate how important waste minimization techniques are to promoting sustainability in the manufacturing industry [199]. The integration of DT into manufacturing has made it possible to monitor and optimize production processes in real-time [85]. It has made it easier to utilize resources more efficiently decrease waste and incorporate the circular economy principles in manufacturing [85]. The present study also validates the role of WR and the promise of sustainability in manufacturing processes.

Hypotheses seven, eight, and nine are based on the moderating relationship of EA on DT towards energy use, RU, and WR. However, the findings of this study support these moderating relationships of EA that if the EA is increased, it will also increase the impact of the DT on different sustainable practices like energy, RU, and WR, which ultimately leads towards sustainability with having a β1 = 0.204, β2 = 0.137, β3= 0.234 and p1 = p2 = p3 = 0.000, respectively. We see results based on the researcher’s past findings based on these relationships supporting these hypotheses in various contexts. The reason for that is that awareness plays a vital role in deploying any policy among the public [200] [201]. The moderating influence of EA on the relation between DT and EU, RU, and WR is evident from the statistics. Manufacturing industries must consider these aspects in the digitalization efforts toward sustainability [202]. Many previous studies are focused on the productivity [203] [204]. The current study focuses on the role of EA that impacts the results of digitalization and assists in the successful incorporation of environmentally friendly practices through DT. A high degree of EA helps digitization initiatives prioritize energy-saving technologies, efficient resource use, and WR techniques [205]. Conversely, organizations with a lower level of EA may fail to pay enough attention to these factors [206]. When compared to earlier research, the finding of this study has moved from just financial benefits to a deeper understanding of the environmental effects of digitization, indicating a growing awareness of the significance of sustainability in advances in technology.

The manufacturing sector can be reshaped by digitalization, which provides a wide range of opportunities that improve sustainability. Industries can greatly improve their use of energy and resources by using digital technology and implementing it into different manufacturing processes. Real-time data analysis, automation, and predictive modeling enable manufacturers to make well-informed decisions on resource allocation and EU [207]. Digitalization also makes smart manufacturing techniques possible with the help of the Internet of Things and analytics. These innovations offer a thorough understanding of the manufacturing atmosphere, making it possible to monitor and manage processes that consume much energy precisely. Thus, manufacturers can better find inefficiencies, optimize processes, and minimize wasted energy, contributing to more profitable operations and sustainability [208]. Furthermore, digitization helps develop novel techniques like digital twins, which can generate digital versions of actual production processes. Manufacturers may model and optimize processes using this tool before implementation, reducing the need for resource-wasting required for trial-and-error procedures [209]. This simulation’s optimization of manufacturing processes made possible results in less material use during production and less waste production. WR, a natural byproduct of optimal energy and RU, substantially contributes to sustainability [210]. Digitalization assists industries in reducing their ecological footprint by minimizing wasteful RU, EU, and ineffective operations. In addition to conserving important resources, WR also lessens the requirement for disposal, which may have significant ecological effects. In short, adopting digitalization in industries like manufacturing facilitates businesses to optimally utilize resources and energy, significantly decreasing waste [211]. This integrated optimization effort supports larger sustainability goals since it reduces the sector’s ecological impact and fosters ecologically friendly processes.

The results validate the ideas of the circular economy by exhibiting that resource reuse, energy efficiency, and waste reduction contribute to manufacturing sustainability. Resource reuse supports conservation, increases product life cycles, and reduces dependency on virgin resources, aligned with the circular economy principle of reusing resources repeatedly. The findings also promote sustainable production and reduce ecological impacts by efficient energy use, particularly during recycling processes that consume less energy than during the process of extraction of raw materials and making them suitable for manufacturing. Furthermore, by adopting WR strategies, waste can be turned into useful inputs, such as reusing byproducts and implementing closed-loop systems, reducing the degradation of the environment while supporting regenerative industrial practices.

Although digitalization may increase productivity and operational efficiency toward the sustainability of the manufacturing industry, several possible challenges need careful consideration. The production of electronic waste is one of the main challenges. A faster replacement of old or obsolete equipment like sensors, etc., will lead to more waste. Inadequate recycling and disposal procedures will lead to environmental degradation if efficient e-waste management systems are not adopted. Many of these electric wastes cannot be managed by ordinary means and will require specialized systems for proper handling and processing. The increase in energy usage due to digital technologies is another important problem. Cloud computing, industrial Internet of Things, and AI require considerable amounts of energy, which increases the electricity demand. This rise in energy consumption can result in higher greenhouse gas emissions. These unintended effects highlight the necessity of implementing technology in a balanced manner. Integrating energy-efficient devices, promoting renewable energy usage, and developing comprehensive e-waste management strategies are essential for ensuring sustainability in the manufacturing industry.

5.1. Implications

5.1.1. Practical Implications

- Digital technology adoption for sustainability: The study’s findings can be used by Pakistani policymakers and practitioners of sustainability to implement digitalized solutions within sustainability initiatives effectively. Adopting digital tools will improve WR efforts, optimize resource utilization, and reduce energy consumption.

- Awareness campaigns: The study highlights the importance of EA for Pakistani people and industries. To increase the moderating influence of awareness on the sustainability impacts of digitalization, governments, and the non-government sector should work together to endorse environmental advocacy and education.

- Skill development: The study emphasizes the importance of education and training initiatives to provide individuals with the requisite digital and sustainability literacy. These initiatives will enable workers and organizations to use digital technologies for sustainable practices.

5.1.2. Managerial Implications

- Digitalization–sustainability alignment: Managers and industrial executives must align the digitization initiatives with EA efforts and sustainability goals. This coordination may result in competitive advantages and enhanced reputation.

- Assessment of environmental impact: Managers need to understand the real implications of digitalization on resource usage, energy consumption, and WR by regularly conducting assessments for environmental impact. These evaluations will guide decision-making and stimulate environmental performance.

- Improved decision-making: Organizations are encouraged to adopt DT for making data-driven decisions about energy efficiency, resource allocation, and waste management using real-time monitoring systems. To optimize and improve operations, investments are needed in data-driven tools.

- Change management and successful digitalization: Effective change management is necessary for managers to implement digital technologies effectively. Stakeholders and staff should be engaged in the implementation to ensure its contribution towards sustainability.

5.1.3. Industry Implications

The findings also have the following implications for industries.

- Innovation and collaboration: Pakistan’s manufacturing sector needs to advance innovation by collaborating with technology suppliers, developers, and research organizations. Joint ventures can result in developing sustainable digital tools specifically appropriate for the requirements of particular industries.

- Policy advocacy: Industries need to adopt and implement laws that encourage the utilization of digital technology for environmental performance.

- Certification: Industries are encouraged to develop industry-wide standards and recognition for digitalization-driven sustainability achievements to motivate industries to seek more sustainable performance.

5.2. Contribution to the Attainment of SDGs

The study has important implications for the attainment of the SDGs.

- The findings of the research outcomes support SDG-7 (Affordable and Clean Energy) and stress the investment in green and clean technology. The contribution of DT is evident in the efficient use of energy, thus by reducing the consumption of energy, the study advances the attainment of SDG-7.

- The study emphasizes the significance of digitization as a driver towards innovation and sustainable scientific advancement, contributing to the attainment of SDG-9 (Industry, Innovation, and Infrastructure).

- The study promotes sustainable urban development by SDG-11 (Sustainable Cities and Communities). The results may help develop smart cities that optimize EU and RU, reduce waste output, and improve all aspects of living for residents as supported by the findings.

- The findings show that digitization has positive relationships with efficient RU, efficient EU, and WR, leading to the concept of sustainability. The findings encourage responsible consumption and production, aligning with SDG-12 (Responsible Consumption and Production).

6. Conclusions

This study aims to examine the impact of DT on the sustainability of the manufacturing sector of Pakistan. The study shows that the relationship is channeled by three variables: EU, RU, and WR. In addition, DT significantly impacts sustainability, but this effect is not so simple. First, due to DT, energy usage, resource usage, and WR are controlled, ultimately leading the firms toward sustainability. While on the other hand, EA will moderate the relationship between DT and these resource efficiency components. Furthermore, if EA is increased, it will lead to resource efficiency components. However, this study concludes that EA had a limited moderating effect on these resource efficiency components. Increasing government awareness-based campaigns on the environment will better lead firms towards sustainable practices. The findings of this study also support this argument in the context of the manufacturing sector of Pakistan.

6.1. Limitations and Future Research Direction

Limitations are boundaries that decide the scope of the study. Researchers may address these limitations to advance the body of knowledge and contribute to further academic and practical developments in the field. The following are the limitations of this study.

- The current study is based on quantitative techniques. Future research can conduct the same study using a qualitative technique to explore new factors that contribute to sustainable practices in the context of the manufacturing industry.

- The population is limited to the manufacturing sector of Pakistan. Further studies can test the same model in different contexts or other geographical regions to increase the generalizability of the findings.

6.2. Recommendations/Implementation in the Context of Uncertainties

Based on the findings, the study provides some important recommendations for uncertain times.

- Nations across the globe need to ensure the implementation of a climate-friendly policy at an uncertain time in the manufacturing industries, providing them with a clear directive regarding the implementation of advanced digital technologies for ensuring the sustainable consumption of resources [212].

- Considering the dynamics of situations, more attractive monetary incentives should be provided for the adoption of digital technologies to ensure the sustainable consumption of resources [213,214].

- Adaptive digital technologies and policies should be implemented in the manufacturing industries, enabling them to adjust according to the uncertainties [212].

- A continuous engagement is necessary for all stakeholders at the industry, national, and international levels for collaborative efforts towards sustainability in uncertain conditions.

- A regular review and update is necessary for the policies [215] and advancement of digital technologies to align them with the changing need or any uncertainty for ensuring the sustainable consumption of resources.

- Contingency planning is necessary [216] for any uncertainty or disruption caused by any environmental changes or technological advancements.

Funding

This research received no external funding.

Institutional Review Board Statement

This study was considered by the Ethics/Research Committee for Research on 22 March 2024, meets the requirements of the National Statement on Ethical Conduct in Human Research (2007), and was APPROVED on 8 April 2024. The study meets the requirements of the National Statement on Ethical Conduct in Human Research (2007). The procedures used in this study adhere to the tents of the international declaration of Helsinki. Project Number: 2024/4/MS.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data set generated during and/or analyzed during the current study is available from the corresponding author upon reasonable request.

Conflicts of Interest

The author declares no conflicts of interest.

Appendix A

| Measurement Instrument | |

| Construct | Items |

| Digital Transformation [144] | The Internet service is available all the time. |

| The cost of the internet connection is reasonable for my household. | |

| The Internet enables me to accomplish my tasks more quickly. | |

| The Internet helps me to find new opportunities (e.g., employment, education, and business) | |

| The Internet helps me to learn and develop new skills and knowledge. | |

| The Internet has had a positive impact on my work performance. | |

| Internet use has become an everyday part of my life. | |

| The Internet helps me to connect with community, social, or sporting groups. | |

| Environmental Awareness [145] | The government provides easy-to-understand information on environmental issues. |

| National regulations on environmental issues need to be communicated properly to the manufacturing industry. | |

| Local environmental should provide regulations on time in the manufacturing industry. | |

| Local environmental regulations can be obtained cheaply by mail, online, or in person to promote sustainability in the manufacturing industry. | |

| National environmental regulations, such as by mail, online, or in-person, can be obtained cheaply to promote sustainability in the manufacturing industry. | |

| Environmental administrative proceedings at the local level are conducted without unreasonable delay to promote sustainability in the manufacturing industry. | |

| Environmental administrative proceedings at the national level are conducted without unreasonable delay to promote sustainability in the manufacturing industry. | |

| Resource Use [146] | Resource usage is necessary to be very efficient in manufacturing industries. |

| Ecofriendly technology should be used for the better use of the resources. | |

| You believe resource usage is important. | |

| Resource usage is necessary to be very efficient in manufacturing industries. | |

| Ecofriendly technology should be used for proper resource usage. | |

| Energy Use [146] | Energy consumption is necessary to be very efficient in manufacturing industries. |