The Use of Castor Oil Resin on Particleboards: A Systematic Performance Review and Life Cycle Assessment

Abstract

1. Introduction

2. Methodology

2.1. Systematic Review Protocol and Selection of Studies of Interest

- -

- Filter 1: The keywords should be identified using the descriptor terms in the Web of Science platform studies titles, keywords, or abstracts. Initially, the terms castor oil resin or castor oil adhesive were applied to verify the breadth of the topic.

- -

- Filter 2: Subsequently, the terms particleboard and oriented strand board (OSB) were included to restrict the proposed topic to the area of interest of this article. Boolean logic was applied, and an asterisk was used in the descriptor term to include plurals and possible variations (castor oil resin or castor oil adhesive) and particleboard*) or (castor oil resin or castor oil adhesive) and (oriented strand board or OSB)).

2.2. Life Cycle Assessment

3. Results and Discussion

3.1. General Overview of PU Resin as a Particleboard Binder

3.2. Comparative Overview Between Castor Oil PU Resin and Other Adhesive Resins

3.3. Life Cycle Assessment Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Iwakiri, S.; Shimizu, J.; de Castro Silva, J.; Del Menezzi, C.H.S.; Puehringher, C.A.; Venson, I.; Larroca, C. Produção de painéis de madeira aglomerada de Grevillea robusta A. Cunn. ex R. Br. Rev. Árvore 2004, 28, 883–887. [Google Scholar] [CrossRef]

- Buzo, A.L.S.C.; Silva, S.A.M.; de Moura Aquino, V.B.; Chahud, E.; Branco, L.A.M.N.; de Almeida, D.H.; Christoforo, A.L.; Almeida, J.P.B.; Lahr, F.A.R. Addition of sugarcane bagasse for the production of particleboards bonded with urea-formaldehyde and polyurethane resins. Wood Res. 2020, 65, 727–736. [Google Scholar] [CrossRef]

- Solt, P.; Konnerth, J.; Gindl-Altmutter, W.; Kantner, W.; Moser, J.; Mitter, R.; van Herwijnen, H.W.G. Technological performance of formaldehyde-free adhesive alternatives for particleboard industry. Int. J. Adhes. Adhes. 2019, 94, 99–131. [Google Scholar] [CrossRef]

- Bekhta, P.; Noshchenko, G.; Réh, R.; Kristak, L.; Sedliačik, J.; Antov, P.; Mirski, R.; Savov, V. Properties of eco-friendly particleboards bonded with lignosulfonate-urea-formaldehyde adhesives and PMDI as a crosslinker. Materials 2021, 14, 4875. [Google Scholar] [CrossRef]

- Oliveira, S.L.; Freire, T.P.; Mendes, L.M.; Mendes, R.F. The effect of post-heat treatment in MDF panels. Mater. Res. 2017, 20, 183–190. [Google Scholar] [CrossRef]

- de Macedo, L.B.; de Moura Aquino, V.B.; Wolenski, A.R.V.; Christoforo, A.L.; Lahr, F.A.R. Paineis híbridos de lâminas e partículas de madeira para uso estrutural. Ambient. Construído 2019, 19, 15–23. [Google Scholar] [CrossRef]

- Iwakiri, S.; de Andrade, A.S.; Junior, A.A.C.; Chipanski, E.D.R.; Prata, J.G.; Adriazola, M.K.O. Produção de painéis aglomerados de alta densificação com uso de resina melamina-ureia-formaldeido. Cerne 2005, 11, 323–328. [Google Scholar]

- Wilczak, L.; Trianoski, R.; Neto, S.C.; de Paula, C.R.P.; Villanova, R.L.; Azevedo, E. Efficiency of castor oil-based polyurethane in the production of plywood panels. Sci. For. Sci. 2019, 47, 463–471. [Google Scholar] [CrossRef]

- Salthammer, T. The formaldehyde dilemma. Int. J. Hyg. Environ. Health 2015, 218, 433–436. [Google Scholar] [CrossRef]

- Arias, A.; González-Rodríguez, S.; Barros, M.V.; Salvador, R.; de Francisco, A.C.; Piekarski, C.M.; Moreira, M.T. Recent developments in bio-based adhesives from renewable natural resources. J. Clean. Prod. 2021, 314, 127892. [Google Scholar] [CrossRef]

- Da Silva Bertolini, M.; Lahr, F.A.R.; Nascimento, M.F.D.; Agnelli, J.A.M. Accelerated artificial aging of particleboards from residues of CCB treated pinus sp. and castor oil resin. Mater. Res. 2013, 16, 293–303. [Google Scholar] [CrossRef]

- Bertolini, M.S.; de Morais, C.A.G.; Christoforo, A.L.; Bertoli, S.R.; Santos, W.N.D.; Lahr, F.A.R. Acoustic absorption and thermal insulation of wood panels: Influence of porosity. BioResources 2019, 14, 3746–3757. [Google Scholar] [CrossRef]

- Sugahara, E.S.; da Silva, S.A.M.; Buzo, A.L.S.C.; de Campos, C.I.; Morales, E.A.M.; Ferreira, B.S.; Azambuja, M.D.A.; Lahr, F.A.R.; Christoforo, A.L. High-density particleboard made from agro-industrial waste and different adhesives. BioResources 2019, 14, 5162–5170. [Google Scholar] [CrossRef]

- Instituto Brasileiro de Madeira e das Estruturas de Madeira. EBRAMEM. In Proceedings of the Encontro Brasileiro em Madeiras e em Estruturas de Madeira, São Pedro, Brazil, 30 July–2 August 2006; p. 278. [Google Scholar]

- Instituto Brasileiro de Madeira e das Estruturas de Madeira. EBRAMEM. In Proceedings of the Encontro Brasileiro em Madeiras e em Estruturas de Madeira, Londrina, Brazil, 14–16 July 2008; p. 278. [Google Scholar]

- Instituto Brasileiro de Madeira e das Estruturas de Madeira. EBRAMEM. In Proceedings of the Encontro Brasileiro em Madeiras e em Estruturas de Madeira, Uberlândia, Brazil, 24–26 July 2002; p. 206. [Google Scholar]

- Fiorelli, J.; Lahar, F.A.R.; Nascimento, M.F.D.; Junior, H.S.; Rossignolo, J.A. Painéis de partículas à base de bagaço de cana e resina de mamona—Produção e propriedades. Acta Sci. Technol. 2011, 33, 401–406. [Google Scholar] [CrossRef]

- Costa, D.; Serra, J.; Quinteiro, P.; Dias, A.C. Life cycle assessment of wood-based panels: A review. J. Clean. Prod. 2024, 444, 140955. [Google Scholar] [CrossRef]

- Silva, V.U.; Nascimento, M.F.; Oliveira, P.R.; Panzera, T.H.; Rezende, M.O.; Silva, D.A.L.; de Moura Aquino, V.B.; Lahr, F.A.R.; Christoforo, A.L. Circular vs. linear economy of building materials: A case study for particleboards made of recycled wood and biopolymer vs. conventional particleboards. Constr. Build. Mater. 2021, 285, 122906. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Lima, L.; Trindade, E.; Alencar, L.; Alencar, M.; Silva, L. Sustainability in the construction industry: A systematic review of the literature. J. Clean. Prod. 2021, 289, 125730. [Google Scholar] [CrossRef]

- Jos, A.; Filho, M.; Savastano, H.; Gustavo, F. Algae application in civil construction: A review with focus on the potential uses of the pelagic Sargassum spp. Biomass 2022, 303, 114258. [Google Scholar] [CrossRef]

- Shamseer, L.; Moher, D.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; Altman, D.G.; Booth, A.; et al. Preferred reporting items for systematic review and meta-analysis protocols (prisma-p) 2015: Elaboration and explanation. BMJ 2015, 349, g7647. [Google Scholar] [CrossRef]

- Silva, V.L.; Sanjuán, N. Opening up the black box: A systematic literature review of life cycle assessment in alternative food processing technologies. J. Food Eng. 2019, 250, 33–45. [Google Scholar] [CrossRef]

- Sugahara, E.; Dias, A.; Botelho, E.; Campos, C.; Dias, A. Life Cycle Assessment of OSB Panels Produced with Alternative Raw Materials. RILEM Bookseries 2023, 45, 959–972. [Google Scholar] [CrossRef]

- Panda, S.S.; Panda, B.P.; Nayak, S.K.; Mohanty, S. A Review on Waterborne Thermosetting Polyurethane Coatings Based on Castor Oil: Synthesis, Characterization, and Application. Polym.-Plast. Technol. Eng. 2018, 57, 500–522. [Google Scholar] [CrossRef]

- Owodunni, A.A.; Lamaming, J.; Hashim, R.; Taiwo, O.F.A.; Hussin, M.H.; Kassim, M.H.M.; Bustami, Y.; Sulaiman, O.; Amini, M.H.M.; Hiziroglu, S. Adhesive application on particleboard from natural fibers: A review. Polym. Compos. 2020, 41, 4448–4460. [Google Scholar] [CrossRef]

- Rabello, L.G.; da Conceição Ribeiro, R.C. Bio-based polyurethane resin: An ecological binder for a novel class of building materials-composites. Mater. Lett. 2022, 311, 131566. [Google Scholar] [CrossRef]

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Garzón-Barrero, N.M.; Shirakawa, M.A.; Brazolin, S.; de Freitas Nuno de Barros Pereira, R.G.; de Lara, I.A.R.; Savastano, H. Evaluation of mold growth on sugarcane bagasse particleboards in natural exposure and in accelerated test. Int. Biodeterior. Biodegrad. 2016, 115, 266–276. [Google Scholar] [CrossRef]

- Fiorelli, J.; Galo, R.G.; Junior, S.L.C.; Belini, U.L.; Lasso, P.R.O.; Savastano, H. Multilayer Particleboard Produced with Agroindustrial Waste and Amazonia Vegetable Fibres. Waste Biomass Valorization 2018, 9, 1151–1161. [Google Scholar] [CrossRef]

- Fiorelli, J.; Bueno, S.B.; Cabral, M.R. Assessment of multilayer particleboards produced with green coconut and sugarcane bagasse fibers. Constr. Build. Mater. 2019, 205, 1–9. [Google Scholar] [CrossRef]

- Yano, B.B.R.; Silva, S.A.M.; Almeida, D.H.; Aquino, V.B.M.; Christoforo, A.L.; Rodrigues, E.F.C.; Junior, A.N.C.; Silva, A.P.; Lahr, F.A.R. Use of sugarcane bagasse and industrial timber residue in particleboard production. BioResources 2020, 15, 4753–4762. [Google Scholar] [CrossRef]

- Silva, S.A.M.; Minillo, L.Q.; Aquino, V.B.D.M.; Lahr, F.A.R.; Christoforo, A.L. Use of Residues from the Cellulose Industry and Sugarcane Bagasse in Particleboards. Eng. Agrícola 2021, 4430, 107–111. [Google Scholar] [CrossRef]

- Varanda, L.D.; Nascimento, M.F.D.; Christoforo, A.L.; Silva, D.A.L.; Lahr, F.A.R. Oat hulls as addition to high density panels production. Mater. Res. 2013, 16, 1355–1361. [Google Scholar] [CrossRef]

- Nogueira, I.M.D.S.; Lahr, F.A.R.; Giacon, V.M. Desenvolvimento e caracterização de painéis de partículas aglomeradas utilizando o resíduo do ouriço da castanha-do-brasil (Bertholletia excelsa) e resina poliuretana derivada do óleo da mamona. Rev. Mater. 2018, 23, e-11985. [Google Scholar] [CrossRef]

- Nasser, S.M.; Morales, E.A.M.; Pereira, L.E.R.; Eugenio, R.A.P.; Biazzon, J.C.; Lima, M.P.; Bueno, M.A.P.; Archangelo, A.; Celestino, V.R.B.; Nasser, H.M.; et al. Mechanical analysis of bamboo and agro-industrial residue one-layer particleboard. BioResources 2020, 15, 2163–2170. [Google Scholar] [CrossRef]

- Pae, J.B.; Nunes, S.T.; Lahr, F.A.R.; de Fátima Nascimento, M.; de Albuquerque Lacerda, R.M. Qualidade de chapas de partículas de Pinus elliottii coladas com resina poliuretana sob diferentes combinações de pressão e temperatura. Cienc. Florest. 2011, 21, 549–556. [Google Scholar] [CrossRef][Green Version]

- Seibel, R.K.; Zimmer, A.; Fiorio, R. Development and characterization of novel castor oil-based polyurethane composites containing wood sawdust and rubber tire powder. Polym. Polym. Compos. 2021, 29, 876–887. [Google Scholar] [CrossRef]

- Barbirato, G.H.A.; Junior, W.E.L.; Hellmeister, V.; Pavesi, M.; Fiorelli, J. OSB Panels with Balsa Wood Waste and Castor Oil Polyurethane Resin. Waste Biomass Valorization 2020, 11, 743–751. [Google Scholar] [CrossRef]

- Ferro, F.S.; Arroyo, F.N.; Rodrigues, E.F.C.; Fraga, I.F.; Almeida, J.P.B.; Ruthes, H.C.; de Moura Aquino, V.B.; Morales, E.A.M.; de Moraes, M.H.M.; Lahr, F.A.R.; et al. Investigation of Pore Size Distribution by Mercury Intrusion Porosimetry (MIP) Technique Applied on Different OSB Panels. BioResources 2021, 16, 6661–6668. [Google Scholar] [CrossRef]

- de Macedo, L.B.; Ferro, F.S.; Varanda, L.D.; Cavalheiro, R.S.; Christoforo, A.L.; Lahr, F.A.R. Propriedades físicas de painéis aglomerados de madeira produzidos com adição de película de polipropileno biorientado. Rev. Bras. Eng. Agrícola Ambient. 2015, 19, 674–679. [Google Scholar] [CrossRef]

- De Macedo, L.B.; Da Silva, M.R.; Da Silva César, A.A.; Panzera, T.H.; Christoforo, A.L.; Lahr, F.A.R. Painéis OSB de madeira Pinus sp. e adição de partículas de polipropileno biorientado (BOPP). Sci. For. Sci. 2016, 44, 887–894. [Google Scholar] [CrossRef][Green Version]

- Campos, P.H.S.; Junior, A.J.S.; de Souza, M.V.; Herradon, M.P.; Libera, V.B.L.; Dezen, L.E.; da Silva, É.V.; Silva, A.G.B.P.; Rodrigues, F.R.; Bispo, R.A.; et al. Evaluation and production of high-strength wood composite panels with polyethylene terephthalate (PET). BioResources 2023, 18, 8528–8535. [Google Scholar] [CrossRef]

- Rodrigues, F.R.; Bispo, R.A.; Cazell, P.H.; Silva, M.J.; Christoforo, A.L.; Silva, S.A.M. Particleboard Composite Made from Pinus and Eucalyptus Residues and Polystyrene Waste Partially Replacing the Castor Oil-Based Polyurethane as Binder. Mater. Res. 2023, 26, e20220594. [Google Scholar] [CrossRef]

- Chen, Y.H.; Wu, C.H.; Chen, Y.C. Optimized condition for eco-friendly wood composites manufactured from castor oil-based polyurethane. Constr. Build. Mater. 2021, 306, 124789. [Google Scholar] [CrossRef]

- Fiorelli, J.; Curtolo, D.D.; Barrero, N.G.; Savastano, H., Jr.; de Jesus Agnolon Pallone, E.M.; Johnson, R. Particulate composite based on coconut fiber and castor oil polyurethane adhesive: An eco-efficient product. Ind. Crops Prod. 2012, 40, 69–75. [Google Scholar] [CrossRef]

- Wechsler, A.; Zaharia, M.; Crosky, A.; Jones, H.; Ramírez, M.; Ballerini, A.; Nuñez, M.; Sahajwalla, V. Macadamia (Macadamia integrifolia) shell and castor (Rícinos communis) oil based sustainable particleboard: A comparison of its properties with conventional wood based particleboard. Mater. Des. 2013, 50, 117–123. [Google Scholar] [CrossRef]

- Fiorelli, J.; De Lucca Sartori, D.; Cravo, J.C.M.; Savastano, H.; Rossignolo, J.A.; Nascimento, M.F.D.; Lahr, F.A.R. Sugarcane bagasse and castor oil polyurethane adhesive-based particulate composite. Mater. Res. 2013, 16, 439–446. [Google Scholar] [CrossRef]

- de Lima Mesquita, A.; Barrero, N.G.; Fiorelli, J.; Christoforo, A.L.; De Faria, L.J.G.; Lahr, F.A.R. Eco-particleboard manufactured from chemically treated fibrous vascular tissue of acai (Euterpe oleracea Mart.) Fruit: A new alternative for the particleboard industry with its potential application in civil construction and furniture. Ind. Crops Prod. 2018, 112, 644–651. [Google Scholar] [CrossRef]

- Chen, Y.C.; Tai, W. Castor oil-based polyurethane resin for low-density composites with bamboo charcoal. Polymers 2018, 10, 1100. [Google Scholar] [CrossRef]

- Junior, W.E.L.; Barbirato, G.H.A.; Pavesi, M.; Soriano, J.; Fiorelli, J. Avaliação do teor ótimo de resinas orgânicas para produção de painéis OSB de madeira Balsa (Ochroma pyramidale) residual. Sci. For. 2021, 49, e3442. [Google Scholar] [CrossRef]

- Alves, L.S.; da Silva, S.A.M.; Azambuja, M.D.S.; Varanda, L.D.; Christóforo, A.L.; Lahr, F.A.R. Particleboard produced with sawmill waste of different wood species. Adv. Mater. Res. 2014, 884–885, 689–693. [Google Scholar] [CrossRef]

- Varanda, L.D.; Yamaji, F.M.; Santos, L.R.O.; Silva, D.A.L.; Christoforo, A.L.; Lahr, F.A.R. Physical performance of particleboards using castor oil-based adhesive. Rev. Bras. Eng. Agric. Ambient. 2018, 22, 707–712. [Google Scholar] [CrossRef]

- NBR 14810:2006; Plywood Sheets-Part 3: Testing Methods, Terminology. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2006.

- Valarelli, I.D.D.; Battistelle, R.A.G.; Bueno, M.A.P.; Bezerra, B.S.; de Campos, C.I.; Alves, M.C.D.S. Physical and mechanical properties of particleboard bamboo waste bonded with urea formaldehyde and castor oil based adhesive. Rev. Mater. 2014, 19, 1–2. [Google Scholar] [CrossRef]

- Fiorelli, J.; Ramos, R.D.; Sayama, J.T.; Barrero, N.G.; Palone, E.D.J.A. Painéis de partículas com resíduos de madeira de reflorestamento. Acta Sci.-Technol. 2014, 36, 251–256. [Google Scholar] [CrossRef]

- Barbirato, G.; Fiorelli, J.; Barrero, N.M.G.; de Jesus Agnolon Pallone, E.M.; Lahr, F.A.R.; Cristoforo, A.L.; Junior, H.S. Painel Aglomerado Híbrido De Casca De Amendoim Reforçado Com Partículas De Madeira Itaúba. Ciência Florest. 2014, 24, 685–697. [Google Scholar] [CrossRef]

- Fiorelli, J.; Christoforo, A.L.; Lahr, F.A.R.; Nascimento, M.F.D.; Curtolo, D.D.; De Lucca Sartori, D.; Belini, U.L. Monolayers particleboards manufactured with wood waste and green coconut fiber. Sci. For. Sci. 2015, 43, 175–182. [Google Scholar]

- Nascimento, M.F.; Lahr, F.A.R.; Christoforo, A.L. Painéis de partículas homogêneas fabricados com resíduos lignoceluósicos e resina alternativa para aplicação em pisos Homogeneous particleboards manufactured with lignocellulosic waste and alternative resin for floor applications. Res. Sci. For. 2016, 44, 1001–1007. [Google Scholar]

- NBR 14535:2008; Wood Furniture: Requirements and Test Methods of Coated Surfaces standard. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2008.

- NBR 14810-2:2013; Medium Density Particleboard—Part 2: Requirements and Test Methods standard. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2013.

- NBR 14810:2018; Medium Density Particleboards—Part 2: Requirements and Test Methods standard. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2018.

- EN 300:2002; Oriented Strand Boards (OSB)—Definitions, Classification, and Specifications standard. European Standard: Lisbon, Portugal, 2002.

- Silva, D.A.L.; Lahr, F.A.R.; Varanda, L.D.; Christoforo, A.L.; Ometto, A.R. Environmental performance assessment of the melamine-urea-formaldehyde (MUF) resin manufacture: A case study in Brazil. J. Clean. Prod. 2015, 96, 299–307. [Google Scholar] [CrossRef]

- Tohmura, S.; Inoue, A.; Sahari, S.H. Influence of the melamine content in melamine-urea-formaldehyde resins on formaldehyde emission and cured resin structure. J. Wood Sci. 2001, 47, 451–457. [Google Scholar] [CrossRef]

- European Panel Federation. Autonomous Agreement on a European Action Guide Regarding the Prevention of Formaldehyde Exposure in the European Panel Industry and Compliance with the Occupational Exposure Limits. 2018. Available online: https://www.efbww.eu/publications/press-releases/action-guide-on-formaldehyde/1697-a (accessed on 19 August 2024).

- Embrapa, Mamona—BRS Energia. 2007. Available online: https://www.embrapa.br/busca-de-solucoes-tecnologicas/-/produto-servico/908/mamona---brs-energia (accessed on 29 May 2024).

| Filters/ Databases | Castor Oil Resin or Castor Oil Adhesive | (Castor Oil Resin or Castor Oil Adhesive) and Particleboard*) or ((Castor Oil Resin or Castor Oil Adhesive) and (Oriented Strand Board or OSB) | Consolidated Base | Comparative Papers |

|---|---|---|---|---|

| 1st Filter | 2nd Filter | |||

| Web of Science | 852 | 90 | 95 | 14 |

| Resin | Acronym | Unit Function |

|---|---|---|

| Urea-formaldehyde resin | UF | 1 kg |

| Melanin urea-formaldehyde resin | MUF | 1 kg |

| Castor oil PU resin | PUR | 1 kg |

| Processes Inputs and Outputs | Data Source |

|---|---|

| INPUTS | |

| Materials | |

| Castor oil PU resin: EU-28: 2-component PUR adhesive based on polyether and castor oil (modified energy consumption based on a Brazilian industry and water consumption) | Ecoinvent 3.7.1 |

| Urea-formaldehyde resin: RER: urea–formaldehyde resin production (modified energy consumption based on a Brazilian industry) | Ecoinvent 3.8 |

| Melamine urea-formaldehyde resin: RER: melamine–formaldehyde resin production (modified energy consumption based on a Brazilian industry) | Ecoinvent 3.7.1 |

| Electricity consumption | Ecoinvent 3.7.1 |

| Electricity: electricity, high voltage, production mix—BR | |

| OUTPUTS | |

| Adhesive resin for particleboard production | - |

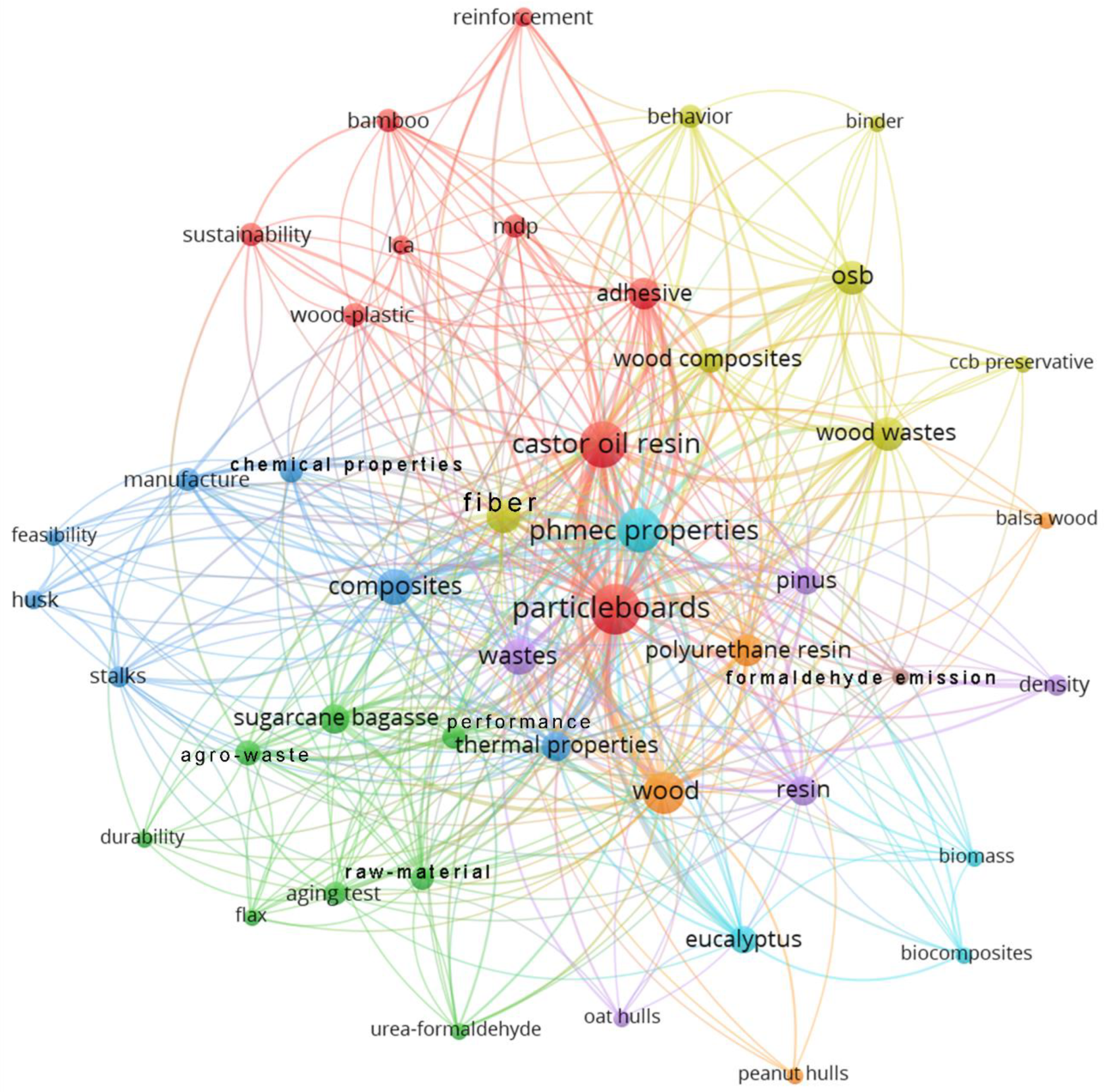

| Keyword | Occurrence | Total Link Strength | |

|---|---|---|---|

| 1 | particleboards | 58 | 252 |

| 2 | castor oil resin | 42 | 203 |

| 3 | phmec properties | 38 | 176 |

| 4 | wood | 30 | 151 |

| 5 | composites | 20 | 121 |

| 6 | wastes | 19 | 103 |

| 7 | osb | 17 | 59 |

| 8 | fiber | 16 | 102 |

| 9 | wood wastes | 16 | 73 |

| 10 | adhesive | 14 | 72 |

| 11 | polyurethane resin | 14 | 72 |

| 12 | thermal properties | 12 | 64 |

| 13 | sugarcane bagasse | 12 | 62 |

| 14 | resin | 10 | 56 |

| 15 | eucalyptus | 9 | 42 |

| Document | Title | Publication Year | Citations | Links | |

|---|---|---|---|---|---|

| 1 | [47] | Particulate composite based on coconut fiber and castor oil polyurethane adhesive: An eco-efficient product | 2012 | 84 | 26 |

| 2 | [26] | A Review on Waterborne Thermosetting Polyurethane Coatings Based on Castor Oil: Synthesis, Characterization, and Application | 2018 | 75 | 0 |

| 3 | [27] | Adhesive application on particleboard from natural fibers: A review | 2020 | 51 | 2 |

| 4 | [32] | Assessment of multilayer particleboards produced with green coconut and sugarcane bagasse fibers | 2019 | 50 | 21 |

| 5 | [19] | Circular vs. linear economy of building materials: A case study for particleboards made of recycled wood and biopolymer vs. conventional particleboards | 2021 | 48 | 9 |

| 6 | [48] | Macadamia (Macadamia integrifolia) shell and castor (Rícinos communis) oil-based sustainable particleboard: A comparison of its properties with conventional wood-based particleboard | 2013 | 44 | 10 |

| 7 | [49] | Sugarcane Bagasse and Castor Oil Polyurethane Adhesive-based Particulate Composite | 2013 | 37 | 11 |

| 8 | [17] | Painéis de partículas à base de bagaço de cana e resina de mamona—produção e propriedades | 2011 | 33 | 13 |

| 9 | [50] | Eco-particleboard manufactured from chemically treated fibrous vascular tissue of acai (Euterpe oleracea Mart.) Fruit: A new alternative for the particleboard industry with its potential application in civil construction and furniture | 2018 | 33 | 7 |

| 10 | [51] | Castor oil-based polyurethane resin for low-density composites with bamboo charcoal | 2018 | 32 | 4 |

| 11 | [40] | OSB Panels with Balsa Wood Waste and Castor Oil Polyurethane Resin | 2020 | 30 | 20 |

| 12 | [31] | Multilayer Particleboard Produced with Agroindustrial Waste and Amazonia Vegetable Fibres | 2018 | 28 | 5 |

| 13 | [52] | Evaluation of the optimum content of organic resins for the production of residual OSB wood of Balsa (Ochroma pyramidale) panels | 2021 | 23 | 0 |

| 14 | [13] | High-density particleboard made from agro-industrial waste and different adhesives | 2019 | 22 | 18 |

| 15 | [11] | Accelerated Artificial Aging of Particleboards from Residues of CCB Treated Pinus sp. and Castor Oil Resin | 2013 | 22 | 15 |

| Country | Documents | Citations | Total Link Strength | |

|---|---|---|---|---|

| 1 | Brazil | 89 | 889 | 148 |

| 2 | Canada | 4 | 30 | 30 |

| 3 | Colombia | 4 | 80 | 18 |

| 4 | United States | 3 | 137 | 52 |

| 5 | Italy | 3 | 39 | 34 |

| 6 | Russia | 2 | 29 | 19 |

| 7 | Belgium | 2 | 21 | 18 |

| 8 | Portugal | 2 | 2 | 16 |

| 9 | Taiwan | 2 | 44 | 12 |

| 10 | Australia | 1 | 44 | 17 |

| 11 | Chile | 1 | 44 | 17 |

| 12 | England | 1 | 19 | 13 |

| 13 | New Zealand | 1 | 14 | 12 |

| 14 | Germany | 1 | 10 | 8 |

| 15 | Malaysia | 1 | 51 | 3 |

| 16 | Nigeria | 1 | 51 | 3 |

| 17 | India | 1 | 75 | 0 |

| Authors | Resin | ρ | TS 24 h | MOR | MOE | IB |

|---|---|---|---|---|---|---|

| (kg/m3) | (%) | (MPa) | (MPa) | (MPa) | ||

| [53] | UF (10%) | 800 | 28.33 | - | - | - |

| [53] | PU (10%) | 800 | 15.51 | - | - | - |

| [54] | MF (13%) | 850–950 | 17.9 | - | - | - |

| [54] | PU (13%) | 850–950 | 11.8 | - | - | - |

| [13] | UF (10%) | >800 | 65.6 | 18 | 2420 | 0.95 |

| [13] | PU (10%) | >800 | 10.9 | 31 | 3020 | 2.52 |

| [2] | UF (10%) | 800 | 82.00 | 4.29 | 495 | 0.06 |

| [2] | PU (10%) | 800 | 6.80 | 35.00 | 3555 | 2.23 |

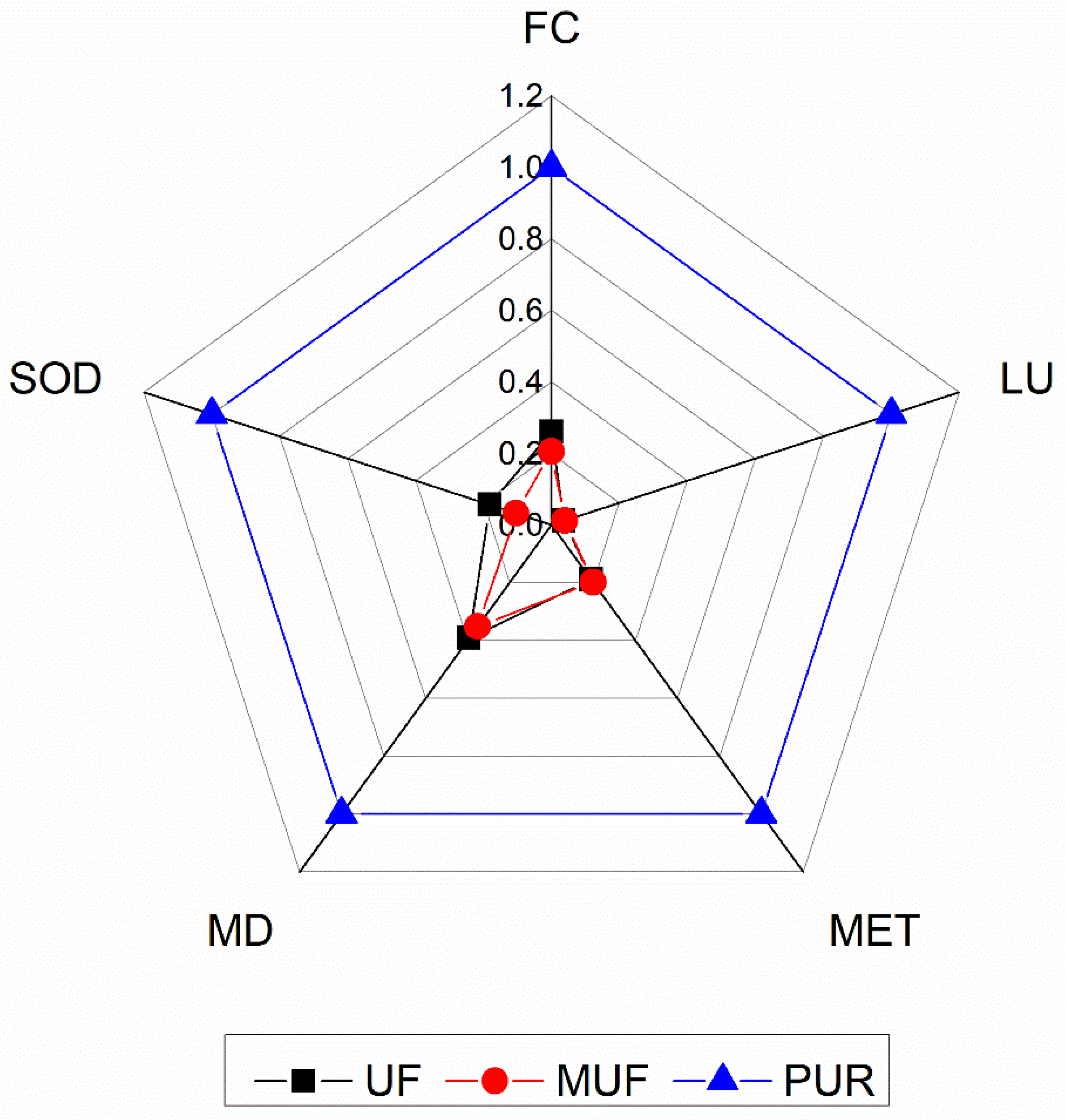

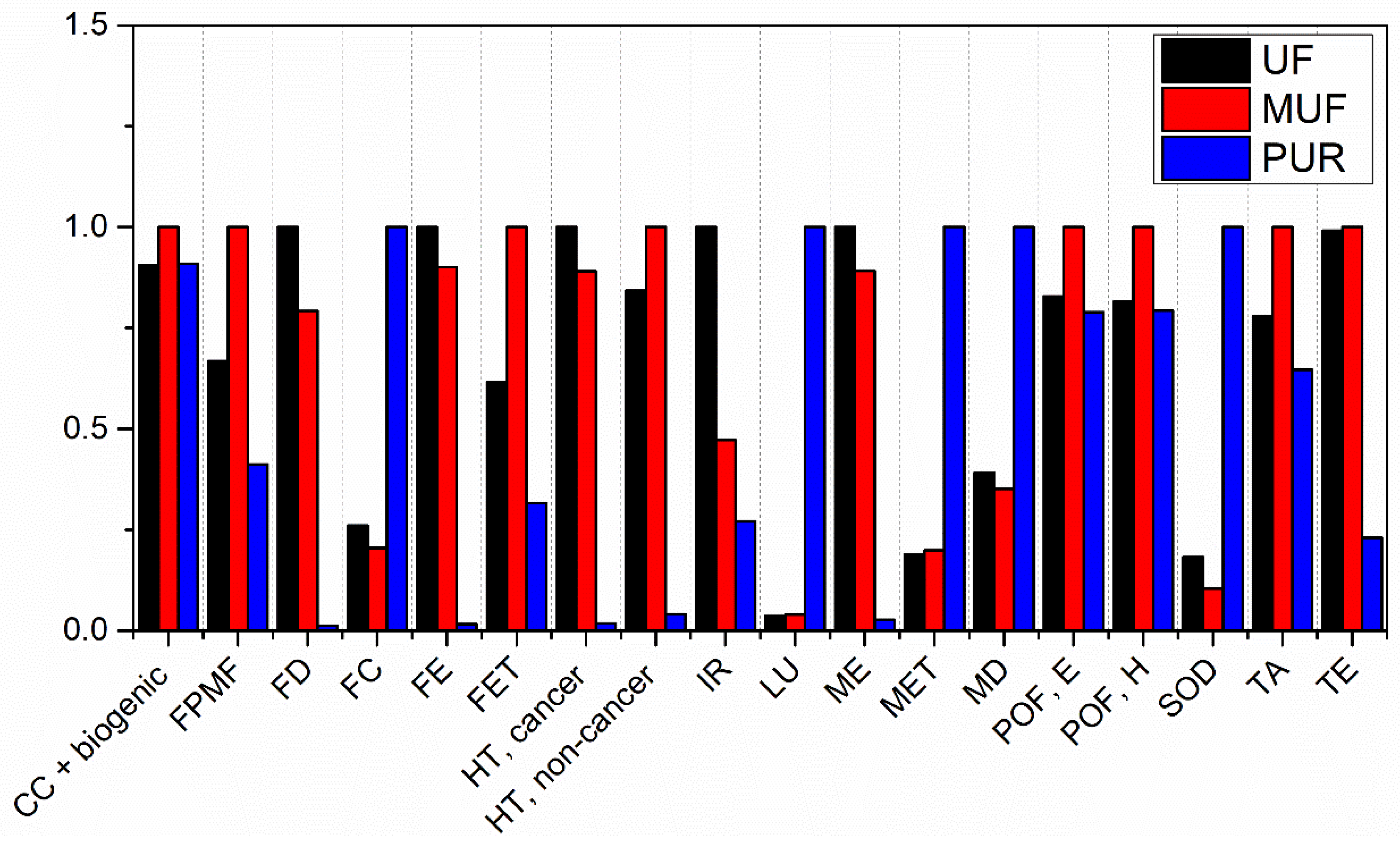

| Impact Category | Acronym | UF | MUF | PUR |

|---|---|---|---|---|

| Climate change, incl biogenic carbon (kg CO2 eq.) | CC + biogenic | 2.52 | 2.78 | 2.53 |

| Fine particulate matter formation (kg PM2.5 eq.) | FPMF | 0.00274 | 0.0041 | 0.00169 |

| Fossil depletion (kg oil eq.) | FD | 1.54 | 1.22 | 0.0186 |

| Freshwater consumption (m3) | FC | 0.127 | 0.1 | 0.488 |

| Freshwater ecotoxicity (kg 1,4 DB eq.) | FE | 0.0999 | 0.09 | 0.00165 |

| Freshwater eutrophication (kg P eq.) | FET | 0.000452 | 0.000733 | 0.000232 |

| Human toxicity, cancer (kg 1,4-DB eq.) | HT, cancer | 0.156 | 0.139 | 0.00275 |

| Human toxicity, non-cancer (kg 1,4-DB eq.) | HT, non-cancer | 2.25 | 2.67 | 0.107 |

| Ionizing radiation (kBq Co-60 eq. to air) | IR | 0.12 | 0.0567 | 0.0325 |

| Land use (Annual crop eq.·y) | LU | 0.0485 | 0.0513 | 1.3 |

| Marine ecotoxicity (kg 1,4-DB eq.) | ME | 0.129 | 0.115 | 0.00348 |

| Marine eutrophication (kg N eq.) | MET | 0.000288 | 0.000302 | 0.00152 |

| Metal depletion (kg Cu eq.) | MD | 0.0117 | 0.0105 | 0.0299 |

| Photochemical ozone formation, ecosystems (kg NOx eq.) | POF, E | 0.00488 | 0.00589 | 0.00465 |

| Photochemical ozone formation, human health (kg NOx eq.) | POF, H | 0.00461 | 0.00565 | 0.00448 |

| Stratospheric ozone depletion (kg CFC-11 eq.) | SOD | 0.0000013 | 0.0000007 | 0.0000069 |

| Terrestrial acidification (kg SO2 eq.) | TA | 0.00842 | 0.0108 | 0.00698 |

| Terrestrial ecotoxicity (kg 1,4-DB eq.) | TE | 11.6 | 11.7 | 2.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duran, A.J.F.P.; Lyra, G.P.; Campos Filho, L.E.; Martins, R.H.B.; Bueno, C.; Rossignolo, J.A.; Fiorelli, J. The Use of Castor Oil Resin on Particleboards: A Systematic Performance Review and Life Cycle Assessment. Sustainability 2025, 17, 3609. https://doi.org/10.3390/su17083609

Duran AJFP, Lyra GP, Campos Filho LE, Martins RHB, Bueno C, Rossignolo JA, Fiorelli J. The Use of Castor Oil Resin on Particleboards: A Systematic Performance Review and Life Cycle Assessment. Sustainability. 2025; 17(8):3609. https://doi.org/10.3390/su17083609

Chicago/Turabian StyleDuran, Afonso José Felício Peres, Gabriela Pitolli Lyra, Luiz Eduardo Campos Filho, Romulo Henrique Batista Martins, Cristiane Bueno, João Adriano Rossignolo, and Juliano Fiorelli. 2025. "The Use of Castor Oil Resin on Particleboards: A Systematic Performance Review and Life Cycle Assessment" Sustainability 17, no. 8: 3609. https://doi.org/10.3390/su17083609

APA StyleDuran, A. J. F. P., Lyra, G. P., Campos Filho, L. E., Martins, R. H. B., Bueno, C., Rossignolo, J. A., & Fiorelli, J. (2025). The Use of Castor Oil Resin on Particleboards: A Systematic Performance Review and Life Cycle Assessment. Sustainability, 17(8), 3609. https://doi.org/10.3390/su17083609