Research on Digital Transformation and the Innovation Model of SMMEs: The Case Study of PAYA

Abstract

1. Introduction

2. Literature Review

2.1. Managerial Cognition

2.2. Digital Economy and Digital Transformation

2.3. Enterprise Innovation and Digital Transformation

2.4. Resource Orchestration Theory

2.5. Research Thinking

- The existing literature primarily discusses the economic consequences of digital transformation on enterprise innovation from a quantitative perspective at the macro and meso levels, while scant literature systematically examines the impact and mechanism of digital transformation on the innovation model of SMMEs at the micro-enterprise level.

- Most existing research focuses on the internals of enterprises, neglecting internal and external coordination in the transformation process, which greatly limits its guiding role in the practice of enterprise digital transformation.

- The research on innovation models of various countries mostly relies on traditional Western innovation theory and rarely combines the practical and developmental needs of Chinese local enterprises, thus neglecting the heterogeneity of Eastern innovation models.

3. Research Data Collection and Design

3.1. Research Methods and the Selection of Research Subjects

3.1.1. Research Methods

3.1.2. Case Selection

3.2. Case Introduction

3.3. Data Sources

3.4. Data Encoding

3.4.1. Coding Process

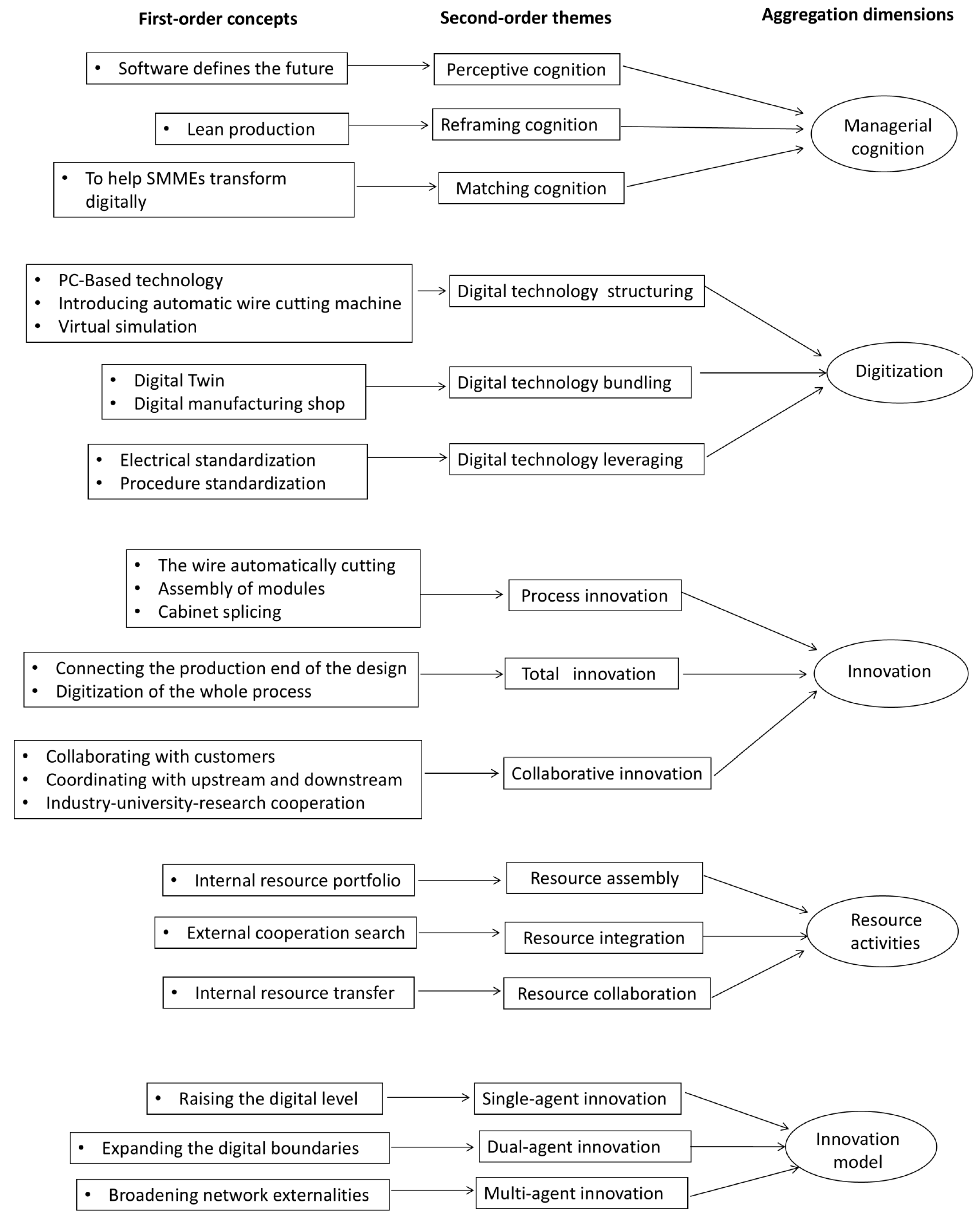

3.4.2. Coding Results

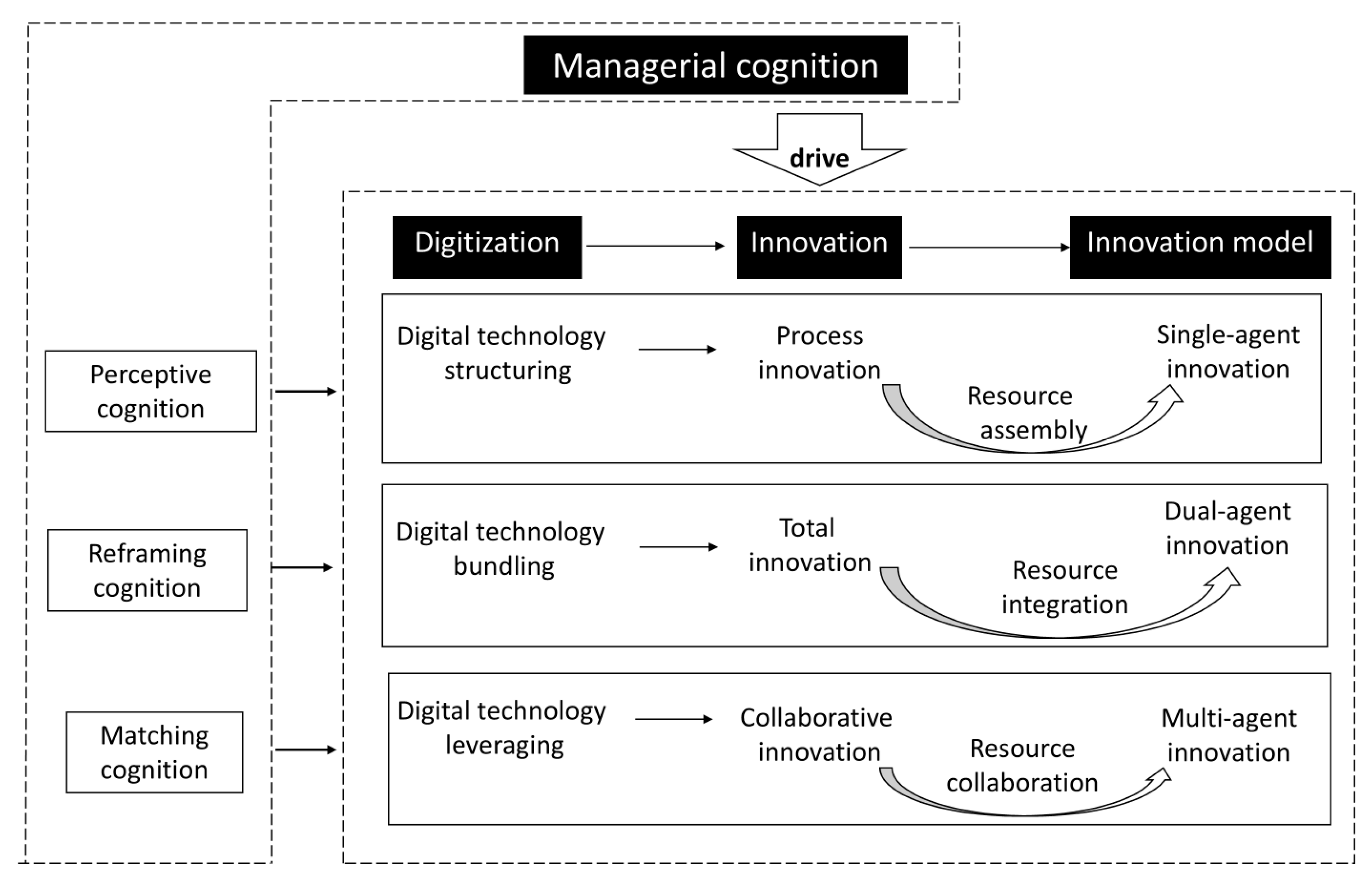

3.5. Research Framework

4. Case Analysis

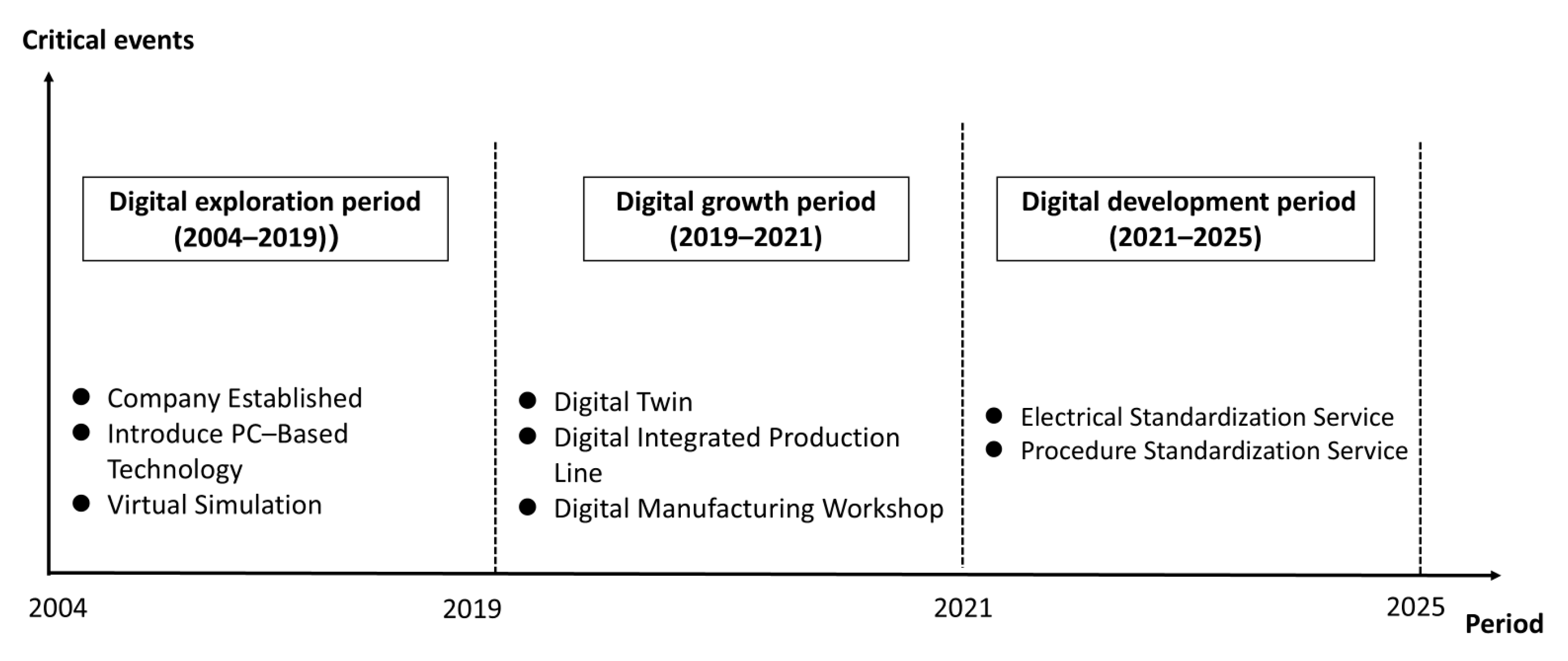

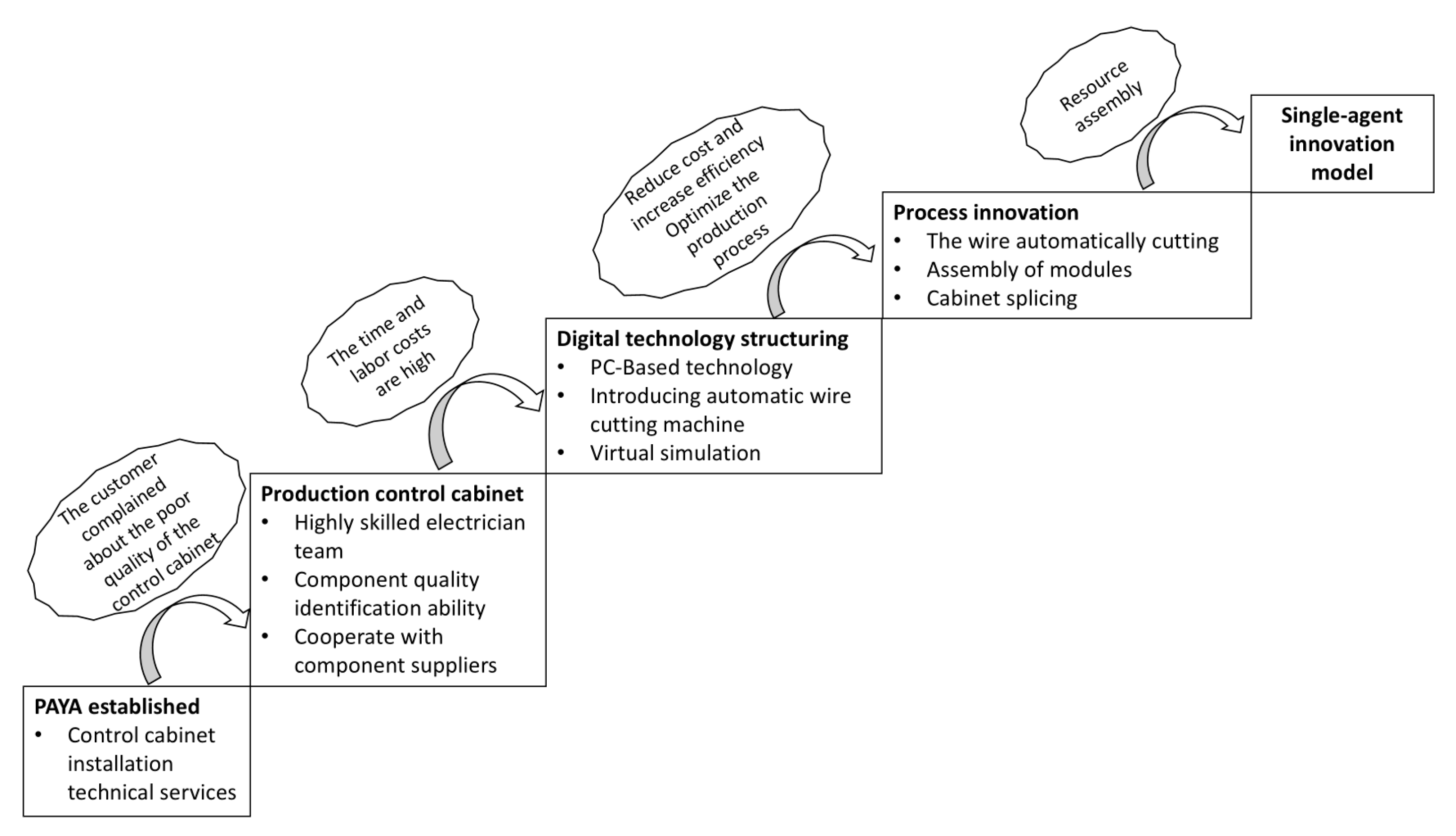

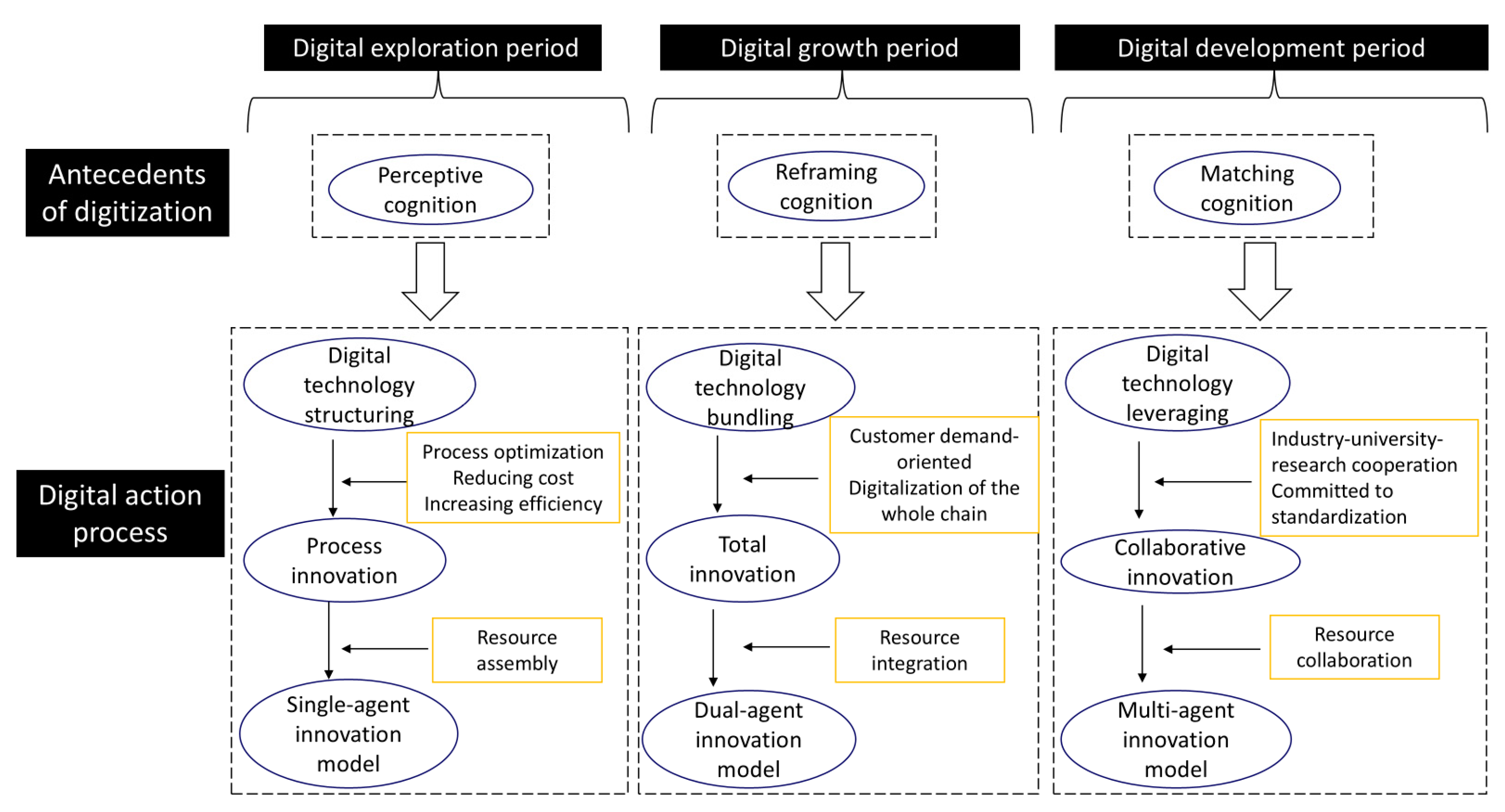

4.1. Digital Exploration Period

4.1.1. Perceptive Cognition

4.1.2. Digital Technology Structuring, Process Innovation, and the Single-Agent Innovation Model

4.1.3. Resource Assembly

4.2. Digital Growth Period

4.2.1. Reframing Cognition

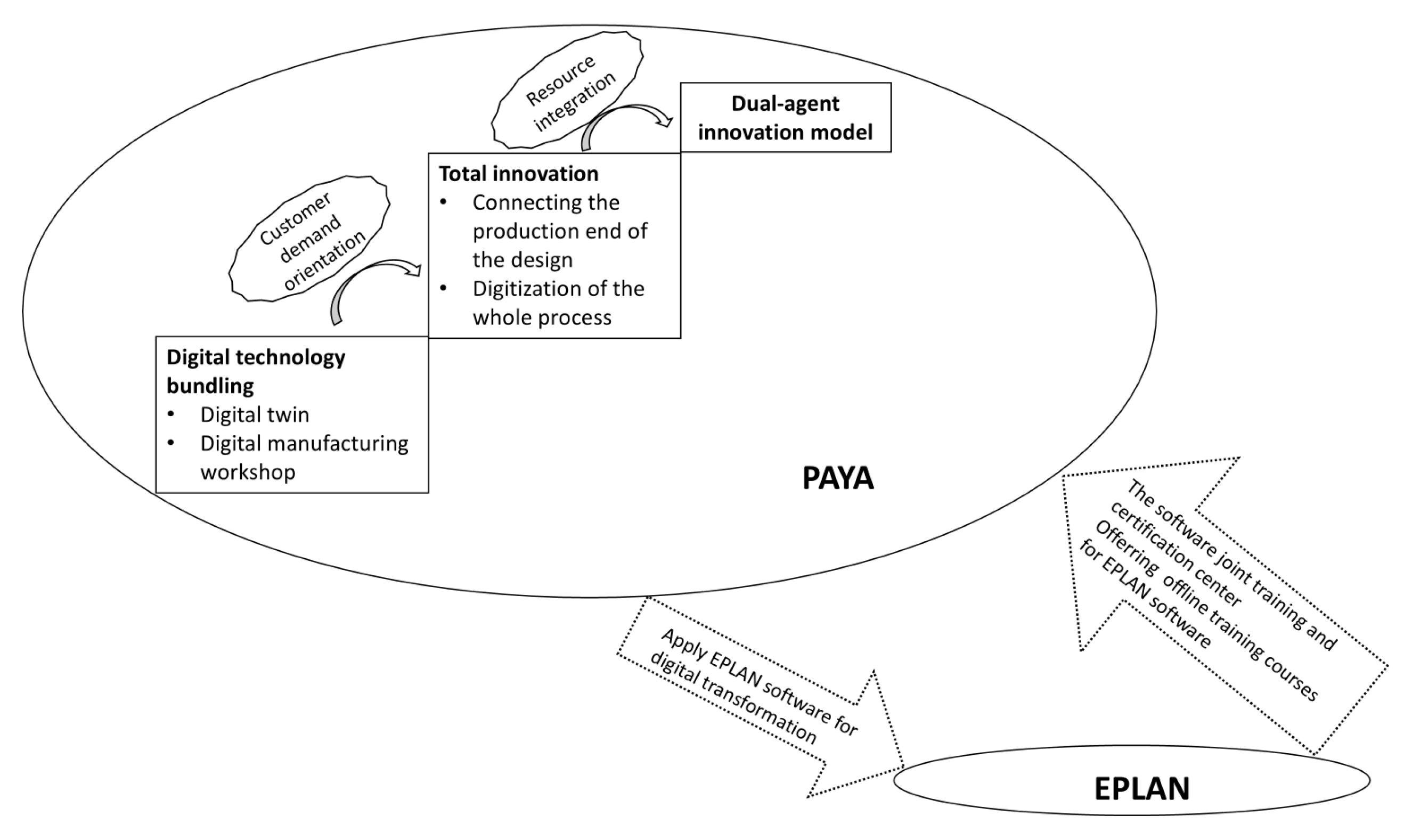

4.2.2. Digital Technology Bundling, Total Innovation, and the Dual-Agent Innovation Model

4.2.3. Resource Integration

4.3. Digital Development Period

4.3.1. Matching Cognition

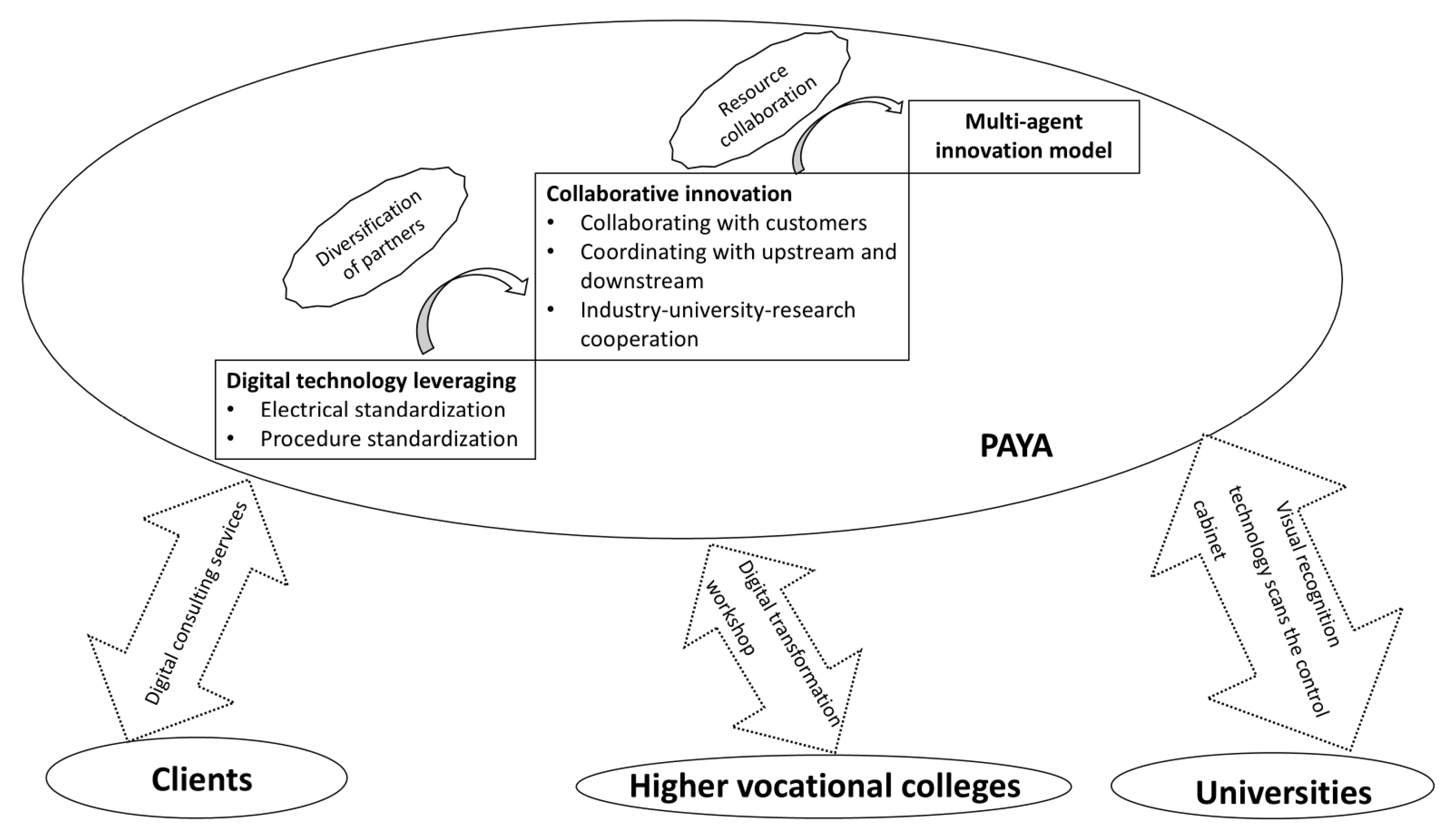

4.3.2. Digital Technology Leveraging, Collaborative Innovation, and the Multi-Agent Innovation Model

4.3.3. Resource Collaboration

5. Discussion

5.1. The Antecedents of Digitalization

5.2. Digital Action Process

5.2.1. Digitalization, Innovation and Innovation Model

5.2.2. Resource Activities

6. Research Implications and Prospects

6.1. Research Conclusions

6.2. Theoretical Contribution

6.3. Practical Implications

6.4. Research Limitations and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bharadwaj, A.; El Sawy, O.A.; Pavlou, P.A.; Venkatraman, N.V. Digital business strategy: Toward a next generation of insights. Mis Q. 2013, 37, 471–482. [Google Scholar] [CrossRef]

- Yu, F.; Cao, J.; Du, H. Digital paradox: The double-edged sword effect of enterprise digitization on innovation performance. RD Manag. 2022, 34, 1–12. [Google Scholar]

- Du, Y.; Cao, L.; Tan, C. How does platformization help manufacturing companies to bridge the digital divide of transformation and upgrading? An exploratory case study based on Zongshen Group. J. Manag. World 2022, 38, 117–139. [Google Scholar]

- Xiao, J.; Wu, Y.; Liu, Y.; Xie, K. New product development innovation with customer digitalized engagement: A comparative case study from the firm-customer coevolutionary perspective. J. Manag. World 2018, 34, 154–173+192. [Google Scholar]

- Ma, J.; Guo, M. Enterprise digital transformation, employees’ digital cognition and innovation performance: Is technology the knife, while I am the lamb to slaughter? Sci. Technol. Prog. Policy 2023, 40, 22–32. [Google Scholar]

- Zheng, S.; Wang, H. How does digital transformation affect the innovation performance of hub firms? An empirical study from the perspective of modularity. Sci. Res. Manag. 2022, 43, 73–82. [Google Scholar]

- Li, X.; Dang, L.; Zhao, C. Digital transformation, global innovation network and innovation performance. China Ind. Econ. 2022, 415, 43–61. [Google Scholar]

- Huang, H.; Wang, G.; Qin, L. Research on resource orchestration influencing growth in technology-based start-ups: From co-evolution perspective of resource base and entrepreneurial capability. China Soft Sci. 2020, 07, 122–137. [Google Scholar]

- March, J.G.; Simon, H.A. Organizations. Am. J. Sociol. 1959, 65, 105–132. [Google Scholar]

- Kumbure, M.M.; Tarkiainen, A.; Luukka, P.; Stoklasa, J.; Jantunen, A. Relation between managerial cognition and industrial performance: An assessment with strategic cognitive maps using fuzzy-set qualitative comparative analysis. J. Bus. Res. 2020, 114, 160–172. [Google Scholar] [CrossRef]

- Hu, J.; Rong, Y.; McKee-Ryan, F.M. Fifty shades of corporate social responsibility: A conceptual synthesis via a decision frame lens. Sustainability 2022, 14, 11505. [Google Scholar] [CrossRef]

- Deng, S.; Rui, M. Top manager’s cognition and firm’s ambidexterity—A case study based on strategic transformation of Zhejiang Kinghing Capital Co., Ltd. China Ind. Econ. 2013, 11, 135–147. [Google Scholar]

- Hambrick, D.C.; Mason, P.A. Upper echelons:The organization as a reflection of its top managers. Acad. Manag. Rev. 1984, 9, 193–206. [Google Scholar] [CrossRef]

- Krasnopevtseva, N.J.; Thomas, C.; Kaminska, R. Organizing for resilience in high-risk organizations: The interplay between managerial coordination and control in resolving stability/flexibility tensions in a nuclear power plant. J. Bus. Res. 2025, 189, 115120. [Google Scholar] [CrossRef]

- Laureiro-Martínez, D.; Brusoni, S. Cognitive flexibility and adaptive decision-making: Evidence from a laboratory study of expert decision makers. Strateg. Manag. J. 2018, 39, 1031–1058. [Google Scholar] [CrossRef]

- Weber, M.M.; Kokott, P. Organizational resilience and the attention-based view of the firm—Empirical evidence from german SMEs. Sustainability 2024, 16, 4691. [Google Scholar] [CrossRef]

- Kubera, P. Behavioural insights in corporate sustainability research: A review and future agenda. Sustainability 2023, 15, 14266. [Google Scholar] [CrossRef]

- Adner, R.; Helfat, C.E. Corporate effects and dynamic managerial capabilities. Strateg. Manag. J. 2003, 24, 1011–1025. [Google Scholar] [CrossRef]

- Kratochvil, R. The process of framing innovation activities: How strategic leaders erode their ideas for radical innovations. Res. Policy 2025, 54, 105107. [Google Scholar] [CrossRef]

- Duchek, S. Organizational resilience: A capability-based conceptualization. Bus. Res. 2020, 13, 215–246. [Google Scholar] [CrossRef]

- Artamoshina, P.; Shirokova, G.; Osiyevskyy, O.; Bodolica, V. ADHD symptoms of CEOs and business model innovation in the SME context. Technovation 2023, 128, 102845. [Google Scholar] [CrossRef]

- Nadkarni, S.; Barr, P.S. Environmental context, managerial cognition, and strategic action: An integrated view. Strateg. Manag. J. 2008, 29, 1395–1427. [Google Scholar] [CrossRef]

- Tapscott, D. The Digital Economy: Promise and Peril in the Age of Networked Intelligence; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

- Karagiannaki, A.; Vergados, G.; Fouskas, K. The impact of digital transformation in the financial services industry: Insights from an open innovation initiative in fintech in Greece. In MCIS 2017 Proceedings; AISeL: Genoa, Italy, 2017. [Google Scholar]

- Vial, G. Understanding digital transformation: A review and a research agenda. J. Strateg. Inf. Syst. 2019, 28, 118–144. [Google Scholar] [CrossRef]

- Fitzgerald, M.; Kruschwitz, N.; Bonnet, D.; Welch, M. Embracing digital technology: A new strategic imperative. MIT Sloan Manag. Rev. Res. Rep. 2014, 55, 1. [Google Scholar]

- Liere-Netheler, K.; Packmohr, S.; Vogelsang, K. Drivers of digital transformation in manufacturing. In Proceedings of the Hawaii International Conference on System Sciences, Waikoloa Village, HI, USA, 3–6 January 2018. [Google Scholar]

- Ilvonen, I.; Thalmann, S.; Manhart, M.; Sillaber, C. Reconciling digital transformation and knowledge protection: A research agenda. Knowl. Manag. Res. Pract. KMRP 2018, 16, 235–244. [Google Scholar] [CrossRef]

- Hess, T.; Matt, C.; Benlian, A. Options for formulating a digital transformation strategy. J. Xi’an Jiaotong Univ. (Soc. Sci.) 2016, 15, 123–139. [Google Scholar]

- Yao, X.; Qi, H.; Liu, L.; Xiao, T. Enterprise digital transformation: Re-understanding and re-starting. J. Xi’an Jiaotong Univ. (Soc. Sci.) 2022, 42, 1–9. [Google Scholar]

- Wang, S.; Zhang, Y. Research on the mechanism path and policy recommendations of digital transformation of foreign trade enterprises. Intertrade 2019, 9, 40–47. [Google Scholar]

- Chen, Q.; Wang, Y.; Wan, M. Research on peer effect of enterprise digital transformation and influencing factors. Chin. J. Manag. 2021, 18, 653–663. [Google Scholar]

- Wu, F.; Hu, H.; Lin, H.; Ren, X. Enterprise digital transformation and capital market performance: Empirical evidence from stock liquidity. J. Manag. World 2021, 37, 130–144+10. [Google Scholar]

- Wang, X.; Yang, Z. The mechanism of enterprise digital transformation from the perspective of high-quality development. Seeker 2022, 04, 126–134. [Google Scholar]

- Zeller, V.; Hocken, C.; Stich, V. Acatech Industrie 4.0 maturity index—A multidimensional maturity model. In Advances in Production Management Systems. Smart Manufacturing for Industry 4.0, Proceedings of the IFIP WG 5.7 International Conference, Seoul, Republic of Korea, 26–30 August 2018; Springer: Seoul, Republic of Korea, 2018. [Google Scholar]

- Tubis, A.A. Digital maturity assessment model for the organizational and process dimensions. Sustainability 2023, 15, 15122. [Google Scholar] [CrossRef]

- Mick, M.M.; Kovaleski, J.L.; Mick, R.L.; Chiroli, D.M. Developing a sustainable digital transformation roadmap for SMEs: Integrating digital maturity and strategic alignment. Sustainability 2024, 16, 8745. [Google Scholar] [CrossRef]

- Lee, K.; Song, Y.; Park, M.; Yoon, B. Development of digital transformation maturity assessment model for collaborative factory involving multiple companies. Sustainability 2024, 16, 8087. [Google Scholar] [CrossRef]

- Golinska-Dawson, P.; Werner-Lewandowska, K.; Kolinska, K.; Kolinski, A. Impact of market drivers on the digital maturity of logistics processes in a supply chain. Sustainability 2023, 15, 3120. [Google Scholar] [CrossRef]

- Joseph, S. The Theory of Economic Development; The Commercial Press: Beijing, China, 1990. [Google Scholar]

- Mchristensen, C. The Innovation’s Dilemma: When New Technologies Cause Great Firms to Fail; Harvard Business School Press: Boston, UK, 1997. [Google Scholar]

- Chesbrough, H. The logic of open innovation: Managing intellectual property. Calif. Manag. Rev. 2003, 45, 33–58. [Google Scholar] [CrossRef]

- Liu, L. Review of incremental, breakthrough and destructive technological innovation. Soft Sci. 2010, 24, 10–13. [Google Scholar]

- Mao, Y.; Wang, J. Research on the independent innovation path based on product upgrading. J. Manag. World 2006, 5, 114–120. [Google Scholar]

- Chen, J. Learning mode from technology introduction to independent innovation. Sci. Res. Manag. 1994, 15, 32–34+31. [Google Scholar]

- Kotsopoulos, D.; Karagianaki, A.; Baloutsos, S. The effect of human capital, innovation capacity, and COVID-19 crisis on knowledge-intensive enterprises’ growth within a VC-driven innovation ecosystem. J. Bus. Res. 2022, 139, 1177–1191. [Google Scholar] [CrossRef]

- Garcia-Macia, D.; Korosteleva, J. Tracing productivity growth channels in the UK. Res. Policy 2025, 54, 105149. [Google Scholar] [CrossRef]

- Khurana, I.; Dutta, D.K.; Ghura, A.S. SMEs and digital transformation during a crisis: The emergence of resilience as a second-order dynamic capability in an entrepreneurial ecosystem. J. Bus. Res. 2022, 150, 623–641. [Google Scholar] [CrossRef]

- Pongtanalert, K.; Assarut, N. Entrepreneur mindset, social capital and adaptive capacity for tourism SME resilience and transformation during the COVID-19 pandemic. Sustainability 2022, 14, 12675. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, D.; Li, S.; Huang, Y.; Ma, J. Exploration on the technology innovation mode of small and medium-sized enterprises. J. Entrep. Sci. Technol. 2021, 34, 71–74. [Google Scholar]

- Huang, Z.; Gong, J.; Wang, X. Research on technological innovation mode of SMEs. Inf. Technol. Stand. 2021, 05, 51–55. [Google Scholar]

- Zhu, X.; Lin, X. Digital transformation of enterprises: Research context combing and integration framework construction. RD Manag. 2022, 34, 141–155. [Google Scholar]

- Kaftan, V.; Kandalov, W.; Molodtsov, I.; Sherstobitova, A.; Strielkowski, W. Socio-economic stability and sustainable development in the post-COVID era: Lessons for the business and economic leaders. Sustainability 2023, 15, 2876. [Google Scholar] [CrossRef]

- Wang, C. Research on the effecting mechanism of digital transformation on corporation innovation performance. Contemp. Econ. Manag. 2021, 43, 34–42. [Google Scholar]

- Yu, D.; Ma, L. Digital transformation, platformization transformation and enterprise innovation performance: Analysis based on the paradigm of Technology-Organization-Innovation. Reform 2024, 2, 55–74. [Google Scholar]

- Xu, H.; Zhou, X.; Zhou, B. Research on the threshold effect of digital transformation on innovation efficiency of manufacturing enterprises. J. Manag. 2024, 37, 100–119. [Google Scholar]

- Zheng, Z.; He, J. Impact of enterprise digital transformation on technology innovation model. Foreign Econ. Manag. 2023, 45, 54–68. [Google Scholar]

- He, Z.; Pan, W.; Pan, H.; Wu, Y. Digital transformation and innovation efficiency of manufacturing firms: Heterogeneity analysis of manufacturing processes and business models. China Soft Sci. 2023, 3, 162–177. [Google Scholar]

- Helfat, C.E.; Finkelstein, S.; Mitchell, W.; Peteraf, M.; Singh, H.; Teece, D.; Winter, S.G. Dynamic Capabilities: Understanding Strategic Change in Organizations; Blackwell: Malden, MA, USA, 2007. [Google Scholar]

- Sirmon, D.G.; Hitt, M.A.; Ireland, R.D. Managing firm resources in dynamic environment to create value: Looking inside the black box. Acad. Manag. Rev. 2007, 32, 273–292. [Google Scholar] [CrossRef]

- Zhang, Q.; Hua, Z. Review of resource orchestration theory and its research progress. Bus. Manag. J. 2020, 42, 193–208. [Google Scholar]

- Zahra, S.A.; Nambisan, S. Entrepreneurship and strategic thinking in business ecosystems. Bus. Horiz. 2012, 55, 219–229. [Google Scholar] [CrossRef]

- Sirmon, D.G.; Hitt, M.A.; Ireland, R.D.; Gilbert, B.A. Resource orchestration to create competitive advantage breadth, depth, and life cycle effects. J. Manag. 2011, 37, 1390–1412. [Google Scholar]

- Xu, B.; Jiang, Q.; Liu, Y.; Duan, L. Research on the formation mechanism of organizational resilience in digitally transformed enterprises—Based on the perspective of resource orchestration theory and configuration theory. Mod. Manag. 2024, 44, 73–84. [Google Scholar]

- Zhou, X.; Sun, R. Research on the value co-creation mechanism of industrial clusters driven by industrial Internet: Based on the perspective of resource orchestration. China Soft Sci. 2024, S1, 74–91. [Google Scholar]

- Rui, T.; Chunpei, L.; Jing, L.; Fengtao, H. Digital capability and innovation ecosystem construction of enterprises based on resource orchestration. Sci. Technol. Prog. Policy 2024, 41, 83–94. [Google Scholar]

- Harrison, J.S.; Freeman, R.E. Stakeholders, social responsability, and perfomance: Empirical evidence and theoretical perspectives. Acad. Manag. J. 1999, 42, 479–485. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods; Sage Publications: Thousand Oaks, CA, USA, 1994. [Google Scholar]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Mao, J.; Su, F. Theoretical contribution to case study—China enterprise management case and quality research forum (2015) review. J. Manag. World 2016, 02, 128–132. [Google Scholar]

- Graebner, E.M.E. Theory building from cases: Opportunities and challenges. Acad. Manag. J. 2007, 50, 25–32. [Google Scholar]

- Gioia, D.A.; Corley, K.G.; Hamilton, A. Seeking qualitative rigor in inductive research: Notes on the Gioia methodology. Organ. Res. Methods 2013, 16, 15–31. [Google Scholar] [CrossRef]

- Ouyang, T.; Zeng, D. Research on technology catch-up mode of commercial aircraft led by latecomer enterprise: From complex system management perspective. Manag. Rev. 2023, 35, 323–334. [Google Scholar]

- Wang, N. Representative or typical? The attributes of the case and the logical basis of the case study methods. Sociol. Stud. 2002, 5, 123–125. [Google Scholar]

- Zhang, J. The goal of case analysis: From story to knowledge. Soc. Sci. China 2018, 8, 126–142+207. [Google Scholar]

- Glaser, B.G.; Strauss, A.L. The Discovery of Grounded Theory: Strategies for Qualitative Research; Aldine Publishing Company: Chicago, IL, USA, 1967. [Google Scholar]

- Walsham, G. Interpretive case studies in IS research: Nature and method. Eur. J. Inf. Syst. 1995, 4, 74–81. [Google Scholar] [CrossRef]

- Van Maanen, J. Reclaiming qualitative methods for organizational research: A preface. Adm. Sci. Q. 1979, 24, 520–526. [Google Scholar] [CrossRef]

- Pan, S.L.; Tan, B. Demystifying case research: A structured–pragmatic–situational (SPS) approach to conducting case studies. Inf. Organ. 2011, 21, 161–176. [Google Scholar] [CrossRef]

- Ye, B.; Yu, C.; Lin, C.; Chen, Q. Will management innovation improve competitive advantage through the non-linear mediating effect of bricolage in SMEs: The moderating effect of leader-follower cognition congruence for management innovation. Manag. Rev. 2023, 35, 94–105. [Google Scholar]

- An, W.; Zhao, X.; Cao, Z.; Zhang, J.; Liu, H. How bricolage drives corporate entrepreneurship: The roles of opportunity identification and learning orientation. J. Prod. Innov. Manag. 2017, 35, 49–65. [Google Scholar] [CrossRef]

- Abdurakhmonov, M.; Ridge, J.W.; Hill, A.D. Unpacking firm external dependence: How government contract dependence affects firm investments and market performance. Acad. Manag. J. 2021, 64, 327–350. [Google Scholar] [CrossRef]

- Sirmon, D.G.; Gove, S.; Hitt, M.A. Resource management in dyadic competitive rivalry: The effects of resource bundling and deployment. Acad. Manag. J. 2009, 51, 919–935. [Google Scholar] [CrossRef]

- Yun, L.; Dong, X.; Xu, H. How do manufacturing enterprises realize digital transformation through resource arrangement—Based on the cognitive perspective of managers. Financ. Account. Mon. 2025, 46, 88–94. [Google Scholar]

- Porfirio, J.; Carrilho, T.; Jardim, J. Leadership characteristics and digital transformation. J. Bus. Res. 2020, 124, 610–619. [Google Scholar] [CrossRef]

- Huang, X.; Peng, Z. Research on the driving factors and modes of network organization evolution from the perspective of managerial cognition: A literature review and research agenda. Foreign Econ. Manag. 2018, 40, 99–115. [Google Scholar]

- Zhao, Y.; Cheng, S.; Liu, D.; Dang, B.; Zhang, W. Cognitive flexibility, digital leadership, and digital transformation. Stud. Sci. Sci. 2024, 42, 2387–2396. [Google Scholar]

- Li, S.; Luo, J.; Zhang, Z. Impact of technical managers′ cognition on the radical innovation of digital workforce tools. Sci. Res. Manag. 2023, 44, 173–183. [Google Scholar]

- Wrede, M.; Velamuri, V.K.; Dauth, T. Top managers in the digital age: Exploring the role and practices of top managers in firms’ digital transformation. Manag. Decis. Econ. 2020, 41, 1549–1567. [Google Scholar] [CrossRef]

- Xu, H.; Guo, J.; Deng, Y. International cognition of top managers and evolution process of marketing dynamic capability. Chin. J. Manag. 2013, 10, 30–40. [Google Scholar]

- Eggers, J.P.; Kaplan, S. Cognition and capabilities: A multi-level perspective. Acad. Manag. Ann. 2013, 7, 295–340. [Google Scholar] [CrossRef]

- Nwankpa, J.K.; Roumani, Y. IT capability and digital transformation: A firm performance perspective. In Proceedings of the Thirty Seventh International Conference on Information Systems, Dublin, Ireland, 11–14 December 2016. [Google Scholar]

- Ferreira, J.J.; Fernandes, C.I.; Ferreira, F.A. To be or not to be digital, that is the question: Firm innovation and performance. J. Bus. Res. 2019, 101, 583–590. [Google Scholar] [CrossRef]

- Sia, S.K.; Weill, P.; Zhang, N. Designing a future-ready enterprise: The digital transformation of DBS bank. Calif. Manag. Rev. 2021, 63, 35–57. [Google Scholar] [CrossRef]

- Kuester, S.; Konya-Baumbach, E.; Schuhmacher, M.C. Get the show on the road: Go-to-market strategies for e-innovations of start-ups. J. Bus. Res. 2018, 83, 65–81. [Google Scholar] [CrossRef]

- Yadav, M.S.; Pavlou, P.A. Marketing in computer-mediated environments: Research synthesis and new directions. J. Mark. 2014, 78, 20–40. [Google Scholar] [CrossRef]

- Gavrila, S.G.; de Lucas Ancillo, A. Spanish SMEs’ digitalization enablers: E-Receipt applications to the offline retail market. Technol. Forecast. Soc. Change 2021, 162, 120381. [Google Scholar] [CrossRef]

- Qi, Y.; Du, B.; Wen, X. Mission embeddedness and pattern selection of digital strategic transformation of SOEs: A case study based on the typical practice of digitalization in three central enterprises. J. Manag. World 2021, 37, 137–158+110. [Google Scholar]

- Tong, J.; Zhang, Q. The implications of digital economy and its remarkable contributions to future economic development. J. Nankai Univ. (Philos. Lit. Soc.) 2022, 3, 19–33. [Google Scholar]

- Xiao, X.; Qi, Y. Value dimension and theoretical logic of industrial digital transformation. Reform 2019, 8, 61–70. [Google Scholar]

- Zhang, J. Research on the Impact of Digital Industrialization on the High-Quality Development of China’s Foreign Trade; Inner Mongolia University of Finance and Economics: Hohhot, China, 2024. [Google Scholar]

- Senyard, J.; Davidsson, P.; Baker, T.; Steffens, P. Resource constraints in innovation: The role of bricolage in new venture creation and firm development. Regional frontiers of entrepreneurship research 2011. In Proceedings of the 8th AGSE International Entrepreneurship Research Exchange, Melbourne, Australia, 1–4 February 2011; pp. 609–622. [Google Scholar]

- Ou, S.; Cha, J. The dynamic impact of entrepreneurial bricolage on resource acquisition of new enterprises: Based on the intermediary effect of entrepreneurship learning. Econ. Surv. 2020, 37, 9. [Google Scholar]

- Zhao, G.; Zhang, F. The impact of start-ups resources bricolage on legitimacy under the adjustment of makerspace service capability. Sci. Technol. Econ. 2020, 33, 56–60. [Google Scholar]

- Ge, B.; Wang, H. An empirical study on resource integration, entrepreneurial learning and innovation of new ventures. South China J. Econ. 2017, 36, 57–70. [Google Scholar]

- Yin, M.; Wang, L. Frontier research of resource combination in entrepreneurship field and future prospects. Foreign Econ. Manag. 2015, 37, 11. [Google Scholar]

- Zeng, P.; Guo, X.; Zhang, Y.; Yang, P. How task environment affects business transformation and upgrading: A moderated mediation model. J. Shaoyang Univ. (Soc. Sci. Ed.) 2022, 21, 11. [Google Scholar]

- Lai, X.; Chen, Y.; Fan, Y. Formation an evolution of data-driven dynamic capabilities. Stud. Sci. Sci. 2023, 41, 113–122. [Google Scholar]

| Data Type | Data Source | Target | Duration | Manuscript |

|---|---|---|---|---|

| First-hand data | Interview | PAYA leader | 4 h | 3.1 w |

| Technical Director | 4 h | 2.69 w | ||

| Partner, EPLAN | 2 h | 2.98 w | ||

| Partner, L-MARK | 3 h | 2.1 w | ||

| Site visit | Digital manufacturing shop | 3 h | 1.56 w | |

| Digital twin technology | 1 h | 0.5 w | ||

| Virtual simulation technology | 1 h | 0.8 w | ||

| Online conference | PAYA leader | 3 h | 2.25 w | |

| Second-hand data | PAYA official website | www.paya.cn (accessed on 1 March 2025) | / | / |

| WeChat official account | PAYA | / | Crawler, 5 w | |

| WeChat video account | PAYA | / | 55 Videos |

| Aggregation Dimensions | Second-Order Themes | First-Order Concepts | Typical Evidence Cited |

|---|---|---|---|

| Managerial cognition | Perceptive cognition | Software defines the future | At that time, I believed that software was the future. Many things that require hardware to solve can be solved with just one piece of software. |

| Digitization | Digital technology structuring | PC-Based technology | The previous PLC is a dedicated controller, and the PC-Based controller can be fully integrated into the information system of the network era. |

| Introducing automatic wire cutting machine | We purchased an automatic wire cutting machine to improve the chaos of wiring harnesses at the production site and reduce waste. | ||

| Virtual simulation | When the production in the laboratory environment changes to the real environment, it is necessary to consider some wear and tear in all aspects of the field environment. In addition to the virtual simulation used in the research and development stage, it can also be used in the actual production line operation process. | ||

| Innovation | Process innovation | The wire automatic cutting | About 70% of the man-hours of a control cabinet are spent on assembly and wiring, often requiring skilled electricians. With the automatic offline machine, a novice with little training can be employed and still maintain high quality and efficiency. |

| Assembly of modules | We divide the area in the control cabinet, and each part corresponds to different functions. It becomes very convenient for workers to install the drawings. | ||

| Cabinet splicing | The multi-function workbench can move, tilt, and lift freely. With the assistance of the workbench, the mounting plate can also tilt and slide into the electric cabinet from the side, which is convenient for the installation of the electric cabinet. | ||

| Resource activities | Resource assembly | Internal resource portfolio | In the beginning, we had nothing but our accumulated technical service experience and accumulated component manufacturers to explore the transformation to automation and digitalization. |

| Innovation model | Single-agent innovation | Raising the digital level | We rely on our own continuous research and attempt to achieve automatic production and digital production upgrades. |

| Aggregation Dimensions | Second-Order Themes | First-Order Concepts | Typical Evidence Cited |

|---|---|---|---|

| Managerial cognition | Reframing cognition | Lean production | We would go to lean management experts to advise us, and their philosophy was not to pass on mistakes to the next step. |

| Digitization | Digital technology bundling | Digital twin | Digital twin is used not simply to input the 3D model but also to input the internal chemical properties, physical properties, and materials into the model. |

| Digital manufacturing workshop | A complete control cabinet production workshop from design to module assembly, line down, and then to cabinet installation was born. | ||

| Innovation | Total innovation | Connecting the production end of the design | We will extend the digital approach to the front end of the design so that the whole content will be more complete. |

| Digitization of the whole process | Based on the EPLAN software design platform, we integrate digital technology and lean production so that the whole process of control cabinet integration is digitized and standardized. | ||

| Resource activities | Resource integration | External cooperation search | We can export the opening diagram of the electrical cabinet through EPLAN software, use CAM software to identify the opening diagram and automatically generate a machining program, and import it into the board box processing center so as to complete the opening of the installation plate, door plate, side plate, and other plates. |

| Innovation model | Dual-agent innovation | Expanding the digital boundaries | We are also a strategic partner of EPLAN, who recently presented our company as a success case at the 6th Intelligent Manufacturing Conference held in Suzhou. |

| Aggregation Dimensions | Second-Order Themes | First-Order Concepts | Typical Evidence Cited |

|---|---|---|---|

| Managerial cognition | Matching cognition | To help SMMEs transform digitally | We have a responsibility to disseminate our digital transformation experience and develop a new technology service for it. |

| Digitization | Digital technology leveraging | Electrical standardization | The design and production of many enterprises are completely separated and become an island. The error from the design end to the production end will waste production, so we first do lean production from the design end. |

| Procedure standardization | Take out the things common to the whole process of the control cabinet and make them modular and standardized so that it is possible to reuse them. | ||

| Innovation | Collaborative innovation | Collaborating with customers | Many small businesses may not be able to afford equipment, but we can create shared workshops. The customer’s data are transmitted, and, as long as they are accurate, my side can produce. |

| Coordinating with upstream and downstream | By integrating upstream and downstream resources and jointly upgrading technology, we can have a perfect supply chain and thus better competitiveness. | ||

| Industry–university–research cooperation | We cooperated with the South China University of Technology on a horizontal project, trying to apply visual recognition technology to control cabinet maintenance. | ||

| Resource activities | Resource collaboration | Internal resource transfer | We hope to say that after the successful internal transformation of the enterprise, there are a small number of customers to try. After success, we hope to extend this methodology to other manufacturing industries, especially SMMEs. |

| Innovation model | Multi-agent innovation | Broadening network externalities | I can carry out systematic coordination with my upstream and downstream peers and also carry out horizontal research with universities such as the South China University of Technology. |

| Digital Transformation Stage | Managerial Cognition | Critical Events | Resource Orchestration | Innovation Model |

|---|---|---|---|---|

| Digital exploration period | Perceptive cognition | Realizing the digitalization of production links | Resource assembly | Single-agent innovation model |

| Digital growth period | Reframing cognition | Realizing the whole chain of digitalization and building a digital workshop | Resource integration | Dual-agent innovation model |

| Digital development period | Matching cognition | Developing digital transformation consulting services | Resource collaboration | Multi-agent innovation model |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Zhang, Y.; Li, X.; Wang, Z.; Zhang, Q. Research on Digital Transformation and the Innovation Model of SMMEs: The Case Study of PAYA. Sustainability 2025, 17, 3458. https://doi.org/10.3390/su17083458

Xu Y, Zhang Y, Li X, Wang Z, Zhang Q. Research on Digital Transformation and the Innovation Model of SMMEs: The Case Study of PAYA. Sustainability. 2025; 17(8):3458. https://doi.org/10.3390/su17083458

Chicago/Turabian StyleXu, Yanmei, Yanan Zhang, Xiang Li, Ziqiang Wang, and Qiwen Zhang. 2025. "Research on Digital Transformation and the Innovation Model of SMMEs: The Case Study of PAYA" Sustainability 17, no. 8: 3458. https://doi.org/10.3390/su17083458

APA StyleXu, Y., Zhang, Y., Li, X., Wang, Z., & Zhang, Q. (2025). Research on Digital Transformation and the Innovation Model of SMMEs: The Case Study of PAYA. Sustainability, 17(8), 3458. https://doi.org/10.3390/su17083458