Life Cycle-Based Product Sustainability Assessment Employing Quality and Cost

Abstract

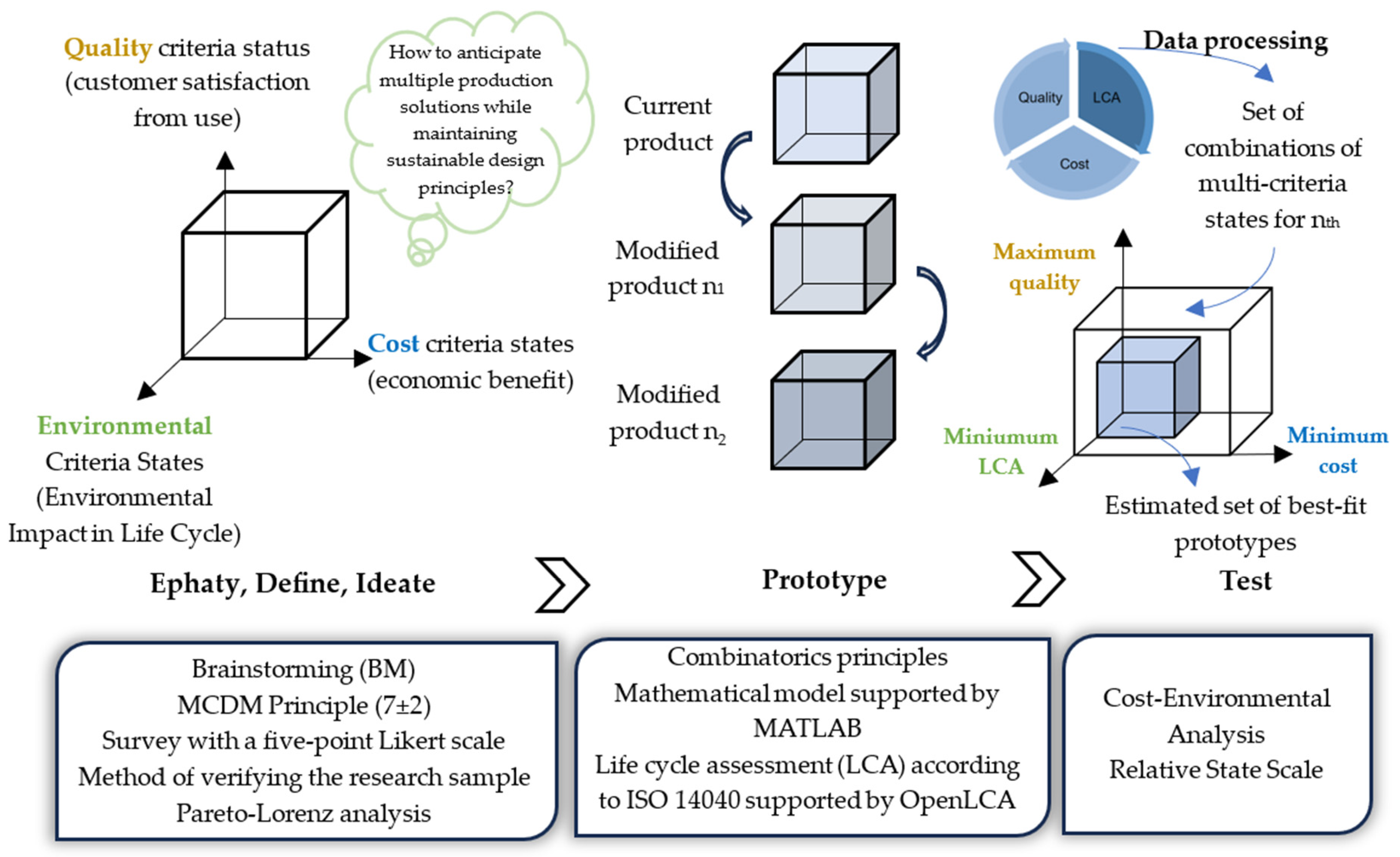

1. Introduction

- Extending the traditional design thinking method to sustainable product development, where the key is to strive not only for products that meet customer requirements, but also those that are environmentally friendly in their life cycle and financially profitable [19,20,21], while taking into account the ideas of S-LCA, we involve customers (users) in the form of stakeholders who define their requirements for product quality criteria;

- Developing a method to integrate LCA results with cost of production (or product cost) in the form of cost–environmental analyses, which is adapted to dynamic estimation and modeling of results instead of extensive, time-consuming LCC methods [10].

2. Method: General Approach and Novelty

3. Test and Illustration of the Method by Case Study

3.1. Research Initiation

3.2. Obtaining and Processing Data from Customers

3.3. Dynamic Generation of Alternative Sets of Product Solutions

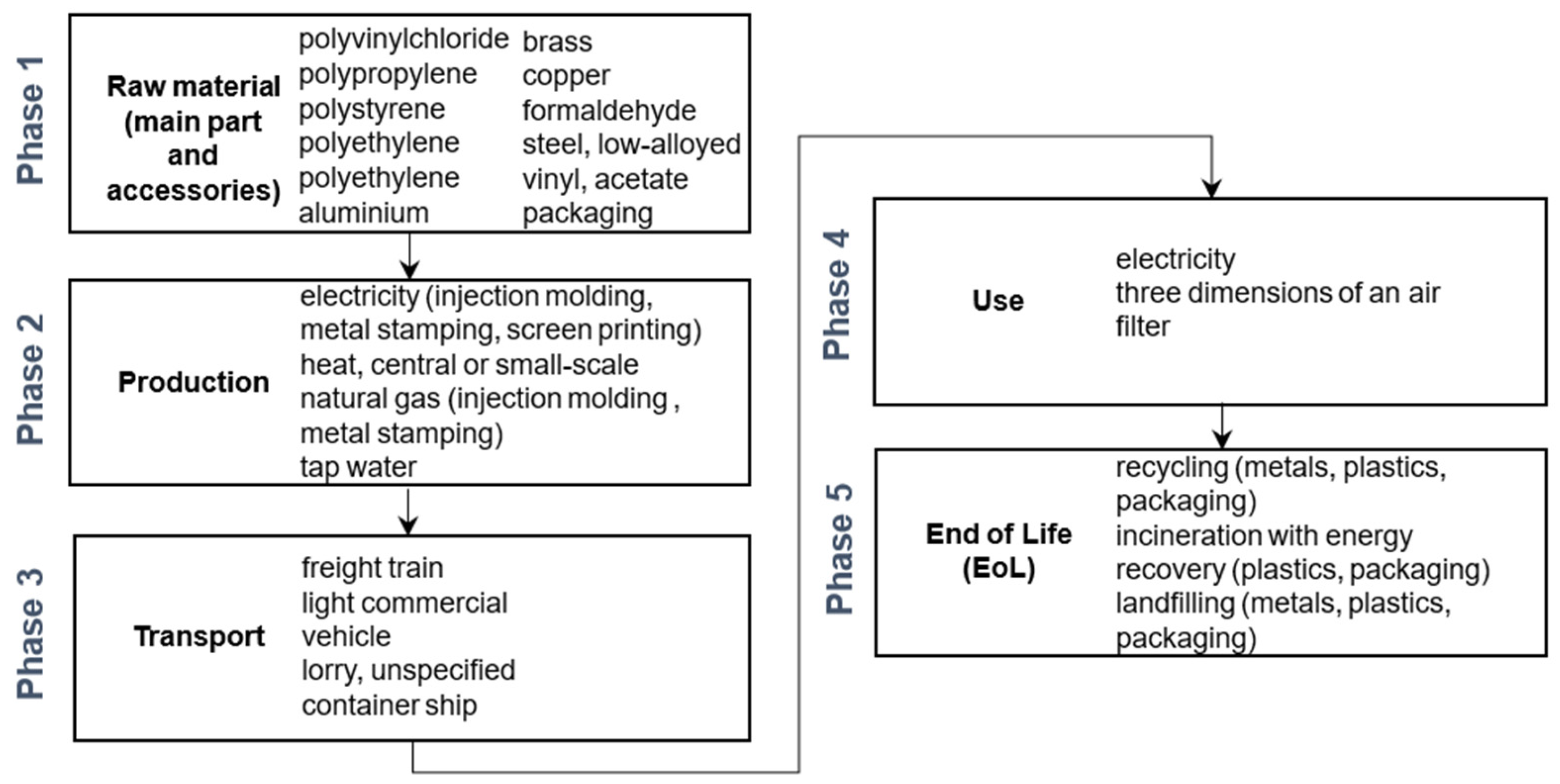

3.4. Prospective Life Cycle Assessment

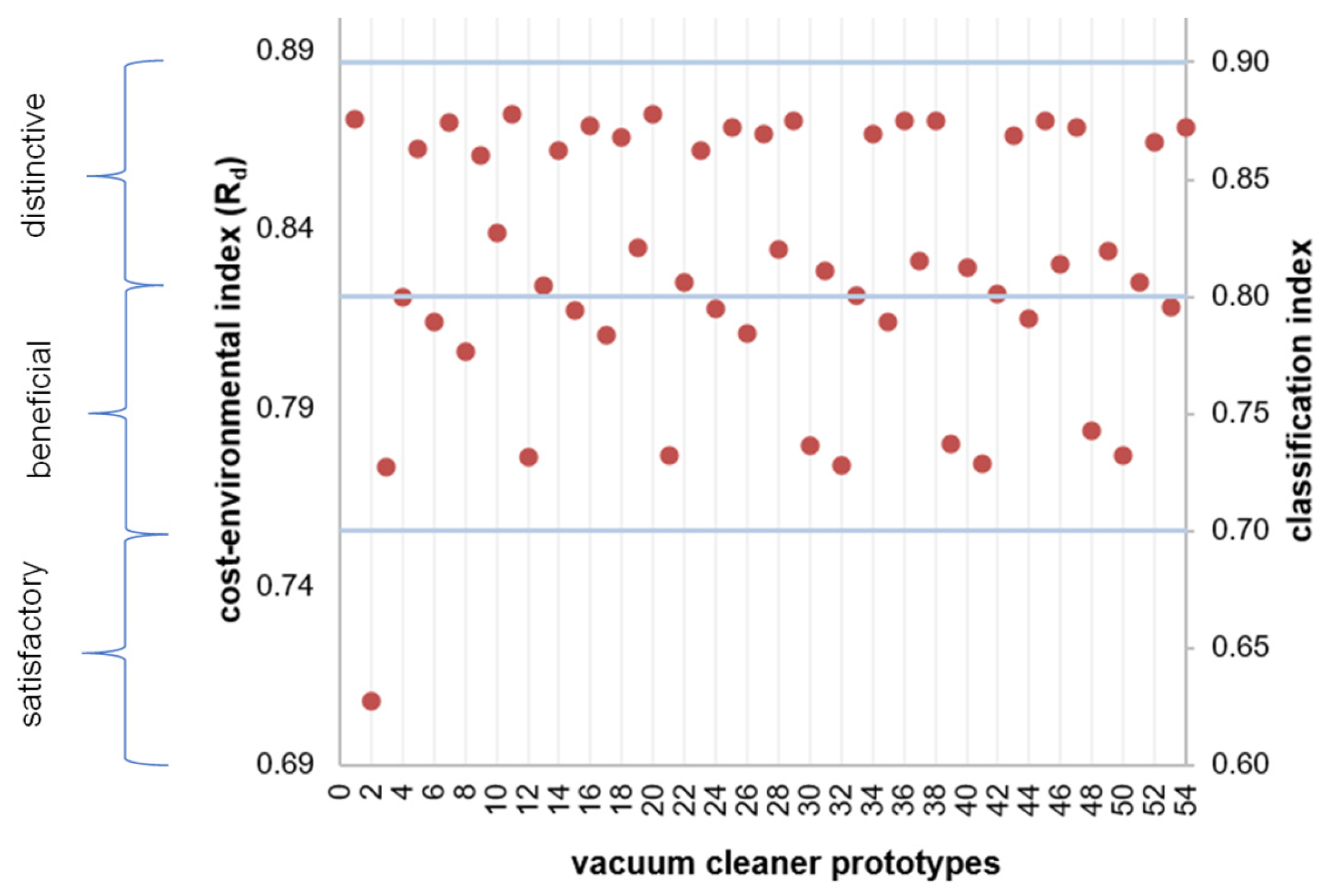

3.5. Predicting the Direction of Product Solutions Taking into Account Costs

4. Results and Discussion

4.1. Contribution to the Iterative Design Thinking (DT)

4.2. Benefits and Limitations: Comparison to Traditional S-LCA, LCA, LCC Methodologies

4.3. Limitations and Development Prospects: Toward Artificial Intelligence (AI)

- Predicting a larger number of combinations of criteria states, e.g., considering a larger number of states and a larger number of criteria. This can help identify combinations that are less costly, including deepening research for a wider range of customer requirements. Currently, according to the combinatorics principles, for 4 criteria and 11 states we have generated 54 combinations, where considering a larger number of states generates a larger number of product alternatives, including a wider range of product possibilities. However, their detailed processing in practice becomes time consuming [13], and the use of AI can predict possible solutions based on those generated so far;

- Estimation of the environmental impact indicator within LCA for prototypes, where it is difficult to predict costs for a large number of them [13], where the number of these prototypes depends on the combinations of criteria states; hence, the more combinations, the need to create extensive LCA models [82], therefore, the use of AI can generate LCA indicators according to a dozen or so estimated according to our approach;

- At the same time, the limitation is the orientation of LCA results depending on one environmental burden criterion (in our case CO2 emissions); the use of machine learning and AI tools could facilitate the entire calculation process, including allowing LCA analysis to be carried out for more criteria;

- Estimating the costs of prototypes, which is not very practical in the case of a large number of them, but it would be possible to develop nonparametric regression models for this purpose [13].

5. Conclusions

- Extension of the iterative design thinking process by using an executive mechanism for development (regarding customers, LCA and production costs);

- Providing and sending customer requests in the form of current and future results;

- Efficient identification of key product criteria that are important for customers, thus providing a specific increase in their satisfaction;

- Dynamic creation of different product solutions supported by computer software with an authorial algorithm, where these solutions are responsible for development;

- Uncomplicated consideration of the prototype cost aspect in relation to hypothetically created derivative designs dependent on the quality and environmental aspect, which provides a simplified cost valuation and their modeling for a number of prototypes;

- The issue of identifying different devices dependent on the quality, LCA and cost aspect;

- Providing support to decision makers, e.g., the designer who implements the product development;

- Reduction of waste by applying actions at the most advanced stage of development;

- Modeling production data at a lower level (prototyping, conceptualization), where real data are often unavailable;

- Supporting the development of enterprises in the field of distribution of offered products.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sharma, A. Product Design and Development Using Artificial Intelligence (AI) Techniques: A Review. engrXiv 2023. [Google Scholar] [CrossRef]

- Altaf, A.; Khan, I.; Khan, A.; Sadiq, S.; Humayun, M.; Khan, S.; Zaman, S.; Khan, A.; Abumousa, R.A.; Bououdina, M. Metal/Covalent Organic Framework Encapsulated Lead-Free Halide Perovskite Hybrid Nanocatalysts: Multifunctional Applications, Design, Recent Trends, Challenges, and Prospects. ACS Omega 2024, 9, 34220–34242. [Google Scholar] [CrossRef] [PubMed]

- Khan, I.; Altaf, A.; Sadiq, S.; Khan, S.; Khan, A.; Khan, S.; Humayun, M.; Khan, A.; Abumousa, R.A.; Bououdina, M. Towards Sustainable Solutions: Comprehensive Review of Advanced Porous Materials for CO2 Capture, Hydrogen Generation, Pollutant Degradation, and Energy Application. Chem. Eng. J. Adv. 2025, 21, 100691. [Google Scholar] [CrossRef]

- Yang, C.; Xu, T.; Ye, J. Applying TRIZ and Kansei Engineering to the Eco-Innovative Product Design towards Waste Recycling with Latent Dirichlet Allocation Topic Model Analysis. Eng. Appl. Artif. Intell. 2024, 133, 107962. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, C. A Dynamic Analysis of a Green Closed-Loop Supply Chain with Different on-Line Platform Smart Recycling and Selling Models. Comput. Ind. Eng. 2025, 200, 110748. [Google Scholar] [CrossRef]

- Valdivia, S.; Backes, J.G.; Traverso, M.; Sonnemann, G.; Cucurachi, S.; Guinée, J.B.; Schaubroeck, T.; Finkbeiner, M.; Leroy-Parmentier, N.; Ugaya, C.; et al. Principles for the Application of Life Cycle Sustainability Assessment. Int. J. Life Cycle Assess. 2021, 26, 1900–1905. [Google Scholar] [CrossRef]

- Proske, M.; Finkbeiner, M. Obsolescence in LCA–Methodological Challenges and Solution Approaches. Int. J. Life Cycle Assess. 2020, 25, 495–507. [Google Scholar] [CrossRef]

- Germani, M.; Gregori, F.; Luzi, A.; Mengarelli, M. Assessing Social Sustainability of Products: An Improved S-LCA Method. In Proceedings of the Product Lifecycle Management in the Era of Internet of Things: 12th IFIP WG 5.1 International Conference, PLM 2015, Doha, Qatar, 19–21 October 2015; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; pp. 529–540. [Google Scholar]

- Klöpffer, W.; Ciroth, A. Is LCC Relevant in a Sustainability Assessment? Int. J. Life Cycle Assess. 2011, 16, 99–101. [Google Scholar] [CrossRef]

- Sakao, T.; Lindahl, M. A Method to Improve Integrated Product Service Offerings Based on Life Cycle Costing. CIRP Annals 2015, 64, 33–36. [Google Scholar] [CrossRef]

- Kambanou, M.L. Life Cycle Costing: Understanding How It Is Practised and Its Relationship to Life Cycle Management—A Case Study. Sustainability 2020, 12, 3252. [Google Scholar] [CrossRef]

- Park, J.-H.; Seo, K.-K.; Wallace, D.; Lee, K.-I. Approximate Product Life Cycle Costing Method for the Conceptual Product Design. CIRP Annals 2002, 51, 421–424. [Google Scholar] [CrossRef]

- Liu, H.; Gopalkrishnan, V.; Quynh, K.T.N.; Ng, W.-K. Regression Models for Estimating Product Life Cycle Cost. J. Intell. Manuf. 2009, 20, 401–408. [Google Scholar] [CrossRef]

- Huertas-Valdivia, I.; Ferrari, A.M.; Settembre-Blundo, D.; García-Muiña, F.E. Social Life-Cycle Assessment: A Review by Bibliometric Analysis. Sustainability 2020, 12, 6211. [Google Scholar] [CrossRef]

- Lehmann, A.; Zschieschang, E.; Traverso, M.; Finkbeiner, M.; Schebek, L. Social Aspects for Sustainability Assessment of Technologies—Challenges for Social Life Cycle Assessment (SLCA). Int. J. Life Cycle Assess. 2013, 18, 1581–1592. [Google Scholar] [CrossRef]

- Vacuum Cleaners: Ecodesign Requirements Apply to This Product. Available online: https://energy-efficient-products.ec.europa.eu/product-list/vacuum-cleaners_en (accessed on 8 April 2025).

- Bachmann, T.M.; van der Kamp, J.; Bianchi, M.; Pihkola, H.; Saavedra del Oso, M. Life Cycle Costing as Part of a Life Cycle Sustainability Assessment of Products: Methodology and Case Studies. Int. J. Life Cycle Assess. 2024, 29, 1863–1879. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D. Analysis of the Possibility of Used of the Quality Management Techniques with Non-Destructive Testing. Teh. Vjesn. Tech. Gaz. 2021, 28, 45–51. [Google Scholar] [CrossRef]

- Nagaraj, V.; Berente, N.; Lyytinen, K.; Gaskin, J. Team Design Thinking, Product Innovativeness, and the Moderating Role of Problem Unfamiliarity. J. Prod. Innov. Manag. 2020, 37, 297–323. [Google Scholar] [CrossRef]

- Seidel, V.P.; Fixson, S.K. Adopting Design Thinking in Novice Multidisciplinary Teams: The Application and Limits of Design Methods and Reflexive Practices. J. Prod. Innov. Manag. 2013, 30, 19–33. [Google Scholar] [CrossRef]

- Liedtka, J. Putting Technology in Its Place: Design Thinking’s Social Technology at Work. Calif. Manag. Rev. 2020, 62, 53–83. [Google Scholar] [CrossRef]

- Arvidsson, R.; Tillman, A.; Sandén, B.A.; Janssen, M.; Nordelöf, A.; Kushnir, D.; Molander, S. Environmental Assessment of Emerging Technologies: Recommendations for Prospective LCA. J. Ind. Ecol. 2018, 22, 1286–1294. [Google Scholar] [CrossRef]

- Adrianto, L.R.; Ciacci, L.; Pfister, S.; Hellweg, S. Toward Sustainable Reprocessing and Valorization of Sulfidic Copper Tailings: Scenarios and Prospective LCA. Sci. Total Environ. 2023, 871, 162038. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Venkatesh, A. An Investigation of How Design-Oriented Organisations Implement Design Thinking. J. Mark. Manag. 2013, 29, 1680–1700. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A.; Gazda, A. A New QFD-CE Method for Considering the Concept of Sustainable Development and Circular Economy. Energies 2023, 16, 2474. [Google Scholar] [CrossRef]

- Veillette, M.; Knibbs, L.D.; Pelletier, A.; Charlebois, R.; Blais Lecours, P.; He, C.; Morawska, L.; Duchaine, C. Microbial Contents of Vacuum Cleaner Bag Dust and Emitted Bioaerosols and Their Implications for Human Exposure Indoors. Appl. Environ. Microbiol. 2013, 79, 6331–6336. [Google Scholar] [CrossRef]

- Gallego-Schmid, A.; Mendoza, J.M.F.; Jeswani, H.K.; Azapagic, A. Life Cycle Environmental Impacts of Vacuum Cleaners and the Effects of European Regulation. Sci. Total Environ. 2016, 559, 192–203. [Google Scholar] [CrossRef]

- Trakumas, S.; Willeke, K.; Grinshpun, S.A.; Reponen, T.; Mainelis, G.; Friedman, W. Particle Emission Characteristics of Filter-Equipped Vacuum Cleaners. AIHAJ Am. Ind. Hyg. Assoc. 2001, 62, 482–493. [Google Scholar] [CrossRef]

- Trakumas, S.; Willeke, K.; Reponen, T.; Grinshpun, S.A.; Friedman, W. Comparison of Filter Bag, Cyclonic, and Wet Dust Collection Methods in Vacuum Cleaners. AIHAJ Am. Ind. Hyg. Assoc. 2001, 62, 573–583. [Google Scholar] [CrossRef]

- Lioy, P.J.; Wainman, T.; Zhang, J.; Goldsmith, S. Typical Household Vacuum Cleaners: The Collection Efficiency and Emissions Characteristics for Fine Particles. J. Air Waste Manag. Assoc. 1999, 49, 200–206. [Google Scholar] [CrossRef]

- Vicente, E.D.; Vicente, A.M.; Evtyugina, M.; Calvo, A.I.; Oduber, F.; Blanco Alegre, C.; Castro, A.; Fraile, R.; Nunes, T.; Lucarelli, F.; et al. Impact of Vacuum Cleaning on Indoor Air Quality. Build. Environ. 2020, 180, 107059. [Google Scholar] [CrossRef]

- Shen, Y.; Zhou, J.; Pantelous, A.A.; Liu, Y.; Zhang, Z. A Voice of the Customer Real-Time Strategy: An Integrated Quality Function Deployment Approach. Comput. Ind. Eng. 2022, 169, 108233. [Google Scholar] [CrossRef]

- Sakao, T. A QFD-Centred Design Methodology for Environmentally Conscious Product Design. Int. J. Prod. Res. 2007, 45, 4143–4162. [Google Scholar] [CrossRef]

- Hassan, A.; Siadat, A.; Dantan, J.-Y.; Martin, P. Conceptual Process Planning—An Improvement Approach Using QFD, FMEA, and ABC Methods. Robot. Comput. Integr. Manuf. 2010, 26, 392–401. [Google Scholar] [CrossRef]

- Gong, X.; Guo, Z.; Xie, Z. Using Kansei Engineering for the Design Thinking Framework: Bamboo Pen Holder Product Design. Sustainability 2022, 14, 10556. [Google Scholar] [CrossRef]

- Yamagishi, K.; Seki, K.; Nishimura, H. Requirement Analysis Considering Uncertain Customer Preference for Kansei Quality of Product. J. Adv. Mech. Des. Syst. Manuf. 2018, 12, JAMDSM0034. [Google Scholar] [CrossRef]

- Yamakawa, E.K.; Aoki, A.R.; Siebert, L.C.; Klinguelfus, G.; Cauchick Miguel, P.A. A Fuzzy-QFD Decision Making Approach for Selecting Industry Energy Efficiency Indicators. In Proceedings of the 2013 IEEE PES Conference on Innovative Smart Grid Technologies (ISGT Latin America), Sao Paulo, Brazil, 15–17 April 2013; pp. 1–5. [Google Scholar]

- Willeke, K.; Trakumas, S.; Grinshpun, S.A.; Reponen, T.; Trunov, M.; Friedman, W. Test Methods for Evaluating the Filtration and Particulate Emission Characteristics of Vacuum Cleaners. AIHAJ Am. Ind. Hyg. Assoc. 2001, 62, 313–321. [Google Scholar] [CrossRef]

- Kumar, S.; Wing, W.; Lee, H. Psychoacoustic Analysis of Vacuum Cleaner Noise. Acoustics 2021, 3, 545–558. [Google Scholar] [CrossRef]

- Čudina, M.; Prezelj, J. Noise Generation by Vacuum Cleaner Suction Units. Part III. Contribution of Structure-Borne Noise to Total Sound Pressure Level. Appl. Acoust. 2007, 68, 521–537. [Google Scholar] [CrossRef]

- Sullivan, G.M.; Artino, A.R. Analyzing and Interpreting Data From Likert-Type Scales. J. Grad. Med. Educ. 2013, 5, 541–542. [Google Scholar] [CrossRef]

- Solis, D.; Hutchinson, D.; Longnecker, N. Visual Discrete Format: An Alternative to Likert-Type Formats of Survey Items Sensitive Enough to Measure Small Changes in Stable Constructs Such as Self-Concept in Science. Int. J. Cogn. Res. Sci. Eng. Educ. (IJCRSEE) 2022, 10, 1–16. [Google Scholar] [CrossRef]

- Joshi, A.; Kale, S.; Chandel, S.; Pal, D. Likert Scale: Explored and Explained. Br. J. Appl. Sci. Technol. 2015, 7, 396–403. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A. A Pro-Environmental Method of Sample Size Determination to Predict the Quality Level of Products Considering Current Customers’ Expectations. Sustainability 2021, 13, 5542. [Google Scholar] [CrossRef]

- Aliaga, C. Statistics in Focus: Population and Social Conditions. How Is the Time of Women and Men Distributed in Europe? Eurostat: Luxembourg, 2006. [Google Scholar]

- Su, C.; Zha, X.; Ma, J.; Li, B.; Wang, X. Dynamic Optimal Control Strategy of CCUS Technology Innovation in Coal Power Stations Under Environmental Protection Tax. Systems 2025, 13, 193. [Google Scholar] [CrossRef]

- Hoła, A.; Sawicki, M.; Szóstak, M. Methodology of Classifying the Causes of Occupational Accidents Involving Construction Scaffolding Using Pareto-Lorenz Analysis. Appl. Sci. 2018, 8, 48. [Google Scholar] [CrossRef]

- Lestyánszka Škůrková, K.; Fidlerová, H.; Niciejewska, M.; Idzikowski, A. Quality Improvement of the Forging Process Using Pareto Analysis and 8D Methodology in Automotive Manufacturing: A Case Study. Standards 2023, 3, 84–94. [Google Scholar] [CrossRef]

- Mu, E.; Pereyra-Rojas, M. Practical Decision Making, 1st ed.; Springer International Publishing: Cham, Switzerland, 2017; Volume 1, ISBN 978-3-319-33860-6. [Google Scholar]

- Ostasz, G.; Siwiec, D.; Pacana, A. Model to Determine the Best Modifications of Products with Consideration Customers’ Expectations. Energies 2022, 15, 8102. [Google Scholar] [CrossRef]

- Siwiec, D.; Bednárová, L.; Pacana, A.; Zawada, M.; Rusko, M. Decision Support in the Selection of Fluorescent Penetrants for Industrial Non-Destructive Testing. Przemysł Chem. 2019, 1, 92–94. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D.; Bednárová, L.; Petrovský, J. Improving the Process of Product Design in a Phase of Life Cycle Assessment (LCA). Processes 2023, 11, 2579. [Google Scholar] [CrossRef]

- Chevalier, J.L.; Le Téno, J.F. Requirements for an LCA-Based Model for the Evaluation of the Environmental Quality of Building Products. Build. Environ. 1996, 31, 487–491. [Google Scholar] [CrossRef]

- Lagerstedt, J.; Luttropp, C.; Lindfors, L.-G. Functional Priorities in LCA and Design for Environment. Int. J. Life Cycle Assess. 2003, 8, 160–166. [Google Scholar] [CrossRef]

- Zhu, X.; Tian, Y.; Wang, S. Comparing Two Types of Mainstream Disposable Lunch Boxes by LCA and Exploring the Possibility of Converting Carbon Dioxide into Products. Heliyon 2023, 9, e13480. [Google Scholar] [CrossRef]

- Chang, H.; Khan, I.; Yuan, A.; Khan, S.; Sadiq, S.; Khan, A.; Shah, S.A.; Chen, L.; Humayun, M.; Usman, M. Polyarylimide-Based COF/MOF Nanoparticle Hybrids for CO 2 Conversion, Hydrogen Generation, and Organic Pollutant Degradation. ACS Appl. Nano Mater. 2024, 7, 10451–10465. [Google Scholar] [CrossRef]

- Khan, A.; Sadiq, S.; Khan, I.; Humayun, M.; Jiyuan, G.; Usman, M.; Khan, A.; Khan, S.; Alanazi, A.F.; Bououdina, M. Preparation of Visible-Light Active MOFs-Perovskites (ZIF-67/LaFeO3) Nanocatalysts for Exceptional CO2 Conversion, Organic Pollutants and Antibiotics Degradation. Heliyon 2024, 10, e27378. [Google Scholar] [CrossRef] [PubMed]

- Grenz, J.; Ostermann, M.; Käsewieter, K.; Cerdas, F.; Marten, T.; Herrmann, C.; Tröster, T. Integrating Prospective LCA in the Development of Automotive Components. Sustainability 2023, 15, 10041. [Google Scholar] [CrossRef]

- Bisinella, V.; Christensen, T.H.; Astrup, T.F. Future Scenarios and Life Cycle Assessment: Systematic Review and Recommendations. Int. J. Life Cycle Assess. 2021, 26, 2143–2170. [Google Scholar] [CrossRef]

- Gao, L.; Wang, Z.; Wang, Y.; Peng, T.; Liu, W.; Tang, R. LCA-Based Multi-Scenario Study on Steel or Aluminum Wheel Hub for Passenger Vehicles. Procedia CIRP 2023, 116, 191–196. [Google Scholar] [CrossRef]

- Bianco, I.; Panepinto, D.; Zanetti, M. End-of-Life Tyres: Comparative Life Cycle Assessment of Treatment Scenarios. Appl. Sci. 2021, 11, 3599. [Google Scholar] [CrossRef]

- Gallego-Schmid, A.; Jeswani, H.K.; Mendoza, J.M.F.; Azapagic, A. Life Cycle Environmental Evaluation of Kettles: Recommendations for the Development of Eco-Design Regulations in the European Union. Sci. Total Environ. 2018, 625, 135–146. [Google Scholar] [CrossRef]

- Mancini, M.S.; Galli, A.; Niccolucci, V.; Lin, D.; Bastianoni, S.; Wackernagel, M.; Marchettini, N. Ecological Footprint: Refining the Carbon Footprint Calculation. Ecol. Indic. 2016, 61, 390–403. [Google Scholar] [CrossRef]

- Lakusic, S. Variants of Determining the Construction Production Carbon Footprint. J. Croat. Assoc. Civ. Eng. 2023, 75, 273–281. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D.; Bednárová, L. Method of Choice: A Fluorescent Penetrant Taking into Account Sustainability Criteria. Sustainability 2020, 12, 5854. [Google Scholar] [CrossRef]

- Kolman, R. Quality Engineering; PWE: Warsaw, Poland, 1992. (In Polish) [Google Scholar]

- Gajdzik, B.; Siwiec, D.; Wolniak, R.; Pacana, A. Approaching Open Innovation in Customization Frameworks for Product Prototypes with Emphasis on Quality and Life Cycle Assessment (QLCA). J. Open Innov. Technol. Mark. Complex. 2024, 10, 100268. [Google Scholar] [CrossRef]

- Luotola, H.; Hellström, M.; Gustafsson, M.; Perminova-Harikoski, O. Embracing Uncertainty in Value-Based Selling by Means of Design Thinking. Ind. Mark. Manag. 2017, 65, 59–75. [Google Scholar] [CrossRef]

- Li, W.-T.; Ho, M.-C.; Yang, C. A Design Thinking-Based Study of the Prospect of the Sustainable Development of Traditional Handicrafts. Sustainability 2019, 11, 4823. [Google Scholar] [CrossRef]

- Rösch, N.; Tiberius, V.; Kraus, S. Design Thinking for Innovation: Context Factors, Process, and Outcomes. Eur. J. Innov. Manag. 2023, 26, 160–176. [Google Scholar] [CrossRef]

- Halvorsen, K. Team Decision Making in the Workplace. J. Appl. Linguist. Prof. Pract. 2013, 7, 273–296. [Google Scholar] [CrossRef]

- Nakata, C. Design Thinking for Innovation: Considering Distinctions, Fit, and Use in Firms. Bus. Horiz. 2020, 63, 763–772. [Google Scholar] [CrossRef]

- Liedtka, J. Innovative Ways Companies Are Using Design Thinking. Strategy Leadersh. 2014, 42, 40–45. [Google Scholar] [CrossRef]

- Elsbach, K.D.; Stigliani, I. Design Thinking and Organizational Culture: A Review and Framework for Future Research. J. Manag. 2018, 44, 2274–2306. [Google Scholar] [CrossRef]

- Micheli, P.; Wilner, S.J.S.; Bhatti, S.H.; Mura, M.; Beverland, M.B. Doing Design Thinking: Conceptual Review, Synthesis, and Research Agenda. J. Prod. Innov. Manag. 2019, 36, 124–148. [Google Scholar] [CrossRef]

- Boons, F.; Montalvo, C.; Quist, J.; Wagner, M. Sustainable Innovation, Business Models and Economic Performance: An Overview. J. Clean. Prod. 2013, 45, 1–8. [Google Scholar] [CrossRef]

- Siwiec, D.; Gajdzik, B.; Gawlik, R.; Wolniak, R.; Pacana, A. Open Eco-Innovations in Sustainable Product Development: Model Framework of Design Thinking in Quality Life Cycle Assessment (DT-QLCA). J. Open Innov. Technol. Mark. Complex. 2025, 11, 100480. [Google Scholar] [CrossRef]

- Luthin, A.; Traverso, M.; Crawford, R.H. Circular Life Cycle Sustainability Assessment: An Integrated Framework. J. Ind. Ecol. 2024, 28, 41–58. [Google Scholar] [CrossRef]

- Kloepffer, W. Life Cycle Sustainability Assessment of Products. Int. J. Life Cycle Assess. 2008, 13, 89–95. [Google Scholar] [CrossRef]

- Seo, K.-K.; Park, J.-H.; Jang, D.-S.; Wallace, D. Approximate Estimation of the Product Life Cycle Cost Using Artificial Neural Networks in Conceptual Design. Int. J. Adv. Manuf. Technol. 2002, 19, 461–471. [Google Scholar] [CrossRef]

- Asiedu, Y.; Gu, P. Product Life Cycle Cost Analysis: State of the Art Review. Int. J. Prod. Res. 1998, 36, 883–908. [Google Scholar] [CrossRef]

- Seo, K.-K.; Park, J.-H.; Jang, D.-S.; Wallace, D. Prediction of the Life Cycle Cost Using Statistical and Artificial Neural Network Methods in Conceptual Product Design. Int. J. Comput. Integr. Manuf. 2002, 15, 541–554. [Google Scholar] [CrossRef]

- Park, P.-J.; Tahara, K.; Inaba, A. Product Quality-Based Eco-Efficiency Applied to Digital Cameras. J. Environ. Manag. 2007, 83, 158–170. [Google Scholar] [CrossRef]

- Manco, P.; Caterino, M.; Rinaldi, M.; Fera, M. Additive Manufacturing in Green Supply Chains: A Parametric Model for Life Cycle Assessment and Cost. Sustain. Prod. Consum. 2023, 36, 463–478. [Google Scholar] [CrossRef]

- Bonilla-Alicea, R.J.; Fu, K. Evaluation of a Challenge-Derived Social Life Cycle Assessment (S-LCA) Framework. Int. J. Sustain. Eng. 2021, 14, 1680–1697. [Google Scholar] [CrossRef]

- Kühnen, M.; Hahn, R. Indicators in Social Life Cycle Assessment: A Review of Frameworks, Theories, and Empirical Experience. J. Ind. Ecol. 2017, 21, 1547–1565. [Google Scholar] [CrossRef]

- Dubois-Iorgulescu, A.-M.; Saraiva, A.K.E.B.; Valle, R.; Rodrigues, L.M. How to Define the System in Social Life Cycle Assessments? A Critical Review of the State of the Art and Identification of Needed Developments. Int. J. Life Cycle Assess. 2018, 23, 507–518. [Google Scholar] [CrossRef]

- Rezaei Kalvani, S.; Sharaai, A.H.; Abdullahi, I.K. Social Consideration in Product Life Cycle for Product Social Sustainability. Sustainability 2021, 13, 11292. [Google Scholar] [CrossRef]

- Manik, Y.; Leahy, J.; Halog, A. Social Life Cycle Assessment of Palm Oil Biodiesel: A Case Study in Jambi Province of Indonesia. Int. J. Life Cycle Assess. 2013, 18, 1386–1392. [Google Scholar] [CrossRef]

- Ghimire, R.; Raji, A. Use of Artificial Intelligence in Design, Development, Additive Manufacturing, and Certification of Multifunctional Composites for Aircraft, Drones, and Spacecraft. Appl. Sci. 2024, 14, 1187. [Google Scholar] [CrossRef]

| Study | Purpose and Scope of the Research | Research Method | Main Results | Mentioned Quality Criteria |

|---|---|---|---|---|

| [26] | Assessment of bioaerosol emissions in different vacuum cleaners | Collection and analysis of air samples in an experimental flow tunnel with operating vacuum cleaners, including testing their emissions from closed-surface cassettes as well as testing dust from a dust bag | Emission of bacteria and molds (Penicillium/Aspergillus) significant (even 1 × 105 Eq. cells/min), content of bacteria and molds in bag dust consistent, where most of the bacteria come from humans, and vacuum cleaners can spread significant amounts of molds and bacteria of human origin, including being a source of exposure to bioaerosols | Vacuum cleaner bag, e.g., vacuum, HEPA dust filter, Hose (suction tube), attachments, method of switching on and off (automatic start/stop), vacuum in the suction tube, purchase price |

| [38] | Evaluation of the overall filtration efficiency of a vacuum cleaner | Filtration analysis by placing the vacuum cleaner in a test chamber where the aerosol concentration was measured at the chamber inlet and outlet | Overall efficiency 100% for industrial vacuum cleaners and most mid-range and high-end home vacuum cleaners | Dust filter, e.g., HEPA or other, installed in the outlet, purchase price, outlet pipe, tank capacity, negative pressure in the suction pipe |

| [27] | Assessment of the environmental impact of vacuum cleaners in LCA and the effects of implementing the provisions of the Directive on Waste Electrical and Electronic Equipment (WEEE) at European level | Ecodesign analysis of the environmental impact of vacuum cleaners, including decarbonization of electricity, product lifespan and end-of-life disposal options | The implementation of the Ecodesign Regulation reduced the environmental impact of vacuum cleaners by approximately 37–44% compared to the areas of analysis considered | Hose (suction tube), bag type (disposable, bagless), engine power, power cables and wires, dust filter type, sockets and plugs, rubber protectors to protect furniture from knocking, accessories (e.g., brushes) |

| [28] | Evaluation of filtration efficiency of industrial and household vacuum cleaners | Studies on the evaluation of cleaning efficiency when using a HEPA filter in industrial and household vacuum cleaners | Similar performance of vacuum cleaners, where household vacuum cleaners equipped with a final HEPA filter effectively collect about 100% of dry dust sucked in by the nozzle, however, industrial vacuum cleaners were more efficient on wet surfaces | Purchase price, Hepa dust filter type, bag type, vacuum in the suction pipe, engine power, suction pipe diameter |

| [29] | Development of a comparative assessment method for dust collection methods used in vacuum cleaners | A method dedicated to the comparison of filter bag, cyclone and wet primary dust collection, where dry aerosols were used, non-hygroscopic test particles | Similar efficiency for dust collection methods: up to 50% for particles of 0.35 m and close to 100% for particles of 1.0 m and larger, where the degree of dependence of initial collection efficiency on airflow rate was strongly related to the type and manufacture of the main dust collector | Dust filter type |

| [30] | Testing of household vacuum cleaners for their fine particulate emission rate and collection efficiency in laboratory conditions | Carbon and Aerosol Engine Emissions Test Using HIAC/Royco 5130A Continuous Light Scattering as a Particle Detector | The lowest particle emission rate was obtained for vacuum cleaners with a HEPA filter, where the filter was placed behind the vacuum cleaner bag and the motor in a sealed housing | Filter type, bag type, suction pipe vacuum and engine power, price |

| [31] | Vacuum cleaners (bagless, wet with bag and HEPA filter) were tested for mass emission factor and number of particulate matter | Chemical characterization of solid particles, including organic elements, carbon, metals, etc. | Particulate matter emissions were significantly higher for vacuum operation (207 ± 99.0 μg min−1), than for bagless (86.1 ± 16.9 μg min−1) and filter vacuum cleaners (75.4 ± 7.89 μg min−1) | Hepa filter, vacuum cleaner bag type |

| Quality Criterion | Source |

|---|---|

| Vacuum cleaner purchase price | [26,28,30,38] |

| Negative pressure in the suction tube | [26,27,28,30] |

| Vacuum cleaner motor power | [27,28,29,30,38] |

| Power cord length | [27] |

| Working range of the vacuum cleaner connected to the power cord | [27] |

| Noise level during vacuum cleaner operation | [39,40] |

| Power cord winding system | [27] |

| Vacuum cleaner tank capacity | [30,38] |

| Thermal protection (against overheating) | Own elaboration based on catalogs of vacuum cleaner |

| Rubber protectors protecting furniture from knocking | [27] |

| Number of accessories included with the vacuum cleaner (suction tubes and nozzles) | [26] |

| Vacuum cleaner dust filter type | [26,27,28,29,30,31,38] |

| Suction hose (suction tube) length | [30] |

| Vacuum cleaner weight | Own elaboration based on catalogs of vacuum cleaner |

| Vacuum cleaner bag type | [26,27,30,31,38] |

| Vacuum cleaner dimensions | Own elaboration based on catalogs of vacuum cleaner |

| Vacuum cleaner under pressure control option in the operating handle | Own elaboration based on catalogs of vacuum cleaner |

| Vacuum cleaner wheel material type | Own elaboration based on catalogs of vacuum cleaner |

| Electric brush socket | [27] |

| Vacuum cleaner appearance/design | Own elaboration based on catalogs of vacuum cleaner |

| Vacuum cleaner on/off switch type | [26] |

| Suction hose (suction tube) diameter | [28,38] |

| Life Cycle Stage | Value | Source |

|---|---|---|

| Raw material (main part and accessories) | ||

| polyvinylchloride, bulk polymerized | 341.34 g | own estimate based on data from the Ecoinvent v3.10 database and [27] |

| polypropylene, granulate | 1104.85 g | own estimate based on data from the Ecoinvent v3.10 database and [27] |

| polystyrene, general purpose | 1107.68 g | According to data from the Ecoinvent v3.10 database |

| polyethylene, high density, granulate | 249.51 g | own estimate based on data from the Ecoinvent v3.10 database and [27] |

| polyethylene, low density, granulate | 29.00 g | according to data from the Ecoinvent v3.10 database |

| aluminum | 375.27 g | own estimate based on data from the Ecoinvent v3.10 database and [27] |

| brass | 19.96 g | own estimate based on data from the Ecoinvent v3.10 database and [27] |

| copper | 176.66 g | own estimate based on data from the Ecoinvent v3.10 database and [27] |

| formaldehyde | 22.91 g | according to data from the Ecoinvent v3.10 database |

| steel, low-alloyed, hot-rolled | 640.75 g | own estimate based on data from the Ecoinvent v3.10 database and [27] |

| vinyl, acetate | 414.20 g | own estimate based on data from the Ecoinvent v3.10 database and [27] |

| packaging (folding boxes, cardboard, polyethylene bags) | 901.27 g | own estimate based on data from the Ecoinvent v3.10 database and [27] |

| Production | ||

| electricity (injection molding, metal stamping, screen printing) | 14.19 kWh | according to data from the Ecoinvent v3.10 database |

| heat, central or small-scale natural gas (injection molding, metal stamping) | 17.13 kWh | according to data from the Ecoinvent v3.10 database |

| tap water | 12.97 l | own estimate based on data from the Ecoinvent v3.10 database and [27] |

| Transport | ||

| transport, freight train | km | according to data from the Ecoinvent v3.10 database |

| transport, freight, light commercial vehicle | km | according to data from the Ecoinvent v3.10 database |

| transport, freight, lorry, unspecified | km | according to data from the Ecoinvent v3.10 database |

| transport, freight, sea, container ship | km | according to data from the Ecoinvent v3.10 database |

| Use | ||

| electricity | 320 kWh | directive 2009/125/EC of the European Parliament and of the Council with regard to ecodesign requirements for vacuum cleaners |

| three dimensions of the air filter | 380 g | self-assessment based on [27] |

| End of Life | ||

| recycling (metals, plastics, packaging) | 2845.00 g | self-assessment based on [27] |

| incineration with energy recovery (plastics, packaging) | 1367.00 g | self-assessment based on [27] |

| landfilling (metals, plastics, packaging) | 1545.00 g | self-assessment based on [27] |

| Life Cycle Stage | B1 | B2 | B3 | B4 | B5 | B6 | B7 |

|---|---|---|---|---|---|---|---|

| Raw material (main part and accessories) | |||||||

| polyvinylchloride, bulk polymerized | 341.34 | 341.34 | 307.21 | 341.34 | 341.34 | 337.93 | 344.75 |

| polypropylene, granulate | 1104.85 | 1104.85 | 1126.95 | 1104.85 | 1104.85 | 1071.7 | 1138 |

| polystyrene, general purpose | 1107.68 | 1107.68 | 1129.83 | 1107.68 | 1107.68 | 1096.6 | 1118.76 |

| polyethylene, high density, granulate | 249.51 | 249.51 | 249.51 | 237.03 | 261.99 | 237.03 | 261.99 |

| polyethylene, low density, granulate | 29 | 29 | 29.87 | 27.55 | 30.45 | 27.55 | 30.45 |

| Aluminum | 371.52 | 379.02 | 386.53 | 375.27 | 375.27 | 337.74 | 412.8 |

| Brass | 19.76 | 20.16 | 20.56 | 18.96 | 20.96 | 19.36 | 20.56 |

| copper | 174.89 | 178.43 | 181.96 | 167.83 | 185.49 | 171.36 | 181.96 |

| formaldehyde | 22.91 | 22.91 | 22.91 | 22.91 | 22.91 | 22.91 | 22.91 |

| steel, low-alloyed, hot rolled | 653.57 | 627.94 | 647.16 | 640.75 | 640.75 | 621.53 | 659.97 |

| vinyl, acetate | 414.2 | 414.2 | 414.2 | 414.2 | 414.2 | 414.2 | 414.2 |

| packaging (folding boxes, cardboard, polyethylene bags) | 892.26 | 910.28 | 901.27 | 901.27 | 901.27 | 874.23 | 928.31 |

| Production | |||||||

| electricity (injection molding, metal stamping, screen printing) | 14.19 | 14.19 | 14.19 | 13.76 | 14.62 | 13.48 | 14.9 |

| heat, central or small-scale natural gas (injection molding, metal stamping) | 16.96 | 17.3 | 16.96 | 16.62 | 17.64 | 17.13 | 17.13 |

| tap water | 12.84 | 13.10 | 12.97 | 12.58 | 13.36 | 12.84 | 13.10 |

| Transport | |||||||

| transport, freight train | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 |

| transport, freight, light commercial vehicle | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

| transport, freight, lorry, unspecified | 2.64 | 2.58 | 2.61 | 2.53 | 2.69 | 2.53 | 2.69 |

| transport, freight, sea, container ship | 4.95 | 4.95 | 4.95 | 4.95 | 4.95 | 4.95 | 4.95 |

| Use | |||||||

| electricity | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 |

| three dimensions of an air filter | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

| End of Life | |||||||

| recycling (metals, plastics, packaging) | 2816.55 | 2873.45 | 2816.55 | 2674.30 | 3015.70 | 2475.15 | 3214.85 |

| incineration with energy recovery (plastics, packaging) | 1339.66 | 1394.34 | 1380.67 | 1367.00 | 1367.00 | 1339.66 | 1394.34 |

| landfilling (metals, plastics, packaging) | 1529.55 | 1560.45 | 1529.55 | 1545.00 | 1545.00 | 1498.65 | 1591.35 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| EI | 0.61 | 0.93 | 1.26 | 0.88 | 1.21 | 1.54 | 1.16 | 1.49 | 1.82 | 0.63 |

| EI (%) | 613.26 | 92.59 | 125.62 | 88.14 | 121.17 | 154.20 | 116.04 | 149.07 | 182.11 | 63.41 |

| Cost (€) | 115.00 | 138.38 | 162.69 | 135.10 | 159.41 | 183.73 | 155.64 | 179.95 | 327.50 | 116.90 |

| ck | 0.19 | 1.49 | 1.30 | 1.53 | 1.32 | 1.19 | 1.34 | 1.21 | 1.80 | 1.84 |

| k | 1.00 | 0.91 | 0.81 | 0.92 | 0.82 | 0.73 | 0.84 | 0.74 | 0.16 | 0.99 |

| E | 1.63 | 0.98 | 0.65 | 1.04 | 0.68 | 0.47 | 0.72 | 0.50 | 0.09 | 1.57 |

| d | 0.69 | 0.05 | 0.03 | 0.52 | 0.03 | 0.02 | 0.04 | 0.02 | 0.00 | 0.68 |

| c | 0.90 | 0.21 | 0.32 | 0.19 | 0.31 | 0.37 | 0.29 | 0.37 | 0.05 | 0.03 |

| Rt | 0.70 | 0.60 | 0.78 | 0.70 | 0.75 | 0.93 | 0.72 | 0.90 | 0.99 | 0.59 |

| Re | 0.72 | 0.95 | 0.87 | 1.03 | 0.88 | 0.81 | 0.89 | 0.82 | 0.69 | 1.15 |

| Rd | 0.71 | 0.77 | 0.82 | 0.86 | 0.81 | 0.87 | 0.81 | 0.86 | 0.84 | 0.87 |

| Rank | 54 | 53 | 35 | 18 | 41 | 8 | 44 | 21 | 22 | 1 |

| Examples of Research with LCC | Mentioned Limitations of LCC | Source | |

|---|---|---|---|

| Traditional use of LCC | Excel and MATLAB R2021a based method and tool supporting the development of integrated product service offerings via LCC where interchangeability between products and services is applied | Lack of widespread use of LCC in practice | [10] |

| Using the LCC method to improve life cycle management (LCM) | Despite the large number of tailored, case-specific methods, LCC is not widely used, and when it is used, it is not at the level of sophistication described in the published literature because practitioners tailor LCC methods individually | [11] | |

| Approximate life cycle costing to help evaluate different product concepts in the early stages of design | Important product criteria determined by statistical analysis, neural network algorithm supports LCC estimation | Lack of detailed information in the early stages of product development and time for detailed LCC for different design concepts | [83] |

| Learning algorithms trained to use known characteristics of existing products to approximate the life cycle cost of new products without having to define new LCC models | Conflicting requirements in the early stages of product development, lack of detailed information, and limited ability to make quick decisions due to the need to develop parametric LCC models for a wide range of concepts or requirements | [82] | |

| Predictive models for product LCC during conceptual design | Developed artificial neural network (ANN) model for predicting product LCC | The need to develop extensive LCC models, lack of access to detailed information that generates a lack of practicality in the use of LCC | [80] |

| Empirical Study on the Performance of Nonparametric Regression Models for LCC Estimation | Difficulty predicting costs for a large number of product prototypes | [13] | |

| LCC-based decision support models | Integration of LCC and LCA to determine economic and environmental production strategies, along with integration of monetary valuation of life cycle assessment (MLCA) to aggregate environmental impact categories | Cost flows in LCC do not always have a direct relationship with physical flows, where it is difficult to directly integrate LCC with LCA | [10,84] |

| Examples of Research with S-LCA | Mentioned Limitations of S-LCA | Source | |

|---|---|---|---|

| Literature Review on S-LCA | Narrative review of works from 2006–2020 according to the Web of Science and Scopus databases | There is a lack of attention paid to society and value chain actors and final consumer stakeholders | [88] |

| Bibliometric analysis of works from 2003–2018 | The difficulty in quantifying data and the subjective nature of some social indicators | [14] | |

| Development of a new S-LCA framework | S-LCA framework by systematic mapping, expert opinion gathering, evaluation by novice user survey | The difficulty in quantifying data and the subjective nature of some social indicators | [85] |

| S-LCA Case Study Analysis | Conceptual analyses of how to define a product system and the implications of their different approaches, including a classification of the criteria used | Conceptual analyzes of how to define a product system and the implications of their different approaches, including a classification of the criteria used | [87] |

| Technology Benchmarking | The complexity of social indicators means that there is a lack of guidance on which impact categories to include, including how to measure some effects | [15] | |

| Creating groups of social criteria within S-LCA | Assessment of the quality of the social criterion on a seven-point Likert scale by stakeholders | Most social impact indicators are difficult to quantify | [89] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siwiec, D.; Pacana, A. Life Cycle-Based Product Sustainability Assessment Employing Quality and Cost. Sustainability 2025, 17, 3430. https://doi.org/10.3390/su17083430

Siwiec D, Pacana A. Life Cycle-Based Product Sustainability Assessment Employing Quality and Cost. Sustainability. 2025; 17(8):3430. https://doi.org/10.3390/su17083430

Chicago/Turabian StyleSiwiec, Dominika, and Andrzej Pacana. 2025. "Life Cycle-Based Product Sustainability Assessment Employing Quality and Cost" Sustainability 17, no. 8: 3430. https://doi.org/10.3390/su17083430

APA StyleSiwiec, D., & Pacana, A. (2025). Life Cycle-Based Product Sustainability Assessment Employing Quality and Cost. Sustainability, 17(8), 3430. https://doi.org/10.3390/su17083430