A Critical Review of Life Cycle Assessments on Bioenergy Technologies: Methodological Choices, Limitations, and Suggestions for Future Studies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Life Cycle Assessment

2.2. Literature Search Strategy and Refining

2.3. Structure of This Review

3. Review

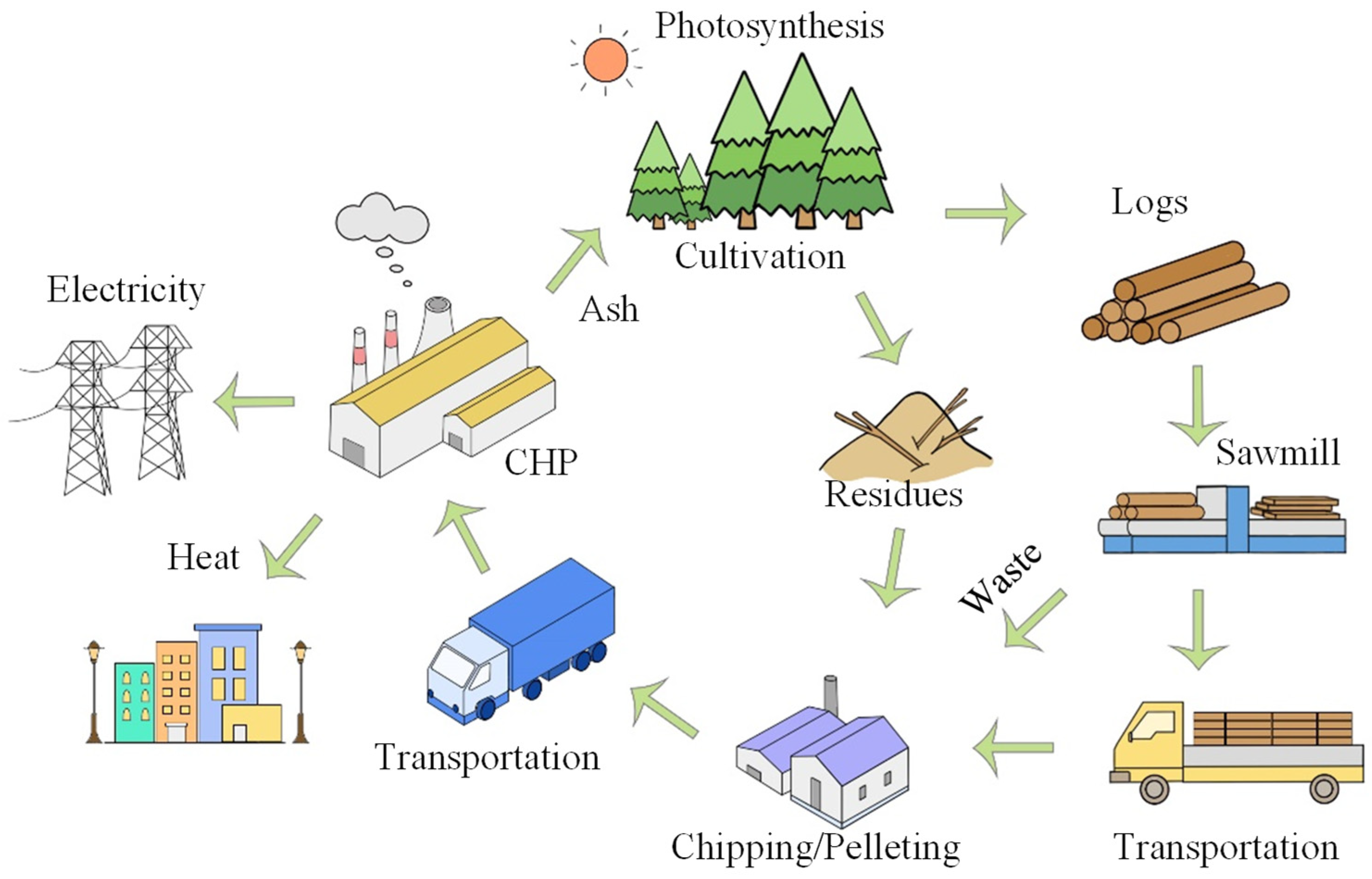

3.1. Biomass Combustion for Heat Supply

3.2. Biomass Power Generation

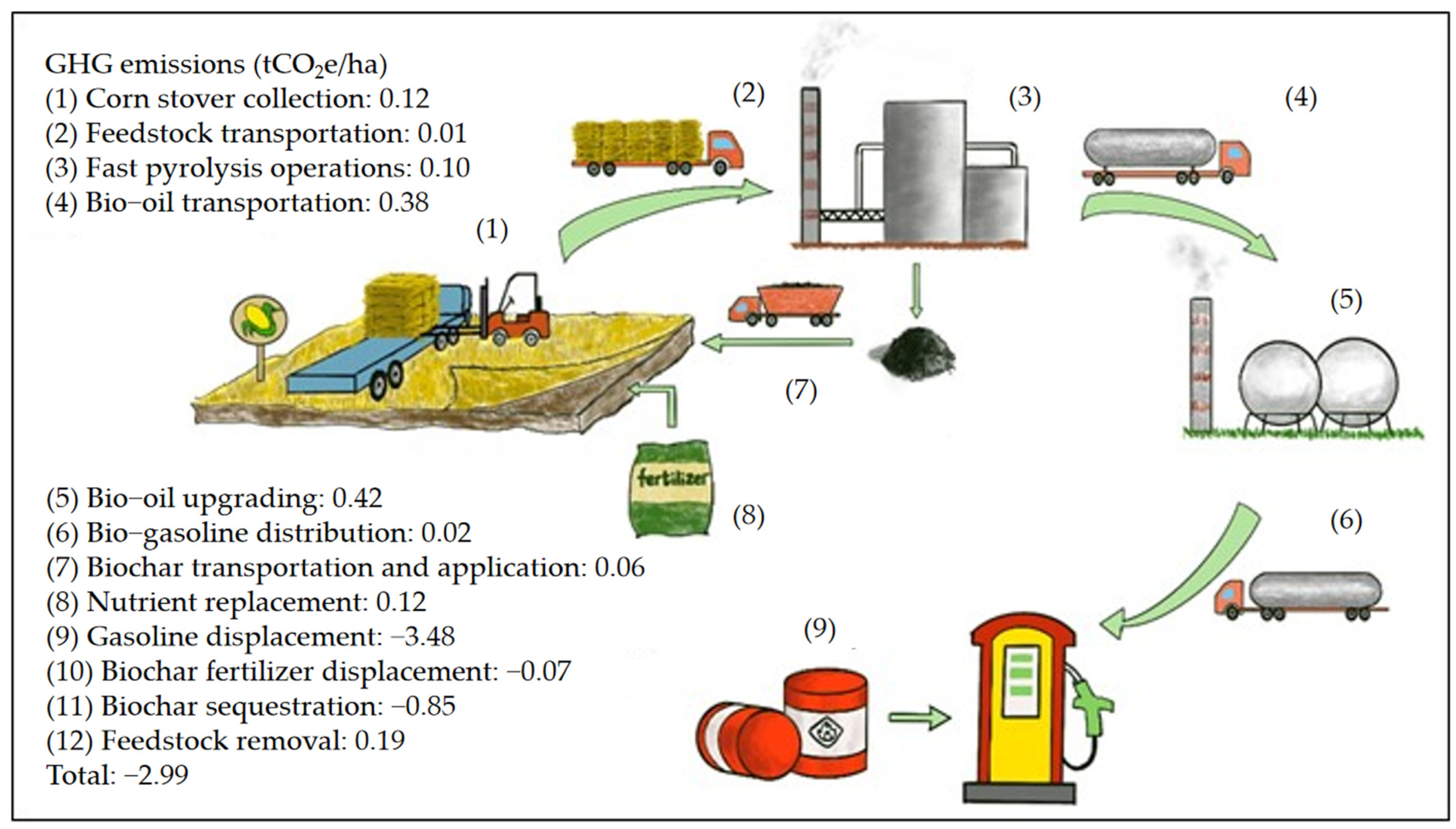

3.3. Biofuels

4. Discussion

4.1. Synthesis

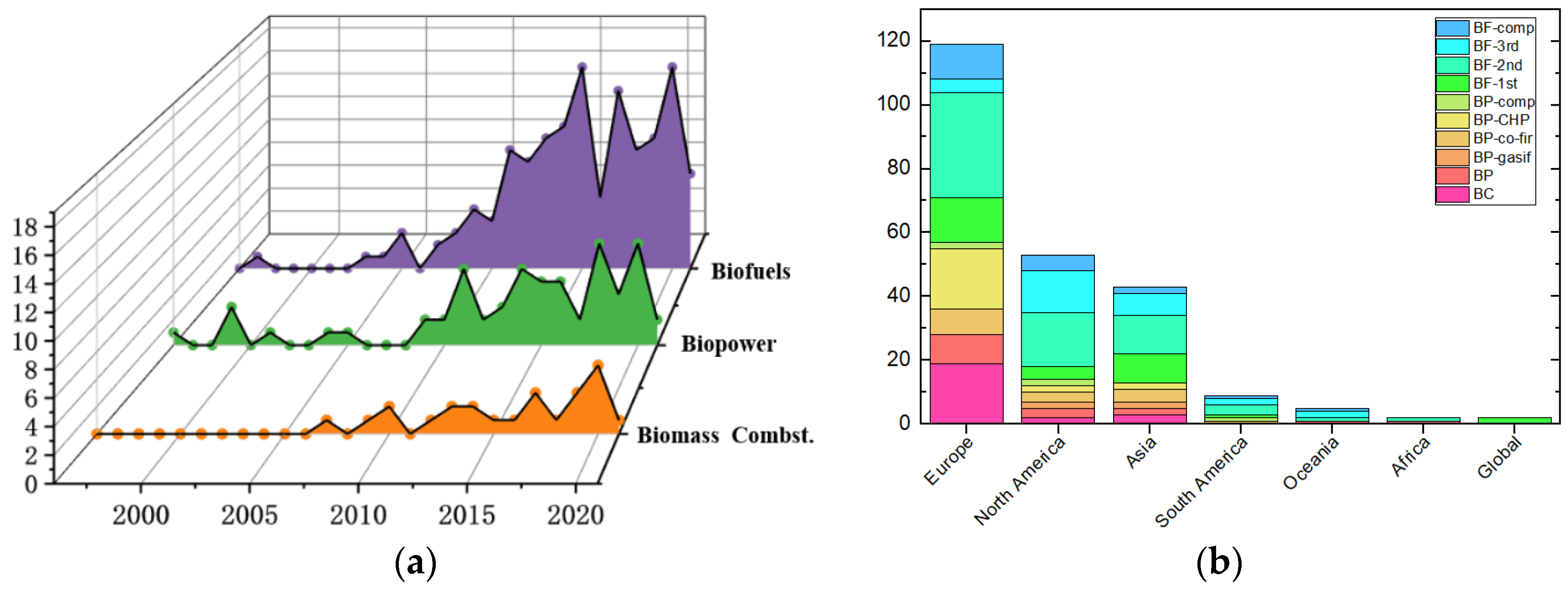

4.1.1. Temporal and Geographical Distribution of Reviewed Bioenergy LCAs

4.1.2. Scales of LCAs

4.1.3. Functional Units

4.1.4. System Boundaries

4.1.5. Impact Categories

4.2. Limitations and Difficulties of Current LCA Studies on Bioenergy Technologies

4.2.1. Absence of Site-Specific Data

4.2.2. Consequential and System-Expansion Approaches

4.2.3. Comparability Between LCAs Related to Functional Units

4.2.4. System Boundary Incomprehensiveness

4.2.5. Impact Categories Beyond GHG and Energy

4.2.6. Absence of LCAs on the Prospective Biotechnologies

4.2.7. Dependence of Life Cycle Assessment Software on Databases and Regional Changes

4.3. Recommendations and Future Research

4.3.1. Adoption of Site-Specific Data

4.3.2. Functional Unit

4.3.3. System Boundaries

4.3.4. Impact Categories

4.3.5. Uncertainty Analysis

4.3.6. General Guidelines for Future Bioenergy LCA

4.3.7. Fourth-Generation Biofuels

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| GHG | Greenhouse gas |

| LCA | Life cycle assessment |

| FU | Functional unit |

| LCI | Life cycle inventory |

| CLCA | Consequential LCA |

| LU | Land use |

| ES | Ecosystem services |

| CHP | Combined heat and power |

| GWP | Global warming potential |

| LUC | Land use change |

| CCS | Carbon capture and storage |

| CCU | Carbon capture and utilization |

References

- Economics, B.E. BP Energy Outlook: 2020 Edition. Available online: https://www.bp.com/en/global/corporate/energy-economics/energy-outlook.html (accessed on 4 July 2024).

- IPCC. Summary for Policymakers. In Global Warming of 1.5 °C; World Meteorological Organization: Geneva, Switzerland, 2018; p. 32. [Google Scholar]

- Liew, W.H.; Hassim, M.H.; Ng, D.K.S. Review of evolution, technology and sustainability assessments of biofuel production. J. Clean. Prod. 2014, 71, 11–29. [Google Scholar] [CrossRef]

- Marvuglia, A.; Benetto, E.; Rege, S.; Jury, C. Modelling approaches for consequential life-cycle assessment (C-LCA) of bioenergy: Critical review and proposed framework for biogas production. Renew. Sustain. Energy Rev. 2013, 25, 768–781. [Google Scholar] [CrossRef]

- Liu, W.; Yu, Z.; Xie, X.; von Gadow, K.; Peng, C. A critical analysis of the carbon neutrality assumption in life cycle assessment of forest bioenergy systems. Environ. Rev. 2018, 26, 93–101. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Aghbashlo, M.; Tabatabaei, M. Life cycle assessment of bioenergy product systems: A critical review. E-Prime-Adv. Electr. Eng. Electron. Energy 2021, 1, 100015. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. Life Cycle Assessment of construction materials: Methodologies, applications and future directions for sustainable decision-making. Case Stud. Constrc. Mat. 2023, 19, e02326. [Google Scholar] [CrossRef]

- Roos, A.; Ahlgren, S. Consequential life cycle assessment of bioenergy systems—A literature review. J. Clean. Prod. 2018, 189, 358–373. [Google Scholar] [CrossRef]

- Hijazi, O.; Munro, S.; Zerhusen, B.; Effenberger, M. Review of life cycle assessment for biogas production in Europe. Renew. Sustain. Energy Rev. 2016, 54, 1291–1300. [Google Scholar] [CrossRef]

- Lazarevic, D.; Martin, M. Life cycle assessments, carbon footprints and carbon visions: Analysing environmental systems analyses of transportation biofuels in Sweden. J. Clean. Prod. 2016, 137, 249–257. [Google Scholar] [CrossRef]

- Liu, H.; Huang, Y.; Yuan, H.; Yin, X.; Wu, C. Life cycle assessment of biofuels in China: Status and challenges. Renew. Sustain. Energy Rev. 2018, 97, 301–322. [Google Scholar] [CrossRef]

- O’Keeffe, S.; Majer, S.; Bezama, A.; Thrän, D. When considering no man is an island—Assessing bioenergy systems in a regional and LCA context: A review. Int. J. Life Cycle Assess. 2016, 21, 885–902. [Google Scholar] [CrossRef]

- Kwon, H.; Hawkins, T.R.; Zaimes, G.G.; Infante, J.; Kite-Powell, H.L.; Stekoll, M.S.; Roberson, L.; Zotter, B.; Augyte, S.; Rocheleau, G.; et al. Life-cycle analysis of offshore macroalgae production systems in the United States. Algal. Res. 2024, 82, 103654. [Google Scholar] [CrossRef]

- Menten, F.; Chèze, B.; Patouillard, L.; Bouvart, F. A review of LCA greenhouse gas emissions results for advanced biofuels: The use of meta-regression analysis. Renew. Sustain. Energy Rev. 2013, 26, 108–134. [Google Scholar] [CrossRef]

- Gaudreault, C.; Wigley, T.B.; Margni, M.; Verschuyl, J.; Vice, K.; Titus, B. Addressing biodiversity impacts of land use in life cycle assessment of forest biomass harvesting. Wiley Interdiscip. Rev. Energy Environ. 2016, 5, 670–683. [Google Scholar] [CrossRef]

- Maia de Souza, D.; Lopes, G.R.; Hansson, J.; Hansen, K. Ecosystem services in life cycle assessment: A synthesis of knowledge and recommendations for biofuels. Ecosyst. Serv. 2018, 30, 200–210. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Yan, B. The hotspots of life cycle assessment for bioenergy: A review by social network analysis. Sci. Total Environ. 2018, 625, 1301–1308. [Google Scholar] [CrossRef]

- Shakelly, N.; Pérez-Cardona, J.R.; Deng, S.; Maani, T.; Li, Z.; Sutherland, J.W. Comparative Life Cycle Assessment of Bioethanol Production from Different Generations of Biomass and Waste Feedstocks. Procedia CIRP 2023, 116, 630–635. [Google Scholar] [CrossRef]

- Krogh, A.; Junginger, M.; Shen, L.; Grue, J.; Pedersen, T.H. Climate change impacts of bioenergy technologies: A comparative consequential LCA of sustainable fuels production with CCUS. Sci. Total Environ. 2024, 940, 173660. [Google Scholar] [CrossRef]

- Ketzer, F.; Skarka, J.; Rösch, C. Critical Review of Microalgae LCA Studies for Bioenergy Production. BioEnergy Res. 2017, 11, 95–105. [Google Scholar] [CrossRef]

- Quinn, J.C.; Davis, R. The potentials and challenges of algae based biofuels: A review of the techno-economic, life cycle, and resource assessment modeling. Bioresour. Technol. 2015, 184, 444–452. [Google Scholar] [CrossRef]

- Patel, M.; Zhang, X.; Kumar, A. Techno-economic and life cycle assessment on lignocellulosic biomass thermochemical conversion technologies: A review. Renew. Sustain. Energy Rev. 2016, 53, 1486–1499. [Google Scholar] [CrossRef]

- Muazu, R.I.; Borrion, A.L.; Stegemann, J.A. Life cycle assessment of biomass densification systems. Biomass Bioenergy 2017, 107, 384–397. [Google Scholar] [CrossRef]

- Ali, S.S.; Abdelkarim, E.A.; Elsamahy, T.; Al-Tohamy, R.; Li, F.; Kornaros, M.; Zuorro, A.; Zhu, D.; Sun, J. Bioplastic production in terms of life cycle assessment: A state-of-the-art review. Environ. Sci. Ecotechnol. 2023, 15, 100254. [Google Scholar] [CrossRef]

- McManus, M.C.; Taylor, C.M.; Mohr, A.; Whittaker, C.; Scown, C.D.; Borrion, A.L.; Glithero, N.J.; Yin, Y. Challenge clusters facing LCA in environmental decision-making—What we can learn from biofuels. Int. J. Life Cycle Assess. 2015, 20, 1399–1414. [Google Scholar] [CrossRef]

- Czyrnek-Delêtre, M.M.; Smyth, B.M.; Murphy, J.D. Beyond carbon and energy: The challenge in setting guidelines for life cycle assessment of biofuel systems. Renew. Energy 2017, 105, 436–448. [Google Scholar] [CrossRef]

- Agostini, A.; Giuntoli, J.; Marelli, L.; Amaducci, S. Flaws in the interpretation phase of bioenergy LCA fuel the debate and mislead policymakers. Int. J. Life Cycle Assess. 2019, 25, 17–35. [Google Scholar] [CrossRef]

- Pantis, A.; Nikoloudakis, C.; Tsoutsos, T. A Critical Review of Macroalgae Exploitation Pathways Implemented under the Scope of Life Cycle Assessment. ChemEngineering 2024, 8, 74. [Google Scholar] [CrossRef]

- Terlouw, T.; Bauer, C.; Rosa, L.; Mazzotti, M. Life cycle assessment of carbon dioxide removal technologies: A critical review. Energ. Environ. Sci. 2021, 14, 1701–1721. [Google Scholar] [CrossRef]

- Cespi, D.; Passarini, F.; Ciacci, L.; Vassura, I.; Castellani, V.; Collina, E.; Piazzalunga, A.; Morselli, L. Heating systems LCA: Comparison of biomass-based appliances. Int. J. Life Cycle Assess. 2013, 19, 89–99. [Google Scholar] [CrossRef]

- Lozano Miralles, J.A.; López García, R.; Palomar Carnicero, J.M.; Martínez, F.J.R. Comparative study of heat pump system and biomass boiler system to a tertiary building using the Life Cycle Assessment (LCA). Renew. Energy. 2020, 152, 1439–1450. [Google Scholar] [CrossRef]

- Solli, C.; Reenaas, M.; Strømman, A.H.; Hertwich, E.G. Life cycle assessment of wood-based heating in Norway. Int. J. Life Cycle Assess. 2009, 14, 517–528. [Google Scholar] [CrossRef]

- Caduff, M.; Huijbregts, M.A.J.; Koehler, A.; Althaus, H.J.; Hellweg, S. Scaling Relationships in Life Cycle Assessment. J. Ind. Ecol. 2014, 18, 393–406. [Google Scholar] [CrossRef]

- Caserini, S.; Livio, S.; Giugliano, M.; Grosso, M.; Rigamonti, L. LCA of domestic and centralized biomass combustion: The case of Lombardy (Italy). Biomass Bioenergy 2010, 34, 474–482. [Google Scholar] [CrossRef]

- Eriksson, O.; Finnveden, G.; Ekvall, T.; Björklund, A. Life cycle assessment of fuels for district heating: A comparison of waste incineration, biomass- and natural gas combustion. Energy Policy 2007, 35, 1346–1362. [Google Scholar] [CrossRef]

- Supasri, T.; Itsubo, N.; Gheewala, S.H.; Sampattagul, S. Life cycle assessment of maize cultivation and biomass utilization in northern Thailand. Sci. Rep. 2020, 10, 3516. [Google Scholar] [CrossRef]

- Kylili, A.; Christoforou, E.; Fokaides, P.A. Environmental evaluation of biomass pelleting using life cycle assessment. Biomass Bioenergy 2016, 84, 107–117. [Google Scholar] [CrossRef]

- Saba, S.; El Bachawati, M.; Malek, M. Cradle to grave Life Cycle Assessment of Lebanese biomass briquettes. J. Clean. Prod. 2020, 253, 119851. [Google Scholar] [CrossRef]

- Styles, D.; Börjesson, P.; D’Hertefeldt, T.; Birkhofer, K.; Dauber, J.; Adams, P.; Patil, S.; Pagella, T.; Pettersson, L.B.; Peck, P.; et al. Climate regulation, energy provisioning and water purification: Quantifying ecosystem service delivery of bioenergy willow grown on riparian buffer zones using life cycle assessment. Ambio 2016, 45, 872–884. [Google Scholar] [CrossRef] [PubMed]

- Tabata, T.; Okuda, T. Life cycle assessment of woody biomass energy utilization: Case study in Gifu Prefecture, Japan. Energy 2012, 45, 944–951. [Google Scholar] [CrossRef]

- Welfle, A.; Gilbert, P.; Thornley, P.; Stephenson, A. Generating low-carbon heat from biomass: Life cycle assessment of bioenergy scenarios. J. Clean. Prod. 2017, 149, 448–460. [Google Scholar] [CrossRef]

- Dyjakon, A.; den Boer, J.; Szumny, A.; den Boer, E. Local Energy Use of Biomass from Apple Orchards—An LCA Study. Sustainability 2019, 11, 1604. [Google Scholar] [CrossRef]

- Fantozzi, F.; Buratti, C. Life cycle assessment of biomass chains: Wood pellet from short rotation coppice using data measured on a real plant. Biomass Bioenergy 2010, 34, 1796–1804. [Google Scholar] [CrossRef]

- Quinteiro, P.; Tarelho, L.; Marques, P.; Martín-Gamboa, M.; Freire, F.; Arroja, L.; Dias, A.C. Life cycle assessment of wood pellets and wood split logs for residential heating. Sci. Total Environ. 2019, 689, 580–589. [Google Scholar] [CrossRef]

- Ruiz, D.; San Miguel, G.; Corona, B.; López, F.R. LCA of a multifunctional bioenergy chain based on pellet production. Fuel 2018, 215, 601–611. [Google Scholar] [CrossRef]

- Schonhoff, A.; Jablonowski, N.D.; Zapp, P. Environmental competitiveness evaluation by life cycle assessment for solid fuels generated from Sida hermaphrodita biomass. Biomass Bioenergy 2021, 145, 105966. [Google Scholar] [CrossRef]

- Benetto, E.; Popovici, E.-C.; Rousseaux, P.; Blondin, J. Life cycle assessment of fossil CO2 emissions reduction scenarios in coal-biomass based electricity production. Energ. Convers. Manag. 2004, 45, 3053–3074. [Google Scholar] [CrossRef]

- Gasol, C.M.; Gabarrell, X.; Anton, A.; Rigola, M.; Carrasco, J.; Ciria, P.; Rieradevall, J. LCA of poplar bioenergy system compared with Brassica carinata energy crop and natural gas in regional scenario. Biomass Bioenergy 2009, 33, 119–129. [Google Scholar] [CrossRef]

- Tsalidis, G.A.; Discha, F.E.; Korevaar, G.; Haije, W.; de Jong, W.; Kiel, J. An LCA-based evaluation of biomass to transportation fuel production and utilization pathways in a large port’s context. Int. J. Energy Environ. Eng. 2017, 8, 175–187. [Google Scholar] [CrossRef]

- Royo, J.; Sebastián, F.; García-Galindo, D.; Gómez, M.; Díaz, M. Large-scale analysis of GHG (greenhouse gas) reduction by means of biomass co-firing at country-scale: Application to the Spanish case. Energy 2012, 48, 255–267. [Google Scholar] [CrossRef]

- Sastre, C.M.; Carrasco, J.; Barro, R.; González-Arechavala, Y.; Maletta, E.; Santos, A.M.; Ciria, P. Improving bioenergy sustainability evaluations by using soil nitrogen balance coupled with life cycle assessment: A case study for electricity generated from rye biomass. Appl. Energy 2016, 179, 847–863. [Google Scholar] [CrossRef]

- Sebastián, F.; Royo, J.; Gómez, M. Cofiring versus biomass-fired power plants: GHG (Greenhouse Gases) emissions savings comparison by means of LCA (Life Cycle Assessment) methodology. Energy 2011, 36, 2029–2037. [Google Scholar] [CrossRef]

- Arteaga-Pérez, L.E.; Vega, M.; Rodríguez, L.C.; Flores, M.; Zaror, C.A.; Casas Ledón, Y. Life-Cycle Assessment of coal–biomass based electricity in Chile: Focus on using raw vs torrefied wood. Energy Sustain. Dev. 2015, 29, 81–90. [Google Scholar] [CrossRef]

- Nuss, P.; Gardner, K.H.; Jambeck, J.R. Comparative Life Cycle Assessment (LCA) of Construction and Demolition (C&D) Derived Biomass and U.S. Northeast Forest Residuals Gasification for Electricity Production. Environ. Sci. Technol. 2013, 47, 3463–3471. [Google Scholar] [CrossRef]

- Tsalidis, G.-A.; Joshi, Y.; Korevaar, G.; de Jong, W. Life cycle assessment of direct co-firing of torrefied and/or pelletised woody biomass with coal in The Netherlands. J. Clean. Prod. 2014, 81, 168–177. [Google Scholar] [CrossRef]

- Zaman, A.U. Comparative study of municipal solid waste treatment technologies using life cycle assessment method. Int. J. Environ. Sci. Technol. 2010, 7, 225–234. [Google Scholar] [CrossRef]

- Saldivar, R.P.; Bilal, M.; Hafiz, M.N. Life cycle assessment in wastewater treatment technology. Curr. Opin. Environ. Sci. Health 2020, 13, 80–84. [Google Scholar] [CrossRef]

- Hsien, H.K. Life cycle impact assessment of various waste conversion technologies. Waste Manag. 2009, 29, 1892–1900. [Google Scholar] [CrossRef]

- Hartmann, D.; Kaltschmitt, M. Electricity generation from solid biomass via co-combustion with coal. Biomass Bioenergy 1999, 16, 397–406. [Google Scholar] [CrossRef]

- Schakel, W.; Meerman, H.; Talaei, A.; Ramírez, A.; Faaij, A. Comparative life cycle assessment of biomass co-firing plants with carbon capture and storage. Appl. Energy 2014, 131, 441–467. [Google Scholar] [CrossRef]

- Zang, G.; Zhang, J.; Jia, J.; Lora, E.S.; Ratner, A. Life cycle assessment of power-generation systems based on biomass integrated gasification combined cycles. Renew. Energ. 2020, 149, 336–346. [Google Scholar] [CrossRef]

- Zhu, Y.; Liang, J.; Yang, Q.; Zhou, H.; Peng, K. Water use of a biomass direct-combustion power generation system in China: A combination of life cycle assessment and water footprint analysis. Renew. Sustain. Energy Rev. 2019, 115, 109396. [Google Scholar] [CrossRef]

- Tagliaferri, C.; Evangelisti, S.; Clift, R.; Lettieri, P. Life cycle assessment of a biomass CHP plant in UK: The Heathrow energy centre case. Chem. Eng. Res. Des. 2018, 133, 210–221. [Google Scholar] [CrossRef]

- Blengini, G.A.; Brizio, E.; Cibrario, M.; Genon, G. LCA of bioenergy chains in Piedmont (Italy): A case study to support public decision makers towards sustainability. Resour. Conserv. Recy. 2011, 57, 36–47. [Google Scholar] [CrossRef]

- De Menna, F.; Vittuari, M.; Molari, G. Impact evaluation of integrated food-bioenergy systems: A comparative LCA of peach nectar. Biomass Bioenergy 2015, 73, 48–61. [Google Scholar] [CrossRef]

- Tonini, D.; Hamelin, L.; Wenzel, H.; Astrup, T. Bioenergy Production from Perennial Energy Crops: A Consequential LCA of 12 Bioenergy Scenarios including Land Use Changes. Environ. Sci. Technol. 2012, 46, 13521–13530. [Google Scholar] [CrossRef] [PubMed]

- Khoshnevisan, B.; Tabatabaei, M.; Tsapekos, P.; Rafiee, S.; Aghbashlo, M.; Lindeneg, S.; Angelidaki, I. Environmental life cycle assessment of different biorefinery platforms valorizing municipal solid waste to bioenergy, microbial protein, lactic and succinic acid. Renew. Sustain. Energy Rev. 2020, 117, 109493. [Google Scholar] [CrossRef]

- Tabata, T.; Torikai, H.; Tsurumaki, M.; Genchi, Y.; Ukegawa, K. Life cycle assessment for co-firing semi-carbonized fuel manufactured using woody biomass with coal: A case study in the central area of Wakayama, Japan. Renew. Sustain. Energy Rev. 2011, 15, 2772–2778. [Google Scholar] [CrossRef]

- Maier, J.M.; Sowlati, T.; Salazar, J. Life cycle assessment of forest-based biomass for bioenergy: A case study in British Columbia, Canada. Resour. Conserv. Recycl. 2019, 146, 598–609. [Google Scholar] [CrossRef]

- Boschiero, M.; Cherubini, F.; Nati, C.; Zerbe, S. Life cycle assessment of bioenergy production from orchards woody residues in Northern Italy. J. Clean. Prod. 2016, 112, 2569–2580. [Google Scholar] [CrossRef]

- Luk, J.M.; Pourbafrani, M.; Saville, B.A.; MacLean, H.L. Ethanol or Bioelectricity? Life Cycle Assessment of Lignocellulosic Bioenergy Use in Light-Duty Vehicles. Environ. Sci. Technol. 2013, 47, 10676–10684. [Google Scholar] [CrossRef]

- Singh, B.; Guest, G.; Bright, R.M.; Strømman, A.H. Life Cycle Assessment of Electric and Fuel Cell Vehicle Transport Based on Forest Biomass. J. Ind. Ecol. 2014, 18, 176–186. [Google Scholar] [CrossRef]

- Tarighaleslami, A.H.; Ghannadzadeh, A.; Atkins, M.J.; Walmsley, M.R.W. Environmental life cycle assessment for a cheese production plant towards sustainable energy transition: Natural gas to biomass vs. natural gas to geothermal. J. Clean. Prod. 2020, 275, 122999. [Google Scholar] [CrossRef]

- Mohee, R.; Beeharry, R.P. Life cycle analysis of compost incorporated sugarcane bioenergy systems in Mauritius. Biomass Bioenergy 1999, 17, 73–83. [Google Scholar] [CrossRef]

- Weldu, Y.W.; Assefa, G.; Jolliet, O. Life cycle human health and ecotoxicological impacts assessment of electricity production from wood biomass compared to coal fuel. Appl. Energy 2017, 187, 564–574. [Google Scholar] [CrossRef]

- Havukainen, J.; Nguyen, M.T.; Väisänen, S.; Horttanainen, M. Life cycle assessment of small-scale combined heat and power plant: Environmental impacts of different forest biofuels and replacing district heat produced from natural gas. J. Clean. Prod. 2018, 172, 837–846. [Google Scholar] [CrossRef]

- Chary, K.; Aubin, J.; Guindé, L.; Sierra, J.; Blazy, J.-M. Cultivating biomass locally or importing it? LCA of biomass provision scenarios for cleaner electricity production in a small tropical island. Biomass Bioenergy 2018, 110, 1–12. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Syu, F.-S.; Chiueh, P.-T.; Lo, S.-L. Life cycle assessment of biochar cofiring with coal. Bioresour. Technol. 2013, 131, 166–171. [Google Scholar] [CrossRef]

- De Laurentiis, V.; Maier, S.; Horn, R.; Uusitalo, V.; Hiederer, R.; Chéron-Bessou, C.; Morais, T.; Grant, T.; Milà i Canals, L.; Sala, S. Soil organic carbon as an indicator of land use impacts in life cycle assessment. Int. J. Life Cycle Assess. 2024, 29, 1190–1208. [Google Scholar] [CrossRef]

- Ambaye, T.G.; Vaccari, M.; Bonilla-Petriciolet, A.; Prasad, S.; van Hullebusch, E.D.; Rtimi, S. Emerging technologies for biofuel production: A critical review on recent progress, challenges and perspectives. J. Environ. Manag. 2021, 290, 112627. [Google Scholar] [CrossRef]

- Babin, A.; Vaneeckhaute, C.; Iliuta, M.C. Potential and challenges of bioenergy with carbon capture and storage as a carbon-negative energy source: A review. Biomass Bioenergy 2021, 146, 105968. [Google Scholar] [CrossRef]

- Lecksiwilai, N.; Gheewala, S.H. Life cycle assessment of biofuels in Thailand: Implications of environmental trade-offs for policy decisions. Sustain. Prod. Consum. 2020, 22, 177–185. [Google Scholar] [CrossRef]

- Ekener, E.; Hansson, J.; Larsson, A.; Peck, P. Developing Life Cycle Sustainability Assessment methodology by applying values-based sustainability weighting—Tested on biomass based and fossil transportation fuels. J. Clean. Prod. 2018, 181, 337–351. [Google Scholar] [CrossRef]

- Gallejones, P.; Pardo, G.; Aizpurua, A.; del Prado, A. Life cycle assessment of first-generation biofuels using a nitrogen crop model. Sci. Total. Environ. 2015, 505, 1191–1201. [Google Scholar] [CrossRef] [PubMed]

- Gaglio, M.; Tamburini, E.; Lucchesi, F.; Aschonitis, V.; Atti, A.; Castaldelli, G.; Fano, E.A. Life Cycle Assessment of Maize-Germ Oil Production and the Use of Bioenergy to Mitigate Environmental Impacts: A Gate-To-Gate Case Study. Resources 2019, 8, 60. [Google Scholar] [CrossRef]

- Sawangkeaw, R.; Teeravitud, S.; Piumsomboon, P.; Ngamprasertsith, S. Biofuel production from crude palm oil with supercritical alcohols: Comparative LCA studies. Bioresour. Technol. 2012, 120, 6–12. [Google Scholar] [CrossRef] [PubMed]

- Humpenöder, F.; Schaldach, R.; Cikovani, Y.; Schebek, L. Effects of land-use change on the carbon balance of 1st generation biofuels: An analysis for the European Union combining spatial modeling and LCA. Biomass Bioenergy 2013, 56, 166–178. [Google Scholar] [CrossRef]

- Kauffman, N.; Hayes, D.; Brown, R. A life cycle assessment of advanced biofuel production from a hectare of corn. Fuel 2011, 90, 3306–3314. [Google Scholar] [CrossRef]

- Styles, D.; Gibbons, J.; Williams, A.P.; Stichnothe, H.; Chadwick, D.R.; Healey, J.R. Cattle feed or bioenergy? Consequential life cycle assessment of biogas feedstock options on dairy farms. GCB Bioenergy 2014, 7, 1034–1049. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Marvuglia, A.; Rege, S.; Benetto, E. Applying consequential LCA to support energy policy: Land use change effects of bioenergy production. Sci. Total. Environ. 2014, 472, 78–89. [Google Scholar] [CrossRef]

- Heller, M.C.; Keoleian, G.A.; Volk, T.A. Life cycle assessment of a willow bioenergy cropping system. Biomass Bioenergy 2003, 25, 147–165. [Google Scholar] [CrossRef]

- Suer, P.; Andersson-Sköld, Y. Biofuel or excavation?—Life cycle assessment (LCA) of soil remediation options. Biomass Bioenergy 2011, 35, 969–981. [Google Scholar] [CrossRef]

- Adhikari, B.; Pellegrino, J. Life-cycle assessment of five microalgae-to-biofuels processes of varying complexity. J. Renew. Sustain. Energy 2015, 7, 043136. [Google Scholar] [CrossRef]

- Beal, C.M.; Gerber, L.N.; Sills, D.L.; Huntley, M.E.; Machesky, S.C.; Walsh, M.J.; Tester, J.W.; Archibald, I.; Granados, J.; Greene, C.H. Algal biofuel production for fuels and feed in a 100-ha facility: A comprehensive techno-economic analysis and life cycle assessment. Algal Res. 2015, 10, 266–279. [Google Scholar] [CrossRef]

- Evans, J.M.; Wilkie, A.C. Life cycle assessment of nutrient remediation and bioenergy production potential from the harvest of hydrilla (Hydrilla verticillata). J. Environ. Manag. 2010, 91, 2626–2631. [Google Scholar] [CrossRef]

- Halleux, H.; Lassaux, S.; Renzoni, R.; Germain, A. Comparative life cycle assessment of two biofuels ethanol from sugar beet and rapeseed methyl ester. Int. J. Life Cycle Assess. 2008, 13, 184–190. [Google Scholar] [CrossRef]

- Yu, S.; Tao, J. Simulation-based life cycle assessment of energy efficiency of biomass-based ethanol fuel from different feedstocks in China. Energy 2009, 34, 476–484. [Google Scholar] [CrossRef]

- Gutiérrez Ortiz, F.J.; Alonso-Fariñas, B.; Campanario, F.J.; Kruse, A. Life cycle assessment of the Fischer-Tropsch biofuels production by supercritical water reforming of the bio-oil aqueous phase. Energy 2020, 210, 118648. [Google Scholar] [CrossRef]

- Roostaei, J.; Zhang, Y. Spatially Explicit Life Cycle Assessment: Opportunities and challenges of wastewater-based algal biofuels in the United States. Algal Res. 2017, 24, 395–402. [Google Scholar] [CrossRef]

- Dornburg, V.; Lewandowski, I.; Patel, M. Comparing the Land Requirements, Energy Savings, and Greenhouse Gas Emissions Reduction of Biobased Polymers and Bioenergy. J. Ind. Ecol. 2008, 7, 93–116. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Life cycle assessment of various cropping systems utilized for producing biofuels: Bioethanol and biodiesel. Biomass Bioenergy 2005, 29, 426–439. [Google Scholar] [CrossRef]

- Aguirre-Villegas, H.A.; Passos-Fonseca, T.H.; Reinemann, D.J.; Armentano, L.E.; Wattiaux, M.A.; Cabrera, V.E.; Norman, J.M.; Larson, R. Green cheese: Partial life cycle assessment of greenhouse gas emissions and energy intensity of integrated dairy production and bioenergy systems. J. Dairy Sci. 2015, 98, 1571–1592. [Google Scholar] [CrossRef]

- Muñoz, I.; del Mar Gómez, M.; Fernández-Alba, A.R. Life Cycle Assessment of biomass production in a Mediterranean greenhouse using different water sources: Groundwater, treated wastewater and desalinated seawater. Agric. Syst. 2010, 103, 1–9. [Google Scholar] [CrossRef]

- Murphy, F.; Devlin, G.; McDonnell, K. Forest biomass supply chains in Ireland: A life cycle assessment of GHG emissions and primary energy balances. Appl. Energy 2014, 116, 1–8. [Google Scholar] [CrossRef]

- Arpornpong, N.; Sabatini, D.A.; Khaodhiar, S.; Charoensaeng, A. Life cycle assessment of palm oil microemulsion-based biofuel. Int. J. Life Cycle Assess. 2015, 20, 913–926. [Google Scholar] [CrossRef]

- Winter, B.; Meys, R.; Bardow, A. Towards aromatics from biomass: Prospective Life Cycle Assessment of bio-based aniline. J. Clean. Prod. 2021, 290, 125818. [Google Scholar] [CrossRef]

- Grau, B.; Bernat, E.; Rita, P.; Jordi-Roger, R.; Antoni, R. Environmental life cycle assessment of rapeseed straight vegetable oil as self-supply agricultural biofuel. Renew. Energy 2013, 50, 142–149. [Google Scholar] [CrossRef]

- Lecksiwilai, N.; Gheewala, S.H.; Silalertruksa, T.; Mungkalasiri, J. LCA of biofuels in Thailand using Thai Ecological Scarcity method. J. Clean. Prod. 2017, 142, 1183–1191. [Google Scholar] [CrossRef]

- Nuss, P.; Gardner, K.H. Attributional life cycle assessment (ALCA) of polyitaconic acid production from northeast US softwood biomass. Int. J. Life Cycle Assess. 2012, 18, 603–612. [Google Scholar] [CrossRef]

- Bradley, T.; Maga, D.; Antón, S. Unified approach to Life Cycle Assessment between three unique algae biofuel facilities. Appl. Energy 2015, 154, 1052–1061. [Google Scholar] [CrossRef]

- Lardon, L.; Hélias, A.; Sialve, B.; Steyer, J.-P.; Bernard, O. Life-Cycle Assessment of Biodiesel Production from Microalgae. Environ. Sci. Technol. 2009, 43, 6475–6481. [Google Scholar] [CrossRef]

- Silva, A.G.; Carter, R.; Merss, F.L.M.; Corrêa, D.O.; Vargas, J.V.C.; Mariano, A.B.; Ordonez, J.C.; Scherer, M.D. Life cycle assessment of biomass production in microalgae compact photobioreactors. GCB Bioenergy 2013, 7, 184–194. [Google Scholar] [CrossRef]

- González-García, S.; Mola-Yudego, B.; Murphy, R.J. Life cycle assessment of potential energy uses for short rotation willow biomass in Sweden. Int. J. Life Cycle Assess. 2012, 18, 783–795. [Google Scholar] [CrossRef]

- Resurreccion, E.P.; Colosi, L.M.; White, M.A.; Clarens, A.F. Comparison of algae cultivation methods for bioenergy production using a combined life cycle assessment and life cycle costing approach. Bioresour. Technol. 2012, 126, 298–306. [Google Scholar] [CrossRef]

- Kesieme, U.; Pazouki, K.; Murphy, A.; Chrysanthou, A. Attributional life cycle assessment of biofuels for shipping: Addressing alternative geographical locations and cultivation systems. J. Environ. Manag. 2019, 235, 96–104. [Google Scholar] [CrossRef]

- Cherubini, F.; Jungmeier, G. LCA of a biorefinery concept producing bioethanol, bioenergy, and chemicals from switchgrass. Int. J. Life Cycle Assess. 2009, 15, 53–66. [Google Scholar] [CrossRef]

- Dias, G.M.; Ayer, N.W.; Kariyapperuma, K.; Thevathasan, N.; Gordon, A.; Sidders, D.; Johannesson, G.H. Life cycle assessment of thermal energy production from short-rotation willow biomass in Southern Ontario, Canada. Appl. Energy 2017, 204, 343–352. [Google Scholar] [CrossRef]

- Alvarenga, R.A.F.; Erb, K.-H.; Haberl, H.; Soares, S.R.; van Zelm, R.; Dewulf, J. Global land use impacts on biomass production—A spatial-differentiated resource-related life cycle impact assessment method. Int. J. Life Cycle Assess. 2015, 20, 440–450. [Google Scholar] [CrossRef]

- Prasara, A.J.; Gheewala, S.H.; Silalertruksa, T.; Pongpat, P.; Sawaengsak, W. Environmental and social life cycle assessment to enhance sustainability of sugarcane-based products in Thailand. Clean Technol. Environ. Policy 2019, 21, 1447–1458. [Google Scholar] [CrossRef]

- Cherubini, F.; Strømman, A.H. Life cycle assessment of bioenergy systems: State of the art and future challenges. Bioresour. Technol. 2011, 102, 437–451. [Google Scholar] [CrossRef]

- Lo Piano, S.; Benini, L. A critical perspective on uncertainty appraisal and sensitivity analysis in life cycle assessment. J. Ind. Ecol. 2020, 26, 763–781. [Google Scholar] [CrossRef]

- Peters, J.F.; Iribarren, D.; Dufour, J. Simulation and life cycle assessment of biofuel production via fast pyrolysis and hydroupgrading. Fuel 2015, 139, 441–456. [Google Scholar] [CrossRef]

- Albini, E.; Bacchi, D.; Ferrara, G.; Francini, G.; Galoppi, G.; Lombardi, L.; Pecorini, I.; Susini, C. Bioenergy recovery from waste: Comparison of different treatment scenarios by LCA. Energy Procedia 2018, 148, 34–41. [Google Scholar] [CrossRef]

- Sills, D.L.; Paramita, V.; Franke, M.J.; Johnson, M.C.; Akabas, T.M.; Greene, C.H.; Tester, J.W. Quantitative Uncertainty Analysis of Life Cycle Assessment for Algal Biofuel Production. Environ. Sci. Technol. 2012, 47, 687–694. [Google Scholar] [CrossRef]

- Lima, R.S.; de Azevedo Caldeira-Pires, A.; Cardoso, A.N. Uncertainty Analysis in Life Cycle Assessments Applied to Biorefineries Systems: A Critical Review of the Literature. Process. Integr. Optim. Sustain. 2020, 4, 1–13. [Google Scholar] [CrossRef]

- Rafaschieri, A.; Rapaccini, M.; Manfrida, G. Life cycle assessment of electricity production from poplar energy crops compared with conventional fossil fuels. Energy Convers. Manag. 1999, 40, 1477–1493. [Google Scholar] [CrossRef]

- Salas, D.A.; Boero, A.J.; Ramirez, A.D. Life cycle assessment of bioenergy with carbon capture and storage: A review. Renew. Sustain. Energy Rev. 2024, 199, 114458. [Google Scholar] [CrossRef]

- Ashokkumar, V.; Chandramughi, V.P.; Kumar, G.; Ngamcharussrivichai, C.; Piechota, G.; Igliński, B.; Kothari, R.; Wei-Hsin, C. Advancements in lignocellulosic biomass: A critical appraisal of fourth-generation biofuels and value-added bioproduct. Fuel 2024, 365, 0016–2361. [Google Scholar] [CrossRef]

- Cavelius, P.; Engelhart-Straub, S.; Mehlmer, N.; Lercher, J.; Awad, D.; Brück, T. The potential of biofuels from first to fourth generation. PLoS Biol. 2023, 21, e3002063. [Google Scholar] [CrossRef]

- Shokravi, H.; Heidarrezaei, M.; Shokravi, Z.; Ong, H.C.; Lau, W.J.; Din, M.F.M.; Ismail, A.F. Fourth generation biofuel from genetically modified algal biomass for bioeconomic development. J. Biotechnol. 2022, 360, 23–36. [Google Scholar] [CrossRef]

- Padder, S.A.; Khan, R.; Rather, R.A. Biofuel generations: New insights into challenges and opportunities in their microbe-derived industrial production. Biomass Bioenergy 2024, 185, 107220. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Tong, R.; Zhai, Q.; Lyu, G.; Li, Y. A Critical Review of Life Cycle Assessments on Bioenergy Technologies: Methodological Choices, Limitations, and Suggestions for Future Studies. Sustainability 2025, 17, 3415. https://doi.org/10.3390/su17083415

Wang K, Tong R, Zhai Q, Lyu G, Li Y. A Critical Review of Life Cycle Assessments on Bioenergy Technologies: Methodological Choices, Limitations, and Suggestions for Future Studies. Sustainability. 2025; 17(8):3415. https://doi.org/10.3390/su17083415

Chicago/Turabian StyleWang, Kan, Ruiqing Tong, Qiang Zhai, Guomin Lyu, and Yongsheng Li. 2025. "A Critical Review of Life Cycle Assessments on Bioenergy Technologies: Methodological Choices, Limitations, and Suggestions for Future Studies" Sustainability 17, no. 8: 3415. https://doi.org/10.3390/su17083415

APA StyleWang, K., Tong, R., Zhai, Q., Lyu, G., & Li, Y. (2025). A Critical Review of Life Cycle Assessments on Bioenergy Technologies: Methodological Choices, Limitations, and Suggestions for Future Studies. Sustainability, 17(8), 3415. https://doi.org/10.3390/su17083415