Compost with High Soil Conditioning Potential Obtained by Composting Using a Portable and Low-Cost System

Abstract

1. Introduction

2. Materials and Methods

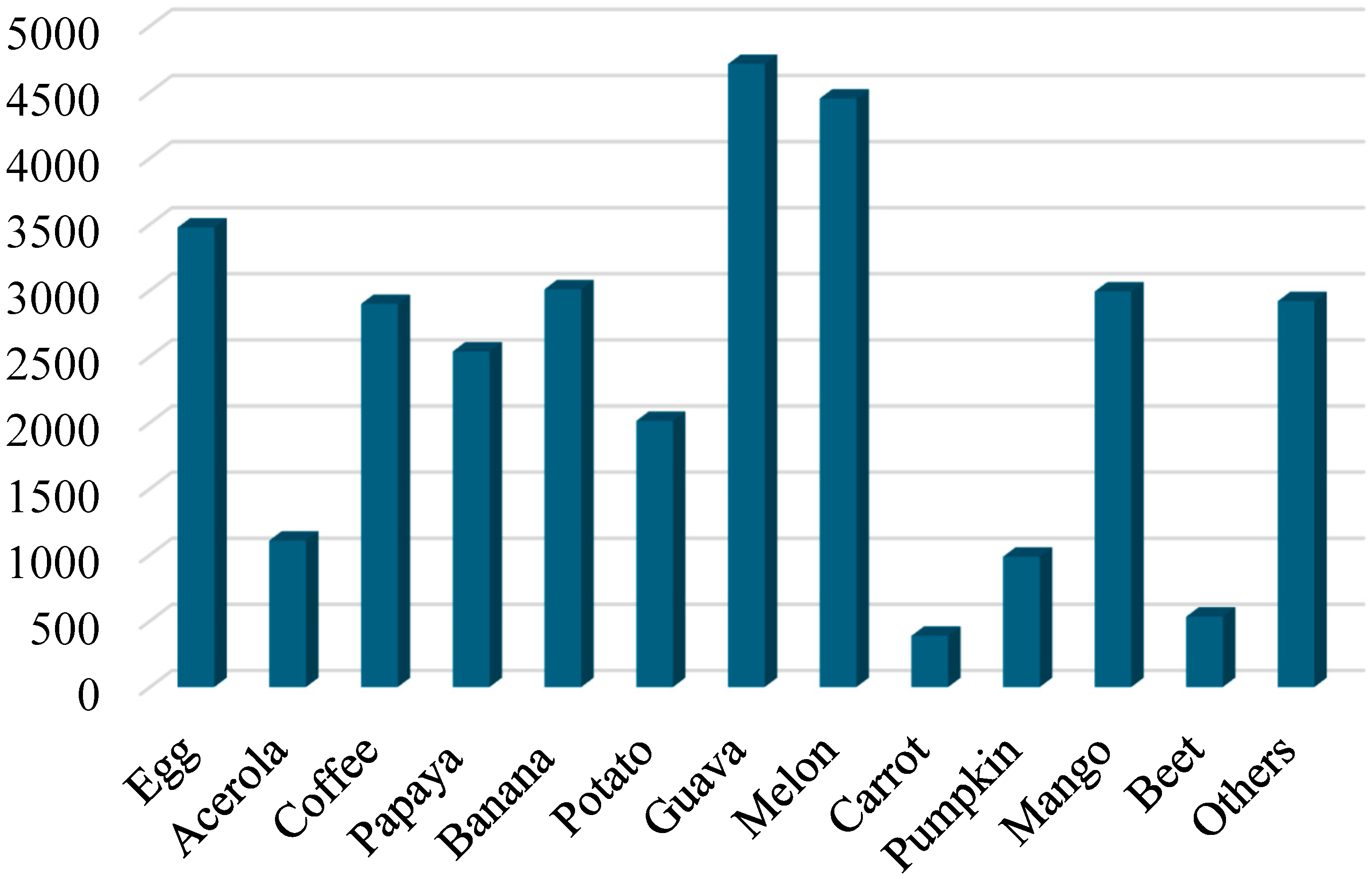

2.1. Collection of Organic Matter

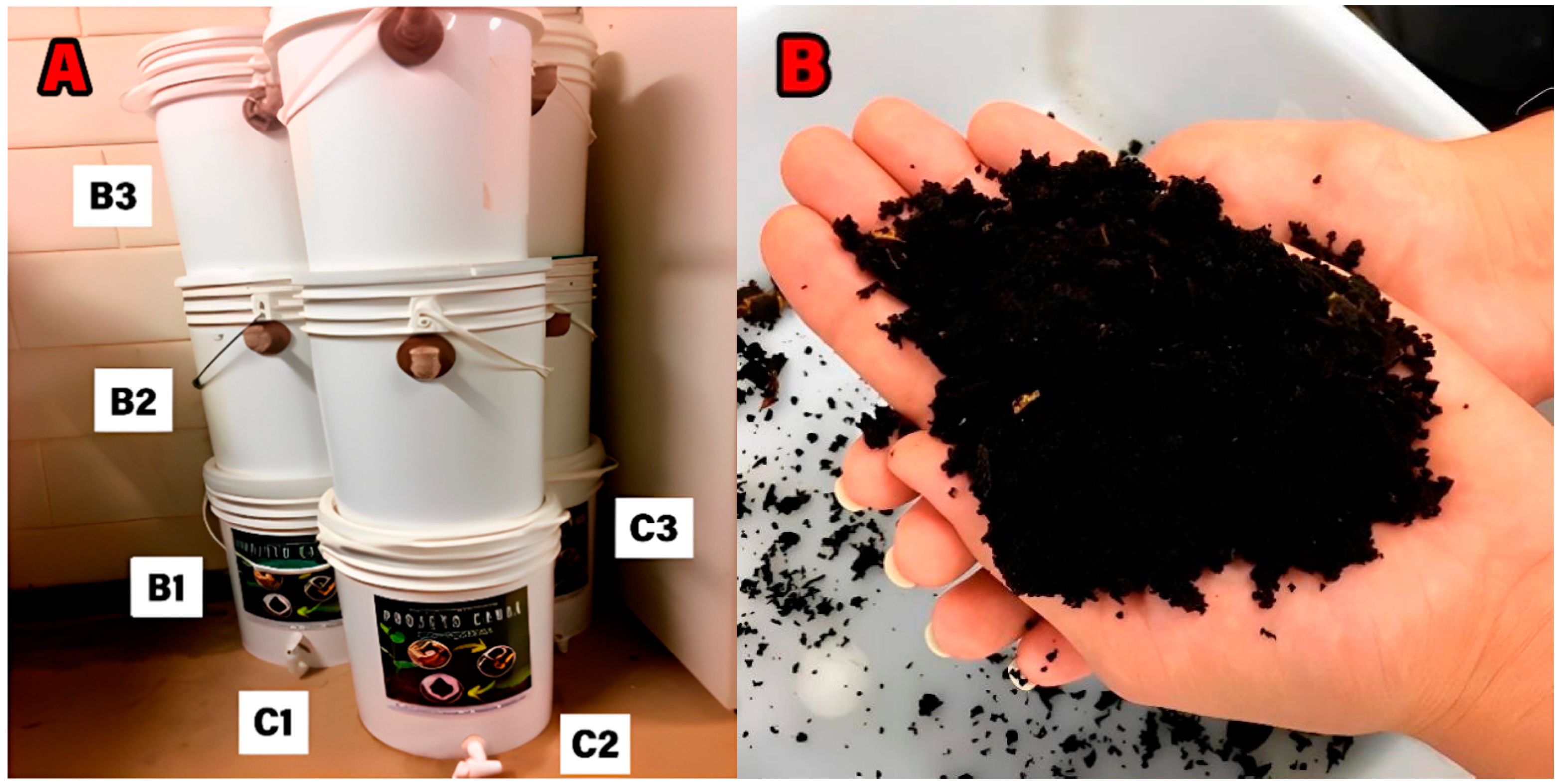

2.2. Production of Organic Compost

2.3. Mass Balance and Yield

2.4. Physical and Chemical Analysis

2.4.1. Sample Preparation

2.4.2. pH CaCl2 0.01 mol.L−1

2.4.3. Physicochemical Parameters Associated with Organic Matter

2.4.4. Macro- and Micronutrients

2.4.5. Heavy Metals

2.4.6. Fecal Coliforms

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brown, D.P. Garbage: How population, landmass, and development interact with culture in the production of waste. Resour. Conserv. Recycl. 2015, 98, 41–54. [Google Scholar] [CrossRef]

- Das, S.; Lee, S.H.; Kumar, P.; Kim, K.H.; Lee, S.S.; Bhattacharya, S.S. Solid waste management: Scope and the challenge of sustainability. J. Clean. Prod. 2019, 228, 658–678. [Google Scholar] [CrossRef]

- Weligama Thuppahige, R.T.; Gheewala, S.H.; Babel, S. Environmental impact of organic fraction of municipal solid waste treatment by composting in Sri Lanka. J. Mater Cycles Waste Manag. 2022, 24, 189–199. [Google Scholar] [CrossRef]

- Gao, X.; Tan, W.; Zhao, Y.; Wu, J.; Sun, Q.; Qi, H.; Xie, X.; Wei, Z. Diversity in the mechanisms of humin formation during composting with different materials. Environ. Sci. Technol. 2019, 53, 3653–3662. [Google Scholar] [CrossRef] [PubMed]

- Canellas, L.P.; Olivares, F.L.; Aguiar, N.O.; Jones, D.L.; Nebbioso, A.; Mazzei, P.; Piccolo, A. Humic and fulvic acids as biostimulants in horticulture. Sci. Hortic. 2015, 196, 15–27. [Google Scholar] [CrossRef]

- Sousa, R.F.D.; Brasil, E.P.F.; Figueiredo, C.C.D.; Leandro, W.M. Soil organic matter fractions in preserved and disturbed wetlands of the cerrado biome. Braz. J. Soil Sci. 2015, 39, 222–231. [Google Scholar] [CrossRef]

- Justi, M.; Morais, E.G.; Silva, C.A. Fulvic acid in foliar spray is more effective than humic acid via soil in improving coffee seedlings growth. Arch. Agron. Soil Sci. 2019, 65, 1969–1983. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, H.; Wu, G.; Chen, X.; Gruda, N.; Li, X.; Dong, J.; Duan, Z. Dose-dependent application of straw-derived fulvic acid on yield and quality of tomato plants grown in a greenhouse. Front. Plant Sci. 2021, 12, 736613. [Google Scholar] [CrossRef]

- Keener, H.M. Challenges and opportunities in composting organic waste. Clim. Change Food Secur. South Asia 2011, 1, 295–324. [Google Scholar] [CrossRef]

- MAPA—Ministry of Agriculture, Livestock and Food Supply. Manual of Official Analytical Methods for Fertilizers and Correctives. 2017. Available online: https://www.gov.br/agricultura/pt-br/assuntos/insumos-agropecuarios/insumos-agricolas/fertilizantes/legislacao/manual-de-metodos_2017_isbn-978-85-7991-109-5.pdf (accessed on 7 June 2024).

- da Silva, N.; Junqueira, V.C.A.; de Arruda Silveira, N.F.; Taniwaki, M.H.; Gomes, R.A.R.; Okazaki, M.M. Manual de Métodos de Análise Microbiológica de Alimentos e Água, 5th ed.; Editora Blucher: São Paulo, Brazil, 2017; pp. 52–59. [Google Scholar]

- García-González, M.C.; Riaño, B.; Teresa, M.; Herrero, E.; Ward, A.J.; Provolo, G.; Moscatelli, G.; Piccinini, S.; Bonmatí, A.; Bernal, M.P.; et al. Treatment of swine manure: Case studies in European’s N-surplus areas. Sci. Agric. 2016, 73, 444–454. [Google Scholar] [CrossRef]

- Barrerna, R.; Sánchez, A. Home Composting: A Review of Scientific Advances. Eng. Proc. 2022, 19, 35. [Google Scholar] [CrossRef]

- Russo, M.A.T. Solid Waste Treatment; Department of Civil Engineering, Faculty of Science and Technology, University of Coimbra: Coimbra, Portugal, 2003. [Google Scholar]

- Sardá, L.G.; Higarashi, M.M.; Muller, S.; Oliveira, P.A.; Comin, J.J. Reducing CO2, CH4 and H2S emissions by composting swine waste. Braz. J. Agric. Environ. Eng. 2010, 14, 1008–1013. [Google Scholar] [CrossRef]

- Jiménez, E.I.; Garcia, V.P. Evaluation of city refuse compost maturity: A review. Biol. Wastes 1989, 27, 115–142. [Google Scholar] [CrossRef]

- Medrado, R.D.; de Faccio Carvalho, P.C.; de Moraes, A.; de Moura Rios, E.; Lang, C.R.; Lopes, É.C.P. Decomposition of crop residues and nitrogen release for corn. Sci. Agrar. 2011, 12, 97–107. [Google Scholar] [CrossRef][Green Version]

- Vásquez, M.A.; Sem, R.; Soto, M. Physico-chemical and biological characteristics of compost from decentralised composting programmes. Bioresour. Technol. 2015, 198, 520–532. [Google Scholar] [CrossRef]

- Cotta, J.A.O.; Carvalho, N.L.C.; Brum, T.S.; Rezende, M.O.O. Composting versus vermicomposting: Comparison of techniques using vegetable waste, cattle manure and sawdust. Sanit. Environ. Eng. 2015, 20, 65–78. [Google Scholar] [CrossRef]

- Soares, J.D.R.; Rezende, R.A.L.S.; Rezende, R.M.; Botrel, E.P.; Carvalho, A.M.C. Composting agricultural waste: A source of humic substances. Sci. Agrar. Parana. 2017, 16, 414–421. [Google Scholar]

- Busato, J.G.; Zandonadi, D.B.; Dobbss, L.B.; Façanha, A.R.; Canellas, L.P. Humic substances isolated from residues of sugar cane industry as root growth promoter. Sci. Agric. 2010, 67, 206–212. [Google Scholar] [CrossRef]

- Pinto, S.D.S.; Souza, A.E.D.; Oliva, M.A.; Pereira, E.G. Oxidative damage and photosynthetic impairment in tropical rice cultivars upon exposure to excess iron. Sci. Agrícola 2016, 73, 217–226. [Google Scholar] [CrossRef]

- Ujj, A.; Kinga, P.; Andras, B.; Laszlo, A.; Dias, F.R.; Csaba, G.; Csaba, F. Analysis of quality of backyard compost and its potential utilization as a circular bio-waste source. Appl. Sci. 2021, 11, 4392. [Google Scholar] [CrossRef]

- Gouveia, N. Solid urban waste: Socio-environmental impacts and prospects for sustainable management with social inclusion. Sci. Collect. Health 2012, 17, 1503. [Google Scholar] [CrossRef]

- Costa, A.R.S.; Ximenes, T.C.F.; Ximenes, A.F.; Beltrame, L.T.C. The process of composting and its potential in the recycling of organic waste. Geama Mag. 2015, 1, 246–260. [Google Scholar]

- Liu, X.; Bai, X.; Dong, L.; Liang, J.; Jin, Y.; Wei, Y.; Li, Y.; Huang, S.; Qu, J. Composting enhances the removal of lead ions in aqueous solution by spent mushroom substrate: Biosorption and precipitation. J. Clean. Prod. 2018, 200, 1–11. [Google Scholar] [CrossRef]

- Eyerkaufer, M.L.; de Oliveira, B.A. Feasibility analysis of swine manure composting. Braz. J. Account. Manag. 2012, 1, 41–52. [Google Scholar] [CrossRef]

- Prates, F.B.D.S.; Veloso, H.S.; Sampaio, R.A.; Zuba Junior, G.R.; Lopes, P.S.N.; Fernandes, L.A.; Maio, M.M. Growth of yellow passion fruit seedlings in response to fertilization with simple superphosphate and rock dust. Ceres Mag. 2010, 57, 239–246. [Google Scholar] [CrossRef]

- Filho, E.T.D.; de Oliveira, A.M.; Nunes, C.G.F.; de Lira, J.F.B.; de Mesquita, L.X. The practice of composting in sustainable soil management. Green J. Agroecol. Sustain. Dev. 2007, 2, 27–36. [Google Scholar]

| Composter | Manure (g) | Sawdust (g) | Bacteria (mL) |

|---|---|---|---|

| 1 | 800 | 800 | 150 |

| 2 | 400 | 1200 | 150 |

| 3 | 1200 | 400 | 150 |

| Composter | Component | ||

|---|---|---|---|

| Wet Solid | Dry Solid | Liquid | |

| 1 | 52,145.92 | 23,318.64 | 28,827.28 |

| 2 | 52,145.92 | 22,358.64 | 29,787.28 |

| 3 | 52,145.92 | 20,438.64 | 31,707.28 |

| Component | |||||

| Composter | Wet Solid | Dry Solid | Bottom Liquid | Net Total | Gases |

| 1 | 18,450.00 | 5685.91 | 14,261.20 | 27,025.29 | 4868.64 |

| 2 | 20,800.00 | 5986.62 | 11,564.50 | 26,377.88 | 1558.64 |

| 3 | 19,300.00 | 5706.42 | 12,857.30 | 26,450.88 | 1138.64 |

| Yield Considering Wet Feed | |||||

| Composter | Wet Solid | Dry Solid | Bottom Liquid | Net Total | Gases |

| 1 | 35.38 | 10.90 | 27.35 | 51.83 | 9.34 |

| 2 | 39.89 | 11.48 | 22.18 | 50.58 | 2.99 |

| 3 | 37.01 | 10.94 | 24.66 | 50.72 | 2.18 |

| Yield Considering Dry Food | |||||

| Composter | Wet Solid | Dry Solid | Bottom Liquid | Net Total | Gases |

| 1 | 79.12 | 24.38 | 61.16 | 115.90 | 20.88 |

| 2 | 93.03 | 26.78 | 51.72 | 117.98 | 6.97 |

| 3 | 94.43 | 27.92 | 62.91 | 129.42 | 5.57 |

| Analysis/Dry Basis | Unit | Composter 1 | Composter 2 | Composter 3 |

|---|---|---|---|---|

| pH CaCl2 0.01 M (Ref. 1:2.5) | pH | 8.10 | 8.20 | 8.40 |

| Total Organic Matter (Combustion) | % | 21.58 | 26.98 | 29.52 |

| Compostable Organic Matter (Titration) | % | 16.55 | 20.93 | 24.66 |

| Organic Matter Resistant to Compost | % | 5.03 | 6.05 | 4.86 |

| Total Carbon (Organic and Mineral) | % | 11.99 | 14.99 | 16.4 |

| Organic Carbon | % | 9.19 | 11.63 | 13.7 |

| Total Nitrogen | % | 0.67 | 0.82 | 0.43 |

| C/N Ratio (Total C and Total N) | - | 18/01 | 18/1 | 38/1 |

| C/N Ratio (Organic and Total N) | - | 14/01 | 14/1 | 32/1 |

| Humic Acids (120 days) | % | 0.82 | 2.46 | 1.64 |

| Fulvic Acid (120 days) | % | 4.10 | 1.64 | 3.28 |

| Total Humic Extract (120 days) | % | 4.92 | 4.10 | 4.92 |

| Humic Acids (240 days) | % | - | - | 5.21 |

| Fulvic Acid (240 days) | % | - | - | 5.21 |

| Total Humic Extract (240 days) | % | - | - | 10.42 |

| Analysis/Dry Basis | Unit | Composter 1 | Composter 2 | Composter 3 |

|---|---|---|---|---|

| Phosphorous (P2O5 Total) | % | 0.32 | 0.3 | 0.31 |

| Potassium (K2O Total) | % | 0.20 | 0.16 | 0.21 |

| Calcium (Ca Total) | % | 12.39 | 13.04 | 10.52 |

| Magnesium (Mg Total) | % | 2.05 | 1.89 | 1.68 |

| Sulfur (S Total) | % | 0.13 | 0.12 | 0.14 |

| Boron (B Total) | mg.Kg−1 | 3 | 3 | 5 |

| Iron (Fe Total) | mg.Kg−1 | 1936 | 1244 | 1121 |

| Copper (Cu Total) | mg.Kg−1 | 9 | 7 | 8 |

| Manganese (Mn Total) | mg.Kg−1 | 301 | 222 | 244 |

| Zinc (Zn Total) | mg.Kg−1 | 19 | 13 | 15 |

| Sodium (Na Total) | mg.Kg−1 | 2 | 2 | 2 |

| Analysis/Dry Basis | Unit | Composter 1 | Composter 2 | Composter 3 |

|---|---|---|---|---|

| Lead (Pb) | mg.Kg−1 | 12.6 | 13.6 | 18.9 |

| Arsenic (As) | mg.Kg−1 | NQ | NQ | NQ |

| Cadmium (Cd) | mg.Kg−1 | NQ | NQ | NQ |

| Fecal Coliforms | (NMP/Kg.MS) | ND | ND | ND |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Sá, T.M.M.; Benevides, B.M.; Rigueira, L.M.B.; Baliza, P.X.; Rocha, E.P.A.; Souza, P.N.d.C.; Maia, F.M.; Rodrigues, R.G.C.; Martins, I.P.S.; Costa, L.F.R.; et al. Compost with High Soil Conditioning Potential Obtained by Composting Using a Portable and Low-Cost System. Sustainability 2025, 17, 3356. https://doi.org/10.3390/su17083356

de Sá TMM, Benevides BM, Rigueira LMB, Baliza PX, Rocha EPA, Souza PNdC, Maia FM, Rodrigues RGC, Martins IPS, Costa LFR, et al. Compost with High Soil Conditioning Potential Obtained by Composting Using a Portable and Low-Cost System. Sustainability. 2025; 17(8):3356. https://doi.org/10.3390/su17083356

Chicago/Turabian Stylede Sá, Tamara Márcia Martins, Bianca Magalhães Benevides, Leila Moreira Bittencourt Rigueira, Patrícia Xavier Baliza, Elem Patrícia Alves Rocha, Patrícia Nirlane da Costa Souza, Fernanda Menezes Maia, Rosilene Gonçalves Costa Rodrigues, Isac Pereira Soares Martins, Luís Felipe Rodrigues Costa, and et al. 2025. "Compost with High Soil Conditioning Potential Obtained by Composting Using a Portable and Low-Cost System" Sustainability 17, no. 8: 3356. https://doi.org/10.3390/su17083356

APA Stylede Sá, T. M. M., Benevides, B. M., Rigueira, L. M. B., Baliza, P. X., Rocha, E. P. A., Souza, P. N. d. C., Maia, F. M., Rodrigues, R. G. C., Martins, I. P. S., Costa, L. F. R., Pimenta, S., Delvaux Júnior, N. d. A., & Rodrigues, L. P. (2025). Compost with High Soil Conditioning Potential Obtained by Composting Using a Portable and Low-Cost System. Sustainability, 17(8), 3356. https://doi.org/10.3390/su17083356