Integrating Industry 4.0, Circular Economy, and Green HRM: A Framework for Sustainable Transformation

Abstract

1. Introduction

Objectives

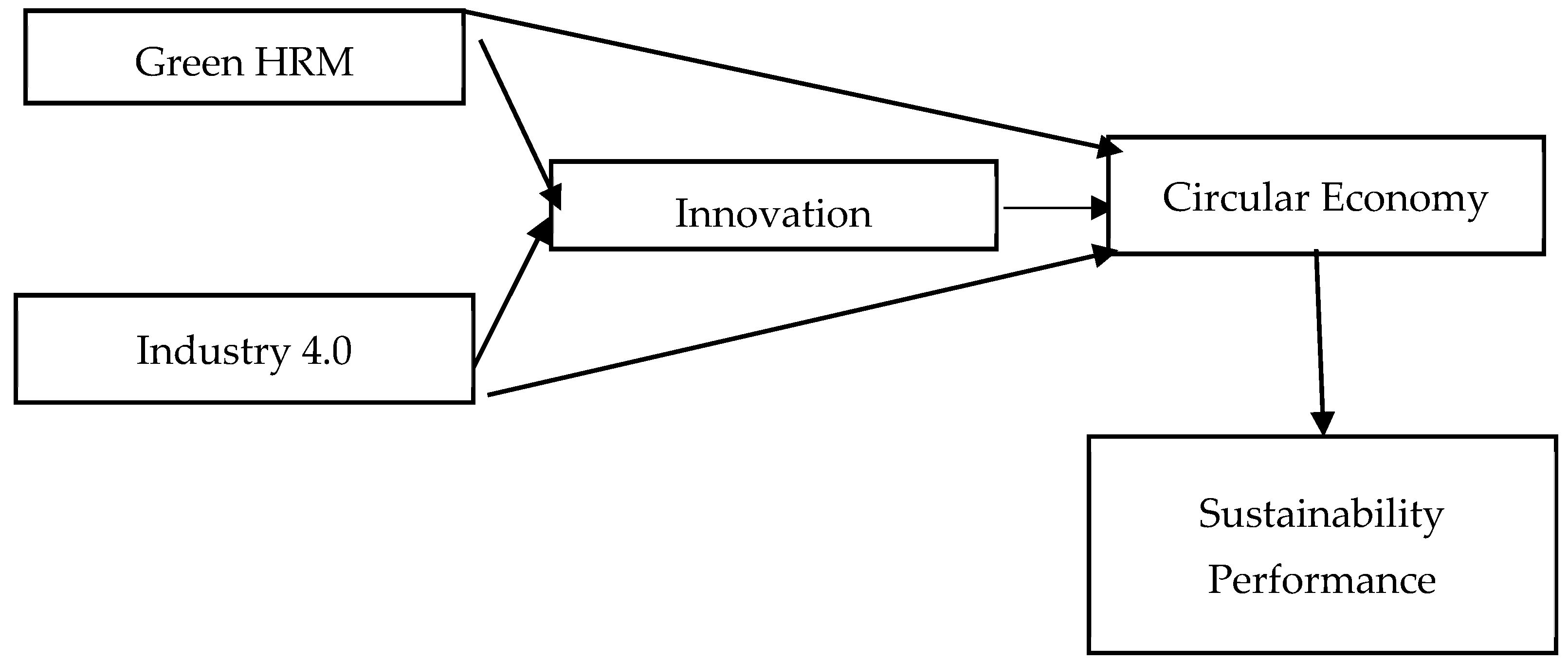

- To analyze the synergies between Industry 4.0 technologies, Circular Economy (CE) principles, and Green Human Resource Management (GHRM) in driving sustainable transformation.

- To identify the key barriers and enablers in the integration of Industry 4.0, CE, and GHRM within organizational structures.

- To develop a conceptual framework that demonstrates how Industry 4.0 and GHRM can enhance CE adoption and operational efficiency.

- To provide practical recommendations for policymakers and industry leaders, bridging the gap between theoretical advancements and real-world applications.

2. Literature Review

2.1. Concepts

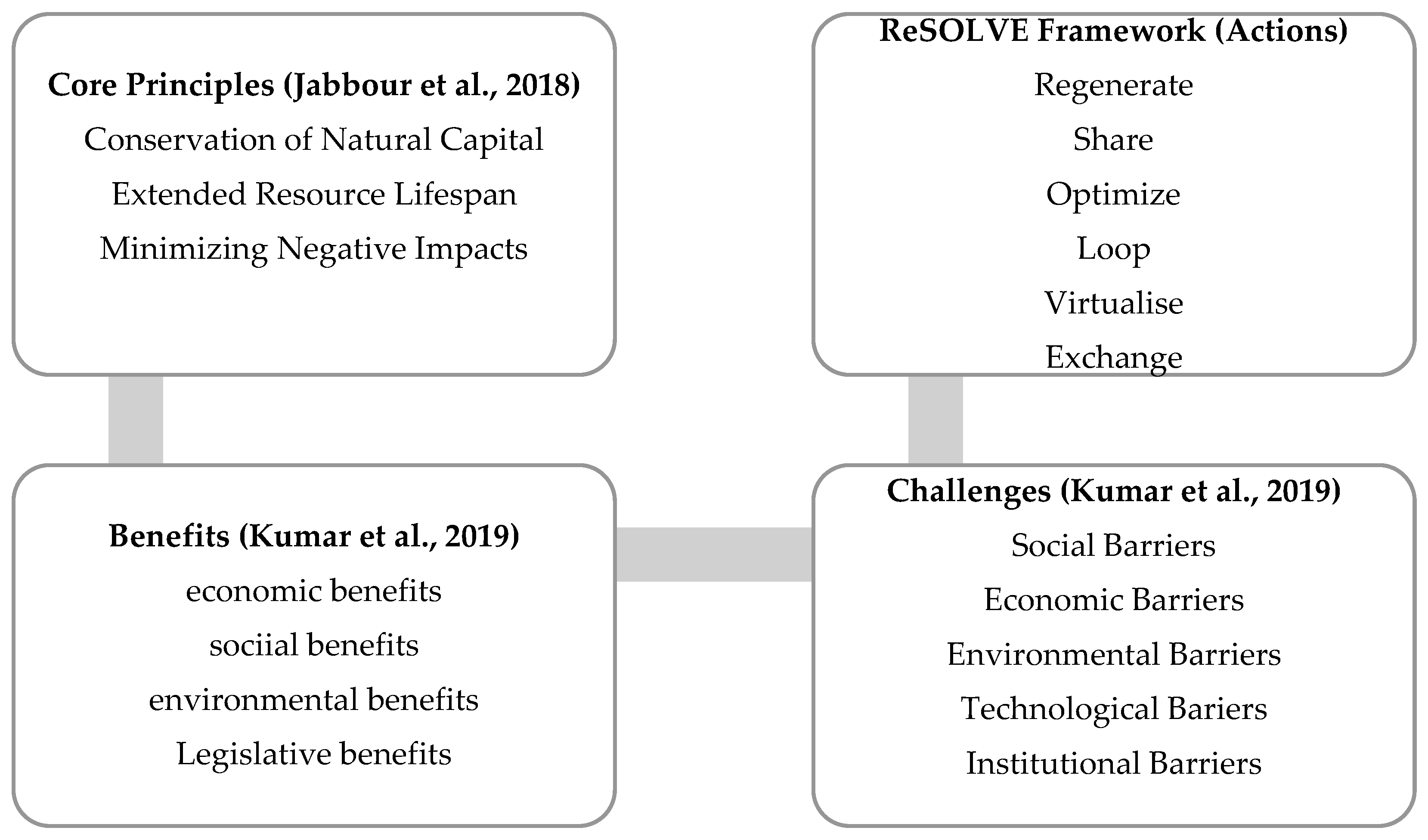

Circular Economy

| Authors | Definitions/Perspectives |

|---|---|

| Boulding (1966) [13] | Defined CE as a basic condition for sustainable life, emphasizing its overarching significance for sustainable economy and ecology. |

| Wang et al. (2014) [14] | Highlighted CE’s potential for preserving the external environment and promoting sustainable development, focusing on resource circulation. |

| Spring and Araujo (2017) [15] | Emphasized closed-loop systems involving reuse, disassembly, and minimizing waste; redefined the consumer’s role as a “value conserver”. |

| Stahel (2016) [16] | Positioned CE as an economic strategy encouraging a new consumption paradigm, reducing material use, and fostering sustainability. |

| Sauvé et al. (2016) [17] | Introduced frameworks for systemic resource decoupling, promoting economies independent of virgin resource use. |

| Ekins et al. (2019) [18] | Focused on CE in the manufacturing industry, emphasizing resource reduction, waste management, and material disposal. |

| Murray et al. (2017) [19] | Described CE as a system connecting economic processes with environmental conservation, focusing on economic stability and sustainability. |

| Kumar et al. (2019) [20] | Developed tangible goals like waste reduction and resource optimization but overlooked socio-economic factors crucial for CE practices. |

| Kristoffersen et al. (2020) [21] | The Smart Circular Economy is conceptualized in a framework that combines data transformation, resource optimization capabilities, and data flow processes to enable circular strategies |

| Kristoffersen et al. (2021) [22] | The Smart Circular Economy is conceptualized in a framework that combines data transformation, resource optimization capabilities, and data flow processes to enable circular strategies |

| Bressanelli et al. (2021) [23] | Circular Economy in the digital age is a regenerative system where waste + data = resource. By harnessing digital technologies, data is transformed into a key enabler that helps convert waste into valuable inputs, driving smarter resource use, transparency, and sustainable value creation. |

| Figg et al. (2023) [24] | The Circular Economy is a multi-level resource use system that stipulates the complete closure of all resource loops. Recycling and other means that optimise the scale and direction of resource flows, contribute to the Circular Economy as supporting practices and activities. In its conceptual perfect form, all resource loops will be fully closed. In its realistic imperfect form, some use of virgin resources is inevitable. |

| Fahimnia et al. (2017); McDowall et al. (2017) [25,26] | Defined CE as a radical improvement over the linear economy, focusing on innovative resource and energy management concepts. |

| Ghisellini et al. (2016) [5] | Stressed the effective utilization of resources and energy, viewing waste as valuable at the end of its lifecycle. |

| MacArthur et al. (2015) [6] | Introduced biological and technical cycles in CE, promoting ecosystem restoration. As well as, extending product lifecycles through reuse and recycling. |

2.2. Industry 4.0

| Authors | Definitions/Perspectives |

|---|---|

| Kang et al. (2016) [1] | Industry 4.0 marks a new era in manufacturing, characterized by IT and sophisticated digital technology integration |

| Shrouf et al. (2014); Lasi et al. (2014) [36,37] | Described Industry 4.0 as a connected industry where machines, employees, and stakeholders exchange data through IoT and electronics, enabling self-organization and automation. |

| Trentesaux and Rault (2017) [38] | Highlighted Industry 4.0 in the context of smart production and products, where machines, components, and devices manage production lines and optimize systems. |

| Lu (2017) [2] | Identified reflexivity, optimization, compatibility, and harness as the main features defining Industry 4.0 processes. |

| Harikannan and Vinodh (2024) [40] | Industry 4.0 refers to a set of technologies that facilitate the development of value chain, resulting in shorter lead times, higher quality products and better organizational performance |

- Cloud Manufacturing: This one establishes an online environment where various manufacturing resources and capacities can be shared. It allows car suppliers and customers to communicate with each other and support services such as design, simulation of production, and assembly. Cloud manufacturing is also capable of e-commerce to improve the operational effectiveness towards other Industry 4.0 technologies like Additive Manufacturing [44].

- Internet of Things (IoT): The IoT interfaces things, devices, and systems by assigning them unique identifiers that allow them to achieve set objectives. This interaction promotes the streaming of data and results in their timely availability to different parties in a Cyber–Physical System, organizations, and people. Second, IoT applications produce huge data content, which can be mined for purposes of value co-creation [41,45,46]

- Additive Manufacturing: Also known as 3D printing, Additive Manufacturing enables the building of parts that do not need conventional tools. This approach relies on the use of virtual designs, which has enabled a decrease in the amount of lead time needed to produce a product and increased interaction and communication between designers, engineers, and users [50].

2.3. Green HRM

3. Theoretical Framework and Research Questions

3.1. Industry 4.0 and Circular Economy

- 1.

- Resource Consumption Reduction (RIC):

- 2.

- Reuse:

- 3.

- Recovery:

- 4.

- Recycling:

- 5.

- Waste Elimination (RWE):

3.2. Industry 4.0 and Innovation

3.3. Innovation and Circular Economy

- Systemic Innovation

- 2.

- Demand-Driven Innovation

- 3.

- Resource efficiency

- 4.

- Product-Service Systems (PSS) and Risk Mitigation

- 5.

- Reverse Logistics as well as Collaboration

- 6.

- Design and Consumer Connection

3.4. HR and Industry 4.0

3.5. HRM and Innovation

3.6. Circular Economy and HR

Novelty and Contribution of the Proposed Framework

4. Discussion

Limitations and Future Research

5. Conclusions

5.1. Theoretical Implications

5.2. Practical Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S. Do Smart Manufacturing: Past Research, Present Findings, and Future Directions. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A Survey on Technologies, Applications and Open Research Issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Walker, R.M.; Chen, J.; Aravind, D. Management Innovation and Firm Performance: An Integration of Research Findings. Eur. Manag. J. 2015, 33, 407–422. [Google Scholar] [CrossRef]

- Rehman, S.U.; Giordino, D.; Zhang, Q.; Alam, G.M. Twin Transitions & Industry 4.0: Unpacking the Relationship between Digital and Green Factors to Determine Green Competitive Advantage. Technol. Soc. 2023, 73, 102227. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- MacArthur, D.E.; Zumwinkel, K.; Stuchtey, M.R. Growth Within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Renwick, D.W.S.; Redman, T.; Maguire, S. Green Human Resource Management: A Review and Research Agenda. Int. J. Manag. Rev. 2013, 15, 1–14. [Google Scholar] [CrossRef]

- Ahmad, S. Green Human Resource Management: Policies and Practices. Cogent Bus. Manag. 2015, 2, 1030817. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards Circular Economy Implementation: A Comprehensive Review in Context of Manufacturing Industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Chiappetta Jabbour, C.J.; Sarkis, J.; Lopes de Sousa Jabbour, A.B.; Scott Renwick, D.W.; Singh, S.K.; Grebinevych, O.; Kruglianskas, I.; Filho, M.G. Who Is in Charge? A Review and a Research Agenda on the ‘Human Side’ of the Circular Economy. J. Clean. Prod. 2019, 222, 793–801. [Google Scholar] [CrossRef]

- Daly, H.E. Beyond Growth: The Economics of Sustainable Development; Beacon Press: Boston, MA, USA, 1996; p. 253. [Google Scholar]

- McDonough, W.; Braungart, M. Remarking the Way We Make Things: Cradle to Cradle; North Point Press: Berkeley, CA, USA, 2002; ISBN 0-86547-587-3. [Google Scholar]

- Boulding, K. The Economics of the Coming Spaceship Earth. In Environmental Quality in a Growing Economy; Jarrett, H., Ed.; Resources for the Future: Washington, DC, USA; Johns Hopkins University Press Johns Hopkins University Press: Baltimore, MD, USA, 1966. [Google Scholar]

- Wang, P.C.; Che, F.; Fan, S.S.; Gu, C. Ownership Governance, Institutional Pressures and Circular Economy Accounting Information Disclosure: An Institutional Theory and Corporate Governance Theory Perspective. Chin. Manag. Stud. 2014, 8, 487–501. [Google Scholar]

- Spring, M.; Araujo, L. Product Biographies in Servitization and the Circular Economy. Ind. Mark. Manag. 2017, 60, 126–137. [Google Scholar] [CrossRef]

- Stahel, W.R. The Circular Economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef] [PubMed]

- Sauvé, S.; Bernard, S.; Sloan, P. Environmental Sciences, Sustainable Development and Circular Economy: Alternative Concepts for Trans-Disciplinary Research. Environ. Dev. 2016, 17, 48–56. [Google Scholar] [CrossRef]

- Ekins, P.; Domenech, T.; Drummond, P. Policies for a Resource Efficient Economy in Europe: Findings From the POLFREE Project. Ecol. Econ. 2019, 155, 1–6. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Kumar, V.; Sezersan, I.; Garza-Reyes, J.A.; Gonzalez, E.D.R.S.; AL-Shboul, M.A. Circular Economy in the Manufacturing Sector: Benefits, Opportunities and Barriers. Manag. Decis. 2019, 57, 1067–1086. [Google Scholar] [CrossRef]

- Kristoffersen, E.; Blomsma, F.; Mikalef, P.; Li, J. The Smart Circular Economy: A Digital-Enabled Circular Strategies Framework for Manufacturing Companies. J. Bus. Res. 2020, 120, 241–261. [Google Scholar] [CrossRef]

- Kristoffersen, E.; Mikalef, P.; Blomsma, F.; Li, J. Towards a Business Analytics Capability for the Circular Economy. Technol. Forecast. Soc. Change 2021, 171, 120957. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Pigosso, D.C.A.; Parida, V. Towards the Smart Circular Economy Paradigm: A Definition, Conceptualization, and Research Agenda. Sustainability 2022, 14, 4960. [Google Scholar] [CrossRef]

- Figge, F.; Thorpe, A.S.; Gutberlet, M. Definitions of the Circular Economy: Circularity Matters. Ecol. Econ. 2023, 208, 107823. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Gunasekaran, A.; Farahani, R. Decision Models for Sustainable Supply Chain Design and Management. Ann. Oper. Res. 2017, 250, 277–278. [Google Scholar] [CrossRef]

- McDowall, W.; Geng, Y.; Huang, B.; Barteková, E.; Bleischwitz, R.; Türkeli, S.; Kemp, R.; Doménech, T. Circular Economy Policies in China and Europe. J. Ind. Ecol. 2017, 21, 651–661. [Google Scholar] [CrossRef]

- Singh, R.; Khan, S.; Dsilva, J. A Framework for Assessment of Critical Factor for Circular Economy Practice Implementation. J. Model. Manag. 2023, 18, 1476–1497. [Google Scholar] [CrossRef]

- Singh, R.; Khan, S.; Centobelli, P. Investigating the Interplay between Social Performance and Organisational Factors Supporting Circular Economy Practices. Sustainability 2022, 14, 16781. [Google Scholar] [CrossRef]

- Kirchherr, J.; Yang, N.H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resour. Conserv. Recycl. 2023, 194, 107001. [Google Scholar] [CrossRef]

- Zhao, S.; Zhu, Q. Remanufacturing Supply Chain Coordination under the Stochastic Remanufacturability Rate and the Random Demand. Ann. Oper. Res. 2017, 257, 661–695. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Olivetti, E.A.; Cullen, J.M.; Potting, J.; Lifset, R. Taking the Circularity to the Next Level: A Special Issue on the Circular Economy. J. Ind. Ecol. 2017, 21, 476–482. [Google Scholar] [CrossRef]

- Khan, S.; Ali, S.S.; Singh, R. Determinants of Remanufacturing Adoption for Circular Economy: A Causal Relationship Evaluation Framework. Appl. Syst. Innov. 2022, 5, 62. [Google Scholar] [CrossRef]

- Lopes de Sousa Jabbour, A.B.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the Circular Economy: A Proposed Research Agenda and Original Roadmap for Sustainable Operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Keilhacker, M.L.; Minner, S. Supply Chain Risk Management for Critical Commodities: A System Dynamics Model for the Case of the Rare Earth Elements. Resour. Conserv. Recycl. 2017, 125, 349–362. [Google Scholar] [CrossRef]

- Lopez, F.J.Z.; Bastein, T.; Tukker, A. Business model innovation for resource-efficiency, circularity and cleaner production: What 143 cases tell us. Ecol. Economics 2019, 155, 20–35. [Google Scholar]

- Shrouf, F.; Ordieres, J.; Miragliotta, G. Smart Factories in Industry 4.0: A Review of the Concept and of Energy Management Approached in Production Based on the Internet of Things Paradigm. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Selangor, Malaysia, 9–12 December 2014; pp. 697–701. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Trentesaux, D.; Rault, R. Designing Ethical Cyber-Physical Industrial Systems. IFAC-PapersOnLine 2017, 50, 14934–14939. [Google Scholar] [CrossRef]

- Khan, S.; Singh, R.; Sá, J.C.; Santos, G.; Ferreira, L.P. Modelling of Determinants of Logistics 4.0 Adoption: Insights from Developing Countries. Machines 2022, 10, 1242. [Google Scholar] [CrossRef]

- Harikannan, N.; Vinodh, S. State of Art Review on Sustainable Manufacturing and Industry 4.0. Bus. Strateg. Environ. 2025, 34, 872–913. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Ahmadov, Y.; Helo, P. A Cloud Based Job Sequencing with Sequence-Dependent Setup for Sheet Metal Manufacturing. Ann. Oper. Res. 2018, 270, 5–24. [Google Scholar] [CrossRef]

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, Investments, and Challenges for Enterprises. Bus. Horiz. 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Yu, C.; Xu, X.; Lu, Y. Computer-Integrated Manufacturing, Cyber-Physical Systems and Cloud Manufacturing—Concepts and Relationships. Manuf. Lett. 2015, 6, 5–9. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A Survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Xu, L.D.; He, W.; Li, S. Internet of Things in Industries: A Survey. IEEE Trans. Ind. Inform. 2014, 10, 2233–2243. [Google Scholar] [CrossRef]

- Akter, S.; Wamba, S.F. Big Data and Disaster Management: A Systematic Review and Agenda for Future Research. Ann. Oper. Res. 2019, 283, 939–959. [Google Scholar] [CrossRef]

- Zhan, Y.; Tan, K.H.; Li, Y.; Tse, Y.K. Unlocking the Power of Big Data in New Product Development. Ann. Oper. Res. 2018, 270, 577–595. [Google Scholar] [CrossRef]

- Du, S.; Tang, W.; Zhao, J.; Nie, T. Sell to Whom? Firm’s Green Production in Competition Facing Market Segmentation. Ann. Oper. Res. 2018, 270, 125–154. [Google Scholar] [CrossRef]

- Holmström, J.; Holweg, M.; Khajavi, S.H.; Partanen, J. The Direct Digital Manufacturing (r)Evolution: Definition of a Research Agenda. Oper. Manag. Res. 2016, 9, 1–10. [Google Scholar] [CrossRef]

- Iddagoda, A.; Dissanyake, H.; Abeysinghe, R. Green Human Resource Management: A Bibliometric Analysis. Rom. J. Econ. 2022, 64, 147–159. [Google Scholar]

- Miah, M.; Szabó-Szentgróti, G.; Walter, V. A Systematic Literature Review on Green Human Resource Management (GHRM): An Organizational Sustainability Perspective. Cogent Bus. Manag. 2024, 11, 2371983. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; Santos, F.C.A.; Nagano, M.S. Contributions of HRM throughout the Stages of Environmental Management: Methodological Triangulation Applied to Companies in Brazil. Int. J. Hum. Resour. Manag. 2010, 21, 1049–1089. [Google Scholar] [CrossRef]

- Saeed, B.B.; Afsar, B.; Hafeez, S.; Khan, I.; Tahir, M.; Afridi, M.A. Promoting Employee’s Proenvironmental Behavior through Green Human Resource Management Practices. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 424–438. [Google Scholar] [CrossRef]

- Pinzone, M.; Guerci, M.; Lettieri, E.; Huisingh, D. Effects of ‘Green’ Training on pro-Environmental Behaviors and Job Satisfaction: Evidence from the Italian Healthcare Sector. J. Clean. Prod. 2019, 226, 221–232. [Google Scholar] [CrossRef]

- Iftikar, T.; Hussain, S.; Malik, M.I.; Hyder, S.; Kaleem, M.; Saqib, A. Green Human Resource Management and Pro-Environmental Behaviour Nexus with the Lens of AMO Theory. Cogent Bus. Manag. 2022, 9, 2124603. [Google Scholar] [CrossRef]

- Iddagoda, A.; Bulińska-Stangrecka, H.; Abeysinghe, R. Greening of Military Personnel. Bezp. Obron. Socjol. 2020, 13, 102–121. [Google Scholar]

- Hong, N.T.H.; Hanh, T.T.; Anh, N.Q.; Anh, D.N.; Ngoc, T.M.; Nhi, N.D.L. Green Human Resources Management and Employees’ Green Behavioral Intention: The Role of Individual Green Values and Corporate Social Responsibility. Cogent Bus. Manag. 2024, 11, 2386464. [Google Scholar] [CrossRef]

- Khan, M.H.; Muktar, S.N. A Bibliometric Analysis of Green Human Resource Management Based on Scopus Platform. Cogent Bus. Manag. 2020, 7, 1831165. [Google Scholar] [CrossRef]

- Khan, S.; Singh, R.; Alnahas, J.; Abbate, S.; Centobelli, P. Navigating the Smart Circular Economy: A Framework for Manufacturing Firms. J. Clean. Prod. 2024, 480, 144007. [Google Scholar] [CrossRef]

- McLuhan, M. The Gutenberg Galaxy: The Making of Typographic Man; University of Toronto Press: Toronto, ON, Canada, 1962; ISBN 0802060412. [Google Scholar]

- Meadows, D. Thinking in Systems; Chelsea Green Publishing: Chelsea, VT, USA, 2008. [Google Scholar]

- Barney, J. Firm Resources and Sustained Competitive Advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Mellor, S.; Hao, L.; Zhang, D. Additive Manufacturing: A Framework for Implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef]

- Kellens, K.; Mertens, R.; Paraskevas, D.; Dewulf, W.; Duflou, J.R. Environmental Impact of Additive Manufacturing Processes: Does AM Contribute to a More Sustainable Way of Part Manufacturing? Procedia CIRP 2017, 61, 582–587. [Google Scholar] [CrossRef]

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-Cycle Economic Analysis of Distributed Manufacturing with Open-Source 3-D Printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef]

- Bloomfield, M.; Borstrock, S. Modeclix. The Additively Manufactured Adaptable Textile. Mater. Today Commun. 2018, 16, 212–216. [Google Scholar] [CrossRef]

- Lahrour, Y.; Brissaud, D. A Technical Assessment of Product/Component Re-Manufacturability for Additive Remanufacturing. Procedia CIRP 2018, 69, 142–147. [Google Scholar] [CrossRef]

- French, R.; Benakis, M.; Marin-Reyes, H. Intelligent Sensing for Robotic Re-Manufacturing in Aerospace—An Industry 4.0 Design Based Prototype. In Proceedings of the 2017 IEEE International Symposium on Robotics and Intelligent Sensors (IRIS), Ottawa, ON, Canada, 5–7 October 2017; pp. 272–277. [Google Scholar] [CrossRef]

- Uriarte-Gallastegi, N.; Landeta-Manzano, B.; Arana-Landín, G.; Laskurain-Iturbe, I. Environmental benefits and weaknesses of additive manufacturing processes in the business sector. Key players influencing the environmental impact of digital manufacturing technologies. Technol. Ind. 2020, 95, 587–590. [Google Scholar] [CrossRef]

- Zhong, S.; Pearce, J.M. Tightening the Loop on the Circular Economy: Coupled Distributed Recycling and Manufacturing with Recyclebot and RepRap 3-D Printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- van Schaik, A.; Reuter, M.A. Recycling Indices Visualizing the Performance of the Circular Economy. World Met Erzmetall 2016, 69, 5–20. [Google Scholar]

- Waibel, M.W.; Steenkamp, L.P.; Moloko, N.; Oosthuizen, G.A. Investigating the Effects of Smart Production Systems on Sustainability Elements. Procedia Manuf. 2017, 8, 731–737. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 Framework: A Systematic Literature Review Identifying the Current Trends and Future Perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Tseng, M.L.; Chiu, A.S.F.; Liu, G.; Jantaralolica, T. Circular Economy Enables Sustainable Consumption and Production in Multi-Level Supply Chain System. Resour. Conserv. Recycl. 2020, 154, 104601. [Google Scholar] [CrossRef]

- Mahapatra, P.; Singh, S.K. Artificial Intelligence and Machine Learning: Discovering New Ways of Doing Banking Business. In Artificial Intelligence and Machine Learning in Business Management; Concepts, Challenges, Case Studies; CRC Press: Boca Raton, FL, USA, 2021; pp. 53–80. [Google Scholar]

- Kumar, V.; Patel, S.; Baburaj, V.; Vardhan, A.; Singh, P.K.; Vaishya, R. Current Understanding on Artificial Intelligence and Machine Learning in Orthopaedics—A Scoping Review. J. Orthop. 2022, 34, 201–206. [Google Scholar] [CrossRef]

- Bag, S.; Luthra, S.; Mangla, S.K.; Kazancoglu, Y. Leveraging Big Data Analytics Capabilities in Making Reverse Logistics Decisions and Improving Remanufacturing Performance. Int. J. Logist. Manag. 2021, 32, 742–765. [Google Scholar] [CrossRef]

- Bag, S.; Dhamija, P.; Luthra, S.; Huisingh, D. How Big Data Analytics Can Help Manufacturing Companies Strengthen Supply Chain Resilience in the Context of the COVID-19 Pandemic. Int. J. Logist. Manag. 2023, 34, 1141–1164. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain Technology and Its Relationships to Sustainable Supply Chain Management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Upadhyay, A.; Mukhuty, S.; Kumar, V.; Kazancoglu, Y. Blockchain Technology and the Circular Economy: Implications for Sustainability and Social Responsibility. J. Clean. Prod. 2021, 293, 126130. [Google Scholar] [CrossRef]

- Aron, C.; Sgarbossa, F.; Ballot, E.; Ivanov, D. Cloud Material Handling Systems: A Cyber-Physical System to Enable Dynamic Resource Allocation and Digital Interoperability. J. Intell. Manuf. 2023, 35, 3815–3836. [Google Scholar] [CrossRef]

- Nascimento, L.; de Oliveira, A.L.; Villela, R.; Wei, R.; Hawkins, R.; Kelly, T. Runtime Model-Based Assurance of Open and Adaptive Cyber-Physical Systems. In Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2023; Volume 661, pp. 534–546. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, L.; Liu, Y.; Cheng, Y.; Wang, L.; Xu, X. Manufacturing Service Management in Cloud Manufacturing: Overview and Future Research Directions. J. Manuf. Sci. Eng. Trans. ASME 2015, 137, 040912. [Google Scholar]

- Du, Y.; Xu, J.; Yuan, X. The Development Relationship between Circular Economy and Advanced Digital Technology: Based on an Innovative Literature Review Method. Environ. Technol. Rev. 2024, 13, 614–638. [Google Scholar] [CrossRef]

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.J.; Garmulewicz, A.; Knowles, S.; Minshall, T.H.W.; Mortara, L.; Reed-Tsochas, F.P.; et al. Unlocking Value for a Circular Economy through 3D Printing: A Research Agenda. Technol. Forecast. Soc. Change 2017, 115, 75–84. [Google Scholar] [CrossRef]

- Colorado, H.A.; Velásquez, E.I.G.; Monteiro, S.N. Sustainability of Additive Manufacturing: The Circular Economy of Materials and Environmental Perspectives. J. Mater. Res. Technol. 2020, 9, 8221–8234. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef]

- Moeuf, A.; Lamouri, S.; Pellerin, R.; Tamayo-Giraldo, S.; Tobon-Valencia, E.; Eburdy, R. Identification of Critical Success Factors, Risks and Opportunities of Industry 4.0 in SMEs. Int. J. Prod. Res. 2020, 58, 1384–1400. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Leng, J.; Zhou, M.; Xiao, Y.; Zhang, H.; Liu, Q.; Shen, W.; Su, Q.; Li, L. Digital Twins-Based Remote Semi-Physical Commissioning of Flow-Type Smart Manufacturing Systems. J. Clean. Prod. 2021, 306, 127278. [Google Scholar] [CrossRef] [PubMed]

- Rocca, R.; Rosa, P.; Sassanelli, C.; Fumagalli, L.; Terzi, S. Integrating Virtual Reality and Digital Twin in Circular Economy Practices: A Laboratory Application Case. Sustainability 2020, 12, 2286. [Google Scholar] [CrossRef]

- Rauschnabel, P.A.; Babin, B.J.; tom Dieck, M.C.; Krey, N.; Jung, T. What Is Augmented Reality Marketing? Its Definition, Complexity, and Future. J. Bus. Res. 2022, 142, 1140–1150. [Google Scholar] [CrossRef]

- Masood, T.; Egger, J. Adopting Augmented Reality in the Age of Industrial Digitalisation. Comput. Ind. 2020, 115, 103112. [Google Scholar] [CrossRef]

- Lin, H.F.; Su, J.Q.; Higgins, A. How Dynamic Capabilities Affect Adoption of Management Innovations. J. Bus. Res. 2016, 69, 862–876. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Fathi, M.; Iranmanesh, M.; Maroufkhani, P.; Morales, M.E. Industry 4.0 Ten Years on: A Bibliometric and Systematic Review of Concepts, Sustainability Value Drivers, and Success Determinants. J. Clean. Prod. 2021, 302, 127052. [Google Scholar] [CrossRef]

- Ciliberto, C.; Szopik-Depczyńska, K.; Tarczyńska-Łuniewska, M.; Ruggieri, A.; Ioppolo, G. Enabling the Circular Economy Transition: A Sustainable Lean Manufacturing Recipe for Industry 4.0. Bus. Strateg. Environ. 2021, 30, 3255–3272. [Google Scholar] [CrossRef]

- Rogers, E.M. Diffusion of Innovations; Free Press of Glencoe: Glencoe, IL, USA, 1962. [Google Scholar]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic Capabilities and Strategic Management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Elkington, J. The Triple Bottom Line. In Environmental Management: Readings and Cases; Sage Publishing: Thousand Oaks, CA, USA, 1997; Volume 2, pp. 49–66. [Google Scholar]

- Horváth, D.; Szabó, R.Z. Driving Forces and Barriers of Industry 4.0: Do Multinational and Small and Medium-Sized Companies Have Equal Opportunities? Technol. Forecast. Soc. Change 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Linder, M.; Williander, M. Circular Business Model Innovation: Inherent Uncertainties. Bus. Strateg. Environ. 2017, 26, 182–196. [Google Scholar] [CrossRef]

- Kant Hvass, K.; Pedersen, E.R.G. Toward Circular Economy of Fashion: Experiences from a Brand’s Product Take-Back Initiative. J. Fash. Mark. Manag. 2019, 23, 345–365. [Google Scholar] [CrossRef]

- Todeschini, B.V.; Cortimiglia, M.N.; Callegaro-de-Menezes, D.; Ghezzi, A. Innovative and Sustainable Business Models in the Fashion Industry: Entrepreneurial Drivers, Opportunities, and Challenges. Bus. Horiz. 2017, 60, 759–770. [Google Scholar] [CrossRef]

- Hecklau, F.; Galeitzke, M.; Flachs, S.; Kohl, H. Holistic Approach for Human Resource Management in Industry 4.0. Procedia CIRP 2016, 54, 1–6. [Google Scholar] [CrossRef]

- El-Haddadeh, R. Digital Innovation Dynamics Influence on Organisational Adoption: The Case of Cloud Computing Services. Inf. Syst. Front. 2020, 22, 985–999. [Google Scholar] [CrossRef]

- Freeman, E.R. Strategic Management A Stakeholder Approach; Epstein, E.M., Ed.; Pitman Publishing Inc: London, UK, 1984; ISBN 0203982215. [Google Scholar]

- Roszkowska-Menkes, M. Institutional Theory. In Encyclopedia of Sustainable Management; Springer: Cham, Switzerland, 2023; pp. 1983–1990. [Google Scholar] [CrossRef]

- Kianto, A.; Sáenz, J.; Aramburu, N. Knowledge-Based Human Resource Management Practices, Intellectual Capital and Innovation. J. Bus. Res. 2017, 81, 11–20. [Google Scholar] [CrossRef]

- Rehman, S.U.; Kraus, S.; Shah, S.A.; Khanin, D.; Mahto, R.V. Analyzing the Relationship between Green Innovation and Environmental Performance in Large Manufacturing Firms. Technol. Forecast. Soc. Change 2021, 163, 120481. [Google Scholar] [CrossRef]

- Renwick, D.W.S.; Jabbour, C.J.C.; Muller-Camen, M.; Redman, T.; Wilkinson, A. Contemporary Developments in Green (Environmental) HRM Scholarship. Int. J. Hum. Resour. Manag. 2016, 27, 114–128. [Google Scholar] [CrossRef]

- Kraus, S.; Rehman, S.U.; García, F.J.S. Corporate Social Responsibility and Environmental Performance: The Mediating Role of Environmental Strategy and Green Innovation. Technol. Forecast. Soc. Change 2020, 160, 120262. [Google Scholar] [CrossRef]

- Singh, S.K.; Del Giudice, M.; Chierici, R.; Graziano, D. Green Innovation and Environmental Performance: The Role of Green Transformational Leadership and Green Human Resource Management. Technol. Forecast. Soc. Change 2020, 150, 119762. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Marrucci, L.; Daddi, T.; Iraldo, F. The Contribution of Green Human Resource Management to the Circular Economy and Performance of Environmental Certified Organisations. J. Clean. Prod. 2021, 319, 128859. [Google Scholar] [CrossRef]

- Pham, N.T.; Hoang, H.T.; Phan, Q.P.T. Green Human Resource Management: A Comprehensive Review and Future Research Agenda. Int. J. Manpow. 2020, 41, 845–878. [Google Scholar] [CrossRef]

- Rafaj, O. The Effect of Human Capital on the Output of Slovak Urban Regions. Sci. Pap. Univ. Pardubic. Ser. D Fac. Econ. Adm. 2020, 28, 1163. [Google Scholar]

- Schein, E. Organizational Culture and Leadership: A Dynamic View; Jossey-Bass: Hoboken, NJ, USA, 1985. [Google Scholar]

- Dahinine, B.; Laghouag, A.; Bensahel, W.; Alsolami, M.; Guendouz, T. Modelling the Combined Effect of Green Leadership and Human Resource Management in Moving to Green Supply Chain Performance Enhancement in Saudi Arabia. Sustainability 2024, 16, 3953. [Google Scholar] [CrossRef]

| Industry 4.0 Technology | Impact on Circular Economy | References |

|---|---|---|

| Internet of Things (IoT) | Enhances resource efficiency and real-time monitoring, enabling predictive maintenance and waste reduction. | Kamble et al. [74]; Tseng et al. [75] |

| Artificial Intelligence (AI) and Machine Learning | Optimizes decision-making for sustainable production, enhances material recovery, and supports energy-efficient processes. | Mahapatra and Singhe [76]; Kumar et al. [77] |

| Big Data and Analytics | Improves lifecycle assessment, waste tracking, and demand forecasting for sustainable supply chains. | Bag et al. [78]; Bag et al. [79] |

| Blockchain | Ensures transparency and traceability in material flows, preventing counterfeiting and promoting closed-loop systems. | Saberi et al. [80]; Upadhyay et al. [81] |

| Cyber–Physical Systems (CPS) | Integrates real-time monitoring and autonomous systems for adaptive, waste-minimizing production processes. | Aron et al. [82]; Nascimento et al. [83] |

| Cloud Computing | Facilitates data storage, sharing, and processing for Circular Economy strategies and digital platforms. | Tao et al. [84]; Du et al. [85] |

| Additive Manufacturing (3D Printing) | Enables on-demand, localized production reducing waste and overproduction while extending product lifecycles. | Despeisse et al. [86]; Colorado et al. [87] |

| Robotics and Automation | Automates resource recovery, dismantling, and sorting processes, improving material reuse and efficiency. | Stock and Seliger [88]; Moeuf et al. [89] |

| Digital Twins | Simulates production and product lifecycle scenarios for sustainable design and optimization. | Tao et al. [90]; Leng et al. [91] |

| Augmented and Virtual Reality (AR/VR) | Enhances worker training for sustainable manufacturing and supports remote monitoring of CE processes. | Rocca [92]; Rauschnabel et al. [93] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, R.; Joshi, A.; Dissanayake, H.; Iddagoda, A.; Khan, S.; Félix, M.J.; Santos, G. Integrating Industry 4.0, Circular Economy, and Green HRM: A Framework for Sustainable Transformation. Sustainability 2025, 17, 3082. https://doi.org/10.3390/su17073082

Singh R, Joshi A, Dissanayake H, Iddagoda A, Khan S, Félix MJ, Santos G. Integrating Industry 4.0, Circular Economy, and Green HRM: A Framework for Sustainable Transformation. Sustainability. 2025; 17(7):3082. https://doi.org/10.3390/su17073082

Chicago/Turabian StyleSingh, Rubee, Amit Joshi, Hiranya Dissanayake, Anuradha Iddagoda, Shahbaz Khan, Maria João Félix, and Gilberto Santos. 2025. "Integrating Industry 4.0, Circular Economy, and Green HRM: A Framework for Sustainable Transformation" Sustainability 17, no. 7: 3082. https://doi.org/10.3390/su17073082

APA StyleSingh, R., Joshi, A., Dissanayake, H., Iddagoda, A., Khan, S., Félix, M. J., & Santos, G. (2025). Integrating Industry 4.0, Circular Economy, and Green HRM: A Framework for Sustainable Transformation. Sustainability, 17(7), 3082. https://doi.org/10.3390/su17073082