Eco-Friendly Lightweight Aggregate Concrete of Structural Grade Made with Recycled Brick Aggregate Containing Expanded Polystyrene Beads

Abstract

1. Introduction

2. Materials and Methods

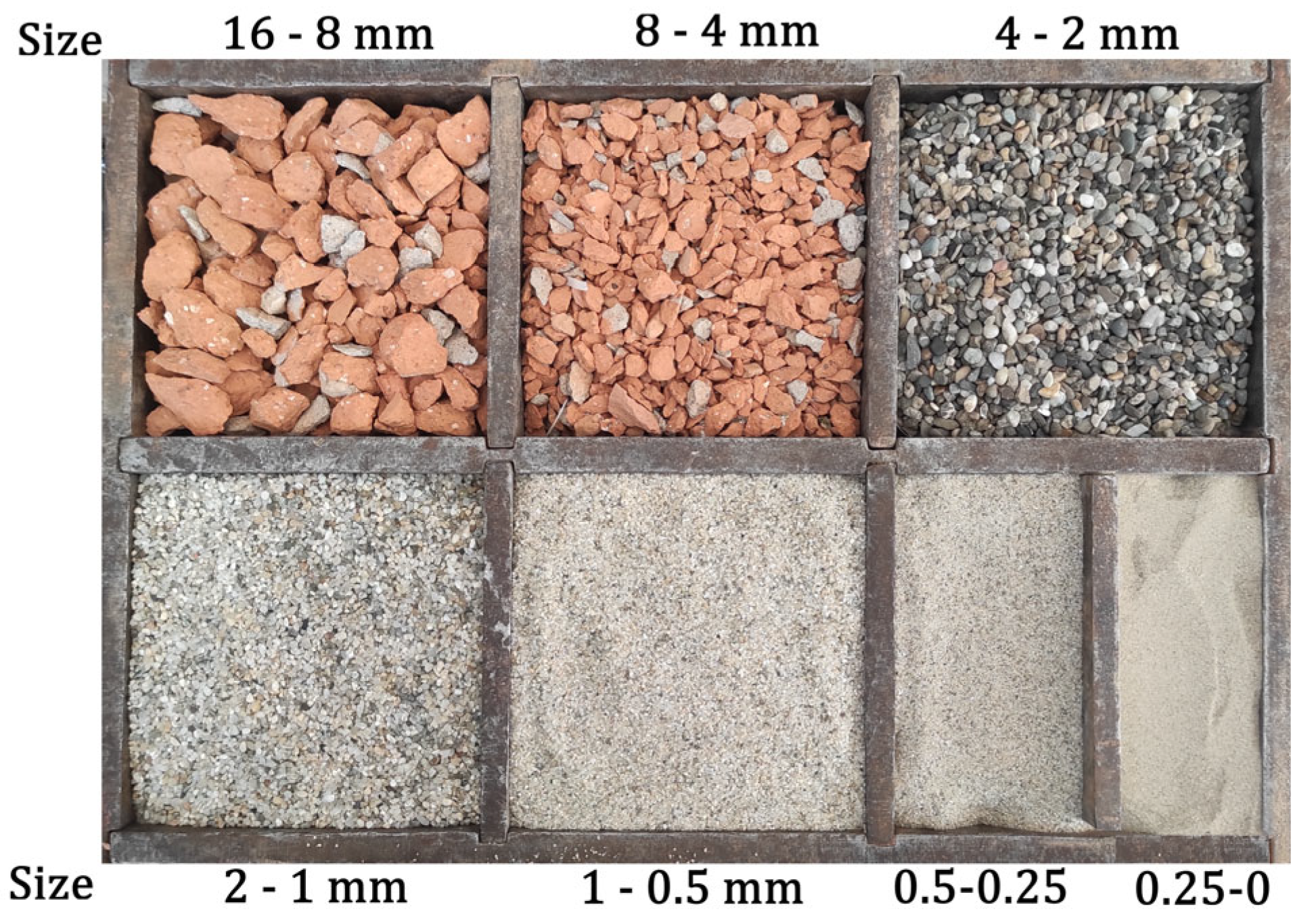

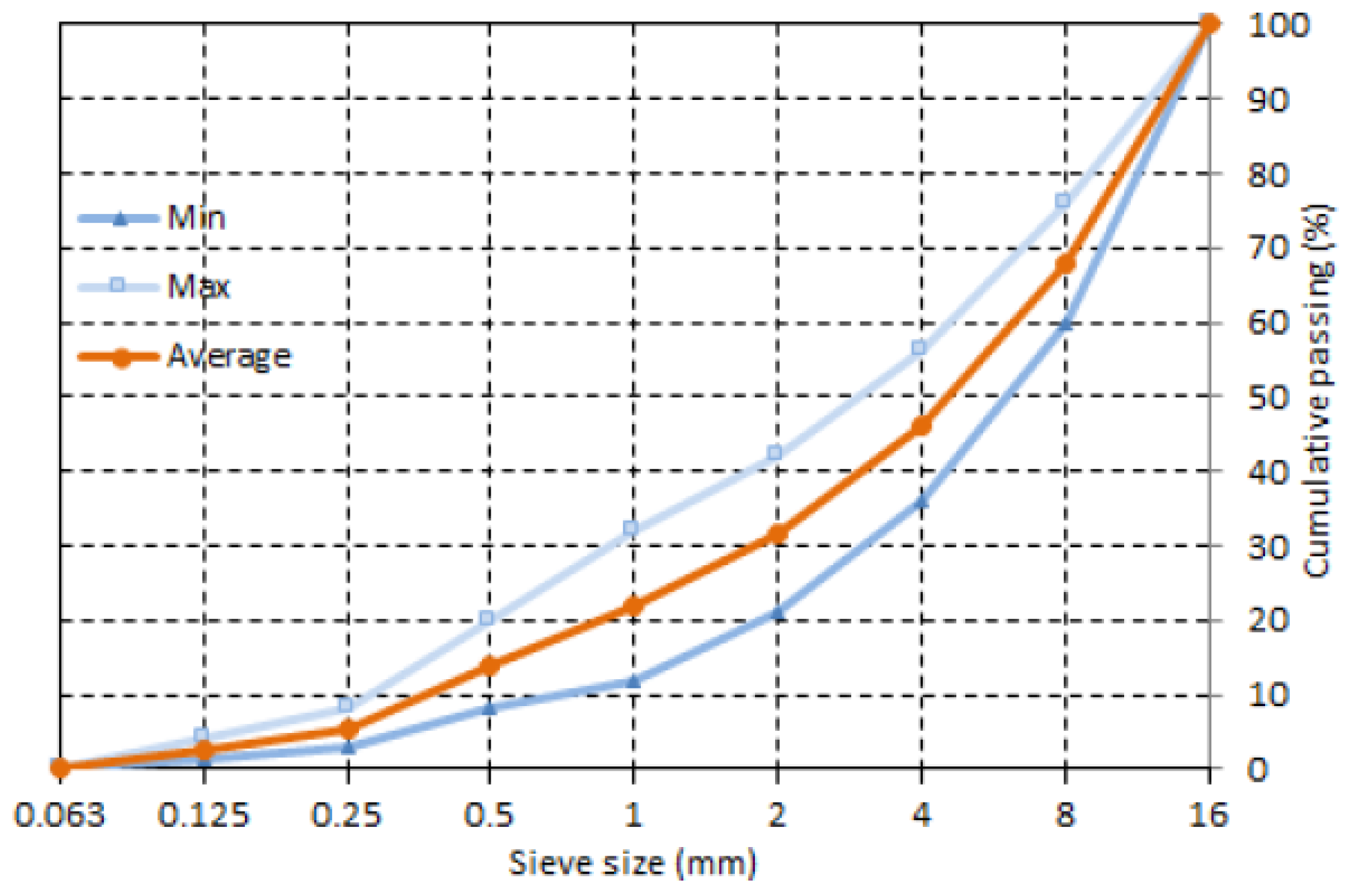

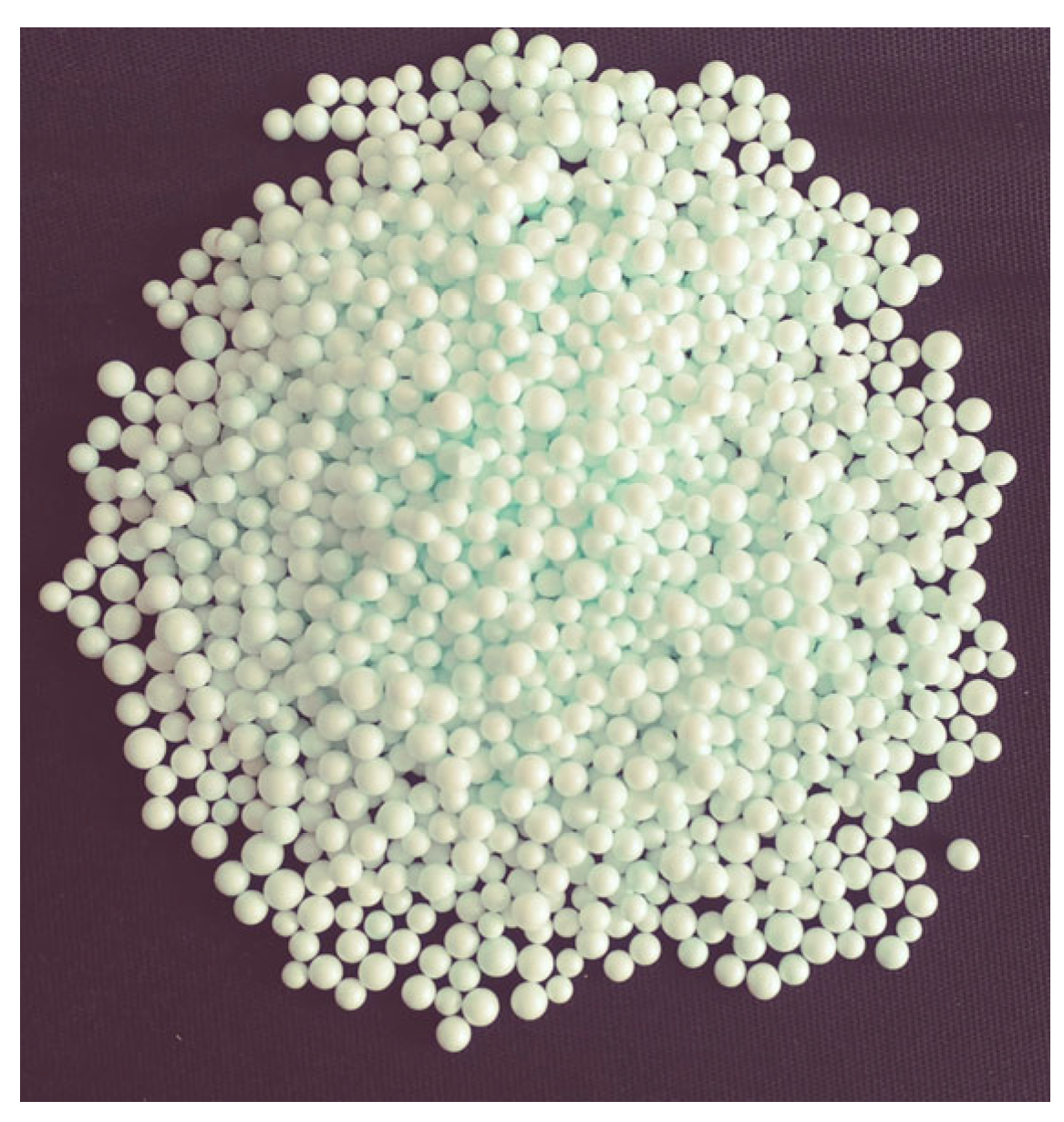

2.1. Materials

2.2. Concrete Mixture Proportions

2.3. Manufacture and Curing of Concrete

2.4. Methods

3. Results and Discussion

3.1. Fresh Properties

3.2. Hardened Properties

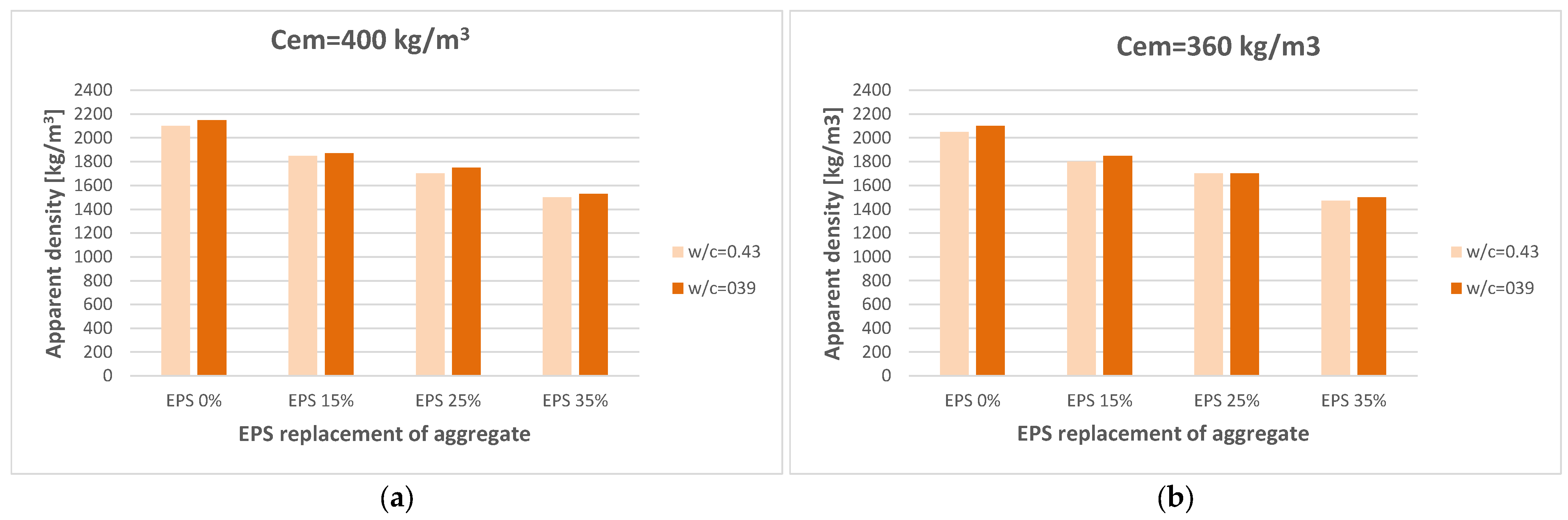

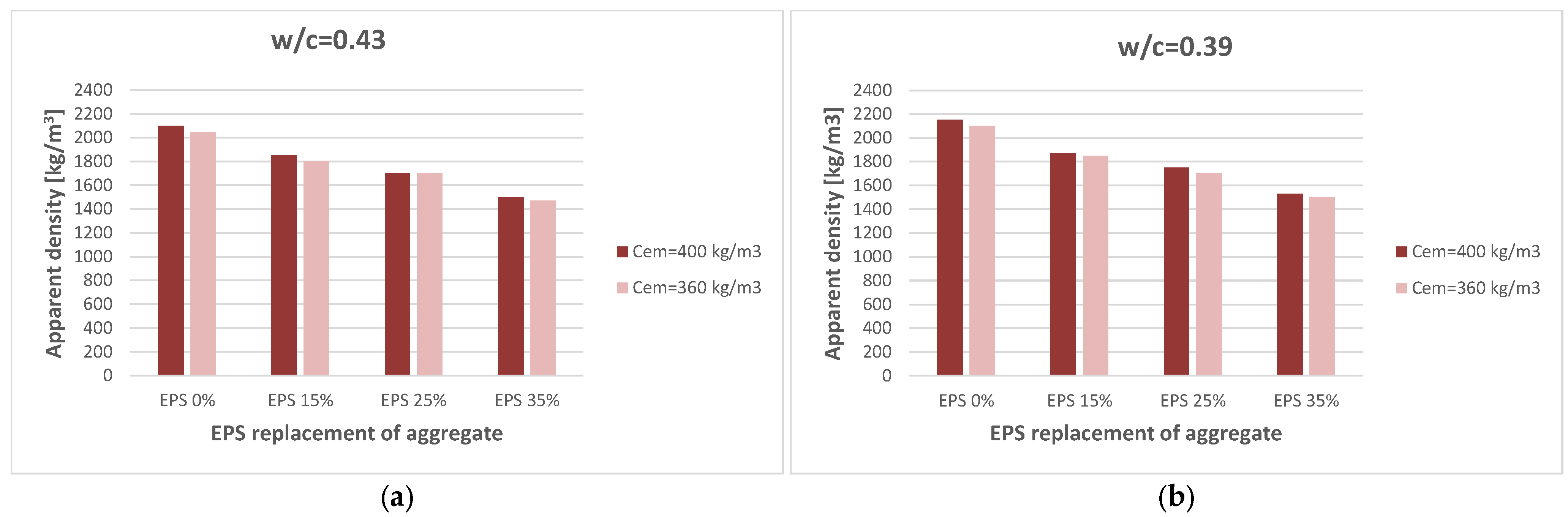

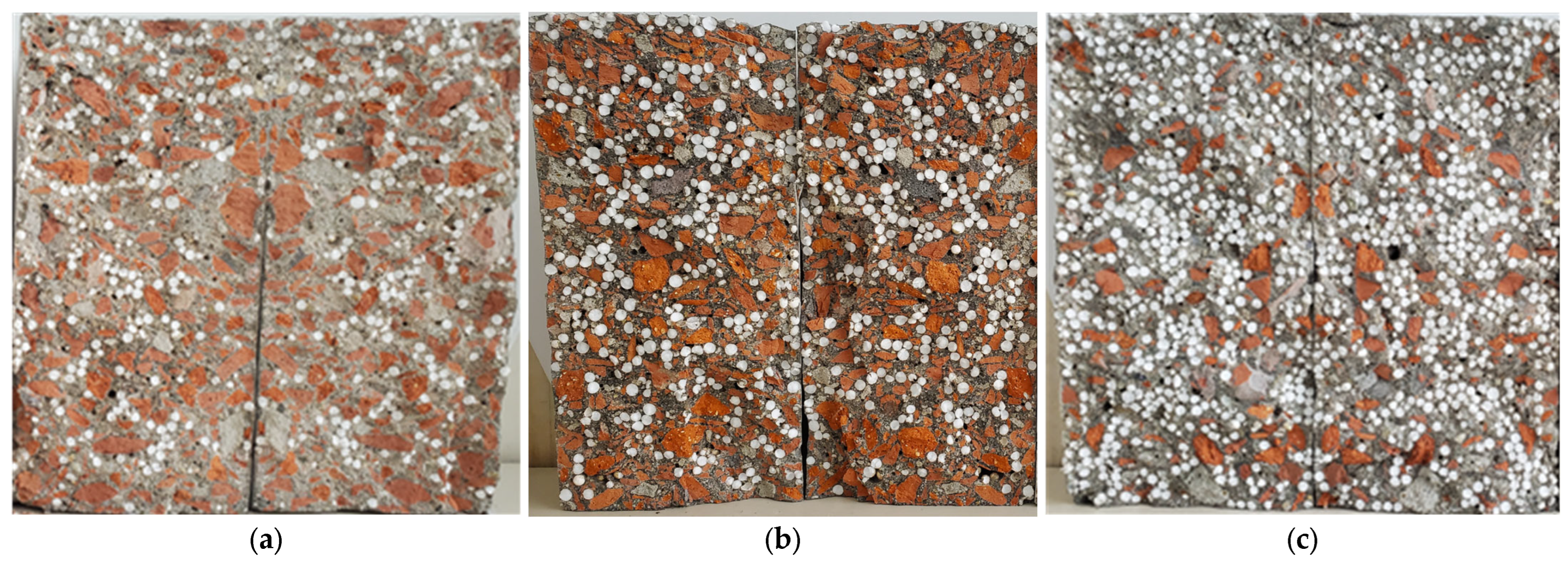

3.2.1. Apparent and Dry Densities and Bead Distribution

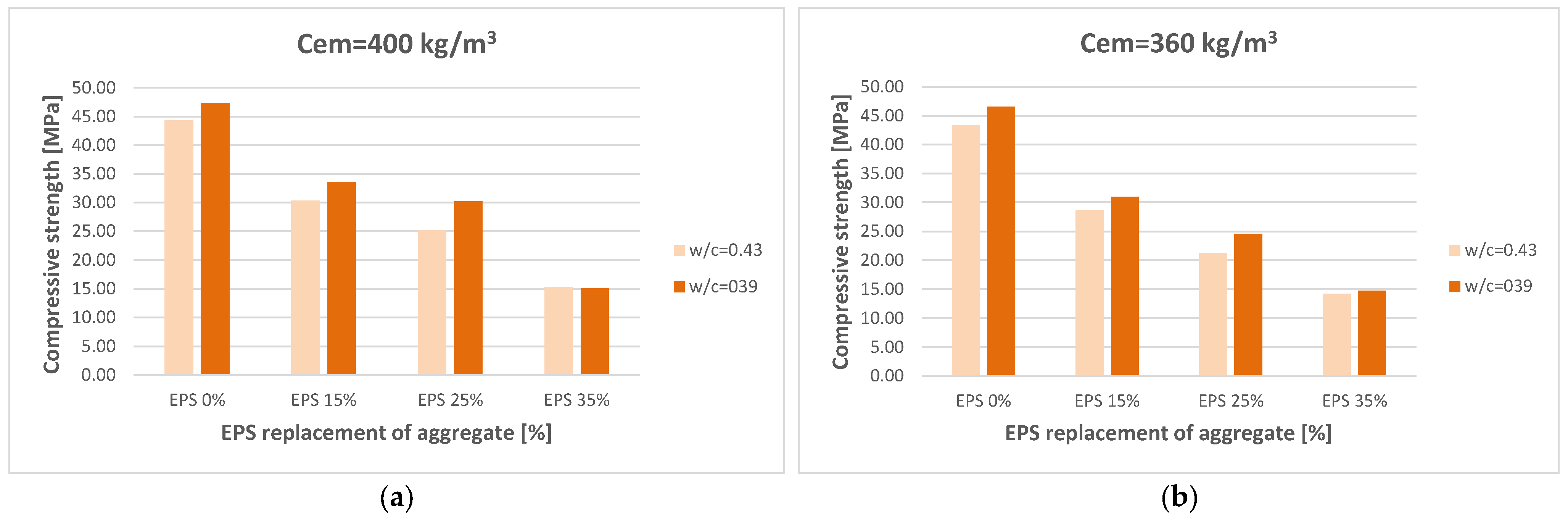

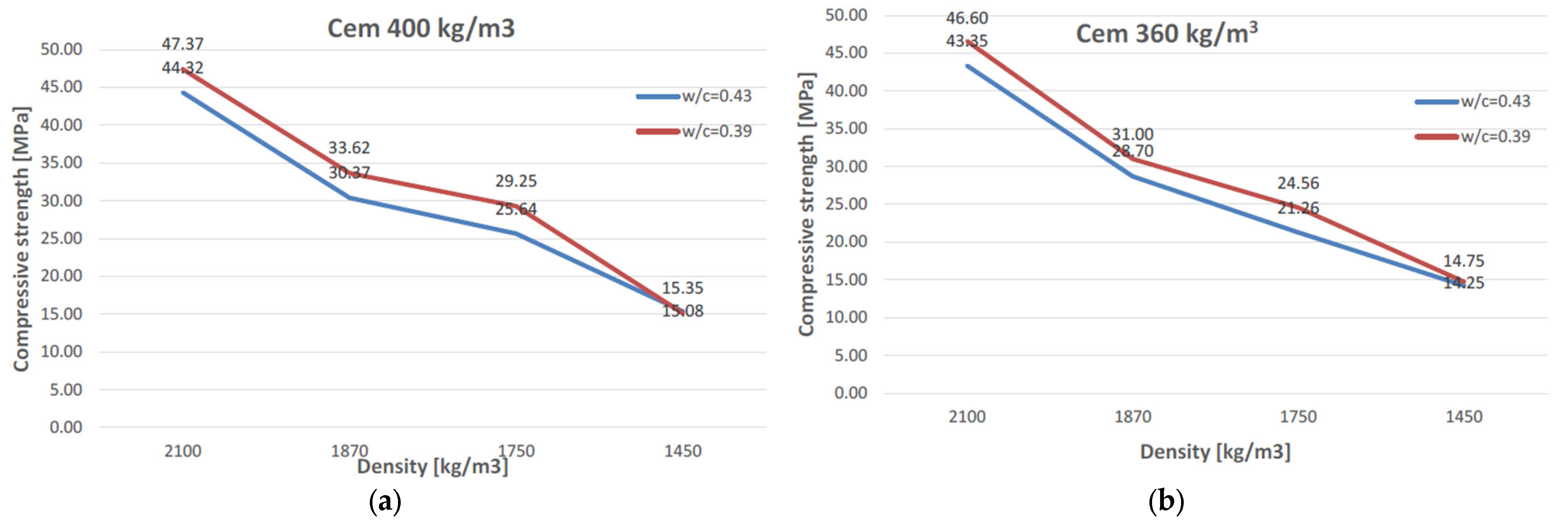

3.2.2. Compressive Strength

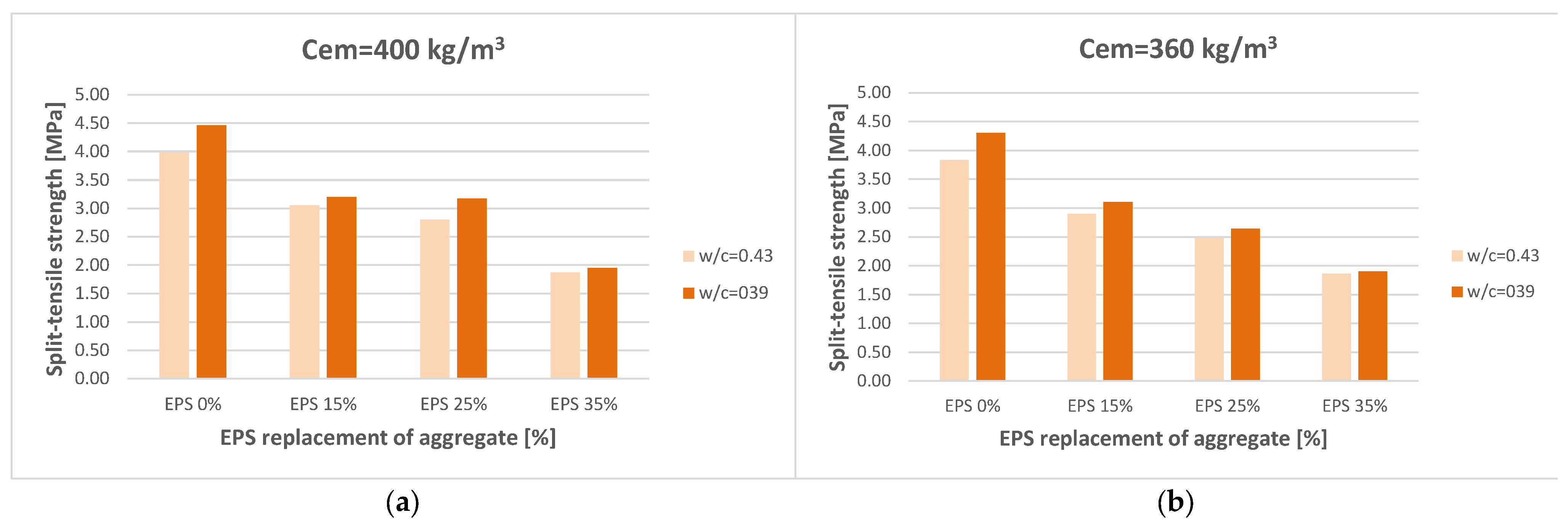

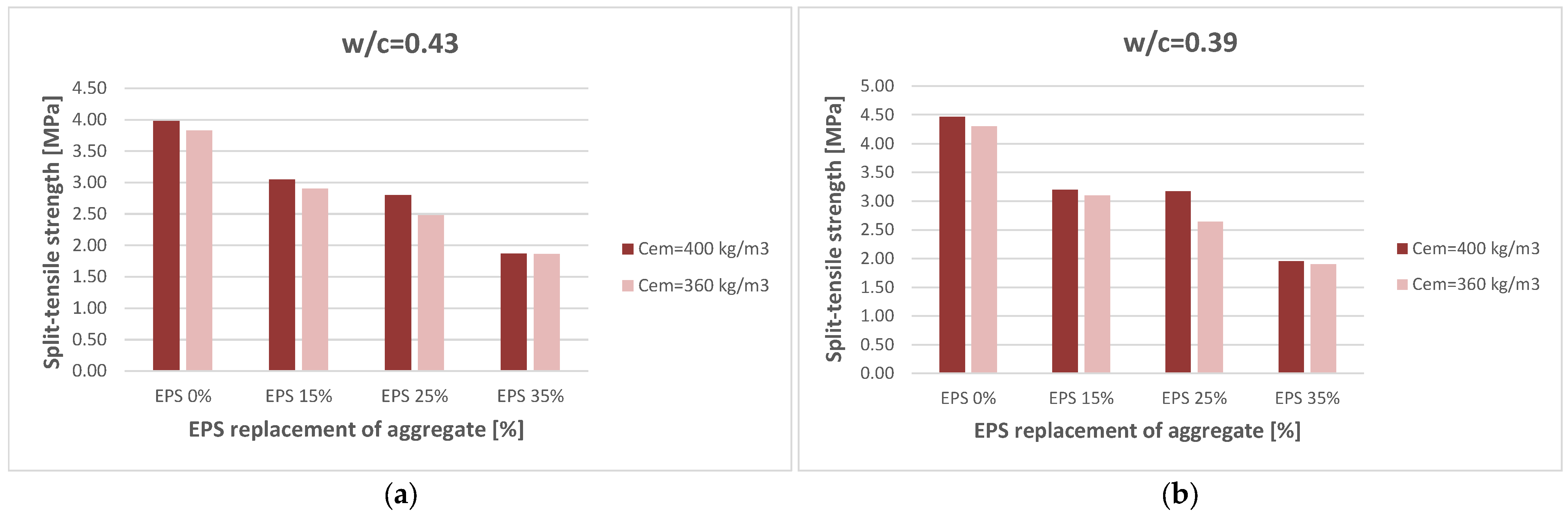

3.2.3. Split-Tensile Strength

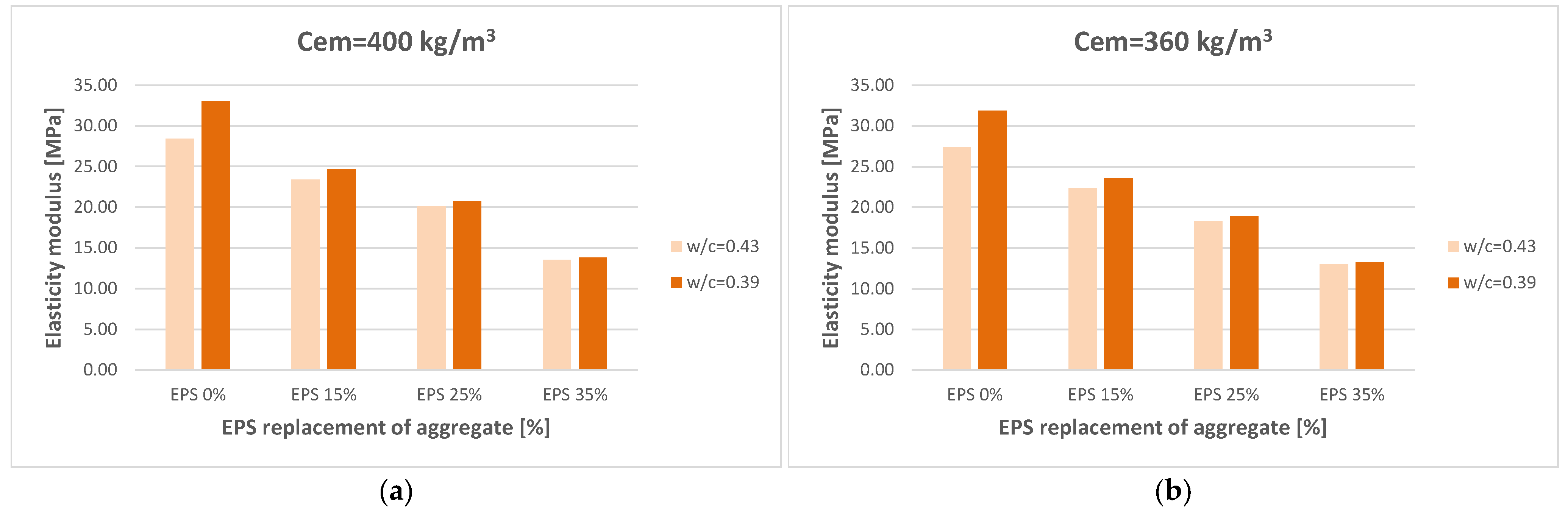

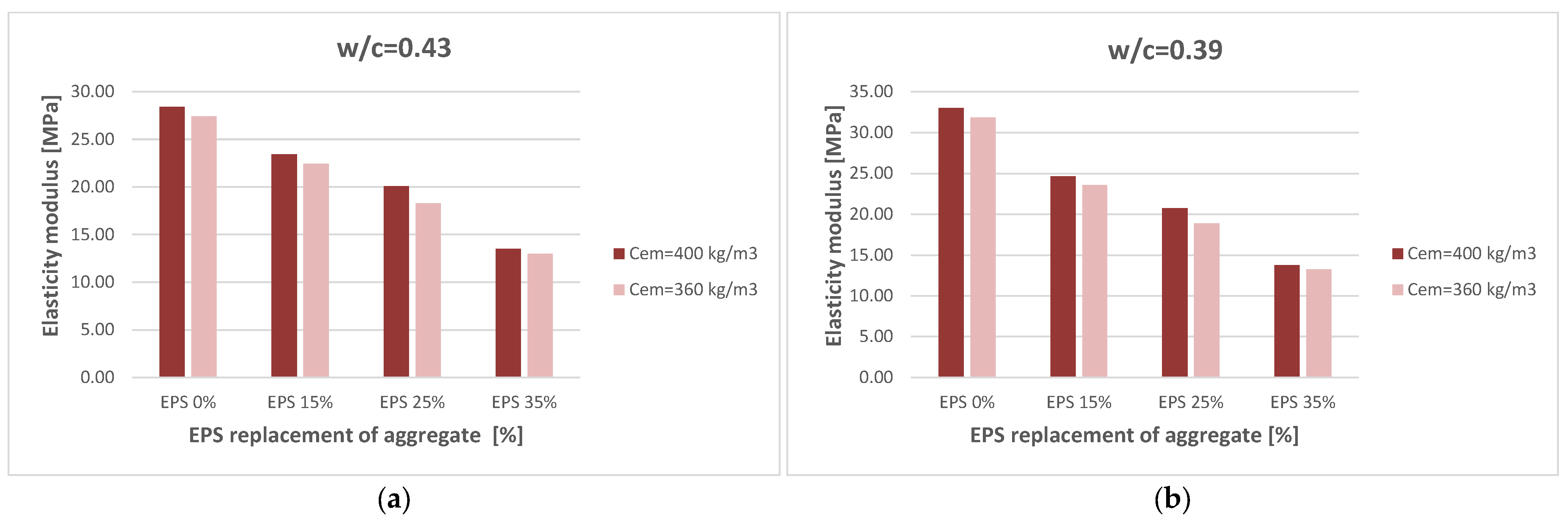

3.2.4. Modulus of Elasticity

3.3. Practical Feasibility of RBAC with EPS Beads

4. Conclusions

- The use of EPS beads together with RBA as an aggregate in concrete can substantially contribute to equilibrating the demand of renewable resources, leading to a beneficial step forward towards sustainability, economy and solid waste management.

- In general, the use of EPS beads decreased the mechanical properties of the recycled brick aggregate concrete; however, the results showed the potential for producing lightweight concrete of different grades, with densities between 1500 and 1800 kg/m3.

- Recycled brick aggregate concrete as a lightweight concrete of structural grade was obtained by replacing the recycled coarse aggregate with EPS beads in percentages no higher than 25% for two different w/c ratios, 0.43 and 0.39, respectively. For the smallest w/c ratio, with the increase in the replacement percentage to 35%, the compressive strength falls into the range corresponding to lightweight concrete of medium strength, according to ACI 213R-14ACI.

- The developed lightweight concrete presents a uniform distribution of the EPS beads in the hardened concrete, avoiding volume concentrations.

- The influence of the w/c ratio on the compressive strength, which is notable at replacement percentages lower than 25%, decreases for higher replacement percentages with EPS beads, for example, 35% in this study.

- With the increase in the cement content from 360 kg/m3 to 400 kg/m3, for all the determined physical and mechanical properties, higher values were recorded; in addition, the slump increased.

- The values of the w/c ratios used in this experimental study may be considered moderate and low–moderate, denoting that higher concrete strengths are possible to obtain for lower ratios, but a lower workability is expected, which can be counteracted by using the chemical admixtures in a higher content.

- With the increase in the replacement percentage of recycled aggregate with EPS beads from 0% to 35%, the slump of the concrete increased; the cause of such an improvement in the slump was the rounded shape of the EPS beads.

- With the increase in the replacement percentage of recycled aggregate with EPS beads from 0% to 35% for the two w/c ratios 0.43 and 0.39, the highest decreases in the apparent density, compressive strength, split-tensile strength and elasticity modulus were 29%, 68%, 57% and 58%, respectively.

- For the replacement percentages of 15% and 25%, the highest decreases in the compressive strength were 34% and 51%, respectively.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yahya, K.; Boussabaine, H. Quantifying environmental impacts and eco-costs from brick waste. Arch. Eng. Des. Manag. 2010, 6, 189–206. [Google Scholar] [CrossRef]

- Duan, H.; Li, J. Construction and demolition waste management: China’s lessons. Waste Manag. Res. J. 2016, 34, 397–398. [Google Scholar] [CrossRef]

- Statistics Unit, Environmental Protection Department. Monitoring of Solid Waste in Hong Kong; Statistics Unit, Environmental Protection Department: Hong Kong, 2017. [Google Scholar]

- Pappu, A.; Saxena, M.; Asolekar, S.R. Solid wastes generation in India and their recycling potential in building materials. Build. Environ. 2007, 42, 2311–2320. [Google Scholar] [CrossRef]

- Zulzaha, F.F. New Plan to Manage Solid Waste Systematically; The Star Malaysia: Petaling Jaya, Malaysia, 2014. [Google Scholar]

- Zhao, Y.; Gao, J.; Chen, F.; Liu, C.; Chen, X. Utilization of waste clay bricks as coarse and fine aggregates for the preparation of lightweight aggregate concrete. J. Clean. Prod. 2018, 201, 706–715. [Google Scholar] [CrossRef]

- Yang, J.; Du, Q.; Bao, Y. Concrete with recycled concrete aggregate and crushed clay bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Zong, L.; Fei, Z.; Zhang, S. Permeability of recycled aggregate concrete containing fly ash and clay brick waste. J. Clean. Prod. 2014, 70, 175–182. [Google Scholar] [CrossRef]

- Zheng, C.; Lou, C.; Du, G.; Li, X.; Liu, Z.; Li, L. Mechanical properties of recycled concrete with demolished waste concrete aggregate and clay brick aggregate. Results Phys. 2018, 9, 1317–1322. [Google Scholar] [CrossRef]

- Bektaş, F. Alkali reactivity of crushed clay brick aggregate. Constr. Build. Mater. 2014, 52, 79–85. [Google Scholar] [CrossRef]

- Cachim, P.B. Mechanical properties of brick aggregate concrete. Constr. Build. Mater. 2009, 23, 1292–1297. [Google Scholar] [CrossRef]

- Nepomuceno, M.C.; Isidoro, R.A.; Catarino, J.P. Mechanical performance evaluation of concrete made with recycled ceramic coarse aggregates from industrial brick waste. Constr. Build. Mater. 2018, 165, 284–294. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, J.; Hu, W.; Du, Z.; Gao, D. Properties of mortar with waste clay bricks as fine aggregate. Constr. Build. Mater. 2018, 166, 898–907. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Mobili, A.; Giosuè, C.; Corinaldesi, V.; Tittarelli, F. Bricks and Concrete wastes as coarse and fine aggregates in sustainable mortars. Adv. Mater. Sci. Eng. 2018, 2018, 8676708. [Google Scholar] [CrossRef]

- Atyia, M.M.; Mahdy, M.G.; Elrahman, M.A. Production and properties of lightweight concrete incorporating recycled waste crushed clay bricks. Constr. Build. Mater. 2021, 304, 124655. [Google Scholar] [CrossRef]

- Wongsa, A.; Sata, V.; Nuaklong, P.; Chindaprasirt, P. Use of crushed clay brick and pumice aggregates in lightweight geopol-ymer concrete. Constr. Build. Mater. 2018, 188, 1025–1034. [Google Scholar] [CrossRef]

- Debieb, F.; Kenai, S. The use of coarse and fine crushed bricks as aggregate in concrete. Constr. Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Kamutha, R.; Vijai, K. Strength of concrete incorporating aggregates recycled from demolition waste. J. Eng. App. Sci. 2010, 5, 64–71. [Google Scholar]

- Duan, Z.; Hou, S.; Xiao, J.; Singh, A. Rheological properties of mortar containing recycled powders from construction and demolition wastes. Constr. Build. Mater. 2020, 237, 117622. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd-Elmoaty, A.-E.M.; Hassan, H.H. Utilization of crushed clay brick in cellular concrete production. Alex. Eng. J. 2014, 53, 119–130. [Google Scholar] [CrossRef]

- Ibrahim, N.M.; Salehuddin, S.; Amat, R.C.; Rahim, N.L.; Izhar, T.N.T. Performance of lightweight foamed concrete with waste clay brick as coarse aggregate. APCBEE Procedia 2013, 5, 497–501. [Google Scholar] [CrossRef]

- Bektas, F.; Wang, K.; Ceylan, H. Effects of crushed clay brick aggregate on mortar durability. Constr. Build. Mater. 2009, 23, 1909–1914. [Google Scholar] [CrossRef]

- EN 1992-1-1; Design of Concrete Structures. General Rules and Rules for Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- Babu, D.S.; Babu, K.G.; Wee, T. Properties of lightweight expanded polystyrene aggregate concretes containing fly ash. Cem. Concr. Res. 2005, 35, 1218–1223. [Google Scholar] [CrossRef]

- Chen, B.; Fang, C. Mechanical properties of EPS lightweight concrete. Proc. Inst. Civ. Eng. Constr. Mater. 2011, 164, 173–180. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Golshekan, M. The effect of expanded polystyrene synthetic particles on the fracture parameters, brittleness and mechanical properties of concrete. Theor. Appl. Fract. Mech. 2018, 94, 160–172. [Google Scholar] [CrossRef]

- Cui, C.; Huang, Q.; Li, D.; Quan, C.; Li, H. Stress–strain relationship in axial compression for EPS concrete. Constr. Build. Mater. 2016, 105, 377–383. [Google Scholar] [CrossRef]

- Miled, K.; Sab, K.; Le roy, R. Particle size effect on EPS lightweight concrete compressive strength: Experimental investigation and modelling. Mech. Mater. 2007, 39, 222–240. [Google Scholar]

- Nor, H.R.S.; Siti, A.S.M.; Muhammad, K.A.R. Application of expanded polystyrene (EPS) in buildings and constructions: A review. J. App. Polym. Sci. 2019, 136, 47529. [Google Scholar]

- Rosca, B.; Corobceanu, V. Structural grade concrete containing expanded polystyrene beads with different particle distributions of normal weight aggregate. Mater. Today Proc. 2020, 42, 548–554. [Google Scholar] [CrossRef]

- Tang, W.C.; Nadeem, Y.; Lo, A. Mechanical and drying shrinkage properties of structural-graded polystyrene aggregate con-crete. Cem. Concr. Comp. 2008, 30, 403–409. [Google Scholar]

- Sadrmomtazi, A.; Sobhani, J.; Mirgozar, M.A.; Najimi, M. Properties of multi-strength grade EPS concrete containing silica fume and rice husk ash. Constr. Build. Mater. 2012, 35, 211–219. [Google Scholar] [CrossRef]

- Rosca, B.; Serbanoiu, A.A. Study on influence of natural aggregate maximum size on compressive strength of polystyrene aggregate concrete of structural grade. Mater. Today Proc. 2022, 61, 433–439. [Google Scholar] [CrossRef]

- Babu, D.S.; Babu, K.G.; Tiong-Huan, W. Effect of polystyrene aggregate size on strength and moisture migration characteristics of lightweight concrete. Cem. Concr. Compos. 2006, 28, 520–527. [Google Scholar] [CrossRef]

- Liu, N.; Chen, B. Experimental study of the influence of EPS particle size on the mechanical properties of EPS lightweight concrete. Constr. Build. Mater. 2014, 68, 227–232. [Google Scholar] [CrossRef]

- Babu, K.; Babu, D. Behaviour of lightweight expanded polystyrene concrete containing silica fume. Cem. Concr. Res. 2003, 33, 755–762. [Google Scholar] [CrossRef]

- Dixit, A.; Pang, S.D.; Kang, S.-H.; Moon, J. Lightweight structural cement composites with expanded polystyrene (EPS) for enhanced thermal insulation. Cem. Concr. Compos. 2019, 102, 185–197. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Termkhajornkit, P.; Kim, Y.H. Review of concrete with expanded polystyrene (EPS): Performance and envi-ronmental aspects. J. Clean. Prod. 2022, 366, 132919. [Google Scholar]

- Adhikary, S.K.; Ashish, D.K. Turning waste expanded polystyrene into light weight aggregate: Towards sustainable construc-tion industry. Sci. Total Environ. 2022, 837, 155852. [Google Scholar]

- Khalil, A.; Heniegal, A.; Attia, M. Behavior of posttensioned fibrous lightweight concrete beams made of natural pumice. In Proceedings of the 2nd International Conference on Sustainable Construction Project Management Sustainable Infrastructures and Transportation for Future Cities, Aswan, Egypt, 15–16 December 2018. [Google Scholar]

- Attia, M.M.; Elsadany, R.A.; Khalil, M.H.; Ahmed, M.; Baktheer, A.; Shawkya, S.M. Physical and mechanical properties of concrete containing plastic tube fibers. Case Stud. Constr. Mater. 2024, 21, e03809. [Google Scholar] [CrossRef]

- EN 934-2; Admixtures for Concrete, Mortar and Grout—Part 2: Concrete Admixtures—Definitions, Requirements, Conformity, Marking and Labelling. European Committee for Standardization (CEN): Brussels, Belgium, 2009.

- EN 12390-1; Testing Hardened Concrete Shape, Dimensions and Other Requirements for Specimens and Moulds. European Committee for Standardization (CEN): Brussels, Belgium, 2021.

- EN 12350-2; Testing Fresh Concrete—Part 2: Slump Test. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- EN 12390-7; Testing Hardened Concrete—Density of Hardened Concrete. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- EN 12390-6; Testing Hardened Concrete—Part 6: Tensile Strength by Splitting Of Test Specimens. European Committee for Standardization (CEN): Brussels, Belgium, 2023.

- EN 12390-13; Testing Hardened Concrete Determination of Secant Modulus of Elasticity in Compression. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- ACI 213R-14; Guide for Structural Lightweight-Aggregate Concrete. American Concrete Institute (ACI): Farmington Hills, MI, USA, 2014.

| Sieve Size (mm) | Fine Aggregate | Sieve Size (mm) | Coarse Aggregate |

|---|---|---|---|

| % Passing by Mass | Natural Sand | % Passing by Mass | CRBA |

| 4 | 100 | 20 | 100 |

| 2 | 32 | 16 | 97.5 |

| 1 | 22.80 | 8 | 68 |

| 0.50 | 13.60 | 4 | 46 |

| 0.25 | 4.40 | - | - |

| 0.063 | 0 | - | - |

| Property | CRBA 1 | Sand |

|---|---|---|

| Specific gravity (SSD) [kg/m3] | 2140 | 2600 |

| Bulk density [kg/m3] | 1040 | 1730 |

| 24 h water absorption [%] | 14.4 | 1.2 |

| Oxide | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | K2O | SO3 | LOI |

| [%] | 60.12 | 21.78 | 6.56 | 4.13 | 2.08 | 0.36 | 0.42 | 2.16 | 2.39 |

| Series | Mix | W/C | CEM [kg/m3] | EPS [%] | RBA [kg/m3] | Sand [kg/m3] | Water [L/m3] | SP [%] |

|---|---|---|---|---|---|---|---|---|

| A (w/c = 0.43) | A400E0 | 0.43 | 400 | 0 | 743 | 817 | 170 | 0.006 |

| A400E15 | 400 | 15 | 580 | 761 | 170 | 0.006 | ||

| A400E25 | 400 | 25 | 472 | 723 | 170 | 0.006 | ||

| A400E35 | 400 | 35 | 363 | 685 | 170 | 0.006 | ||

| A360E0 | 360 | 0 | 776 | 852 | 153 | 0.006 | ||

| A360E15 | 360 | 15 | 606 | 794 | 153 | 0.006 | ||

| A360E25 | 360 | 25 | 492 | 754 | 153 | 0.006 | ||

| A360E35 | 360 | 35 | 379 | 715 | 153 | 0.006 | ||

| B (w/c = 0.39) | B400E0 | 0.39 | 400 | 0 | 761 | 836 | 154 | 0.010 |

| B400E15 | 400 | 15 | 594 | 778 | 154 | 0.010 | ||

| B400E25 | 400 | 25 | 483 | 740 | 154 | 0.010 | ||

| B400E35 | 400 | 35 | 372 | 701 | 154 | 0.010 | ||

| B360E0 | 360 | 0 | 791 | 870 | 139 | 0.010 | ||

| B360E15 | 360 | 15 | 618 | 810 | 139 | 0.010 | ||

| B360E25 | 360 | 25 | 502 | 770 | 139 | 0.010 | ||

| B360E35 | 360 | 35 | 387 | 730 | 139 | 0.010 |

| Property Under Evaluation | Standard |

|---|---|

| Slump test | EN 12350-2 [45] |

| Apparent density of hardened concrete | EN 12390-7 [46] |

| Compressive strength | EN 12390-3 [47] |

| Split-tensile strength | EN 12390-6 [48] |

| Modulus of elasticity | EN 12390-13 [49] |

| Mix | EPS Replacement in Aggregate | Volume of EPS in Mix | Slump |

|---|---|---|---|

| [%] | [%] | [mm] | |

| A400E0 | 0 | 0 | 30 |

| A400E15 | 15 | 10.25 | 50 |

| A400E25 | 25 | 17.08 | 100 |

| A400E35 | 35 | 23.91 | 130 |

| A360E0 | 0 | 0 | 20 |

| A360E15 | 15 | 10.69 | 45 |

| A360E25 | 25 | 17.82 | 70 |

| A360E35 | 35 | 24.95 | 100 |

| B400E0 | 0 | 0 | 25 |

| B400E15 | 15 | 10.49 | 40 |

| B400E25 | 25 | 17.48 | 80 |

| B400E35 | 35 | 24.47 | 95 |

| B360E0 | 0 | 0 | 20 |

| B360E15 | 15 | 10.91 | 40 |

| B360E25 | 25 | 18.18 | 60 |

| B360E35 | 35 | 25.45 | 80 |

| Mix | EPS Replacement in Aggregate | Volume of EPS in Mix | Apparent Density | Relative Value | Dry Density |

|---|---|---|---|---|---|

| [%] | [%] | [kg/m3] | [kg/m3] | ||

| A400E0 | 0 | 0 | 2100 | 1.00 | 2010 |

| A400E15 | 15 | 10.25 | 1850 | 0.88 | 1770 |

| A400E25 | 25 | 17.08 | 1700 | 0.81 | 1630 |

| A400E35 | 35 | 23.91 | 1500 | 0.71 | 1440 |

| A360E0 | 0 | 0 | 2050 | 1.00 | 1970 |

| A360E15 | 15 | 10.69 | 1800 | 0.88 | 1730 |

| A360E25 | 25 | 17.82 | 1700 | 0.83 | 1640 |

| A360E35 | 35 | 24.95 | 1470 | 0.72 | 1420 |

| B400E0 | 0 | 0 | 2150 | 1.00 | 2080 |

| B400E15 | 15 | 10.49 | 1870 | 0.87 | 1810 |

| B400E25 | 25 | 17.48 | 1750 | 0.82 | 1700 |

| B400E35 | 35 | 24.47 | 1530 | 0.71 | 1490 |

| B360E0 | 0 | 0 | 2100 | 1.00 | 2040 |

| B360E15 | 15 | 10.91 | 1850 | 0.88 | 1800 |

| B360E25 | 25 | 18.18 | 1700 | 0.81 | 1660 |

| B360E35 | 35 | 25.45 | 1500 | 0.72 | 1460 |

| Mix | EPS Replacement in Aggregate | Volume of EPS in Mix | Compressive Strength | Relative Value | Split-Tensile Strength | Relative Value |

|---|---|---|---|---|---|---|

| [%] | [%] | [MPa] | [MPa] | |||

| A400E0 | 0 | 0 | 44.32 | 1.00 | 3.98 | 1.00 |

| A400E15 | 15 | 10.25 | 30.37 | 0.69 | 3.05 | 0.77 |

| A400E25 | 25 | 17.08 | 25.64 | 0.58 | 2.80 | 0.70 |

| A400E35 | 35 | 23.91 | 15.35 | 0.35 | 1.87 | 0.46 |

| A360E0 | 0 | 0 | 43.35 | 1.00 | 3.83 | 1.00 |

| A360E15 | 15 | 10.69 | 28.70 | 0.66 | 2.90 | 0.75 |

| A360E25 | 25 | 17.82 | 21.26 | 0.49 | 2.48 | 0.64 |

| A360E35 | 35 | 24.95 | 14.25 | 0.33 | 1.86 | 0.48 |

| B400E0 | 0 | 0 | 47.37 | 1.00 | 4.46 | 1.00 |

| B400E15 | 15 | 10.49 | 33.62 | 0.71 | 3.20 | 0.72 |

| B400E25 | 25 | 17.48 | 29.25 | 0.62 | 3.17 | 0.70 |

| B400E35 | 35 | 24.47 | 15.08 | 0.32 | 1.95 | 0.43 |

| B360E0 | 0 | 0 | 46.60 | 1.00 | 4.30 | 1.00 |

| B360E15 | 15 | 10.91 | 31.00 | 0.66 | 3.10 | 0.72 |

| B360E25 | 25 | 18.18 | 24.56 | 0.53 | 2.64 | 0.61 |

| B360E35 | 35 | 25.45 | 14.75 | 0.32 | 1.90 | 0.44 |

| Mix | EPS Replacement in Aggregate | Volume of EPS in Mix | Modulus of Elasticity Ecs | Relative Value |

|---|---|---|---|---|

| [%] | [%] | [GPa] | ||

| A400E0 | 0 | 0 | 28.40 | 1.00 |

| A400E15 | 15 | 10.25 | 23.40 | 0.82 |

| A400E25 | 25 | 17.08 | 20.10 | 0.71 |

| A400E35 | 35 | 23.91 | 13.50 | 0.47 |

| A360E0 | 0 | 0 | 27.40 | 1.00 |

| A360E15 | 15 | 10.69 | 22.40 | 0.81 |

| A360E25 | 25 | 17.82 | 18.30 | 0.67 |

| A360E35 | 35 | 24.95 | 13.00 | 0.47 |

| B400E0 | 0 | 0 | 33.02 | 1.00 |

| B400E15 | 15 | 10.49 | 24.63 | 0.75 |

| B400E25 | 25 | 17.48 | 20.72 | 0.63 |

| B400E35 | 35 | 24.47 | 13.78 | 0.42 |

| B360E0 | 0 | 0 | 31.86 | 1.00 |

| B360E15 | 15 | 10.91 | 23.58 | 0.74 |

| B360E25 | 25 | 18.18 | 18.87 | 0.60 |

| B360E35 | 35 | 25.45 | 13.27 | 0.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosca, B. Eco-Friendly Lightweight Aggregate Concrete of Structural Grade Made with Recycled Brick Aggregate Containing Expanded Polystyrene Beads. Sustainability 2025, 17, 3050. https://doi.org/10.3390/su17073050

Rosca B. Eco-Friendly Lightweight Aggregate Concrete of Structural Grade Made with Recycled Brick Aggregate Containing Expanded Polystyrene Beads. Sustainability. 2025; 17(7):3050. https://doi.org/10.3390/su17073050

Chicago/Turabian StyleRosca, Bogdan. 2025. "Eco-Friendly Lightweight Aggregate Concrete of Structural Grade Made with Recycled Brick Aggregate Containing Expanded Polystyrene Beads" Sustainability 17, no. 7: 3050. https://doi.org/10.3390/su17073050

APA StyleRosca, B. (2025). Eco-Friendly Lightweight Aggregate Concrete of Structural Grade Made with Recycled Brick Aggregate Containing Expanded Polystyrene Beads. Sustainability, 17(7), 3050. https://doi.org/10.3390/su17073050