Mechanical Properties of Composite Materials Obtained with Clay Matrices and Plant Waste Inserts

Abstract

1. Introduction

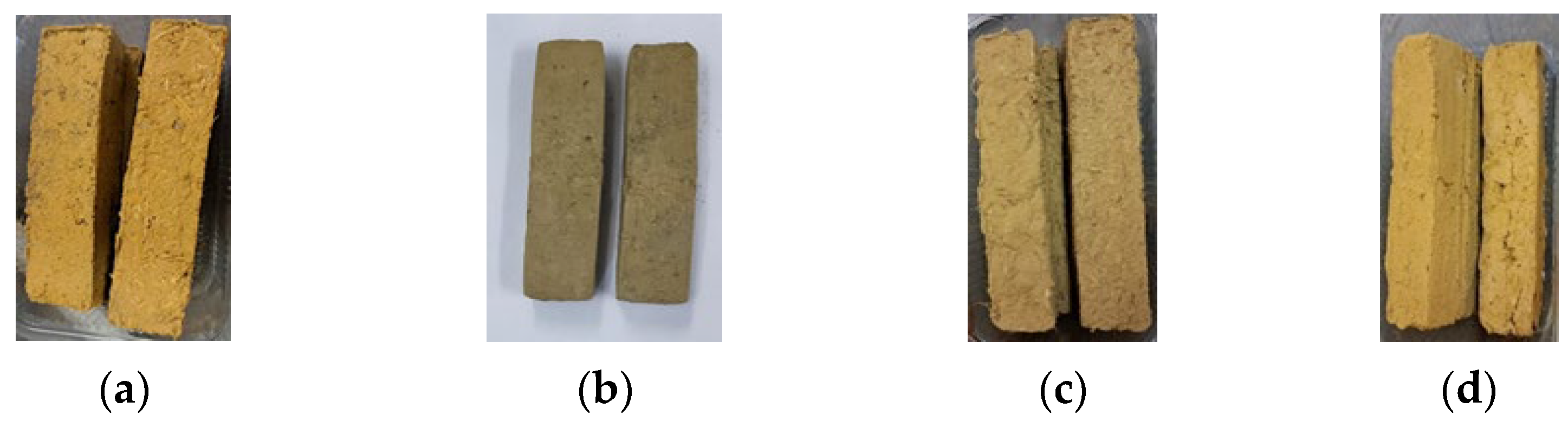

2. Materials and Methods

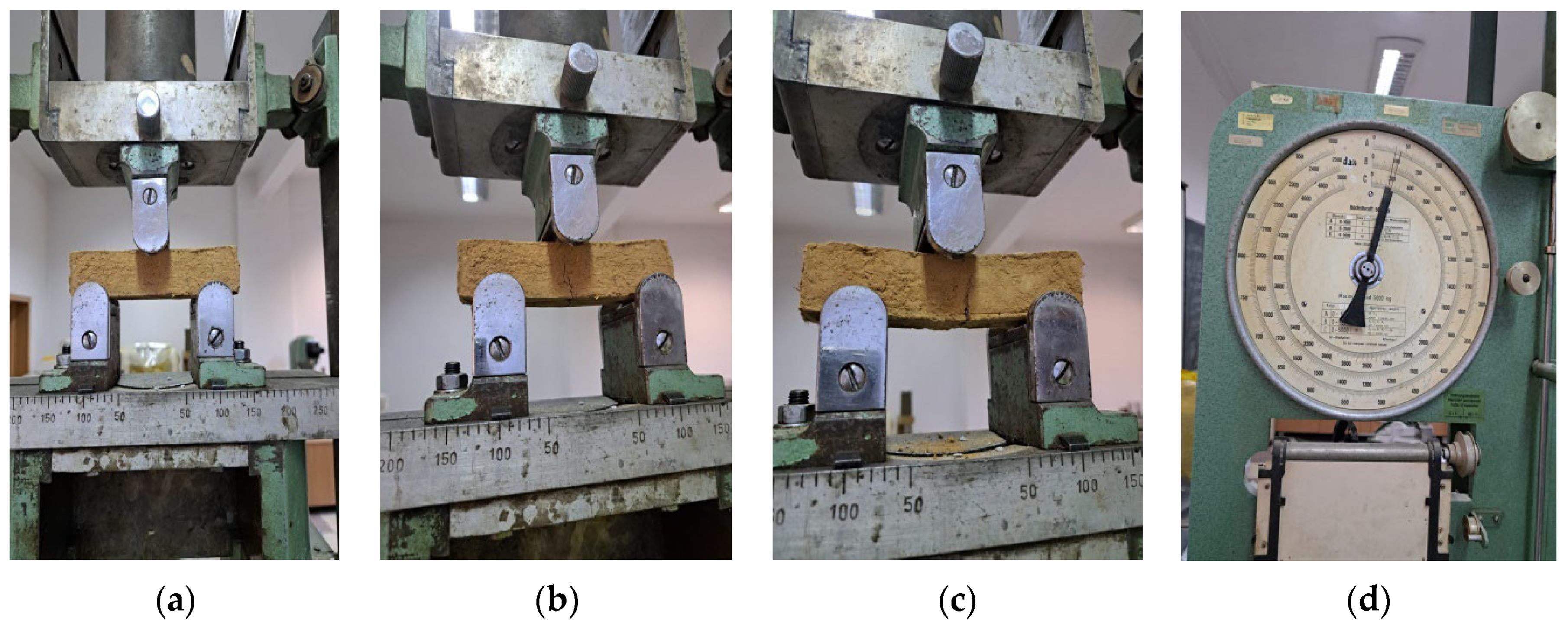

2.1. Methodology of Experiments for Bending Stress

- F—pressing force (N);

- b—length of the sample (mm);

- h—height of the sample (mm);

- l—length between supports, (mm);

- bending resistance (N/mm2);

- —average bending strength (N/mm2).

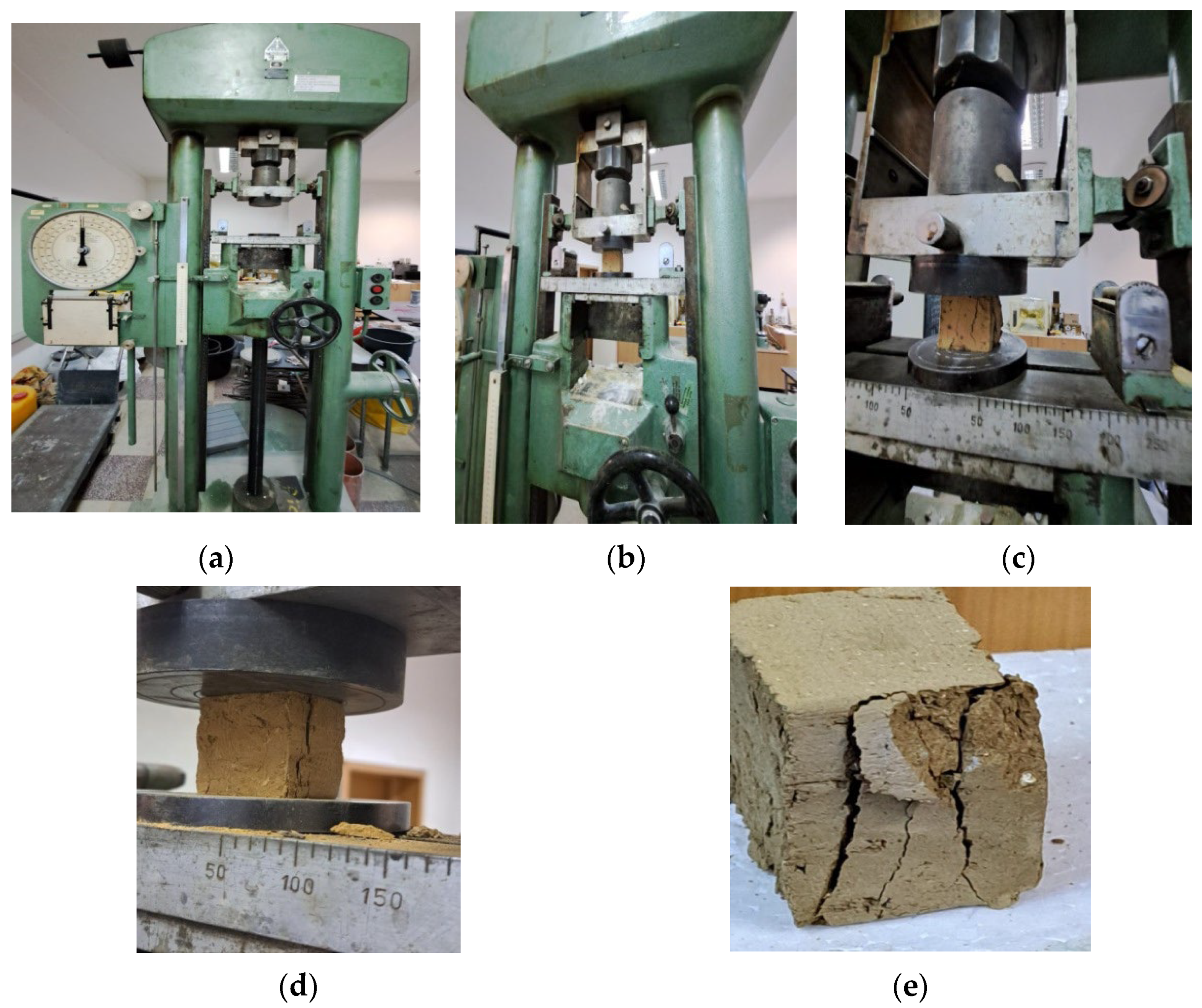

2.2. Methodology of Compression Experiments

- A—area of the composite material, (mm2);

- —compressive strength, (N/mm2);

- —average compressive strength, (N/mm2).

3. Results

3.1. Results Regarding the Mechanical Resistance of Bricks Made of Composite Material

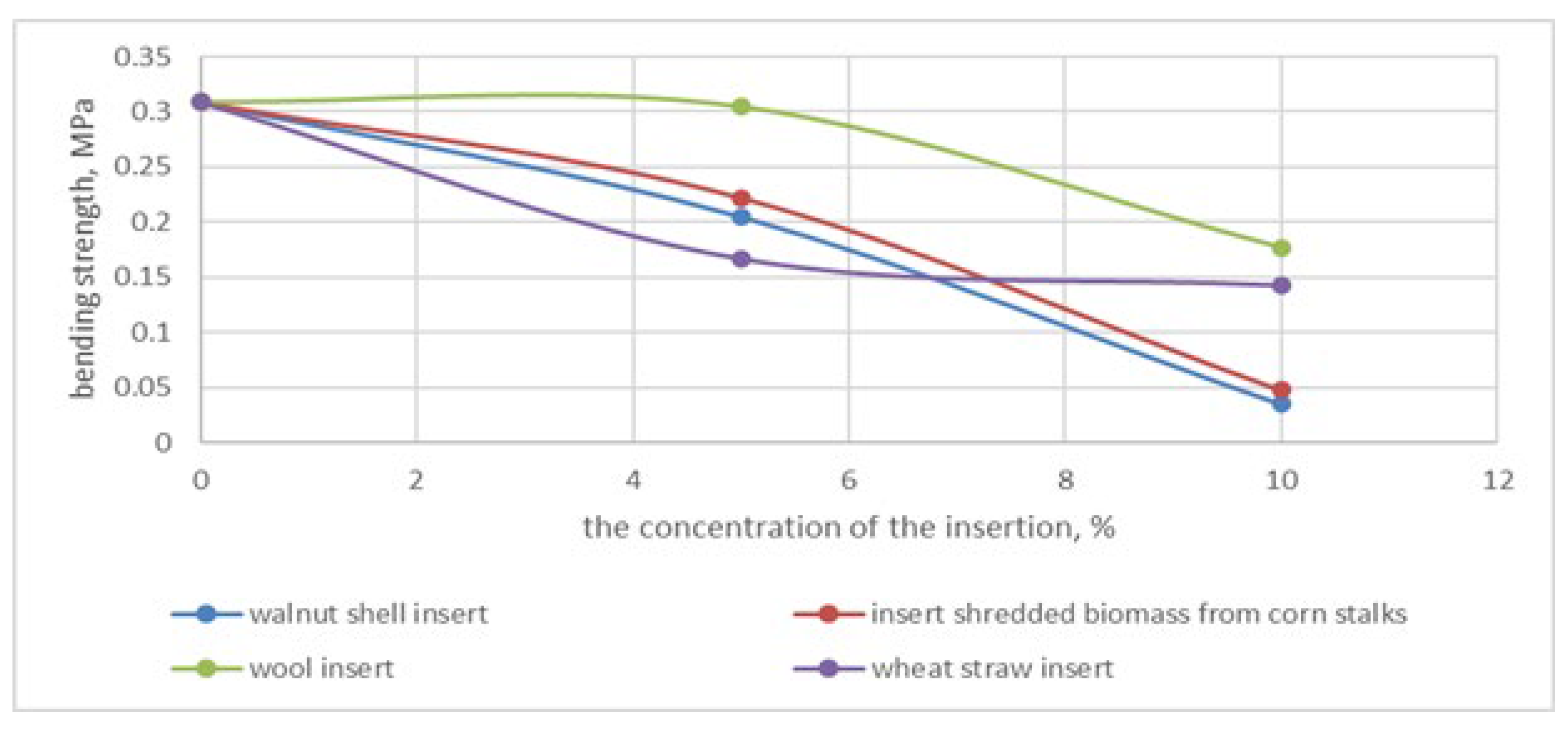

3.1.1. Bend Request

3.1.2. Compression Request

4. Discussion

Mechanical Resistance Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Surdu, E.; Farcas-Flamaropol, D.C.; Cardei, P.; Durbaca, I.; Sporea, N. Research on the Recovery of Some Agricultural Waste for the Manufacture of Composite Materials with Clay Matrices. J. Eng. Stud. Res. 2023, 29, 51–62. [Google Scholar] [CrossRef]

- Farcas-Flamaropol, D.C.; Surdu, E.; Iatan, R.; Cardei, P.; Ramona, M. Preliminary Research Regarding the Creation of a Category of Composite Material Based on a Mud Matrix and Agricultural Waste as Filler Materials. INMATEH–Agric. Eng. 2023, 71, 205–214. [Google Scholar] [CrossRef]

- Romano, N.; Lignola, G.P.; Brigante, M.; Bosso, L.; Chirico, G.B. Residual life and degradation assessment of wood elements used in soil bioengineering structures for slope protection. Ecol. Eng. 2016, 90, 498–509. [Google Scholar] [CrossRef]

- Nguyen, P.Q.; Courchesne, N.M.D.; Duraj-Thatte, A.; Praveschotinunt, P.; Joshi, S.N. Engineered living materials: Prospects and challenges for using biological systems to direct the assembly of smart materials. Adv. Mater. 2018, 30, 19. [Google Scholar] [CrossRef]

- Sima, E. Materiale Compozite-Necesitate si Provocare in Contextul Dezvoltarii Durabile. Buletinul AGIR Nr. 4. 2017, pp. 143–146. Available online: https://www.agir.ro/buletine/2928.pdf (accessed on 10 April 2024).

- Sfanta Scriptura (Biblia), Vechiul Testament, Iesirea (Exodul), Cap. 5, 7. Available online: https://biblia.crestini.com/explicatia-cartii/exod/ (accessed on 10 April 2024).

- Dexonline. Available online: https://dexonline.ro/definitie/chirpici (accessed on 10 April 2024).

- Meyers, L. How to Make Mud Bricks Used in Adobe Huts. 2012. Available online: https://www.heifer.org/blog/how-to-make-mud-bricks-used-in-adobe-huts.html (accessed on 10 April 2024).

- Breton, J.F. Chapter 5. Earth and Wood Architecture. In Les Batisseurs sur les Deux Rives de la Mer Rouge; Open Edition Books; Éditions de Boccard: Paris, France, 2015. [Google Scholar] [CrossRef]

- Sheweka, S. Using Mud Bricks as a Temporary Solution for Gaza Reconstruction. Energy Procedia 2011, 6, 236–240. [Google Scholar] [CrossRef]

- Mohammed, A.; Bahobail, M.A. The mud additives and their effects on thermal conductivity of adobe bricks. J. Eng. Sci. 2012, 40, 21–34. [Google Scholar] [CrossRef]

- Sharma, V.; Marwaha, B.M.; Vinayak, H.K. Enhancing durability of adobe by natural reinforcement for propagating sustainable mud housing. Int. J. Sustain. Built Environ. 2016, 5, 141–155. [Google Scholar] [CrossRef]

- Niroumand, H.; Zain, M.F.M.; Jamil, M. Various Types of Earth Buildings. Procedia-Soc. Behav. Sci. 2013, 89, 226–230. [Google Scholar] [CrossRef]

- Rosenberg, D.; Love, S.; Hubbard, E.; Klimscha, F. 7200 years old constructions and mudbrick technology: The evidence from Tel Tsaf. Jordan Valley, Israel. PLoS ONE 2020, 15, e0227288. [Google Scholar] [CrossRef]

- Sruthi, G.S. Mud Architecture. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 47–52. Available online: http://www.ijirset.com/ (accessed on 10 April 2024).

- Moquin, M. Ancient solutions for future sustainability: Building with adobe, rammed earth, and mud. In Proceedings of the CIB TG 16, Sustainable Construction, Tampa, FL, USA, 6–9 November 1994; pp. 543–552. Available online: https://www.irbnet.de/daten/iconda/CIB_DC24848.pdf (accessed on 10 April 2024).

- Al-Ajimi, F.; Abdalla, H.; Abdelghaffar, M.; Almatawah, J. Strength Behavior of Mud Brick in Building Construction. Open J. Civ. Eng. 2016, 6, 482–494. [Google Scholar] [CrossRef]

- Tarrad, M. A Vision to Review Mud Architecture, a Community Heritage Architecture in Jordan, for Low Income. Int. J. Des. Nat. Ecodyn. 2020, 15, 269–275. [Google Scholar] [CrossRef]

- Illampas, R.; Ioannou, I.; Charmpis, D.C. A Study of the Mechanical Behaviour of Adobe Masonry. WIT Trans. Built Environ. 2011, 118, 485–496. [Google Scholar] [CrossRef]

- Zaremba, M.; Trzciński, J.; Szczepański, T.; Bobrowska, A.; Welc, F. Influence of deterioration on the preservation of mud brick architecture based on the monuments from the tell el-retaba archaeological site. Int. J. Conserv. Sci. 2021, 12, 67–86. Available online: https://ijcs.ro/public/IJCS-21-05_Zaremba.pdf (accessed on 10 April 2024).

- Garcia, M.A.O.; Pabon, S.B.C.; Anseli, L.A.M.; Arias, L.P. Analysis of Physical and Mechanical Properties of Mud Brick Enhanced with Asphalt Recycling. INGE CUC 2020, 16, 2. Available online: https://revistascientificas.cuc.edu.co/ingecuc/article/view/2485/3561#figures (accessed on 10 April 2024).

- Binici, H.; Aksogan, O.; Bodur, M.N.; Akca, E.; Kapur, S. Thermal isolation and mechanical properties of fibre reinforced mud bricks as wall materials. Constr. Build. Mater. 2006, 21, 901–906. [Google Scholar] [CrossRef]

- Salih, M.M.; Osofero, A.I.; Imbabi, M.S. Mechanical properties of fibre-reinforced mud bricks. In Proceedings of the 2nd Conference of Civil Engineering, Da Nang, Vietnam, 5–7 May 2018; Available online: https://www.researchgate.net/publication/329786369_Mechanical_Properties_of_Fibre-reinforced_mud_bricks (accessed on 10 April 2024).

- Habib, A.; Begum, M.R.; Salam, M.A. Effect of stone dust on the mecanical properties of adobe brick. Int. J. Innov. Sci. Eng. Technol. 2015, 2, 631–637. Available online: http://www.ijiset.com/ (accessed on 10 April 2024).

- Revuelta-Acosta, J.D.; Garcia-Diaz, A.; Soto-Zarazua, G.M.; Rico-Garcia, E. Adobe as a Sustainable Material: A Thermal Performance. J. Appl. Sci. 2010, 10, 2211–2216. Available online: https://docsdrive.com/pdfs/ansinet/jas/2010/2211-2216.pdf (accessed on 10 April 2024).

- Wikipedia. Available online: https://ro.wikipedia.org/wiki/Argil%C4%83 (accessed on 10 April 2024).

- Esanatos.com. Available online: https://www.esanatos.com/naturist/terapia-cu-argila/ce-este-argila-compozitia-chim54771.php (accessed on 10 April 2024).

- Lamrani, M.; Mansour, M.; Laaroussi, N.; Khalfaoui, M. Thermal study of clay bricks reinforced by three ecological materials in south of Morocco. Energia Procedia 2019, 156, 273–277. [Google Scholar] [CrossRef]

- Salih, M.M.; Osofero, A.I.; Imbabi, M.S. Development of Lightweight Fiber Reinforced Clay Bricks. In Proceedings of the 2nd International Conference on Green Engineering for Sustainable Development; IC-GESD 2017, Kano, Nigeria, 5–7 December 2017; Available online: https://www.researchgate.net/publication/329786354_Development_of_Lightweight_Fiber_Reinforced_Clay_Bricks (accessed on 10 April 2024).

- Rajapakse, A.M.; Sanjula, S.N.; Nishantha, K.; Bandara, T.R.; Mudunkotuwa, Y. Cement and Clay Briks Reinforced with Coconut Fiber and Fiber Dust. Adv. Technol. 2022, 2, 233–248. [Google Scholar] [CrossRef]

- El Hazzat, O. Straw Reinforced Unifired Clay bricks. Al Akhawayn University, School of Science and Engineering. 2020. Available online: https://www.scribd.com/document/588874713/Straw-Reinforced-Unfired-Clay-Bricks (accessed on 10 April 2024).

- Ibrahim, Y.E.; Adamu, M.; Marouf, M.L.; Ahmed, O.S.; Drmosh, Q.A.; Malik, M.A. Mechanical Performance of Date-Palm-Fiber-Reinforced Concrete Containing Silica Fume. Buildings 2022, 12, 1642. [Google Scholar] [CrossRef]

- Damanik, N.H.C.; Susanto, D.; Suganda, E. The Compressive Strength of Unifired Clay Brick with Sugarcane Bagasse Fiber (SBF) and Bio-Enzyme Reinforcements. Int. J. Technol. 2020, 11, 1422–1429. [Google Scholar] [CrossRef]

- Golewski, G.L. The Role of Pozzolanic Activity of Siliceous Fly Ash in the Formation of the Structure of Sustainable Cementitious Composites. Sustain. Chem. 2022, 3, 520–534. [Google Scholar] [CrossRef]

- Santos Ribeiro, M.C.; Fiúza, A.; Ferreira, A.; De Lurdes Dinis, M.; Meira Castro, A.C.; Meixedo, J.P.; Alvim, M.R. Recycling Approach towards Sustainability Advance of Composite Materials’ Industry. Recycling 2016, 1, 178–193. [Google Scholar] [CrossRef]

- Ouakarrouch, M.; El Azhary, K.; Mansour, M.; Laaroussi, N.; Garoum, M. Thermal study of clay bricks reinforced by sisal-fibers used in construction in south of Morocco. Energy Rep. 2020, 6, 81–88. [Google Scholar] [CrossRef]

- Popa, N.; Durbaca, I.; Cardei, P.; Voicu, G.; Dinca, M.; Timofte, D. Researches concerning the strength characteristics of the composite materials which use wastes from leather industry. U. P. B. Sci. Bull. 2014, 76, 3. Available online: https://www.scientificbulletin.upb.ro/rev_docs_arhiva/full03c_109255.pdf (accessed on 10 April 2024).

- Mirea, A.C.; Stăncel, C.D.; Buțu, M.; Buzatu, M.; Avasiloaiei, C.; Niculescu, F.; Mateescu, A. Synthesis of novel aa7075 composite materials, reinforced in-situ with TIB2, for special applications. U. P. B. Sci. Bull. 2023, 85, 3. Available online: https://www.scientificbulletin.upb.ro/rev_docs_arhiva/full84e_918607.pdf (accessed on 10 April 2024).

- Hannachi, M.; Nechiche, M.; Azem, S. Development of biodegradable composite materials based on polylactic-acid (pla) and olive kernels/alfa fibers reinforcements. U. P. B. Sci. Bull. 2021, 83, 3. Available online: https://www.scientificbulletin.upb.ro/rev_docs_arhiva/fulld00_939444.pdf (accessed on 10 April 2024).

- Martínez, B.; Bernat-Maso, E.; Gil, L. Applications and Properties of Hemp Stalk-Based Insulating Biomaterials for Buildings: Review. Materials 2023, 16, 3245. [Google Scholar] [CrossRef]

- Pederneiras, C.M.; Veiga, R.; De Brito, J. Rendering Mortars Reinforced with Natural Sheep’s Wool Fibers. Materials 2019, 12, 3648. [Google Scholar] [CrossRef]

- Fatma, S.; Hameed, A.; Noman, M.; Ahmed, T.; Shahid, M.; Tariq, M.; Sohail, I.; Tabassum, R. Lignocellulosic Biomass: A Sustainable Bioenergy Source for the Future. Protein Pept. Lett. 2018, 25, 148–163. [Google Scholar] [CrossRef]

- Metzger, J.O.; Hüttermann, M.A. Sustainable global energy supply based on lignocellulosic biomass from afforestation of degraded areas. Naturwissenschaften 2009, 96, 279–288. [Google Scholar] [CrossRef] [PubMed]

- Surdu, E.; Farcaș-Flamaropol, D.C.; Iatan, R.; Cârdei, P.; Sporea, N.; Tomescu, G.; Durbacă, I. Heat transmission through walls of composite material with clay matrix. INMATEH Agric. Eng. 2024, 73, 416–426. Available online: https://openurl.ebsco.com/EPDB%3Agcd%3A9%3A17620409/detailv2?sid=ebsco%3Aplink%3Acrawler&id=ebsco%3Adoi%3A10.35633%2Finmateh-73-35#:~:text=10.35633/inmateh%2D73%2D35 (accessed on 10 April 2024). [CrossRef]

- Bucur, F.; Pascu, L.; Birtok Baneasa, C.; Budiul Berghian, A.; Socalici, A. Research on the production of composite materials for brake shoes. U. P. B. Sci. Bull. 2022, 84, 1. Available online: https://www.scientificbulletin.upb.ro/rev_docs_arhiva/full06f_296080.pdf (accessed on 10 April 2024).

- Dobre, L.M.; Stoica, A.; Stroescu, M.; Jinga, S.; Jipa, I.; Dobre, T. Characterization of composite materials based on biocellulose membranes impregnated with silver particles as antimicrobial agent. U. P. B. Sci. Bull. 2010, 72, 4. Available online: https://www.scientificbulletin.upb.ro/rev_docs_arhiva/rez683.pdf (accessed on 10 April 2024).

- Ben Guida, D.M. Adobe Bricks: The Best Eco-Friendly Building Material. Adv. Mater. 2015, 1105, 386–390. [Google Scholar] [CrossRef]

- Salih, M.M.; Osofero, A.I.; Imbabi, M.S. Critical review of recent development in fiber reinforced adobe bricks for sustainable construction. Front. Struct. Civ. Eng. 2020, 14, 839–854. [Google Scholar] [CrossRef]

- Kusić, D.; Božić, U.; Monzón, M.; Paz, R.; Bordón, P. Thermal and Mechanical Characterization of Banana Fiber Reinforced Composites for Its Application in Injection Molding. Materials 2020, 13, 3581. [Google Scholar] [CrossRef]

- Sorohan, S.; Manea, I.; Constantinescu, O.M.; Vasiliu, N. Fem analysis of the composite materials used in civil buildings. U. P. B. Sci. Bull. 2020, 82, 4. Available online: https://www.scientificbulletin.upb.ro/rev_docs_arhiva/full1c7_891113.pdf (accessed on 10 April 2024).

- Stochioiu, C.; Gheorghiu, H.M. On the time-dependant characterisation procedures of bio-composite materials. U. P. B. Sci. Bull. 2019, 81, 4. Available online: https://www.scientificbulletin.upb.ro/rev_docs_arhiva/full70b_431849.pdf (accessed on 10 April 2024).

- Durbacă, A.C.; Iatan, R.; Durbacă, I.; Diniță, A.; Rusănescu, C.O. Experimental aspects of the application of strain gauges on sandwich type circular plates from polymer composite materials in pressure vessels. U. P. B. Sci. Bull. 2018, 80, 3. Available online: https://www.scientificbulletin.upb.ro/rev_docs_arhiva/fulle23_230617.pdf (accessed on 10 April 2024).

- Blasi, A.; Verardi, A.; Lopresto, C.G.; Siciliano, S.; Sangiorgio, P. Lignocellulosic Agricultural Waste Valorization to Obtain Valuable Products: An Overview. Recycling 2023, 8, 61. [Google Scholar] [CrossRef]

- Bumanis, G.; Argalis, P.P.; Sahmenko, G.; Mironovs, D.; Rucevskis, S.; Korjakins, A.; Bajare, D. Thermal and Sound Insulation Properties of Recycled Expanded Polystyrene Granule and Gypsum Composites. Recycling 2023, 8, 19. [Google Scholar] [CrossRef]

- Saccani, A.; Fiorini, M.; Burzotta, G. Sustainable Bio-Composites Obtained from Recycling Post-Industrial PLA and Fillers Derived from Coffee Production. Recycling 2022, 7, 89. [Google Scholar] [CrossRef]

- Argalis, P.P.; Sinka, M.; Bajare, D. Recycling of Cement–Wood Board Production Waste into a Low-Strength Cementitious Binder. Recycling 2022, 7, 76. [Google Scholar] [CrossRef]

- Robu, I. Lucrări Practice de Materiale de Construcție; Ed. Conspress: București, Romania, 2013. [Google Scholar]

- Pompas, F. Tabele pentru Rezistenta Materialelor UNITATI DE MASURA. Available online: https://www.academia.edu/4962211/Tabele_pentru_Rezistenta_Materialelor_UNITATI_DE_MASURA_Tabela_1Last (accessed on 4 December 2024).

- Schicker, A.; Gier, S. Optimizing the Mechanical Strength of Adobe Bricks. Clays and Clay Minerals. Springer Link. 2009. Available online: https://link.springer.com/article/10.1346/CCMN.2009.0570410 (accessed on 10 April 2024).

- Statistics Kingdom. Available online: https://www.statskingdom.com/410multi_linear_regression.html (accessed on 12 April 2024).

- MathSoft, Inc. Mathcad User’s Guide, Mathcad 2000 Professional, 2nd ed.; Mathsoft Inc.: Cambridge, MA, USA, 1999; pp. 1–335. [Google Scholar]

- Binici, H.; Kaplan, H.; Yilmaz, S. Influence of marble and limestone dusts as additives on some mechanical properties of concrete. Sci. Res. Essay 2007, 2, 372–379. Available online: https://www.researchgate.net/publication/228372302_Influence_of_marble_and_limestone_dusts_as_additives_on_some_mechanical_properties_of_concrete (accessed on 10 April 2024).

- Binici, H.; Aksogan, O.; Shah, T. Investigation of fibre reinforced mud brick as a building material. Constr. Build. Mater. 2005, 19, 313–318. [Google Scholar] [CrossRef]

- Binici, H. The Engineering Properties of Traditional and Fibre Reinforced Mud Brick. Euro. J. Adv. Eng. Technol. 2017, 4, 311–318. Available online: http://www.ejaet.com/ (accessed on 10 April 2024).

- Ouakarrouch, M.; Laaroussi, N.; Garoum, M. Thermal characterization of a new bio-composite building material based on plaster and waste chicken feathers. Renew. Energy Environ. Sustain. 2020, 5, 2. [Google Scholar] [CrossRef]

- Hale, D.K. A Field Investigation of Composite Mud Brick Compressive Strength. Master’s Thesis, Michigan Technological University, Houghton, MI, USA, 2015. [Google Scholar] [CrossRef]

- Rios-Soberanis, C.R.; Verriest, A.; Peraza-Gongora, J.; Borges-Palomo, D.S.; Rodriguez-Laviada, J. Experimental Characterization of Flexural Strength and Water Absorption Properties of Mud-Bricks Manufactured Under Prehispanic Technique and the Addition of Asphalt Additives. Int. J. Archit. Herit. 2024, 1–11. [Google Scholar] [CrossRef]

| The Concentration of the Insert | Walnut Shell Insert | Insert Shredded Biomass from Corn Stalks | Wool Insert | Wheat Straw Insert |

|---|---|---|---|---|

| 0 | 0.3083 | 0.3083 | 0.3083 | 0.3083 |

| 5 | 0.205 | 0.2221 | 0.3042 | 0.1668 |

| 10 | 0.0352 | 0.0477 | 0.1768 | 0.1428 |

| The Concentration of the Insert | Walnut Shell Insert | Insert Shredded Biomass from Corn Stalks | Wool Insert | Wheat Straw Insert |

|---|---|---|---|---|

| 0 | 3.06 | 3.06 | 3.06 | 3.06 |

| 5 | 1.5 | 1.49 | 1.85 | 1.41 |

| 10 | 0.89 | 1.34 | 1.88 | 0.9 |

| 15 | 0.89 | 0.95 | 0.64 | |

| 20 | 0.49 | 1.6 | ||

| 25 | 0.72 | 1.16 | ||

| 30 | 0.9 | 1.04 | ||

| 35 | 0.56 | 0.8 | ||

| 40 | 0.7 | 1.03 | ||

| 45 | 0.55 | 0.36 | ||

| 50 | 0.32 | 0.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Surdu, E.; Iatan, R.; Cardei, P.; Sporea, N.; Farcas-Flamaropol, D.-C.; Durbaca, I. Mechanical Properties of Composite Materials Obtained with Clay Matrices and Plant Waste Inserts. Sustainability 2025, 17, 2888. https://doi.org/10.3390/su17072888

Surdu E, Iatan R, Cardei P, Sporea N, Farcas-Flamaropol D-C, Durbaca I. Mechanical Properties of Composite Materials Obtained with Clay Matrices and Plant Waste Inserts. Sustainability. 2025; 17(7):2888. https://doi.org/10.3390/su17072888

Chicago/Turabian StyleSurdu, Elena, Radu Iatan, Petru Cardei, Nicoleta Sporea, Dana-Claudia Farcas-Flamaropol, and Ion Durbaca. 2025. "Mechanical Properties of Composite Materials Obtained with Clay Matrices and Plant Waste Inserts" Sustainability 17, no. 7: 2888. https://doi.org/10.3390/su17072888

APA StyleSurdu, E., Iatan, R., Cardei, P., Sporea, N., Farcas-Flamaropol, D.-C., & Durbaca, I. (2025). Mechanical Properties of Composite Materials Obtained with Clay Matrices and Plant Waste Inserts. Sustainability, 17(7), 2888. https://doi.org/10.3390/su17072888