1. Introduction

Over the past few decades, the complexity of financial decisions has increased significantly, highlighting the need to develop efficient analysis techniques for financial decision-making in different fields. Therefore, it is essential to identify methods for comparing various design assumptions to determine the one with the least impact on the environment.

Construction projects carry financial and economic risks [

1,

2,

3]. These risks have the potential to influence the success of projects in terms of time, cost, and quality [

4]. Turner [

5] points out that incomplete or inaccurate cost estimation is a high-impact risk factor in financial risk management. Managing financial and economic risks is essential to minimize project losses [

6]. Financial and economic risks, particularly those involving land reclamation, are critical in construction projects.

The discourse on financial and economic risks in construction projects offers a global overview of infrastructure challenges. Meanwhile, Vojvodina, Serbia, presents a unique case study. It illustrates these challenges on a microscale. The region’s reliance on an extensive network of pumping stations for agricultural productivity, which is in dire need of modernization, underscores the importance of accurately estimating costs and managing financial risks. This is particularly pressing as the region seeks to balance technological upgrades with sustainable agricultural practices. Thus, the general principles of financial risk management in construction projects find a specific and urgent application in the context of Vojvodina’s land reclamation efforts, highlighting the need for a comprehensive multicriteria financial analysis.

In Vojvodina, approximately 50% of the area has been historically threatened by floods from rivers flowing through the region, internal waters, and high groundwater levels. These areas have been transformed into fertile fields through the regulation of river courses, flood defenses, and drainage. As of 2005, 92% of Vojvodina’s territory was utilized for agricultural purposes [

1]. However, such systems require continuous maintenance and modernization, making financial analysis pivotal in assessing the feasibility of these projects. Previous studies have highlighted the importance of financial risk management in the construction sector, with incomplete or inaccurate cost estimations identified as significant risk factors.

Given the increasing complexity of financial decisions, this study presents a multicriteria analysis to assess the financial feasibility of various design options for land reclamation in AP Vojvodina, Serbia. This analysis, based on data from 104 pumping stations, aimed to determine the optimal design variant by evaluating both the economic and technical criteria. The optimal functioning of pumping stations is necessary for the effective protection of agricultural and urban areas within land reclamation systems, whose water regimes are managed by the pumping stations.

The pumping stations that were the subjects of this study were located in a relatively wide area; therefore, the analysis of their condition and operation was conducted according to their affiliation with the land reclamation system.

Most pumping stations are technologically obsolete and problematic for maintenance and require the replacement of old parts and equipment. In light of climate change and adaptation measures, the need for energy saving, increased energy efficiency, and environmental protection, it is necessary to reconstruct and modernize the existing facilities and equipment of the pumping stations.

Numerous studies have emphasized the importance of financial risk management in large-scale construction projects, particularly in regions that are prone to natural hazards. Turner [

7] identified incomplete or inaccurate cost estimation as a high-impact risk factor in financial risk management, a sentiment echoed in subsequent studies focused on the construction sector. However, there remains a gap in the literature concerning the application of multicriteria analysis in the financial feasibility assessment of land reclamation projects.

To comprehensively address these challenges, this study employs a multicriteria analysis (MCA) methodology. The MCA allows the evaluation of various land reclamation design variants by integrating economic and technical criteria. This methodology not only facilitates a holistic assessment of potential technological upgrades but also emphasizes investment and operational costs over long-term benefits. The following section details the multicriteria analysis approach, outlining the criteria for variant evaluation and the process for determining the optimal design variant.

To enhance the reliability and transparency of the analysis, additional models were employed, including AHP for assigning weights, TOPSIS for ranking the variants, and fuzzy logic for handling uncertainties in the evaluation of the criteria.

2. Literature Review

Energy optimization strategies, including variable-speed pumping units and enhanced control systems, have demonstrated potential for substantial energy savings in water supply and district heating stations [

8,

9,

10,

11]. Innovative approaches, such as hydrogen storage for power outage mitigation in mine water pumping stations, are being investigated to enhance resilience [

12]. Researchers also emphasize the significance of considering economic, social, and environmental factors in modernization efforts [

13]. The collective findings of these investigations highlight the critical importance of implementing adaptable, energy-conserving, and environmentally responsible strategies in the design and renovation of pumping stations to effectively confront impending challenges.

Adloff and Neckel [

14] propose a framework for the different perspectives on sustainability—modernization, transformation, and control—which provides a better understanding of how infrastructure projects can align with sustainable development goals. Shahidehpour et al. [

15] emphasize the importance of implementing smart technologies into urban infrastructure, such as SCADA systems, to significantly increase operational efficiency and reduce costs, a finding that aligns with this study’s results.

In the field of energy efficiency, Aguero et al. [

16] point out that investments in advanced technologies can simultaneously improve energy efficiency and reduce environmental impacts, a concept directly applicable to pumping station modernization. Drăghici et al. [

9] further explore the optimization of pumping systems at a water treatment plant in Timișoara, showing how such improvements reduce energy consumption and increase efficiency. Similarly, Paranchuk and Lysiak [

10] advocate for the introduction of energy-efficient power and automation systems, which enable significant energy savings and enhance system performance.

Sȃrbu and Valea [

11] identify the potential for energy savings in pumping stations through modern technologies, particularly in district heating systems. This finding underscores the importance of strategies that balance operational cost reduction and system functionality. Li et al. [

17] contribute to this discussion by analyzing modern pumping system behavior, emphasizing the importance of optimizing technical parameters to improve performance, which is directly relevant to this study’s analysis.

D’Obyrn et al. [

18] emphasize the importance of adapting pumping station designs to local hydrogeological and mining factors, advocating for the integration of local characteristics into modernization processes. This aligns with Moropoulou et al. [

19], who highlight sustainable rehabilitation through innovative technologies as a foundation for resource conservation and cost reduction. Rodríguez-Díaz et al. [

20] discuss the paradox of irrigation system modernization, pointing out that increased water efficiency may lead to higher energy demands, thus requiring careful planning to balance efficiency and sustainability.

Kasner et al. [

21] emphasize the principles of efficiency and sustainability in the modernization of wind farms, which are applicable to infrastructure projects like pumping stations. Grabowski et al. [

22] introduce the concept of infrastructure as a socio-ecological–technical system, advocating for an interdisciplinary approach to modernization. Mala-Jetmarova et al. [

23] focus on integrated approaches in optimizing water distribution systems, highlighting the need to balance hydraulic efficiency and costs, which is critical for pumping station modernization.

Pulido-Calvo and Gutierrez-Estrada [

24] stress the importance of careful selection and optimization in pumping station operations to reduce costs and increase reliability, aligning directly with this study’s objectives. Briceño-León et al. [

25] apply the Analytical Hierarchy Process (AHP) to pumping station design, providing a structured framework for decision-making that considers both technical and economic aspects. This approach enables the rational ranking of solutions and the selection of optimal modernization strategies.

Gutiérrez-Bahamondes et al. [

26] highlight the importance of precise planning for sustainability and cost-effectiveness, which is crucial for long-term success in pumping station modernization. Świętochowska et al. [

27] analyze the energy aspects in pumping station operations, showing that the application of modern technologies can significantly contribute to sustainable development and CO

2 emission reduction.

Cook et al. [

28] develop a framework for integrating climate data into engineering methods, while Kasprzyk et al. [

29] propose robust water management strategies that balance efficiency and resilience. Creaco et al. [

30] advocate for the phased construction of water distribution networks to address demand uncertainties, while Groves and Lempert [

31] emphasize the importance of planning under high uncertainty. Haasnoot et al. [

32] highlight flexible strategies for managing water resources, while de Haan et al. [

33] emphasize the importance of flexibility in infrastructure systems to adapt to changing demands. Vrijling [

34] introduces a probabilistic approach to flood defense design, which is crucial for managing water resources effectively. Rao and Mamatha [

35] focus on water quality preservation through efficient treatment systems, while Abdelfattah and El-Shamy [

36] analyze zero-liquid-discharge (ZLD) technologies for reducing pollution and improving ecological resilience.

Finally, recent studies [

37,

38] explore smart water management systems and innovative technologies for optimizing pumping station operations. Brears [

39] highlights the role of green technologies in preserving water quality and reducing carbon emissions, and Dinar [

40] emphasizes economic modeling approaches for resource allocation and sustainable technology investment.

The existing literature focuses extensively on technical and economic aspects of pumping station modernization individually but lacks a comprehensive framework that integrates these with the specific environmental and socio-economic dimensions of regions like Vojvodina. Our study addresses this gap by incorporating a multicriteria analysis specific to the region’s conditions.

3. Methodology

Multicriteria analysis is a valuable method for conducting financial feasibility studies of land reclamation projects. By integrating various criteria and decision-making factors, multicriteria analysis allows for a comprehensive evaluation of the financial viability of such projects, offering a more comprehensive approach than traditional single-criterion methods [

41]. This allows for the consideration of multiple quantitative and qualitative factors in financial decision-making. This approach enables stakeholders to simultaneously consider multiple dimensions. Overall, multicriteria analysis enhances financial modeling by emphasizing the multidimensional aspects of financial decisions and providing a systematic framework for problem structuring and trade-off analysis [

42]. Multicriteria analysis facilitates the effective management of financial risks in land reclamation projects by enabling a comprehensive evaluation of diverse economic and technical factors, which together provide more resilient and cost-effective decision-making.

To conduct a feasibility analysis of land reclamation in the observed territory, the financial feasibility of 104 pumping stations was examined.

Evaluation Criteria

The multicriteria analysis in this study evaluates different design variants for land reclamation based on several criteria, including the investment costs, operational costs, and long-term economic benefits of each option. The criteria were selected based on their relevance to both economic and technical performance, with input from experts in the field and stakeholders in the Vojvodina region.

A special tool in Excel was developed for multicriteria analysis (MCA). Based on preselected parameters, a ranking of pumping stations was performed within each considered variant (for each considered variant, the pumping stations were ranked from the most favorable for modernization to the least favorable for modernization within the analyzed variant).

In addition, the considered variants were ranked for each pumping station (for each pumping station, the variants were ranked from the one that was the most favorable for implementation to the one that was the least favorable for implementation).

The parameters scored in the MCA were as follows:

CAPEX—capital expenditures;

OPEX—operating expenses;

Economic price of pumped water (EPPW);

Electricity consumption (EC).

Considering the substantial disparity in the CAPEX values across pumping stations, the relative OPEX/CAPEX ratio was individually assessed for each station within the variant. This assessment is scored on a scale ranging from 0 to 100.

Another criterion evaluated was the deviation from the average economic price of water. Because the economic price of water remains consistent for each pumping station within a specific variant, this criterion was scored neutrally at 50 points.

The third criterion assessed was the variance from the average electricity consumption, with each pumping station receiving a score between 0 and 100. This criterion is significant because of its role in resource conservation and combating climate change, particularly in reducing CO2 emissions amidst the prevailing energy crisis.

Multicriteria analysis (MCA) was conducted with each of the three relative criteria scored on a scale from 0 to 100. The weightings assigned to these criteria are as follows: the first criterion (OPEX/CAPEX ratio) has a weight of 35%, the second criterion (deviation from the average economic price of water) has a weight of 35%, and the third criterion (deviation from average electricity consumption) has a weight of 30%.

The chosen weightings reflect a careful balance between the immediate cost efficiency (OPEX/CAPEX ratio), long-term affordability for users (economic price of water), and environmental sustainability (electricity consumption). The emphasis on the OPEX/CAPEX ratio and the economic price of water at 35% each indicates that the project’s primary objectives are to achieve financial feasibility and maintain affordability. Meanwhile, the 30% weight for electricity consumption ensures that these financial objectives are pursued without compromising energy efficiency and environmental stewardship, which are also key considerations in modern infrastructure projects.

By prioritizing these criteria in this manner, the analysis aligns with the project’s goals of ensuring that the upgraded pumping stations are not only cost-effective and affordable but also sustainable in the long run. This approach helps balance the need for modernization with budget constraints, environmental impacts, and the socio-economic context of the region.

We defined the range of scales used for scoring the OPEX/CAPEX as follows:

from 0% to 5%, 100.00 points;

from 5% to 10%, 90.00 points;

from 10% to 15%, 80.00 points;

from 15% to 20%, 70.00 points;

from 20% to 25%, 60.00 points;

from 25% to 30%, 50.00 points;

from 30% to 35%, 40.00 points;

from 35% to 40%, 30.00 points;

from 40% to 45%, 20.00 points;

from 45% to 50%, 10.00 points;

>50%, 0.00 points.

For the deviation from the average EPPW as well as the deviation from the average electricity consumption, the scale was defined as follows:

from −100% to −90%, 100.00 points;

from −90% to −70%, 90.00 points;

from −70% to −50%, 80.00 points;

from −50% to −30%, 70.00 points;

from −30% to −10%, 60.00 points;

from −10% to 10%, 50.00 points;

from 10% to 30%, 40.00 points;

from 30% to 50%, 30.00 points;

from 50% to 70%, 20.00 points;

from 70% to 90%, 10.00 points;

>90%, 0.00 points.

In addition to its performance in multicriteria analysis, Variant 3.1 (V3.1) aligns closely with broader strategic objectives that are central to the success of the land reclamation project and the long-term development of the Vojvodina region. These objectives include sustainability, long-term resilience, and adaptability to climate change, all of which are critical in ensuring that the project’s outcomes are not only economically viable but also environmentally and socially responsible.

4. Variants, Investment, and Operating Costs

The technical potential for the modernization and automation of each pumping station was thoroughly assessed by evaluating the variants. This assessment encompasses the required equipment and associated work, with a particular focus on the investment expenditure necessary for implementation.

Variant 1 (V1): This variant focuses on basic upgrades to meet flood defense requirements through the replacement or repair of nonfunctional mechanical and electrical equipment and necessary structural repairs. It operates the pumping station manually. The primary benefit is that it addresses the immediate operational needs with minimal investment, making it suitable for scenarios with tight budget constraints or where minimal changes are required.

Variant 2 (V2): V2 introduces automation and local control to the pumping station by replacing all mechanical and electrical equipment with their modern counterparts. This enables the operation of the station in the local automatic mode and includes the establishment of a local SCADA system. The primary benefits are moderate upgrades that enhance performance and efficiency over V1, offering a balance between cost and technological advancement.

Variant 3 (V3): This variant extends the automation capabilities introduced in V2 by incorporating remote control from a centralized command center and utilizing a Hydrological Information System (HIS) for the comprehensive monitoring and management of the reclamation area. V3 represents a significant investment in technology and infrastructure aimed at maximizing efficiency, cost-effectiveness, and long-term sustainability. It is distinguished from V2 by its advanced monitoring and control capabilities, making it suitable for scenarios that prioritize comprehensive overhauls and futureproofing.

Variant 3.1 (V3.1): Similarly to V3, it includes the establishment of a local SCADA system and a control command center but does not integrate a system for monitoring the entire reclamation area. Despite this, it emerged as the most favorable option for most pumping stations, suggesting that it offers a practical balance of advanced control features without the full extent of V3’s monitoring capabilities. This variant is characterized by its focus on optimizing operational efficiency and control, while being slightly less comprehensive than V3.

4.1. Investment and Operating Costs for Different Variants

For each variant and pumping station, the required investment costs were evaluated as input parameters for the economic–financial analysis.

The assessment of the investment value—the price of the reconstruction of buildings—was given for certain groups of work based on checking the current prices on the market and expert judgment.

The price of installing new pump aggregates was calculated based on the power of the pump, and according to the dependence of the price of the pump and the power, the accompanying necessary equipment was included in the price.

The price of the overhaul of the existing pumps that are in operation was calculated as 25% of the price of a new pump, which depends on whether it is a question of regular maintenance (up to 5% of the price of a new pump) or a serious failure of the pump (which can be up to 40% of the price), so the repair price was calculated as an average value of 25%.

The prices of the required automatically raked screens and front screens were given on the basis of the unit summary price per 1 m width, which was 40,000 EUR/pcs;

The price estimate of the hydraulic equipment in the pumping station (pumps, pressure fittings, and assembly) was calculated based on the current prices in the market.

Electrical equipment and work (medium-voltage equipment, electrical drive and control cabinets, measuring equipment, lighting, burglary protection, lightning rods, and grounding) was calculated based on current market prices.

The monitoring of the hydro-information system, including the installation of meteorological stations, the monitoring of the canal network, sluice gates, measuring groundwater level, and land, was conducted based on the watershed area size with a price of 50 EUR/ha;

Construction works were calculated based on the area of the structure according to the estimated unit value of the reconstruction:

Exterior condition of the building—facade construction: 30 EUR/m2;

Roof covering: 50 EUR/m2;

Interior condition of the building—painting of the walls: 5 EUR/m2;

Interior condition of the building—floor covering: 30 EUR/m2;

Carpentry: 200 EUR/m2;

Protective fence, 2.2 m high: 100 EUR/m2).

Annual driving and operating costs were given through annual driving costs: the consumption of electricity, manpower, and equipment and facility maintenance costs.

The dominant cost in the operation of pumping stations is the cost of electricity consumption. The energy used for pumping depends on the annual amount of pumped water Q (m3/day), average head H (m), and pump efficiency η (%).

According to the control measurements, which were carried out during the preparation of the Study on Water Management in the area of one of the pumping stations, it was concluded that it is necessary to replace the pumps with new ones at some pumping stations because the efficiency of the pumps varies approximately from 60 to 90% of the nominal catalog values. The obtained results were dominantly affected by the age of the individual pumps and, accordingly, by the low pump efficiency coefficient.

Therefore, the calculation of the consumed energy within V1 for the existing pumping units for the nominal capacity of the unit (Q) and the head (H) was performed with the pump efficiency coefficient η = 60% and the average annual working hours.

The calculation of the energy consumption for new pumps within V2 and V3 for the nominal capacity of the unit (Q) and the head (H) was performed with a pump efficiency coefficient η = 75% and expected annual working hours that were 10% less than the current ones.

The unit price of electricity (EUR/kWh) is now subject to change and was calculated using the price of 0.1 EUR/kWh of consumed energy. The annual labor costs are EUR 10,000.00 within V1 and V2 and EUR 5000 within V3 because automatic operation is foreseen and less labor is required.

For the annual maintenance costs for equipment (hydromechanical equipment, electrical equipment, and equipment required for the automatic operation of pumping stations), 1.4% was adopted in relation to the investment. Building maintenance costs (mowing and repairs) were estimated for Variant 1 at EUR 2000, and for V2 and V3 at EUR 1200. For each pumping station, the investment and operational costs were calculated individually.

Table 1 summarizes the operating and investment costs for all pumping stations in relation to the variants.

The investment costs for all pumping stations by variant in the context of equipment (technical measures) are shown in

Table 2.

The operating costs for all pumping stations by variants in the context of equipment (technical measures) are shown in

Table 3.

4.2. Levelized Costs of Pumping Water—LCOPW

The levelized cost of pumping water (LCOPW) is an economic measure used to compare the economic costs of pumped water across different production technologies. The economic cost of production can be classified into the following groups:

Capital costs: Initial expenses for plant construction.

Operation and maintenance (O&M) costs: Costs incurred during the system operation. These costs can be categorized as fixed and variable costs. Fixed costs are incurred, regardless of what the plant produces. They consist of staff salaries, security costs, insurance, etc. Variable costs are directly related to the production costs. Financing costs were ignored in the calculation of economic prices.

Levelized cost (LC) is a useful tool because it allows the comparison of different production technologies with different capital costs, operating costs, and so on. The economic price can be viewed from an economic perspective as the ‘average’ water pumping price that a particular project must earn to equalize revenues and costs. Economic cost is used as a relative measure to compare different technologies, rather than as an absolute measure that informs investment decisions. The actual planning of the system must also consider reliability issues (such as availability during periods of peak demand), as well as other factors. Consequently, policymakers primarily use economic prices for long-term planning and for the development of incentive mechanisms. Finally, investors are interested in economic costs to understand the long-term economic trends for which cost reduction would greatly improve their competitiveness.

Economic cost determines whether a project is cost-effective or profitable. Using the economic price for project evaluation is one of the first fundamental steps in the analysis of projects of this type. Economic cost is an important calculation that allows financial analysts to compare different technologies. It allows these comparisons to be made regardless of unequal life spans, different capital costs, project sizes, and different risks associated with each project. This is because the economic price reflects the cost per unit obtained by discounting the physical volume and corresponding costs, and the risk of each project is an implication of the specific discount rate used to value projects. The economic cost was calculated by first taking the net present value of the total costs of building and operating the system. This number was then divided by the total amount of water pumped over its lifetime. The economic cost of water (LCOPW) was calculated using the following formula:

The cost of investment expenditure (I), the operating costs of maintenance and operation (M), and fuel consumption (if any) (F) are calculated. The total production includes the sum of the total pumped water during the projected period (E). The last two important factors to consider in the equation are the project discount rate (p) and the lifetime of the project in years (t).

The sum of the discounted balances of pumped water in the projected period and the sum of costs (investment and operation) in the projected period, that is, their quotient, give the economic price of pumped water. Thus, all discounted values, that is, the results of the analysis of the economic price of pumped water, were reduced to today’s comparable moment. The economic price of pumped water at the level of the entire system and land reclamation (melioration) areas is 0.59 EUR/m3. The calculated economic price serves as an orientation for the projection of income in projected balances and cash flows. Revenues were calculated based on the calculated fees (tariffs) for drainage.

4.3. AHP, Topsis and Fuzzy, Model

The Analytical Hierarchy Process (AHP) was used to assign weights to the criteria, enabling the quantification of preferences through pairwise comparisons (Kaliszewski & Podkopaev, 2016 [

43]). The pairwise comparison matrix was normalized, and the weights were calculated as the average values of the normalized elements. In this study, the trapezoidal membership function was used because it allows for more flexible assessments when data availability is limited. The trapezoidal function is particularly useful in cases where it is necessary to define intervals of uncertainty rather than precise values, thereby reducing the risk of subjective errors. The algorithm used for determining membership values is based on defuzzification using the centroid method, which enables the conversion of interval values into final weighted scores. The rules were defined to prioritize alternatives with lower operating costs and better energy efficiency, in accordance with the objectives of the sustainable modernization of pumping stations. Fuzzy logic was implemented using the MATLAB R2024b Fuzzy Logic Toolbox, which facilitates the creation and testing of uncertainty-based systems. Integration with Excel was carried out by exporting the results of the fuzzy evaluation into .csv format, which was then imported into Excel for further processing and comparative analysis with the results obtained using the AHP and TOPSIS methods. To reduce subjectivity in weight determination using the AHP method, a consistency check (Consistency Index—CI and Consistency Ratio—CR) was performed, with the calculated value being below the threshold of 0.1, indicating a high level of consistency in the assessments. Five experts participated in forming the matrix for the Analytical Hierarchy Process (AHP). To validate the consistency and reliability of the expert judgments, the coefficient of concordance (W) was calculated. The obtained coefficient of concordance value was 0.78, indicating a high level of agreement among the experts, thereby confirming the reliability and validity of the results obtained. Additionally, for the further validation of the weights, a comparison with the entropy method was conducted, where the weights showed a similar distribution, confirming that the subjective assessments of experts did not significantly deviate from the objective data. The OPSIS method was chosen because it allows for the processing of multiple criteria with different measurement units while minimizing the impact of extreme values, whereas fuzzy logic was used due to its ability to handle uncertainty in expert evaluations and criteria that are not strictly quantitative. Compared to the PROMETHEE method, which provides multicriteria preferences but does not handle uncertainty, fuzzy logic enabled a more flexible evaluation of alternatives. The ELECTRE method was also considered but was not used because it does not allow for the easy defuzzification of assessments into a single score. The consistency of the matrix was verified by calculating the Consistency Index (CI) and the Consistency Ratio (CR). The matrix was considered consistent if the CR was less than 0.1 [

44].

Table 4 presents the Analytical Hierarchy Process (AHP) matrix, used to determine the relative importance of criteria in the decision-making process. The matrix includes the pairwise comparisons of four key criteria: CAPEX (capital expenditure), OPEX (operational expenditure), EPPW (economic price of water), and electricity consumption.

Table 5 presents the results of the normalization of the pairwise comparison matrix from the Analytical Hierarchy Process (AHP) and the calculated weighted values for each criterion.

The TOPSIS method (Technique for Order of Preference by Similarity to Ideal Solution) was used for ranking the alternatives. This process involves normalizing the data to eliminate differences in measurement units, assigning weights based on AHP results, and calculating relative distances (Huang & Li, 2012 [

45]). Using these distances, each alternative was assigned a score that reflected its overall performance relative to the ideal solution, enabling a clear ranking. This method assessed each alternative based on its proximity to the ideal solution (V

+) and the anti-ideal solution (V

−).

The following formulas were applied for the following (Lai et al., 1994 [

46]):

Calculation of weighted values: vij = wj⋅ rij

Ideal (V+) and anti-ideal (V−) solution:

For criteria maximization: V+ = {max(vij)}

For criteria minimization: V− = {min (vij)}

- 2.

Calculation of distances and final TOPSIS score:

rij: normalized value for the i-th alternative and j-th criterion;

wj: weight of the j-th criterion;

vij: weighted value;

Si+, Si−: distances from the ideal and anti-ideal solutions, respectively;

Ci: final TOPSIS score.

Table 6 presents the distances from the ideal and anti-ideal solutions, as well as the final TOPSIS score for each alternative.

Fuzzy logic was also applied to handle uncertainty and assign interval weights to the criteria. This method utilizes trapezoidal fuzzy numbers to enable more flexible evaluations in situations where subjective judgments or a lack of precise data exist. Each criterion was assessed through a range of values (minimum, average, and maximum), reducing the risk of subjective errors. Defuzzification was performed to convert interval values into single weighted scores, facilitating easier comparison and the ranking of alternatives. The definition of a trapezoidal fuzzy number is as follows:

F = (a,b,c,d).

Defuzzification (centroid method):

The defuzzified values were then used for weighting the criteria and calculating the overall scores of the alternatives. The obtained values are presented in

Table 7.

5. Results

This section presents the results of the MCA, AHA, and TOPSIS methods.

In the ranking process, predetermined parameters were utilized, namely the following: CAPEX, OPEX, economic price of pumped water (EPPW), and electricity consumption.

Considering the significant variation in CAPEX values across variants, the relative OPEX/CAPEX ratio was evaluated for each variant and scored on a scale from 0 to 100. Another criterion assessed was the deviation from the average economic price of water for all variants, which was scored on a scale from 0 to 100. Furthermore, the deviation from the average electricity consumption for each variant was scored on a scale of 0 to 100.

When ranking the variants for each pumping station, a multicriteria analysis (MCA) was conducted by scoring each of the three relative criteria on a scale from 0 to 100 (

Table 8). The weightings assigned to these criteria were as follows: 35% for the first criterion (OPEX/CAPEX ratio), 35% for the second criterion (deviation from the average economic price of water), and 30% for the third criterion (deviation from the average electricity consumption).

As stated in the previous chapter, the OPEX/CAPEX ratio was evaluated for each variant, scored on a scale from 0 to 100 (

Table 9).

As stated in

Table 8 and

Table 9 V1 had a total CAPEX of EUR 16,203,292.04, with an average of EUR 155,800.89 per station. V1 had the lowest investment, making it suitable for budget-constrained scenarios. V2’s total CAPEX jumped to EUR 76,396,183.58, with an average of EUR 734,578.69 per station. A significant increase in investment reflects the introduction of automation. The CAPEX of V3 further increased to EUR 148,700,852.78, with an average of EUR 1,429,815.89, due to the addition of centralized control and HIS. Although similar to V3 in many aspects, V3.1 had a slightly lower total CAPEX of EUR 117,684,078.58, averaging EUR 1,131,576.8 per station, due to the omission of HIS, making it less costly while still providing substantial upgrades.

The operating expenses (OPEX) for each variant showed distinct differences. Variant 1 (V1) had the highest total OPEX of EUR 5,951,863.50, averaging EUR 57,229.46 per station because of manual operation, which results in higher labor and maintenance costs. In contrast, Variant 2 (V2) saw a reduction in OPEX to EUR 5,189,390.76, with an average of EUR 49,897.99 per station, because automation leads to more efficient operations and lower costs. Variant 3 (V3) experienced a slight increase in OPEX to EUR 6,064,283.61, averaging EUR 58,310.42 per station, primarily because of the additional expenses associated with extensive monitoring and control features. However, Variant 3.1 (V3.1) achieved the lowest OPEX at EUR 4,954,459.22, with an average of EUR 47,639.03 per station, as it maintains automation benefits while avoiding the extra costs linked to a comprehensive Hydrological Information System (HIS).

The economic price of pumped water (EPPW) varied across variants, reflecting their respective technological investments. For Variant 1 (V1), EPPW was 0.38/m3, which was below the system-wide average, indicating lower technological investment. In Variant 2 (V2), the EPPW increased to EUR 0.49/m3, which was closer to the average, owing to the improved efficiency brought about by automation. Variant 3 (V3) had the highest EPPW at EUR 0.69/m3, driven by the inclusion of full monitoring capabilities. Meanwhile, Variant 3.1 (V3.1) achieved an EPPW of EUR 0.58/m3, balancing cost with efficiency by offering more advanced features than V2, but without the full extent of V3’s monitoring capabilities. From the presented data, it is evident that the V3.1 Variant achieved the best results in terms of energy balance and operating costs. However, it is interesting to note that although V3 had a higher investment cost, it provided additional benefits in terms of reducing fluctuations in energy consumption. This difference may be crucial for decision-making in regions where electricity costs are high or where seasonal variations in consumption are significant. In this context, a decision-maker may prefer V3 over V3.1 if there is a need for additional long-term system stability.

In terms of electricity consumption, Variant 1 (V1) had the highest total consumption, amounting to EUR 3,686,160.34, which reflects the inefficiencies associated with older equipment. Variant 2 (V2) significantly reduced the electricity consumption to EUR 2,664,879.91, owing to the implementation of more efficient pumps. While Variant 3 (V3) maintained the same electricity consumption level as V2, it enhanced the overall system efficiency through better control and monitoring. Similarly, Variant 3.1 (V3.1) matched the electricity consumption of V2 and V3 at EUR 2,664,879.91, achieving efficiency gains without incurring additional costs associated with a comprehensive Hydrological Information System (HIS).

The final rating was calculated as a weighted average of the OPEX/CAPEX score, the σµEPPW score, and the σEC score, as well as their corresponding weights (

Table 10).

According to the analysis, V3.1 emerged as the most favorable option for the largest number of pumps, specifically, 90 out of the 104 considered pumping stations (

Figure 1).

Since there are 104 pumping stations, we aimed to understand the consistency of the scores across the stations, as well as to rank the options based on their average performance and consistency. The results were collected using standard and low standard deviations. V3.1 had the highest average score of approximately 71.75, with a standard deviation of 11.55, making it the top-ranked option. V3 followed closely, with an average score of approximately 71.35 and a standard deviation of 11.65, ranked second. Option V2 came in third, with an average score of approximately 69.74 and a standard deviation of 13.21. Option V1 had the lowest average score of approximately 50.98, with the highest standard deviation of 17.15, indicating that it was the least preferred option based on performance across the stations.

6. Sensitivity Analysis

Given that future values introduce a certain degree of uncertainty in the evaluation of a project’s effectiveness, a sensitivity analysis was conducted as part of the financial analysis. This analysis aimed to determine the project’s profitability threshold by varying key parameters.

The sensitivity analysis examined the project’s responsiveness to changes in several initial parameters. These parameters included the following:

Increase/decrease in electricity prices for water pumping by 10% and 20%.

Increase/decrease in income from activities by 10% and 20%.

Increase/decrease in investment value by 10% and 20%.

Increase/decrease in interest rates by 10% and 20%.

The assumptions for various ’scenarios’ and the results of the sensitivity analysis for the financial analysis are presented in the subsequent tables and figures.

Table 11 displays the sensitivity analysis results for this project.

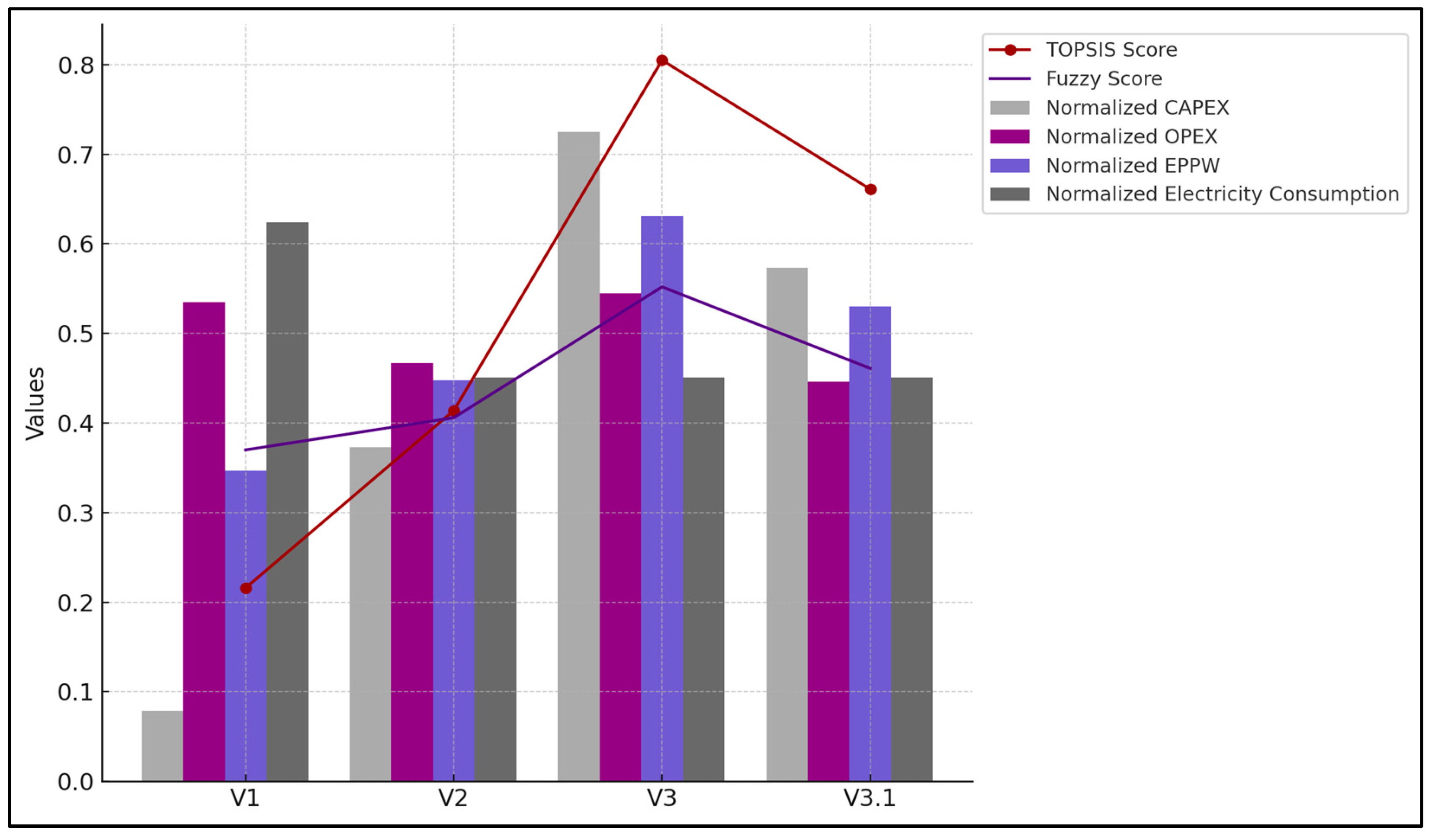

The analysis of the AHP and TOPSIS results revealed a clear distinction among the evaluated variants, reflecting their relative strengths and weaknesses in meeting the defined criteria (

Table 8). Variant V3 stood out as the most favorable option, achieving the highest TOPSIS score, which highlighted its alignment with the ideal solution. This outcome was driven by its superior performance in key criteria such as CAPEX and EPPW, underscoring its financial and operational efficiency. The balance of these metrics positions V3 as the optimal choice, particularly in contexts where maximizing cost-effectiveness and operational returns is essential. Close behind, Variant V3.1 demonstrated a competitive profile, reflecting a strong combination of performance metrics that approach the ideal, though slightly less robust than V3. Its relatively balanced scores across CAPEX and EPPW suggested that it is a viable alternative, especially when specific trade-offs between cost and operational outcomes are acceptable. This highlighted its potential as a secondary option in scenarios where flexibility in prioritizing certain criteria exists. Variants V2 and V1, however, fell short of aligning with the ideal solution. While V2 exhibited moderate alignment, its comparative weaknesses in CAPEX and EPPW limit its potential to rival the leading options. Similarly, V1, with the lowest overall score, struggled to present a compelling case for selection due to its suboptimal balance across critical criteria.

The integration of trapezoidal fuzzy numbers into the evaluation process enhanced the analysis by addressing uncertainties and providing a more nuanced understanding of the alternatives (

Table 11). The defuzzied scores aligned closely with the TOPSIS results, reinforcing the reliability of the rankings while offering additional insights into the stability of the evaluated criteria. Variant V3 consistently emerged as the most favorable option, with the highest defuzzied score, confirming its balanced performance across financial and operational metrics. Its alignment in both deterministic and fuzzy evaluations highlighted its robustness and suitability as the optimal choice, particularly in contexts requiring both cost-effectiveness and operational efficiency. Similarly, Variant V3.1 demonstrated strong potential as a viable alternative, with a defuzzied score that closely followed V3. This consistency across methods reflected its balanced trade-offs between key criteria, making it a competitive option when slight variations in priorities are acceptable. Its proximity to V3 underscores its relevance in decision-making scenarios where flexibility in the weighting of criteria is needed. Variant V2, while showing moderate alignment, revealed its limitations through a defuzzied score that lagged the top two alternatives. Although it may suit contexts with specific budgetary constraints or altered weighting preferences, its overall performance suggested a narrower applicability. Meanwhile, Variant V1 remained the least favorable option, with a defuzzied score that reinforced its lower alignment with the ideal solution (

Figure 2). Its weaker performance across critical criteria limited its feasibility as a strong candidate.

7. Discussion

V1 had the lowest performance and scored the lowest across most criteria. It represents the most conservative or minimal investment that is potentially suitable for scenarios where budget constraints are the tightest or minimal changes are needed.

V2 showed moderate improvement across all criteria compared to V1. This could be seen as a balanced option, offering a good compromise between cost and performance enhancements. It is suitable for scenarios in which moderate upgrades are both feasible and beneficial.

V3 closely matched V2 in all criteria, according to the scores. This measure might involve similar upgrades to V3 but may be configured differently or target different operational efficiencies. This seems to offer no distinct advantage over the V3.

V3.1 scores the highest in all criteria, indicating the most significant investment and the highest expected performance improvement. This represents a comprehensive approach, likely to include extensive upgrades or enhancements. This measure is most suitable for scenarios in which maximum efficiency, reduced operational costs, and long-term savings are prioritized, despite higher initial costs.

When comparing investment with return, V3.1 and V2 offer higher scores, suggesting better performance across the board, but likely at higher costs. V1, while being the least costly, offers the least benefits, making it suitable only where minimal changes are required.

Higher scores in V3.1 suggest higher risks but potentially higher rewards, particularly in terms of long-term savings and efficiency. V2 and V3 offer a middle ground, balancing costs and benefits.

The choice between these variants depends on the project’s specific goals and constraints. V3.1 is ideal for comprehensive overhauls, where futureproofing and maximizing operational efficiency are crucial. V2 could be preferable for moderate upgrades with noticeable benefits, but with controlled costs.

The stakeholders involved in the project were local government bodies, agricultural producers, water management authorities, and environmental groups. Each stakeholder had distinct priorities that needed to be balanced. For example, agricultural producers are primarily concerned with maintaining affordable water prices to ensure the economic viability of their operations. Environmental groups and government bodies, on the other hand, were focused on sustainability, particularly in terms of reducing energy consumption and minimizing the environmental impact of the pumping stations. The decision to prioritize criteria such as the OPEX/CAPEX ratio and deviation from the economic price of water reflects a compromise aimed at addressing the diverse concerns of these stakeholders. V3.1 emerged as the preferred variant because it effectively balanced these preferences, offering advanced automation and control features that reduce operational costs while avoiding the higher expenses associated with the comprehensive monitoring systems in V3.

The primary objectives of the project were to modernize pumping stations to enhance operational efficiency, ensure long-term financial sustainability, and support agricultural productivity in the region. These objectives necessitated a focus on minimizing operational expenses and maintaining an affordable economic price for pumped water, both of which were critical for the long-term success of the project. The decision to weigh the OPEX/CAPEX ratio and the economic price of water more heavily in the multicriteria analysis was a direct reflection of these objectives. V3.1 was selected because it provided the best alignment with these goals, delivering a high level of modernization without overburdening the financial resources required for ongoing operations.

The Vojvodina region, where the project is located, faces specific challenges, including aging infrastructure, frequent flooding, and the need to balance modernization with environmental sustainability. The region’s reliance on pumping stations for both agricultural productivity and flood defense makes it imperative that the chosen variant not only improves efficiency but also ensures resilience against environmental risks. Furthermore, the economic constraints faced by the region meant that the project had to be financially viable in terms of both initial investment and long-term operational costs. V3.1 was chosen because it addresses these regional challenges by providing an optimal balance of cost-effectiveness and technological advancement. Its ability to deliver significant improvements in efficiency and control, without the additional complexity and cost of the full monitoring systems in V3, makes it the most practical and sustainable choice for the region.

In addition to multicriteria analysis, V3.1 aligns closely with the objectives central to the success of the land reclamation project and the development of the Vojvodina region.

V3.1 enhances operational efficiency and reduces environmental impact by optimizing electricity consumption and lowering operational costs. The use of modern automation technologies contributes to reducing greenhouse gas emissions, aligning with regional sustainability goals without requiring excessive capital investment.

V3.1 improves the resilience of pumping stations through advanced automation and control systems, which ensures reliable operation even under extreme weather conditions. This is crucial for regions prone to flooding, where reliable water management is essential for protecting agricultural and urban areas.

V3.1 offers a modular approach that allows for future upgrades, making it adaptable to changing climate conditions and technological advancements. This flexibility ensures that the system can evolve over time, providing a sustainable solution that remains effective in the long term.

The integration of AI technologies in Variant V3.1 could potentially offer further reductions in operational costs and energy consumption, aligning with our goals for sustainable development and efficiency improvements.

In summary, V3.1 not only meets the project’s technical and economic criteria but also supports the region’s broader goals of sustainability, resilience, and adaptability, making it a strategic choice for the modernization of pumping stations.

8. Conclusions

The multicriteria analysis identified V3.1 as the optimal variant for the modernization of pumping stations involved in the land reclamation project in Vojvodina. This measure, which balances capital and operational expenditures with an advanced level of automation, was found to be the most favorable option for 90 of the 104 pumping stations evaluated. The results of the analysis demonstrated that V3.1 achieved the highest overall score (67.5 points out of 100), outperforming the other evaluated variants in terms of cost-effectiveness and operational efficiency. It is evident that the V3.1 Variant achieves the best results in terms of energy balance and operating costs. However, it is interesting to note that although the V3 Variant has a higher investment cost, it provides additional benefits in terms of reducing fluctuations in energy consumption. This difference may be crucial for decision-making in regions where electricity costs are high or where seasonal variations in consumption are significant. In this context, a decision-maker may prefer V3 over V3.1 if there is a need for additional long-term system stability. These additional analyses provide a deeper perspective that connects technical and economic factors with real conditions in managing pumping stations.

This finding suggests that investing in V3.1, which includes local SCADA systems and centralized control, provides the best return on investment while ensuring robust operational capabilities. This measure also aligns with the strategic goals of enhancing water management efficiency and sustainability in the region, addressing both the current and future challenges associated with climate change and resource conservation.

The project’s economic and financial analysis further confirmed the feasibility and profitability of implementing V3.1, with a positive economic net present value (ENPV) and an internal rate of return (EIRR) exceeding the social discount rate. These results underscore the project’s viability and potential to deliver long-term benefits to the region’s agricultural and urban areas.

The selection of V3.1 as the preferred variant was the result of a nuanced decision-making process that carefully considered stakeholders’ preferences, project objectives, and the unique challenges faced by the Vojvodina region. By prioritizing criteria that reflected these considerations, V3.1 emerged as the variant that best met the project’s goals of sustainability, long-term resilience, adaptability to climate change, and modernity.

This decision underscores the importance of a balanced approach in infrastructure projects, where multiple factors must be harmonized to achieve the most favorable outcomes for all stakeholders involved.

AHP ensured the objective determination of weights for the criteria, allowing for the precise expression of the participants’ preferences in the decision-making process. The validation of consistency (CI and CR) provided additional confidence in the results. This method was essential for the weighted evaluation of the economic and technical aspects such as CAPEX, OPEX, EPPW, and energy consumption.

TOPSIS enabled a clear ranking of the variants based on their distance from the ideal solution. This method highlighted Variant V3.1 as the closest to the ideal solution, while also demonstrating its ability to balance key criteria. The precision in identifying the best-performing variants makes TOPSIS an invaluable tool in multicriteria analyses.

Fuzzy logic introduced flexibility into the analysis by enabling the handling of uncertainty through trapezoidal fuzzy numbers. This approach reduced the risk of subjective errors and provided additional robustness to the evaluation. Defuzzification allowed the conversion of interval values into single scores, making the comparison of variants simpler and more precise.

The findings indicate that Variant V3.1, although slightly more expensive initially compared to V2, offers significant long-term benefits, including reduced operational costs and improved energy efficiency. Its ability to balance costs with modernization and environmental benefits makes it the optimal choice for most pumping stations in the region.

Variant V3, while more technically advanced, entails significantly higher capital costs, making it a less attractive option in budget-constrained scenarios. On the other hand, V2 represents a good compromise for scenarios with moderate budget constraints, whereas V1 remains suitable for minimal interventions.

A key limitation of this study is its focus on the AP Vojvodina region in Serbia, which may restrict the applicability of our findings to other regions with different characteristics. Owing to this limitation, the multicriteria analysis represents the best solution considering all factors. In the future, advanced analyses should be conducted using new technologies. However, the multicriteria analysis framework developed here can be adapted to other regions facing similar challenges, offering a versatile tool for financial feasibility assessment in diverse land reclamation contexts.

This study presents a snapshot analysis based on the current data. Longitudinal studies that monitor the performance and financial viability of implemented designs over time could provide valuable insights into the accuracy of feasibility assessments and the long-term sustainability of projects.

Addressing these limitations in future research could significantly enhance the understanding of the financial feasibility of land reclamation projects and provide policymakers and practitioners with a more robust tool for decision-making in the face of complex environmental, social, and economic challenges.

Future studies should collect comprehensive datasets encompassing the technical specifications of pumping stations, the detailed financial records of past and projected costs, and data on environmental impacts, particularly focusing on energy consumption and CO2 emissions. Socio-economic data, including their effects on employment and local communities, are also crucial. The research process should start with a thorough data collection phase, focusing on the identified required data. Following data preprocessing, the next step involves selecting and weighting the criteria through stakeholder engagement. The subsequent steps included the development of the MCA models, scenario analysis through simulations, and finally, the derivation of policy implications based on the findings. Future research should explore the operationalization of AI for predictive maintenance and the IoT for real-time monitoring and detail the technical requirements and potential data sources for these technologies. The application of AI could optimize maintenance schedules, whereas IoT devices could provide real-time data on station performance. Research should also consider social equity aspects to ensure that modernization efforts do not disproportionately impact vulnerable communities.

Future research should explore the integration of AI technologies in the modernization of pumping stations, focusing on the potential to further enhance sustainability, reduce operational costs, and improve system resilience against the impacts of climate change.

Overall, this study highlights the importance of applying a comprehensive multicriteria analysis to decision-making processes for infrastructure projects. The findings of this study can guide policymakers and stakeholders in making informed decisions that balance economic viability, environmental sustainability, and operational resilience.