Hydration Products and Properties of Nanocellulose Fibre-Reinforced Mortar †

Abstract

1. Introduction

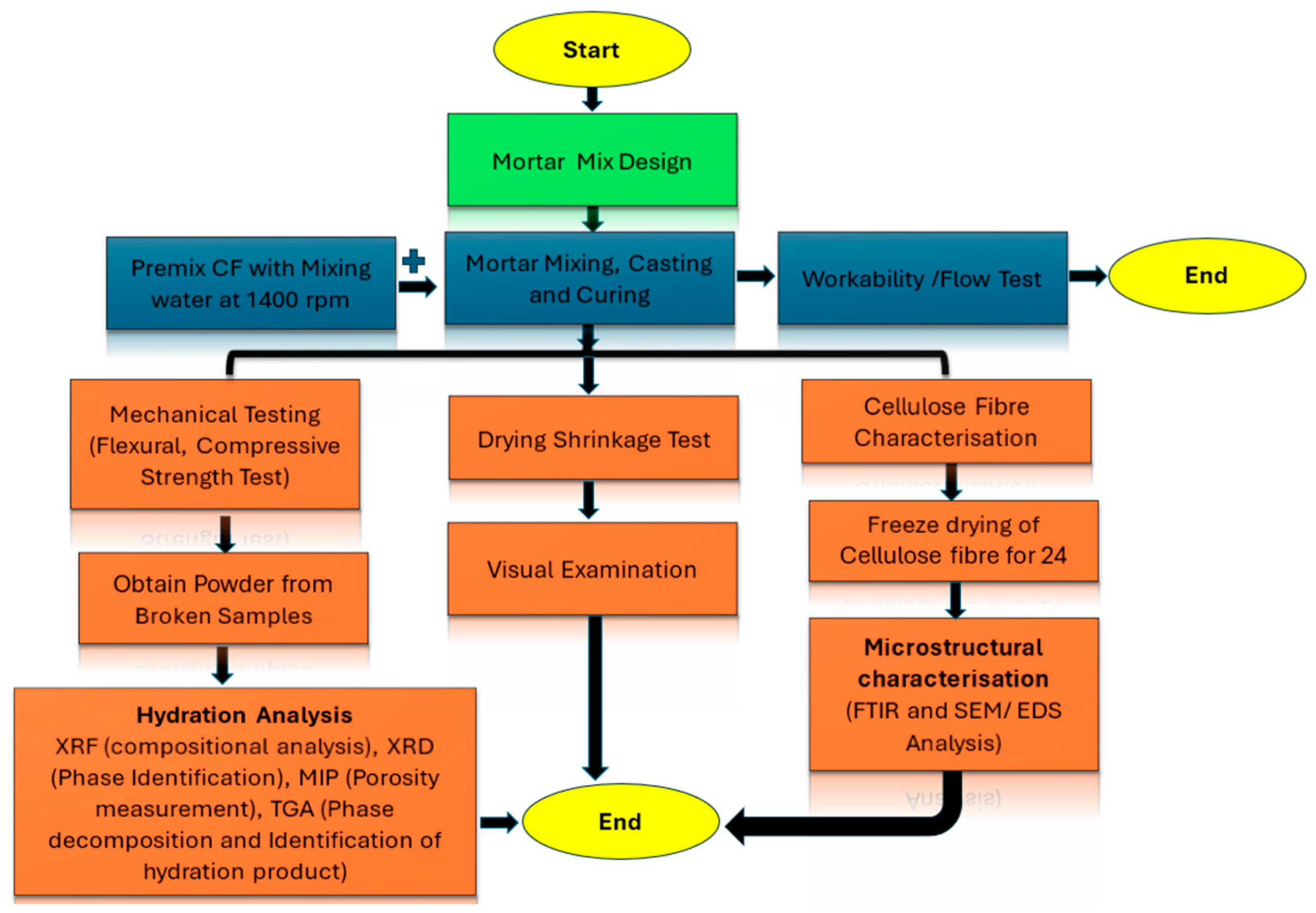

2. Materials and Methods

2.1. Materials and Mixes

2.2. Specimen Preparation

2.2.1. Flexural, Compression, and Drying Shrinkage Test Specimens

2.2.2. Mercury Intrusion Porosimetry (MIP)

2.2.3. XRD, XRF (X-Ray Fluorescence) and FT-IR (Fourier-Transform Infrared Spectroscopy)

2.3. Test Procedures

2.3.1. FT-IR

2.3.2. Scanning Electron Microscopy/Energy-Dispersive X-Ray Spectroscopy (SEM/EDS)

2.3.3. Workability and Flexural and Compressive Strength

2.3.4. Drying Shrinkage and MIP Test

2.3.5. TGA and XRD

3. Results and Discussion

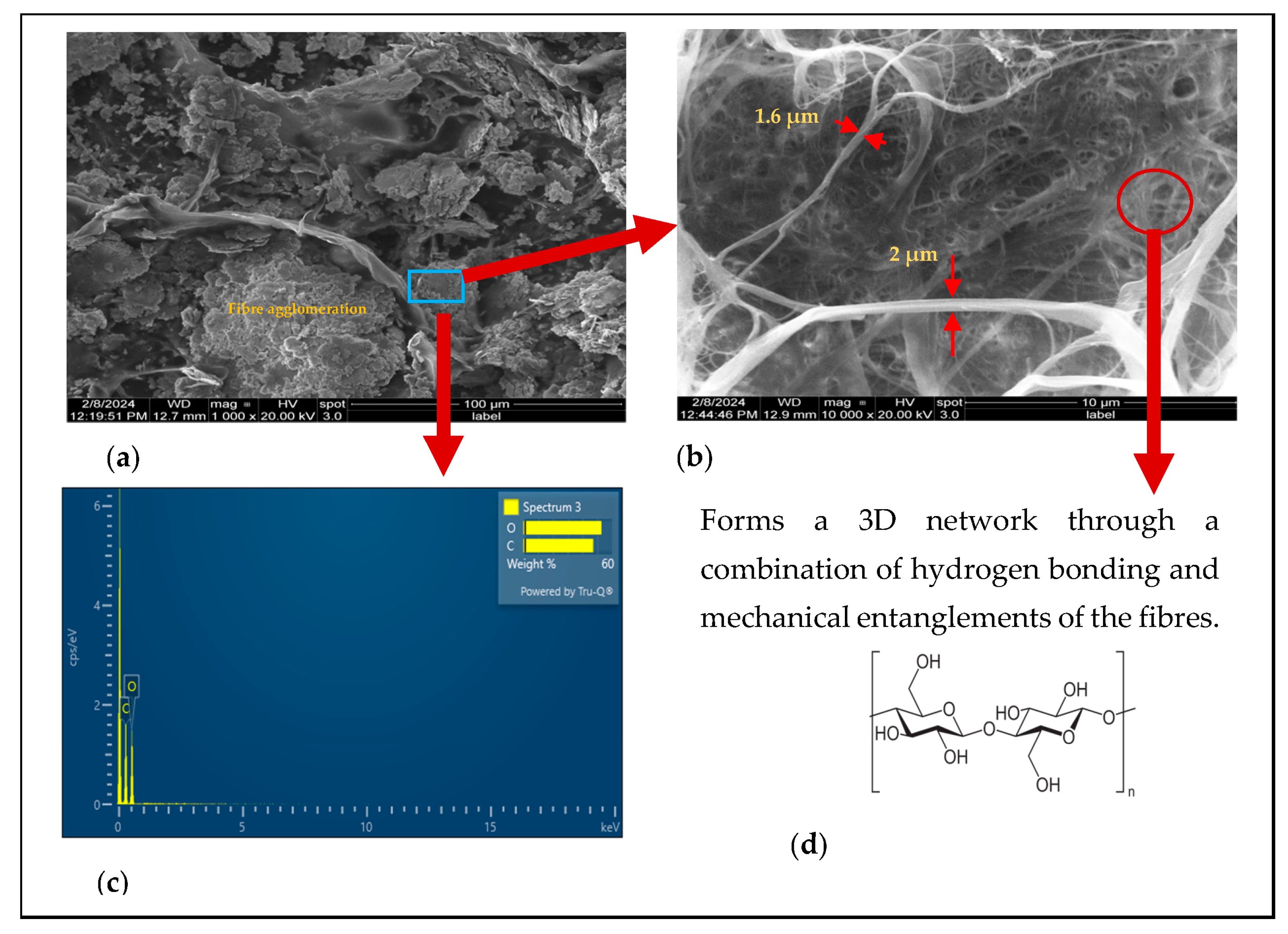

3.1. FT-IR and SEM-EDS Analysis

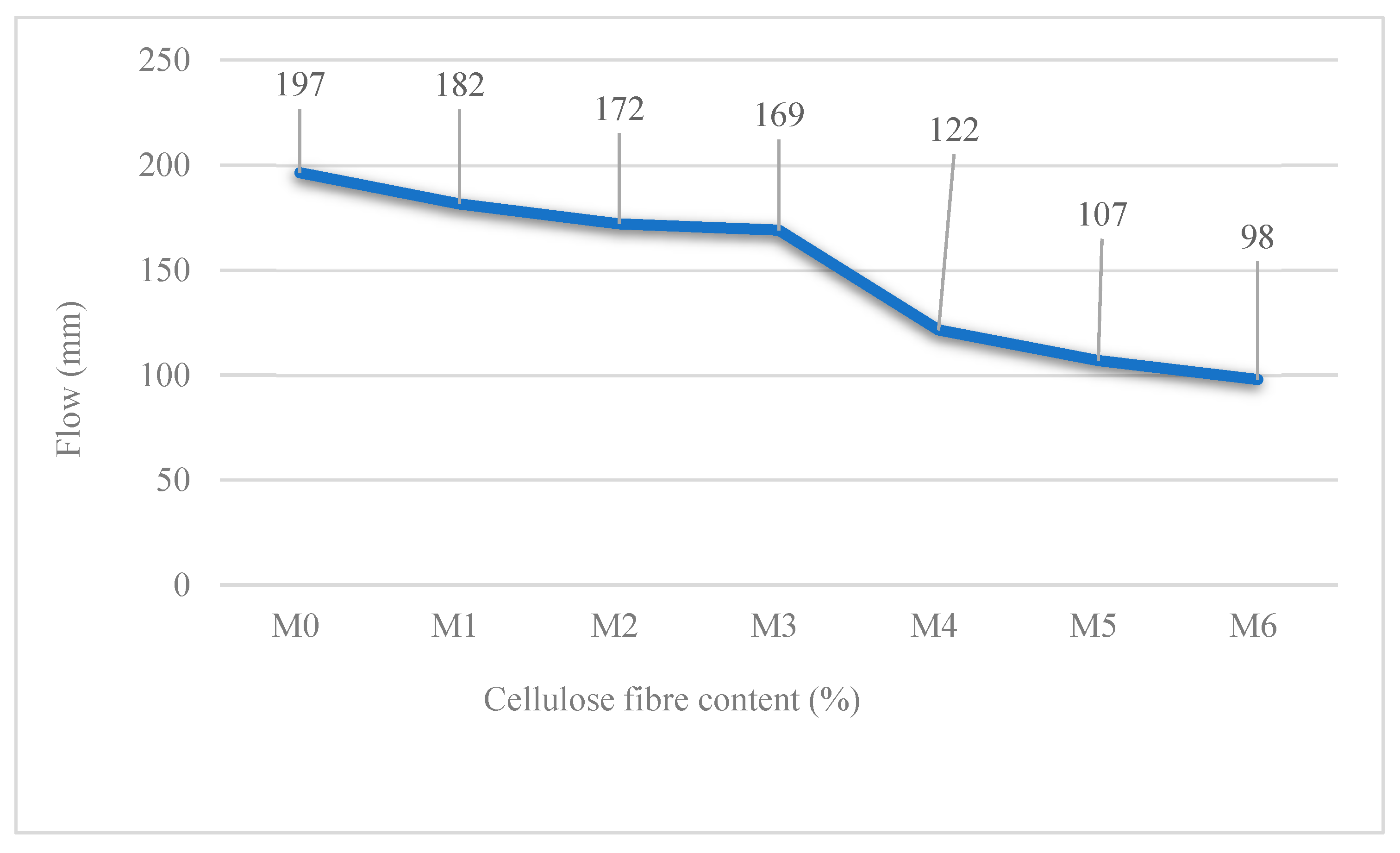

3.2. Workability

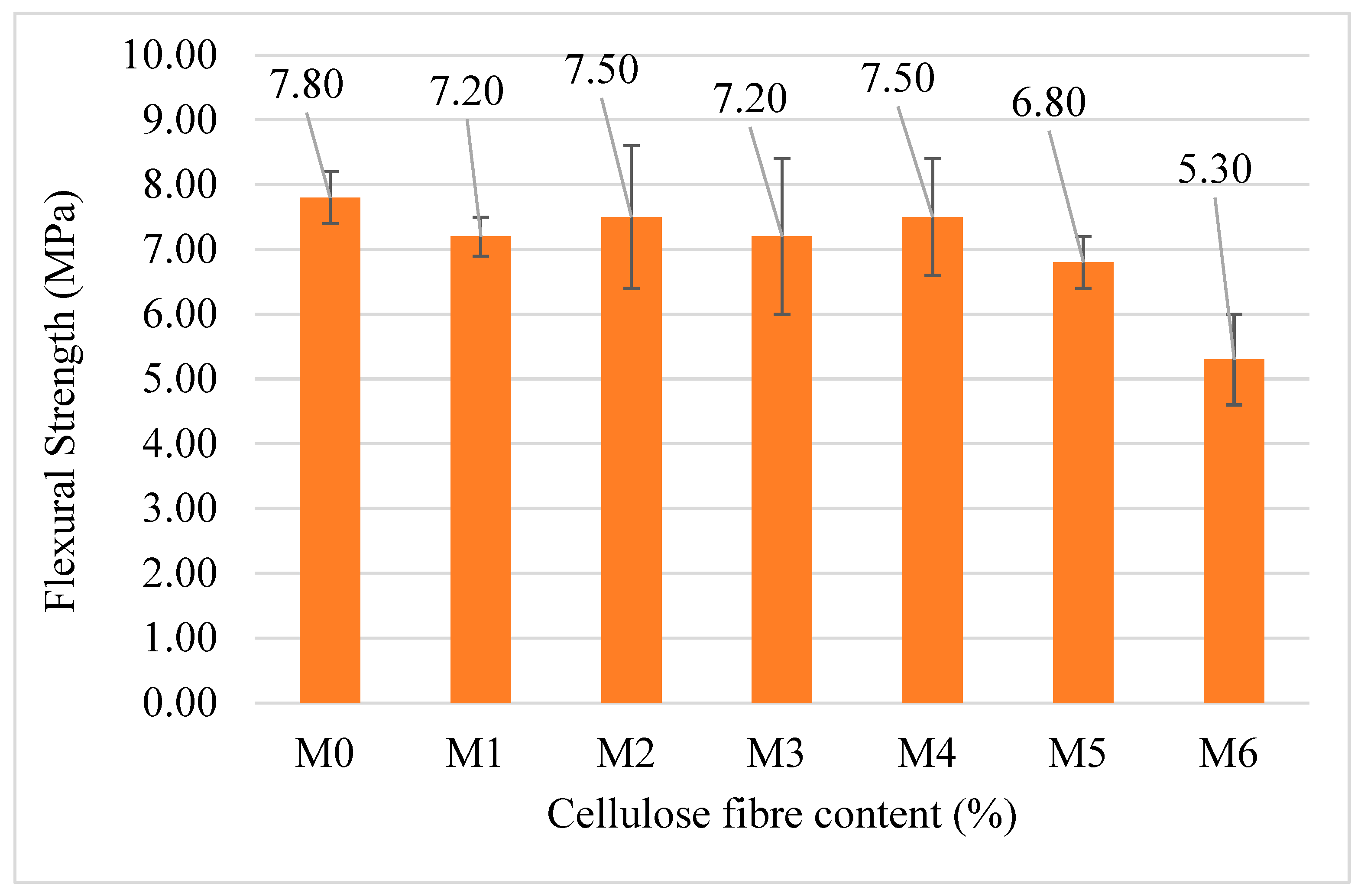

3.3. Flexural and Compressive Strength

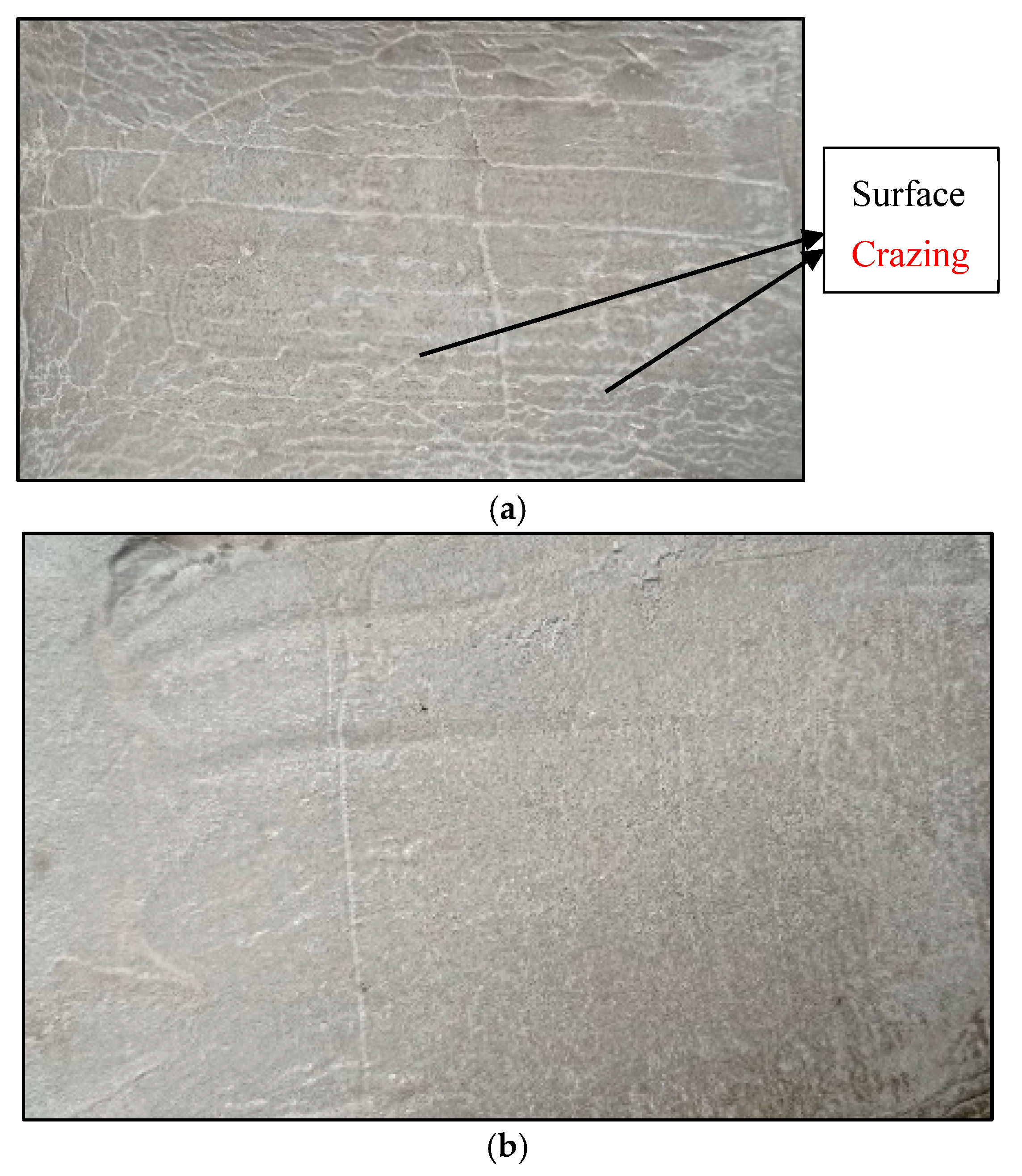

3.4. Drying Shrinkage Test and Visual Examination

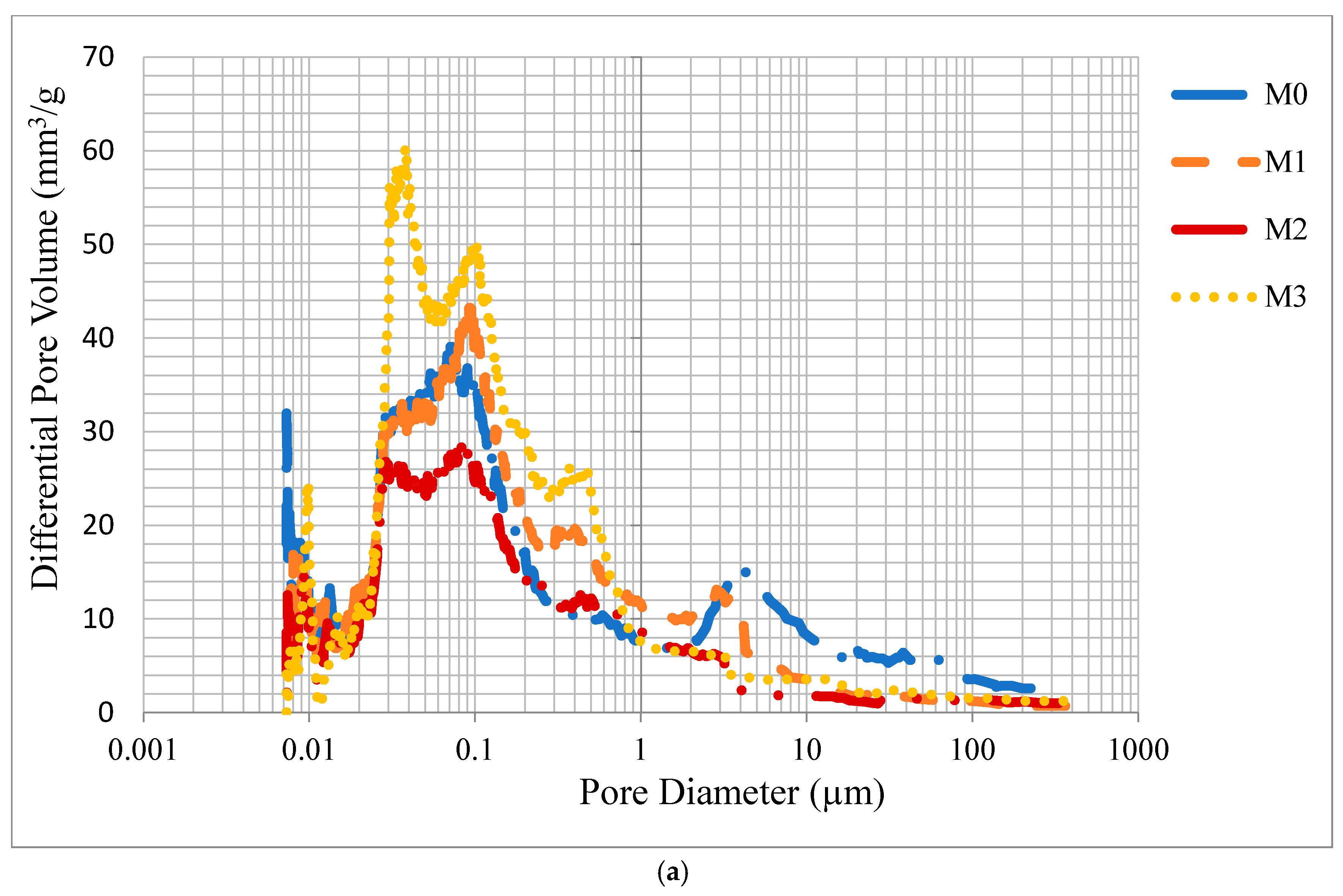

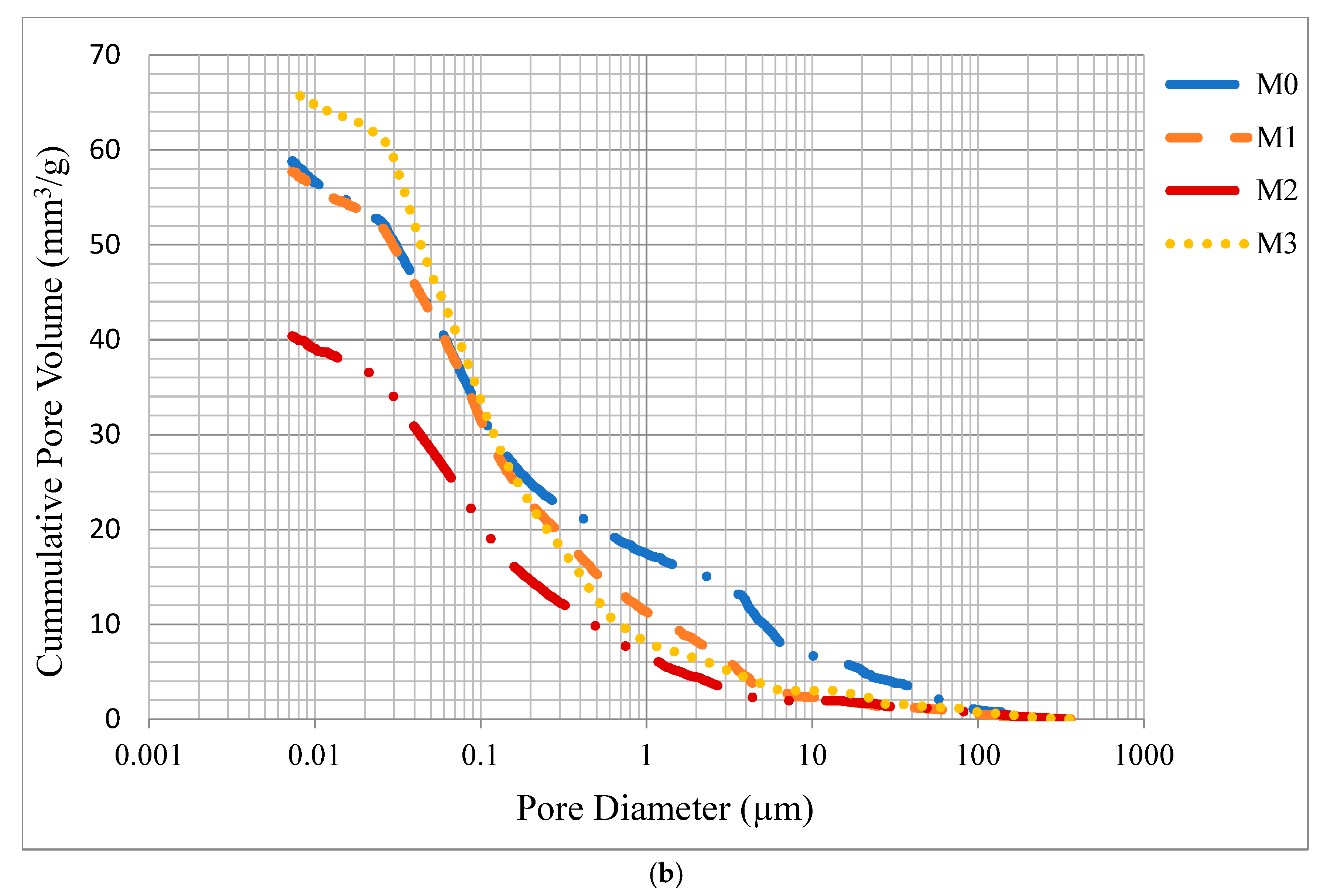

3.5. Mercury Intrusion Porosimetry (MIP)

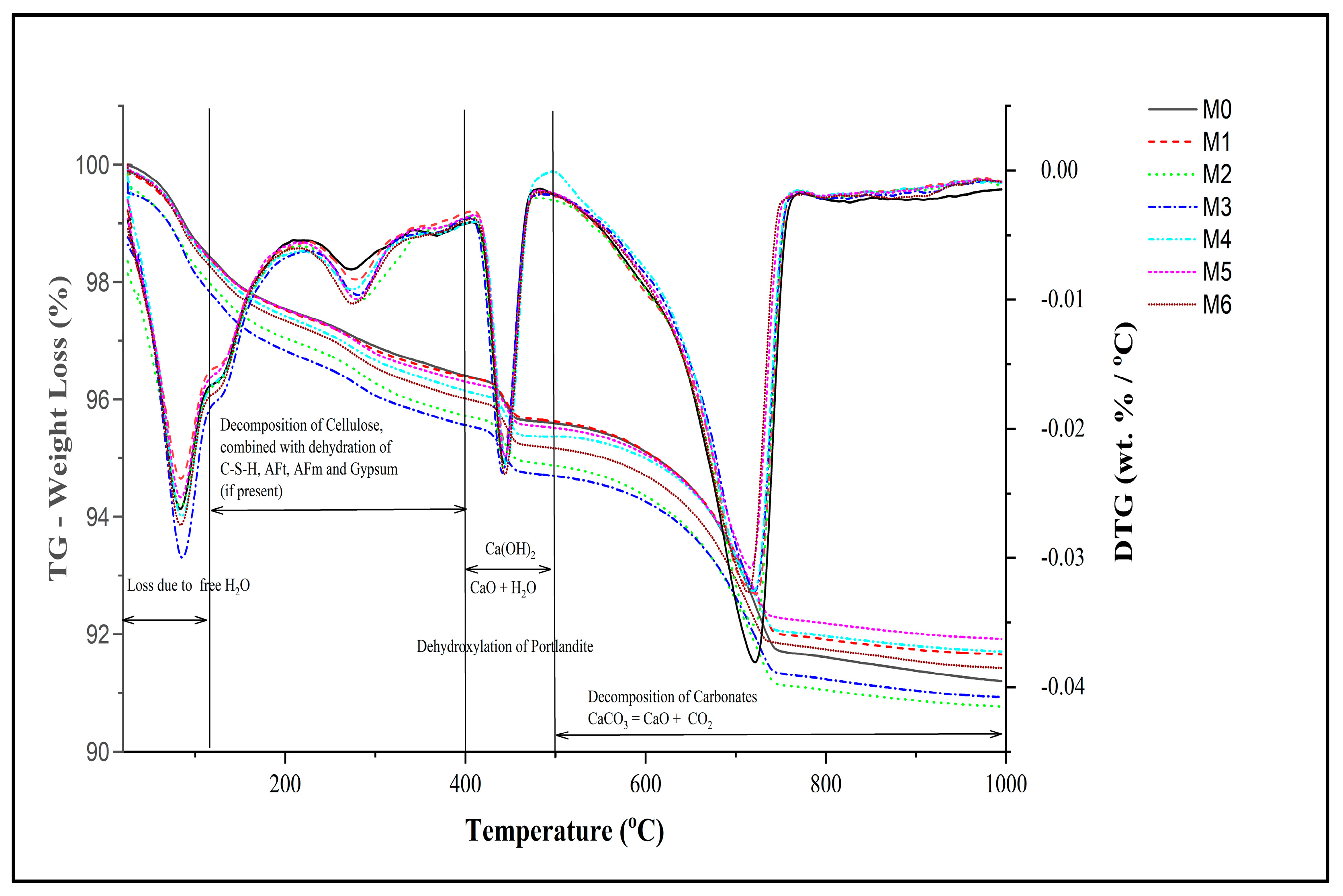

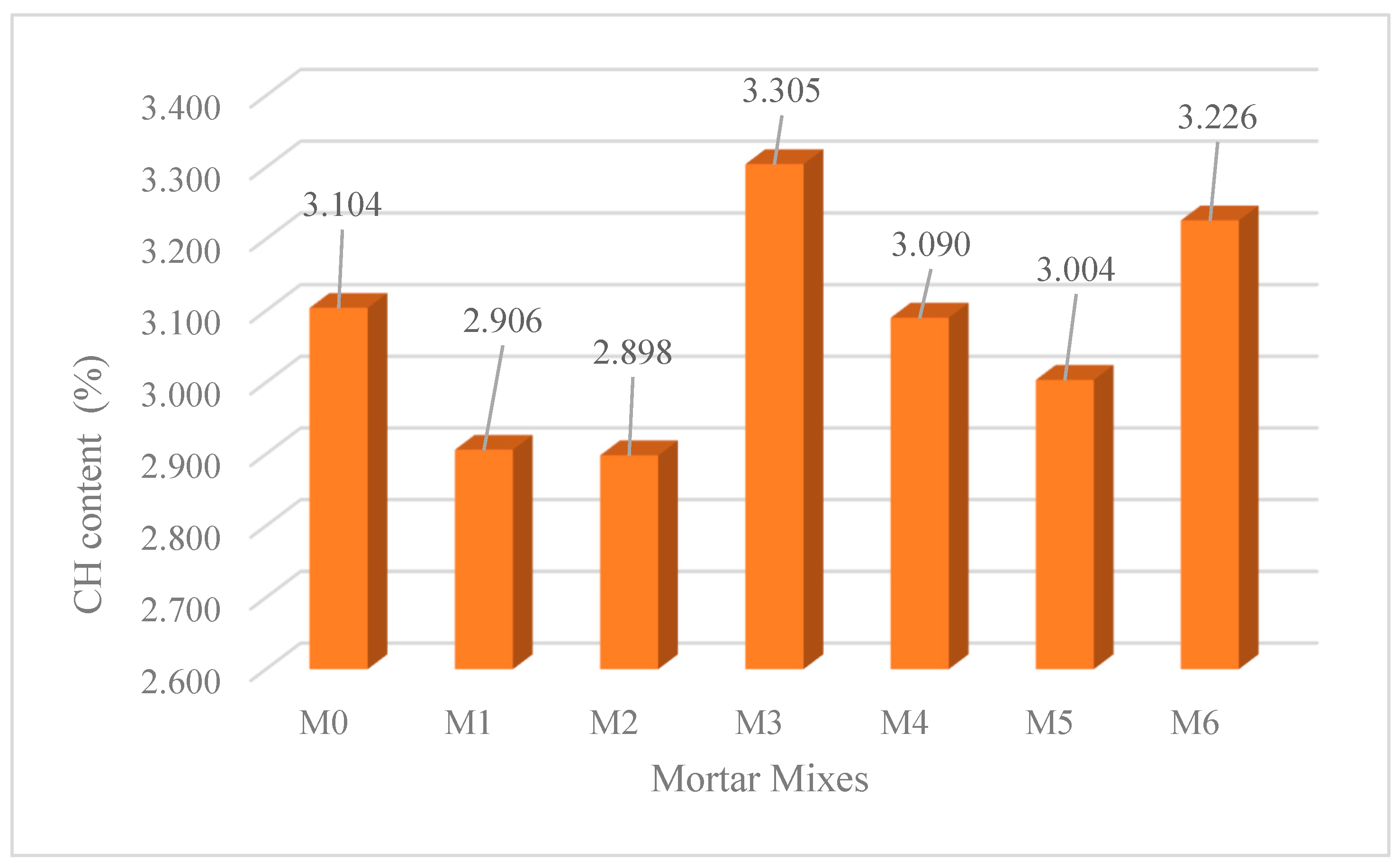

3.6. Thermogravimetric Analysis

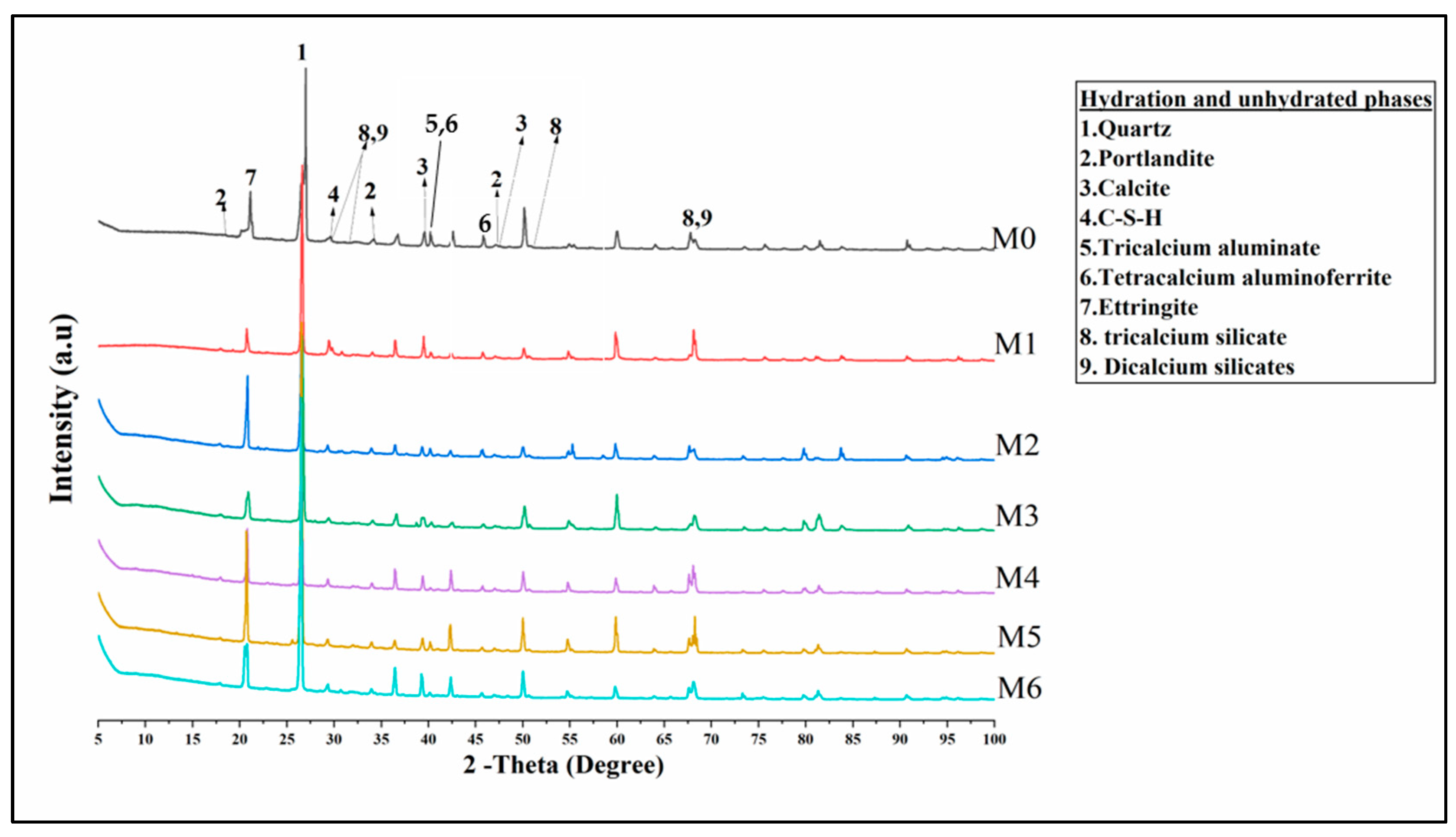

3.7. XRD Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arbelaiz, A.; Ibarbia, J.; Imaz, B.; Soto, L. Natural Fiber–Reinforced Cement Mortar Composite Physico Mechanical Properties: From Cellulose Microfibers to Nanocellulose. J. Mater. Civ. Eng. 2023, 35, 4023094. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; García-Hortal, J.; Bizinotto, M.B. Fiber-Matrix Interactions in Cement Mortar Composites Reinforced with Cellulosic Fibers. Cellulose 2011, 18, 281–289. [Google Scholar] [CrossRef]

- Zaki, S.I. Application of ultra cellulose fiber for the enhancement of the durability and shrinkage of cement pastes exposed to normal and aggressive curing conditions. Nanotechnol. Constr. A Sci. Internet-J. 2015, 8, 121–142. [Google Scholar] [CrossRef]

- Kulisch, D.; Katz, A.; Zhutovsky, S. Quantification of Residual Unhydrated Cement Content in Cement Pastes as a Potential for Recovery. Sustainability 2023, 15, 263. [Google Scholar] [CrossRef]

- Pandey, K.; Pal, T.; Sharma, R.; Kar, K.K. Study of Matrix–Filler Interaction through Correlations between Structural and Viscoelastic Properties of Carbonous-Filler/Polymer-Matrix Composites. J. Appl. Polym. Sci. 2020, 137, 48660. [Google Scholar] [CrossRef]

- Luna, F.; Pérez, A.; Alonso, M. The Influence of Curing and Aging on Chloride Transport through Ternary Blended Cement Concrete. Mater. Construcc. 2018, 68, 171. [Google Scholar] [CrossRef]

- Mejdoub, R.; Hammi, H.; Suñol, J.J.; Khitouni, M.; M’nif, A.; Boufi, S. Nanofibrillated Cellulose as Nanoreinforcement in Portland Cement: Thermal, Mechanical and Microstructural Properties. J. Compos. Mater. 2017, 51, 2491–2503. [Google Scholar] [CrossRef]

- D’Erme, C.; Caseri, W.R.; Santarelli, M.L. Effect of Fibrillated Cellulose on Lime Pastes and Mortars. Materials 2022, 15, 459. [Google Scholar] [CrossRef]

- Kawashima, S.; Shah, S.P. Early-Age Autogenous and Drying Shrinkage Behavior of Cellulose Fiber-Reinforced Cementitious Materials. Cem. Concr. Compos. 2011, 33, 201–208. [Google Scholar] [CrossRef]

- ISO 15901-1:2016; Evaluation of Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption—Mercury Porosimetry. ISO: Geneva, Switzerland, 2016.

- EN 1008:2002; Mixing Water for Concrete. Specification for Sampling, Testing and Assessing the Suitability of Water, Including Water Recovered from Processes in the Concrete Industry, as Mixing Water for Concrete. The European Standard: Brussels, Belgium, 2002.

- Sappi Maastricht B.V. Valida. Available online: https://www.sappi.com/valida-home (accessed on 20 January 2025).

- Ojedokun, O.O.; Mangat, P.S. Chemical composition and physico-mechanical properties of carbonated alkali activated concrete and mortar. J. Build. Eng. 2023, 71, 106480. [Google Scholar] [CrossRef]

- Agunbiade, T.; Mangat, P.S. Mechanical and Chemical Properties of Nanocellulose Fibre Reinforced Mortar. In Proceedings of the Sixth International Conference on Sustainable Construction Materials and Technologies, Lyon, France, 9–14 June 2024; pp. 347–360. [Google Scholar] [CrossRef]

- BS EN 1015-3:1999; Methods of Test for Mortar for Masonry. Determination of Consistency of Fresh Mortar (by Flow Table). BSI Knowledge: London, UK, 1999.

- BS EN 12390-4:2019; Testing Hardened Concrete. Compressive Strength. Specification for Testing Machines. British Standard: London, UK, 2019.

- BS EN 1881-206:1986; Testing Concrete. Recommendations for Determination of Strain in Concrete. British Standard: London, UK, 1986.

- BS EN 812-103.2:1989; Testing Aggregates. Method for Determination of Particle Size Distribution. Sedimentation Test View Details. British Standard: London, UK, 1989.

- Malvern Panalytical. PANalytical. X’Pert HighScore; Version 5.1; Malvern Panalytical B.V.: Almelo, The Netherlands, 2021. [Google Scholar]

- Poletto, M.; Pistor, V.; Zeni, M.; Zattera, A.J. Crystalline properties and decomposition kinetics of cellulose fibers in wood pulp obtained by two pulping processes. Polym. Degrad. Stab. 2011, 96, 679–685. [Google Scholar] [CrossRef]

- Rosa, M.D.; Medeiros, E.; Malmonge, J.A.; Gregorski, K.S.; Wood, D.F.; Mattoso, L.H.; Glenn, G.; Orts, W.J.; Imam, S.H. Cellulose nanowhiskers from coconut husk fibers: Effect of preparation conditions on their thermal and morphological behavior. Carbohydr. Polym. 2010, 81, 83–92. [Google Scholar] [CrossRef]

- Wu, J.; Ding, Q.; Yang, W.; Wang, L.; Wang, H. Influence of Submicron Fibrillated Cellulose Fibers from Cotton on Hydration and Microstructure of Portland Cement Paste. Molecules 2021, 26, 5831. [Google Scholar] [CrossRef]

- Goncalves, J.; El-Bakkari, M.; Boluk, Y.; Bindiganavile, V. Cellulose nanofibres (CNF) for sulphate resistance in cement based systems. Cem. Concr. Compos. 2019, 99, 100–111. [Google Scholar] [CrossRef]

- Hoyos, C.G.; Zuluaga, R.; Gañán, P.; Pique, T.M.; Vazquez, A. Cellulose nanofibrils extracted from fique fibers as bio-based cement additive. J. Clean. Prod. 2019, 235, 1540–1548. [Google Scholar] [CrossRef]

- Panda, S.S.; Bisaria, S.K.; Singh, M.R. The spectroscopic and microscopic evaluation of cellulose used in conservation of archival materials. Microchem. J. 2021, 160, 105707. [Google Scholar] [CrossRef]

- Zhao, H.; Kwak, J.; Conradzhang, Z.; Brown, H.; Arey, B.; Holladay, J. Studying cellulose fiber structure by SEM, XRD, NMR and acid hydrolysis. Carbohydr. Polym. 2007, 68, 235–241. [Google Scholar] [CrossRef]

- Sawsen, C.; Fouzia, K.; Mohamed, B.; Moussa, G. Effect of flax fibers treatments on the rheological and the mechanical behavior of a cement composite. Constr. Build. Mater. 2015, 79, 229–235. [Google Scholar] [CrossRef]

- Buch, N.; Rehman, O. Impact of Processed Cellulose Fibers on Portland Cement Concrete Properties. Transp. Res. Rec. 1999, 1668, 72–80. [Google Scholar] [CrossRef]

- Wu, F.; Yu, Q.; Liu, C.; Brouwers, H.J.H.; Wang, L.; Liu, D. Effect of fibre type and content on performance of bio-based concrete containing heat-treated apricot shell. Mater. Struct. 2020, 53, 137. [Google Scholar] [CrossRef]

- Sangkeaw, P.; Thongchom, C.; Keawsawasvong, S.; Prasittisopin, L. Mechanical Properties and Microstructure of Cellulose Fiber- and Synthetic Fiber-Reinforced High-Strength Concrete. Arab. J. Sci. Eng. 2025, 50, 2149–2168. [Google Scholar] [CrossRef]

- Rocha, D.L.; Júnior, L.T.; Marvila, M.; Pereira, E.; Souza, D.; de Azevedo, A. A Review of the Use of Natural Fibers in Cement Composites: Concepts, Applications and Brazilian History. Polymers 2022, 14, 2043. [Google Scholar] [CrossRef]

- MacVicar, R.; Matuana, L.M.; Balatinecz, J.J. Aging mechanisms in cellulose fiber reinforced cement composites. Cem. Concr. Compos. 1999, 21, 189–196. [Google Scholar] [CrossRef]

- Lee, H.-J.; Kim, S.-K.; Lee, H.-S.; Kim, W. A Study on the Drying Shrinkage and Mechanical Properties of Fiber Reinforced Cement Composites Using Cellulose Nanocrystals. Int. J. Concr. Struct. Mater. 2019, 13, 39. [Google Scholar] [CrossRef]

- Ban, Y.; Zhi, W.; Fei, M.; Liu, W.; Yu, D.; Fu, T.; Qiu, R. Preparation and Performance of Cement Mortar Reinforced by Modified Bamboo Fibers. Polymers 2020, 12, 2650. [Google Scholar] [CrossRef]

- Filho, R.D.T.; Ghavami, K.; Sanjuán, M.A.; Free, G.L.E. Restrained and drying shrinkage of cement mortar composites reinforced with vegetable fibres. Cem. Concr. Compos. 2005, 27, 537–546. [Google Scholar] [CrossRef]

- Aitcin, P.C.; Neville, A.; Acker, P. Integrated view of shrinkage deformation. Concr. Int. 1997, 19, 35–41. [Google Scholar]

- Filho, R.D.T. Natural Fibre Reinforced Mortar Composites: Experimental Characterisation; DEC-PUC: Rio de Janeiro, Brazil, 1997. [Google Scholar]

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Collier, N.C. Transition and decomposition temperatures of cement phases—A collection of thermal analysis data. Ceram.-Silik. 2016, 60, 338–343. [Google Scholar] [CrossRef]

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford Publishing: London, UK, 1997. [Google Scholar]

- El-Sayed, S.A.; Mostafa, M.E. Kinetic Parameters Determination of Biomass Pyrolysis Fuels Using TGA and DTA Techniques. Waste Biomass Valorization 2015, 6, 401–415. [Google Scholar] [CrossRef]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Powers, T.C.; Brownyard, T.L. Studies of the Physical Properties of Hardened Portland Cement Paste. ACI J. Proc. 1947, 43, 933–992. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Pearson Education Limited: Harlow, UK, 2012. [Google Scholar]

| wt.% | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Oxides | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | TiO2 | P2O5 | MnO | SO3 | LOI |

| OPC | 11.10 | 8.35 | 3.16 | 64.20 | 2.09 | 1.19 | 0.23 | 1.88 | 2.01 | 2.14 | 3.60 | 0.05 |

| Sharp Sand | 91.70 | 6.10 | 1.62 | 0.28 | 0.03 | - | 0.21 | - | - | - | - | 0.06 |

| wt.% of Mortar | |||||||

|---|---|---|---|---|---|---|---|

| Mixes | M0 | M1 | M2 | M3 | M4 | M5 | M6 |

| CF content | 0 | 0.15 | 0.31 | 0.45 | 0.51 | 0.99 | 1.50 |

| Mortar Mixes | WLF 35–105 °C | WLB 105–210 °C | WLB 210–350 °C | WLB 350–410 °C | WLCH% 410–480 °C | WLCALCITE% 480–750 °C | WLT% 35–1000 °C |

|---|---|---|---|---|---|---|---|

| M0—0%CF | 1.476 | 0.943 | 0.853 | 0.273 | 0.755 | 3.962 | 8.726 |

| M1—0.15%CF | 1.404 | 0.910 | 0.896 | 0.228 | 0.707 | 3.697 | 8.178 |

| M2—0.31%CF | 1.404 | 0.913 | 0.895 | 0.236 | 0.705 | 3.695 | 8.140 |

| M3—0.45%CF | 1.649 | 1.062 | 0.991 | 0.268 | 0.804 | 3.437 | 8.547 |

| M4—0.51%CF | 1.453 | 0.987 | 0.989 | 0.284 | 0.752 | 3.347 | 8.122 |

| M5—0.99%CF | 1.436 | 0.927 | 0.970 | 0.260 | 0.731 | 3.308 | 7.927 |

| M6—1.5%CF | 1.538 | 0.986 | 1.046 | 0.279 | 0.785 | 3.398 | 8.389 |

| Mortar Mixes | CH Measured (%) | CC Measured (%) | WLF (%) | WLB (%) | WLT (%) | Degree of Hydration (%) |

|---|---|---|---|---|---|---|

| M0—0% CF | 3.104 | 9.004 | 1.476 | 2.533 | 4.009 | 12.28 |

| M1—0.15% CF | 2.906 | 8.402 | 1.404 | 2.221 | 3.624 | 11.92 |

| M2—0.31% CF | 2.898 | 8.397 | 1.404 | 2.026 | 3.430 | 11.95 |

| M3—0.45% CF | 3.305 | 7.812 | 1.649 | 2.207 | 3.855 | 13.59 |

| M4—0.51% CF | 3.090 | 7.606 | 1.453 | 2.060 | 3.513 | 13.09 |

| M5—0.99% CF | 3.004 | 7.519 | 1.436 | 1.462 | 2.898 | 12.55 |

| M6—1.5% CF | 3.226 | 7.724 | 1.538 | 1.168 | 2.706 | 13.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agunbiade, T.; Mangat, P.S. Hydration Products and Properties of Nanocellulose Fibre-Reinforced Mortar. Sustainability 2025, 17, 2719. https://doi.org/10.3390/su17062719

Agunbiade T, Mangat PS. Hydration Products and Properties of Nanocellulose Fibre-Reinforced Mortar. Sustainability. 2025; 17(6):2719. https://doi.org/10.3390/su17062719

Chicago/Turabian StyleAgunbiade, Taiwo, and P. S. Mangat. 2025. "Hydration Products and Properties of Nanocellulose Fibre-Reinforced Mortar" Sustainability 17, no. 6: 2719. https://doi.org/10.3390/su17062719

APA StyleAgunbiade, T., & Mangat, P. S. (2025). Hydration Products and Properties of Nanocellulose Fibre-Reinforced Mortar. Sustainability, 17(6), 2719. https://doi.org/10.3390/su17062719