Abstract

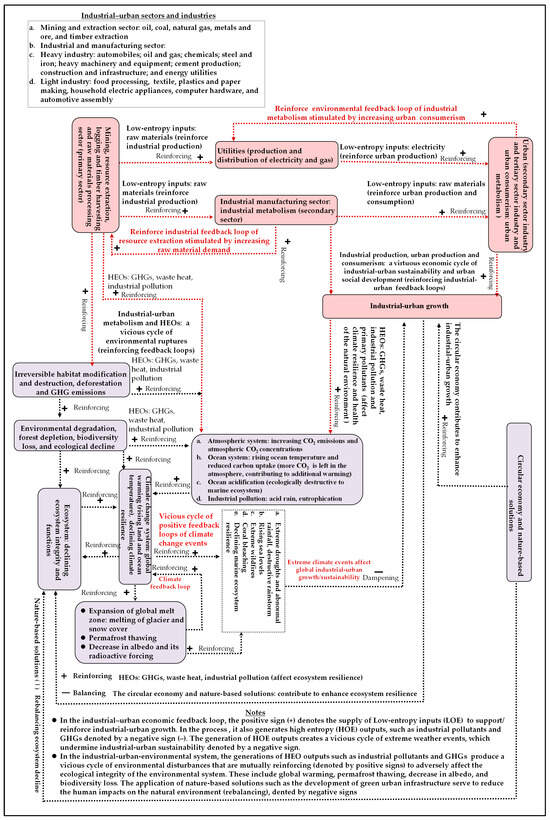

Circular economic strategies have been widely deployed across the world to decouple industrial–urban growth from resource use and carbon emissions, aiming to mitigate environmental degradation. Despite these efforts, the global circularity gap has widened, and widespread crisis-ridden environmental repercussions continue to drive our planetary system closer to ecosystem collapse and climate breakdown. This article critically analyzes this circularity paradox based on an integrated conceptual framework grounded in environmental economic principles, system theory, the laws of thermodynamics, and empirical case studies. The analysis elucidates the macro-level dynamics and intricate feedback mechanisms between industrial–urban systems and environmental systems, revealing the underlying ecological conflicts and environmental forces that drive deleterious changes in ecosystems and the climate system. These changes causally impede sustainable industrial–urban development. The findings underscore that addressing environmental threats to industrial–urban sustainability requires not only enhancing the efficient use and sustainable management of natural resources but, more importantly, prioritizing the preservation and restoration of ecosystem resilience and climate system stability.

1. Introduction

At present, the world is in the throes of rural–urban migration on an unprecedented scale—a phenomenon that has significantly reshaped global demographics and economic systems. Between 1965 and 2023, the global urban population soared by more than 400%, from 877 million to 4.6 billion. This rapid urbanization is often catalyzed by the establishment of industrial facilities within a region, which generate a high demand for labor and accelerate rural-to-urban migration. Industrial–urban development and rural–urban migration are mutually reinforcing, systemically interconnected, and converge upon the prospect of growth. Indeed, the industrial–urban economy accounts for more than 80% of a nation’s gross domestic product (GDP) growth. It thus follows that the world’s cities are the most powerful locomotives of global economic expansion, despite accounting for less than 3% of the Earth’s land surface area [1,2].

However, the ever-expanding industrial–urban economy poses one of the greatest environmental problems facing humanity today: the unsustainable extraction and consumption of Earth’s finite natural resources. Empirical data indicate that between 2016 and 2021, the global economic system—or, more specifically, the global industrial–urban system—consumed approximately 582 billion tones of materials, nearly equivalent to the 740 billion tones consumed in the entire 20th century [3]. This unsustainable resource exploitation exerts immense pressure on the global ecosystems and the climate system, driven by the unregulated extraction of virgin resources and accelerating material consumption. Evidence suggests that resource extraction is responsible for over 90% of global biodiversity loss and water stress, while material consumption contributes to approximately 70% of global greenhouse gas (GHG) emissions [3]. These dynamics have led to the intertwined crises of biodiversity loss and climate change [3,4,5], which pose profound threats to the sustainability of industrial–urban development. Consequently, maintaining the ecological integrity of ecosystems and the resilience of the climate system is of paramount importance to ensuring sustainable industrial–urban development.

This scenario poses one of the most formidable challenges to humanity today. Specifically, the current scale of human resource extraction and consumption—referred to here as industrial–urban capitalist production and resource consumption, or industrial-urban metabolism (see Section 4.2)—has exceeded the Earth’s biocapacity. For instance, humanity is currently using natural resources at a rate 1.75 times faster than the planet’s regenerative capacity [6]. The systemic nature of environmental degradation is best exemplified by the mining and extractive industries—the fourth-largest drivers of deforestation, affecting up to 1/3 of the world’s forest ecosystems [7,8]. Furthermore, the mining sector, characterized by its high energy intensity, is a significant contributor to GHG emissions. As of 2020, the global extractive industry emitted 7.7 billion tons of CO2 equivalents (CO2e), accounting for approximately 15% of global anthropogenic carbon emissions [9,10]. Industrial–urban growth also intensifies climate change due to its heavy reliance on carbon-intensive energy systems. Despite a record increase of 473 gigawatts (GW) in renewable energy capacity in 2023, fossil fuels continue to dominate the global energy mix, constituting 84% of total energy consumption. Notably, coal production reached all-time high of 179 exajoules in 2023, exceeding previous records [11,12]. Industrial energy consumption remains the largest source of global GHG emissions and the primary driver of climate change [13,14,15,16].

These trends are undermining the integrity of the climate system and global ecosystems. In particular, industrial–urban capitalist production and resource consumption are associated with an escalating metabolic rift, characterized by environmental destabilization, the impending collapse of ecosystems, and the looming threat of climate breakdown [17]. These changing environmental events pose profound challenges for policymakers and necessitate the development of robust regulatory frameworks. In response, the circular economy model has emerged as a sustainable framework for devising strategies and action plans centered on economic efficiency, resource circularity, and sustainability. Its primary objective is to decouple industrial–urban growth from material consumption and carbon emissions, thereby safeguarding the resilience of the climate system and ecosystems [18].

Informed by a circular worldview of sustainability, industrial stakeholders and global leaders have invested substantive efforts in advancing sustainable production and efficient resource management. These initiatives include sustainable product design, waste recycling, the deployment of renewable energy technologies to replace fossil fuels, the development of a green urban infrastructure, and the transition to low-carbon economies. These measures collectively underpin the rationale for a circular economy [19,20,21,22,23].

Despite these efforts, the global circularity gap has widened, the integrity of the climate system and ecosystems continues to deteriorate, and new environmental threats and challenges continue to emerge. The promise of a circular economy—envisioned as a pathway to a post-fossil fuel world and a more sustainable industrial–urban economy—appears increasingly elusive. The persistent overexploitation of natural resources, widespread anthropogenic biodiversity loss, and record-high GHG emissions remain the most significant challenges confronting us today [24,25,26,27].

In summary, the logic of circularity, which seeks to promote resource sustainability and environmental efficiency, has paradoxically resulted in increased material consumption, increased carbon emissions, widespread environmental degradation, and acute ecological impoverishment. Humanity has reached a critical juncture where the industrial–urban economy’s insatiable demand for resources, unrelenting fossil fuel combustion, and escalating waste generation are pushing the planetary system toward irreversible collapse. This raises serious doubts about the efficacy of the circular economy model as a transformative solution to the unsustainable trajectory of industrial–urban growth and the myriad environmental crises it engenders.

1.1. Research Problem, Questions, and Objectives

The central problem addressed in this study is the apparent impasse of the circular economy model to have reached in achieving industrial–urban sustainability. More specifically, this study seeks to address the following research questions:

- Why has the circular economy model has been unable to deliver on its promise of industrial–urban sustainability, as reflected in its widening circularity gap?

- What are the underlying environmental forces and ecological conflicts driving the metabolic rift in the industrial–urban system in the context of circularity?

- How can a systems-based approach shed light on the myriad environmental repercussions caused by industrial–urban growth?

The primary objective of this study is to critically evaluate the limitations of the circular economy model and propose a systems-based framework to better understand and address the environmental challenges of industrial–urban growth. By integrating environmental economic concepts, system theory, and the laws of thermodynamics, this study aims to

- Develop a conceptual and causal framework to analyze the irreversible metabolic processes of resource transformation in the industrial–urban system;

- Qualitatively and quantitatively assess the cause–effect relationships driving environmental degradation;

- Provide practical insights for policymakers, industrialists, and consumers to adopt more sustainable production and consumption practices.

1.2. Justification and Relevance

This study is motivated by the urgent need to address the real and potential environmental crises caused by industrial–urban growth. The circular economy, while theoretically sound, has not been able to deliver the expected outcomes. This bespeaks of a need to critically reevaluate the assumptions and limitations underlying the concept. By uncovering the systemic forces and feedback processes underlying industrial–urban metabolism, this study contributes to advancing knowledge of sustainable resource use and management, and environmental conservation. It also lays the foundation for more effective policy responses and encourages stakeholders to adopt environmentally sustainable practices.

The remainder of this paper is organized as follows: Section 2 describes the methodology for the present study. Section 3 provides a literature review and hypotheses related to the circular economy. Section 4 discusses the conceptual underpinnings governing the present analysis. Section 5 provides an empirical study of the circular economy in practice. Section 6 critically examines the role and limitations of the circular economy in addressing the ecological threats of industrial–urban growth. Section 7 introduces a system dynamic causal model to assess the environmental disruptions arising from the complex interactions of socioeconomic, industrial, and environmental factors. Section 8 discusses the results. Finally, Section 9 concludes the paper with policy recommendations and directions for future research.

This study presents a comprehensive and interdisciplinary approach to evaluating the challenges and limitations of the circular economy model in addressing the sustainability of industrial–urban systems. By integrating environmental economics, system theory, the laws of thermodynamics, and empirical case studies, we aim to develop a conceptual and causal framework that captures the complexities of resource transformation and the environmental consequences of industrial–urban growth. What follows is a breakdown of the methodology of the present study.

2. Methodology

- (i)

- Literature review and hypotheses

- The study begins with a literature review of the circular economy, highlighting its principles and limitations in addressing industrial–urban sustainability.

- (ii)

- Theoretical and conceptual foundations

- It defines the term “industrial–urban system” to establish a clear scope for the analysis, emphasizing the interconnectedness of socioeconomic, industrial, and environmental factors.

- It provides discussions on the laws of thermodynamics and system theory to explain the irreversible nature of resource transformation and its environmental implications. Using coal pyrolysis, it demonstrates the metabolic processes of irreversible resource consumption and transformation, uncovering the environmental forces at work in the linear resource transformation process, which gives rise to high entropy effects on the ecological integrity of the environmental system.

- (iii)

- Empirical illustration

- Using myriad case studies, we demonstrate the functional perspectives of the circular economy in promoting economic efficiency (productive and allocative efficiency), resource efficiency and sustainability, and environmental efficiency.

- (iv)

- Discussion

- It critiques the circular economy model for its failure to account for the metabolic processes and conflicts inherent in industrial–urban growth, which often lead to policy failures.

- It highlights the limitations of the circular economy in reversing ecological threats, arguing that it inadequately addresses the complex interactions and conflicts within industrial–urban systems.

- (v)

- System dynamic causal model

- To address the shortcomings of the circular economy model, we construct a system dynamic causal model of industrial–urban sustainability.

- This model aims to elucidate the environmental disruptions caused by the interplay of socioeconomic, industrial, and environmental factors, providing a more holistic understanding of the environmental complexities governing the industrial–urban system.

- (vi)

- Conclusions and policy implications

- The final section summarizes the findings and emphasizes the need for more effective policy responses based on the insights gained from the system dynamic model.

- The study underscores the importance of engaging policymakers, industrialists, consumers, and the global community in addressing environmental concerns related to production and resource consumption.

- It calls for more sustainable practices and attitudes to mitigate the environmental consequences of industrial–urban growth.

Overall, this study contributes to shed light on the environmental challenges of industrial–urban systems and provides a foundation for developing more sustainable practices and policies. By questioning the circular economy model and proposing an alternative framework, we aim to foster a deeper understanding of the complex dynamics at play in the industrial–urban system and encourage more proactive and informed decision-making.

3. Literature Review and Hypotheses

In the past few decades, there has been a profusion of studies related to the topic of the circular economy (CE). This reflects the growing importance of the CE as a transformative paradigm for achieving industrial urban sustainability through sustainable resource use and management. The CE is also increasingly recognized as a strategic means to address pressing global environmental challenges, such as climate change and ecosystem degradation. This section explores the theoretical foundations, key concepts, and approaches to the CE, highlighting its potential to decouple economic growth or industrial-urban growth, for that matter, from resource consumption and environmental degradation. It also identifies critical gaps in the literature, particularly the hidden environmental effects of the CE, and proposes a system causal analysis framework to address these limitations.

3.1. Key Concepts of and Approaches to the Circular Economy

The circular economy is grounded in the principles of economic efficiency, resource efficiency, closed-loop systems, and industrial–urban metabolism. At its core, the CE seeks to minimize waste and maximize production and consumption (economic efficiency) through efficient use of resources (resource efficiency). It includes strategies such as recycling, reuse, and reduction (the 3R framework). These strategies aim to create closed-loop systems where materials are continuously cycled back into production processes, reducing the reliance on finite resources and mitigating environmental impacts.

For instance, in the context of solid waste management, Ryen et al. (2022), Herbst et al. (2024), and Bandh et al. (2024) highlight the significance of closing resource loops—a core concept in the CE—through increased recycling, extended product life cycles, and reduced excess production at the source [21,22,28]. These strategies are aligned with the 3R framework to enhance the material cycle, minimize waste, and maximize resource efficiency and sustainability. In particular, Bandh et al. (2024) argue that creating a closed-loop system through the 3R framework not only enhances resource efficiency and sustainability based on recycling practices by transforming waste into new products but also contributes to promoting environmental efficiency through an ecological footprint reduction, creates jobs, and supports eco-friendly industries.

In the mining industry, Hamraoui et al. (2024) emphasize the importance of water recycling as a critical solution for managing mining residues and conserving water resources. This approach not only reduces ecological footprints, leading to environmental efficiency, but also ensures operational water stability, illustrating the application of CE principles in resource-intensive sectors. Similarly, Upadhyay et al. (2021) identify recycling, reuse, and waste management as key drivers for transitioning to a circular economy, underscoring the importance of industrial symbiosis—a concept where waste from one process becomes a resource for another [23,29]. On the other hand, Jose et al. (2024) and Magalini et al. (2025) advocate the integration of circular economy principles into mining practices, focusing on circularity and recycling as key strategies. These include closing material loops through waste valorization, resource recovery from mine tailings, water reuse in mining processes, and decarbonization through innovative solutions such as hydrogen technology. The authors claim that these strategic environmental efficient circular economy measures offer a promising path toward reducing environmental harm while promoting sustainable resource management [30,31].

At the urban level, the European Investment Bank (2022, 2023), Anttiroiko (2023) and the World Economic Forum (2018) advocate for the establishment of circular cities characterized by regenerative and restorative urban systems. These systems aim to minimize resource consumption and waste generation through modular and flexible building designs, repurposing, and refurbishment. This approach aligns with the circular urban metabolism framework, which views cities as dynamic systems where resources flow in closed loops, reducing the reliance on finite resources, mitigating the environmental impacts, and, hence, enhancing resource efficiency and sustainability and environmental efficiency [32,33,34,35].

Huttmanová et al. (2023) further argue that cities play a critical role in advancing the CE by adopting resource efficiency models [36]. These models contribute to decoupling social well-being and economic growth from resource consumption, a central tenet of the CE. Similarly, the European Environmental Agency (2015) and Material Economics (2018) highlight the potential of the CE in achieving low-carbon industrial transitions through material recirculation, product material efficiency, and circular business models. These strategies are classified under the industrial ecology approach, which seeks to optimize resource use and minimize emissions in heavy industries, leading to resource efficiency and sustainability, and environmental efficiency [37,38]. Similarly, Pegorin et al. (2024) argue that the urban systems play a central role in the transition to the circular economy though the deployment of resource efficiency strategies such as waste recycling, resource life cycle optimization, and regenerative and resource efficiency practices [39].

One general finding that may be derived from the above studies is that decoupling economic activity from the consumption of finite resources or through the creation of closed-loop cycles in which waste is minimized or eliminated and resources are reused and recycled is of great significance to enhance sustainable industrial–urban growth. To be sure, all these studies aptly describe the problems of unsustainable resource extraction, consumption, and production, and the resultant impacts of industrial pollution and waste generation. They also rightly pointed out the importance of adopting closed-loop product life cycle management or recycling and resource decoupling as mitigating solutions.

3.2. Theoretical Foundations and Classifications

The theoretical underpinnings of the circular economy are rooted in industrial ecology, systems thinking, economic efficiency, resource efficiency, and thermodynamic principles. Industrial ecology seeks to design and manage industrial–urban production and consumption by optimizing resource use (resource efficiency) and minimizing high entropy industrial waste production (environmental efficiency), such as waste production and GHG emissions, in heavy industries, while systems thinking emphasizes the interconnectedness of industrial and urban systems and their interactions with the natural environment.

The thermodynamic principles, particularly the irreversible nature of resource transformation, highlight the limitations of the CE in closing the circularity gap to achieving absolute industrial–urban sustainability. These principles reveal hidden environmental effects, such as the rebound effect expressed in terms of a reduction in expected gains from the deployment of production or renewable energy technology and the thermodynamic constraints of industrial metabolic processes of resource transformation, which can undermine the environmental benefits of the CE. These are detrimental to the resilience of the climate system and ecosystems, which underpins industrial–urban sustainability.

3.3. Research Gap and Hypotheses

Despite the advancements of CR as a strategic means to enhance economic growth or industrial–urban sustainability, a critical gap remains in the literature. While existing studies aptly describe the problems of unsustainable resource extraction, consumption, and production, they often overlook the hidden environmental effects of the CE. These effects include the rebound effect (where efficiency gains lead to increased resource use), resource leakage (where materials are lost during recycling processes), and thermodynamic inefficiencies (where energy losses occur during resource transformation). Such effects, if unaddressed, can undermine the environmental benefits of the CE and exacerbate climate change and ecosystem degradation.

If these effects are left out of the account or are being downplayed, they will adversely affect the environmental system, especially the climate system and ecosystems. It must be contended that the transition to a sustainable economy or urban future requires more than just a green transformation from linear methods of production and consumption to continuous cycles of resource efficiency and waste reduction. To address this gap, this study proposes a system causal analysis framework that examines the dynamic interactions between industrial–urban resource transformation processes and their environmental impacts. This framework integrates theoretical concepts (e.g., thermodynamic principles of irreversible resource transformation) with empirical approaches (e.g., case studies of CE implementation) to provide a more nuanced understanding of the CE’s limitations and potential. By doing so, this study aims to contribute to the development of a pragmatically effective CE model that balances industrial–urban growth with environmental sustainability.

3.4. Hypotheses

This study hypothesizes that

- The circular economy, while widely advocated as a solution for industrial–urban sustainability, faces significant theoretical and ecological constraints due to the irreversible nature of resource transformation and the hidden environmental effects of resource extraction, consumption, and transformation.

- By integrating thermodynamic principles, system theory, and empirical case studies, we propose that a more effective model of industrial–urban sustainability must account for the dynamic interactions and conflicts inherent in resource transformation processes. This approach is expected to reveal the limitations of current circular economic strategies and provide a foundation for more pragmatic and effective policy responses.

- Addressing the hidden environmental effects of CE, such as the rebound effect, and thermodynamic constraints of industrial–urban resource transformations is critical for achieving climate–ecosystem resilience and long-term industrial–urban sustainability.

4. Conceptual Underpinnings

4.1. Industrial–Urban System

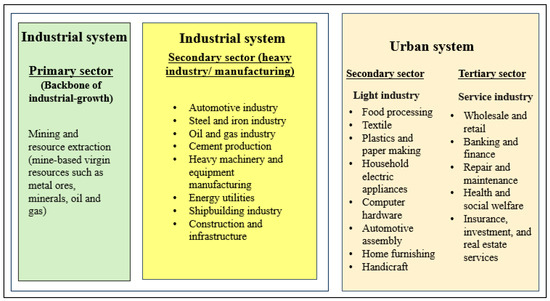

At the outset, it is important to define the term “industrial–urban system” to better understand its interrelated system component relationships that make up the industrial–urban system as a whole. The industrial–urban system is a complex network of interrelated components that drive economic activity; natural resource extraction, consumption and transformation; and urban development. For the purpose of this analysis and as shown in Figure 1, the industrial–urban system is divided into two subsystems—the industrial system and the urban system—each characterized by distinct economic or industrial activities and environmental impacts, as briefly indicated below.

Figure 1.

The industrial–urban system at a glance.

- Industrial system: The industrial system is basically involved in the promotion of capital- and energy-intensive industrial activity. Fundamentally, as shown below, they can be divided into two sectors depending on the types of economic or industrial activity on which they focus:

- (i)

- The primary sector includes mining, oil and gas extraction, quarrying, forestry, and agriculture. In particular, the mining industry is involved in the extraction of virgin raw materials, including mineral resources such as iron, copper, and nickel (metallic); sand and gravel (non-metallic); and oil, gas, and coal from the earth. The mining industry plays a pivotal role in supplying raw materials for global industrial–urban growth.

- (ii)

- The secondary sector focuses on transforming raw materials derived from the primary sector into finished products, that is, industrial and consumer goods. This sector is further divided into

- Heavy industries responsible for the large-scale production of intermediate goods that require significant capital investments such as heavy machinery and large factories, which occupy vast areas of land and are often located far away from urban areas due to their environmental impacts. These include petroleum refining, steel and iron manufacturing, automobile and heavy machinery manufacturing, cement production, non-ferrous metal refining, agriculture, and the construction industry.

- Light industries are responsible for the small-scale manufacturing of consumer goods that are less capital-intensive or less environmentally damaging. They are typically located near urban centers such as business parks or industrial estates. These industries include the textile industry, food processing, plastic manufacturing, plastics and papermaking, household electronic production, and computer hardware.

- Urban system: This system is the primary site for the consumption of goods and services and does not host primary industries. It supports light industries and the development of economic and social infrastructure (e.g., transportation networks, schools, and hospitals). Unlike rural systems, which are dominated by primary activities like agriculture, urban systems focus on consumption and service provision.

The industrial–urban system operates as an input–output transformation process, converting virgin resources into useful goods and services (low entropy outputs). However, this process is intrinsically connected to an irreversible resource conversion process that points linearly in the direction of degeneration, degradation, or decay (see Section 4.3 below), leading to a qualitative change in the system or environmental decay. To mitigate these impacts, promoting industrial–urban sustainability—defined as development that is economically, socially, and environmentally sustainable—is essential. The emphasis must be placed on protecting climate resilience and ecosystem integrity, which underpin sustainable industrial–urban growth.

4.2. Industrial–Urban Metabolism

This section seeks to develop the fundamental concepts for the exposition of material relations and the mechanics of resource transformation underlying the industrial–urban growth process, hereby referred to as industrial metabolism and urban metabolism and collectively known as industrial–urban metabolism.

- Industrial metabolism can be defined as the industrial conversion of raw materials, including energy resources derived from the primary sector, into finished products or goods and services (low-entropy outputs (LEOs)) in the industrial system [40,41,42].

- Urban metabolism: This pertains to the flow of LEOs from industrial systems to support urban growth and light industrial activity. It also involves the development of economic and social infrastructure, leading to the generation of high-entropy outputs (HEOs) such as solid waste and GHGs. Economic infrastructure refers to the development of transportation networks and communication systems that support urban economic activity and growth. Meanwhile, social infrastructure is related to the development of the basic facilities, services, and amenities that enhance urban welfare or social wellbeing. This includes the construction of bridges, schools, hospitals, and public transportation, as well as the provision of spaces or parks.

The study of industrial metabolism allows us to gain improved knowledge and understanding of the industrial–urban uses of materials and their total impacts on the environment. The environmental impact is mainly due to the generation of industrial pollution, solid waste, and GHGs (high-entropy outputs (HEOs)) arising from industrial–urban resource use [43,44,45]. Industrial pollution includes air pollution, water pollution, and soil pollution [46,47,48,49,50].

4.3. Entropy and the Laws of Thermodynamics

Resource transformation is governed by the principles of thermodynamics, particularly the concept of entropy, which is related to the First and Second Laws of Thermodynamics and the Law of Conservation of Mass, as explained below.

- The concept of entropy: Entropy is a fundamental concept in thermodynamics that measures the degree of disorder or instability within a system. The higher the entropy of a system, the higher its state of disorder or instability. It thus follows that high entropy connotes a disintegrated state arising from the accumulation of less useful or low-quality (high-entropy) materials, such as dissipated waste heat or GHGs, from fossil fuel combustion. Furthermore, entropy also quantifies the amount of energy that is no longer available to perform useful work. In practical terms, it reflects the depletion of high-grade energy or low-entropy materials—resources that humans can efficiently transform into work or useful products. However, this transformation process is inherently irreversible, as energy and materials degrade into less useful forms over time [51,52,53].

- The concept of thermodynamics: Thermodynamics is the study of energy, energy transformations, and their relationships with matter and entropy. It explains how thermal energy is converted to or from other forms of energy and how matter is affected by these processes. Thermodynamics provides a framework for understanding the constraints and efficiencies of energy and material transformations, particularly in industrial and natural systems.

- First Law of Thermodynamics: Central to the term thermodynamics is the First Law of Thermodynamics or the Law of Conservation of Energy, which states that energy can neither be created nor destroyed but only transformed from one form to another. This principle underscores the finite nature of energy within a closed system, emphasizing that the total energy remains constant even as it changes forms. For example, the chemical energy stored in fossil fuels can be transformed into thermal energy, mechanical energy, or electrical energy, but the total energy content remains unchanged [51,52].

- Second Law of Thermodynamics: Central to the concept of entropy is the Second Law of Thermodynamics, which states that in any energy transformation, the total entropy of a system and its surroundings always increases. This means that while energy is conserved (as per the First Law), its quality degrades over time, leading to greater disorder and irreversible environmental degradation. For instance, when fossil fuels are burned, their high-grade energy is transformed into useful work, but a significant portion is also dissipated as waste heat and GHGs—high-entropy byproducts that contribute to environmental instability. This irreversible process highlights the inherent inefficiencies (thermodynamic constraints) and environmental costs associated with energy use and material consumption [51,52,53].

- The law of Conservation of Mass: This law, which is a fundamental principle in chemistry and physics, is closely related to the Law of Conservation of Energy. It states that mass is neither created nor destroyed in chemical reactions but always conserved. This means that the total mass of any element or compound at the beginning of a chemical reaction must be equal to the total mass of that element at the end of the reaction, even as it changes form. For example, in the combustion of fossil fuels, the masses of carbon, hydrogen, and oxygen atoms are conserved, even as they are transformed into carbon dioxide, water, and other byproducts [54]. This law complements the First Law of Thermodynamics, which states that energy is also conserved in transformations. Together, these principles underscore the interconnectedness of energy and matter, highlighting that while their forms may change, their total quantities remain constant. However, these transformations often result in increased entropy, as energy and matter degrade into less useful forms, leading to greater disorder and environmental instability, as governed by the Second Law of Thermodynamics.

The above laws and their connections to entropy highlight the irreversible nature of resource transformation and are critical for understanding the thermodynamic constraints on industrial–urban systems and the challenges of achieving sustainability.

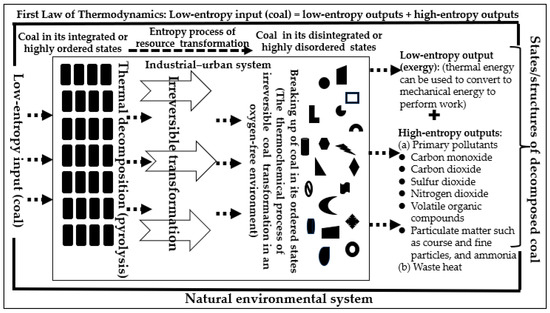

4.4. The Laws of Thermodynamics in Practice: Coal Pyrolysis

Coal, which is the largest source of low-entropy energy for electricity generation worldwide, is a good example. Depending on the type, coal contains 4000–15,000 Btus (British thermal units)/pound. Anthracite has the highest carbon content (between 86% and 97%) and a heat value of nearly 15,000 Btus/pound, whereas lignite has a 25% to 35% carbon content and a heat value between 4000 and 8300 Btus/pound. The other elements present in coal include hydrogen, sulfur, oxygen, and nitrogen. As shown in Figure 2, when coal is used as an energy source to fuel industrial–urban economic activity such as cement production or manufacturing, it does not actually burn but undergoes a thermal decomposition process known as pyrolysis [55,56].

Figure 2.

Thermochemical process of irreversible resource transformation (coal).

Coal pyrolysis is a complex heating process that occurs at elevated temperatures between 400 °C to 800 °C in the absence of oxygen. In the thermal and catalytic pyrolysis process, coal in its highly ordered state (low–entropy state) is transformed or broken up to produce a large amount of thermal energy or heat (exergy), which can be converted into mechanical energy using a heat engine to perform work (LEOs). However, because full conversion from thermal energy to mechanical energy is not possible, this results in significant energy losses, such as waste heat in its high entropy state (HEOs). Other high-entropy byproducts of the decomposed coal include carbon monoxide, carbon dioxide, sulfur dioxide, nitrogen dioxide, volatile organic compounds, particulate matter, and ammonia [57,58,59]. All these HEOs dissipate into the natural environment, causing severe and irreversible damage to the natural system.

It may be pointed out that the total mass present in hydrocarbon coal resources before a chemical reaction is the same as that after the chemical reaction in different forms of HEOs and LEOs. Thus, the mass of hydrocarbon resources is conserved. In other words, the total mass of the reactants is simply rearranged, such that the physical properties of the reactants may change, but their chemical makeup does not. This implies that humans cannot completely throw something away. Everything we think have been thrown away still remains in the environment in one form or another. When waste is discarded in an industrial–urban system, it does not disappear. It may change location or forms, but it still exists and is likely to have some impact on the environment.

The above discussion brings us to the Second Law of Thermodynamics. While the First Law is concerned with irreversible resource transformation from one form to another, the Second Law states that such transformation points into the direction of increased entropy or disorder. Technically speaking, it points toward the thermodynamic time arrow of irreversibility, which progresses gradually from low entropy to greater entropy (disorderliness) [51,52,54,60]. From an industrial–urban perspective, the thermodynamic time arrow of irreversibility is characterized by increasing metabolic rifts or ruptures. Metabolic rupture may be defined as an environmental impairment arising from the extraction of virgin resources and irreversible industrial–urban resource transformation processes. Metabolic rupture may take the form of habitat destruction, environmental degradation, biodiversity loss, and global warming or climate change.

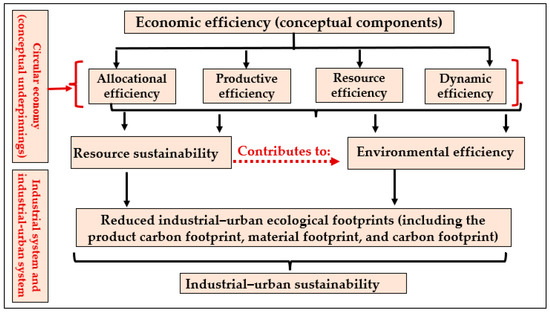

4.5. The Circular Economy and Economic Efficiency

The circular economy is fundamentally rooted in the principle of economic efficiency, which seeks to optimize the allocation and use of resources to maximize output while minimizing waste and environmental impacts. This principle is operationalized through four key concepts, allocative efficiency, productive efficiency, dynamic efficiency, and resource efficiency, as discussed below (Figure 3).

Figure 3.

The circular economy and industrial–urban sustainability. Note: Allocational efficiency, productive efficiency, resource efficiency, and dynamic efficiency singly or collectively contribute to resource sustainability and environmental sustainability. Resource sustainability leads to environmental efficiency. Taken together, all these efficiency or suitability components contribute to reduce industrial–urban footprints and, hence, lead to industrial–urban sustainability.

- Allocative efficiency refers to the optimal distribution of resources to meet societal needs and wants. It ensures that resources are allocated in a way that maximizes societal welfare, where the marginal utility (demand) equals the marginal cost (supply). In the context of the circular economy, allocative efficiency is achieved by producing and distributing goods and services that align with consumer demand while minimizing waste. For example, producing durable goods that can be reused or recycled reduces the need for virgin materials and minimizes waste generation.

- Productive efficiency focuses on maximizing output with minimal resource input. It involves using resources in the most efficient way to produce goods and services, thereby reducing material and energy waste. In the circular economy, productive efficiency is enhanced through practices such as remanufacturing, recycling, and waste minimization. For instance, recycling metals like aluminum reduces the need for the energy-intensive extraction of virgin materials, thereby lowering both material and carbon footprints.

- Dynamic efficiency emphasizes the roles of innovation, research and development (R&D), and technological advancement in improving resource efficiency over time. It involves investing in human capital, adopting advanced technologies, and fostering innovation to reduce the long-run average cost of production. For example, the deployment of renewable energy technologies and the development of biodegradable materials contribute to reducing the reliance on finite resources and minimizing environmental impacts.

- Resource efficiency is defined as the production of more outputs (economic value) with fewer resource inputs or the decoupling of economic growth from resource consumption. The resources used here refer basically to natural resources, such as renewable and non-renewable primary raw materials (minerals, ores, fossil fuels, and biomass), and ecosystem services.

The application of the principle of economic efficiency in circular economy-related strategies in waste reduction seems to provide one of the most effective solutions to reduce the waste footprint. This, in turn, contributes to reductions in material consumption and waste generation. It is relevant to point out that more than 90% of what we take from the earth to fulfil our needs and wants goes to waste. Furthermore, the various economic efficiency components discussed above are causally connected to the circular economy aspects of resource sustainability, environmental efficiency, and the ecological footprint, as discussed below (Figure 3).

4.6. Resource Sustainability, Environmental Efficiency, and Ecological/Environmental Footprints

The concepts of resource sustainability, environmental efficiency, and ecological footprints are central to understanding the environmental implications of industrial–urban systems and the potential of the circular economy to mitigate these impacts.

- Resource sustainability refers to the long-term availability and responsible management of natural resources, especially nonrenewable and exhaustible resources, to meet the needs of present and future generations. Achieving resource sustainability requires practices such as recycling, reuse, and remanufacturing, which reduce the extraction of virgin materials and minimize waste. For example, recycling paper and plastics reduces the demand for raw materials like timber and petroleum, thereby conserving natural resources and reducing environmental degradation.

- Environmental efficiency is defined as the ratio of the minimum environmental damage or negative environmental externalities to the observed level of inputs. It focuses on optimizing resource use and production processes to minimize environmental impacts. In the context of industrial–urban systems, environmental efficiency can be enhanced through sustainable production practices, such as energy-efficient manufacturing processes and the use of renewable energy sources. For instance, adopting energy-efficient technologies in the construction industry reduces GHG emissions and lowers the ecological footprint of urban development, thus promoting environmental protection.

- The ecological footprint measures the total biologically productive land and water area required to support industrial–urban activity. It assesses the environmental impacts of resource consumption and waste generation, highlighting the need to decouple economic growth from resource use. For example, the ecological footprint of urban systems often exceeds the available biocapacity, leading to environmental degradation and the depletion of natural capital [61,62]. Natural capital may include land, water, minerals, forest products, fossil fuels, and land resources for settlements and infrastructure development. It also covers life-supporting ecosystem services (critical natural capital) to support and sustain industrial–urban socio-economic activity (Figure 1). The ecological footprint is measured in terms of global hectares (gha) or the number of planets required to sustain the human economy [63]. The subsets of ecological footprints, which focus on specific footprint, are as follows:

- The carbon footprint measures the volume of GHG emissions from industrial and socioeconomic activities. It focuses on CO2 emission standards, which are expressed in terms of CO2 equivalents (CO2e). The units of measurement can be kilograms or tons of CO2e. Reducing the carbon footprint through renewable energy adoption and energy efficiency is critical for mitigating climate change.

- The product carbon footprint measures the total GHG emissions throughout the product’s life cycle. Reducing the product carbon footprint through circular economy practices, such as upstream innovation, which focuses on redesigning products and materials at their source to minimize waste and pollution, contributes to enhancing sustainable industrial–urban development

- The material footprint is a consumption-based indicator of resource extraction and utilization. This refers to the total amount of raw materials, such as biomass, fossil fuels, metal ores, and non-metallic minerals, extracted to meet the final consumption needs. Reducing the material footprint through circular economy practices, such as recycling and resource efficiency, is essential for achieving sustainable industrial–urban development.

- The environmental footprint is broader in scope than the ecological footprint, encompassing the impacts of human activities on the environment, including the appropriation and use of energy resources, materials, and land for production, agriculture, housing, and infrastructure development. It also considers the impacts on ecosystems and the climate system. For example, the environmental footprint of urban expansion includes habitat destruction, biodiversity loss, and increased GHG emissions, all of which contribute to environmental degradation and climate change. In particular, the environmental footprint concerns the analysis of a vicious cycle of environmental changes arising from human economic exploitation of nature to sustain industrial–urban growth. A vicious cycle of environmental changes refers to a situation where negative environmental impacts (positive feedback loops) create conditions that further aggravate those impacts (reinforcing loop), leading to a continuous cycle of downward spiral.

- The integration of the concepts of resource sustainability, environmental efficiency, and ecological footprints into the circular economy framework provides a holistic approach to addressing the environmental challenges of industrial–urban systems. However, the circular economy must go beyond resource efficiency and waste reduction to account for the broader environmental impacts (environmental footprints) of resource transformation, such as entropy production and the overburdening of carbon sinks. This requires a shift from a narrow focus on economic efficiency to a more comprehensive approach that prioritizes the environmental resilience of the climate system and ecological integrity of ecosystems

5. Circular Economy in Practice

As inferred from the above discussion, a circular economy basically operates under the conceptual assumption of economic efficiency, focusing on achieving resource sustainability and environmental efficiency (Figure 3). This contributes to reducing the ecological footprint, leading to industrial–urban sustainability. From an operational perspective, achieving industrial–urban sustainability relies on the scientific recognition of a green transition from a conventional linear take–make–dispose economy to a circular economy model of economic efficiency. This may be achieved through waste minimization, optimal resource allocation, efficient production, and life cycle extension.

The proper beginning of the articulation of a circular economy with resource sustainability and environmental efficiency is in the mining sector because of its high energy consumption rates. Energy consumption accounts for approximately 30% of the mining sector’s cash operating costs and 10% of the global energy consumption, mostly sourced from fossil fuel burning [10,64,65,66,67]. The mining industry is also one of the world’s largest carbon emitters, accounting for approximately 8–10% of the global energy-related GHG emissions [9,68,69,70].

To avoid disruptive effects on the environment, the Anglo-Australian mining multinational, corporation Rio Tinto deployed renewable energy (dynamic efficiency) in 2019 to enhance environmental efficiency. Its objective was to reduce the annual carbon footprint of the Kennecott Utah copper mine by as much as 65% and permanently shut down its coal power plant (environmental efficacy) [71]. In 2023, it was announced that its entire fossil diesel consumption, from haul trucks to all heavy machinery, smelters, and refineries, would be replaced with renewable diesel during its Kennecott Copper operation in Utah. This is expected to contribute to a reduction in direct emissions from its operating plants of 495,000 tons of CO2e per annum (environmental efficiency) [72,73].

Many major mining countries across the world have undertaken similar resource and environmental efficiency steps to decarbonize their mining activities. These include the following:

- In Chile, the Antofagasta Zaldivar copper mine operates with 100% renewable electricity derived from solar, wind, and hydropower, enabling the company to remove emissions equivalent to 350,000 tons of GHGs per year (dynamic efficiency and environmental efficiency) [74]. Miner Anglo American, a British multinational mining company located in London, England installed a floating island of solar panels on Las Tórtolas Pond at the Los Bronces copper mine located approximately 42 kilometers (km) west of the Andes Mountains of Chile, near Santiago to boost the use of renewable energy and reduce its carbon footprint. Floating solar projects are expected to reduce carbon emissions by approximately 58 tons/y (dynamic efficiency and environmental efficiency) [75,76].

- In South Africa, Richard Bay Minerals located in KwaZulu-Natal, a world leader specializing in heavy mineral extraction and refining, entered into renewable power purchase agreements with the Bolobedu Solar PV plant in Limpopo in 2022 and the Khangela Emoyeni Wind Farm in 2024. Its objective is to optimize the use of solar and wind power in the mining sector (dynamic efficiency and resource sustainability). These are expected to meet approximately 43% of their energy needs, which originally came from traditional energy sources (environmental efficacy) [77].

- The Fortescue Metals Group located in East Perth, Western Australia, which is engaged in the mining and exploration of iron ore in Western Australia, has developed a large-scale renewable energy and green hydrogen production capacity across Australia. Its objective is to replace carbon-based fuels with green electricity, hydrogen, and ammonia (dynamic efficiency). Its Pilbara Energy Connect project, for example, is expected to cut up to 285,000 tons of CO2 per year compared with gas-based electricity generation (environmental efficiency) [78,79].

- Other global renewable energy initiatives in the mining industry include (a) the deployment of the Cambridge Energy Partners’ Nomad mobile solar power array at the Akyem gold mine in Ghana by the American mining corporation Newmont (environmental efficiency) [78,80] and (b) the deployment of solar–diesel hybrid power technology, which was developed by the UK-based power generation company Aggreko, in the Bisha mine in Eritrea. The mine is owned by the Chinese mining company as well as the Gold Fields-owned Granny Smith gold mine in Western Australia (environmental efficiency) [78]. Other initiatives include (c) the development of low-carbon mining technologies to decarbonize mining operations in the Canadian mining industry (dynamic efficiency and environmental efficiency) [81,82]. This includes the pH7 Technologies’ chemical process solution that allows the extraction of valuable metals without producing wastewater, effluent or off-gassing [83]. (d) The deployment of solar and wind technology in the Canadian-owned FQM’s Kansanshi mine in the Northwestern Province of Zambia, one of the largest copper mines in the world (environmental efficiency) [84]; (e) the construction a 36 MW solar power station in Sukari gold mine by the Egyptian government (environmental efficiency) [84]; (f) the construction of a 34 MW solar power plant and a battery system of 18 MW in Kinross Gold mine in Mauritania (environmental efficiency) [84]; and (g) the development of a 15 MW AC Solar PV Plant in the oldest commercial uranium mine in Namibia, Rössing Uranium, among others (environmental efficiency), are other examples [84].

Fundamentally, the green transitions of the mining sector, as discussed above, focus on the supply side of the circular economy equation, that is, reducing the carbon footprints associated with the extraction of virgin resources through electricity decarbonization or the deployment of renewable energy technology. However, it is also important to consider the demand side of the circularity model. This requires us to consider how a circular economy may contribute to reducing carbon and material footprints through the sustainable and efficient use of raw material inputs via economic efficiency practices. This is particularly true in the energy- and material-intensive industrial sectors, as shown in Figure 1.

To begin with, many manufacturers and industrialists worldwide have adopted various demand-side economic efficiency measures through improved recyclability throughout the different life cycle stages of their production processes. These cover, for example, virgin resource extraction, manufacturing and processing, transport, distribution to consumption, and end-of-life cycle [85,86,87,88]. The central theme is to reduce ecological footprints, particularly carbon and material footprints, through the sustainable use and management of resources. This is in line with the concepts of resource efficiency, resource sustainability, and environmental efficiency discussed above.

By way of illustration, many multinational mining companies in the mining sector such as Novum Energy located in Houston, United States·, Rio Tinto located in southwestern Spain, in the Andalusia region near the city of Huelva, BHP, an Anglo-Australian mining and petroleum company located in Melbourne, Australia and Anglo American located in London, England, have put in place various circular economy practices such as recycling, waste reduction and elimination, carbon emission reduction, and mining waste conversion into byproducts or new products using the best technology available (dynamic efficiency) [89]. In the industrial production and manufacturing sectors, upstream innovation or upstream resource circularity has also been deployed as an eco-friendly strategy to reduce carbon and product footprints. This contributes to enhance industrial–urban sustainability (dynamic efficiency and environmental efficiency).

The upstream circularity strategy, which is premised on the principles of elimination, reuse, and material circulation, seeks to prevent waste generation (resource efficiency and sustainability) at its source rather than deal with it in the postproduction stage. This necessitates the development of new and resource-efficient material inputs, product and package designs, and business models that minimize the use of low-entropy material inputs or reduce the generation of HEOs during preproduction. Examples include the (a) use of recyclable and reusable and biodegradable materials in the production process and (b) promotion of upstream innovative practices in modular product designs that allow sub-assemblies and components to be organized as distinct building blocks or modules. To enhance its efficiency, such practices many further be integrated through configuration to meet various customer needs or engineering requirements. Other examples include the (c) enhancement of innovative strategies or advanced material technology that extends the product lifetime and (d) deployment of resource sustainability strategies that facilitate easier recycling and recovery of valuable resources, reduce waste generation, and prevent landfilling [90,91].

Additionally, many companies have implemented downstream innovation or resource circularity measures alongside upstream resource circularity strategies to reinforce resource efficiency and reduce the waste footprint. Downstream circularity involves optimizing the scale of resource collection, sorting, and recycling capacities by developing new collection, sorting, and recycling technologies. These may involve retaining serviceable parts, refurbishing usable parts, reworking components from obsolete products (remanufacture), and primary recycling by processing materials into another “high-value application” [92,93].

In a specific case study, in the late 2000s, China endorsed the circular economy as a national priority to promote resource efficiency and sustainability practices. The objective was to address environmental challenges through the adoption of the proposal on the Acceleration of Development in Circular Economy in 2005. To reinforce its efficiency measure, China enacted the Circular Economy Promotion Law in 2008. Seemingly recognizing the potential circularity benefits in the car manufacturing sector, China announced the Swap for Old for Remanufacturing Policy in 2013 [94,95,96].

Against this backdrop, in 2010, China’s vehicle sales increased by 32%, hitting 18.06 million sold, making it the largest auto industry in the world [97,98]. In addition, the number of automobiles in China surged to 100 million owing to the rapid increase in private car ownership in 2011, making it the largest vehicle-consuming market in the world [99]. Thus, the potential for recovering, reusing, recycling, and remanufacturing or re-engineering the entire life cycle of automotive products and materials, such as engines, steering gearboxes, transmissions, and car frames, was promising. This substantially contributed to decouple auto-industrial growth from resource use. Specifically, it helps enhance resource efficiency and sustainability by reducing material footprints, resource extraction, and environmental efficiency by reducing carbon and waste footprints. Some 656.9 kg/vehicle of iron, 150.2 kg/vehicle of aluminum, and 7.9 kg/vehicle of copper have been estimated to be recovered from end-of-life passenger cars in China in 2018. Additionally, a total carbon emission reduction that amounted to 3816.1 kgCO2eq/vehicle was achieved [100].

In Europe, the European Commission adopted the New Circular Economy Action Plan (CEAP) in 2020. The CEAP is central to the European Green Deal adopted in 2019, which aims to set directions for the European Union (EU) to achieve climate neutrality by 2050. The new action plan aims to enhance sustainable resource management and development along the entire life cycle of products. It targets upstream and downstream circularity innovation and encourages sustainable consumption practices to reduce consumption footprints. In 2019, EU Ecodesign Working Plan 2016–2019 was put into practice, placing great emphasis on promoting product durability, repairability, and recyclability. In particular, it is stipulated that by 2030, EU member states are required to recycle at least 70% of all packaging waste, and by 2035, recycle at least 65% of the municipal waste [101].

To further enhance circularity initiatives, the European Investment Bank provided EUR 3.83 billion to co-finance 132 circular economy projects in a variety of sectors from 2019 to 2023 [98]. Based on this financial initiative, PackBenefit, a Spanish fiber-based food bio-packaging manufacturing company, entered into a EUR 13 million venture debt agreement with the investment bank. The main objective was to expand its manufacturing capacity for recyclable and compostable food trays for the European market. Furthermore, with support from the investment bank, Elval, a Greek copper and aluminum manufacturer, invested in state-of-the-art equipment to increase its aluminum scrap recycling capacity and manufacture recyclable aluminum packaging solutions. Other circularity initiatives include investments in waste sorting and biogas facilities in Belgium and the Netherlands, investment in energy efficiency, and waste reduction in industrial sectors such as component manufacturing, mining, and infrastructure in Greece [102].

As shown in Table 1, many companies in the EU, United Kingdom, United States, and Africa have also undertaken initiatives to accelerate the green transition to a circular economy, sustainable waste management, and recycling in their production chains or business activities of different scales. These circularity initiatives collectively contribute to enhancing resource efficiency, sustainability, and environmental efficiency, leading to smaller ecological footprints, particularly material and carbon footprints.

Table 1.

Circular economy practices around the world. Note: Compiled by the author from different sources.

6. How Circular Is Our Circular Economy?

6.1. Introduction to Circular Economy Efforts

The above discussions and the examples in Section 5 above are by no means exhaustive, but they are more than adequate to reflect the fact that industrialists or manufacturers worldwide have undertaken a wide range of circular economy measures to balance resource consumption with resource extraction and reduce ecological or material and carbon footprints. However, despite these initiatives, the global industrial–urban economy is becoming less circular, with circularity declining from 9.1% in 2018 to 7.2% in 2023 [116]. This decline signifies the deterioration of the ecological or material and carbon footprints of our industrial–urban system and humanity’s unsustainable use of natural resources. These are summarized below.

6.2. Urban Resource Consumption and Waste Generation

As shown below, cities play significant roles in global resource consumption and waste generation.

- Cities across the globe account for 75% of natural resource consumption and up to 80% of primary energy consumption.

- Cities also depend on the natural environment as sinks for the assimilation of 70% of the energy-related GHG emissions and 50% of solid waste production [117,118,119].

- The global industrial–urban material economy currently requires approximately 100 billion tons of material resource inputs, including 42.8 billion tons of non-metallic minerals, 9.4 billion tons of metallic ores, 15.5 billion tons of fossil fuels, 24.9 billion tons of biomass, and 8.65 billion tons of recycled materials to sustain itself.

- This means that the flows and stocks of resources into the industrial and urban systems have more than tripled since 1970 and almost doubled since 2000. Specifically, the global material demand increased from 7.4 tons/person in 1970 to 12 tons/person today [120].

6.3. Waste and Recycling Challenges

As shown below, the massive consumption of resources and waste generation, as elucidated above, pose an immense challenge to the 3R framework of resource efficiency and sustainability.

- Of the 100 billion tons of resources that flow into the global industrial–urban economy every year, more than 90% end up as GHG emissions or waste and only 7.2% of the total amount of waste materials generated in the industrial–urban metabolic process of transformation is being recycled.

- In the urban consumer sector, despite all the recycling technologies in use approximately 80% of waste is not recycled or recovered but becoming part of landfill sites.

- Of the 300 million tons of plastic produced globally each year, only 9% is reused or recycled, whereas the rest ends up in landfills or the natural environment, which will be transformed into microplastics that are detrimental to human health and the ecosystems [121].

- Approximately 11 billion tons of solid waste comprising solid waste (comprising residential, commercial, and institutional waste) and more than two billion tons of municipal waste are generated around the world every year [50,122]. This threatens to erode the biocapacity of the Earth to absorb waste materials generated by human economic activity.

6.4. Resource Extraction and Biocapacity Depletion

The rate of global resource consumption has exceeded the rate of natural resource replenishment, and the rates of waste generation and GHG emissions have surpassed the waste and carbon assimilation capacities of nature, as demonstrated in the following scenarios:

- Natural resource extractions have increased substantially by almost 400% since 1970 owing to the rapid growth of urbanization, population growth, and expanding industrial–urban metabolism [123].

- By 1 August 2024, the entire world had already used up all the biological resources beyond the Earth’s biocapacity to regenerate during the entire year. Most of these natural resources were channeled to run activities in industrial–urban system [124].

- Overall, the global economy required 1.75 planets to provide resources, including metal ores, nonmetallic minerals, and fossil fuels for consumption and waste assimilation in 2024 [125]. This translates to mean that humanity is using nature 1.75 times faster than our planet’s biocapacity can regenerate.

6.5. Projected Resource Demand

- The global extraction of virgin resources is projected to increase by 60% by 2060, with severe environmental impacts on the climate system and terrestrial ecosystems [4].

- Fossil fuels still dominate the global energy supply, accounting for 84% in 2023, while renewable energy sources like wind and solar contribute only 12% of global power generation [12,126]. With the share of fossil fuels in global energy supply, which has been stuck for decades at around 80%, the demand for fossil fuels is likely to remain consistent in many years to come, contributing significantly to aggravating GHG emissions and climate change.

6.6. Industrial–Urban Resource Consumption and Environmental Impacts

As shown below, industrial–urban resource metabolism and consumption result in massive industrial pollution and severe environmental impacts.

- Industrial emissions have increased by approximately 70% since 2000, primarily due to the growing global demand for industrial goods [127,128].

- Industry accounts for approximately nine Gt of direct CO2 emissions globally. Three heavy industries, namely, steel, cement, and chemical production, accounted for 70% of these emissions [127,128].

- Many industrial processes involve chemical reactions and the release of high-entropy waste heat, which cannot be fully decarbonized using current commercially available technologies or circular economy practices [127,128].

- The fossil fuel-dominated global industrial–urban energy system represents the biggest source of pollution in the world, contributing to 70% of the global GHG emissions, the bulk of which are fossil CO2 emissions [129]. Mining activity-induced GHG emissions also contribute to reinforcing the levels of GHG emissions, particularly the rates of CO2 emission.

- The extraction and production of virgin raw materials in the mining industry contributed to 23% of global GHG emissions in 2015, compared with 15% in 1995 [130].

- In 2023, the tropics lost 3.7 million hectares of primary forest, basically through mechanical clearing for agriculture and logging. This produced 2.4 billion tons of CO2, which is equivalent to almost half of the annual fossil fuel emissions of the United States [131].

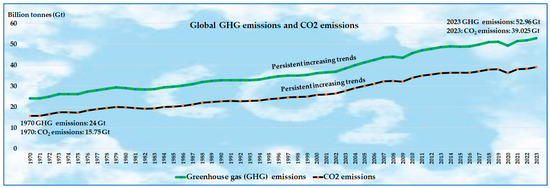

Demonstrably, as shown in Figure 4, GHG and fossil fuel CO2 emissions have increased by 120% and 147% from 15.75 million tons in 1970 to 39 million tons in 2023 and from 24 million tons to 53 million tons in the same period, respectively. Overall, GHG emissions, including CO2 emissions, increased by about 131% from 39.75 billion tons to 91.99 billion tons in the same period [132]. The rising trends have been persistent except during the COVID-19 pandemic in late 1990 and early 2020, which brought the global economic activity to a near standstill.

Figure 4.

Global CO2 emissions and GHG emissions (historical trends). Note: CO2 emission and GHG emission trends have persistently increased since 1970, except during the outbreak of COVID-19 in late 2019, where most economic activity halted. Source of data: [132].

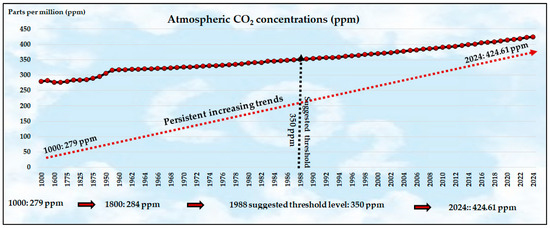

The continued emission of CO2 has resulted in a persistent increase in the atmospheric CO2 concentration, aggravating the impacts of global warning, climate change, and biodiversity impoverishment. As shown in Figure 5, the atmospheric CO2 concentration has increased from 279 ppm (parts per million) in 1000 to 284 ppm in 1800 during the Holocene epoch [133]—an epoch characterized by very stable and relatively cool climate conditions. It may be noted that atmospheric CO2 concentrations of between 280 and 350 ppm are considered ideal levels for human life [134]. In 1998, the world had first breached the safe levels of 350 ppm at 351.69 ppm. Since then, they have increased persistently, reaching 424.61 ppm in 2024. Overall, atmospheric CO2 concentrations have increased by 50% from 279 ppm in 1000 to 424.61 ppm in 2024. This will adversely affect the resilience of the climate system and ecosystems (24).

Figure 5.

Atmospheric CO2 concentrations (historical trends). Source of data: [129,133].

6.7. Limitations of the Circular Economy Model

- Current circular economy practices focus on decoupling industrial–urban growth from material consumption and carbon emissions but often neglect the broader environmental consequences of industrial activity, such as habitat destruction, industrial pollution, waste accumulation, and environmental degradation (environmental footprints).

- The circular economy model fails to fully account for the environmental impacts of irreversible resource transformation. Consequently, this gives rise to its failure to reveal the wide range of environmental disruptive effects caused by the industrial–urban metabolic process of resource transformation.

- Without addressing these environmental repercussions, even achieving circularity goals may not lead to true sustainability, as additional environmental disruptions could cancel out resource decoupling gains.

6.8. Need for a New Approach

- The current approach to circular economy practices is incomplete and risks widening the circularity gap by ignoring the systemic environmental impacts of the metabolic process of industrial–urban resource consumption and transformation.

- A new approach is needed to explore the causal relationships underlying industrial–urban growth and its environmental consequences.

- This approach should provide a comprehensive inventory of environmental repercussions, their impacts on natural systems, and their threats to environmental resilience and industrial–urban sustainability.

- Improved policy interventions and control methods are essential to address these challenges, as discussed in the next section.

7. System Dynamic Causal Model for Industrial–Urban Sustainability

7.1. System Thinking, System Theory and System Dynamics: Some Fundamental Concepts

The industrial–urban system, which integrates natural systems, is a complex system whose interactions can only be understood through system theory. This section introduces the foundational concepts of system thinking, system theory, and system dynamics to provide context for the sustainability assessment of industrial–urban–environmental systems. This is systematically discussed below.

- A “system” is defined as any group of interacting, interrelated, or interdependent components that form a complex and unified whole with a specific purpose. In other words, a system is more than the sum of its parts, and its components function collectively to achieve systemic goals. System thinking is a thought process to conceptualize or understand a system holistically by examining the linkages and interactions between the component parts that make up the system as a whole. It focuses on identifying patterns of behavior, such as feedback loops, rather than isolating individual components or events [135,136]. System thinking does not use computer simulation but takes into consideration of the interdependencies between elements of a system, looking for patterns (feedback loop structure) of system behavior rather than focusing on just its parts or isolated facts [137]. Unlike a traditional linear analysis, system thinking emphasizes the interdependencies within a system and its emergent properties, which arise from the interactions of its components.

- System theory provides a conceptual framework for understanding systems by focusing on the relationships between their components and their interactions with other systems [138]. It is particularly useful for analyzing complex systems that that are impossible to fully comprehend, rationalize, predict, or model using standard approaches such as linear statistical models. System theory enables a holistic examination of how smaller subsystems influence larger, more complex systems.

- System dynamics, grounded in systems thinking and system theory, is a methodology for modeling and analyzing complex systems. It focuses on understanding the interactions between the components of a system and how these interactions drive system behavior over time. System dynamics assumes that the structure of a system and the relationships between its components are more important than the components themselves. The term “dynamics” refers to the time-varying behavior of multiple interconnected components in response to input signals [139,140,141]. System dynamics is particularly useful for capturing the complexity and emergent properties of systems, which are properties that arise only when components interact as a whole [142]. Emergent properties are properties that only manifest when a collection or combination of individual system components interact within a system as a whole. They are new properties that do not belong to the individual components themselves [137].

System dynamics hinges on the assumption that a system must be far from equilibrium. That is, it is an open system with a constant flow of energy, matter, or information in and out of the system boundaries. When a system is far from equilibrium, fluctuations or perturbations (input signals/inputs, see below) constantly attempt to move the system away from its stable conditions.

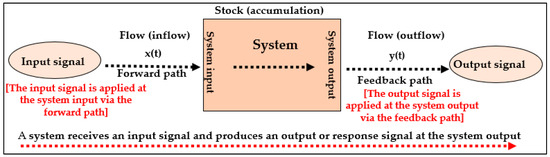

- A system is characterized by an input signal, x(t) (input), and output signal y(t). The term signal generally refers to a time-variant physical phenomenon. It can be of any dimension or form that contains information about the attributes, behavior, or observable changes in a natural or physical system. The input signal controls the system, while the output signal is produced by the system in response to the input signal to achieve a desired output and response. A system may have multiple input signals and output signals. System signals x(t) and output (response) signal, y(t) are best represented by stocks and flows. A stock refers to an accumulation of inputs, whereas a flow, which can be an inflow or outflow, denotes the movement of stock units per time across system boundaries (Figure 6). Stocks may change through connected inflow and outflows [136,137].

Figure 6. Signal and system relationships. Note: In response to the inflow of system input, the system generates a system output, which produces an output or response signal via the feedback path to neutralize the effect of the system input.

Figure 6. Signal and system relationships. Note: In response to the inflow of system input, the system generates a system output, which produces an output or response signal via the feedback path to neutralize the effect of the system input.

7.1.1. Analog and Discrete Signals

Most signals that occur in the natural world are analog signals, represented by x(t), which are defined over a continuum of time or space. Analog signals are continuous and vary or fluctuate as a function of time t, conveying dynamic information to stimulate system responses. Continuous time signals can be distinguished from discrete signals defined at discrete times. In contrast, discrete signals are defined at distinct, non-continuous, separate, or specific points in time or amplitude. For this study, we focus on continuous-time signals, as they are more representative of the dynamic behavior of industrial–urban systems [143].

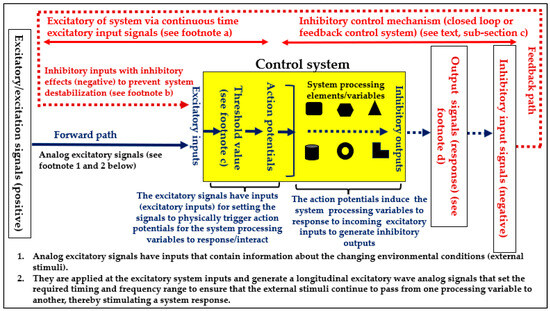

7.1.2. Excitatory and Inhibitory Inputs

System signals can be classified as excitatory or inhibitory. An excitatory input is a signal that helps create the required conditions to physically trigger action potentials for the system variables or processing elements to act upon and neutralize the incoming pressures through feedback control (see Section 7.3.1 below). An action potential is defined as a sudden, fast, transitory, and propagating change of system components triggered by external force of disturbances (excitatory signals/inputs). This activates the system components to respond through the generation of inhibitory outputs with the objective of halting or inhibiting the excitation triggered by the action potentials. Excitatory inputs are often positively weighted and valued (reinforcing), while inhibitory outputs or responses are negatively weighted and valued (balancing). These are applied to the system as inhibitory inputs to cancel or reduce excitatory signals or inputs.