Reuse of Mine Tailings Through Geopolymerization Applied to 3D Printing: A Review of Progress, Challenges and Perspectives

Abstract

1. Introduction

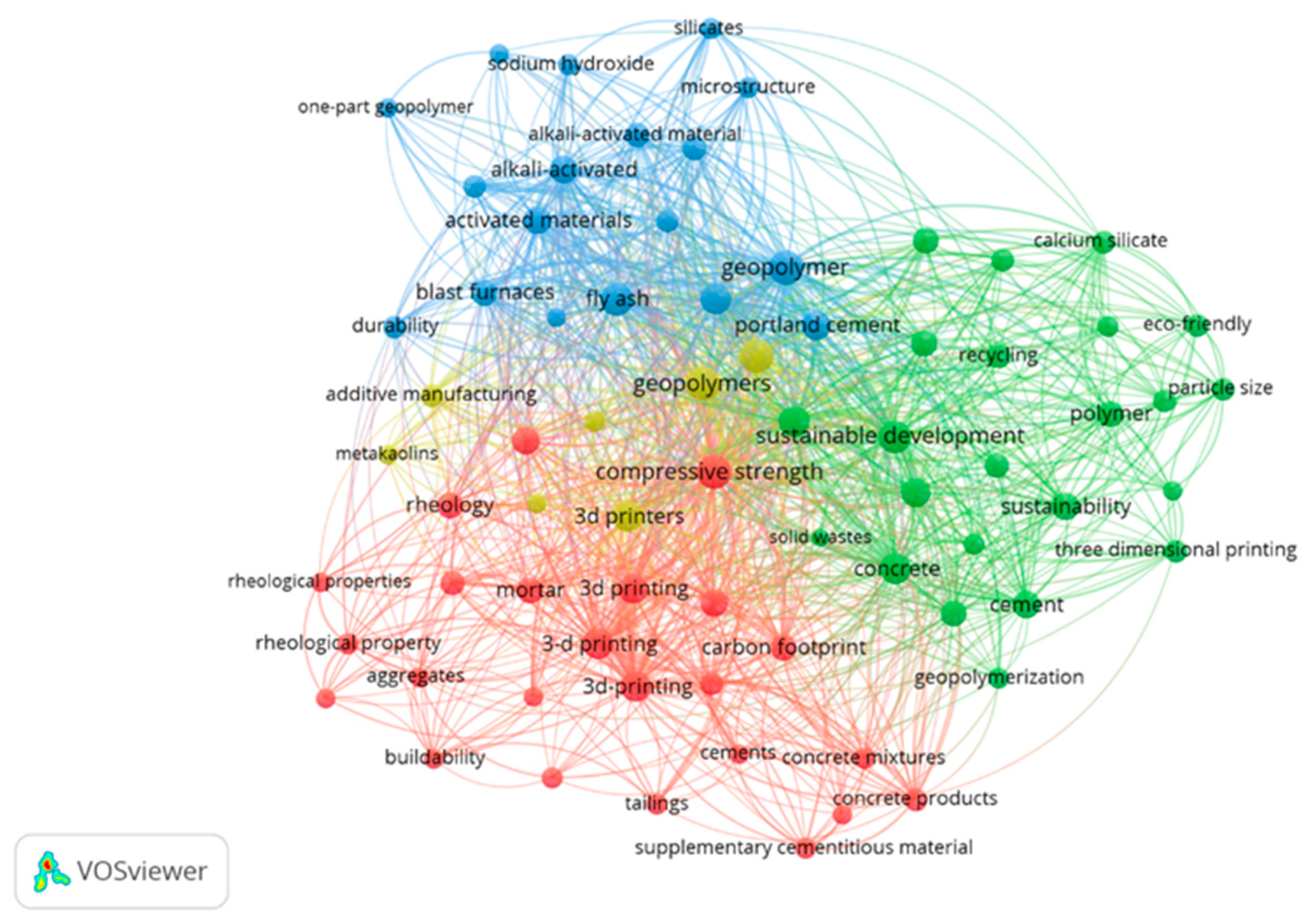

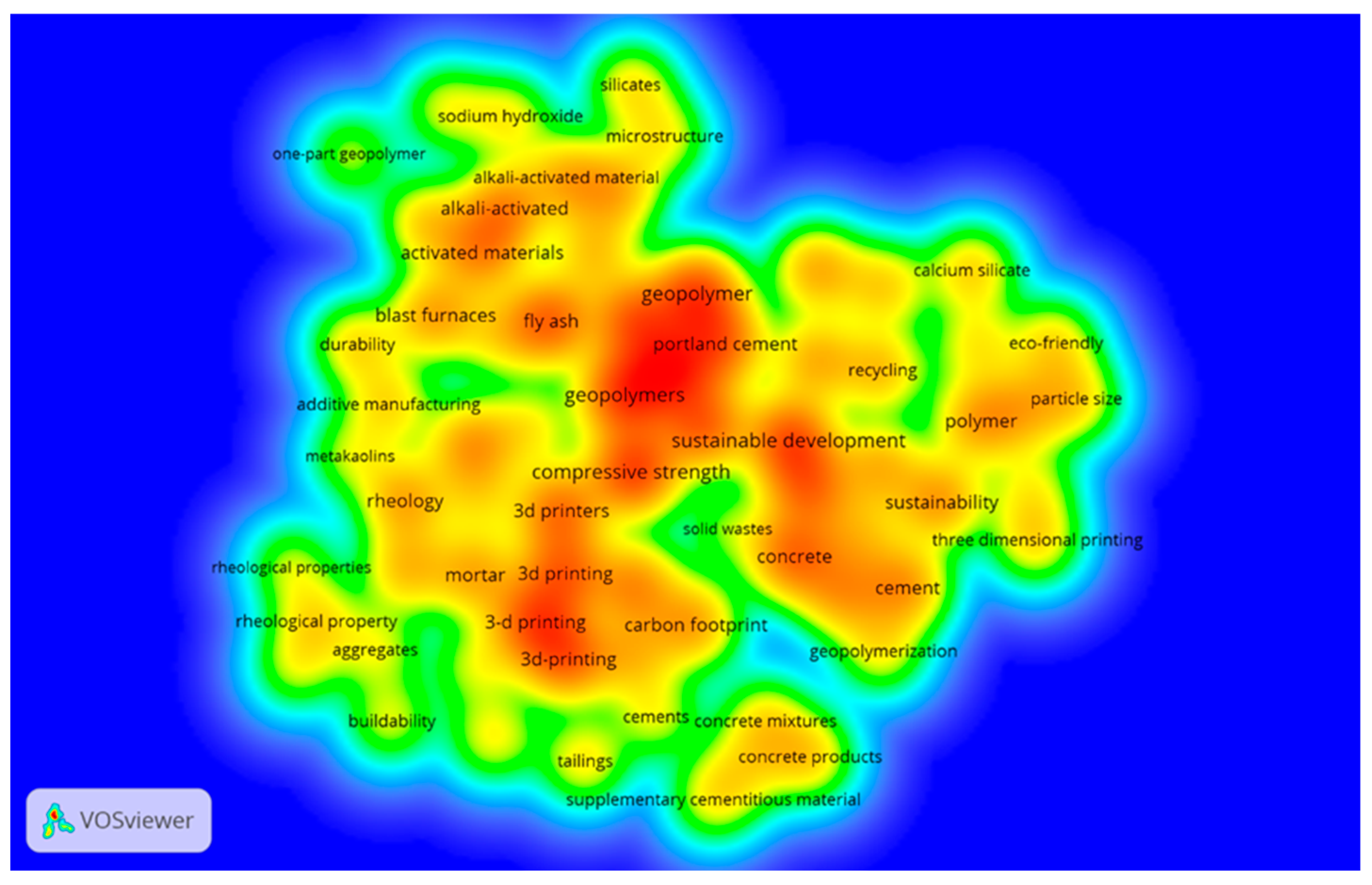

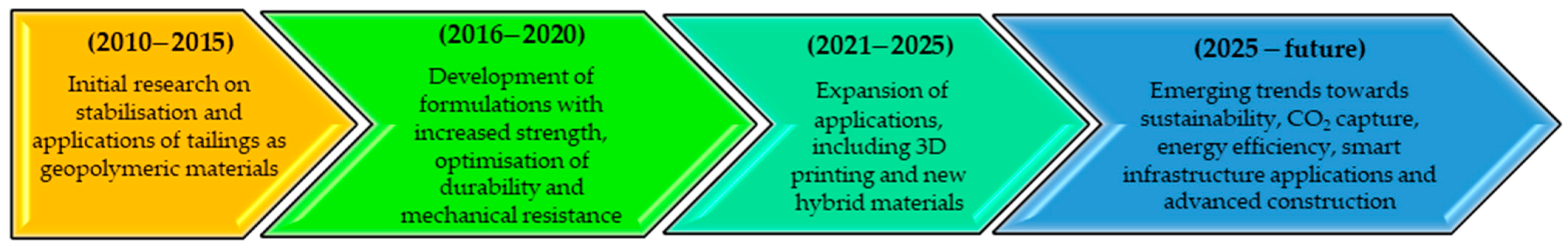

2. Bibliometric Analysis

3. Challenges in Reusing Tailings

3.1. Determining Factors in the Chemistry of Geopolymers

3.2. Sorption Mechanisms of Geopolymers

3.3. Geopolymerization of Mining Tailings: Potential and Challenges

| Element | Immobilization Method | Immobilization Efficiency (%) | Impact on Mechanical Properties | References |

|---|---|---|---|---|

| Hg | Adsorption on aluminosilicate matrix | 90 | No significant effect | [60] |

| Cu | Encapsulation in geopolymeric matrix | 98 | Improves mechanical stability | [27,101] |

| Pb | Formation of stable hydroxycarbonates | 95 | Increased durability | [51,91] |

| Zn | Encapsulation in geopolymeric structure | 80 | Minimal reduction in strength | [51,102] |

| As | Precipitation of Fe–As and Ca–As | 95.4 | No significant adverse effects | [91,104] |

| Cr | Reduction of Cr(VI) to Cr(III) and formation of hydrotalcites | Variable | Depends on the type of activator | [103] |

4. Three-Dimensional Printing of Construction Materials

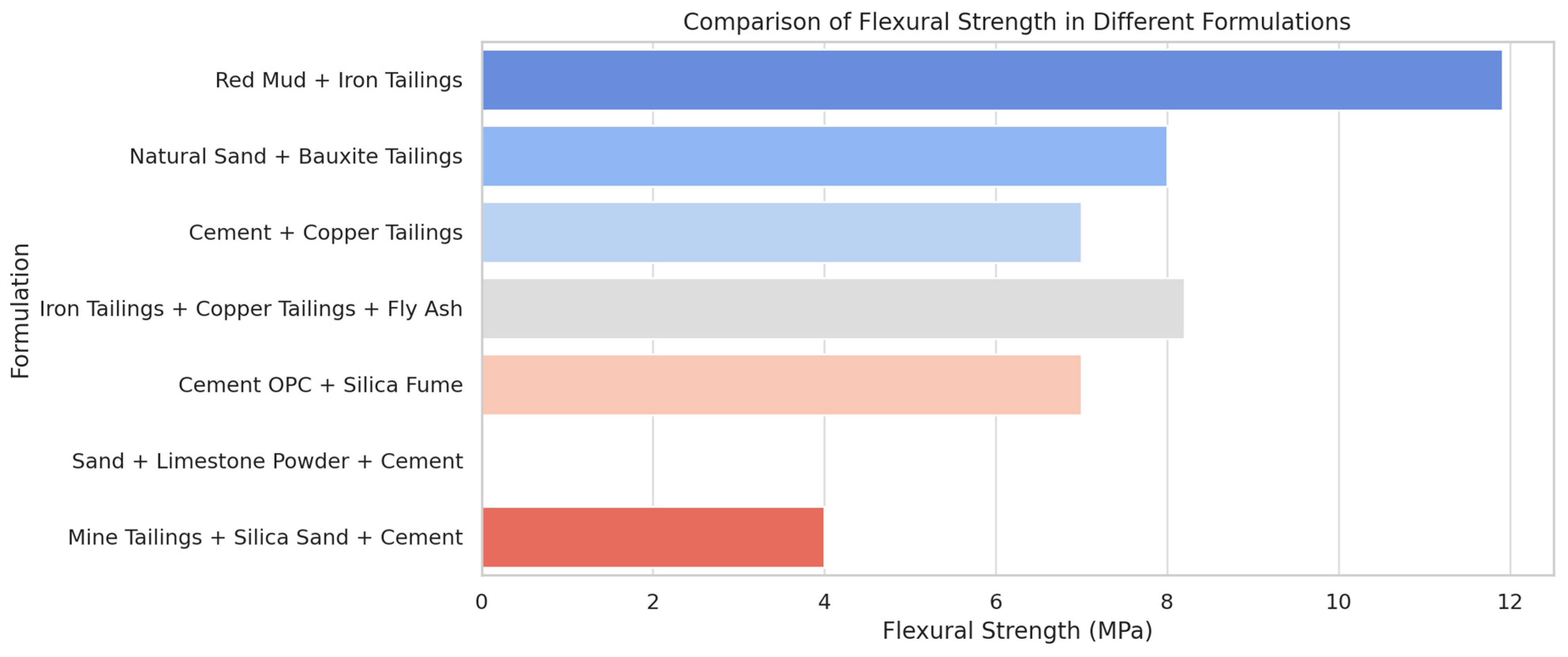

5. Comparative Analysis of Tailings Geopolymers and Cements in 3D Printing

5.1. Geopolymers with Tailings in 3D Printing Applications

5.2. Other Components for 3D Printing of Geopolymers

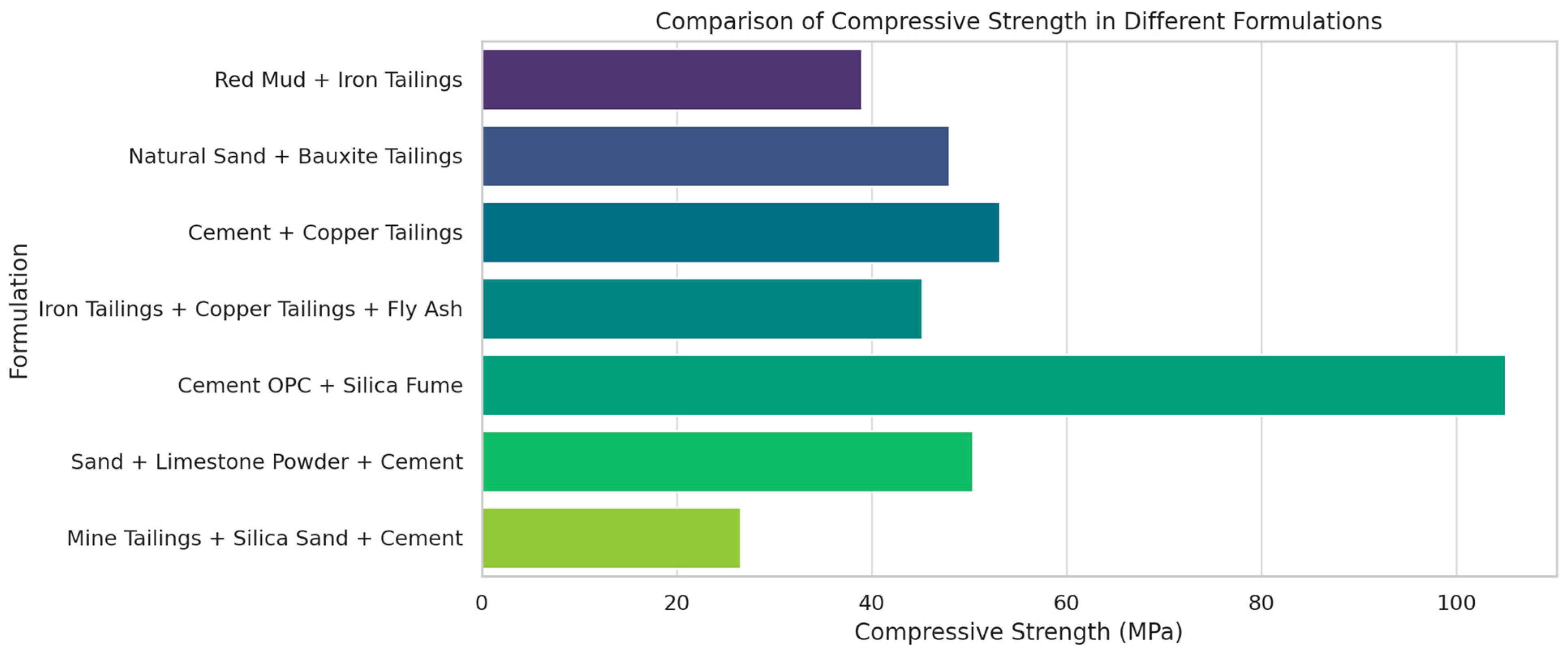

5.3. Mining Tailings and Cementitious Mixtures for 3D Printing

6. The Sustainability Perspective in Tailings Geopolymerization

7. Final Remarks and Future Directions

Author Contributions

Funding

Conflicts of Interest

References

- Radebe, N.; Chipangamate, N. Mining industry risks, and future critical minerals and metals supply chain resilience in emerging markets. Resour. Policy 2024, 91, 104887. [Google Scholar] [CrossRef]

- Yu, H.; Li, H. How does the global metal industry value network affect industrial structure upgrading? The perspective of industry chain. Resour. Policy 2023, 85, 104055. [Google Scholar] [CrossRef]

- Adiansyah, J.S.; Rosano, M.; Vink, S.; Keir, G. A framework for a sustainable approach to mine tailings management: Disposal strategies. J. Clean. Prod. 2015, 108, 1050–1062. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Cano, D.; Custodio, M. Socio-Environmental Risks Linked with Mine Tailings Chemical Composition: Promoting Responsible and Safe Mine Tailings Management Considering Copper and Gold Mining Experiences from Chile and Peru. Toxics 2023, 11, 462. [Google Scholar] [CrossRef] [PubMed]

- Cacciuttolo, C.; Atencio, E. Past, Present, and Future of Copper Mine Tailings Governance in Chile (1905–2022): A Review in One of the Leading Mining Countries in the World. Int. J. Environ. Res. Public Health 2022, 19, 13060. [Google Scholar] [CrossRef] [PubMed]

- Doussoulin, J.P.; Mougenot, B. Mapping mining and ecological distribution conflicts in Latin America, a bibliometric analysis. Resour. Policy 2022, 77, 102650. [Google Scholar] [CrossRef]

- De Echave, J.; Diez, A.; Huber, L.; Revesz, B.; Ricard, X.; Tanaka, M.; Minería y conflicto social; Instituto de Estudios Peruanos; Centro de Investigación y Promoción del Campesinado (Peru); Centro de Estudios Regionales Andinos “Bartolomé de Las Casas” (Eds.) Consorcio de Investigación Económica y Social (Peru), 1st ed.; CLACSO: Lima, Peru, 2009. [Google Scholar]

- Manrique Zuñiga, E.; Toledo Gutierrez, C.; Villacorta Chambi, S.P. Geoethics and Mining Activity in Peru. In Geoethics in Peru; Villacorta Chambi, S.P., Ed.; Springer International Publishing: Berlin/Heidelberg, Germany, 2022; pp. 47–57. [Google Scholar] [CrossRef]

- Ji, Z.; Zhang, G.; Liu, R.; Qu, J.; Liu, H. Potential applications of solid waste-based geopolymer materials: In wastewater treatment and greenhouse gas emission reduction. J. Clean. Prod. 2024, 443, 141144. [Google Scholar] [CrossRef]

- Qu, C.; Qin, Y.; Wang, T. From cement to geopolymers: Performances and sustainability advantages of ambient curing. J. Build. Eng. 2024, 91, 109555. [Google Scholar] [CrossRef]

- Sruthi, S.; Priya, A.K. A Review on Eco-Green Geopolymer Concrete. Int. J. Sci. Res. 2017, 6, 1167–1172. [Google Scholar]

- Cheng, T.W.; Lee, M.L.; Ko, M.S.; Ueng, T.H.; Yang, S.F. The heavy metal adsorption characteristics on metakaolin-based geopolymer. Appl. Clay Sci. 2012, 56, 90–96. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, Y.; Meng, L.; Cheng, J.; Ouyang, F.; Duan, P.; Li, W.; Zhang, H.; Zhu, Y.; Zhang, Z. Performance and heavy metal leaching of porous geopolymer based on solid wastes. Constr. Build. Mater. 2024, 427, 136186. [Google Scholar] [CrossRef]

- Mohd Tahir, M.F.; Abdullah, M.M.A.B.; Abd Rahim, S.Z.; Mohd Hasan, M.R.; Saafi, M.; Putra Jaya, R.; Mohamed, R. Potential of industrial By-Products based geopolymer for rigid concrete pavement application. Constr. Build. Mater. 2022, 344, 128190. [Google Scholar] [CrossRef]

- Muttashar, M.; Lokuge, W.; Karunasena, W. Geopolymer concrete: The green alternative with suitable structural properties. In Proceedings of the 23rd Australasian Conference on the Mechanics of Structures and Materials (ACMSM23), Byron Bay, Australia, 9–12 December 2014. [Google Scholar]

- Ahmari, S.; Zhang, L. Production of eco-friendly bricks from copper mine tailings through geopolymerization. Constr. Build. Mater. 2012, 29, 323–331. [Google Scholar] [CrossRef]

- Inayath Basha, S.; Ur Rehman, A.; Khalid, H.R.; Aziz, M.A.; Kim, J. 3D Printable Geopolymer Composites Reinforced with Carbon-Based Nanomaterials—A Review. Chem. Rec. 2023, 23, e202300054. [Google Scholar] [CrossRef]

- Kong, X.; Dai, L.; Wang, Y.; Qiao, D.; Hou, S.; Wang, S. Influence of kenaf stalk on printability and performance of 3D printed industrial tailings based geopolymer. Constr. Build. Mater. 2022, 315, 125787. [Google Scholar] [CrossRef]

- Carlos, M.-A.; Nataniel, L.; Tolomeo, S.; Luis, M.-A. Treatment of Mining and Thermoelectric Waste Through the Geopolymerization Process. SHS Web Conf. 2021, 100, 05003. [Google Scholar] [CrossRef]

- Komnitsas, K.; Zaharaki, D.; Perdikatsis, V. Effect of Synthesis Parameters on the Compressive Strength of Low-Calcium Ferronickel Slag Inorganic Polymers. J. Hazard. Mater. 2008, 161, 760–768. [Google Scholar] [CrossRef]

- Srinivasamurthy, L.; Chevali, V.S.; Zhang, Z.; Longhi, M.A.; Loh, T.W.; Wang, H. Mechanical property and microstructure development in alkali activated fly ash slag blends due to efflorescence. Constr. Build. Mater. 2022, 332, 127273. [Google Scholar] [CrossRef]

- Alves, L. A Quick Overview on Geopolymer Chemistry and General Properties. Res. Dev. Mater. Sci. 2019, 12, 1249–1251. [Google Scholar] [CrossRef]

- Castillo, H.; Collado, H.; Droguett, T.; Sánchez, S.; Vesely, M.; Garrido, P.; Palma, S. Methodologies for the Possible Integral Generation of Geopolymers Based on Copper Tailings. Minerals 2021, 11, 1367. [Google Scholar] [CrossRef]

- Morales-Aranibar, C.; Linares-Gutiérrez, N.; Morales-Aranibar, L. Immobilization of copper sulfide flotation tailings through the use of geopolymers, Tacna–Perú. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1065, 012009. [Google Scholar] [CrossRef]

- Taki, K.; Mukherjee, S.; Patel, A.K.; Kumar, M. Reappraisal review on geopolymer: A new era of aluminosilicate binder for metal immobilization. Environ. Nanotechnol. Monit. Manag. 2020, 14, 100345. [Google Scholar] [CrossRef]

- Archez, J.; Texier-Mandoki, N.; Bourbon, X.; Caron, J.F.; Rossignol, S. Shaping of geopolymer composites by 3D printing. J. Build. Eng. 2021, 34, 101894. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Wei, K.; Gao, H.; Liu, Z.; She, Y.; Chen, F.; Gao, H.; Yu, Q. Rheology control and shrinkage mitigation of 3D printed geopolymer concrete using nanocellulose and magnesium oxide. Constr. Build. Mater. 2024, 429, 136421. [Google Scholar] [CrossRef]

- Simão, L.; Fernandes, E.; Hotza, D.; Ribeiro, M.J.; Montedo, O.R.K.; Raupp-Pereira, F. Controlling efflorescence in geopolymers: A new approach. Case Stud. Constr. Mater. 2021, 15, e00740. [Google Scholar] [CrossRef]

- Pobłocki, K.; Pawlak, M.; Drzeżdżon, J.; Gawdzik, B.; Jacewicz, D. Clean production of geopolymers as an opportunity for sustainable development of the construction industry. Sci. Total Environ. 2024, 928, 172579. [Google Scholar] [CrossRef]

- Camargos, J.S.F.; Dias, E.A.P.; Da Silva, G.M.; Nunes, V.A.; Borges, P.H.R. Development of sustainable foamed alkali-activated materials for modular construction. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 436. [Google Scholar] [CrossRef]

- Petronijević, N.; Alivojvodić, V.; Sokić, M.; Marković, B.; Stanković, S.; Radovanović, D. Sustainable mining towards accomplishing circular economy principles. J. Appl. Eng. Sci. 2020, 18, 493–499. [Google Scholar] [CrossRef]

- Freire, A.L.; José, H.J.; Moreira, R.D.F.P.M. Potential applications for geopolymers in carbon capture and storage. Int. J. Greenh. Gas Control 2022, 118, 103687. [Google Scholar] [CrossRef]

- Freire, A.L.; Da Silva, A.; Della Rocca, D.G.; Da Silveira Salla, J.; Castellã Pergher, S.B.; Rodríguez-Castellón, E.; José, H.J.; De Fátima Peralta Muniz Moreira, R. Synthesis and characterization of geopolymers based on phosphate mining tailings and its application for carbon dioxide and nitrogen adsorption. Ceram. Int. 2024, 51, 8396–8407. [Google Scholar] [CrossRef]

- Zhang, L.; Ahmari, S.; Zhang, J. Synthesis and characterization of fly ash modified mine tailings-based geopolymers. Constr. Build. Mater. 2011, 25, 3773–3781. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L. Durability and leaching behavior of mine tailings-based geopolymer bricks. Constr. Build. Mater. 2013, 44, 743–750. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L. Utilization of cement kiln dust (CKD) to enhance mine tailings-based geopolymer bricks. Constr. Build. Mater. 2013, 40, 1002–1011. [Google Scholar] [CrossRef]

- Barrie, E.; Cappuyns, V.; Vassilieva, E.; Adriaens, R.; Hollanders, S.; Garcés, D.; Paredes, C.; Pontikes, Y.; Elsen, J.; Machiels, L. Potential of inorganic polymers (geopolymers) made of halloysite and volcanic glass for the immobilisation of tailings from gold extraction in Ecuador. Appl. Clay Sci. 2015, 109–110, 95–106. [Google Scholar] [CrossRef]

- Singh, G.I.; Deshwal, B.; Bhattacharyya, S.K. Effect of sodium carbonate/sodium silicate activator on the rheology, geopolymerization and strength of fly ash/slag geopolymer pastes. Cem. Concr. Compos. 2019, 97, 226–238. [Google Scholar] [CrossRef]

- Lopez Gonzalez, P.L.; Novais, R.M.; Labrincha, J.A.; Blanpain, B.; Pontikes, Y. Modifications of basic-oxygen-furnace slag microstructure and their effect on the rheology and the strength of alkali-activated binders. Cem. Concr. Compos. 2019, 97, 143–153. [Google Scholar] [CrossRef]

- Kiventerä, J.; Lancellotti, I.; Catauro, M.; Poggetto, F.D.; Leonelli, C.; Illikainen, M. Alkali activation as new option for gold mine tailings inertization. J. Clean. Prod. 2018, 187, 76–84. [Google Scholar] [CrossRef]

- Paiva, H.; Yliniemi, J.; Illikainen, M.; Rocha, F.; Ferreira, V. Mine Tailings Geopolymers as a Waste Management Solution for A More Sustainable Habitat. Sustainability 2019, 11, 995. [Google Scholar] [CrossRef]

- Li, X.; Zhang, N.; Yuan, J.; Wang, X.; Zhang, Y.; Chen, F.; Zhang, Y. Preparation and microstructural characterization of a novel 3D printable building material composed of copper tailings and iron tailings. Constr. Build. Mater. 2020, 249, 118779. [Google Scholar] [CrossRef]

- Wan, Q.; Rao, F.; Song, S.; García, R.E.; Estrella, R.M.; Patiño, C.L.; Zhang, Y. Geopolymerization reaction, microstructure and simulation of metakaolin-based geopolymers at extended Si/Al ratios. Cem. Concr. Compos. 2017, 79, 45–52. [Google Scholar] [CrossRef]

- Borges, P.H.R.; Ramos, F.C.R.; Caetano, T.R.; Panzerra, T.H.; Santos, H. Reuse of iron ore tailings in the production of geopolymer mortars. REM-Int. J. Eng. 2019, 72, 581–587. [Google Scholar] [CrossRef]

- Manjarrez, L.; Zhang, L. Utilization of Copper Mine Tailings as Road Base Construction Material through Geopolymerization. J. Mater. Civ. Eng. 2018, 30, 04018201. [Google Scholar] [CrossRef]

- Beulah, M.; Sudhir, M.R.; Mohan, M.K.; Gayathri, G.; Jain, D. Mine Waste-Based Next Generation Bricks: A Case Study of Iron Ore Tailings, Red Mudand GGBS Utilization in Bricks. Adv. Mater. Sci. Eng. 2021, 9499613. [Google Scholar] [CrossRef]

- Li, D.; Ramos, A.O.; Bah, A.; Li, F. Valorization of lead-zinc mine tailing waste through geopolymerization: Synthesis, mechanical, and microstructural properties. J. Environ. Manag. 2024, 349, 119501. [Google Scholar] [CrossRef]

- Li, P.; Luo, S.; Wang, Y.; Zhang, L.; Wang, H.; Teng, F. Mix design and mechanical properties of geopolymer building material using iron ore mine tailings. Renew. Sust. Energ. Rev. 2025, 211, 115274. [Google Scholar] [CrossRef]

- Subramanian, S.; Davis, R.P.; Thomas, B.S. Sustainable engineered geopolymer composites: A study on the potential of fly ash, BOF slag, and iron ore tailings. Environ. Eng. Res. 2024, 29, 230540. [Google Scholar] [CrossRef]

- Asadizadeh, M.; Hedayat, A.; Tunstall, L.; Gonzalez, J.A.V.; Alvarado, J.W.V.; Neira, M.T. The impact of slag on the process of geopolymerization and the mechanical performance of mine-tailings-based alkali-activated lightweight aggregates. Constr. Build. Mater. 2024, 411, 134347. [Google Scholar] [CrossRef]

- Zhao, S.; Xia, M.; Yu, L.; Huang, X.; Jiao, B.; Li, D. Optimization for the preparation of composite geopoly-mer using response surface methodology and its application in lead-zinc tailings solidification. Constr. Build. Mater. 2021, 266, 120969. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Effect of alkali reactions on the rheology of one-part 3D printable geopolymer concrete. Cem. Concr. Compos. 2021, 116, 103899. [Google Scholar] [CrossRef]

- Lu, H.; Zhan, X.; Yue, Z.; Xie, Z.; Zhao, P.; Wang, W.; He, X.; Wang, J. Low-carbon coal fly ash/superfine iron tailings-based three-dimensional printed geopolymer (CS-3DPG) rapid prototyping: The role and impact mechanism of carbonate series accelerator (CSA). Constr. Build. Mater. 2024, 446, 138040. [Google Scholar] [CrossRef]

- Munir, Q.; Peltonen, R.; Kärki, T. Printing Parameter Requirements for 3D Printable Geopolymer Materials Prepared from Industrial Side Streams. Materials 2021, 14, 4758. [Google Scholar] [CrossRef] [PubMed]

- Rezaei Shahmirzadi, M.; Gholampour, A.; Kashani, A.; Ngo, T.D. Geopolymer mortars for use in construction 3D printing: Effect of LSS, graphene oxide and nanoclay at different environmental conditions. Constr. Build. Mater. 2023, 409, 133967. [Google Scholar] [CrossRef]

- Shoaei, P.; Kjøniksen, A.-L.; Pamies, R.; Pilehvar, S. Characterization of 3D-printable geopolymer mortars: Effect of binder composition and basalt fiber reinforcement. Case Stud. Constr. Mater. 2024, 20, e03335. [Google Scholar] [CrossRef]

- Santana, H.A.; Amorim Júnior, N.S.; Ribeiro, D.V.; Cilla, M.S.; Dias, C.M.R. 3D printed mesh reinforced geopolymer: Notched prism bending. Cem. Concr. Compos. 2021, 116, 103892. [Google Scholar] [CrossRef]

- Scanferla, P.; Conte, A.; Sin, A.; Franchin, G.; Colombo, P. The effect of fillers on the fresh and hardened properties of 3D printed geopolymer lattices. Open Ceram. 2021, 6, 100134. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, A.; Sitharam, T.G. Experimental study on strength, durability, hydraulic and toxicity characteristics of soil treated with mine tailings based geopolymers for sustainable road subgrade application. Constr. Build. Mater. 2024, 414, 134894. [Google Scholar] [CrossRef]

- Lu, X.; Guo, J.; Chen, F.; Tian, M. Synthesis of ternary geopolymers using prediction for effective solidification of mercury in tailings. J. Environ. Sci. 2025, 147, 392–403. [Google Scholar] [CrossRef]

- Párraga Morales, D.; Rivera, E.O.; Lotero, A.; Moncaleano, C.J.; Consoli, N.C. Potential Reuse of Andean Highlands Tin Tailings in Geotechnical Works Through Geopolymer Binder Stabilization. Geotech. Geol. Eng. 2024, 42, 6071–6093. [Google Scholar] [CrossRef]

- Wang, J.; Wang, W.; Lu, L.; Luo, Q.; Lai, J.; Xie, X.; Li, B.; Zhuang, R.; He, Y. Strength development and polymerization reaction mechanism of sulfur-tailings-based geopolymer produced with CaO and Na2SiO3 composite activator. Constr. Build. Mater. 2024, 421, 135692. [Google Scholar] [CrossRef]

- Wang, R.; Wang, J.; Dong, T.; Ouyang, G. Structural and mechanical properties of geopolymers made of aluminosilicate powder with different SiO2/Al2O3 ratio: Molecular dynamics simulation and microstructural experimental study. Constr. Build. Mater. 2020, 240, 117935. [Google Scholar] [CrossRef]

- Da Costa Gonçalves, L.F.; Balestra, C.E.T.; Ramirez Gil, M.A. Evaluation of mechanical, physical and chemical properties of ecological modular soil-alkali activated bricks without Portland cement. Envion. Dev. 2023, 48, 100932. [Google Scholar] [CrossRef]

- Javed, U.; Uddin Ahmed Shaikh, F.; Kumar Sarker, P. Microstructural investigation of thermo-mechanically processed lithium slag for geopolymer precursor using various characterization techniques. Constr. Build. Mater. 2022, 342, 127952. [Google Scholar] [CrossRef]

- Tang, L.; He, Z.; Tang, J.; Yang, R.; Pei, S.; Xia, Y.; Yu, J. Study on the microscopic characteristics and hydration mechanism of thermo-alkali activated electrolytic manganese residue geopolymers. Constr. Build. Mater. 2024, 438, 137279. [Google Scholar] [CrossRef]

- Yu, K.; Jia, M.; Tian, W.; Yang, Y.; Liu, Y. Enhanced thermo-mechanical properties of cementitious composites via red mud-based microencapsulated phase change material: Towards energy conservation in building. Energy 2024, 290, 130301. [Google Scholar] [CrossRef]

- Bianchi, I.; Volpe, S.; Fiorito, F.; Forcellese, A.; Sangiorgio, V. Life cycle assessment of building envelopes manufactured through different 3D printing technologies. J. Clean. Prod. 2024, 440, 140905. [Google Scholar] [CrossRef]

- Huo, B.; Zhang, Y.; Wang, D. Optimizing CO2 capture property of alkali-activated ladle slag materials with sodium dodecyl sulfate. Powder Technol. 2025, 449, 120388. [Google Scholar] [CrossRef]

- Amer, I.; Abdelkhalik, A.; Mayhoub, O.A.; Kohail, M. Development of Sustainable Slag-based Geopolymer Concrete Using Different Types of Chemical Admixtures. Int. J. Concr. Struct. Mater. 2024, 18, 27. [Google Scholar] [CrossRef]

- Bouchikhi, A.; Amar, M.; Arroug, L.; Safhi, A.E.M.; Haddaji, Y. Characterizing nano-indentation and microstructural properties of mine tailings-based geopolymers. Case Stud. Constr. Mater. 2024, 21, e03899. [Google Scholar] [CrossRef]

- Perera-Mercado, Y.; Zhang, N.; Hedayat, A.; Figueroa, L.; Saucedo-Salazar, E.; Clements, C.; Bolaños Sosa, H.G.; Tupa, N.; Morales, I.Y.; Canahua Loza, R.S. Production and Incorporation of Calcium-Hydrolyzed Nanoparticles in Alkali-Activated Mine Tailings. Nanomater 2023, 13, 1875. [Google Scholar] [CrossRef]

- Qu, C.; Wang, Y. Flame-retardant coatings with ultraviolet resistance by doping KH-560 modified nano-silica into Na2SiO3/NaOH-activated copper tailings geopolymer. Constr. Build. Mater. 2024, 446, 138004. [Google Scholar] [CrossRef]

- Zheng, C.; Mao, Z.; Chen, L.; Qian, H.; Wang, J. Development of a novel rapid repairing agent for concrete based on GFRP waste powder/GGBS geopolymer mortars. J. Build. Eng. 2023, 71, 106542. [Google Scholar] [CrossRef]

- Kantarci, F.; Maraş, M.M. Fabrication of Novel Geopolymer Grout as Repairing Material for Application in Damaged RC Beams. Int. J. Civ. Eng. 2022, 20, 461–474. [Google Scholar] [CrossRef]

- Liu, J.; Chen, W.; Xie, G.; Xie, X.; Ning, Q.; Bai, X. Strength characteristics and electrochemical impedance spectroscopy study of red mud-coal metakaolin geopolymer in a hydrochloric acid environment. Int. J. Electrochem. Sci. 2023, 18, 100182. [Google Scholar] [CrossRef]

- Jacob, R.; Trout, N.; Solé, A.; Clarke, S.; Fernández, A.I.; Cabeza, L.F.; Saman, W.; Bruno, F. Novel geopolymer for use as a sensible storage option in high temperature thermal energy storage systems. In Proceedings of the SolarPACES 2019: International Conference on Concentrating Solar Power and Chemical Energy Systems, Daegu, Republic of Korea, 1–4 October 2020; p. 190019. [Google Scholar] [CrossRef]

- Araya, N.; Kraslawski, A.; Cisternas, L.A. Towards mine tailings valorization: Recovery of critical materials from Chilean mine tailings. J. Clean. Prod. 2020, 263, 121555. [Google Scholar] [CrossRef]

- Abbadi, A.; Mucsi, G. A review on complex utilization of mine tailings: Recovery of rare earth elements and residue valorization. J. Environ. Chem. Engin. 2024, 12, 113118. [Google Scholar] [CrossRef]

- Moukannaa, S.; Nazari, A.; Bagheri, A.; Loutou, M.; Sanjayan, J.G.; Hakkou, R. Alkaline fused phosphate mine tailings for geopolymer mortar synthesis: Thermal stability, mechanical and microstructural properties. J. Non-Cryst. Solids 2019, 511, 76–85. [Google Scholar] [CrossRef]

- Fernández-Martínez, R.; Corrochano, N.; Álvarez-Quintana, J.; Ordóñez, A.; Álvarez, R.; Rucandio, I. Assessment of the ecological risk and mobility of arsenic and heavy metals in soils and mine tailings from the Carmina mine site (Asturias, NW Spain). Environ. Geochem. Health 2024, 46, 90. [Google Scholar] [CrossRef]

- He, X.; Yuhua, Z.; Qaidi, S.; Isleem, H.F.; Zaid, O.; Althoey, F.; Ahmad, J. Mine tailings-based geopolymers: A comprehensive review. Ceram. Int. 2022, 48, 24192–24212. [Google Scholar] [CrossRef]

- Jaskoski, M. Environmental Licensing and Conflict in Peru’s Mining Sector: A Path-Dependent Analysis. World Dev. 2014, 64, 873–883. [Google Scholar] [CrossRef]

- Chitsaz, S.; Tarighat, A. Molecular dynamics simulation of N-A-S-H geopolymer macro molecule model for prediction of its modulus of elasticity. Constr. Build. Mater. 2020, 243, 118176. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer: Chemistry Applications, 5th ed; Institut Géopolymère: Saint-Quentin, France, 2020. [Google Scholar]

- White, C.E.; Provis, J.L.; Proffen, T.; Van Deventer, J.S.J. Molecular mechanisms responsible for the structural changes occurring during geopolymerization: Multiscale simulation. AIChE J. 2012, 58, 2241–2253. [Google Scholar] [CrossRef]

- Hoc Thang, N. Geopolymerization: A Review on Physico-chemical Factors Influence to the Reaction Process. J. Polym. Compos. 2020, 8, 1–9. [Google Scholar] [CrossRef]

- Nasir, M.; Mahmood, A.H.; Bahraq, A.A. History, recent progress, and future challenges of alkali-activated binders–An overview. Constr. Build. Mater. 2024, 426, 136141. [Google Scholar] [CrossRef]

- Shehata, N.; Sayed, E.T.; Abdelkareem, M.A. Recent progress in environmentally friendly geopolymers: A review. Sci. Total. Environ. 2021, 762, 143166. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.-Y.; Alrefaei, Y.; Wang, Y.-S.; Dai, J.-G. Recent advances in molecular dynamics simulation of the N-A-S-H geopolymer system: Modeling, structural analysis, and dynamics. Constr. Build. Mater. 2021, 276, 122196. [Google Scholar] [CrossRef]

- Bah, A.; Jin, J.; Ramos, A.O.; Bao, Y.; Ma, M.; Li, F. Arsenic(V) immobilization in fly ash and mine tailing-based geopolymers: Performance and mechanism insight. Chemosphere 2022, 306, 135636. [Google Scholar] [CrossRef]

- Madirisha, M.M.; Dada, O.R.; Ikotun, B.D. Chemical fundamentals of geopolymers in sustainable construction. Mater. Today Sustain. 2024, 27, 100842. [Google Scholar] [CrossRef]

- Chen, K.; Wu, D.; Xia, L.; Cai, Q.; Zhang, Z. Geopolymer concrete durability subjected to aggressive environments–A review of influence factors and comparison with ordinary Portland cement. Constr. Build. Mater. 2021, 279, 122496. [Google Scholar] [CrossRef]

- Cuccia, V.; Freire, C.B.; Ladeira, A.C.Q. Radwaste oil immobilization in geopolymer after non-destructive treatment. Prog. Nucl. Energy 2020, 122, 103246. [Google Scholar] [CrossRef]

- Guo, B.; Pan, D.; Liu, B.; Volinsky, A.A.; Fincan, M.; Du, J.; Zhang, S. Immobilization mechanism of Pb in fly ash-based geopolymer. Constr. Build. Mater. 2017, 134, 123–130. [Google Scholar] [CrossRef]

- Ji, Z.; Su, L.; Pei, Y. Synthesis and toxic metals (Cd, Pb, and Zn) immobilization properties of drinking water treatment residuals and metakaolin-based geopolymers. Mater. Chem. Phys. 2020, 242, 122535. [Google Scholar] [CrossRef]

- Zhang, Q.; Cao, X.; Sun, S.; Yang, W.; Fang, L.; Ma, R.; Lin, C.; Li, H. Lead zinc slag-based geopolymer: Demonstration of heavy metal solidification mechanism from the new perspectives of electronegativity and ion potential. Environ. Pollut. 2022, 293, 118509. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Wang, K.; Li, Q.; Wang, J.; Ling, Y. Fabrication and engineering properties of concretes based on geopolymers/alkali-activated binders—A review. J. Clean. Prod. 2020, 258, 120896. [Google Scholar] [CrossRef]

- Zhang, W.; Li, J.; Huang, X.; Chen, Z.; Lang, L.; Huang, K. Unraveling the cation adsorption of geopolymer binder: A molecular dynamics study. Chemosphere 2023, 335, 139118. [Google Scholar] [CrossRef] [PubMed]

- Kriven, W.M.; Leonelli, C.; Provis, J.L.; Boccaccini, A.R.; Attwell, C.; Ducman, V.S.; Ferone, C.; Rossignol, S.; Luukkonen, T.; Van Deventer, J.S.J.; et al. Why geopolymers and alkali-activated materials are key components of a sustainable world: A perspective contribution. J. Am. Ceram. 2024, 107, 5159–5177. [Google Scholar] [CrossRef]

- Xie, R.; Ge, R.; Li, Z.; Qu, G.; Zhang, Y.; Xu, Y.; Zeng, Y.; Li, Z. Synthesis and influencing factors of high-performance concrete based on copper tailings for efficient solidification of heavy metals. J. Environ. Manag. 2023, 325, 116469. [Google Scholar] [CrossRef]

- Wan, Q.; Rao, F.; Song, S.; Zhang, Y. Immobilization forms of ZnO in the solidification/stabilization (S/S) of a zinc mine tailing through geopolymerization. J. Mater. Res. Technol. 2019, 8, 5728–5735. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, Y.; Guo, Z.; Ding, H. Stabilization/solidification of hexavalent chromium containing tailings using low-carbon binders for cemented paste backfill. J. Environ. Chem. Eng. 2021, 9, 104738. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, Z.; Zhou, X.; Wang, J.; Liu, D. Simultaneous stabilization/solidification of arsenic in acidic wastewater and tin mine tailings with synthetic multiple solid waste base geopolymer. J. Environ. Manag. 2022, 320, 115783. [Google Scholar] [CrossRef]

- Alcayaga Restelli, A.; Avudaiappan, S.; Arrué Muñoz, R.F.; Canales, C.; Gómez, R. Tailings as a Sustainable Resource in 3D Printed Concrete for the Mining Industry: A Literature Review. In Recent Advances on the Mechanical Behaviour of Materials; Saavedra Flores, E.I., Astroza, R., Das, R., Eds.; Springer Nature: Cham, Switzerland, 2024; Volume 462, pp. 89–107. [Google Scholar] [CrossRef]

- Hossain, M.A.; Zhumabekova, A.; Paul, S.C.; Kim, J.R. A Review of 3D Printing in Construction and its Impact on the Labor Market. Sustainability 2020, 12, 8492. [Google Scholar] [CrossRef]

- Xiao, J.; Ji, G.; Zhang, Y.; Ma, G.; Mechtcherine, V.; Pan, J.; Wang, L.; Ding, T.; Duan, Z.; Du, S. Large-scale 3D printing concrete technology: Current status and future opportunities. Cem. Concr. Res. 2021, 122, 104115. [Google Scholar] [CrossRef]

- Khan, M.S.; Sanchez, F.; Zhou, H. 3-D printing of concrete: Beyond horizons. Cem. Concr. Res. 2020, 133, 106070. [Google Scholar] [CrossRef]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D Printing of Buildings and Building Components as the Future of Sustainable Construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef]

- Wang, Y. Application and Development Prospect of 3D Printing Concrete Material in Construction Field. In Proceedings of the 2024 8th International Conference on Civil. Architecture and Structural Engineering (ICCASE 2024), Guangzhou, China, 19–21 April 2024; Yuan, B., Bilgin, H., Luo, Q., Han, Z., Eds.; Atlantis Press International BV: Dordrecht, The Netherlands, 2024; Volume 33, pp. 407–419. [Google Scholar] [CrossRef]

- Mahadevan, M.; Francis, A.; Thomas, A. A simulation-based investigation of sustainability aspects of 3D printed structures. J. Build. Eng. 2020, 32, 101735. [Google Scholar] [CrossRef]

- Sovetova, M.; Calautit, J.K. Influence of printing parameters on the thermal properties of 3D-printed construction structures. Energy 2024, 305, 132265. [Google Scholar] [CrossRef]

- Hou, S.; Duan, Z.; Xiao, J.; Ye, J. A review of 3D printed concrete: Performance requirements, testing measurements and mix design. Constr. Build. Mater. 2021, 273, 121745. [Google Scholar] [CrossRef]

- De Souza, E.A.; Borges, P.H.R.; Stengel, T.; Nematollahi, B.; Bos, F.P. 3D printed sustainable low-cost materials for construction of affordable social housing in Brazil: Potential, challenges, and research needs. J. Build. Eng. 2024, 87, 108985. [Google Scholar] [CrossRef]

- Zaid, O.; El Ouni, M.H. Advancements in 3D printing of cementitious materials: A review of mineral additives, properties, and systematic developments. Constr. Build. Mater. 2024, 427, 136254. [Google Scholar] [CrossRef]

- Besklubova, S.; Skibniewski, M.J.; Zhang, X. Factors Affecting 3D Printing Technology Adaptation in Construction. J. Constr. Eng. Manag. 2021, 147, 04021026. [Google Scholar] [CrossRef]

- Bedarf, P.; Dutto, A.; Zanini, M.; Dillenburger, B. Foam 3D printing for construction: A review of applications, materials, and processes. Autom. Constr. 2021, 130, 103861. [Google Scholar] [CrossRef]

- Furet, B.; Poullain, P.; Garnier, S. 3D printing for construction based on a complex wall of polymer-foam and concrete. Addit. Manuf. 2019, 28, 58–64. [Google Scholar] [CrossRef]

- Schuldt, S.J.; Jagoda, J.A.; Hoisington, A.J.; Delorit, J.D. A systematic review and analysis of the viability of 3D-printed construction in remote environments. Autom. Constr. 2021, 125, 103642. [Google Scholar] [CrossRef]

- Han, Y.; Yang, Z.; Ding, T.; Xiao, J. Environmental and economic assessment on 3D printed buildings with recycled concrete. J. Clean. Prod. 2021, 278, 123884. [Google Scholar] [CrossRef]

- Leles Da Silva, M.D.; Silva, L.F.; Toralles, B.M.; Cardoso, F.A.R.; Corso, M.; Soto Herek Rezende, L.C. Building a sustainable future: The role of additive manufacturing in civil construction. Case Stud. Constr. Mater. 2024, 20, e02976. [Google Scholar] [CrossRef]

- Setaki, F.; Van Timmeren, A. Disruptive technologies for a circular building industry. Build. Environ. 2022, 223, 109394. [Google Scholar] [CrossRef]

- Lv, X.; Qin, Y.; Liang, H.; Cui, X. Effects of modifying agent on rheology and workability of alkali-activated slag paste for 3D extrusion forming. Constr. Build. Mater. 2021, 302, 124062. [Google Scholar] [CrossRef]

- Xia, M.; Sanjayan, J.G. Methods of enhancing strength of geopolymer produced from powder-based 3D printing process. Mater. Lett. 2018, 227, 281–283. [Google Scholar] [CrossRef]

- Lu, H.; Wang, J.; Zhan, X.; Zhao, P.; Xie, Z.; Wang, S.; Yue, Z. Effects of retarders on the rheological properties of coal fly ash/superfine iron tailings-based 3D printing geopolymer: Insight into the early retarding mechanism. Constr. Build. Mater. 2024, 411, 134445. [Google Scholar] [CrossRef]

- Zhang, D.-W.; Wang, D.; Lin, X.-Q.; Zhang, T. The study of the structure rebuilding and yield stress of 3D printing geopolymer pastes. Constr. Build. Mater. 2018, 184, 575–580. [Google Scholar] [CrossRef]

- Zhou, Z.; Geng, J.; Jin, C.; Liu, G.; Xia, Z. Influence of Residue Soil on the Properties of Fly Ash–Slag-Based Geopolymer Materials for 3D Printing. Materials 2024, 17, 2992. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, N.; Yuan, J.; Zhao, J.; Zhang, J.; Zhang, Y. Mortar Designed from Red Mud with Iron Tailings and Moulded by 3D Printing. Bull. Environ. Contam. Toxicol. 2022, 109, 95–100. [Google Scholar] [CrossRef]

- Zhou, L.; Gou, M.; Zhang, H. Investigation on the applicability of bauxite tailings as fine aggregate to prepare 3D printing mortar. Constr. Build. Mater. 2023, 364, 129904. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V.; Soriano, L.; Tashima, M.M. “Alternative activators in alkali-activated cements”. Rev. ALCONPAT 2022, 12, 16–31. [Google Scholar] [CrossRef]

- Pintos, S.; Freire, L.; Rodríguez, P.; Guzmán, G.J.; Fernández, J.; Lago, J.M.; Trancón, C. Cell geopolymers: Development of ecological light concrete without cement (GEOCEL project). Rev. Mater. Compuestos 2022, 4, 19. Available online: https://www.scipedia.com/public/Pintos_et_al_2022b (accessed on 24 February 2025). [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Singh, A.; Wang, Y.; Zhou, Y.; Sun, J.; Xu, X.; Li, Y.; Liu, Z.; Chen, J.; Wang, X. Utilization of antimony tailings in fiber-reinforced 3D printed concrete: A sustainable approach for construction materials. Constr. Build. Mater. 2023, 408, 133689. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, C.; Ma, J.; Jiao, H.; Kim, M. Utilization of solid mine waste in the building materials for 3D printing. PLoS ONE 2023, 18, e0292951. [Google Scholar] [CrossRef]

- Álvarez-Fernández, M.-I.; Prendes-Gero, M.-B.; González-Nicieza, C.; Guerrero-Miguel, D.-J.; Martínez-Martínez, J.E. Optimum Mix Design for 3D Concrete Printing Using Mining Tailings: A Case Study in Spain. Sustainability 2021, 13, 1568. [Google Scholar] [CrossRef]

- Acordi, J.; Simão, L.; Faraco, M.N.S.; Borgert, C.H.; Olivo, E.; Montedo, O.R.K.; Raupp-Pereira, F. Waste valorization of coal mining waste from a circular economy perspective: A Brazilian case study based on environmental and physicochemical features. Resour. Policy 2023, 80, 103243. [Google Scholar] [CrossRef]

- Marinina, O.; Kirsanova, N.; Nevskaya, M. Circular Economy Models in Industry: Developing a Conceptual Framework. Energies 2022, 15, 9376. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Tayeh, B.A.; Zeyad, A.M.; De Azevedo, A.R.G.; Ahmed, H.U.; Emad, W. Recycling of mine tailings for the geopolymers production: A systematic review. Case Stud. Constr. Mater. 2022, 16, e00933. [Google Scholar] [CrossRef]

- Lu, X.; Tian, Y.; Jiskani, I.M.; Zhou, W.; Zhao, B.; Ding, X.; Ao, Z. Innovate geopolymer synthesis for green mine road construction: Analysis of efflorescence behavior and strength analysis. Constr. Build. Mater. 2023, 401, 132963. [Google Scholar] [CrossRef]

- Gao, Z.; Li, Y.; Qian, H.; Wei, M. Environmental, economic, and social sustainability assessment: A case of using contaminated tailings stabilized by waste-based geopolymer as road base. Sci. Total Environ. 2023, 888, 164092. [Google Scholar] [CrossRef] [PubMed]

- Kodikara, J.; Sounthararajah, A.; Chen, L. Reimagining unbound road pavement technology: Integrating testing, design, construction and performance in the post-digital era. Transp. Geotech. 2024, 47, 101274. [Google Scholar] [CrossRef]

- Esmaeili, J.; Aslani, H.; Onuaguluchi, O. Reuse Potentials of Copper Mine Tailings in Mortar and Concrete Composites. J. Mater. Civ. Eng. 2020, 32, 04020084. [Google Scholar] [CrossRef]

| Type of Tailings | Raw Material/Average Particle Size | Relationships Between Reactants and Reagents and Water (pH) | Temperature (Ta), Activation and Curing Time (CT) | References |

|---|---|---|---|---|

| Ilmenite (TiO2) Titanium mine (Engebø, Naustdal, Norway) | MT/Slag-0.5: 40%; 16 µm GGBFS: 60%, 6–10 µm, BF: 10–20 µm | Sodium Silicate (SiO2/Na2O):1.5 pH: 12.5 S/L: 0.34/NaOH 10 M, Na2SiO3 (35% solids), Superplasticizer FLUBE OS 39 (1.5%) | Tª: 25 °C CT: 28 days | [56] |

| MT/Slag-0.5: 40%, 16 µm GGBFS: 60%, 6–10 µm BF: 0.5%, 10–20 µm | Sodium Silicate (SiO2/Na2O):1.5 pH: 12.5 S/L: 0.34/NaOH 10 M, Na2SiO3 (35% solids), Superplasticizer FLUBE OS 39 (1%) | |||

| Iron tailings (SIT) hematite (Fe2O3) Maanshan Nanshan Mining Co., Ltd. (Maanshan, China) | CS-3DPG (sin CSA) SIT 46.7%, 40 µm, CFA: 22.94%, 50 µm | S/L: 38% Alkaline activator module (SiO2/Na2O): 1 Na2SiO3 (30%), NaOH (6%) SC (0.4%) as a retarder | Tª: 25 ± 1 °C HR: 50% ± 5% CT: 28 days | [53] |

| SIT: 50%, 40 µm CFA: 44%, 50 µm CSA: 6% | S/L: 38% Alkaline activator module (SiO2/Na2O): 1 Na2SiO3 (30%), NaOH (6%) SC (0.4%), CSA (6%) as an accelerator | |||

| Iron tailings (SIT) hematite (Fe2O3) Maanshan Nanshan Mining Co., Ltd. (Maanshan, China) | SC Retarder-Free Mixture SIT 80%: 19.8 µm, CFA 20%: 30 µm | S/L: 38% Alkaline activator module (SiO2/Na2O): 1 NaOH Not specified Na2SiO3 (6%); SC (0.4%) | Tª: 25 °C ± 1 °C, HR: 50% ± 5% | [125] |

| Mix with 0.4% SC SIT 80%: 19.8 µm CFA 20%: 30 µm | S/L: 38% Alkaline activator module (SiO2/Na2O): 1 NaOH Not specified Na2SiO3 (6%); SC (0.4%) |

| System | Mechanical and Setting Properties | Microstructure and Chemical Composition Properties | Rheological and 3D Printing Properties | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compressive Strength (UCS) | Flexural Strength | Setting Time | SEM/EDS | XRD | FTIR | Rheology/Thixotropy | Form Stability | Workability | Extrudability | Buildability | Vol. Pores | References | |

| MPa | min | % | % | ||||||||||

| MT/Slag-0.5 | 31 | 4.8 | 120 | Dense, without fibers | ND | ND | 1000 Pa·s (Viscosity at 0.1 s−1) | 4 | 155 (0% fiber) | 5 | 10 | 12 | [56] |

| MT/Slag-0.5 with BF | 28 | 5.5 | 170 | Porous microstructure with matrix-fiber separation | ND | ND | 700 Pa·s (Viscosity at 0.1 s−1) | Lower stability with fibers, deformation > 18% | 145 mm (0.5% fiber) | 30 | 8 | 16 | |

| CS-3DPG (without CSA) | 21.5 (3 days) 28.3 (7 days) 35.8 (28 days) | 4.2 | 15 | Dense texture 10% porosity | Gelatinous phases such as N–A–S–H and C–(A)–S–H | More compact gel with a higher proportion of Si-O bonds. | Yield stress of 284.5 Pa and plastic viscosity of 18.8 Pa·s | Good stability, no deformation | Good (flow-through) 187 mm | 30 | Stable formation, layer height 1 cm | 35 | [53] |

| CS-3DPG (with CSA) | 24.18 (3 days) 28.00 (28 days) | 5 | 9 | C–(A)–S–H gel near calcium carbonate. | C–(A)–S–H and N–A–S–H phases. A higher density was observed in the samples with 6% CSA. | C–(A)–S–H and N–A–S–H gels | Yield stress of 778.5 Pa and plastic viscosity of 38.5 Pa·s after the addition of CSA | Ability to maintain up to 11 layers without deformation, indicating high stability in 3D construction | Very good (high fluidity) 173 mm for mixing with CSA | 30 | High buildability and adequate structural support | 30 | |

| without Retardants (SC) | 22.29 (3 days) 33.07 (28 days) | ND | 514 | C–(A)–S–H and N–A–S–H gels were observed | C–(A)–S–H and N–A–S–H gels | Formation of C–(A)–S–H and N–A–S–H gels | Evaluation of plastic viscosity and shear stress.284 Pa (stress), 18.8 Pa⋅s | Stable form | Good | 30 | Adequate | ND | [125] |

| with Retarders (SC) | 19.80 (3 days) 32.14 (28 days) | ND | 698 | C–(A)–S–H and N–A–S–H gels and unreacted components were observed. | Less gel formation | A decrease in the intensity of the Si–O–T peak was observed compared to CS-3DPG. | Evaluation of plastic viscosity and shear stress.248.2 Pa (stress), 16.43 Pa·s | Stable form | Enhanced with SC | 30 | Enhanced with SC | ND | |

| Type of Raw Material | Raw Material/ Average Particle Size | Relationships Between Reactants and Reagents and Water (pH) | Temperature (Tª), Humidity (H), Activation Time (AT) and Curing Time (CT) | References |

|---|---|---|---|---|

| GGBS and FA supplied by Independent Cement and Lime Pty Ltd., (Melbourne, Australia) | GGBS: 50%, 14 µm FA: 50%, 10 µm | (Na2SiO3): 10% w/w, (MAS—Magnesio Aluminio Silicato): 0.75% w/w, Retarder (Sucrose): 1.5% w/w S/L: 0.31, SiO2/Al2O3 = 4.42, H2O/Na2O = 22.38 | Tª: 23.5 °C H: 40% CT:24 h | [52] |

| FA: Changsha (China). GGBFS KSC and KF: Changsha, (China). | FA: 78.5%, 50 µm GGBFS: 19.5%, 45 µm KSC: 1.5%, 1000 µm KF: 0.2%, 15,000 µm | Na2SiO3 (42%) + NaOH (96%) 10 M: 20% S/L: 2.5:1 Retarder (Sodium Gluconate) C₆H₁₁NaO₇): 1% SiO2/Na2O: 1 | Tª: 25 °C AT: 54 min CT: 28 days | [18] |

| FA: Ningbo (China); GGBS: Ningbo (China); RS: Construction site in Ningbo City; Superplasticizer: Zhejiang Province | FA: 64%, 16.90 µm GGBS: 16% RS: 20% | Na2SiO3 (17.74%) 12 M NaOH 8 M (2.35%) Superplasticizer Polycarboxylate (0.67%) | Tª: 20 ± 2 °C AT: 24 min CT: 28 days | [127] |

| Ash from paper mill boiler (AP), construction and demolition wasten (C&D), metakaolin, sand (coarse and fine), recycled glass wool (Finland) | AP: 7%, 50–100 µm C&D: 10%, 4000 µm, metakaolin: 13%, 2–10 µm, Course MT: 30%, 1000–2000 µm Fine MT: 9%, 100–500 µm Glass wool: 2%, 3 mm | S/L: 3:1 (Na2SiO3): 10 M | Tª: 60 °C by 24 h in oven, followed by 48 h at room temperature CT: 28 days | [54] |

| BFS: Capital Iron and Steel, Beijing (China) Steel Slag (SS) Beijing, (China) | BFS: 81%, ~10 µm SS: 9%, ~20 µm | S/L: 0.35 Na2SiO3 10 M: 8.1% NaOH 8 M: 0.9% Defoamer (0.5%) Superplasticizer (1%) Redispersible latex (1%) 0.5 Si/Na ratio (best performance), 0.6, 0.7, 0.8, 0.9, 1.0 | Tª: 25 °C CT: 7 days | [126] |

| Compressive Strength (UCS) | Flexural Strength | Setting Time | Rheology and Thixotropy | Form Stability | Workability | Extrudability | Buildability | References |

|---|---|---|---|---|---|---|---|---|

| MPa | MPa | min | Fluency | Layer height | Nº of layers | |||

| At 28 days: Perpendicular: 37 Lateral: 35 Longitudinal: 32 | At 28 days: Perpendicular: 6 Lateral: 5.5 Longitudinal: 5 | 40 | Yield Stress: Increases with time, 4500 Pa at 60 min (10ACT) Apparent Viscosity: Decreases with shear rate; initial values close to 10,000 Pa·s for 10ACT | 70% after extrusion; good recovery to ensure shape stability | decreases with increasing activator content. | Good Easily extruded without blockages during the printing process | Stable; >120 layers without collapsing (height 1.4 m) | [52] |

| ND | 10.56 | 57 | Initial viscosity of 0.75 × 106 mPa·s viscosity after extrusion of 8.24 × 106 mPa·s | SRRt (shape retention in thickness): 96%, SRRw (shape retention in width): 96% | Excellent extrudability and shape retention in multi-layer prints | The mixture was extruded smoothly through the nozzle, showing good fluidity. | 6 layers | [18] |

| 29 | N/D | Initial: 42 End: 58 | Plastic Viscosity 7.98 (Pa·s) Apparent Viscosity 1500 (Pa·s) Static Yield Stress 2800 (Pa) | Layer Height 160 mm | fluidity in range 155–160 mm | Layer Height 24 mm | 47 layers without deformation | [127] |

| 12.02 (28 days) | 6.7 | A: 38–44 (20 °C) + 23 (60 °C) B: shorter setting time as tª increases | Initial viscosity: 1200–1500 Pa·s; viscosity increase to 2200 Pa·s after 10 min standing; Reflow time: 5–8 s after 10 min standing Thixotropy improved with heating to 60 °C; Flow index: 0.87 at 20 °C (indicates pseudoplastic behavior) | A: deformation 4.1 mm at 20 °C 1.6 mm at 100 °C B: deformation 2.5 mm at 20 °C 1.8 mm at 100 °C | Adjustable with water/silicate ratios optimal with 28–31% liquid volume | Stable layer height after 10 min of mixing; maximum 20 min of extrudability without loss of shape | Up to 20 layers with good shape retention in extrusion tests | [54] |

| Max. 53.04 for Si/Na = 0.9 37.90 for Si/Na = 0.5 | ND | ND | Plastic Viscosity (η) 0.78 Pa·s for Si/Na = 0.5; decreases with increasing Si/Na, 0.42 Pa·s for Si/Na = 1.0 Yield Stress (s₀)—20 min 5.30 Pa for Si/Na = 1.0; increases with decreasing Si/Na to 3.439 Pa (Si/Na = 0.5) | Structural Recovery (SRE) The best mix has a SRE of 132 J/s m2 for Si/Na = 0.5 after 20 min, | Stress Development increase from 1.71 Pa (1 min) to 5.3 Pa (20 min), depending on rest time and Si/Na | Layer Evaluated by printing in 10 mm layers | Maximum stability with Si/Na = 0.5, supporting 20 layers | [126] |

| Raw Material | S/L | Temperature, Activation Time and Curing | SEM and EDS | XRD | Compressive Strength (UCS) | Flexural Strength | References |

|---|---|---|---|---|---|---|---|

| MPa | MPa | ||||||

| Red Mud: 15% FA: 9% Iron MT: 45% PC: 24% BSC: 0% FDN: 1% | 0.183 | Tª: 20 °C CT: 7–28 days | C–S–H, ettringite, Ca(OH)2 observed; compact microstructure with aggregates wrapped in C–S–H gel | Quartz, calcite, hematite and gibbsite in red mud; calcite, clinochlore, and magnesiohornblende in iron MT | 39 (28 days) | 11.91 (28 days) | [128] |

| Sand: 65% Bauxite MT: 35% PC: 42.5% SAC: 0.125 SP: 0.03 HPMC: 0.002 Water: 0.31 | 3.2:1 | Tª: 20 °C CT: 60 days | ND | ND | Max. 48 (60 days) 24 (3 days) 32 (7 days) | Max. 8 (60 days) 4 (3 days) 5 (7 days) | [129] |

| PC: 69.96% FA: 19.99% SF: 9.99% Cu MT: 29.98% PP: 0.055% | 0.26 | Tª: 20 °C CT: 28 days | ND | ND | 53.2 (28 days) | Molded: 7.0 Printed: 4.8 | [132] |

| Fe MT: (40%) Cu MT: (10%) FA (19%) BC (30%) FDN (1%) | 0.20 | Tª: 20 °C CT: 7–28 days | Three-dimensional structure of C–S–H and ettringite crystals, forming a dense matrix | Quartz, ettringite, calcite, albite, perovskite, Ca2SiO4, and C-S-H gel | 45.2 | 8.2 | [42] |

| PC: 40.63% SF: 4.06% Si sand: 11.30% Sb MT: 29.32% | 0.35 PVA: 0.12% HPMC: 0.04% SP: 0.29% Na-G: 1 g Nanoclay: 3 g water: 14.22% | Tª: 20 °C CT: 7–28 days | Improved microstructure with reduced porosity and cracks | Detection of C-S-H phases and pozzolanic reactions | 105 | 7.0 | [133] |

| Sand: 24% Limestone powder: 16% PC: 23.3% FA: 10% Water: 10% PCE: 0.083% | 0.45 | Tª: 20 °C CT: 7–28 days | dense structures with minimal transition zone | ND | 50.39 | ND | [134] |

| MT 20% PC: 20% MasterRheobuild-1000: (1.0%) MasterSet AC 100: (1.0%) | 4 | Tª: ~25 °C CT: 28 days | ND | ND | 26.6 (28 days) | 4 | [135] |

| Setting Time | Hydration Kinetics Analysis | Rheology and Thixotropy | Form Stability | Workability | Extrudability | Buildability | Density | Environmental Toxicity Testing | References |

|---|---|---|---|---|---|---|---|---|---|

| Min | g/cm3 | ||||||||

| Initial: 50 End: 85 | ND | Fluidity adjusted to 205 mm | ND | Good | 3 cm in diameter | ND | ND | Values below the limits established in GB 8978-1996 | [128] |

| 44 | Greater hydration delay with higher glue content | 12,000 Pa·s | Deformación estructural: 1.4% | Good | Good | Good | 2.43 | ND | [129] |

| ND | ND | Fluency—V-Funnel Test (s) 22.1 (R0) to 26.4 s (R50) | 40–50 min of rest | Good | High: 5.4 L/min, continuous up to 80 min | 138 mm | ND | ND | [132] |

| Initial: 50 End: 82 | ND | Flow: 197.5 mm, suitable for 3D extrusion | High, allows maintaining the integrity of the layers during printing | Suitable for continuous extrusion; good interlayer adhesion and shape stability | High; material is extruded evenly without obstructions in the system | High; supports prints up to 1.8 m × 1.8 m × 1.8 m | 2.03 | Values below the limits established in GB 8978-1996 | [42] |

| ND | ND | HPMC controlled and super-suitable for 3D printing | High, suitable for layer-by-layer extrusion | Improved with SP and other optimal 3D printing | High, with speed of 8830 mm3/s | Maximum printing height: 480 mm | 2.25 | In progress; preliminary results within safe limits | [133] |

| Initial: 75 End: 120 | ND | Slump 8.18 cm at 20 min (within optimal range of 3.5–8 cm for printability) Extension Diameter 20.26 cm on jump table test at 20 min (within range of 17–20.5 cm) | Good (4%) | Aspect Ratio Aℎw 3.5 (optimal), indicating high structural stability in layers | Volumetric Contraction (%) 0.6% at 180 min, showing moderate stability | Good, with stable shape maintenance during layer-by-layer printing | ND | ND | [134] |

| 60 | ND | Dimensional Stability in Fluidity (cm) At 1 min: 19.0 × 19.0 At 10 min: 20.0 × 21.0 At 20 min: 19.5 × 20.0 | 2.5 cm of bearable height every 7 min | (Mini Abrams Cone) Extension 77, 73 × 75 | Joint Adhesion Strength (MPa) 1.67 | At 7 min per 2.5 cm layer: construction of up to 1 m in 4.6 h | ND | ND | [135] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales Aranibar, C.G.; La Rosa Toro Gómez, A.; da Silva, J.L.; Morales-Aranibar, L.; Arán, D. Reuse of Mine Tailings Through Geopolymerization Applied to 3D Printing: A Review of Progress, Challenges and Perspectives. Sustainability 2025, 17, 2617. https://doi.org/10.3390/su17062617

Morales Aranibar CG, La Rosa Toro Gómez A, da Silva JL, Morales-Aranibar L, Arán D. Reuse of Mine Tailings Through Geopolymerization Applied to 3D Printing: A Review of Progress, Challenges and Perspectives. Sustainability. 2025; 17(6):2617. https://doi.org/10.3390/su17062617

Chicago/Turabian StyleMorales Aranibar, Carlos Genaro, Adolfo La Rosa Toro Gómez, José Luiz da Silva, Luis Morales-Aranibar, and Diego Arán. 2025. "Reuse of Mine Tailings Through Geopolymerization Applied to 3D Printing: A Review of Progress, Challenges and Perspectives" Sustainability 17, no. 6: 2617. https://doi.org/10.3390/su17062617

APA StyleMorales Aranibar, C. G., La Rosa Toro Gómez, A., da Silva, J. L., Morales-Aranibar, L., & Arán, D. (2025). Reuse of Mine Tailings Through Geopolymerization Applied to 3D Printing: A Review of Progress, Challenges and Perspectives. Sustainability, 17(6), 2617. https://doi.org/10.3390/su17062617