Systematic Digital Twin-Based Development Approach for Holistic Sustainable Electric Traction Motors

Abstract

1. Introduction

2. Materials and Methods (State of the Art)

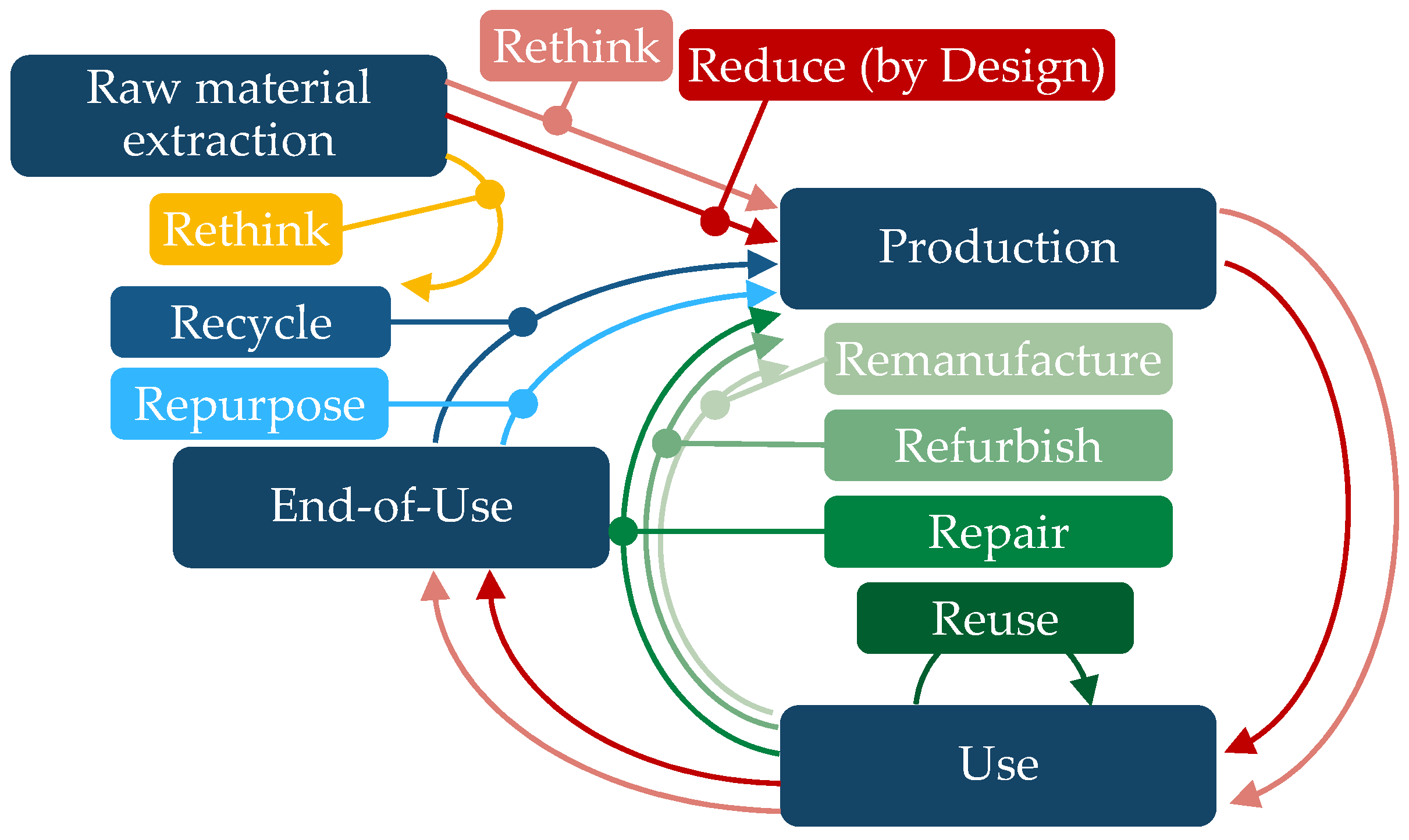

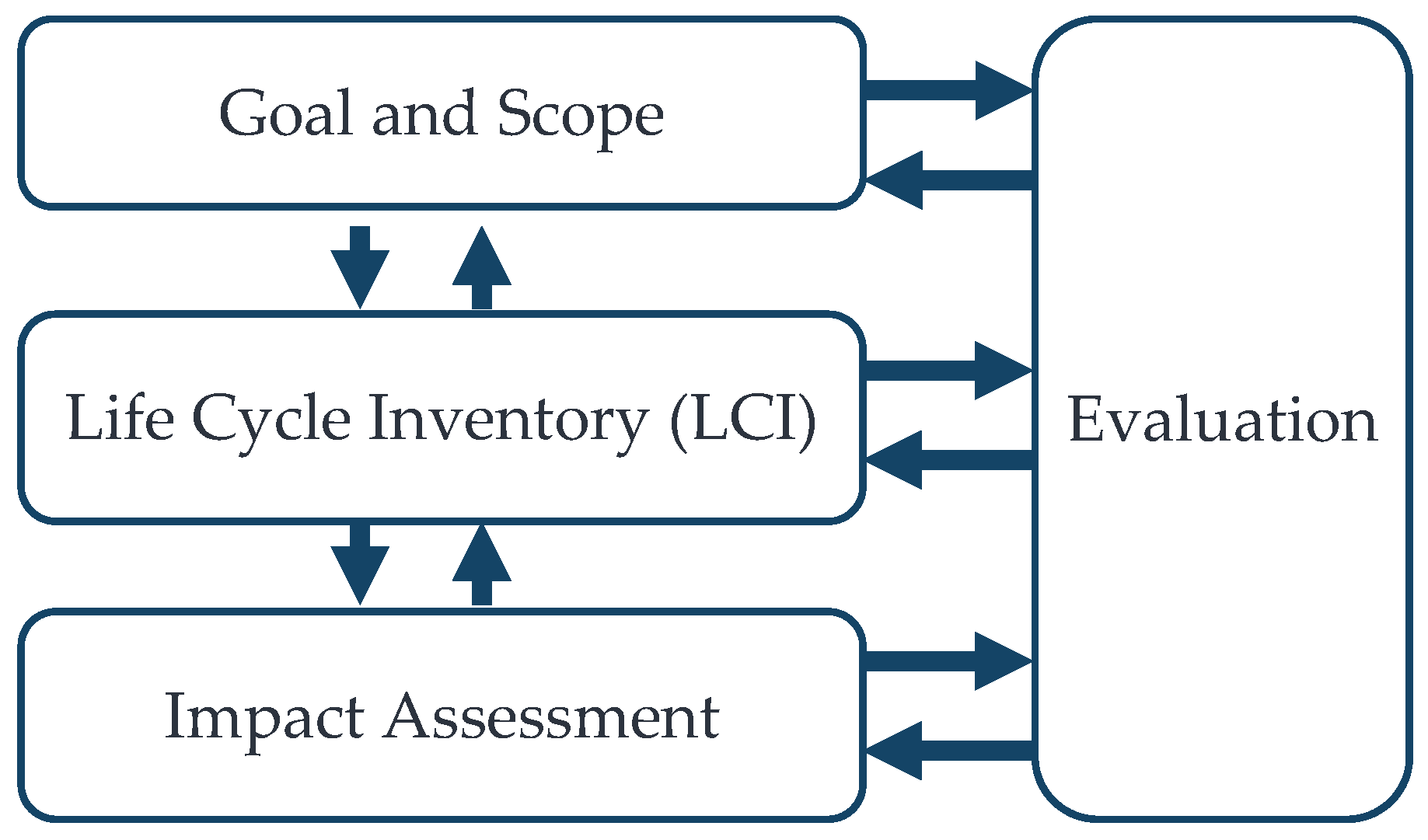

2.1. Lifecycle of a Product and Analyzing Methods

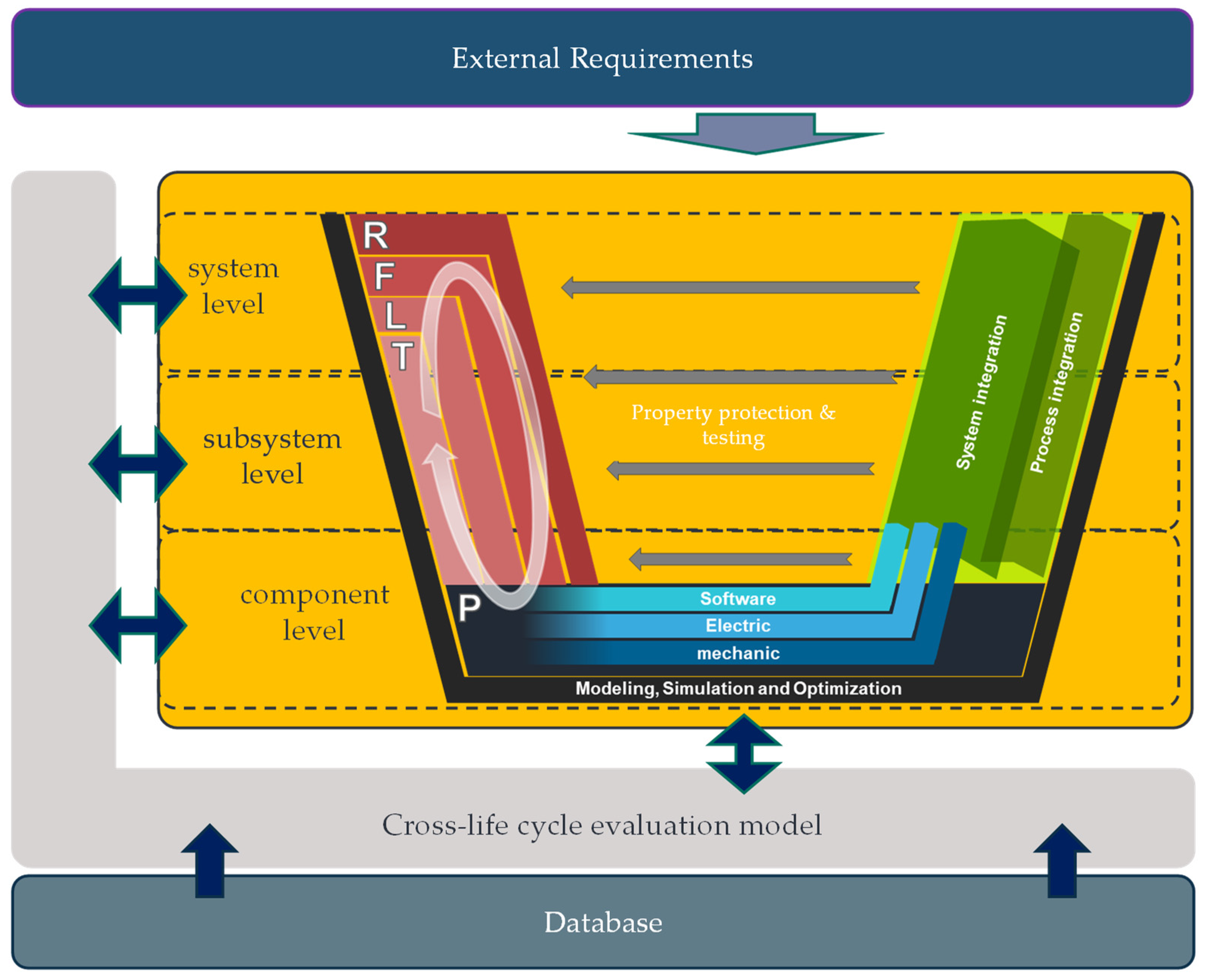

2.2. Development Approaches

2.3. Digital Twin in Manufacturing and Product Development

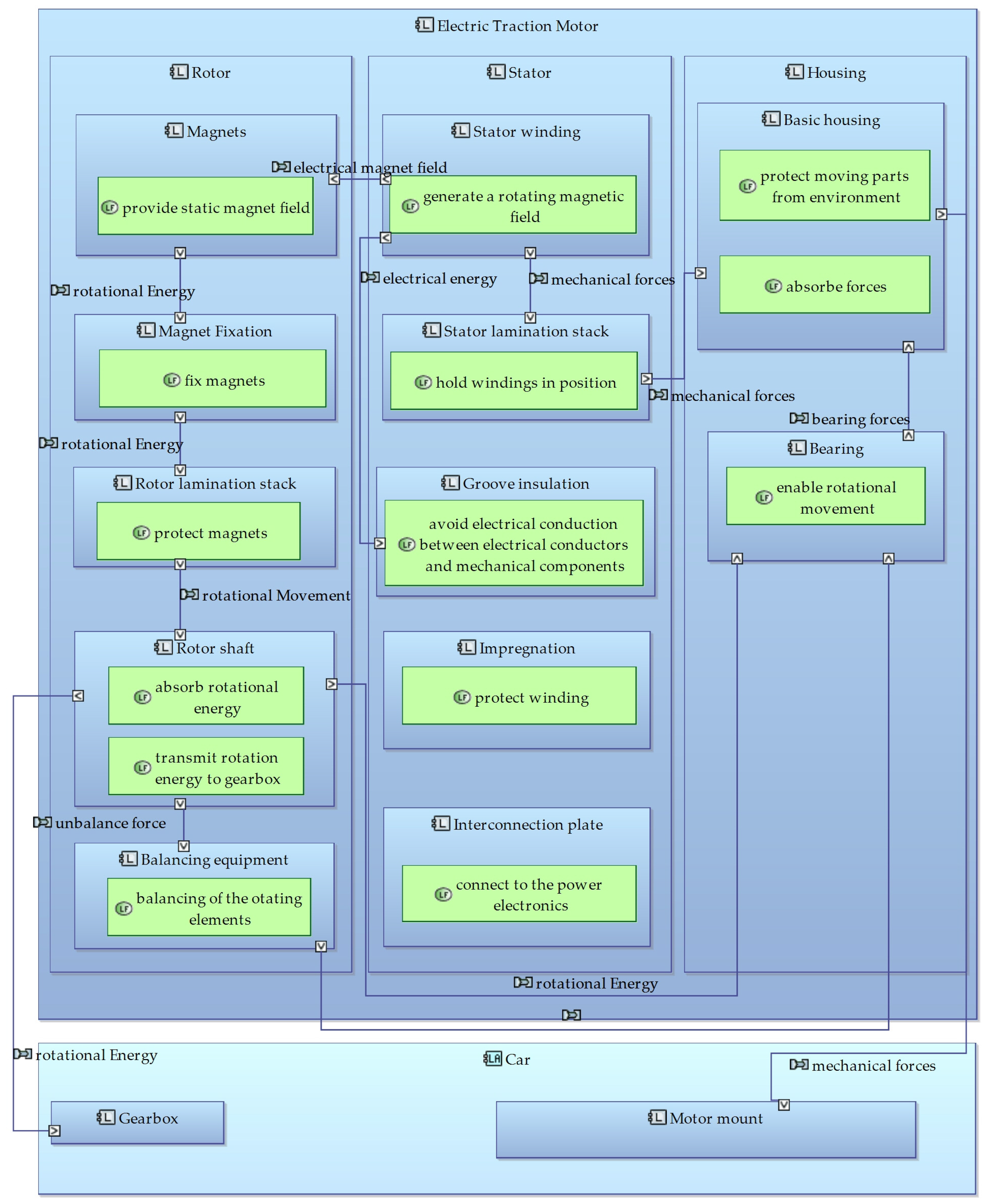

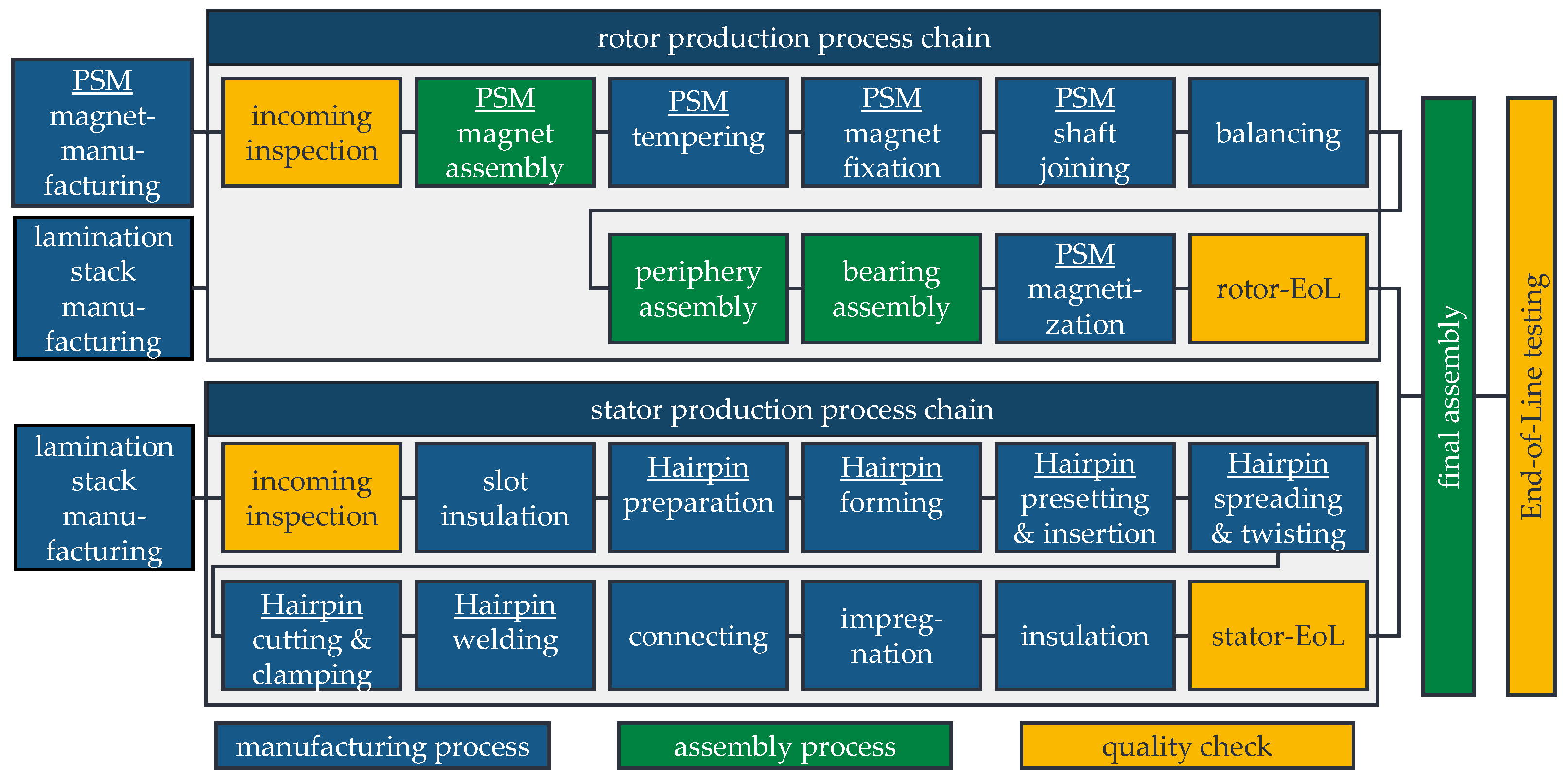

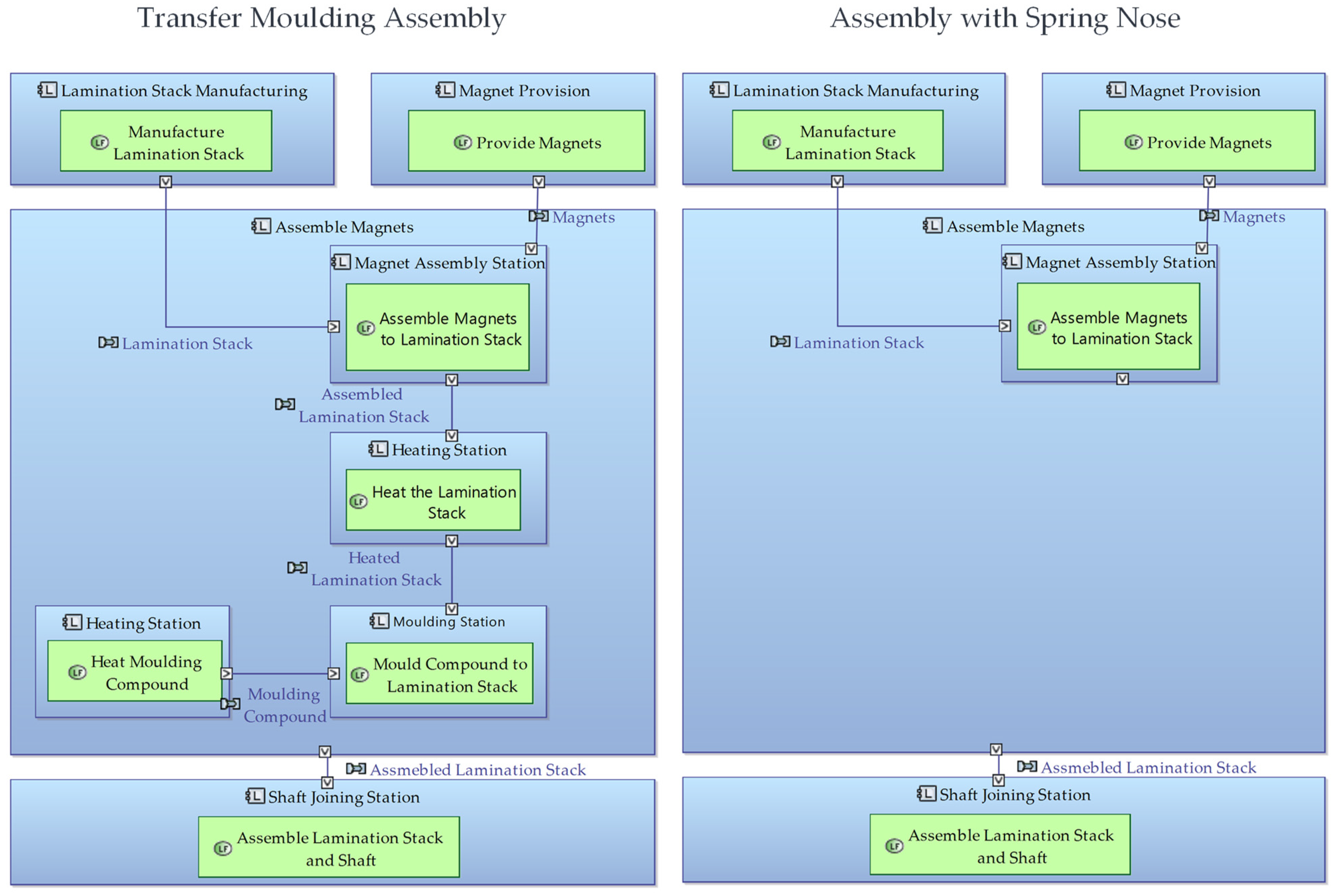

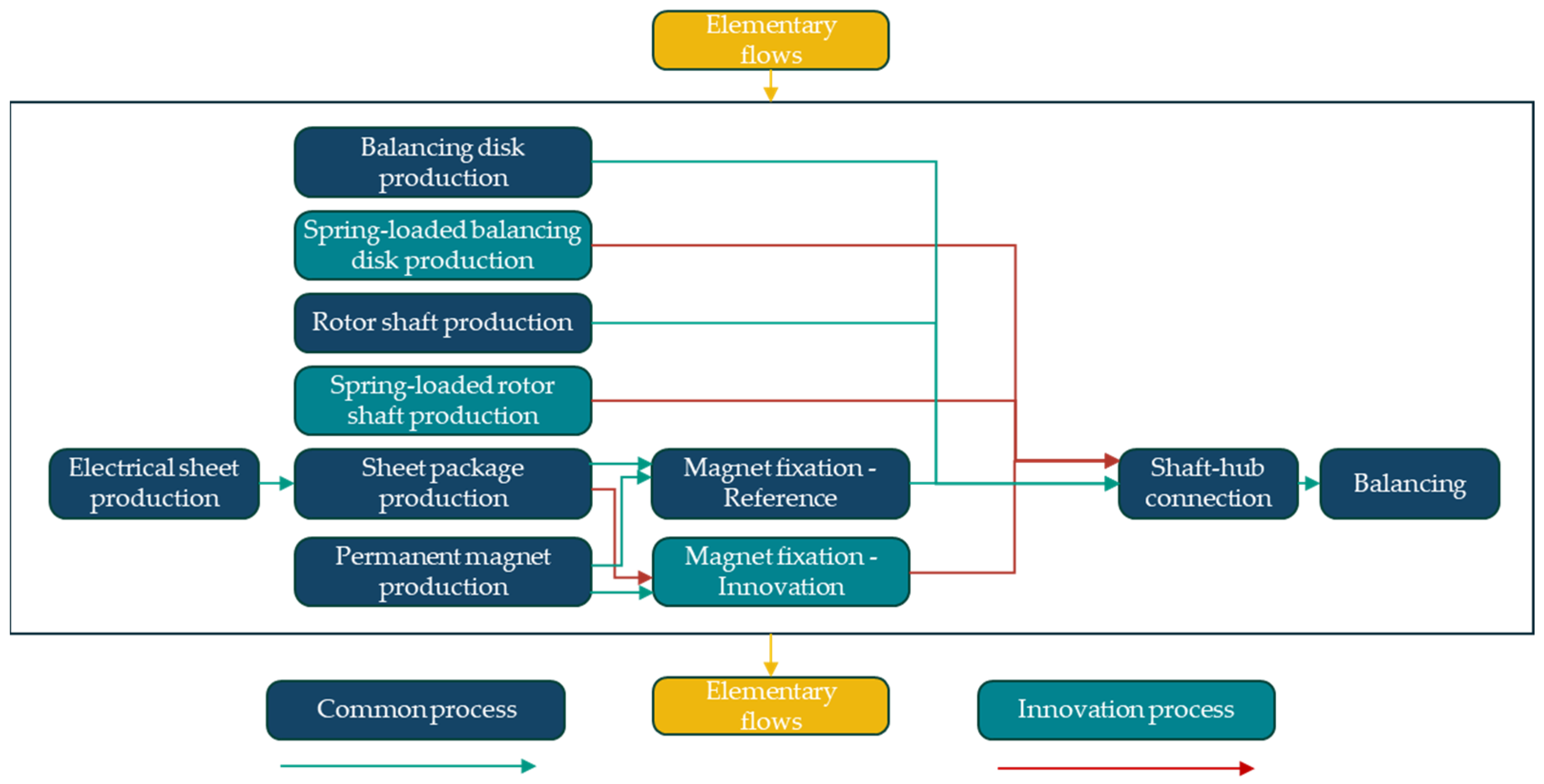

3. Methodology

3.1. Methodology Requirements

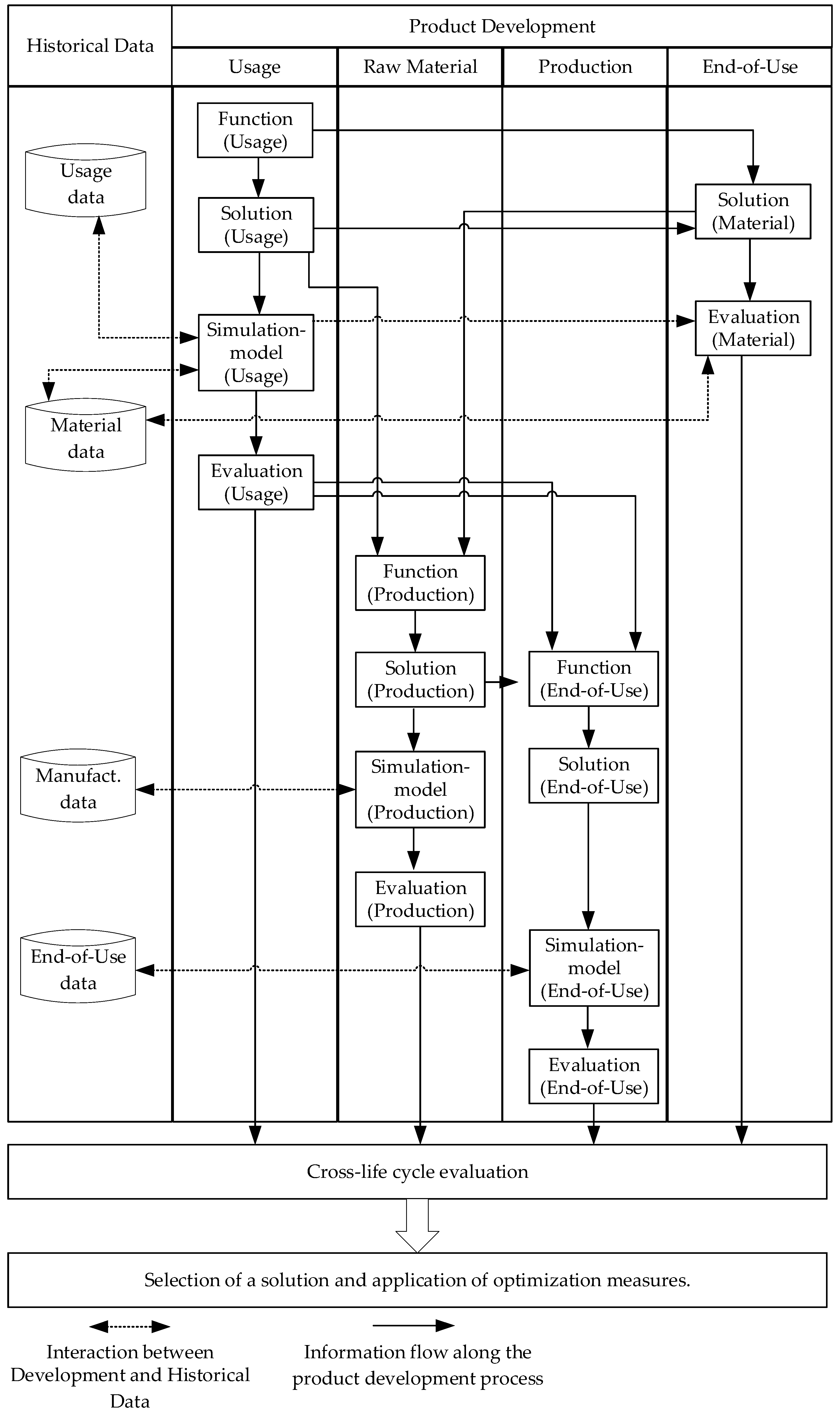

3.2. Cross-Lifecycle Development Approach

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations. Sustainable Development Goals. Available online: https://sdgs.un.org/ (accessed on 10 May 2024).

- Europäische Komission. Der Europäische Grüne Deal. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0021.02/DOC_2&format=PDF (accessed on 31 October 2024).

- European Commission. ‘Fit for 55’: Delivering the EU’s 2030 Climate Target on the Way to Climate Neutrality. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52021DC0550&from=DE (accessed on 31 July 2021).

- Elkington, J. The triple bottom line. Environ. Manag. Read. Cases 1997, 2, 49–66. [Google Scholar]

- DeStatis—Statistisches Bundesamt. Europäischer Green Deal: Klimaneutralität bis 2050. Available online: https://www.destatis.de/Europa/DE/Thema/GreenDeal/GreenDeal.html#798700 (accessed on 31 October 2024).

- Zhang, X.; Xu, Z.; Gerada, C.; Gerada, D. Carbon Emission Analysis of Electrical Machines. In Proceedings of the 2021 24th International Conference on Electrical Machines and Systems (ICEMS), Gyeongju, Republic of Korea, 31 October–3 November 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1678–1683, ISBN 978-8-9865-1021-8. [Google Scholar]

- Linder, M.; Nauclér, T.; Nekovar, S.; Pfeiffer, A.; Vekic, N. The Race to Decarbonize Electric-Vehicle Batteries. Available online: https://www.mckinsey.com/~/media/mckinsey/industries/automotive%20and%20assembly/our%20insights/the%20race%20to%20decarbonize%20electric%20vehicle%20batteries/the-race-to-decarbonize-electric-vehicle-batteries-vf.pdf?shouldIndex=false (accessed on 4 November 2023).

- Stanek, R.; Kirchen, J.; Klein, A.; Rupp, M.; Flemming, J.; Steiner, L.; Knecht, T. Wertschöpfungspotenziale von E-Motoren für den Automobilbereich in Baden-Württemberg: Themenpapier Cluster Elektromobilität Süd-West; e-mobil BW GmbH-Landesagentur für neue Mobilitätslösungen und Automotive: Stuttgart, Germany, 2021. [Google Scholar]

- Qiao, Q.; Zhao, F.; Liu, Z.; Jiang, S.; Hao, H. Cradle-to-gate greenhouse gas emissions of battery electric and internal combustion engine vehicles in China. Appl. Energy 2017, 204, 1399–1411. [Google Scholar] [CrossRef]

- Tong, W. Mechanical Design and Manufacturing of Electric Motors, 2nd ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA; London, UK; New York, NY, USA, 2022; ISBN 9781003097716. [Google Scholar]

- Doppelbauer, M. Introduction to Electromobility; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2024; ISBN 978-3-658-45481-4. [Google Scholar]

- ISO 59004:2024-05; Circular Economy—Vocabulary, Principles and Guidance for Implementation. ISO: Geneva, Switzerland, 2024. Available online: https://www.dinmedia.de/de/norm/iso-59004/380983795 (accessed on 17 December 2024).

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Wößner, W.; Gürbüz, H.; Heim, M.; Klein, N.; Schulz, J.; Fleischer, J. Federnde Rotorkomponenten für elektrische Antriebe. Z. Wirtsch. Fabr. 2022, 117, 667–672. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain: Policy Report; PBL Netherlands Assessment Agency: The Hague, The Netherlands, 2017. [Google Scholar]

- Lanza, G.; Klenk, F.; Martin, M.; Brützel, O.; Hörsting, R. Sonderforschungsbereich 1574: Kreislauffabrik für das ewige innovative Produkt. Z. Wirtsch. Fabr. 2023, 118, 820–825. [Google Scholar] [CrossRef]

- Haynsworth, H.C.; Lyons, T. Remanufacturing by design, the missing link, 28th ed. Prod. Inventory Manag. 1987, 28, 24–29. [Google Scholar]

- Ehrlenspiel, K.; Kiewert, A.; Lindemann, U.; Mörtl, M. Kostengünstig Entwickeln und Konstruieren; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 978-3-642-41958-4. [Google Scholar]

- Scholz, U.; Pastoors, S.; Becker, J.H.; Hofmann, D.; van Dun, R. (Eds.) Praxishandbuch Nachhaltige Produktentwicklung; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 978-3-662-57319-8. [Google Scholar]

- DIN EN ISO 14040:2021-02; Umweltmanagement_-Ökobilanz_-Grundsätze und Rahmenbedingungen (ISO_14040:2006_+ Amd_1:2020); Deutsche Fassung EN_ISO_14040:2006_+ A1:2020. Beuth Verlag GmbH: Berlin, Germany, 2021.

- DIN EN ISO 14044:2021-02; Umweltmanagement_-Ökobilanz_-Anforderungen und Anleitungen (ISO_14044:2006_+ Amd_1:2017_+ Amd_2:2020); Deutsche Fassung EN_ISO_14044:2006_+ A1:2018_+ A2:2020. Beuth Verlag GmbH: Berlin, Germany, 2021.

- Auer, J.; Meincke, A. Comparative life cycle assessment of electric motors with different efficiency classes: A deep dive into the trade-offs between the life cycle stages in ecodesign context. Int. J. Life Cycle Assess. 2018, 23, 1590–1608. [Google Scholar] [CrossRef]

- Grosse Erdmann, J.; Mahr, A.; Derr, P.; Walczak, P.; Koller, J. Comparative Life Cycle Assessment of Conventionally Manufactured and Additive Remanufactured Electric Bicycle Motors; Publish-Ing: Hannover, Germany, 2023. [Google Scholar]

- DIN EN 60300-3-3:2005-03; Zuverlässigkeitsmanagement_-Teil_3-3: Anwendungsleitfaden_-Lebenszykluskosten (IEC_60300-3-3:2004); Deutsche Fassung EN_60300-3-3:2004. DIN Media GmbH: Berlin, Germany, 2005.

- Camargos, P.H.; da Costa, G.F.; Caetano, R.E. Determining the life cycle cost and reliability of an induction motor designed for light vehicle applications: A comparative analysis. Electr. Eng. 2022, 104, 2849–2858. [Google Scholar] [CrossRef]

- Dietz, T.; Pott, A.; Hägele, M.; Verl, A. A new, uncertainty-aware Cost-model for cost-benefit assessment of robot systems. In Proceedings of the IEEE ISR 2013, Seoul, Republic of Korea, 24–26 October 2013. [Google Scholar]

- Landscheidt, S.; Kans, M. Method for Assessing the Total Cost of Ownership of Industrial Robots. Procedia CIRP 2016, 57, 746–751. [Google Scholar] [CrossRef]

- Hoogmartens, R.; van Passel, S.; van Acker, K.; Dubois, M. Bridging the gap between LCA, LCC and CBA as sustainability assessment tools. Environ. Impact Assess. Rev. 2014, 48, 27–33. [Google Scholar] [CrossRef]

- Albers, A.; Bursac, N.; Wintergerst, E. Product generation development–importance and challenges from a design research perspective. New Dev. Mech. Mech. Eng. 2015, 13, 16–21. [Google Scholar]

- Scholz, J.; Zeidler, S.; Koessler, F.; Fleischer, J. Systematic Lightweight Design of Production Equipment with a Digital Toolchain. In Production at the Leading Edge of Technology; Bauernhansl, T., Verl, A., Liewald, M., Möhring, H.-C., Eds.; Springer: Cham, Switzerland, 2024; pp. 24–33. ISBN 978-3-031-47393-7. [Google Scholar]

- Kaspar, J.; König, K.; Scholz, J.; Quirin, S.; Kleiner, S.; Fleischer, J.; Herrmann, H.-G.; Vielhaber, M. SyProLei—A systematic product development process to exploit lightweight potentials while considering costs and CO2 emissions. Procedia CIRP 2022, 109, 520–525. [Google Scholar] [CrossRef]

- Albers, A.; Lanza, G.; Klippert, M.; Schäfer, L.; Frey, A.; Hellweg, F.; Müller-Welt, P.; Schöck, M.; Krahe, C.; Nowoseltschenko, K.; et al. Product-Production-CoDesign: An Approach on Integrated Product and Production Engineering Across Generations and Life Cycles. Procedia CIRP 2022, 109, 167–172. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- van Doorsselaer, K.; Koopmans, R.J. Ecodesign; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2020; ISBN 978-1-56990-861-7. [Google Scholar]

- Westkämper, E. Zukunftsperspektiven der digitalen Produktion. In Digitale Produktion; Westkämper, E., Spath, D., Constantinescu, C., Lentes, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 309–327. ISBN 978-3-642-20258-2. [Google Scholar]

- DIN EN ISO 14051:2011-12; Umweltmanagement—Materialflusskostenrechnung—Allgemeine Rahmenbedingungen (ISO 14051:2011); Deutsche und Englische Fassung EN ISO 14051:2011. Beuth Verlag GmbH: Berlin, Germany, 2011. [CrossRef]

- Niazi, A.; Dai, J.S.; Balabani, S.; Seneviratne, L. Product Cost Estimation: Technique Classification and Methodology Review. Int. J. Prod. Res. 2006, 128, 563–575. [Google Scholar] [CrossRef]

- Scholz, J.; Dilger, L.J.; Friedmann, M.; Fleischer, J. A Methodology for Sustainability Assessment and Decision Support for Sustainable Handling Systems. Procedia CIRP 2023, 116, 47–52. [Google Scholar] [CrossRef]

- Saaty, T.L. Time dependent decision-making; dynamic priorities in the AHP/ANP: Generalizing from points to functions and from real to complex variables. Math. Comput. Model. 2007, 46, 860–891. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure. VDI-Richtlinie 2221 Blatt 1: Entwicklung Technischer Produkte und Systeme: Modell der Produktentwicklung; Beuth Verlag: Berlin, Germany, 2019; Available online: https://www.vdi.de/richtlinien/details/vdi-2221-blatt-1-entwicklung-technischer-produkte-und-systeme-modell-der-produktentwicklung (accessed on 31 October 2024).

- Verein Deutscher Ingenieure. VDI-Guidline 2206: Development of Mechatronic and Cyber-Physical Systems; Beuth Verlag: Berlin, Germany, 2021; Available online: https://www.vdi.de/en/home/vdi-standards/details/vdivde-2206-development-of-mechatronic-and-cyber-physical-systems (accessed on 31 October 2024).

- Kupfer, R.; Schilling, L.; Spitzer, S.; Zichner, M.; Gude, M. Neutral lightweight engineering: A holistic approach towards sustainability driven engineering. Discov. Sustain. 2022, 3, 1049. [Google Scholar] [CrossRef]

- Scholz, J.; Kaspar, J.; Quirin, S.; Kneidl, B.; Kleiner, S.; Friedmann, M.; Fleischer, J.; Herrmann, H.-G.; Vielhaber, M. Konzept eines systemischen Entwicklungsprozesses zur Hebung von Leichtbaupotenzialen. Z. Wirtsch. Fabr. 2021, 116, 797–800. [Google Scholar] [CrossRef]

- Scholz, J.; Kaspar, J.; König, K.; Friedmann, M.; Vielhaber, M.; Fleischer, J. Lightweight design of a gripping system using a holistic systematic development process—A case study. Procedia CIRP 2023, 118, 187–192. [Google Scholar] [CrossRef]

- Voirin, J.-L. Model-Based System and Architecture Engineering with the Arcadia Method; ISTE Press: London, UK; Kidlington, UK; Oxford, UK, 2018; ISBN 9780081017944. [Google Scholar]

- Sinnwell, C.; Krenkel, N.; Aurich, J.C. Conceptual manufacturing system design based on early product information. CIRP Ann. 2019, 68, 121–124. [Google Scholar] [CrossRef]

- Stark, R.; Kind, S.; Neumeyer, S. Innovations in digital modelling for next generation manufacturing system design. CIRP Ann. 2017, 66, 169–172. [Google Scholar] [CrossRef]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.-Y.; Nee, A.Y.C. Digital twin-driven product design framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.-H. Konstruktionslehre: Grundlagen Erfolgreicher Produktentwicklung; Methoden und Anwendung, 7th ed.; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 978-3-540-34060-7. [Google Scholar]

- Lo, C.K.; Chen, C.H.; Zhong, R.Y. A review of digital twin in product design and development. Adv. Eng. Inform. 2021, 48, 101297. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar] [CrossRef]

- Arnemann, L.; Winter, S.; Quernheim, N.; Grieser, P.; Anderl, R.; Schleich, B. Information Model to Return Data of Digital Twins into Product Design. Procedia CIRP 2023, 116, 173–178. [Google Scholar] [CrossRef]

- Doppelbauer, M. Grundlagen der Elektromobilität; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2020; ISBN 978-3-658-29729-9. [Google Scholar]

- Cai, W.; Wu, X.; Zhou, M.; Liang, Y.; Wang, Y. Review and Development of Electric Motor Systems and Electric Powertrains for New Energy Vehicles. Automot. Innov. 2021, 4, 3–22. [Google Scholar] [CrossRef]

- Heim, M.; Wirth, F.; Boschert, L.; Fleischer, J. An Approach for the Disassembly of Permanent Magnet Synchronous Rotors to Recover Rare Earth Materials. Procedia CIRP 2023, 116, 71–76. [Google Scholar] [CrossRef]

- Wirth, F.J. Prozessgeregelte Formgebung von Hairpin-Steckspulen für Elektrische Traktionsmotoren, 1st ed.; Shaker: Düren, Germany, 2025; ISBN 978-3-8440-9751-1. [Google Scholar]

- Klein, N.; Wirth, F.; Fleischer, J. Methodology for the Implementation of a Consistent Information Model for the Electric Drives Production. In Proceedings of the 2023 13th International Electric Drives Production Conference (EDPC), Regensburg, Germany, 29–30 November 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–8, ISBN 979-8-3503-7049-2. [Google Scholar]

- Klein, N.; Franken, L.; Heim, M.; Kößler, F.; Dönges, B.; Fleischer, J. Assessment of product carbon footprint reduction potential using lightweight rotor components for electric traction motors. In Proceedings of the Decarbonizing Value Chains Proceedings of the 20th Global Conference on Sustainable Manufacturing (GCSM 2024), Ho Chi Minh City, Vietnam, 9–11 October 2024. [Google Scholar]

| Parameter | Product Hierarchy Level | Parameter | Product Hierarchy Level |

|---|---|---|---|

| Installation Space | System Level | Number of Phases/Strands | Stator |

| Torque | System Level | Maximum Outer Diameter | Stator |

| Speed | System Level | Winding Type | Stator |

| Service Life | System Level | Winding Scheme | Stator |

| t_max_operation | System Level | Slot Width | Stator |

| Load Requirements | System Level | Yoke Height | Stator |

| Motor Type | System Level | Number of Pole Pairs | Stator |

| Cooling Concept | System Level | Balancing Quality | Rotor |

| Nominal Speed | System Level | Permissible unbalance on bearing side A | Rotor |

| Permissible unbalance on bearing side B | Rotor | ||

| Inner Lamination Diameter | Rotor | ||

| Outer Lamination Diameter | Rotor | ||

| Maximum Axial Length | Rotor | ||

| Magnet Grade | Rotor | ||

| Burst Speed | Rotor | ||

| Overspeed | Rotor |

| Parameter | Unit | Datatype | Product Hierarchy Level |

|---|---|---|---|

| lamination_diameter_inner | mm | FLOAT | Rotor |

| lamination_diameter_outer | mm | FLOAT | Rotor |

| tolerances | - | STRING | Rotor |

| lenght_axial | mm | FLOAT | Rotor |

| bearing_type | - | STRING | Rotor |

| position_bearing_A | mm | FLOAT | Rotor |

| position_bearing_B | mm | FLOAT | Rotor |

| shaft_material | - | STRING | Rotor |

| lamination_stack_material | - | STRING | Rotor |

| magnets_material | - | STRING | Rotor |

| magnets_number | - | INT | Rotor |

| magnets_size | mm × mm | FLOAT | Rotor |

| magnet_grade | - | STRING | Rotor |

| balancing_quality | - | FLOAT | Rotor |

| unbalance_A_amplitude | gmm | FLOAT | Rotor |

| unbalance_A_phase | deg | FLOAT | Rotor |

| unbalance_B_amplitude | gmm | FLOAT | Rotor |

| unbalance_B_phase | deg | FLOAT | Rotor |

| rotor_weight | kg | FLOAT | Rotor |

| … | … | … | … |

| Criteria | Unit | Lightweight Rotor | Conventional Rotor |

|---|---|---|---|

| acidification—acidification (incl. fate, average Europe total, A&B) | kg SO2-Eq | 1.0415 | 1.1012 |

| climate change—global warming potential (GWP100) | kg CO2-Eq | 254.25 | 265.9 |

| ecotoxicity: freshwater—freshwater aquatic ecotoxicity (FAETP inf) | kg 1,4-DCB-Eq | 645.38 | 686.2 |

| ecotoxicity: marine—marine aquatic ecotoxicity (MAETP inf) | kg 1,4-DCB-Eq | 9.1 × 105 | 9.64 × 105 |

| ecotoxicity: terrestrial—terrestrial ecotoxicity (TETP inf) | kg 1,4-DCB-Eq | 1.3495 | 11.042 |

| energy resources: non-renewable—abiotic depletion potential (ADP): fossil fuels | MJ | 2896.2 | 3021 |

| eutrophication—eutrophication (fate not incl.) | kg PO4-Eq | 0.4981 | 0.5201 |

| human toxicity—human toxicity (HTP inf) | kg 1,4-DCB-Eq | 484.86 | 764.04 |

| material resources: metals/minerals—abiotic depletion potential (ADP): elements (ultimate reserves) | kg Sb-Eq | 0.0012 | 0.0016 |

| ozone depletion—ozone layer depletion (ODP steady state) | kg CFC-11-Eq | 1.14 × 10−5 | 1.14 × 10−5 |

| photochemical oxidant formation—photochemical oxidation (high NOx) | kg ethylene-Eq | 0.0847 | 0.0868 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scholz, J.; Klein, N.; Kößler, F.; Fleischer, J. Systematic Digital Twin-Based Development Approach for Holistic Sustainable Electric Traction Motors. Sustainability 2025, 17, 2518. https://doi.org/10.3390/su17062518

Scholz J, Klein N, Kößler F, Fleischer J. Systematic Digital Twin-Based Development Approach for Holistic Sustainable Electric Traction Motors. Sustainability. 2025; 17(6):2518. https://doi.org/10.3390/su17062518

Chicago/Turabian StyleScholz, Johannes, Nicolaus Klein, Florian Kößler, and Jürgen Fleischer. 2025. "Systematic Digital Twin-Based Development Approach for Holistic Sustainable Electric Traction Motors" Sustainability 17, no. 6: 2518. https://doi.org/10.3390/su17062518

APA StyleScholz, J., Klein, N., Kößler, F., & Fleischer, J. (2025). Systematic Digital Twin-Based Development Approach for Holistic Sustainable Electric Traction Motors. Sustainability, 17(6), 2518. https://doi.org/10.3390/su17062518