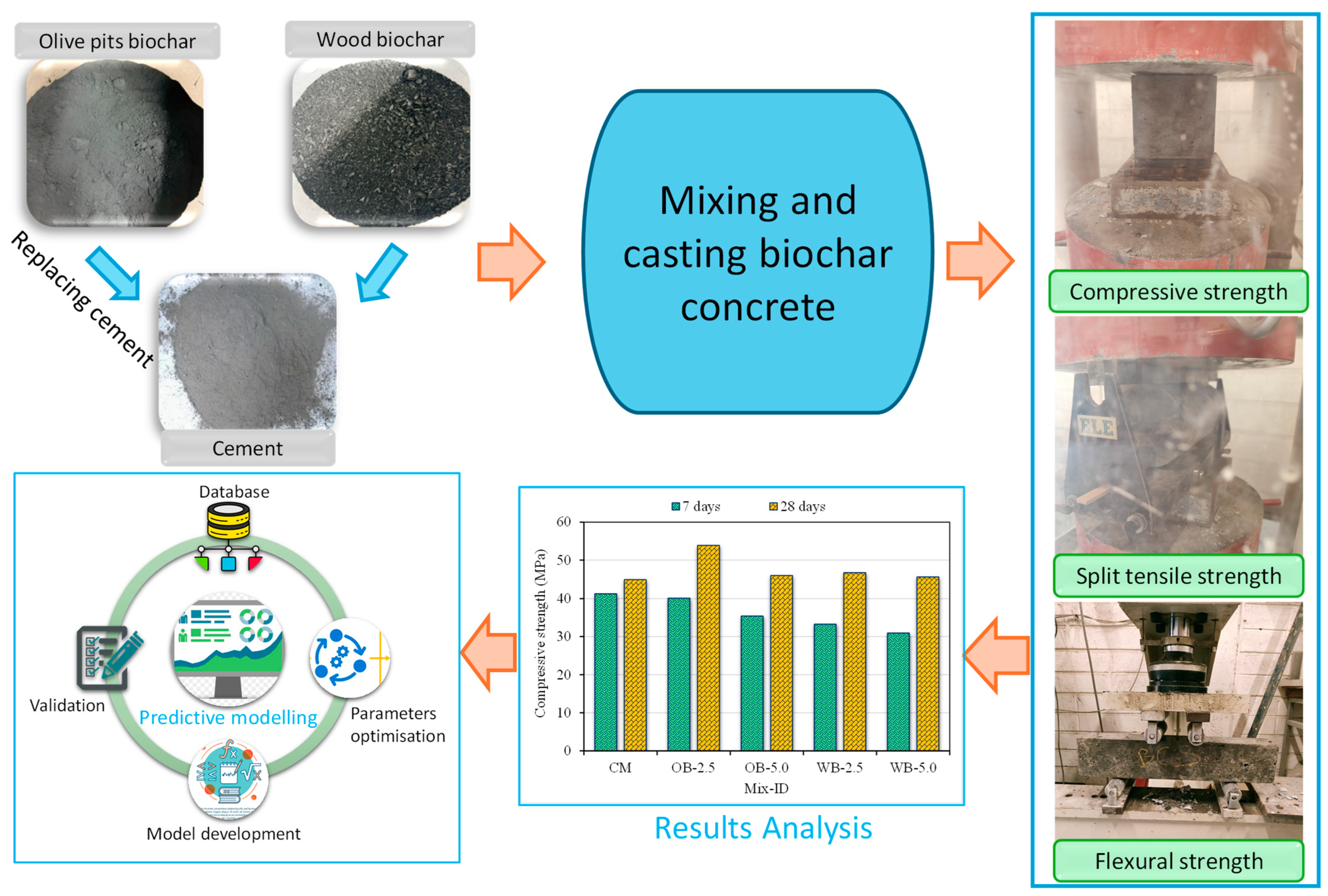

Advancing Sustainable Concrete Using Biochar: Experimental and Modelling Study for Mechanical Strength Evaluation

Abstract

1. Introduction

2. Research Methods

2.1. Experimental Study

- = maximum load in N.

- = cross-sectional area of the contact specimen in mm2 (10,000 mm2 in this study).

- = height of the cylinder specimen in mm (200 mm in this study).

- = diameter of the cylinder specimen in mm (100 mm in this study).

- = distance between the support rollers in mm (300 mm in this study).

- and = cross-sectional dimensions of beams (100 mm in this study).

2.2. Modelling Study

2.2.1. Model Development with GEP

2.2.2. Models’ Validation Strategy

2.2.3. SHAP Analysis Method

3. Results and Discussion

3.1. Experimental Results

3.1.1. Compressive Strength

3.1.2. Split Tensile Strength

3.1.3. Flexural Strength

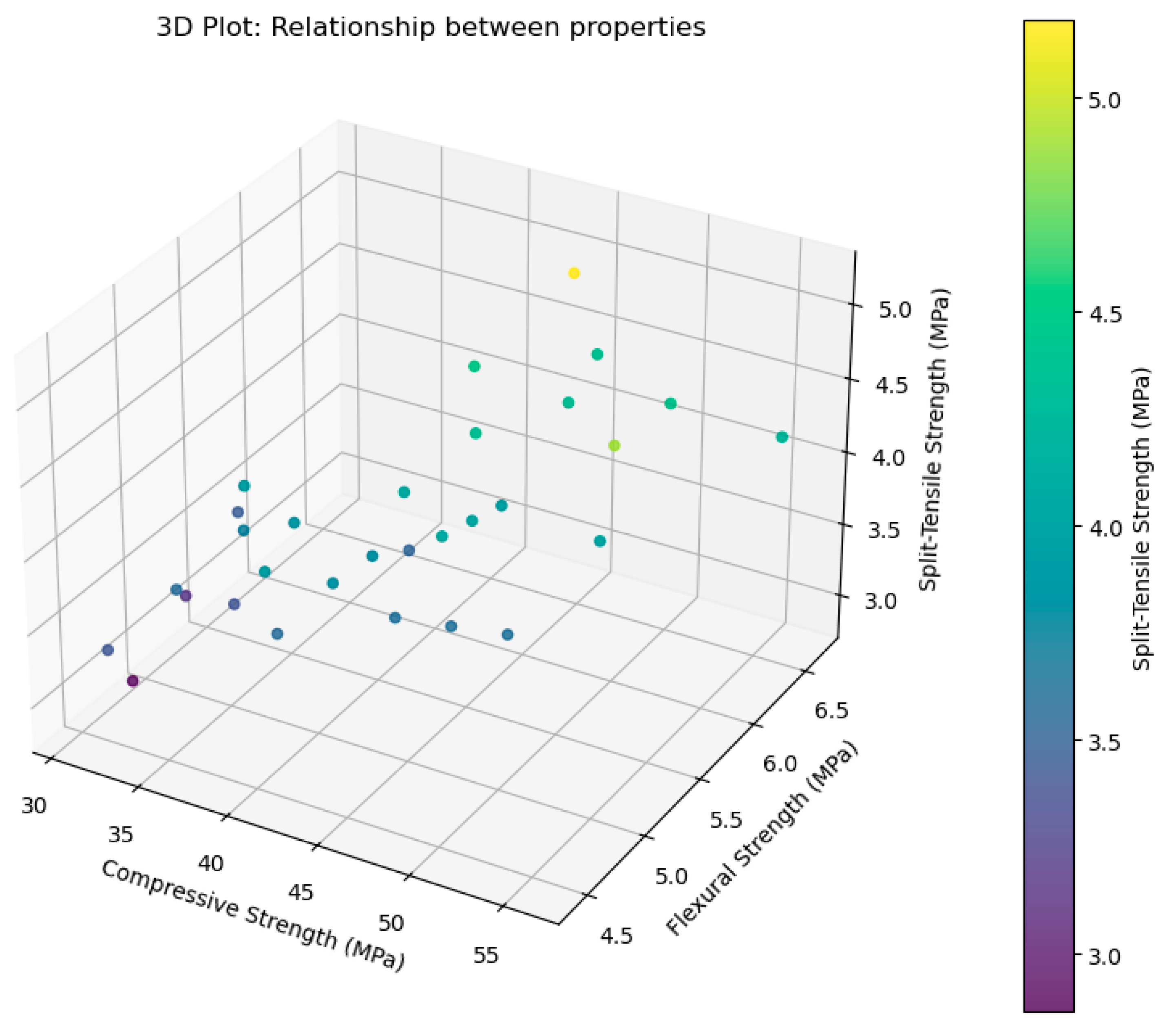

3.1.4. Relationship Between Mechanical Strengths

3.2. Modelling Results

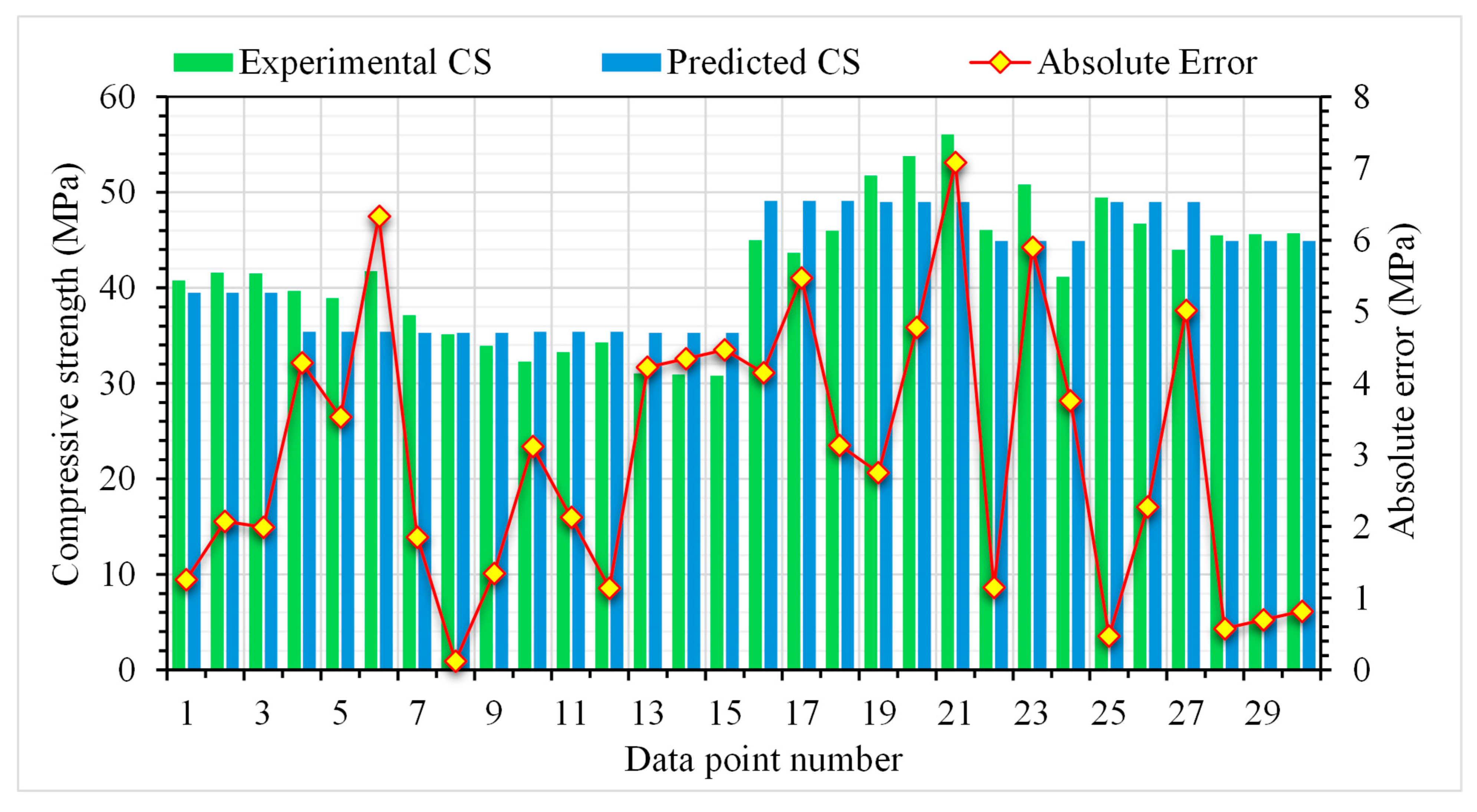

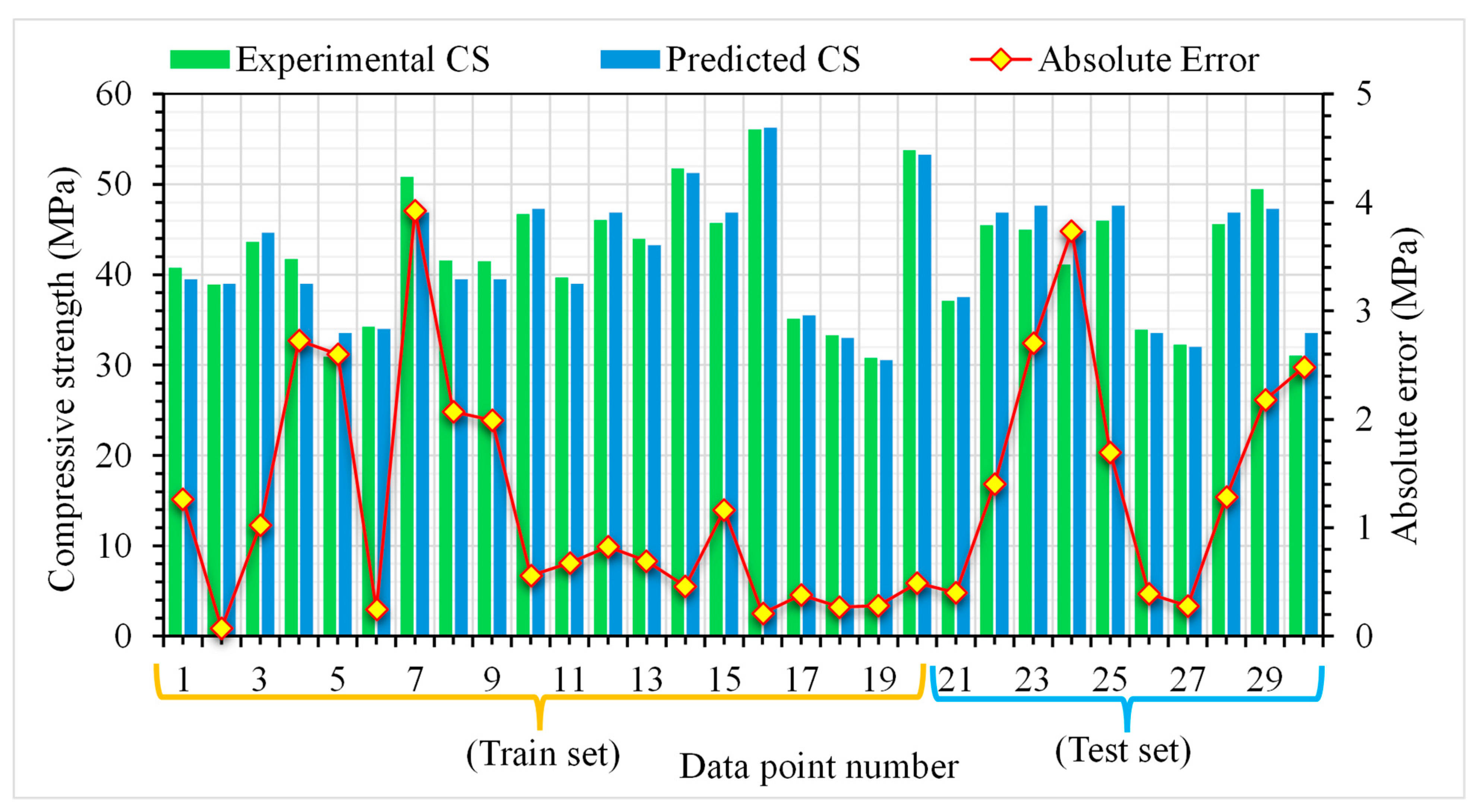

3.2.1. Linear Regression CS Model

3.2.2. GEP CS Model

3.2.3. Models’ Comparison with Validation Metrics

3.2.4. SHAP Analysis Results

4. Conclusions

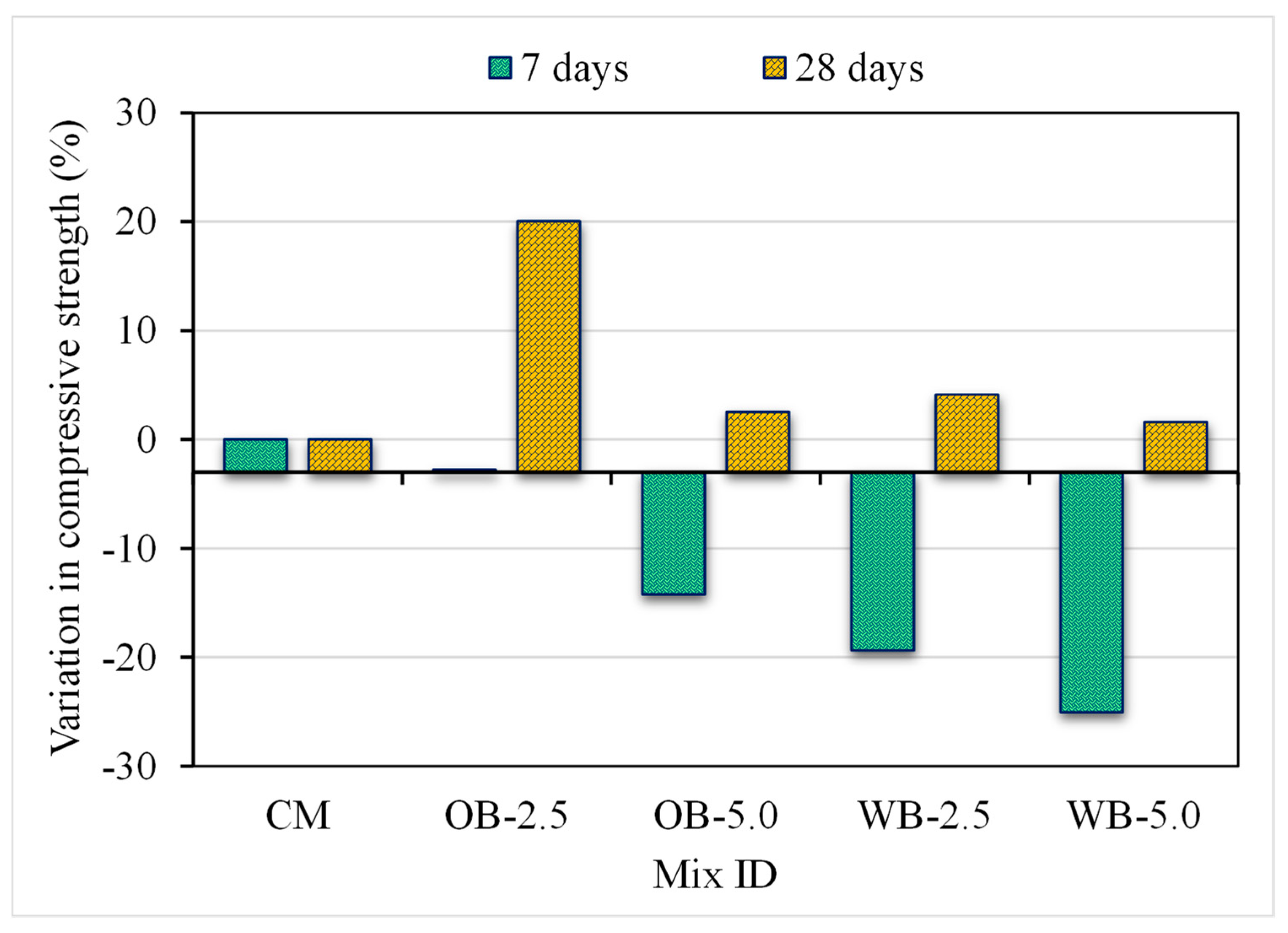

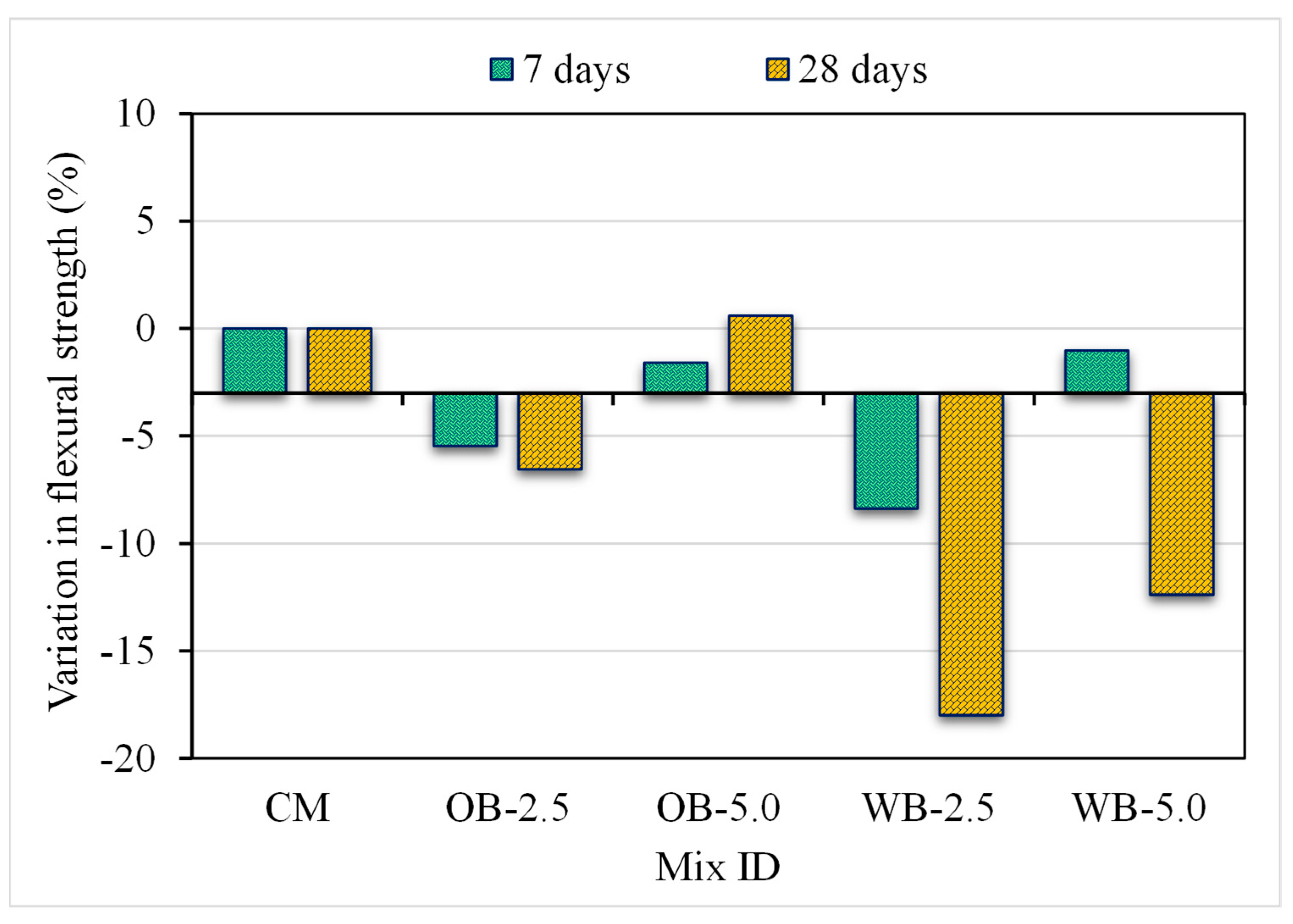

- At 7 days of testing, the CS, STS, and FS of biochar concrete were mostly lower than the control mix (CM), but at 28 days of testing, a significant strength gain was observed. This might be due to the water-absorbing nature of biochar delaying cement hydration, but by 28 days, the slow release of this absorbed water (internal curing) and the filler effect of finer biochar particles can enhance overall strength.

- Olive pit biochar of 2.5 wt.% increased the CS by approximately 20% compared to the CM at 28 days, whereas 2.5 wt.% wood biochar increased the 28-day CS by around 4% due to relatively larger particles compared to olive pit biochar. The finer particles of olive pits result in a more compact matrix, thereby resulting in an increased CS. However, the 5 wt.% biochar (both olive pits and wood) caused a decrease in CS but was comparable to the CM.

- The maximum STS and FS were noted at 5 wt.% olive pit biochar. There was an increase in the STS of around 8% compared to the CM, and FS was like the CM with olive pit biochar of 5 wt.% at 28 days. Wood biochar concrete mixes showed a reduced STS of around 16.6% and 6.8% and FS of around 18% and 14.4% compared to the CM at 28 days with 2.5 and 5 wt.% biochar, respectively.

- The optimal biochar replacement percentage is highly dependent on the biochar source and particle size, and its incorporation affects CS, STS, and FS differently, indicating that not all strength characteristics examined in this study respond equally to biochar addition.

- The linear regression model with R2 of 0.73 for the CS of biochar concrete showed moderate accuracy, while the GEP model effectively captured the non-linear behaviour of biochar concrete, achieving a higher R2 of 0.93 and lower error values. This indicates a superior predictive capability of GEP for CS, reflecting the complex interaction among cement, biochar, and curing time. This approach has been provisionally shown to be acceptable for small data sizes used in this study; however, further research on multiple datasets is required before this can be stated definitively.

- SHAP analysis showed that curing time exerts a more positive influence on CS, aligning with experimental findings of higher strength at later ages. While biochar content generally demonstrated a negative impact, certain levels showed favourable effects. Higher cement content correlated positively with CS, emphasising the need for balanced mix proportions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Senadheera, S.S.; Gupta, S.; Kua, H.W.; Hou, D.; Kim, S.; Tsang, D.C.W.; Ok, Y.S. Application of biochar in concrete—A review. Cem. Concr. Compos. 2023, 143, 105204. [Google Scholar] [CrossRef]

- Semieniuk, G.; Yakovenko, V.M. Historical evolution of global inequality in carbon emissions and footprints versus redistributive scenarios. J. Clean. Prod. 2020, 264, 121420. [Google Scholar] [CrossRef]

- Churkina, G.; Organschi, A.; Reyer, C.P.O.; Ruff, A.; Vinke, K.; Liu, Z.; Reck, B.K.; Graedel, T.E.; Schellnhuber, H.J. Buildings as a global carbon sink. Nat. Sustain. 2020, 3, 269–276. [Google Scholar] [CrossRef]

- Rose, D.; Shirzad, S. Innovations in Green Concrete: Combining Metakaolin and Arundo Grass Biochar for Enhanced Sustainability. Sustainability 2024, 16, 11219. [Google Scholar] [CrossRef]

- Mosaberpanah, M.A.; Olabimtan, S.B.; Balkis, A.P.; Rabiu, B.O.; Oluwole, B.O.; Ajuonuma, C.S. Effect of Biochar and Sewage Sludge Ash as Partial Replacement for Cement in Cementitious Composites: Mechanical, and Durability Properties. Sustainability 2024, 16, 1522. [Google Scholar] [CrossRef]

- Winters, D.; Boakye, K.; Simske, S. Toward carbon-neutral concrete through biochar–cement–calcium carbonate composites: A critical review. Sustainability 2022, 14, 4633. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Y.; Wang, L.; Ruan, S.; Chen, J.; Li, H.; Yang, J.; Mechtcherine, V.; Tsang, D.C.W. Biochar-augmented carbon-negative concrete. Chem. Eng. J. 2022, 431, 133946. [Google Scholar] [CrossRef]

- Azzi, E.S.; Karltun, E.; Sundberg, C. Prospective life cycle assessment of large-scale biochar production and use for negative emissions in Stockholm. Environ. Sci. Technol. 2019, 53, 8466–8476. [Google Scholar] [CrossRef]

- Sun, Y.; Xiong, X.; He, M.; Xu, Z.; Hou, D.; Zhang, W.; Ok, Y.S.; Rinklebe, J.; Wang, L.; Tsang, D.C.W. Roles of biochar-derived dissolved organic matter in soil amendment and environmental remediation: A critical review. Chem. Eng. J. 2021, 424, 130387. [Google Scholar] [CrossRef]

- Shaheen, S.M.; Niazi, N.K.; Hassan, N.E.E.; Bibi, I.; Wang, H.; Tsang, D.C.W.; Ok, Y.S.; Bolan, N.; Rinklebe, J. Wood-based biochar for the removal of potentially toxic elements in water and wastewater: A critical review. Int. Mater. Rev. 2019, 64, 216–247. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, Y.; Wan, Z.; Jing, F.; Li, Z.; Chen, J.; Tsang, D.C.W. Tailored design of food waste hydrochar for efficient adsorption and catalytic degradation of refractory organic contaminant. J. Clean. Prod. 2021, 310, 127482. [Google Scholar] [CrossRef]

- Vincevica-Gaile, Z.; Zhylina, M.; Shishkin, A.; Ansone-Bertina, L.; Klavins, L.; Arbidans, L.; Dobkevica, L.; Zekker, I.; Klavins, M. Selected residual biomass valorization into pellets as a circular economy-supported end-of-waste. Clean. Mater. 2025, 15, 100295. [Google Scholar] [CrossRef]

- Katish, M.; Allen, S.; Squires, A.; Ferrandiz-Mas, V. Experimental study of phase change material (PCM) biochar composite for net-zero built environment applications. Clean. Mater. 2024, 14, 100274. [Google Scholar] [CrossRef]

- Chanda, R.; Jahid, T.; Karmokar, A.; Hossain, B.; Moktadir, M.; Islam, M.S.; Aich, N.; Biswas, B.K. Functionalized biochar from vegetable waste for phosphorus removal from aqueous solution and its potential use as a slow-release fertilizer. Clean. Mater. 2025, 15, 100287. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, Q.; Jin, X.; Dong, X.; Peng, J.; Wu, M.; Liang, N.; Pan, B.; Xing, B. Negative impacts of biochars on urease activity: High pH, heavy metals, polycyclic aromatic hydrocarbons, or free radicals? Environ. Sci. Technol. 2018, 52, 12740–12747. [Google Scholar] [CrossRef]

- Lin, X.; Li, W.; Guo, Y.; Dong, W.; Castel, A.; Wang, K. Biochar-cement concrete toward decarbonisation and sustainability for construction: Characteristic, performance and perspective. J. Clean. Prod. 2023, 419, 138219. [Google Scholar] [CrossRef]

- Wu, T.; Ng, S.T.; Chen, J. Deciphering the CO2 emissions and emission intensity of cement sector in China through decomposition analysis. J. Clean. Prod. 2022, 352, 131627. [Google Scholar] [CrossRef]

- Galusnyak, S.C.; Petrescu, L.; Cormos, C.-C. Environmental impact assessment of post-combustion CO2 capture technologies applied to cement production plants. J. Environ. Manag. 2022, 320, 115908. [Google Scholar] [CrossRef]

- Chen, X.; Li, J.; Xue, Q.; Huang, X.; Liu, L.; Poon, C.S. Sludge biochar as a green additive in cement-based composites: Mechanical properties and hydration kinetics. Constr. Build. Mater. 2020, 262, 120723. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Novel biochar-concrete composites: Manufacturing, characterization and evaluation of the mechanical properties. Sci. Total Environ. 2018, 616–617, 408–416. [Google Scholar] [CrossRef]

- Creamer, A.E.; Gao, B.; Zhang, M. Carbon dioxide capture using biochar produced from sugarcane bagasse and hickory wood. Chem. Eng. J. 2014, 249, 174–179. [Google Scholar] [CrossRef]

- Liu, R.; Xiao, H.; Guan, S.; Zhang, J.; Yao, D. Technology and method for applying biochar in building materials to evidently improve the carbon capture ability. J. Clean. Prod. 2020, 273, 123154. [Google Scholar] [CrossRef]

- Praneeth, S.; Guo, R.; Wang, T.; Dubey, B.K.; Sarmah, A.K. Accelerated carbonation of biochar reinforced cement-fly ash composites: Enhancing and sequestering CO2 in building materials. Constr. Build. Mater. 2020, 244, 118363. [Google Scholar] [CrossRef]

- Qin, Y.; Pang, X.; Tan, K.; Bao, T. Evaluation of pervious concrete performance with pulverized biochar as cement replacement. Cem. Concr. Compos. 2021, 119, 104022. [Google Scholar] [CrossRef]

- Sirico, A.; Belletti, B.; Bernardi, P.; Malcevschi, A.; Pagliari, F.; Fornoni, P.; Moretti, E. Effects of biochar addition on long-term behavior of concrete. Theor. Appl. Fract. Mech. 2022, 122, 103626. [Google Scholar] [CrossRef]

- Restuccia, L.; Ferro, G.A. Influence of filler size on the mechanical properties of cement-based composites. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 797–805. [Google Scholar] [CrossRef]

- Cao, M.; Mao, Y.; Khan, M.; Si, W.; Shen, S. Different testing methods for assessing the synthetic fiber distribution in cement-based composites. Constr. Build. Mater. 2018, 184, 128–142. [Google Scholar] [CrossRef]

- Ben Chaabene, W.; Flah, M.; Nehdi, M.L. Machine learning prediction of mechanical properties of concrete: Critical review. Constr. Build. Mater. 2020, 260, 119889. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Shahmansouri, A.A.; Fakoor, M. Post-fire compressive strength of recycled PET aggregate concrete reinforced with steel fibers: Optimization and prediction via RSM and GEP. Constr. Build. Mater. 2020, 252, 119057. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Babanajad, S.K.; Alavi, A.H.; Farnam, Y. Novel approach to strength modeling of concrete under triaxial compression. J. Mater. Civ. Eng. 2012, 24, 1132–1143. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Yun, G.J.; Alavi, A.H. An evolutionary approach for modeling of shear strength of RC deep beams. Mater. Struct. 2013, 46, 2109–2119. [Google Scholar] [CrossRef]

- Tian, Q.; Lu, Y.; Zhou, J.; Song, S.; Yang, L.; Cheng, T.; Huang, J. Supplementary cementitious materials-based concrete porosity estimation using modeling approaches: A comparative study of GEP and MEP. Rev. Adv. Mater. Sci. 2024, 63, 20230189. [Google Scholar] [CrossRef]

- Tian, Q.; Lu, Y.; Zhou, J.; Song, S.; Yang, L.; Cheng, T.; Huang, J. Compressive strength of waste-derived cementitious composites using machine learning. Rev. Adv. Mater. Sci. 2024, 63, 20240008. [Google Scholar] [CrossRef]

- Tian, Q.; Lu, Y.; Zhou, J.; Song, S.; Yang, L.; Cheng, T.; Huang, J. Exploring the viability of AI-aided genetic algorithms in estimating the crack repair rate of self-healing concrete. Rev. Adv. Mater. Sci. 2024, 63, 20230179. [Google Scholar] [CrossRef]

- Jalal, F.E.; Xu, Y.; Iqbal, M.; Javed, M.F.; Jamhiri, B. Predictive modeling of swell-strength of expansive soils using artificial intelligence approaches: ANN, ANFIS and GEP. J. Environ. Manag. 2021, 289, 112420. [Google Scholar] [CrossRef]

- Kashem, A.; Karim, R.; Malo, S.C.; Das, P.; Datta, S.D.; Alharthai, M. Hybrid data-driven approaches to predicting the compressive strength of ultra-high-performance concrete using SHAP and PDP analyses. Case Stud. Constr. Mater. 2024, 20, e02991. [Google Scholar] [CrossRef]

- Karim, R.; Islam, M.H.; Datta, S.D.; Kashem, A. Synergistic effects of supplementary cementitious materials and compressive strength prediction of concrete using machine learning algorithms with SHAP and PDP analyses. Case Stud. Constr. Mater. 2024, 20, e02828. [Google Scholar] [CrossRef]

- Kashem, A.; Karim, R.; Das, P.; Datta, S.D.; Alharthai, M. Compressive strength prediction of sustainable concrete incorporating rice husk ash (RHA) using hybrid machine learning algorithms and parametric analyses. Case Stud. Constr. Mater. 2024, 20, e03030. [Google Scholar] [CrossRef]

- Habibur Rahman Sobuz, M.; Khan, M.H.; Kawsarul Islam Kabbo, M.; Alhamami, A.H.; Aditto, F.S.; Saziduzzaman Sajib, M.; Johnson Alengaram, U.; Mansour, W.; Hasan, N.M.S.; Datta, S.D.; et al. Assessment of mechanical properties with machine learning modeling and durability, and microstructural characteristics of a biochar-cement mortar composite. Constr. Build. Mater. 2024, 411, 134281. [Google Scholar] [CrossRef]

- Chen, Y.; Zou, Z.; Jin, X.; Wang, J.; Tan, K. Biochar-enhanced concrete mixes: Pioneering multi-objective optimization. J. Build. Eng. 2024, 88, 109263. [Google Scholar] [CrossRef]

- Boudermine, H.; Boumaaza, M.; Belaadi, A.; Bourchak, M.; Bencheikh, M. Performance analysis of biochar and W. Robusta palm waste reinforced green mortar using response surface methodology and machine learning methods. Constr. Build. Mater. 2024, 438, 137214. [Google Scholar] [CrossRef]

- Singh, N.; Kumar, P.; Goyal, P. Reviewing the behaviour of high volume fly ash based self compacting concrete. J. Build. Eng. 2019, 26, 100882. [Google Scholar] [CrossRef]

- IS. EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. National Standards Authority of Ireland: Dublin, Ireland, 2019.

- IS. EN 12390-4:2019; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. National Standards Authority of Ireland: Dublin, Ireland, 2019.

- IS. EN 12390-6:2023; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. National Standards Authority of Ireland: Dublin, Ireland, 2023.

- IS. EN 12390-5:2019; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. National Standards Authority of Ireland: Dublin, Ireland, 2019.

- Sufian, M.; Ullah, S.; Ostrowski, K.A.; Ahmad, A.; Zia, A.; Śliwa-Wieczorek, K.; Siddiq, M.; Awan, A.A. An Experimental and Empirical Study on the Use of Waste Marble Powder in Construction Material. Materials 2021, 14, 3829. [Google Scholar] [CrossRef] [PubMed]

- Alsharari, F.; Khan, K.; Amin, M.N.; Ahmad, W.; Khan, U.; Mutnbak, M.; Houda, M.; Yosri, A.M. Sustainable use of waste eggshells in cementitious materials: An experimental and modeling-based study. Case Stud. Constr. Mater. 2022, 17, e01620. [Google Scholar] [CrossRef]

- Lyngdoh, G.A.; Zaki, M.; Krishnan, N.M.A.; Das, S. Prediction of concrete strengths enabled by missing data imputation and interpretable machine learning. Cem. Concr. Compos. 2022, 128, 104414. [Google Scholar] [CrossRef]

- Taffese, W.Z.; Espinosa-Leal, L. Prediction of chloride resistance level of concrete using machine learning for durability and service life assessment of building structures. J. Build. Eng. 2022, 60, 105146. [Google Scholar] [CrossRef]

- Ahmad, A.; Ahmad, W.; Aslam, F.; Joyklad, P. Compressive strength prediction of fly ash-based geopolymer concrete via advanced machine learning techniques. Case Stud. Constr. Mater. 2022, 16, e00840. [Google Scholar] [CrossRef]

- Cao, Q.; Yuan, X.; Nasir Amin, M.; Ahmad, W.; Althoey, F.; Alsharari, F. A soft-computing-based modeling approach for predicting acid resistance of waste-derived cementitious composites. Constr. Build. Mater. 2023, 407, 133540. [Google Scholar] [CrossRef]

- Farooq, F.; Ahmed, W.; Akbar, A.; Aslam, F.; Alyousef, R. Predictive modeling for sustainable high-performance concrete from industrial wastes: A comparison and optimization of models using ensemble learners. J. Clean. Prod. 2021, 292, 126032. [Google Scholar] [CrossRef]

- Aslam, F.; Farooq, F.; Amin, M.N.; Khan, K.; Waheed, A.; Akbar, A.; Javed, M.F.; Alyousef, R.; Alabdulijabbar, H. Applications of gene expression programming for estimating compressive strength of high-strength concrete. Adv. Civ. Eng. 2020, 2020, 8850535. [Google Scholar] [CrossRef]

- Mohammed, A.K.; Hassan, A.M.T.; Mohammed, A.S. Predicting the compressive strength of green concrete at various temperature ranges using different soft computing techniques. Sustainability 2023, 15, 11907. [Google Scholar] [CrossRef]

- Li, Y.; Wang, G.; Amin, M.N.; Khan, A.; Qadir, M.T.; Arifeen, S.U. Towards improved flexural behavior of plastic-based mortars: An experimental and modeling study on waste material incorporation. Mater. Today Commun. 2024, 40, 109391. [Google Scholar] [CrossRef]

- Lundberg, S.M.; Lee, S.-I. A unified approach to interpreting model predictions. arXiv 2017, arXiv:1705.07874. [Google Scholar] [CrossRef]

- Abdulalim Alabdullah, A.; Iqbal, M.; Zahid, M.; Khan, K.; Nasir Amin, M.; Jalal, F.E. Prediction of rapid chloride penetration resistance of metakaolin based high strength concrete using light GBM and XGBoost models by incorporating SHAP analysis. Constr. Build. Mater. 2022, 345, 128296. [Google Scholar] [CrossRef]

- Sirico, A.; Bernardi, P.; Sciancalepore, C.; Vecchi, F.; Malcevschi, A.; Belletti, B.; Milanese, D. Biochar from wood waste as additive for structural concrete. Constr. Build. Mater. 2021, 303, 124500. [Google Scholar] [CrossRef]

- Aneja, A.; Sharma, R.L.; Singh, H. Mechanical and durability properties of biochar concrete. Mater. Today Proc. 2022, 65, 3724–3730. [Google Scholar] [CrossRef]

- Jia, Y.; Li, H.; He, X.; Li, P.; Wang, Z. Effect of biochar from municipal solid waste on mechanical and freeze–thaw properties of concrete. Constr. Build. Mater. 2023, 368, 130374. [Google Scholar] [CrossRef]

- Murali, G.; Wong, L.S. A comprehensive review of biochar-modified concrete: Mechanical performance and microstructural insights. Constr. Build. Mater. 2024, 425, 135986. [Google Scholar] [CrossRef]

| Mix ID | Biochar Type | Biochar Content (wt.% of Cement) | Cement (kg/m3) | Biochar (kg/m3) | Water (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) |

|---|---|---|---|---|---|---|---|

| CM | - | 0 | 479 | 0 | 225 | 603 | 1073 |

| OB-2.5 | Olive pits | 2.5 | 467 | 12.0 | 225 | 603 | 1073 |

| OB-5.0 | Olive pits | 5.0 | 455 | 24.0 | 225 | 603 | 1073 |

| WB-2.5 | Wood | 2.5 | 467 | 12.0 | 225 | 603 | 1073 |

| WB-5.0 | Wood | 5.0 | 455 | 24.0 | 225 | 603 | 1073 |

| Hyperparameter | Value |

|---|---|

| population_size | 1000 |

| generations | 8 |

| stopping_criteria | 0.00001 |

| function_set | ‘add’, ‘sub’, ‘mul’, ‘div’, ‘sqrt’ |

| parsimony_coefficient | 0.001 |

| max_samples | 0.9 |

| metric | MSE |

| verbose | 1 |

| random_state | 42 |

| n_jobs | −1 |

| K-fold splits | 5 |

| Parameter | Linear Regression Model | GEP Model |

|---|---|---|

| R2 | 0.735 | 0.932 |

| MAE | 3.009 | 1.794 |

| MAPE | 7.30 | 4.30 |

| RMSE | 3.551 | 2.079 |

| OBJ | 3.781 | 2.005 |

| SI | 0.085 | 0.051 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, W.; Veeraghantla, V.S.S.C.S.; Byrne, A. Advancing Sustainable Concrete Using Biochar: Experimental and Modelling Study for Mechanical Strength Evaluation. Sustainability 2025, 17, 2516. https://doi.org/10.3390/su17062516

Ahmad W, Veeraghantla VSSCS, Byrne A. Advancing Sustainable Concrete Using Biochar: Experimental and Modelling Study for Mechanical Strength Evaluation. Sustainability. 2025; 17(6):2516. https://doi.org/10.3390/su17062516

Chicago/Turabian StyleAhmad, Waqas, Venkata Satya Sai Chandra Sekhar Veeraghantla, and Aimee Byrne. 2025. "Advancing Sustainable Concrete Using Biochar: Experimental and Modelling Study for Mechanical Strength Evaluation" Sustainability 17, no. 6: 2516. https://doi.org/10.3390/su17062516

APA StyleAhmad, W., Veeraghantla, V. S. S. C. S., & Byrne, A. (2025). Advancing Sustainable Concrete Using Biochar: Experimental and Modelling Study for Mechanical Strength Evaluation. Sustainability, 17(6), 2516. https://doi.org/10.3390/su17062516

_Su.png)