Optimization and Performance Comparison of Heat Pump Supplemental Heating Systems in a Heat Supply Station

Abstract

1. Introduction

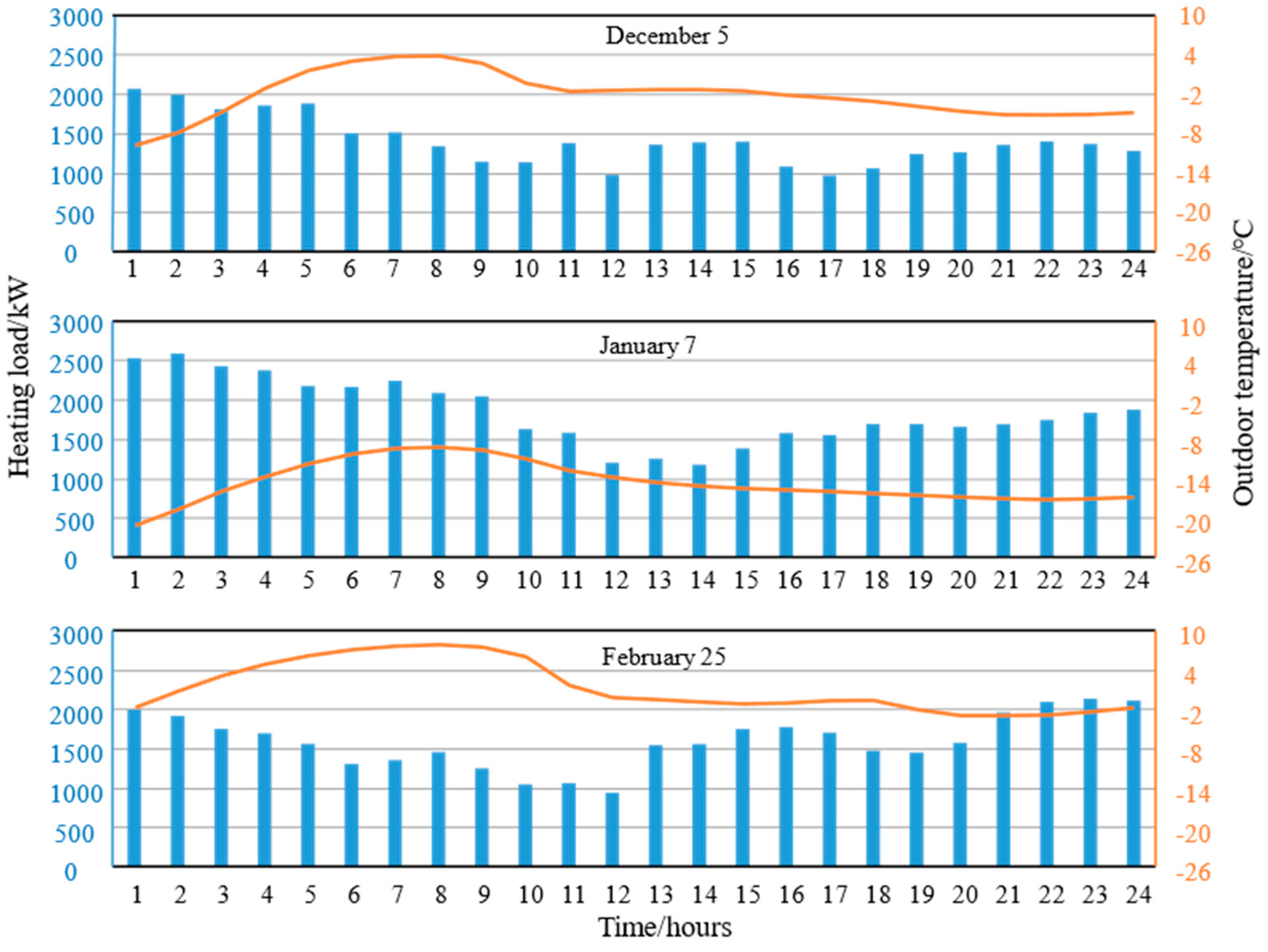

2. Case Study

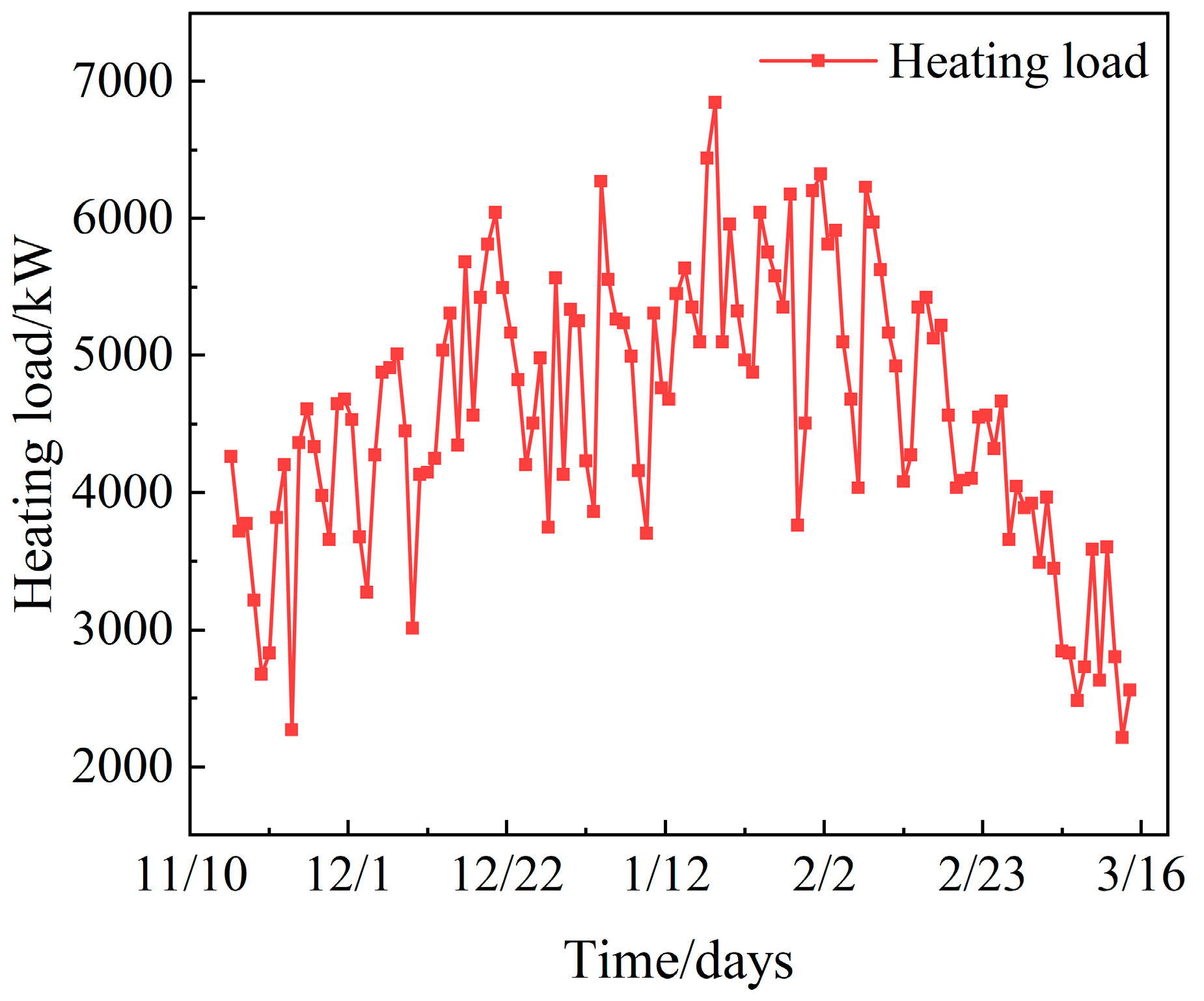

2.1. Additional Heat Demand

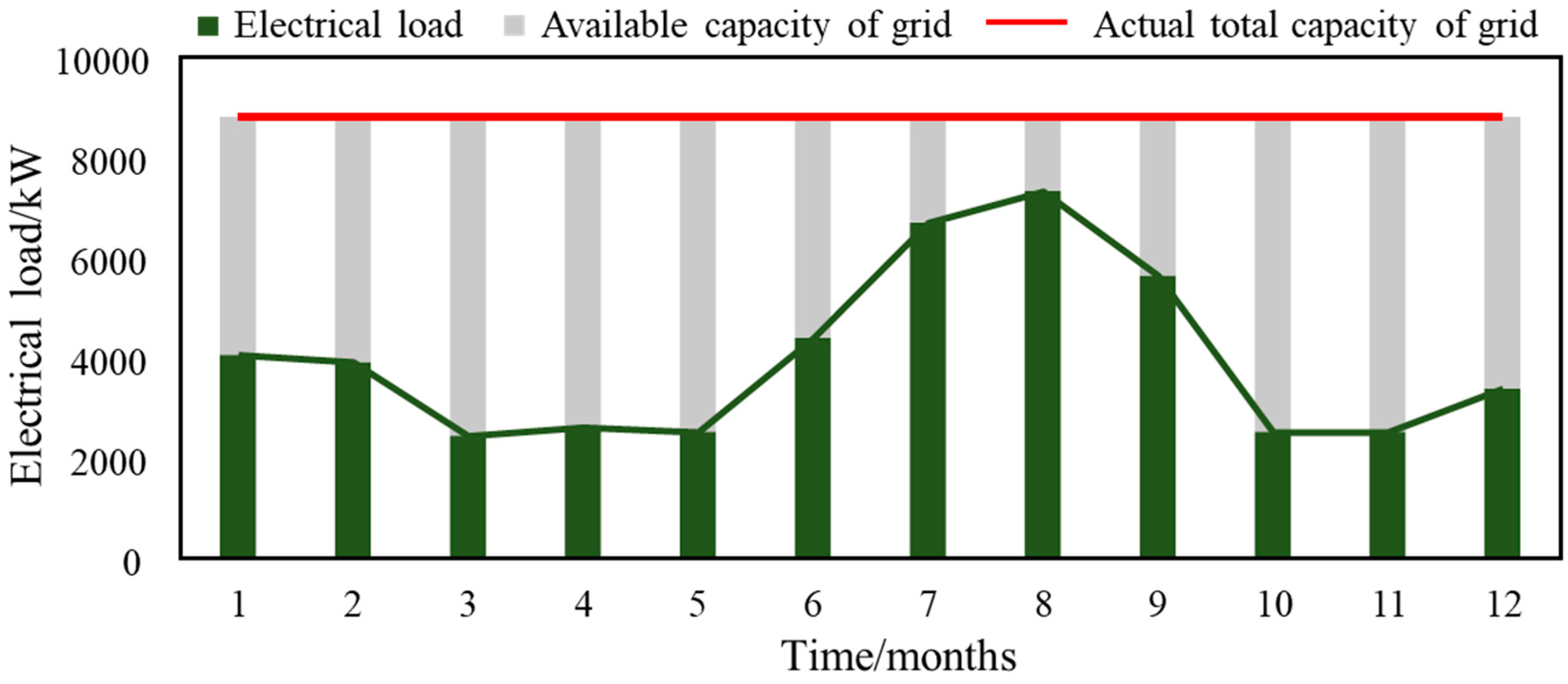

2.2. Available Capacity of the Grid

3. Heat Pump Supplemental Heating Systems

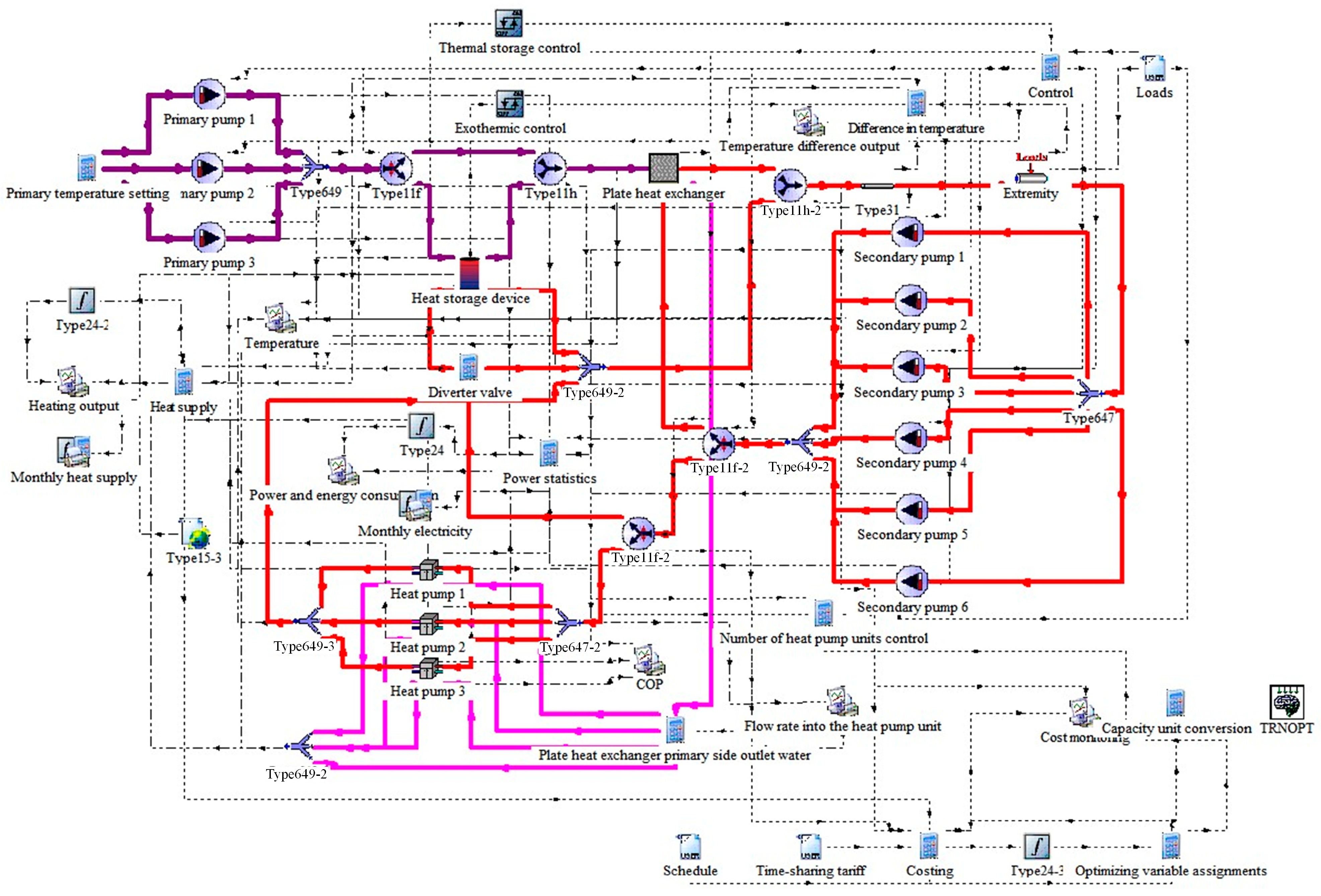

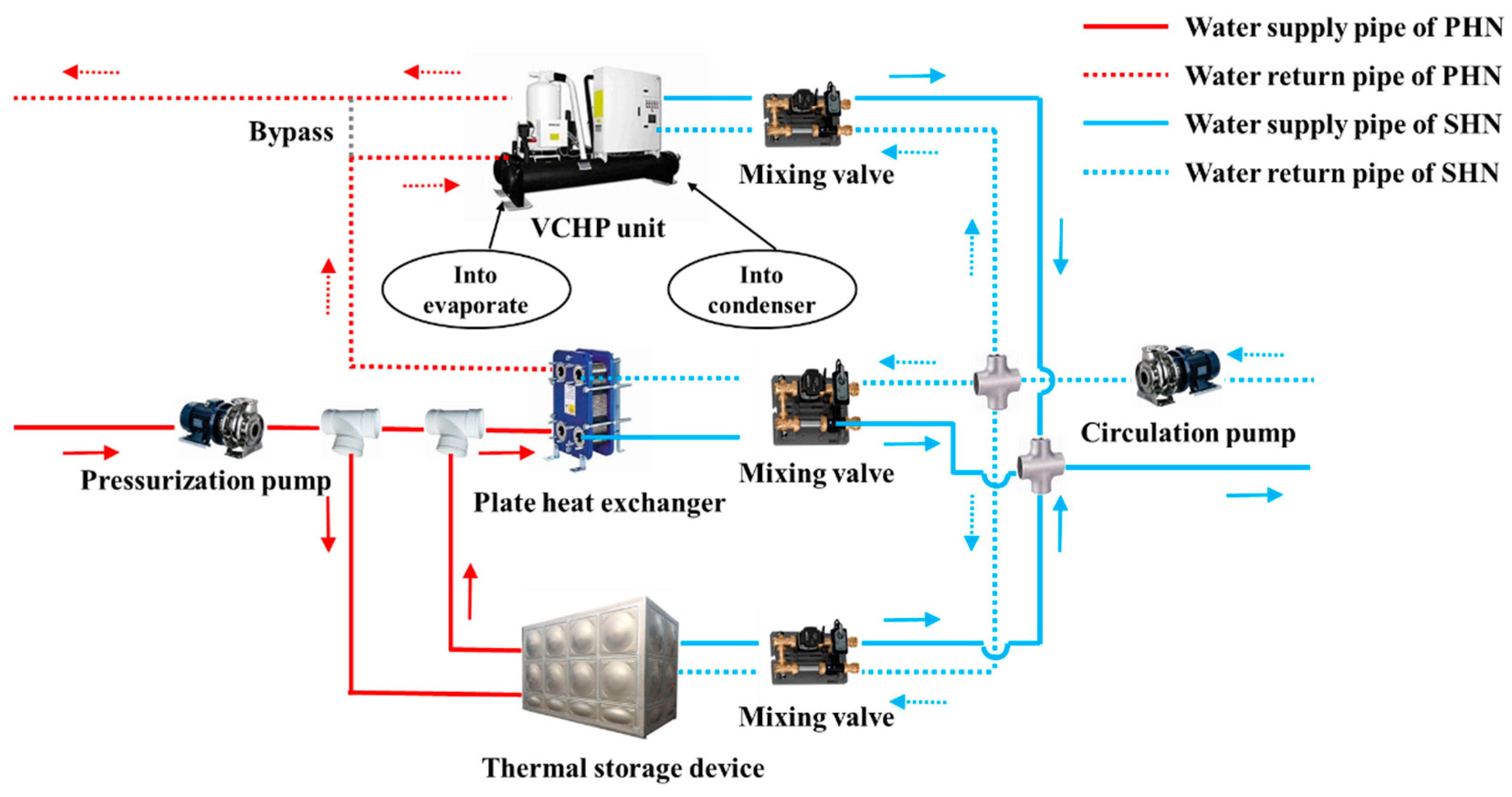

3.1. Electric-Driven VCSHS

- (1)

- When the cost of electric heating exceeds the cost of purchasing heat from the municipal heating network, the heating priorities are, in descending order, the plate heat exchanger, thermal storage device, and VCHP.

- (2)

- Conversely, when the cost of electric heating is lower than the cost of purchasing heat from the municipal heating network, the heating priorities are, in descending order, the VCHP, thermal storage device, and plate heat exchanger.

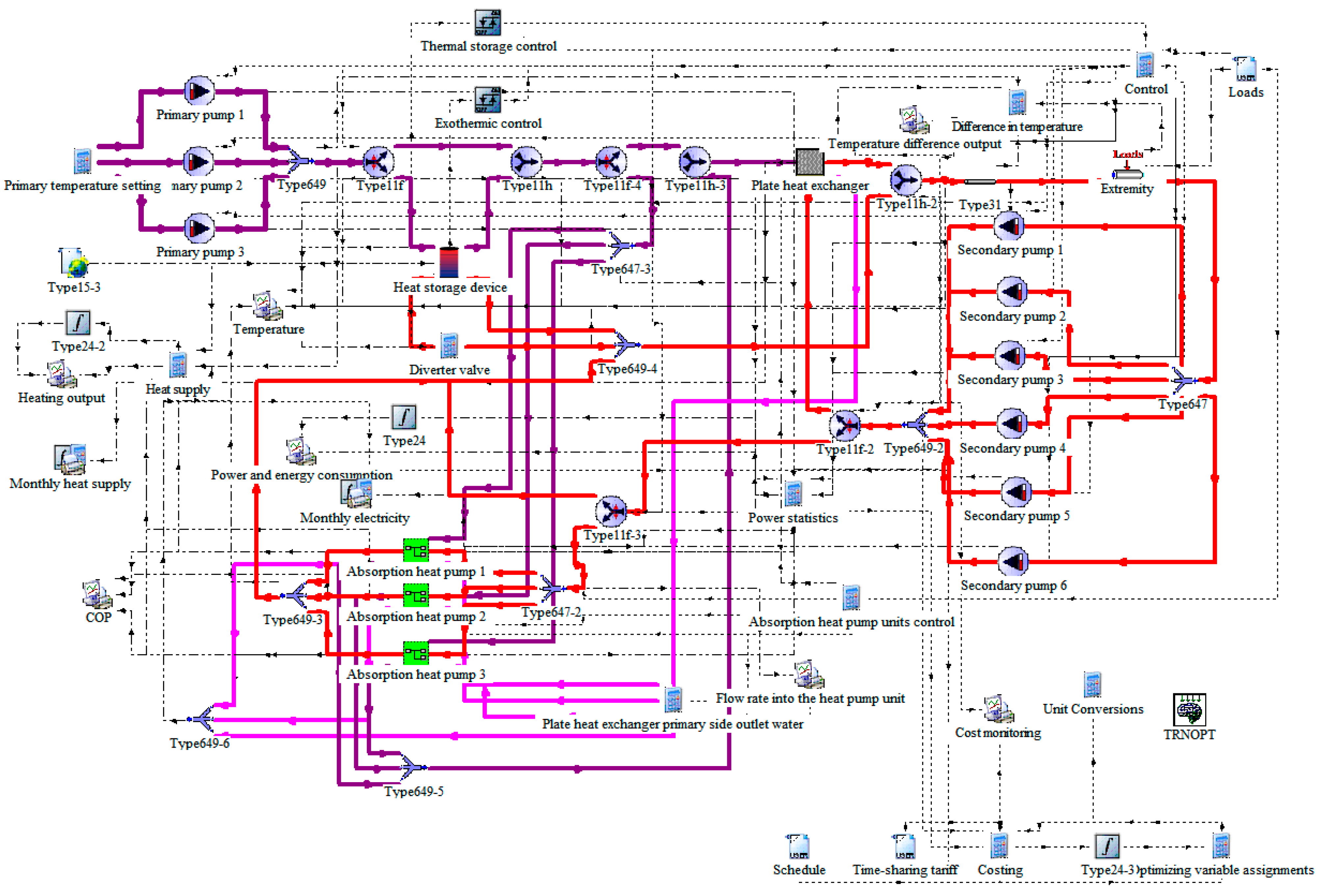

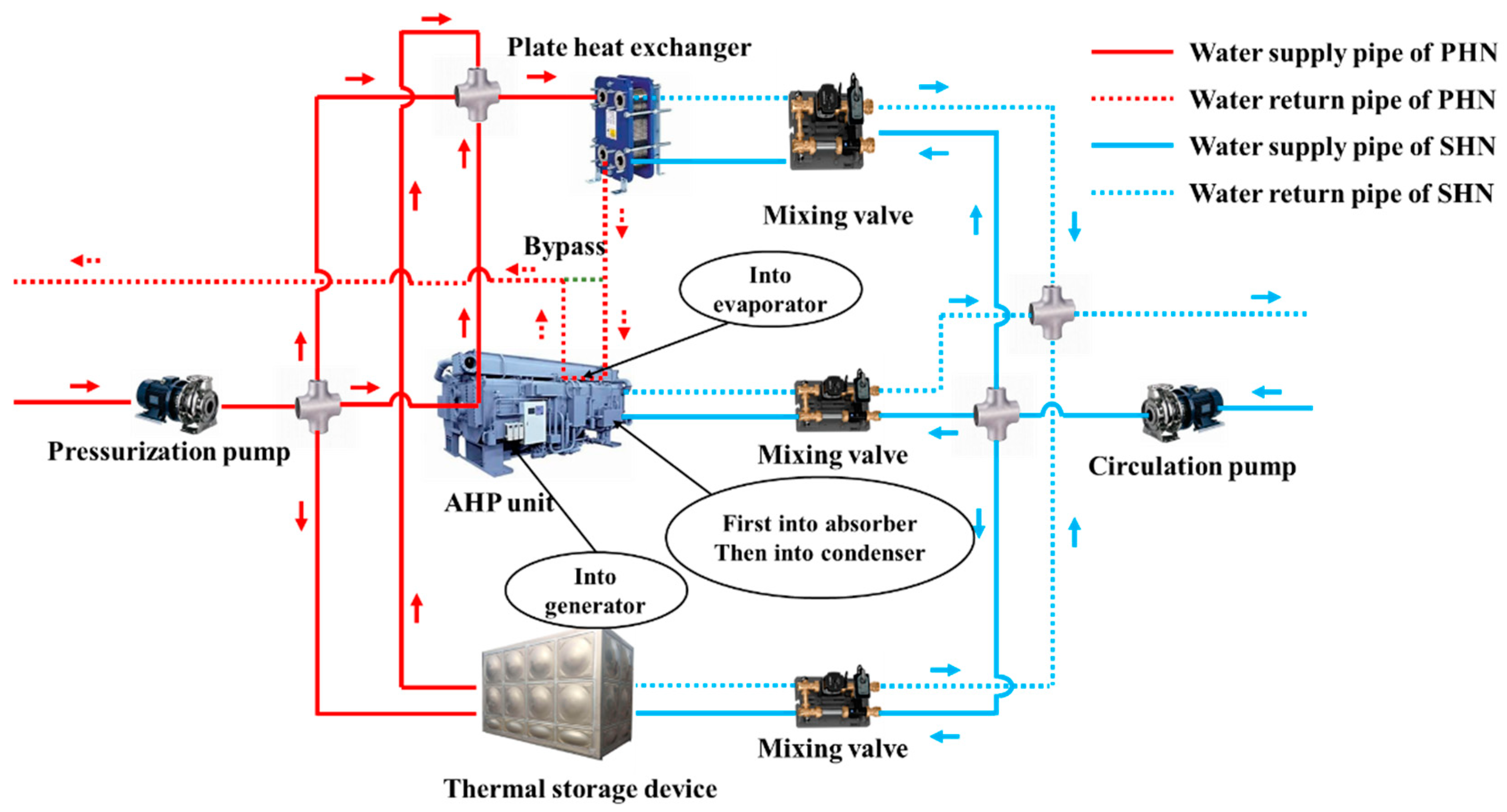

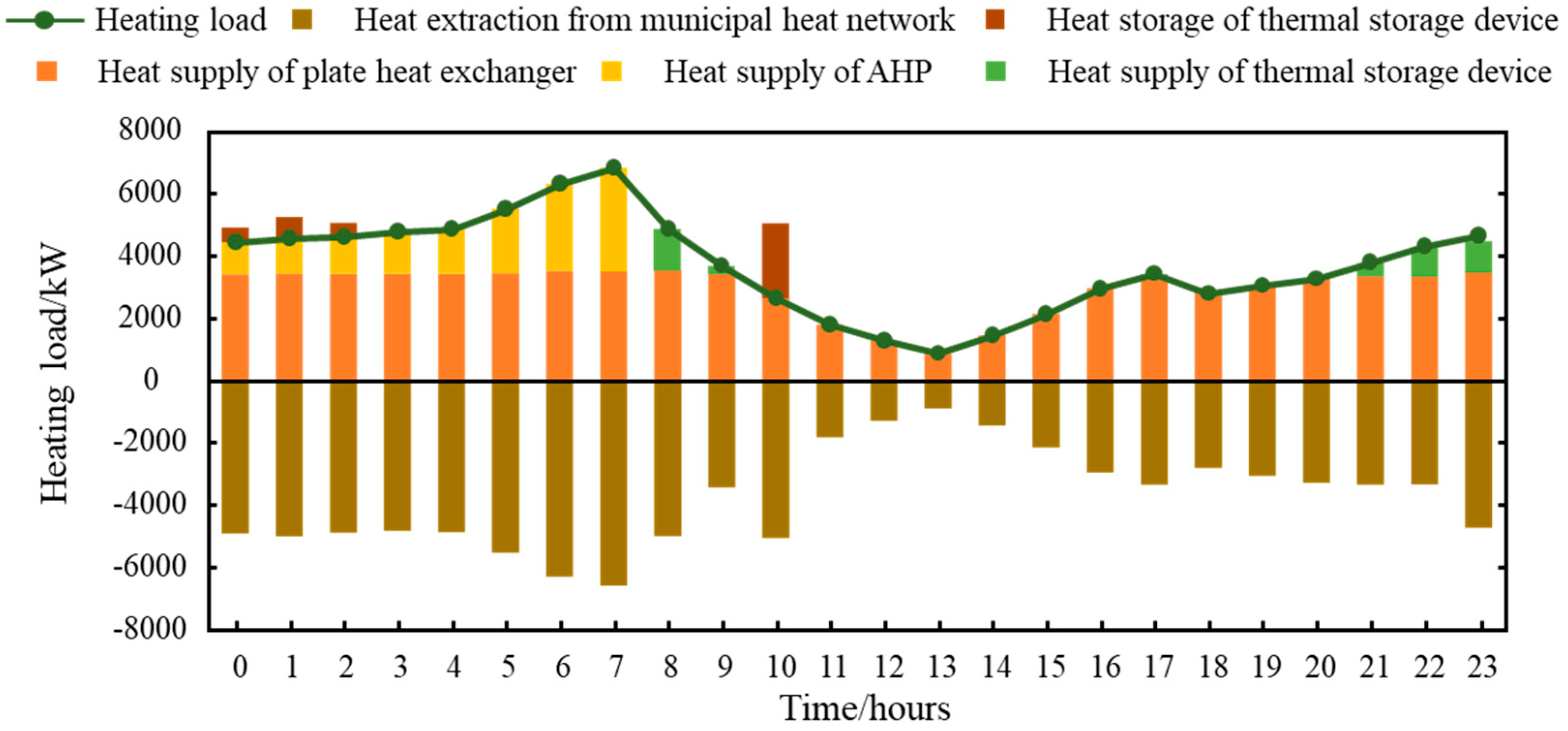

3.2. Hot-Water-Driven ASHS

- (1)

- If the heating load does not exceed the heating capacity of the plate heat exchanger, there is no need to activate the heat pump or the thermal storage device for supplemental heating.

- (2)

- If the heating load exceeds the heating capacity of the plate heat exchanger but the thermal storage device still contains stored heat, priority is given to using it to meet the excess demand.

- (3)

- Only when the heating load exceeds the heating capacity of the plate heat exchanger, and when all of the stored heat in the thermal storage device has been depleted, will the AHP be activated to provide additional heating.

4. Methods

4.1. Mathematical Models

- (1)

- Vapor-compression heat pump unit:

- (2)

- Absorption heat pump unit:

- (3)

- Plate heat exchanger:

- (4)

- Thermal storage device:

- (5)

- Mixing valve:

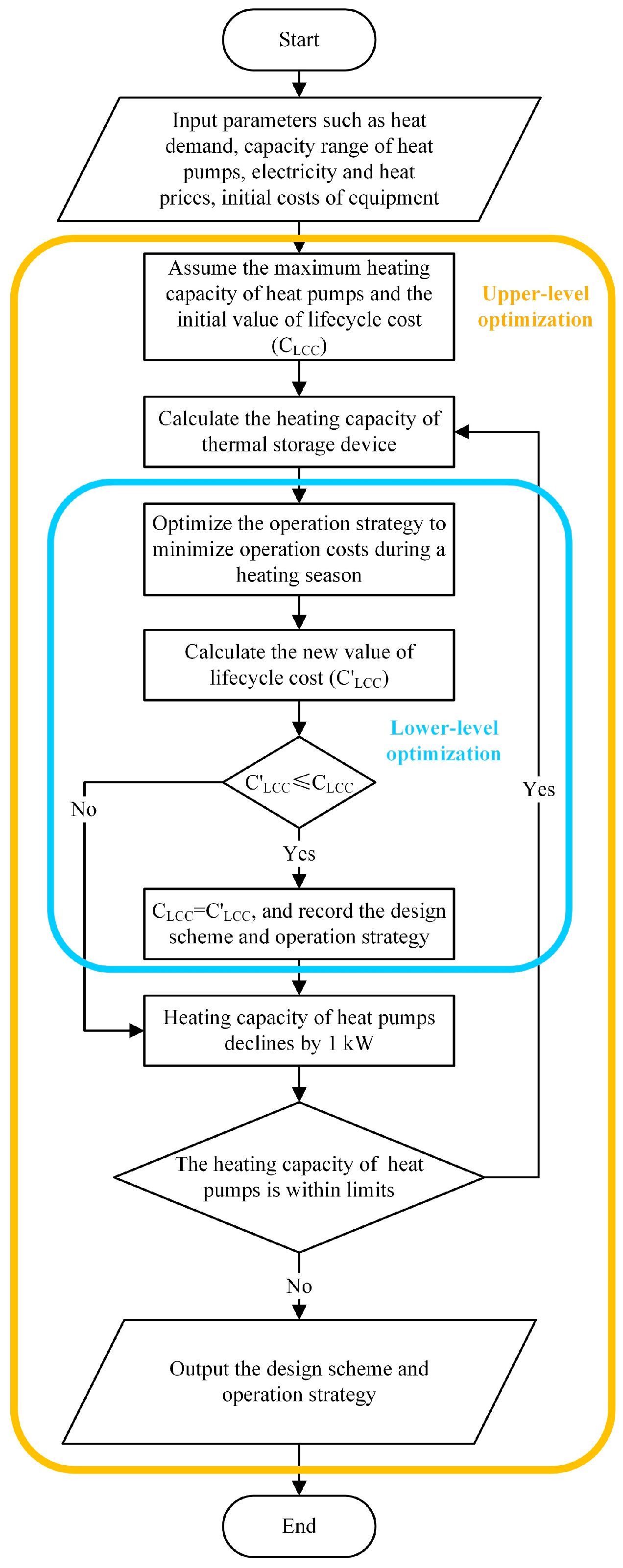

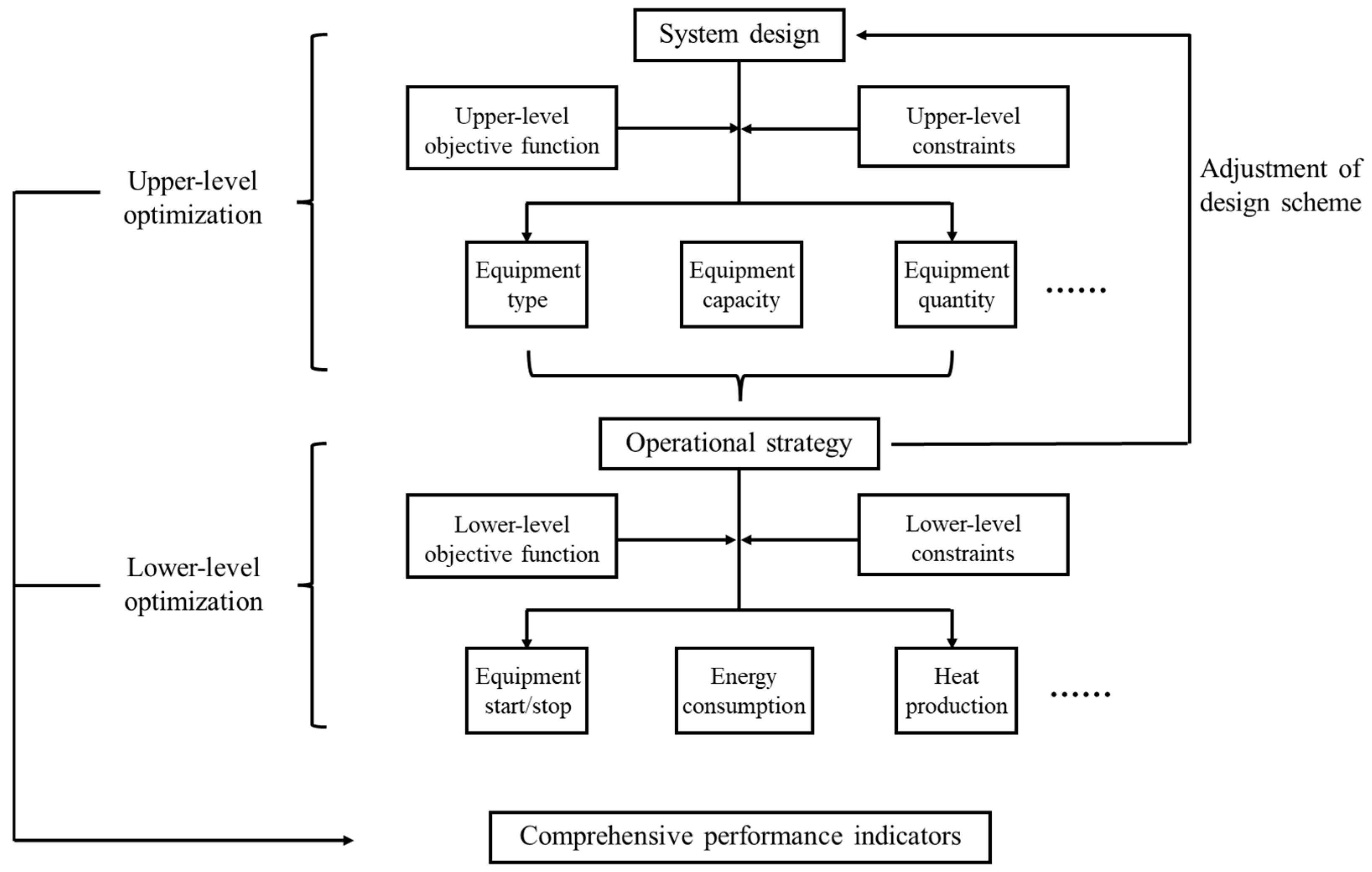

4.2. Bilevel Optimization

4.2.1. Design Optimization

- (1)

- Objective function:

- (2)

- Constraints:

4.2.2. Operational Optimization

- (1)

- Objective function:

- (2)

- Constraints:

4.2.3. Solving Method

4.3. Performance Evaluation Indicators

- (1)

- Economic indicators:

- (2)

- Environmental indicators:

5. Results and Discussion

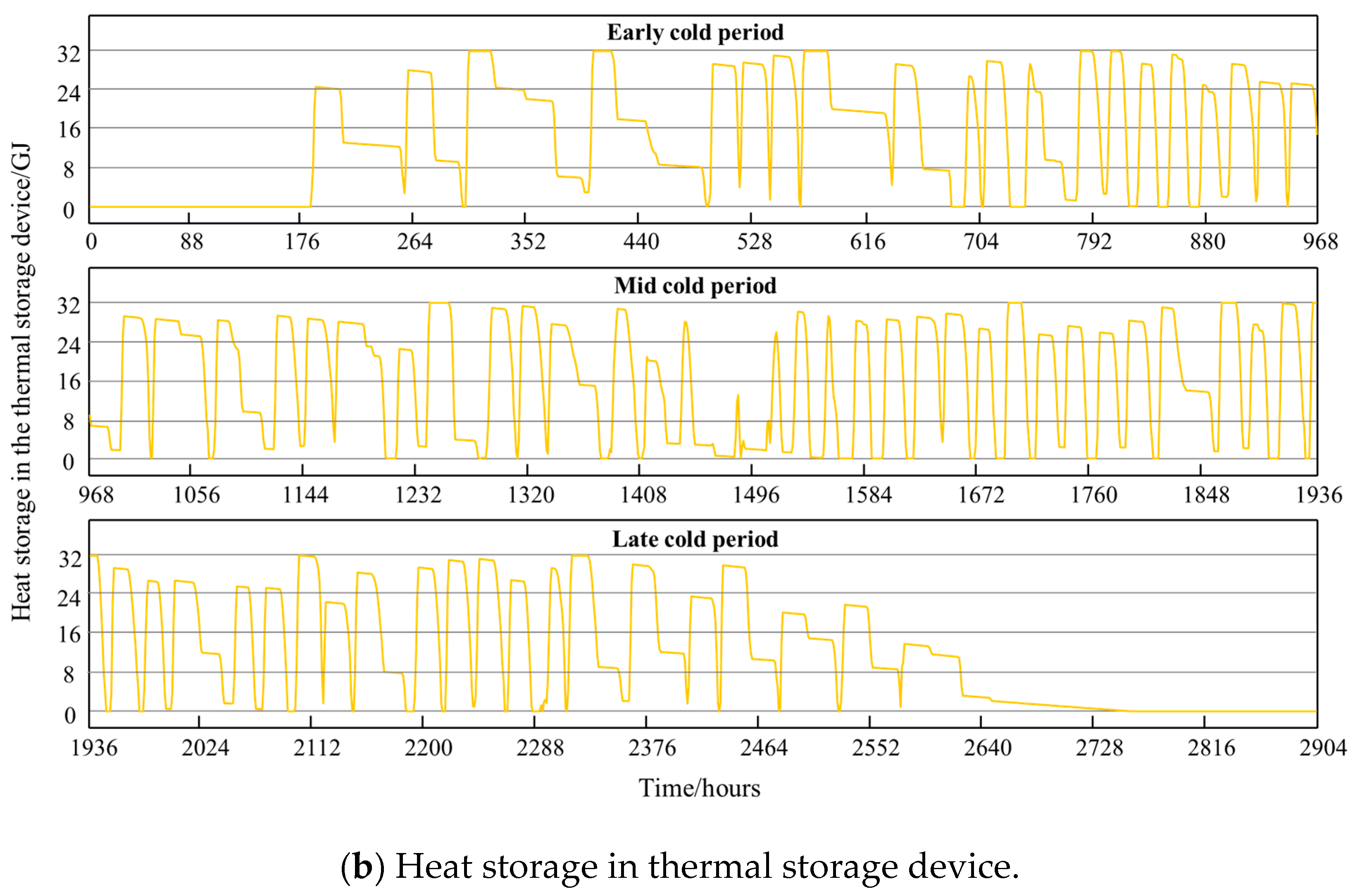

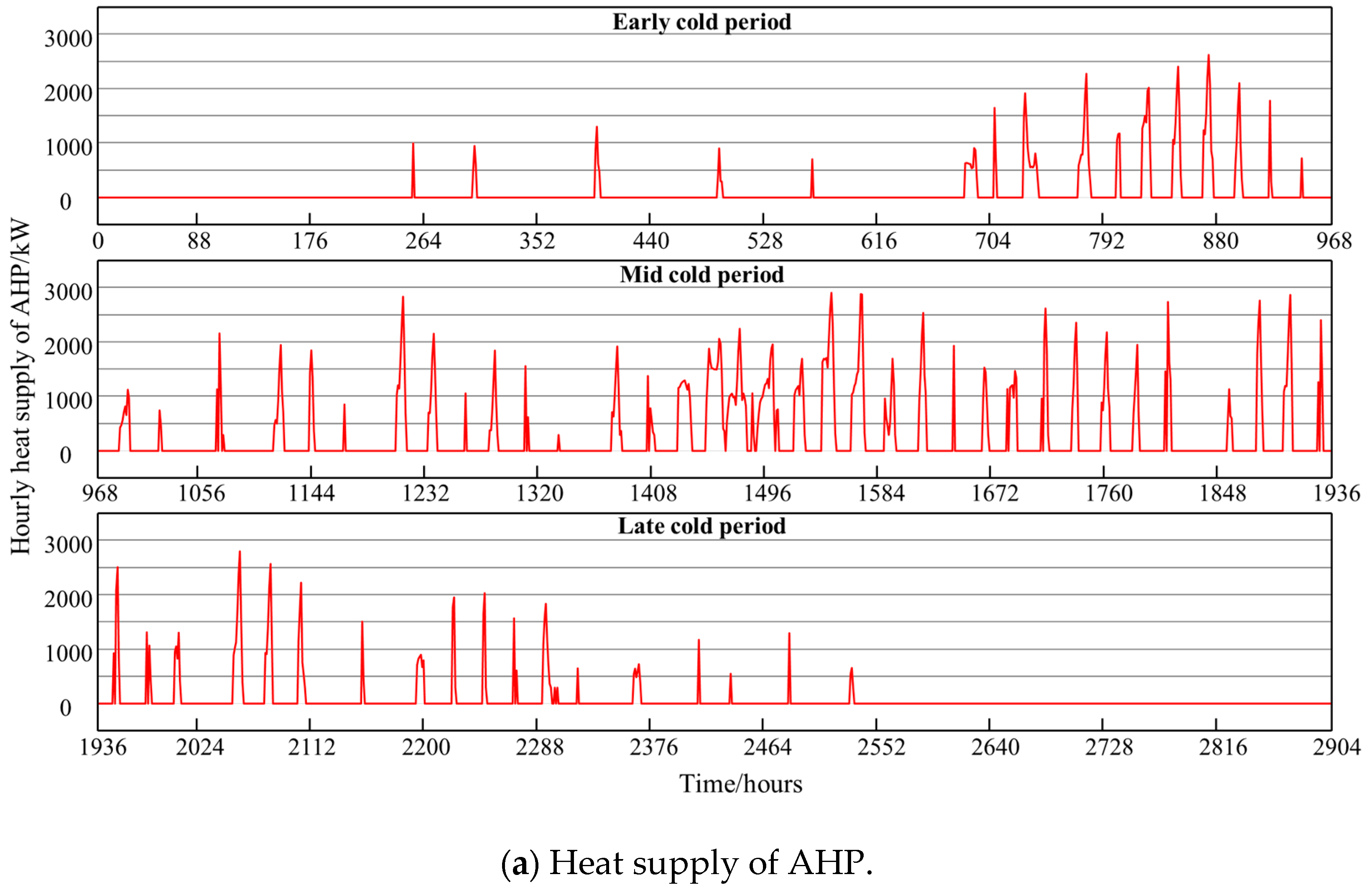

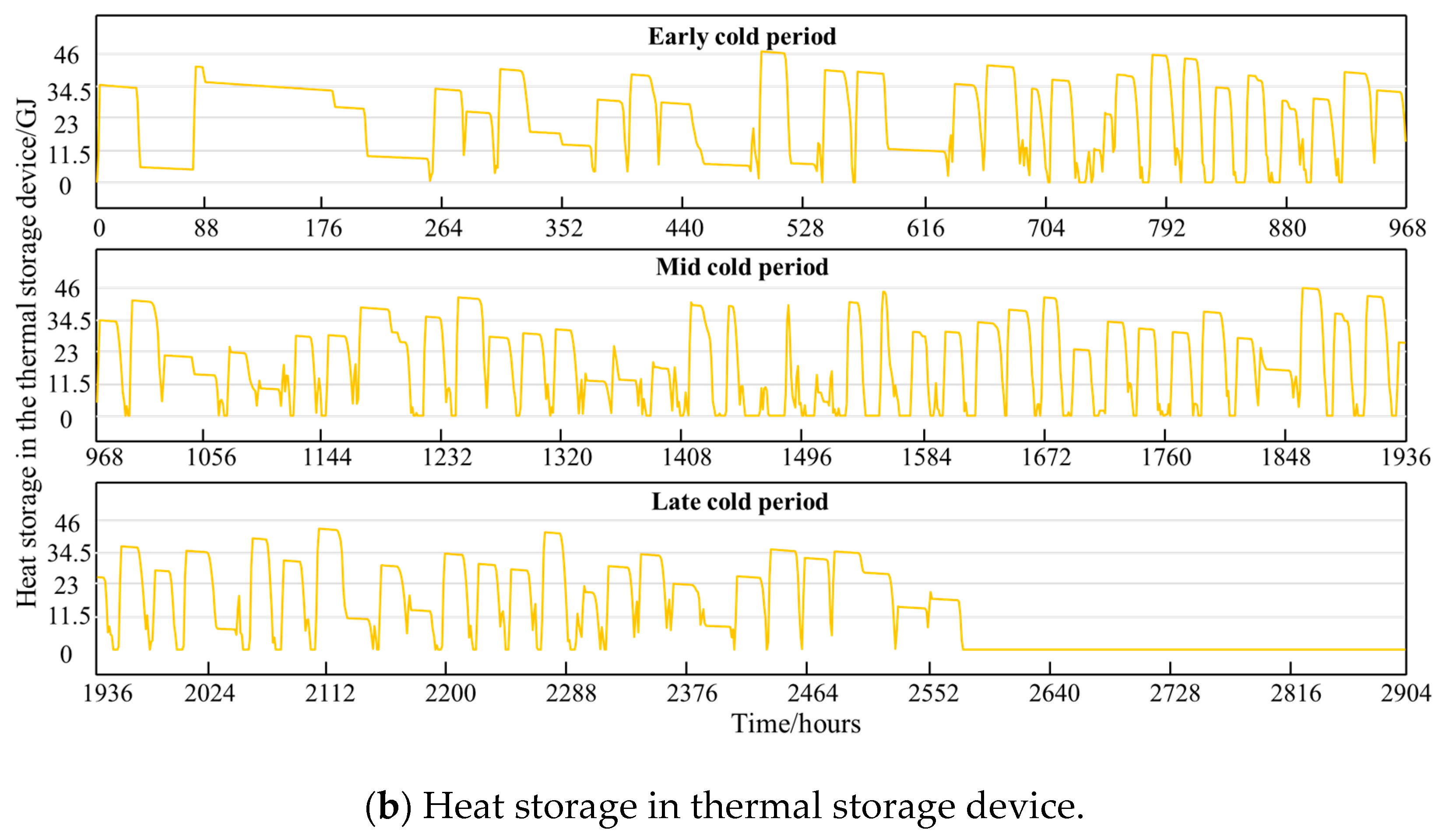

5.1. Results of System Optimization

5.2. Performance Analysis

5.2.1. Analysis of Energy Consumption

5.2.2. Economic Analysis

5.2.3. Analysis of New Equipment Footprint

5.3. Analysis of Regional Applicability

6. Conclusions

- (1)

- Confronted with the dual challenges of inadequate heating capacity of the heat supply station and elevated return water temperature of the PHN, heat pump technology can be employed to further extract heat from the PHN and transfer it to the SHN.

- (2)

- The VCSHS exhibits higher electricity consumption, whereas the ASHS demonstrates greater thermal energy consumption. Overall, the operational energy consumption of the VCSHS is 0.85% higher than that of the ASHS, leading to a 2% increase in carbon emissions.

- (3)

- In the cold region, the NPV of the VCSHS is about 1 million CNY higher than that of the ASHS, resulting in better economics, while in the severe cold region with the lower heat price, the ASHS is more favorable for promotion.

- (4)

- The footprint required for the new equipment in the VCSHS is 99.552 m2, nearly 30% smaller than that in the ASHS, resulting in significant space savings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations | Subscripts | ||

| AHP | Absorption heat pump | ac | Available capacity of grid |

| ASHS | Absorption heat pump supplemental heating system | c | Condenser |

| CNY | Chinese Yuan | dem | Heat demand |

| COP | Coefficient of performance | h | Heat |

| LMTD | Logarithmic mean temperature difference | hs | Heat storage |

| NPV | Net present value | hr | Heat release |

| PHN | Primary heat network | cw | Cold water |

| SHN | Secondary heat network | e | Evaporator |

| VCHP | Vapor-compression heat pump | ee | Electric equipment |

| VCSHS | Vapor-compression heat pump supplemental heating system | el | Electricity |

| Symbols | g | Generator | |

| a, b, c, d, e, f, g, h, i | Correction factors | HP | Heat pump |

| C | Cost, CNY | hw | Hot water |

| cp | Specific heat capacity, kJ/kg·K | IC | Initial cost |

| E | Electricity consumption, W | in | Inlet |

| F | Heat transfer area, m2 | LCC | Lifecycle cost |

| FPHN | CO2 emission factor of the PHN, gCO2/kWh | m | Mixed water |

| FPG | CO2 emission factor of the PG, gCO2/kWh | max | Maximum value |

| G | Flow rate, m3/h | min | Minimum value |

| K | Heat transfer coefficient, W/m2·K | OC | Operational cost |

| n | Service life of equipment, years | out | Outlet |

| P | Price, CNY | p | Heat loss of plate heat exchanger |

| Q | Heat capacity, W | PG | Power grid |

| r | Discount rate, % | PHE | Plate heat exchanger |

| T | Temperature, °C | r | Return water |

| W | Power, W | s | Supply water |

| α | Status variable, using to illustrate whether the TS is charging or discharging | sup | Heat supply |

| η | Efficiency, % | t | Heat loss of thermal storage device |

| τ | Time, s | TS | Thermal storage device |

| Φ | Heat storage, W | z | Total water |

Appendix A

| Envelope Type | Materials | Thickness (mm) | Thermal Conductivity (W/m·K) | Specific Heat Capacity (kJ/kg·K) |

|---|---|---|---|---|

| External walls | Fireproof heat-retaining board | 60 | 0.045 | 1.22 |

| Cement mortar | 80 | 0.81 | 1.05 | |

| Reinforced concrete | 120 | 1.74 | 0.92 | |

| Cement mortar | 20 | 0.81 | 1.05 | |

| Cement mortar | 20 | 0.93 | 1.05 | |

| Concrete of grade C20 | 40 | 1.51 | 0.92 | |

| Roof | Extruded polystyrene board | 115 | 0.03 | 1.22 |

| Concrete | 70 | 0.89 | 1.05 | |

| Reinforced concrete | 120 | 1.74 | 0.92 |

References

- Li, Y.; Ding, Z.; Shakerin, M.; Zhang, N. A multi-objective optimal design method for thermal energy storage systems with PCM: A case study for outdoor swimming pool heating application. J. Energy Storage 2020, 29, 101371. [Google Scholar] [CrossRef]

- Fletcher, C.; Ripple, W.J.; Newsome, T.; Barnard, P.; Beamer, K.; Behl, A.; Bowen, J.; Cooney, M.; Crist, E.; Field, C.; et al. Earth at risk: An urgent call to end the age of destruction and forge a just and sustainable future. PNAS Nexus 2024, 3, 106. [Google Scholar] [CrossRef]

- Du, Y.; Blocken, B.; Pirker, S. A novel approach to simulate pollutant dispersion in the built environment: Transport-based recurrence CFD. Build. Environ. 2020, 170, 106604. [Google Scholar] [CrossRef]

- Hua, E.; Engel, B.A.; Guan, J.; Yin, J.; Wu, N.; Han, X.; Sun, S.; He, J.; Wang, Y. Synergy and competition of water in Food-Energy-Water Nexus: Insights for sustainability. Energy Convers. Manag. 2022, 266, 115848. [Google Scholar] [CrossRef]

- Toroxel, J.L.; Silva, S.M. A review of passive solar heating and cooling technologies based on bioclimatic and vernacular architecture. Energies 2024, 17, 1006. [Google Scholar] [CrossRef]

- Agathokleous, R.; Barone, G.; Buonomano, A.; Forzano, C.; Kalogirou, S.A.; Palombo, A. Building facade integrated solar thermal collectors for air heating: Experimentation, modelling and applications. Appl. Energy 2019, 239, 658–679. [Google Scholar] [CrossRef]

- Tumminia, G.; Guarino, F.; Longo, S.; Aloisio, D.; Cellura, S.; Sergi, F.; Brunaccini, G.; Antonucci, V.; Ferraro, M. Grid interaction and environmental impact of a net zero energy building. Energy Convers. Manag. 2020, 203, 112228. [Google Scholar] [CrossRef]

- Eslami, S.; Noorollahi, Y.; Marzband, M.; Anvari-Moghaddam, A. District heating planning with focus on solar energy and heat pump using GIS and the supervised learning method: Case study of Gaziantep, Turkey. Energy Convers. Manag. 2022, 269, 116131. [Google Scholar] [CrossRef]

- Li, Y.; Nord, N.; Xiao, Q.; Tereshchenko, T. Building heating applications with phase change material: A comprehensive review. J. Energy Storage 2020, 31, 101634. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Liu, X.; Wan, F.; Zheng, W. Multi-Objective Optimization with Active–Passive Technology Synergy for Rural Residences in Northern China. Energies 2024, 17, 1539. [Google Scholar] [CrossRef]

- Elżbieta, K.; Katarzyna, Ł.; Piotr, P. Use of Renewable Energy Sources in the European Union and the Visegrad Group Countries-Results of Cluster Analysis. Energies 2021, 14, 5680. [Google Scholar] [CrossRef]

- Connolly, D. Heat roadmap europe: Quantitative comparison between the electricity, heating, and cooling sectors for different European countries. Energy 2017, 139, 580–593. [Google Scholar] [CrossRef]

- Hua, P.; Wang, H.; Xie, Z.; Lahdelma, R. District heating load patterns and short-term forecasting for buildings and city level. Energy 2024, 289, 129866. [Google Scholar] [CrossRef]

- Yuan, M.; Mathiesen, V.B.; Schneider, N.; Xia, J.; Zheng, W.; Sorknæs, P.; Lund, H.; Zhang, L. Renewable energy and waste heat recovery in district heating systems in China: A systematic review. Energy 2024, 294, 130788. [Google Scholar] [CrossRef]

- Pellegrini, M.; Bianchini, A. The innovative concept of cold district heating networks: A literature review. Energies 2018, 11, 236. [Google Scholar] [CrossRef]

- Averfalk, H.; Ingvarsson, P.; Persson, U.; Gong, M.; Werner, S. Large heat pumps in Swedish district heating systems. Renew. Sustain. Energy Rev. 2017, 79, 1275–1284. [Google Scholar] [CrossRef]

- Ji, Y.; Chen, X.; Yang, X.; Wang, X.; Wang, X.; Xie, J.; Ju, G. Research on the framework and meteorological parameter optimization method of dynamic heating load prediction model for heat-exchange stations. Energy 2024, 309, 133125. [Google Scholar] [CrossRef]

- Jobard, X.; Padey, P.; Guillaume, M.; Duret, A.; Pahud, D. Development and testing of novel applications for adsorption heat pumps and chillers. Energies 2020, 13, 615. [Google Scholar] [CrossRef]

- Volkova, A.; Krupenski, I.; Ledvanov, A.; Hlebnikov, A.; Lepiksaar, K.; Latõšov, E.; Mašatin, V. Energy cascade connection of a low-temperature district heating network to the return line of a high-temperature district heating network. Energy 2020, 198, 117304. [Google Scholar] [CrossRef]

- Sun, F.; Xie, Y.; Svendsen, S.; Fu, L. New low-temperature central heating system integrated with industrial exhausted heat using distributed electric compression heat pumps for higher energy efficiency. Energies 2020, 13, 6582. [Google Scholar] [CrossRef]

- Anand, A.; Deb, C. The potential of remote sensing and GIS in urban building energy modelling. Energy Built Environ. 2024, 5, 957–969. [Google Scholar] [CrossRef]

- United Nations, Department of Economic and Social Affairs, Population Division. World Urbanization Prospects: The 2018 Revision; United Nations: New York, NY, USA, 2019. [Google Scholar]

- Song, Z.; Wang, N.; You, S.; Wang, Y.; Zhang, H.; Wei, S.; Zheng, X.; Guo, J. Integration of geothermal water into secondary network by absorption-heat-pump-assisted district heating substations. Energy Build. 2019, 202, 109403. [Google Scholar] [CrossRef]

- Gao, P.; Chang, M.-M.; Zhang, C.-L.; Shao, L.L. System principles and applications of hybrid sorption–compression heat pump—A review. Int. J. Refrig. 2019, 108, 14–25. [Google Scholar] [CrossRef]

- Gado, M.G.; Hassan, H. Energy-saving potential of compression heat pump using thermal energy storage of phase change materials for cooling and heating applications. Energy 2023, 263, 126046. [Google Scholar] [CrossRef]

- Gadd, H.; Werner, S. Thermal energy storage systems for district heating and cooling. In Advances in Thermal Energy Storage Systems; Woodhead Publishing: Cambridge, UK, 2021; pp. 625–638. [Google Scholar]

- Olympios, A.V.; Sapin, P.; Freeman, J.; Olkis, C.; Markides, C.N. Operational optimisation of an air-source heat pump system with thermal energy storage for domestic applications. Energy Convers. Manag. 2022, 273, 116426. [Google Scholar] [CrossRef]

- Love, J.; Smith, A.Z.; Watson, S.; Oikonomou, E.; Summerfield, A.; Gleeson, C.; Biddulph, P.; Chiu, L.F.; Wingfield, J.; Martin, C.; et al. The addition of heat pump electricity load profiles to GB electricity demand: Evidence from a heat pump field trial. Appl. Energy 2017, 204, 332–342. [Google Scholar] [CrossRef]

- Đuranović, M.; Živić, M.; Stojkov, M.; Lujić, R. Analysis of energy consumption of a thermo-technical system with an absorption heat pump. Teh. Vjesn. 2024, 31, 967–972. [Google Scholar]

- Tarique, S.M.; Siddiqui, M.A. Performance and economic study of the combined absorption/compression heat pump. Energy Convers. Manag. 1999, 40, 575–591. [Google Scholar] [CrossRef]

- Dzierwa, P.; Peret, P.; Trojan, M.; Kaczmarski, K. Energy and economic analysis of flue gas heat recovery systems improving the energy efficiency of gas cogeneration units. E3S Web Conf. 2024, 551, 01006. [Google Scholar] [CrossRef]

- Mirl, N.; Schmid, F.; Bierling, B.; Spindler, K. Design and analysis of an ammonia-water absorption heat pump. Appl. Therm. Eng. 2020, 165, 114531. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, S.; Fu, Y.; Liu, M.; Liu, J.; Yan, J. Heat–power decoupling for the CHP unit by utilizing heat storage in the district heating system integrated with heat pumps: Dynamic modeling and performance analysis. Energy 2024, 306, 132485. [Google Scholar] [CrossRef]

- Wang, X.; Tian, H.; Yan, F.; Feng, W.; Wang, R.; Pan, J. Optimization of a distributed energy system with multiple waste heat sources and heat storage of different temperatures based on the energy quality. Appl. Therm. Eng. 2020, 181, 115975. [Google Scholar] [CrossRef]

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste heat recovery technologies and applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Jiang, X.; Jing, Z.; Li, Y.; Wu, Q.; Tang, W. Modelling and operation optimization of an integrated energy based direct district water-heating system. Energy 2014, 64, 375–388. [Google Scholar] [CrossRef]

- Buoro, D.; Pinamonti, P.; Reini, M. Optimization of a distributed cogeneration system with solar district heating. Appl. Energy 2014, 124, 298–308. [Google Scholar] [CrossRef]

- Allouhi, A.; Agrouaz, Y.; Amine, M.B.; Rehman, S.; Buker, M.; Kousksou, T.; Jamil, A.; Benbassou, A. Design optimization of a multi-temperature solar thermal heating system for an industrial process. Appl. Energy 2017, 206, 382–392. [Google Scholar] [CrossRef]

- Carpaneto, E.; Lazzeroni, P.; Repetto, M. Optimal integration of solar energy in a district heating network. Renew. Energy 2015, 75, 714–721. [Google Scholar] [CrossRef]

- Building Energy Efficiency Research Centre of Tsinghua University. China Building Energy Efficiency Annual Development Research Report 2023; China Architecture & Building Press: Beijing, China, 2023. [Google Scholar]

| Item | Parameter | Value |

|---|---|---|

| Plate heat exchanger (original) | Design heating capacity | 3352 kW |

| Rated outlet temperature | 50 °C | |

| Pressurization pump (original) | Number of units | 3 units |

| Rated flow rate | 16 m3/h | |

| Circulation pump (original) | Number of units | 3 units |

| Rated flow rate | 98 m3/h | |

| Heat pump | Number of units | 3 units |

| Power range | 20–100% | |

| Pressurization pump (only for ASHS) | Number of units | 1 unit |

| Circulation pump | Number of units | 3 units |

| Thermal storage device | Maximum storage temperature | 90 °C |

| Minimum discharge temperature | 55 °C | |

| PHN | Supply water temperature | 110 °C |

| SHN | Peak heating load | 6846 kW |

| Supply water temperature | 55 °C | |

| Return water temperature | 45 °C |

| Item | Classification | Value |

|---|---|---|

| Initial cost | VCHP | 450 CNY/kW |

| AHP | 750 CNY/kW | |

| Water pump | 140 CNY/(m3/h) | |

| Thermal storage device | 5000 CNY/GJ | |

| Installation cost | 2.5% of purchasing cost | |

| Electricity price | Peak hours (10:00–13:00, 17:00–22:00) | 1.29 CNY/kWh |

| Plain hours (7:00–10:00, 13:00–17:00, 22:00–23:00) | 0.77 CNY/kWh | |

| Valley hours (23:00–7:00 the next day) | 0.29 CNY/kWh | |

| Heat price | - | 86.5 CNY/GJ |

| Break-even point | Break-even point is the cost of electric heating that is equal to the heat price | 0.3114 CNY/kWh |

| Item | VCSHS | ASHS |

|---|---|---|

| Rated capacity of heat pump 1 | 1100 kW | 1050 kW |

| Rated capacity of heat pump 2 | 850 kW | 750 kW |

| Rated capacity of heat pump 3 | 1200 kW | 1150 kW |

| Rated flow rate of circulation pump 1 | 94 m3/h | 97 m3/h |

| Rated flow rate of circulation pump 2 | 98 m3/h | 91 m3/h |

| Rated flow rate of circulation pump 3 | 102 m3/h | 106 m3/h |

| Rated flow rate of pressurization pump 1 | - | 16 m3/h |

| Thermal storage device capacity | 32.52 GJ | 46.61 GJ |

| Category | Item | VCSHS | ASHS |

|---|---|---|---|

| Electricity (kWh) | Pressurization pump | 1.16 × 104 | 9.79 × 103 |

| Circulation pump | 6.51 × 104 | 6.51 × 104 | |

| Heat pump | 9.32 × 104 | - | |

| Total | 1.70 × 105 | 7.49 × 104 | |

| Heat (kWh) | Plate heat exchanger | 6.84 × 106 | 6.88 × 106 |

| Heat pump | 3.67 × 105 | 3.32 × 105 | |

| Thermal storage device | 2.85 × 105 | 3.20 × 105 | |

| Total | 7.50 × 106 | 7.53 × 106 | |

| CO2 emissions (tons) | Total | 2221.97 | 2179.04 |

| System Type | Initial Cost (Million CNY) | Annual Operational Cost (Million CNY) | NPV (Million CNY) |

|---|---|---|---|

| VCSHS | 1.7087 | 2.4830 | 19.0305 |

| ASHS | 2.8749 | 2.4662 | 18.0744 |

| Equipment Type | VCSHS | ASHS |

|---|---|---|

| Heat pump 1 | Length × width: 3540 × 2100 mm Occupied area: 7.434 m2 | Length × width: 5000 × 2250 mm Occupied area: 11.25 m2 |

| Heat pump 2 | Length × width: 3500 × 1800 mm Occupied area: 6.3 m2 | Length × width: 3950 × 2180 mm Occupied area: 8.611 m2 |

| Heat pump 3 | Length × width: 3540 × 2100 mm Occupied area: 7.434 m2 | Length × width: 5000 × 2250 mm Occupied area: 11.25 m2 |

| Circulation pump 1 | Length × width: 1800 × 860 mm Occupied area: 1.548 m2 | Length × width: 1800 × 860 mm Occupied area: 1.548 m2 |

| Circulation pump 2 | Length × width: 1800 × 860 mm Occupied area: 1.548 m2 | Length × width: 1800 × 860 mm Occupied area: 1.548 m2 |

| Circulation pump 3 | Length × width: 1800 × 860 mm Occupied area: 1.548 m2 | Length × width: 1800 × 860 mm Occupied area: 1.548 m2 |

| Pressurization pump 1 | - | Length × width: 1300 × 540 mm Occupied area: 0.702 m2 |

| Thermal storage device | Height: 3000 mm Occupied area: 73.74 m2 | Height: 3000 mm Occupied area: 105.69 m2 |

| Total | 99.552 m2 | 142.147 m2 |

| Shenyang | Beijing | |

|---|---|---|

| Climate zone | Severe cold region | Cold region |

| Heating season | 1 November–31 March | 15 November–15 March |

| Peak heating load | 7470 kW | 6846 kW |

| Heating shortfall | 4118 kW | 3494 kW |

| Electricity price | 0.781 CNY/kWh | Peak hours: 1.29 CNY/kWh Plain hours: 0.77 CNY/kWh Valley hours: 0.29 CNY/kWh |

| Heat price | 44 CNY/GJ | 86.5 CNY/GJ |

| Break-even points | 0.1584 CNY/kWh | 0.3114 CNY/kWh |

| System Type | Equipment Type | Shenyang | Beijing |

|---|---|---|---|

| VCSHS | Heat pump | 4000 kW | 3150 kW |

| Thermal storage device | 31.08 GJ | 32.52 GJ | |

| ASHS | Heat pump | 3350 kW | 2950 kW |

| Thermal storage device | 59.44 GJ | 46.61 GJ |

| Representative City | System Type | Electricity Consumption (kWh) | Heat Consumption (kWh) | Initial Cost (Million CNY) | Annual Operational Cost (Million CNY) | NPV (Million CNY) |

|---|---|---|---|---|---|---|

| Shenyang | VCSHS | 1.13 × 106 | 1.56 × 107 | 2.0575 | 3.3534 | 12.6108 |

| ASHS | 1.96 × 105 | 1.65 × 107 | 2.9349 | 2.7664 | 18.5799 | |

| Beijing | VCSHS | 1.70 × 105 | 7.50 × 106 | 1.7087 | 2.4830 | 19.0305 |

| ASHS | 7.49 × 104 | 7.53 × 106 | 2.8749 | 2.4662 | 18.0744 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, Z.; Wang, Q.; He, Y.; Liu, S.; Wang, Z.; Fan, X.; Zhang, H.; Zheng, W. Optimization and Performance Comparison of Heat Pump Supplemental Heating Systems in a Heat Supply Station. Sustainability 2025, 17, 2513. https://doi.org/10.3390/su17062513

Wan Z, Wang Q, He Y, Liu S, Wang Z, Fan X, Zhang H, Zheng W. Optimization and Performance Comparison of Heat Pump Supplemental Heating Systems in a Heat Supply Station. Sustainability. 2025; 17(6):2513. https://doi.org/10.3390/su17062513

Chicago/Turabian StyleWan, Zhihao, Qianying Wang, Yuesong He, Sujie Liu, Zhaoying Wang, Xianwang Fan, Huan Zhang, and Wandong Zheng. 2025. "Optimization and Performance Comparison of Heat Pump Supplemental Heating Systems in a Heat Supply Station" Sustainability 17, no. 6: 2513. https://doi.org/10.3390/su17062513

APA StyleWan, Z., Wang, Q., He, Y., Liu, S., Wang, Z., Fan, X., Zhang, H., & Zheng, W. (2025). Optimization and Performance Comparison of Heat Pump Supplemental Heating Systems in a Heat Supply Station. Sustainability, 17(6), 2513. https://doi.org/10.3390/su17062513