Abstract

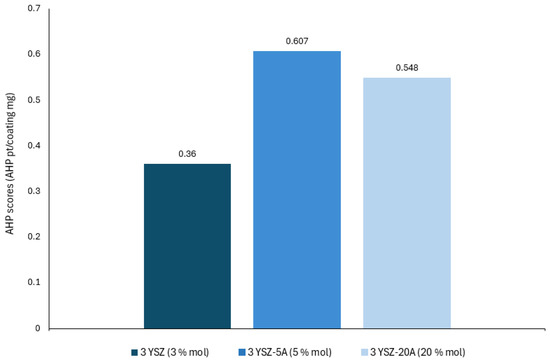

Sol-gel coatings are commonly used to prevent corrosion from molten salt mixtures in CSP plants. Until now, they have been driven primarily by cost considerations, without integrating environmental criteria into the modeling and decision-making process. The novelty of this study lies in the development of an evaluation framework that incorporates environmental impact alongside technical and economic factors, providing a more sustainable approach. This work assesses porosity, thermal shock resistance, and thickness to determine the optimal sol-gel coating. For this purpose, the multi-criteria decision-making technique “Analytic Hierarchy Process” (AHP) and the Life Cycle Assessment (LCA) methodology are implemented. The results show that the scores obtained for the 3YSZ-5A (5% mol) coating are higher than those of the 3YSZ (3% mol) and 3YSZ-20A (20% mol) coatings, between 1.52 and 1.69, respectively. The 3YSZ-5A coating (5% mol) is the optimal solution among all the systems analyzed, with a score of 0.61 AHP pt. The coating of the same type and higher molar concentration (20%) achieved 0.55 AHP pt. Finally, the 3YSZ type coating received the lowest rating, with a score of 0.36 AHP pt. The insights generated in this research will support decision-making in the design and maintenance of CSP plants.

1. Introduction

Global energy needs have increased as a result of rising standards of comfort and living [1]. In addition, the depletion of fossil fuels and the cost of traditional energy sources have led scientists to focus to renewable energy [2]. Solar energy is considered one of the most accessible renewable energy supplies [3]. Solar thermal technologies include Concentrated Solar Power (CSP), where the linear Fresnel, solar power tower, parabolic dish, compound parabolic trough and parabolic trough collector are the most common types [4].

Currently, Parabolic Trough Solar Collectors (PTSCs) are the most mature and commercially viable technology [5]. This makes them suitable for industrial and residential applications. In a PTSC system, the incoming solar radiation is reflected onto a receiver tube, where the solar energy is absorbed. In this technology, temperatures range from 60 °C to 400 °C, with electricity generation being the most efficient application [6].

On the other hand, molten salt (MS) mixtures are gaining relevance as heat transfer base fluids due to their ability to operate over a wider temperature range [7]. The use of molten salt mixtures in CSP plants improves their reliability and reduces the levelized cost of energy [8]. This is mainly because fluids such as water, oil or ethylene glycol have a boiling point below 400 °C [9].

However, the degradation of materials due to corrosion has been an important topic of study, especially related to molten salts [10]. In this context, the corrosiveness of solar salt to certain metals and its solidification at around 230 °C entail risks for system components and fluid circulation. This compromises the structural integrity of thermal storage system components, including piping, tanks and valves [11].

1.1. CSP Plant Protective Coatings

Protective coatings are one of the most widely applied passive protection methods in the prevention of corrosion of metallic elements in CSP plants [12]. Nowadays, several scientific studies address the influence of coverings on the corrosion caused by molten nitrate salts on the metallic elements of CSP power plants. Among them, protective coatings manufactured by sol-gel methods, spray application, thermal spraying, diffusion coverings and suspension ones are the most important [7].

Sol-gel is a widely applied method for developing coatings, particularly those composed of oxides, which are among the most commonly used to mitigate corrosion, wear and heat degradation [13]. Their widespread application is attributed to their excellent protective performance in these conditions. Furthermore, sol-gel coatings have gained significant acceptance in various industries due to their cost-effectiveness and desirable properties [14]. Among them, Yttria-Stabilized Zirconia (YSZ) is a suitable choice because of its properties [15]. Yttria-stabilized zirconia is a ceramic material in which the ZrO2 structure is stabilized by the addition of yttrium oxide [13]. In contrast to other coatings, such as Al2O3, YSZ ceramic coatings offer higher thermal and chemical stability, good thermal shock resistance and anti-aging performance [16].

Sol-gel is a method for producing solids from molecules converted into a colloidal solution (sol), resulting in an integrated state (gel) [17]. The process consists of coating a substrate with a precursor solution containing the coating material, allowing solvent evaporation and/or chemical reactions to transform it into a gel layer [15]. Among the main advantages are its low initial cost, good adaptability to tanks and pipelines, good corrosion resistance and low cost of ownership, as well as good resistance to corrosion and low processing temperature [17]. In addition, this type of coating prolongs the service life and increases various capabilities of the materials (wear resistance, thermal resistance, hardness, etc.) while maintaining their basic properties [18]. Sol-gel solutions can be deposited through various methods, such as spin-coating, sputtering, electro-deposition, and dip-coating, among others [19].

1.2. Background

The maturity of molten salt storage technology has led to more than 80% of CSP capacity under construction incorporating PTSC technologies. In the context of the decarbonization of the energy sector, it is necessary to incorporate new materials and/or develop studies that analyze not only technical and economic criteria, but also ecological and/or sustainable aspects [20]. However, the use of molten salts as a heat transfer fluid presents certain challenges, primarily related to their high freezing temperature and the corrosion they may induce in the metallic components of the facilities [21]. In this regard, it is crucial to evaluate corrosion mitigation strategies through the optimization of salt composition, the selection of corrosion-resistant materials and/or the development of optimal protective coatings.

In the field of protective coatings, research has traditionally focused on the techno-economic analysis of different solutions, evaluating and characterizing their response and/or efficiency against corrosion. Along these lines, authors such as Dorcheh and Galetz (2016) analyzed the efficiency of aluminum slurry coatings as a solution to the corrosion process suffered by P91 and SS304 in molten nitrate salt [22]. Gomes et al. (2016) evaluated the corrosion resistance of two stainless steels during isothermal immersion in a mixture of nitrate salt [23]. Gomez-Vidal and Morton (2016) evaluated the use of SiO2 coatings on SS347 steel working in contact with eutectic mixtures of carbonates and chlorides [24]. Audigié et al. (2017) proposed and developed aluminide slurry coatings deposited on ferritic–martensitic steel P92 [25].

Other authors, such as Tsuda et al. (2018), developed a porous coating of black pigments and TiO2 that showed higher absorbance and durability than Pyromark in tests at high temperatures [26]. Fähsing et al. (2018) investigated the corrosion behavior in molten salts of T91 and VM12 coated and uncoated ferritic–martensitic steels for application in CSP plants [27]. Fernandez and Cabeza (2020) analyzed the corrosion resistance of different alumina-forming alloys in contact with a molten salt of ternary chloride for CSP applications [28]. Luo et al. (2022) conducted immersion corrosion tests to explore the corrosion behavior of the aluminide coating prepared on LiNaK molten carbonate salt [29]. Finaly, Siripongsakul et al. (2024) evaluated the addition of Si in NiCrAl coatings on AISI 304 stainless steel exposed to molten nitrate salt [30].

In the last decade, the interest in ceramic protective coatings based on sol-gel technologies has significantly increased in the context of CSP plants. This trend is attributed to their excellent performance in terms of corrosion resistance, wear and high-temperature stability, making them a promising alternative for enhancing the durability and efficiency of components exposed to extreme conditions. As a result, new research lines have emerged, focusing on the detailed analysis of this type of coating, evaluating its applicability in various configurations and operational conditions. In this regard, several authors have explored the development and optimization of this type of coating. Mihelcic et al. (2015) developed coatings for solar thermal energy conversion by sol-gel immersion coating methods [31]. Joly et al. (2015) prepared precursor solutions by the sol-gel method to deposit Cu-Co-Mn-Si oxides as black selective coatings on CSP receiver tubes [32]. Pérez et al. (2017) deposited sol-gel coatings of ZrO2–Y2O3 on AISI 304 substrates by isothermal immersion in solar salts. The results showed that it is necessary to study the coatings at times longer than 1000 h [19]. Encinas-Sánchez et al. (2023) evaluated the protective behavior of sol-gel ZrO2–3%molY2O3 deposited with a dip-coating technique on steel. It was demonstrated that these coatings are an option to mitigate corrosion processes caused by molten salts [18]. Rossi et al. (2024) developed a multilayer spectrally selective coating for CSP receiver tubes, designed for open-air operation at 600 °C. The coating, based on a W-Cr-Ti infrared reflector and absorber layers obtained via sol-gel, thermal oxidation and sputtering, demonstrated high thermal stability after 2000 h of aging [33]. Nishath Tharanum et al. (2025) deposited thin films of V2O5 onto an Al-6061 substrate using a sol-gel process combined with the spin-coating technique. They evaluated the anticorrosion properties of the coated substrate and concluded that the surface exhibited enhanced corrosion resistance compared to the uncoated material [34]. Finally, Sibin et al. (2025) developed fractal-textured Cu-MnOx and Cu-CoOx solar absorber coatings for CSP plants using electrodeposition on Inconel 625. These coatings achieved ~96% optical efficiency, surpassing previous reports by ~5%. Durability tests confirmed their stability under mechanical and environmental stress, ensuring long-term suitability for CSP applications [35].

There is a limited body of scientific literature addressing the search for the optimal sol-gel coating based on comparative analytical methods. Moridi et al. (2021) applied the Analytic Hierarchy Process (AHP) to assess the improvement in corrosion resistance of three thin films of ZrO2 and ZrO2–Al2O3 doped with corrosion inhibitors (benzotriazole and cerium nitrate) and deposited via the dip-coating technique. To this end, the films were characterized in terms of chemical composition, crystalline structure, surface morphology and thickness using techniques such as X-ray diffraction and ellipsometry [36]. Other authors, such as Lagopati et al. (2024), employed the TOPSIS method to determine the optimal combination of physicochemical parameters in the synthesis of nanomaterials and to select the best alternative among fifteen sol-gel samples of nanostructured TiO2 [37]. However, none of these studies considered the environmental dimension, which is a crucial aspect in the characterization of ceramic coatings, as it constrains their design and production.

In the CSP field, some multidimensional comparative analyses have been conducted for different plant components and/or facilities. For instance, Botejara-Antúnez et al. (2025) analyzed the environmental, technical and economic aspects of various types of heat transfer fluids (HTFs) for parabolic trough solar collector (PTSC) plants, demonstrating the critical role of such analyses in CSP decision-making processes [38]. However, no studies have addressed the identification of the optimal sol-gel coating for CSP plants based on the specific characteristics and requirements of these facilities. Therefore, the objective of the present study is to fill this gap in the scientific literature by seeking to reduce the environmental impact associated with this type of energy production facility and by providing an optimal solution based on environmental impact considerations and the previously defined technical requirements.

1.3. Novelty and Objectives of the Research

Until now, sol-gel coatings of the metallic elements of CSP plants have been applied to try to minimize the cost variable and maximize the critical thickness of passive protection. However, this approach has predominantly focused on technical and economic factors, often overlooking environmental considerations.

This study aims to address this gap in current methodologies by creating a decision-making framework using the “Analytic Hierarchy Process” (AHP) [39]. This approach facilitates a comprehensive and organized assessment of sol-gel coatings in CSP plants, factoring in multiple criteria such as technical, economic and environmental considerations. By incorporating Life Cycle Assessment (LCA) [40], the framework provides a detailed, quantitative evaluation of the environmental impact throughout the lifecycle of each coating [41].

The integration of AHP and LCA in this study introduces a more thorough and sustainable evaluation compared to traditional approaches. The results will enable the identification of the most environmentally efficient coating options that satisfy both performance and economic criteria, fostering a more sustainable trajectory for CSP technologies.

The knowledge gained will assist decision-makers in selecting optimal sol-gel coatings for CSP plants, aiding the sector in achieving its dual objectives of high performance and reduced environmental impact, while contributing to the broader sustainability goals of the industry.

2. Materials and Methods

A comparative analysis has been made between 3 sol-gel solutions used in CSP plants operating with molten salt mixtures, based on their main characteristics (technical, environmental and economic). The Analytic Hierarchy Process was used for this purpose.

Corrosion resistance, thermal stability, reflection rate and energy efficiency were considered as limiting factors. Thus, the study was restricted to the use of sol-gel solutions based on zirconium ions (Zr4⁺). Likewise, stabilizers such as yttria (Y2O3), magnesium oxide (MgO) and calcium oxide (CaO) were evaluated to mitigate the structural degradation of the coating and optimize its mechanical and thermal properties. Experimental results indicated that yttria, as a stabilizing agent, prevents the transition between tetragonal-monoclinic phases, allowing the retention of the tetragonal and/or cubic phases in a stable or metastable state at room temperature [42]. This fact provides the sol-gel solutions with high stiffness, wear resistance, chemical inertness and ionic conductivity [43]. Consequently, the exclusive use of yttria stabilizers was chosen. Finally, the use of alumina (Al2O3), in different concentrations, as a dopant agent in the coating enrichment was evaluated [44].

To guarantee adequate protection against corrosion and degradation caused by molten salts, all the substrates underwent a pre-treatment of polishing and roughing, ensuring the correct adhesion of the sol-gel coating. Moreover, the multilayer dip-coating technique was employed to coat the different sol-gel solutions. This optimizes the operation and durability of metallic CSP components by ISO 12944 [45]. Finally, the experimental analysis of the coatings under study, including their preparation, characterization and validation, was based on a previous publication by the researchers Díaz-Parralejo et al. [44].

Table 1 lists the inventory of characteristic variables of the sol-gel coatings under study.

Table 1.

Inventory of the sol-gel coatings analyzed.

2.1. Analytic Hierarchy Process

AHP is an analytical technique used to evaluate both quantifiable and intangible criteria [46], which employs a pairwise comparison procedure to arrive at a scale of preferences among sets of alternatives. A scale describes how preference levels defined in words are translated into numerical values [47]. To apply this technique, it is necessary to decompose an unstructured complex problem into its parts; arrange these parts, or variables, in a hierarchical order; assign numerical values to subjective judgments about the relative importance of each variable; and synthesize the judgments to determine which variables have the highest priority. By reducing complex decisions to a series of pairwise comparisons and synthesizing the results, AHP helps capture both subjective and objective aspects of a decision [48].

The AHP technique has serious advantages over other multi-criteria decision-making (MCDM) methods, notably, its ability to integrate quantitative and qualitative criteria. This feature is especially relevant in scenarios where the evaluation of alternatives relies heavily on the perception and expert knowledge of decision-makers. By combining objective data with structured subjective judgments, AHP facilitates a more informed and transparent selection of the optimal alternative [49]. It also ensures consistency in decision-making by verifying the consistency of the judgments made, thus reducing the subjectivity inherent in multi-criteria evaluation [50].

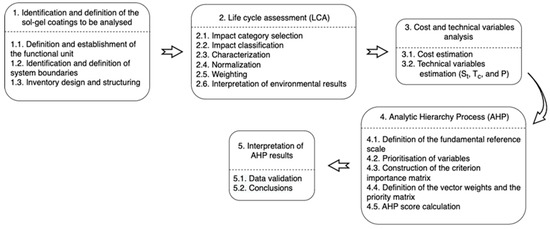

Figure 1 summarizes the workflow adopted in this investigation.

Figure 1.

Research workflow.

First, the 3 most representative sol-gel coatings for molten salt CSP plant facilities were identified and defined, and their environmental impact was analyzed according to the LCA methodology. This methodology is used to assess the environmental impact associated with a product, service or project, by identifying and quantifying the inputs and outputs of the defined system, as well as evaluating its potential impacts [51]. Its procedures are based on ISO 14040 [52] and ISO 14044 [53]. SimaPro 9.6 software [54] was used to evaluate the different elements that compose it and to quantify the environmental performance.

Second, estimated data on cost, thermal shock, thickness and porosity were collected (see Table 1) [12,44]. In addition, to define the coatings and the multidimensional analysis, the coating mg was established as a functional unit.

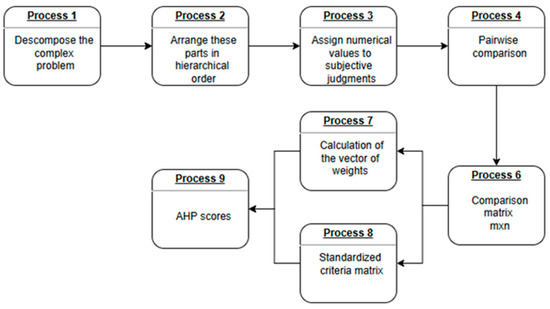

The AHP method was then applied, following the procedure shown in Figure 2.

Figure 2.

AHP method flowchart.

The different characteristic parameters were compared pairwise, as shown in Table 2. Subjective ratings were then recorded in an m x n-dimensional comparison matrix (Equation (1)), where n is the number of variables analyzed. The matrix cells were defined as the nearest integer values approximating the ratio of weights to variables.

Table 2.

Fundamental scale of preference [55].

Equation (1) shows the importance level (IL) of each variable in the AHP study once the pairwise comparison process has been performed, where n is the number of variables and a is each of the terms in the matrix. The method followed was calculating the right normalized principal weight vector of the matrix, as presented in Equation (2).

where

and

where sn is the sum of the items of the row of the criteria’s importance matrix under research, wn is each of the terms of the weight vector and xnn is the multiplication of each of the parts composing each row of the criteria’s importance matrix.

The different criteria for consideration were standardized in the interval [0, 1]. A standardized criteria matrix [SC] was established, as shown in Equation (5). In this way, the best value was given a score of 1, while the worst value received a score of 0.

where i is each of the sol-gel coatings analyzed and P is the different normalized values.

With the numerical judgments of the IL matrix and having calculated the vector of weights, the problem now is to calculate λmax, the principal eigenvalue of the IL matrix. For this, the linear equation must be solved, as presented in Equation (6).

Furthermore, to ensure the consistency of the subjective perception and the accuracy of the comparative weights, two indices, including the consistency index (CI) and the consistency ratio (CR), are suggested [56], as presented in Equations (7) and (8).

where λmax is the maximum eigenvalue and n is the number of factors in the judgment matrix. Consequently, the consistency ratio (CR) was defined as shown in Equation (8):

where RI refers to a random consistency index, which is derived from a large sample of randomly generated reciprocal matrices using the fundamental scale of preference. The RI for different-size matrices can be calculated by the right eigenvector method. A value of CI and CR ≤ 0.1 is considered acceptable. Higher values of CI and CR require the decision-maker to revise his judgments [57].

Finally, from the vector of weights and the matrix of standardized criteria, the AHP scores were established, as shown in Equation (9).

Additionally, a sensitivity analysis was performed to verify the robustness of the method. Sensitivity analysis provides an examination of the effects of input data used in a model on the outputs of the model. The use of sensitivity analysis eliminates uncertainties that may arise, ensures the stability of the data and better controls the data. Sensitivity analysis provides an examination of the effects of input data used in a model on the outputs of the model. The use of sensitivity analysis eliminates uncertainties that may arise, ensures data stability and better controls the data [58].

2.2. Life Cycle Assessment

To evaluate the environmental impact of the different sol-gel solutions, the Life Cycle Assessment (LCA) methodology was used, adopting the ISO 14040 [52] and ISO 14044 [53] standards as a reference framework. The sol-gel solutions were modelled using SimaPro 9.6 from PRé Sustainability (Amersfoot, Netherlands), software to evaluate and quantify their characteristic environmental performance [54]. The Ecoinvent 3.11 database was used as a source of environmental information [59], which offers complete life cycle inventories and allows the application of various impact assessment methods. For impact assessment, the internationally widely recognized ReCiPe 2016 method was chosen, which is distinguished by its combined midpoint and endpoint approach [60]. In addition, the hierarchical analytical perspective was adopted to account for a finite time horizon in a standard development framework [61].

2.2.1. LCA Approach and Functional Unit

Provided in Supplementary Material.

2.2.2. Impact Categories

Provided in Supplementary Material.

3. Results

The following presents the results obtained from the environmental impact analysis, the multidimensional hierarchical analysis, and, lastly, the sensitivity analysis of the applied method.

3.1. Results of Life Cycle Assessment

Table 3 presents the LCA results by impact category for each of the heat transfer fluid types analyzed.

Table 3.

LCA results by impact category.

One observes that, both 3YSZ-5A (5% mol) and 3YSZ-20A (20% mol) sol-gel coatings are the least favorable, presenting the highest scores in 12 of 18 impact categories.

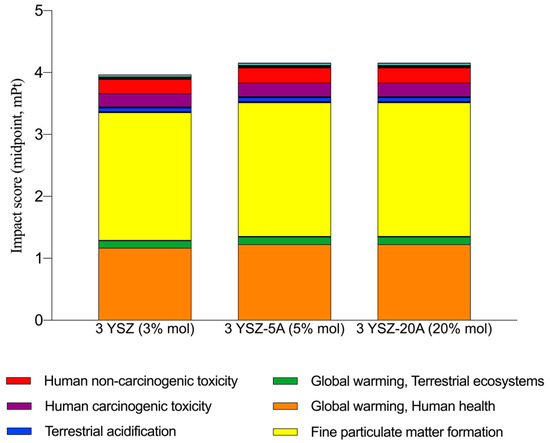

3.1.1. Results According to Midpoint Approach

Figure 3 shows the individual scores for the midpoint categories. One observes that the FPMF, GWHH, HnCT and HCT categories were those with the highest values.

Figure 3.

Impact scores for the midpoint categories.

Both, 3YSZ-5A (5% mol) and 3YSZ-20A (20% mol) sol-gel coatings stand out as the most harmful to the environment when all the categories are considered, regardless of their molar composition, with an absolute impact of 4.16 mPt. The most important categories were (in decreasing order): FPMF (2.16 mPt), GWHH (1.23 mPt), HnCT (0.25 mPt), HCT (0.22 mPt), GWTE (0.12 mPt) and TA (0.06 mPt).

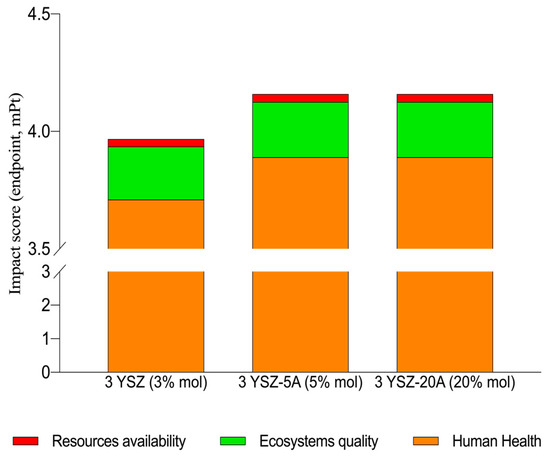

3.1.2. Results According Endpoint Approach

Figure 4 shows the results under the endpoint approach for each of the sol-gel coatings under study. In this way, it is possible to compare the different fluids by aggregating the impacts by protection areas. One observes that the least favorable sol-gel coating are 3YSZ-5A (5% mol) and 3YSZ-20A (20% mol), regardless of its molar composition, since they have an impact of 4.16 mPt, of which 3.89 mPt are attributable to the Human Health protection area (HH, 93.5%), 0.24 mPt to the Ecosystems Quality protection area (EQ, 5.8%) and 0.03 mPt to the Resources Availability protection area (RA, 0.7%). It can be seen that the Resources Availability (RA) protection area had hardly any impact.

Figure 4.

Impact scores for the endpoint categories.

3.2. Multidimensional Hierarchical Analysis

The order of priority was established through a consensus-based approach by a panel of expert engineers with more than 150 years of combined experience in the CSP field. A hierarchy of preference was defined, where cost was the priority variable, followed by the environmental variable based on LCA scores, then thermal shock, then thickness and lastly, porosity.

The matrix of criteria reflects the priority assigned to the variables under study after the pairwise comparison process (see Equation (10)).

To establish the vector of weights, first, the parameters sc, sLCA, sSt, sTc and sP, as well as stotal, were calculated based on Equations (3) and (4), as shown in Equations (11)–(16).

With these values found, the normalized parameters of the weight vector were calculated, as shown in Equations (17)–(21). Among the five variables analyzed, the results show that the cost variable was the most critical and prioritized at the time of designing, sizing and producing the sol-gel coatings. This variable had a weight of 51.0%. This was succeeded by the environmental variable LCA score, with a contribution of 26.0%. The technical factor St was ranked as the third most important, with an average contribution of 13.0%. Finally, Tc and P occupied the lowest positions, with contributions of 6.4% and 3.3%, respectively.

The normalization of the different considered criteria was performed simultaneously with the calculation of the weight vector. For this purpose, the characteristic values of the cost variables, LCA score, thermal shock, thickness and porosity of the sol-gel coatings were transformed to a dimensionless range within the interval [0, 1]. This transformation allowed the construction of the normalized matrix of criteria or priorities [SC], in which a value of 1 was assigned to the most favorable criterion and 0 to the least favorable, and linear interpolation was applied for the intermediate values. The mathematical formulation of this matrix is shown in Equation (22).

To establish the consistency of the method, the Consistency Index was calculated as shown in Equation (24). For this purpose, firstly, was calculated by solving Equation (23).

The result obtained for this equation is .

On the other hand, the consistency radius (CR) has also been calculated, as shown in Equation (25). The value of the denominator of this equation has been obtained from the table of Random Consistency Indices according to the number of criteria considered, as shown by the authors Tzeng & Huang et al. [56].

Since both the CI and CR results are less than 0.1, it is concluded that the result of the hierarchical analytical process is reliable.

Finally, the different AHP scores were established, as shown in Equation (26).

Figure 5 presents the normalized results of the multidimensional hierarchical analytical process for each sol-gel coating proposal in order of priority.

Figure 5.

Multidimensional analytic hierarchy process score.

Multidimensional analysis reveals that sol-gel coating type 3YSZ-5A (5% mol) is the best alternative for passive protection of metallic elements of CSP plants.

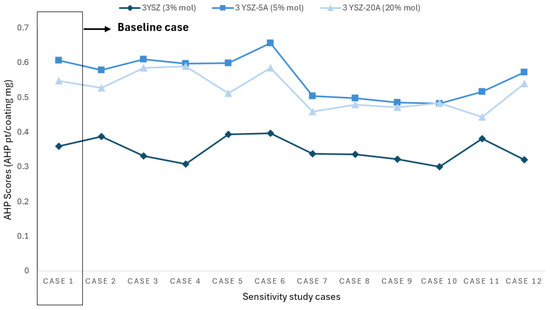

3.3. Sensitivity Analysis

The final AHP results for the various alternatives depend to a large extent on the preference weights assigned to the different criteria. Since these weights are often based on subjective judgments, the stability of the results with a variety of preference weights must be tested. To this end, a sensitivity analysis has been conducted based on 12 different perspectives on the relative importance of the criteria (see Figure 6).

Figure 6.

Sensitivity analysis of the AHP method.

By increasing or decreasing the scores given to the importance of the criteria, the resulting changes after applying the method are observed. Therefore, the sensitivity analysis provides information on the stability of the ranking. If the ranking is very sensitive to small changes in the criterion weights, a careful review of the weights is recommended [62].

Cost has been established as the highest priority criterion in all the study cases proposed in the sensitivity analysis, to maximize the economic profitability of the CSP plant. In this way, the other criteria have been adjusted accordingly. Since price and quality are interconnected, fixing the cost allows a clearer sensitivity analysis to be performed, observing how the criteria associated with quality vary. Thus, the impact of quality on the final decision is evaluated objectively [63].

When analyzing Figure 6, it is observed that, despite the variation in the preference weights of the different criteria, the scores remain relatively stable. In all cases, the 3YSZ-5A coating (5% mol) obtains the highest score, followed by the 3 YSZ coating (3% mol), while the 3YSZ-20A coating (20% mol) is in the last position.

However, when criteria 3 and 4 are given equal priority, the scores of the 3YSZ-20A (20% mol) coating are farther apart than the AHP scores of the 3YSZ-5A coating (5% mol). Additionally, it is observed that when criteria 2 and 3 are given the same weighting, the 3YSZ-20A (20% mol) coating is closer to the 3YSZ-5A (5% mol) coating, with differences ranging from 0.056% to 0.002%, depending on the case study.

4. Discussion

The AHP decision-making technique has been employed for pairwise comparison of the alternatives considered, providing a systematic and rigorous structure in the decision-making process. This approach not only facilitates the decomposition of the problem into hierarchical levels but also allows for the verification of the consistency of the judgments made, thereby reducing the subjectivity inherent in the evaluation of multiple criteria [64].

It is interesting to note that the multi-criteria decision technique used has several advantages. This method, well-established in the scientific community, relies on a decision rule framework to streamline the assessment of subjective factors across multiple dimensions [65]. Regardless of the complexity or number of variables influencing the decision, the AHP technique reduces the process to pairwise comparisons, significantly enhancing analytical clarity [66]. A particularly noteworthy feature is its capacity to integrate both measurable and non-measurable criteria, enabling a more comprehensive representation of the problem and yielding highly precise and reliable outcomes. Furthermore, the adaptability of the AHP method allows its application across diverse fields and contexts [67].

Despite its strengths, the AHP presents some limitations. The main shortcoming associated with AHP relates to the notion of using a discrete scale (1–9) for judgments. A decision-maker often finds it difficult to provide a discrete scale for priority weights since real-world decision problems can be complex [68]. This limitation can be addressed by performing a sensitivity analysis that tests the stability of the method despite the assigned criteria weights.

On the other hand, the quality of its results heavily depends on the expertise and judgment of the participating panel of experts. Thus, the opinion of the different experts involved in the study for the prioritization of the variables could be biased. This may occur due to their personal experiences. However, the contribution of a solvent panel of experts with joint experience in industrial engineering diminished this risk. In addition, another limitation arises in that the AHP method does not consider the interrelationships between the elements, since it assumes that the criteria are independent of each other. Finally, managing a larger number of criteria and alternatives can make data interpretation more difficult [69]. However, this and the other limitations can be handled by testing consistency during calculations and limiting the number of criteria [70].

Analyzing the results obtained from the multidimensional hierarchical analysis for the variables and weights described in Equation (26), a common trend is observed in the sol-gel coatings analyzed. The results show that the scores obtained for the 3YSZ-5A coating are higher than those of the 3YSZ and 3YSZ-20A coatings, between 1.52 and 1.69 times higher as a function of their molar concentration.

These findings are in line with the results obtained by authors Ghafari et al. (2019) and Moridi et al. (2021), who carried out a multidimensional analysis of different zirconia oxide (ZrO2)-based sol-gel coatings stabilized with different inhibitors (C6H5N3 y CeNO3) [36,44]. These studies confirm how stabilized coatings present more favorable AHP scores, with similar trends and translated into values up to 18.34% higher. The present study proposes the use of the Y2O3 inhibitor, whose benefits have been highlighted by many authors and which presents AHP scores up to 59.3% better. Furthermore, the use of this inhibitor avoids the monocyclic crystalline phase, reducing the risk of detachment and cracking in the coating [71].

It was observed how the 3YSZ (3% mol) coating obtained the lowest environmental impact values, up to 1.05 times more favorable than Al2O3 coatings (3YSZ-5A and 3YSZ-20A). These results resemble those obtained by Encinas-Sánchez et al. (2018), who evaluated the environmental performance of sol-gel protective coatings in corrosive environments inside CSP plants [15], obtaining similar trends. However, a significant difference lies in the use of the ReCiPe 2016 environmental impact assessment method. This method has 22 midpoint environmental impact categories [72], compared to the 3 categories of the ILCD method used by the authors Encinas-Sánchez et al. (2018). This aspect enhances the robustness of the results, facilitating and improving their comparability. Moreover, the ILCD method is outdated compared to ReCiPe 2016, which is widely validated in the scientific literature and stands as the most advanced LCA methodology to meet current LCA requirements through its dual impact characterization approach [73]. Finally, the environmental database used in both studies is the same, Ecoinvent, being more updated in the present study (Ecoinvent 3.11 vs. Ecoinvent 3.0) [59].

Applied to the evaluation of sol-gel coatings, specifically YSZ-type coatings, the AHP method has proven particularly effective, providing a systematic approach to assess multiple factors, including technical, environmental, and economic considerations. Unlike decision-making methods such as Simple Additive Weighting (SAW) or TOPSIS, AHP employs pairwise comparisons, enhancing the reliability and consistency of expert judgments [74]. Moreover, its hierarchical structure facilitates the integration of critical performance metrics relevant to CSP systems, enabling a comprehensive and reliable evaluation.

The findings shown in this research were derived from a real model, tested with laboratory-scale samples and implemented in the international projects European Parabolic Trough with Molten Salt (EuroPaTMoS) and Advancing Innovations in Molten Salts (ADVIAMOS). Therefore, the uncertainty of the input data does not impact the results if another sample is taken. Furthermore, these findings will facilitate further research in the field of CSP plants. It is important to consider that the methodology used in this research can be applied to other coatings used in CSP plants and even to different applications using these coatings. For this reason, it is essential to continue this research by analyzing and applying the AHP method to other coatings used in CSP plants, such as TiO2 and SiO2-ZrO2.

As a future line of research, it is proposed to investigate the advantages of other methods that consider possible interactions between the different elements or alternatives. Among them, the Analytic Network Process, which allows considering the internal relationships between the elements, can be considered. This method follows a process which is similar to AHP but, additionally, the elements of the same cluster are compared among themselves regardless of the hierarchy. For example, criteria are compared with each other pairwisely with respect to each of them in separate tables using Saaty’s scale [75]. This method allows a simplified representation of the complex interactions, interdependencies and feedback relationships between the different components of intricate decision systems. Moreover, the criteria influence each other, forming a network rather than a hierarchy [76]. However, the problem of inconsistency becomes a more serious concern than in AHP [75].

Another line of research may be to introduce the Fuzzy Analytic Hierarchy Process (FAHP). This method allows to calculation of the rating value on the preference scale, with a scale of membership between 0 and 1 [77]. The main motivation behind the incorporation of fuzzy set theory into the original AHP is based on the argument that human judgments and preferences cannot be accurately represented by crisp numbers due to the uncertainty inherent in human perception. In the FAHP, weights are calculated from fuzzy comparison matrices that are then used to rank the available alternatives along with the scores obtained by the alternatives for each criterion. Therefore, determining the weights from the comparison matrices is one of the key steps in the process. However, in the case of FAHP, calculating weights from fuzzy comparison matrices is not straightforward due to the complexities associated with fuzzy number arithmetic [78]. Finally, it would be interesting to highlight the multidimensional feasibility of the studies performed. The technique based on the Pareto front could be a very interesting tool to be integrated into future research [79].

5. Conclusions

The AHP technique has demonstrated its utility in defining the characteristic dimensions of sol-gel coatings for metallic components in CSP plants, facilitating the search for the selection of the optimal solution. Therefore, the AHP method can be used in future research lines in which other coatings used in CSP plants are analyzed, such as TiO2 and SiO2-ZrO2. Nonetheless, this research recognizes the limitations of the method itself, such as the subjectivity of expert judgment and the independence of the criteria.

The effectiveness of these coatings has been validated previously by the authors Díaz-Parralejo et al. [44]. Thus, the results of this research show that the 3YSZ-5A coating (5% mol) is the most favorable option among the evaluated systems. This coating achieved the highest performance rating, reaching 0.61 AHP pt/coating mg. This coating has good technical properties, a high thermal shock resistance (St) and the lowest cost of the three coatings analysed. The coating of the same type and higher molar concentration (20%) obtained intermediate scores of 0.55 AHP pt/coating mg. Finally, the 3YSZ (3% mol) coating exhibited the lowest performance among the evaluated options, scoring 0.36 AHP pt/coating mg. Nevertheless, the comparison of these results is limited due to the paucity of available scientific bibliography.

Finally, it should be noted that the coatings studied are being evaluated on the basis of their application to the pilot CSP plant of the European ADVIAMOS project. Therefore, the insights generated through this research contribute to informed decision-making in the design and maintenance of these plants by providing engineering managers with a detailed view of CSP plants, thereby increasing the socio-economic and environmental benefits.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su17062449/s1, Table S1: Impact categories employed in the LCA under ReCiPe 2016 method [60,80,81].

Author Contributions

Conceptualization: J.G.-S.-C.; Data curation: M.B.-A. and A.D.-P.; Formal analysis: J.G.-S.-C., M.B.-A. and M.J.G.-G.; Funding acquisition: J.G.-S.-C.; Investigation: J.G.-S.-C., M.B.-A., A.D.-P. and M.J.G.-G.; Methodology: J.G.-S.-C., M.B.-A. and M.J.G.-G.; Project administration: M.B.-A. and M.J.G.-G.; Resources: M.B.-A. and M.J.G.-G.; Software: M.B.-A.; Supervision: J.G.-S.-C., M.B.-A. and A.D.-P.; Validation: J.G.-S.-C. and A.D.-P.; Visualization: M.J.G.-G.; Writing—original draft: M.J.G.-G.; Writing—review & editing: J.G.-S.-C. and M.B.-A. All authors have read and agreed to the published version of the manuscript.

Funding

Grant PCI2022-134993-2 funded by MCIN/AEI/10.13039/501100011033 and by the “European Union NextGenerationEU/PRTR” and Líneas de Ayudas para la Investigación en Plantas Termosolares (2024/00325/001).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article/Supplementary Material.

Acknowledgments

The authors wish to acknowledge the following government agencies: Ministerio de Ciencia e Innovación, Agencia Estatal de Investigación y Consejería para la Transición Ecológica y Sostenibilidad de la Junta de Extremadura.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Khanmohammadi, S.; Genceli, H.; Pakseresht, A.; Bellotti, D. Optimal Design of a Solar-Driven Kalina System for Combined Power and Desalination Purposes. Sol. Energy 2024, 268, 112277. [Google Scholar] [CrossRef]

- Obalalu, A.M.; Memon, M.A.; Olayemi, O.A.; Olilima, J.; Fenta, A. Enhancing Heat Transfer in Solar-Powered Ships: A Study on Hybrid Nanofluids with Carbon Nanotubes and Their Application in Parabolic Trough Solar Collectors with Electromagnetic Controls. Sci. Rep. 2023, 13, 9476. [Google Scholar] [CrossRef] [PubMed]

- Pineda, F.; Rosenkranz, A.; Pérez, F.J. Perspectives on Solar Salt-Based Nanofluids Used in Concentrated Solar Power Plants. Sol. RRL 2024, 8, 2400110. [Google Scholar] [CrossRef]

- Saddouri, I.; Rejeb, O.; Semmar, D.; Jemni, A. A Comparative Analysis of Parabolic Trough Collector (PTC) Using a Hybrid Nanofluid. J. Therm. Anal. Calorim. 2023, 148, 9701–9721. [Google Scholar] [CrossRef]

- Hu, T.; Zhang, H.; Kwan, T.H.; Wang, Q.; Pei, G. Thermal Performance Analysis of Eccentric Double-Selective-Coated Parabolic Trough Receivers with Flat Upper Surface. Renew. Energy 2024, 220, 119613. [Google Scholar] [CrossRef]

- Golzar, A.; Aghaei, A.; Mohsenimonfared, H.; Joshaghani, A.H. Numerical Simulation of a Parabolic Through Solar Collector with a Novel Geometric Design Equipped with an Elliptical Absorber Tube Under the Influence of Magnetic Field. Arab. J. Sci. Eng. 2024, 1–21. [Google Scholar] [CrossRef]

- Castro-Quijada, M.; Jullian, D.; Walczak, M.; Pineda, F.; Videla, Á. Quaternary Nitrate and Chloride Molten Salts for the next Concentrating Solar Power Plants: Corrosion Considerations for the Use of AISI 304L Steel. Sol. Energy Mater. Sol. Cells 2024, 274, 112971. [Google Scholar] [CrossRef]

- Starke, A.R.; Cardemil, J.M.; Bonini, V.R.B.; Escobar, R.; Castro-Quijada, M.; Videla, Á. Assessing the Performance of Novel Molten Salt Mixtures on CSP Applications. Appl. Energy 2024, 359, 122689. [Google Scholar] [CrossRef]

- Abir, F.M.; Altwarah, Q.; Rana, M.T.; Shin, D. Recent Advances in Molten Salt-Based Nanofluids as Thermal Energy Storage in Concentrated Solar Power: A Comprehensive Review. Materials 2024, 17, 955. [Google Scholar] [CrossRef]

- Carbajales, R.; Sobrino, C.; Alvaredo, P. Multi-Principal Element Alloys for Concentrating Solar Power Based on Molten Salt. Sol. Energy Mater. Sol. Cells 2024, 271, 112861. [Google Scholar] [CrossRef]

- Yang, P.; Deng, Z.; Chen, B.; Wang, Y. High-Temperature Dynamic Corrosion Mechanisms of Austenitic Stainless and Carbon Steels in Nitrates for Concentrating Solar Power. Sol. Energy Mater. Sol. Cells 2024, 266, 112690. [Google Scholar] [CrossRef]

- Pantoja-Pertegal, J.L.; Díaz-Parralejo, A.; Macías-García, A.; Sánchez-González, J.; Cuerda-Correa, E.M. Design, Preparation, and Characterization of Yttria-Stabilized Zirconia (YSZ) Coatings Obtained by Electrophoretic Deposition (EPD). Ceram. Int. 2021, 47, 13312–13321. [Google Scholar] [CrossRef]

- Won Kim, D.; Kim, E.-J.; Lee, C.-L.; Moon, K.-S. Spontaneous Adsorption Effect of Graphitic Carbon Nitride Nanosheets to Improve Sintering Behavior of Yttria-Stabilized Zirconia Microbeads. Appl. Surf. Sci. 2024, 654, 159447. [Google Scholar] [CrossRef]

- Papadopoulos, N.D.; Vourna, P.; Milidonis, K.; Eliades, A.; Falaras, P. Fostering Wider Application of Anti-Soiling Strategies in Existing Solar Power Plants: A Comparative Study of Novel Quaternarized Silica Hybrids with Commercial Self-Cleaning Coatings. Mater. Chem. Phys. 2024, 315, 129046. [Google Scholar] [CrossRef]

- Encinas-Sánchez, V.; Batuecas, E.; Macías-García, A.; Mayo, C.; Díaz, R.; Pérez, F.J. Corrosion Resistance of Protective Coatings against Molten Nitrate Salts for Thermal Energy Storage and Their Environmental Impact in CSP Technology. Sol. Energy 2018, 176, 688–697. [Google Scholar] [CrossRef]

- Cao, F.; Kraemer, D.; Tang, L.; Li, Y.; Litvinchuk, A.P.; Bao, J.; Chen, G.; Ren, Z. A High-Performance Spectrally-Selective Solar Absorber Based on a Yttria-Stabilized Zirconia Cermet with High-Temperature Stability. Energy Environ. Sci. 2015, 8, 3040–3048. [Google Scholar] [CrossRef]

- Dosta, S.; Betancor, L.; Barreneche, C. Overview of Surface Engineering Technology to Improve the Energy Efficiency in Concentrated Solar Power (CSP) Plants. Sol. Energy Mater. Sol. Cells 2024, 277, 113090. [Google Scholar] [CrossRef]

- Encinas-Sánchez, V.; Macías-García, A.; de Miguel, M.T.; Pérez, F.J.; Rodríguez-Rego, J.M. Electrochemical Impedance Analysis for Corrosion Rate Monitoring of Sol–Gel Protective Coatings in Contact with Nitrate Molten Salts for CSP Applications. Materials 2023, 16, 546. [Google Scholar] [CrossRef]

- Pérez, F.J.; Encinas-Sánchez, V.; Lasanta, M.I.; de Miguel, M.T.; García-Martín, G. Dip-Coated ZrO2-Y2O3 Coatings Tested in Molten Salts for CSP Applications. In Proceedings of the 22nd SolarPACES 2016 International Conference, Abu Dhabi, UAE, 11–14 October 2017; p. 120002. [Google Scholar]

- Gamarra, A.R.; Banacloche, S.; Lechon, Y.; del Río, P. Assessing the Sustainability Impacts of Concentrated Solar Power Deployment in Europe in the Context of Global Value Chains. Renew. Sustain. Energy Rev. 2023, 171, 113004. [Google Scholar] [CrossRef]

- Roper, R.; Harkema, M.; Sabharwall, P.; Riddle, C.; Chisholm, B.; Day, B.; Marotta, P. Molten Salt for Advanced Energy Applications: A Review. Ann. Nucl. Energy 2022, 169, 108924. [Google Scholar] [CrossRef]

- Soleimani Dorcheh, A.; Galetz, M.C. Slurry Aluminizing: A Solution for Molten Nitrate Salt Corrosion in Concentrated Solar Power Plants. Sol. Energy Mater. Sol. Cells 2016, 146, 8–15. [Google Scholar] [CrossRef]

- Gomes, A.; Paiva Luís, T.; Figueira, I.; Diamantino, T.C. Corrosion Behavior of Stainless Steel Alloys in Molten Solar Salt. In Proceedings of the EuroSun 2016 Conference, Palma de Mallorca, Spain, 11–14 October 2016; International Solar Energy Society: Freiburg, Germany, 2016; pp. 1–8. [Google Scholar]

- Gomez-Vidal, J.C.; Morton, E. Castable Cements to Prevent Corrosion of Metals in Molten Salts. Sol. Energy Mater. Sol. Cells 2016, 153, 44–51. [Google Scholar] [CrossRef]

- Audigié, P.; Bizien, N.; Baráibar, I.; Rodríguez, S.; Pastor, A.; Hernández, M.; Agüero, A. Aluminide Slurry Coatings for Protection of Ferritic Steel in Molten Nitrate Corrosion for Concentrated Solar Power Technology. In Proceedings of the 22nd SolarPACES 2016 International Conference, Abu Dhabi, UAE, 11–14 October 2016; p. 70002. [Google Scholar]

- Tsuda, K.; Murakami, Y.; Torres, J.F.; Coventry, J. Development of High Absorption, High Durability Coatings for Solar Receivers in CSP Plants. In Proceedings of the SolarPACES 2017: International Conference on Concentrating Solar Power and Chemical Energy Systems, Santiago, Chile, 26–29 September 2017; p. 40039. [Google Scholar]

- Fähsing, D.; Oskay, C.; Meißner, T.M.; Galetz, M.C. Corrosion Testing of Diffusion-Coated Steel in Molten Salt for Concentrated Solar Power Tower Systems. Surf. Coat. Technol. 2018, 354, 46–55. [Google Scholar] [CrossRef]

- Fernández, A.G.; Cabeza, L.F. Anodic Protection Assessment Using Alumina-Forming Alloys in Chloride Molten Salt for CSP Plants. Coatings 2020, 10, 138. [Google Scholar] [CrossRef]

- Luo, J.; Liu, H.H.; Li, N.; Zhao, L.J.; Cui, X.Y.; Xiong, T.Y. Robust Corrosion Performance of Cold Sprayed Aluminide Coating in Ternary Molten Carbonate Salt for Concentrated Solar Power Plants. Sol. Energy Mater. Sol. Cells 2022, 237, 111573. [Google Scholar] [CrossRef]

- Siripongsakul, T.; Kettrakul, P.; Kanjanaprayut, N.; Promdirek, P. Effect of Si Addition in NiCrAl Coating on Corrosion in Molten Nitrate Salt. Metals 2024, 14, 902. [Google Scholar] [CrossRef]

- Mihelčič, M.; Francetič, V.; Kovač, J.; Šurca Vuk, A.; Orel, B.; Kunič, R.; Peros, D. Novel Sol–Gel Based Selective Coatings: From Coil Absorber Coating to High Power Coating. Sol. Energy Mater. Sol. Cells 2015, 140, 232–248. [Google Scholar] [CrossRef]

- Joly, M.; Bouvard, O.; Gascou, T.; Antonetti, Y.; Python, M.; González Lazo, M.A.; Loesch, P.; Hessler-Wyser, A.; Schüler, A. Optical and Structural Analysis of Sol–Gel Derived Cu–Co–Mn–Si Oxides for Black Selective Solar Nanocomposite Multilayered Coatings. Sol. Energy Mater. Sol. Cells 2015, 143, 573–580. [Google Scholar] [CrossRef]

- Rossi, G.; D’Angelo, A.; Diletto, C.; Esposito, S.; Guglielmo, A.; Lanchi, M. New Spectrally Selective Coatings for CSP Linear Receivers Operating in Air at High Temperature. Appl. Res. 2024, 3, e202200117. [Google Scholar] [CrossRef]

- Nishath Tharanum, S.; Parveez Ahmed, H.M.; Shabanabanu Beena, P.; Jambaladinni, S.; Prasanna, B.M.; Santhosh Kumar, M.V.; Jagadeesh, M.R. A Novel Approach for the Synthesis of V2O5 Thin Films Coating by Sol–Gel Technique for Anti-Corrosive Applications. Iran. J. Sci. 2025, 1–11. [Google Scholar] [CrossRef]

- Sibin, K.P.; Pitchumani, R. Multiscale Textured Solar Absorber Coatings for Next-Generation Concentrating Solar Power. Renew. Sustain. Energy Rev. 2025, 207, 114959. [Google Scholar] [CrossRef]

- Asl, R.M.; Yousefpour, M.; Shanaghi, A. The Investigation of Corrosion Behavior of ZrO2–Al2O3-Inhibitor/AA2024 Nanocomposite Thin Film Using Sol-Gel and AHP-TOPSIS Method. Mater. Chem. Phys. 2021, 262, 124220. [Google Scholar] [CrossRef]

- Lagopati, N.; Trachanas, G.P.; Doukas, H. Multi-Criteria Decision-Making Approach for Pre-Synthesis Selection of the Optimal Physicochemical Properties of TiO2 Photocatalytic Nanoparticles for Biomedical and Environmental Applications. Molecules 2024, 29, 3726. [Google Scholar] [CrossRef] [PubMed]

- Botejara-Antúnez, M.; González-Domínguez, J.; Rebollo-Castillo, F.J.; García-Sanz-Calcedo, J. Life Cycle and Environmental Impact Assessment of Heat Transfer Fluids in Parabolic Trough CSP Plants. Sustain. Energy Technol. Assess. 2025, 74, 104188. [Google Scholar] [CrossRef]

- Saaty, R.W. The Analytic Hierarchy Process—What It Is and How It Is Used. Math. Model. 1987, 9, 161–176. [Google Scholar] [CrossRef]

- Borgaonkar, A.; McNamara, G. Environmental Impact Assessment of Anti-Corrosion Coating Life Cycle Processes for Marine Applications. Sustainability 2024, 16, 5627. [Google Scholar] [CrossRef]

- Botejara-Antúnez, M.; González-Domínguez, J.; García-Sanz-Calcedo, J. Comparative Analysis of Flat Roof Systems Using Life Cycle Assessment Methodology: Application to Healthcare Buildings. Case Stud. Constr. Mater. 2022, 17, e01212. [Google Scholar] [CrossRef]

- Kelly, P.M.; Francis Rose, L.R. The Martensitic Transformation in Ceramics—Its Role in Transformation Toughening. Prog. Mater. Sci. 2002, 47, 463–557. [Google Scholar] [CrossRef]

- Zarinejad, M.; White, T.; Tong, Y.; Rimaz, S. Martensitic Transformation Temperatures of Ceramics. Adv. Eng. Mater. 2022, 24, 2200606. [Google Scholar] [CrossRef]

- Díaz-Parralejo, A.; Díaz-Díez, M.Á.; Sánchez-González, J.; Macías-García, A.; Carrasco-Amador, J.P. Mechanical Properties and Thermal Shock in Thin ZrO2–Y2O3–Al2O3 Films Obtained by the Sol-Gel Method. Ceram. Int. 2021, 47, 80–86. [Google Scholar] [CrossRef]

- ISO 12944-2:2017; International Organization for Standarization Paints and Varnishes—Corrosion Protection of Steel Structures by Protective Paint Systems—Part 2: Classification of Environments. International Organization for Standarization: Geneva, Switzerland, 2017.

- Vargas, L.G. An Overview of the Analytic Hierarchy Process and Its Applications. Eur. J. Oper. Res. 1990, 48, 2–8. [Google Scholar] [CrossRef]

- Lipovetsky, S. Understanding the Analytic Hierarchy Process. Technometrics 2021, 63, 278–279. [Google Scholar] [CrossRef]

- Baghaei Oskouei, S.; Frate, G.F.; Christodoulaki, R.; Bayer, Ö.; Akmandor, İ.S.; Desideri, U.; Ferrari, L.; Drosou, V.; Tarı, İ. Solar-Powered Hybrid Energy Storage System with Phase Change Materials. Energy Convers. Manag. 2024, 302, 118117. [Google Scholar] [CrossRef]

- Mohanty, R.P.; Deshmukh, S.G. Use of Analytic Hierarchic Process for Evaluating Sources of Supply. Int. J. Phys. Distrib. Logist. Manag. 1993, 23, 22–28. [Google Scholar] [CrossRef]

- Tavana, M.; Soltanifar, M.; Santos-Arteaga, F.J. Analytical Hierarchy Process: Revolution and Evolution. Ann. Oper. Res. 2023, 326, 879–907. [Google Scholar] [CrossRef]

- Curran, M.A. Life Cycle Assessment: An International Experience. Environ. Prog. 2000, 19, 65–71. [Google Scholar] [CrossRef]

- ISO 14040:2006/Amd1:2021; International Organization for Standardization Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standarization: Geneva, Switzerland, 2021.

- ISO 14044:2006/Amd1:2021; International Organization for Standardization Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standarization: Geneva, Switzerland, 2021.

- PRé Sustainability, B.V. SimaPro 9.6; PRé Sustainability: Amersfoort, The Netherlands, 2024. [Google Scholar]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Tzeng, G.-H.; Huang, J.-J. Multiple Attribute Decision Making; Chapman and Hall: Londond, UK; CRC: Boca Raton, FL, USA, 2011; ISBN 9781439861585. [Google Scholar]

- Saaty, T.L.; Vargas, L.G. Models, Methods, Concepts & Applications of the Analytic Hierarchy Process; International Series in Operations Research & Management Science; Springer US: Boston, MA, USA, 2012; Volume 175, ISBN 978-1-4614-3596-9. [Google Scholar]

- Çolak, H.E.; Memişoğlu Baykal, T.; Genç, N. Multicriteria Decision and Sensitivity Analysis Support for Optimal Airport Site Locations in Ordu Province, Turkey. Ann. GIS 2023, 29, 441–468. [Google Scholar] [CrossRef]

- Ecoinvent Association. Ecoinvent 3.11; Ecoinvent Association: Zurich, Switzerland, 2024. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Pré Sustainability, B.V. Simapro Database Manual; Pré Sustainability: Amersfoort, The Netherlands, 2020. [Google Scholar]

- Chang, C.-W.; Wu, C.-R.; Lin, C.-T.; Chen, H.-C. An Application of AHP and Sensitivity Analysis for Selecting the Best Slicing Machine. Comput. Ind. Eng. 2007, 52, 296–307. [Google Scholar] [CrossRef]

- Psomas, E.; Dimitrantzou, C.; Vouzas, F. Practical Implications of Cost of Quality: A Systematic Literature Review. Int. J. Product. Perform. Manag. 2022, 71, 3581–3605. [Google Scholar] [CrossRef]

- Ashtiani, M.; Abdollahi Azgomi, M. A Multi-Criteria Decision-Making Formulation of Trust Using Fuzzy Analytic Hierarchy Process. Cogn. Technol. Work 2015, 17, 465–488. [Google Scholar] [CrossRef]

- Mu, E.; Pereyra-Rojas, M. Understanding the Analytic Hierarchy Process. In Practical Decision Making: An Introduction to the Analytic Hierarchy Process (AHP) Using Super Decisions; Springer: Cham, Switzerland, 2017; pp. 7–22. [Google Scholar]

- de F.S.M. Russo, R.; Camanho, R. Criteria in AHP: A Systematic Review of Literature. Procedia Comput. Sci. 2015, 55, 1123–1132. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C.; Ameyaw, E.E.; Owusu, E.K.; Pärn, E.; Edwards, D.J. Review of Application of Analytic Hierarchy Process (AHP) in Construction. Int. J. Constr. Manag. 2019, 19, 436–452. [Google Scholar] [CrossRef]

- Tyagi, S.; Chambers, T.; Yang, K. Enhanced Fuzzy-Analytic Hierarchy Process. Soft Comput. 2018, 22, 4431–4443. [Google Scholar] [CrossRef]

- Farsi, H.; Dizene, R.; Flamant, G.; Notton, G. Multi-Criteria Decision Making Methods for Suitable Site Selection of Concentrating Solar Power Plants. Sustainability 2024, 16, 7673. [Google Scholar] [CrossRef]

- Lin, G.; Zhang, Q.; Zhang, Y.; Shen, C.; Xu, H.; Wang, S. Performance Assessment of Public Transport Networks: An AHP-ANP Approach. Heliyon 2024, 10, e40309. [Google Scholar] [CrossRef]

- Yamada, T.; Okuda, R.; Hirakoso, H.; Kozuka, H. Sol–Gel Preparation of Yttria-Stabilized Zirconia Thin Films and Transfer to Polycarbonate Substrates. J. Sol-Gel Sci. Technol. 2019, 92, 554–561. [Google Scholar] [CrossRef]

- Duan, Y.; Guo, F.; Gardy, J.; Xu, G.; Li, X.; Jiang, X. Life Cycle Assessment of Polysilicon Photovoltaic Modules with Green Recycling Based on the ReCiPe Method. Renew. Energy 2024, 236, 121407. [Google Scholar] [CrossRef]

- Verbitsky, O.; Pushkar, S. Eco-Indicator 99, ReCiPe and ANOVA for Evaluating Building Technologies under LCA Uncertainties. Environ. Eng. Manag. J. 2018, 17, 2549–2559. [Google Scholar] [CrossRef]

- Nazim, M.; Wali Mohammad, C.; Sadiq, M. A Comparison between Fuzzy AHP and Fuzzy TOPSIS Methods to Software Requirements Selection. Alex. Eng. J. 2022, 61, 10851–10870. [Google Scholar] [CrossRef]

- Asadabadi, M.R.; Chang, E.; Saberi, M. Are MCDM Methods Useful? A Critical Review of Analytic Hierarchy Process (AHP) and Analytic Network Process (ANP). Cogent Eng. 2019, 6, 1623153. [Google Scholar] [CrossRef]

- Santos, J.M.R.C.A.; Fernandes, G. Prioritizing Stakeholders in Collaborative Research and Innovation Projects Toward Sustainability. Proj. Manag. J. 2024, 55, 423–440. [Google Scholar] [CrossRef]

- Ksantini, F.; Sdiri, A.; Aydi, A.; Almeida-Ñauñay, A.F.; Achour, H.; Tarquis, A.M. A Comparative Study Based on AHP and Fuzzy Logic Approaches for Landslide Susceptibility Zoning Using a GIS-Based Multi-Criteria Decision Analysis. Euro-Mediterr. J. Environ. Integr. 2024, 1–20. [Google Scholar] [CrossRef]

- Ahmed, F.; Kilic, K. Fuzzy Analytic Hierarchy Process: A Performance Analysis of Various Algorithms. Fuzzy Sets Syst. 2019, 362, 110–128. [Google Scholar] [CrossRef]

- Ghosh, S.; Mandal, M.C.; Ray, A. Investigating the Key Performance Parameters of Green Supply Chain Management for Sustainability in Tea Processing Firms Using Pareto Analysis. J. Inst. Eng. Ser. C 2023, 104, 113–122. [Google Scholar] [CrossRef]

- Turhan Kara, I.; Kiyak, B.; Colak Gunes, N.; Yucel, S. Life Cycle Assessment of Aerogels: A Critical Review. J. Sol-Gel Sci. Technol. 2024, 111, 618–649. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. (Eds.) Life Cycle Assessment; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-56474-6. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).