Valorisation of Limestone in Sustainable Cements

Abstract

1. Introduction

- CEM II/C-M: This class reduces the minimum K content of the previous CEM II from 65% to 50%;

- CEM VI: A new cement class not included in EN 197-1, featuring a K content of 35–49%, 31–59% blast furnace slag (BFS), and 6–20% natural pozzolan, fly ash, or limestone.

2. Experimental Program

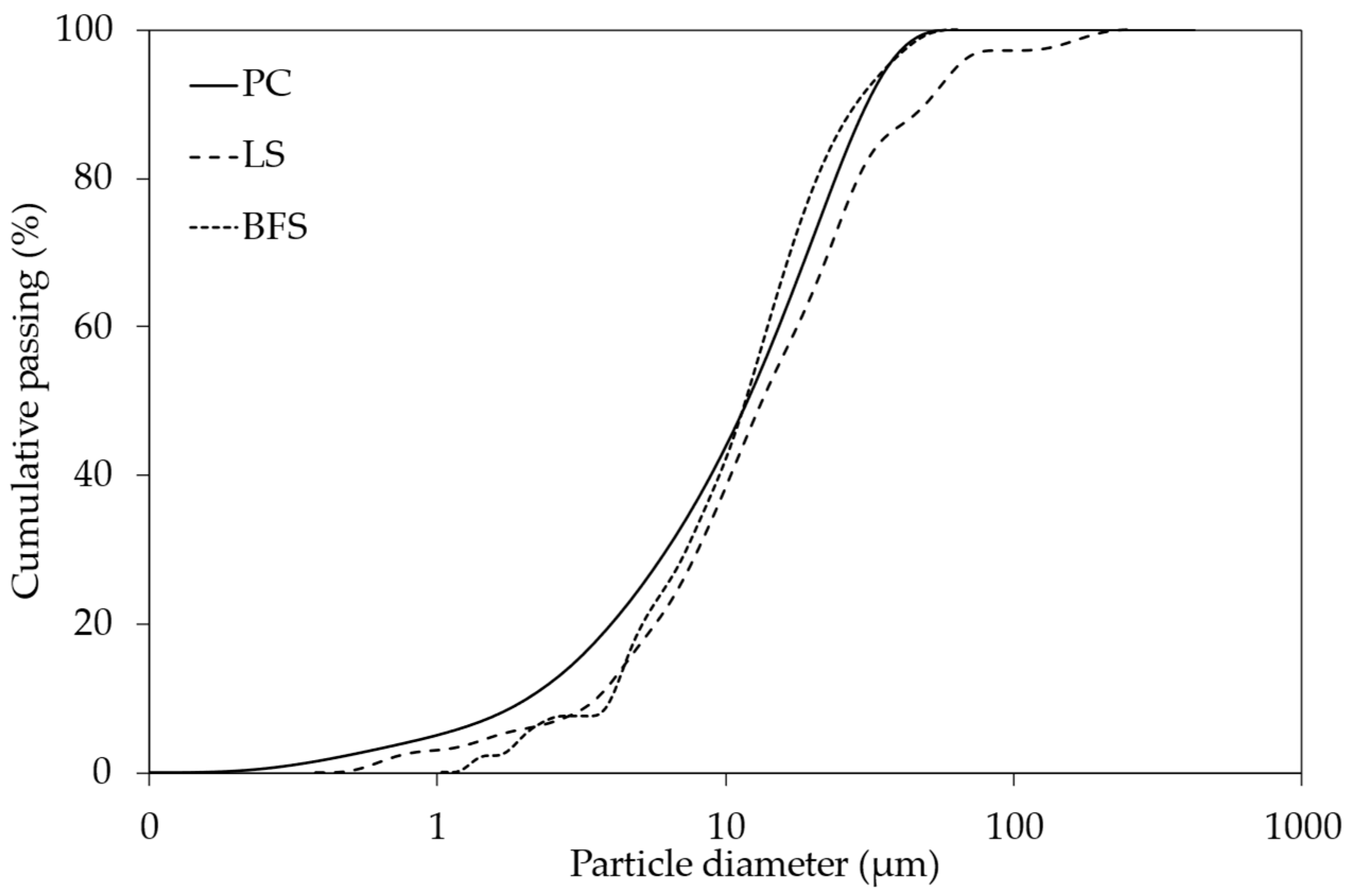

2.1. Materials

2.2. Methods

2.2.1. Formulation of the Binders

2.2.2. Setting Time

2.2.3. Standard Mortars Preparation and Classification

2.2.4. Mechanical Characterisation

2.2.5. Microstructural Analysis

2.2.6. Capillary Water Absorption

2.2.7. Drying Shrinkage

2.2.8. Lyfe Cycle Assessment Analysis

3. Results and Discussion

3.1. Fresh State Properties

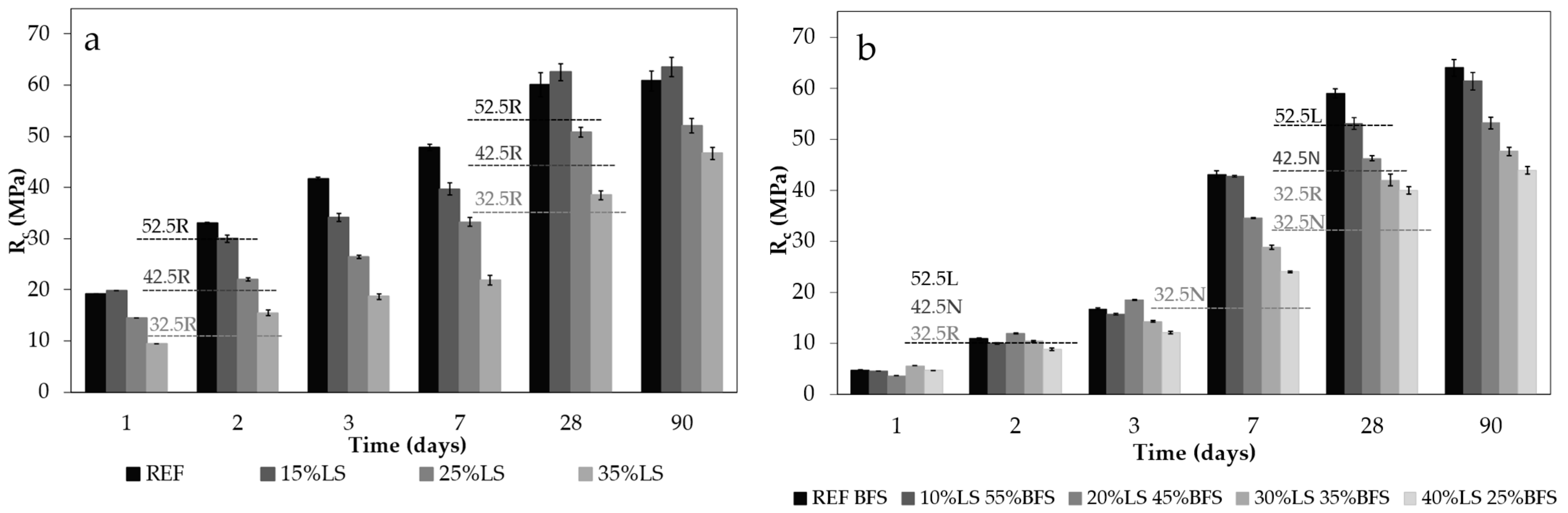

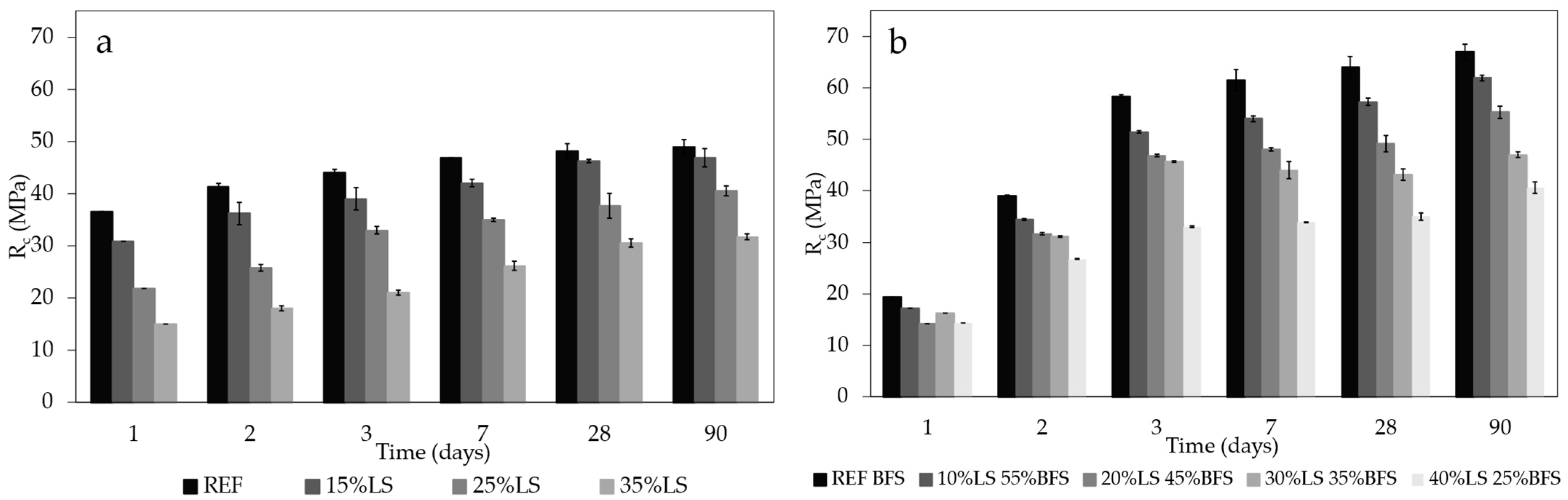

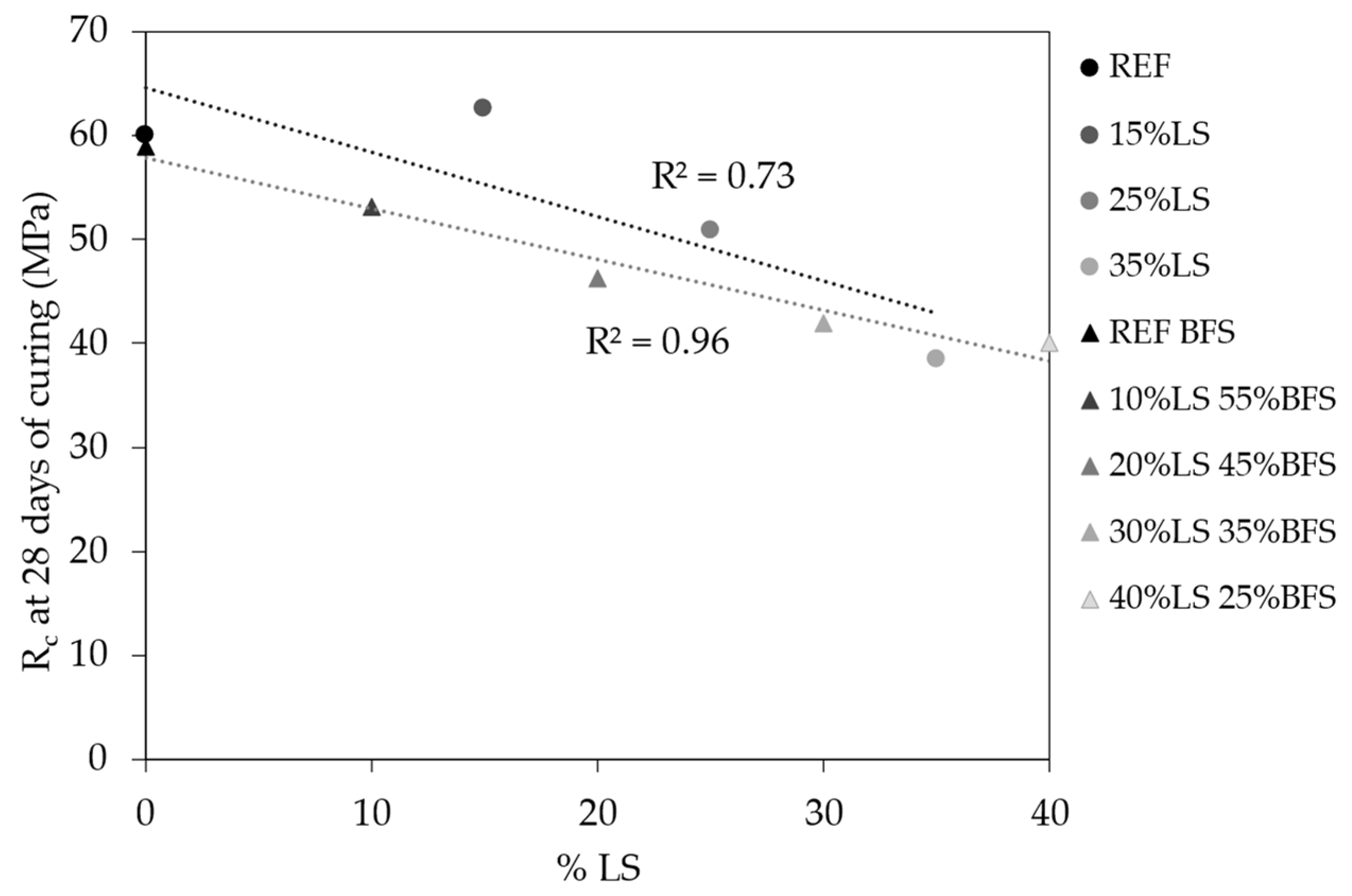

3.2. Strength Class and Mechanical Properties

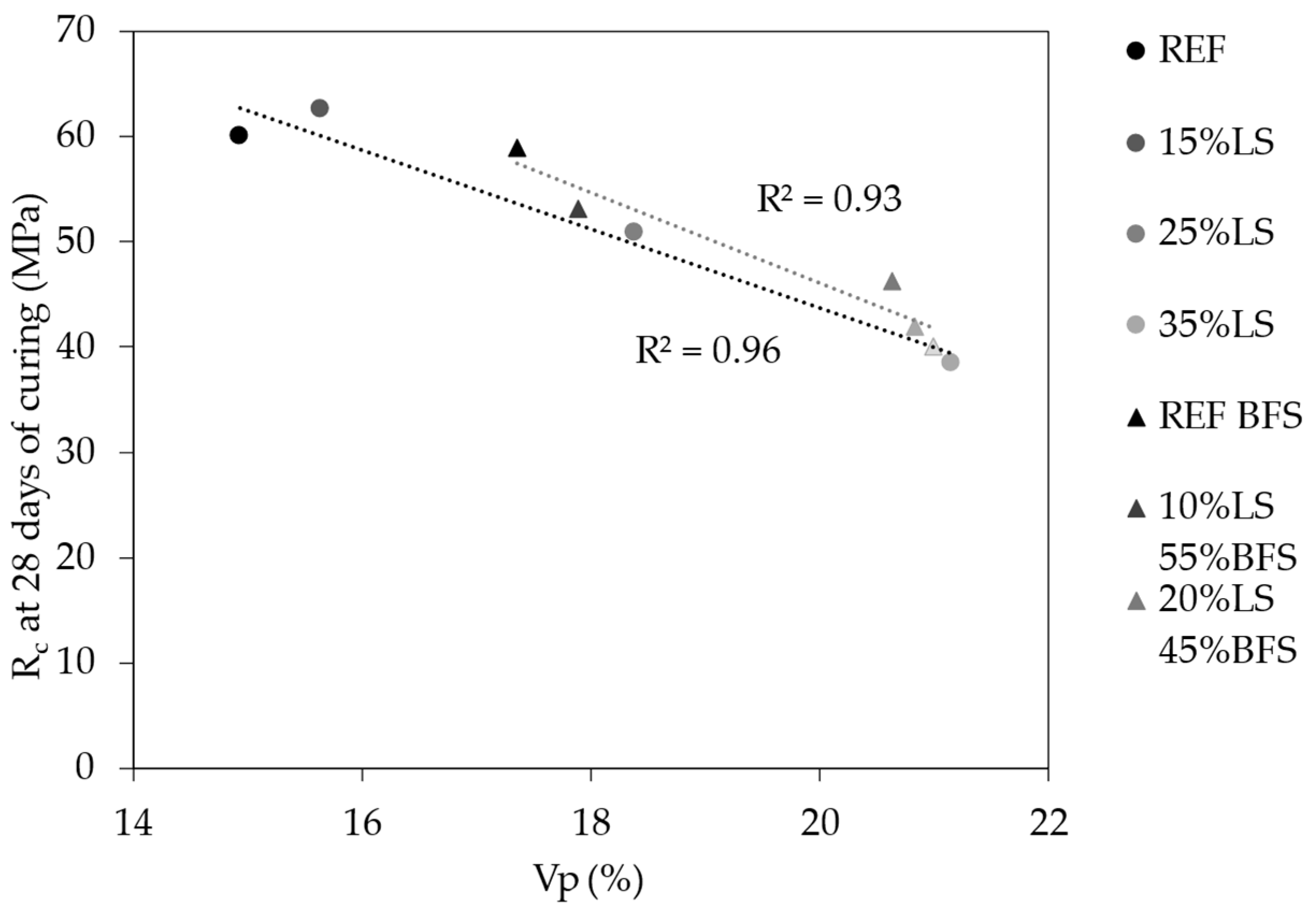

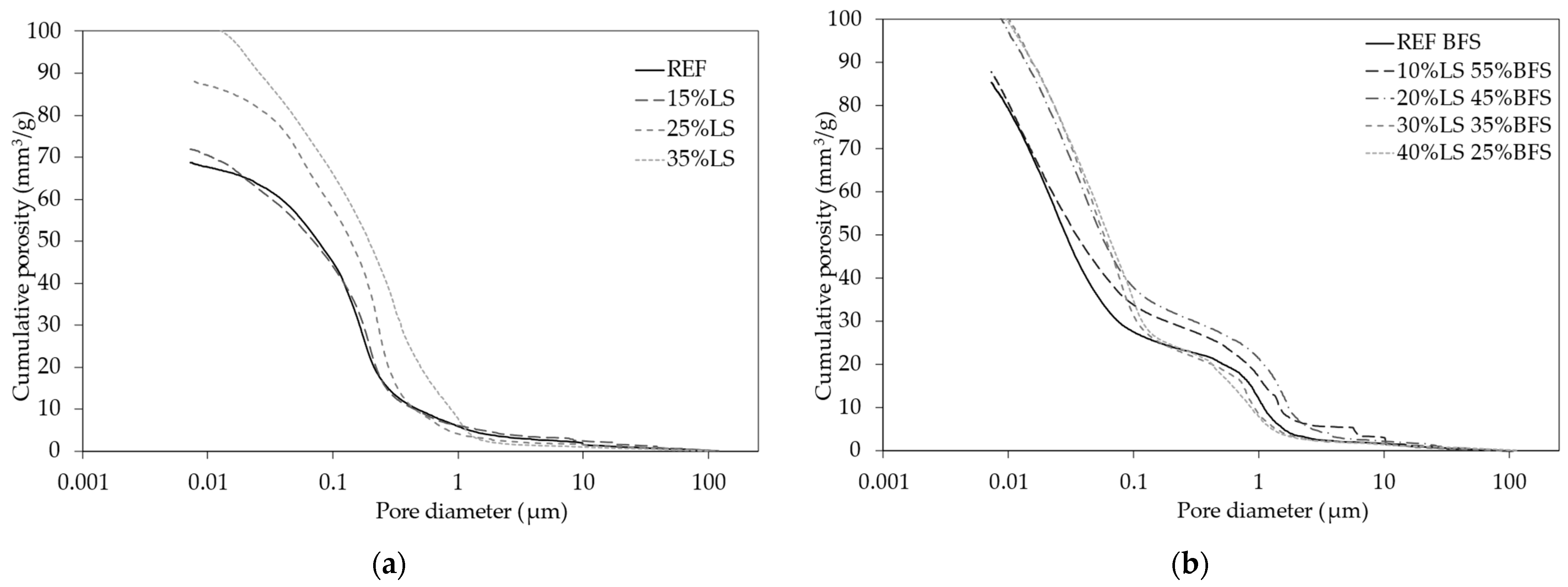

3.3. Microstructural Properties

- High Rc and low Vp: mortars with superior compressive strength and minimal porosity;

- Medium Rc and Vp: mortars with moderate compressive strength and porosity;

- Low Rc and high Vp: mortars with lower compressive strength and higher porosity.

- Macropores: width greater than 50 nm;

- Mesopores: width between 2 nm and 50 nm;

- Micropores: width of 2 nm or smaller;

- Supermicropores: 0.7 nm to 2 nm;

- Ultra-micropores: approximately 0.7 nm in width.

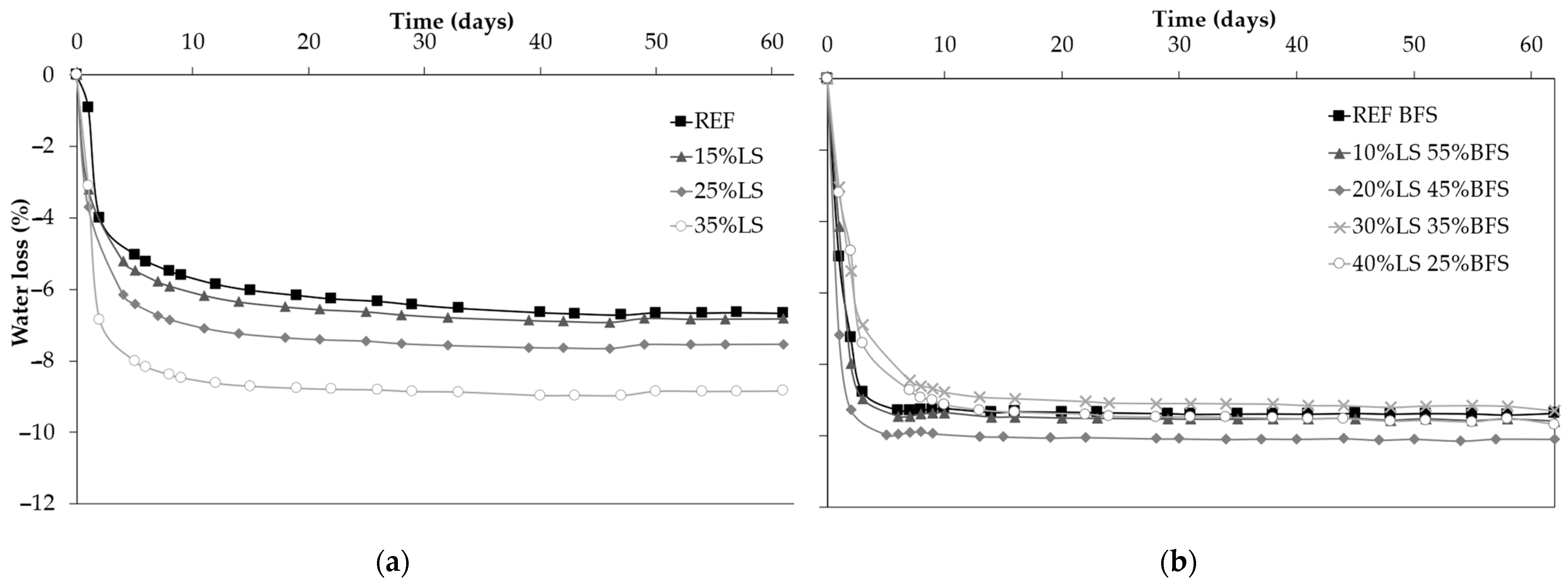

3.4. Capillary Water Absorption

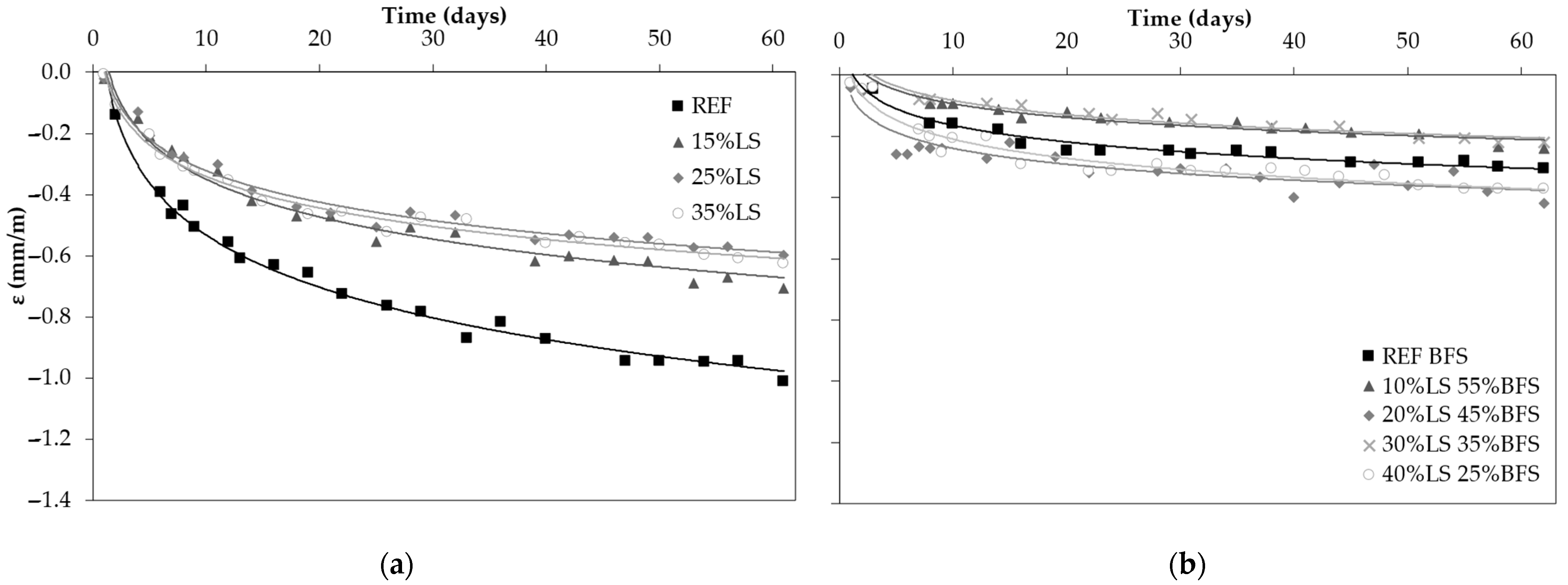

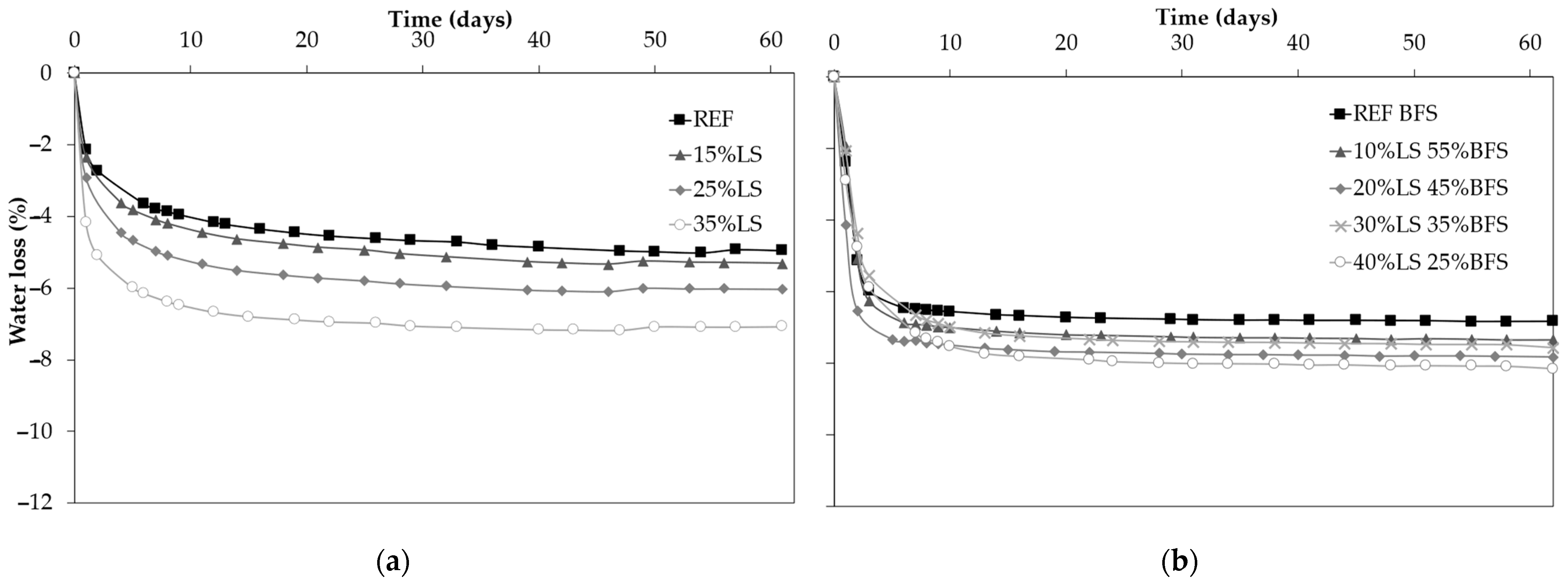

3.5. Drying Shrinkage

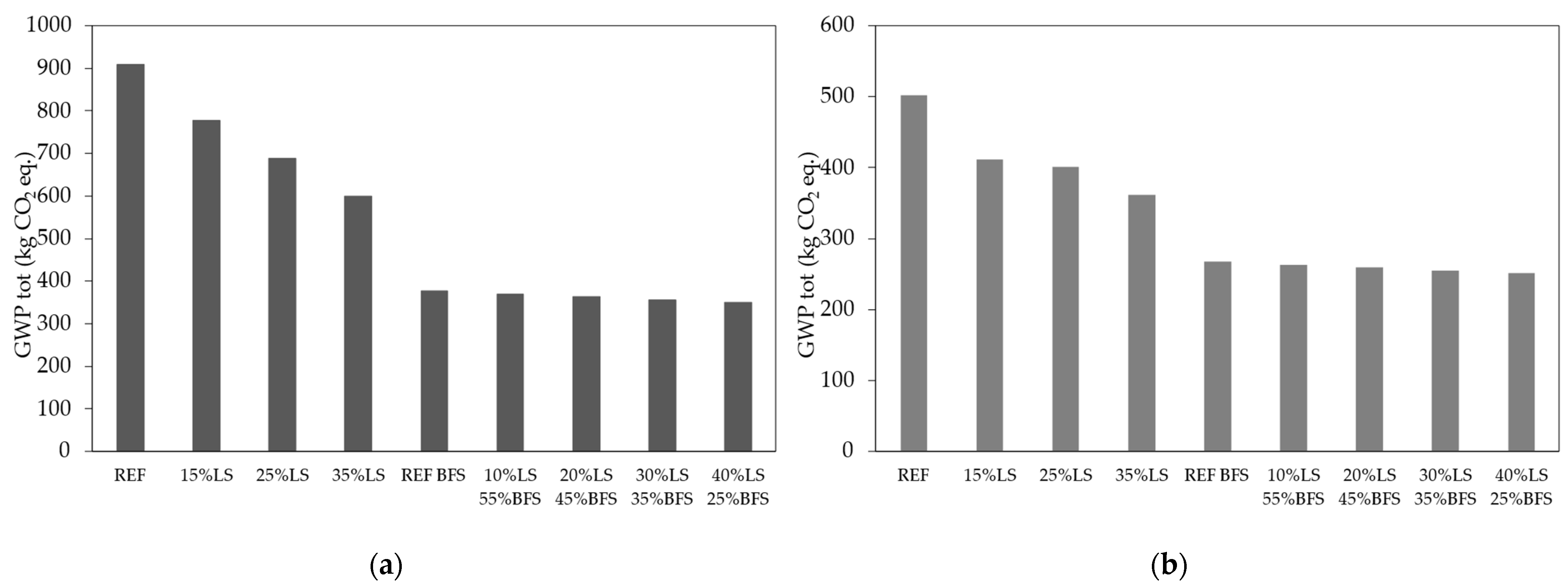

3.6. LCA Analysis

4. Conclusions

- Both hydraulic binders can be classified as structural cements. In particular, for CEM II/B-LL the strength classes are: 52.5R with 0–15% LS, 42.5R with 25% LS, and 32.5R with 35% LS. For CEM VI the strength classes are: 52.5L with 0–10% LS, 42.5N with 20% LS, 32.5R with 30% LS, and 32.5N with 40% LS, despite the maximum BFS substitution with LS exceeding the limit established by the standard (20%);

- LS substitution increases the setting time of CEM II/B due to the reduced PC content and the inert nature of LS but not that of CEM VI since BFS acts only as a slow-reacting pozzolanic binder;

- When cured at a low temperature (10 °C), all CEM VI mortars maintain their mechanical properties, even at higher LS levels, making them particularly good in cold climates;

- The total porosity and the capillary water absorption of the mortars increase with LS content but less in CEM VI;

- In CEM II/B-LL, the free shrinkage of the mortars decreases with LS substitution due to the reduced binder paste and increased inert material content. In CEM VI mortars, free shrinkage increases with LS content up to 20% but decreases at higher LS levels (30–40%) due to the reduced BFS. Restrained shrinkage is lower in CEM VI mortars than in CEM II/B-LL, reflecting lower mechanical properties;

- The total GWP of CEM II/B-LL decreases significantly with higher LS content due to the inert nature of LS and lack of energy-intensive processing. Substituting 15%, 25%, and 35% PC with LS reduces environmental impact by 12%, 20%, and 28%, respectively. CEM VI is less sensible to BFS replacement with LS since the GWP remains almost constant up to a 40% substitution. However, CEM VIs reach a 50% lower environmental impact than CEM II/B-LLs, highlighting their superior sustainability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baek, C.; Park, S.-H.; Suzuki, M.; Lee, S.-H. Life cycle carbon dioxide assessment tool for buildings in the schematic design phase. Energy Build. 2013, 61, 275–287. [Google Scholar] [CrossRef]

- Reddy, B.V.V.; Jagadish, K.S. Embodied energy of common and alternative building materials and technologies. Energy Build. 2003, 35, 129–137. [Google Scholar] [CrossRef]

- Victoria University. Embodied Energy Coefficients. 2017. Available online: www.wgtn.ac.nz/architecture/centres/cbpr/resources/pdfs/ee-coefficients.pdf (accessed on 8 January 2025).

- Hammond, G.; Jones, C. Embodied Carbon. The Inventory of Carbon and Energy (ICE); Lowrie, F., Tse, P., Eds.; Version 2; University of Bath with BSRIA, iCAT: Bracknell, UK, 2011. [Google Scholar]

- Custom Market Insight. Available online: https://www.custommarketinsights.com/ (accessed on 8 January 2025).

- Coley, J. Global Concrete Report 2023. Available online: https://www.proids-online.com/products/reports/global-concrete-report-2023 (accessed on 8 January 2025).

- EN 197-1:2000; Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardization: Brussels, Belgium, 2000.

- Bharadwaj, K.; Isgor, O.B.; Weiss, W.J. Supplementary cementitious materials in Portland-limestone cements. ACI Mater. J. 2022, 119, 141–154. [Google Scholar] [CrossRef]

- Mapiravana, J. Building Materials for a Sustainable Future—Cement; Alive2green: Cape Town, South Africa, 2014; pp. 1–9. Available online: https://researchspace.csir.co.za/server/api/core/bitstreams/20597aea-ae7d-4073-908b-12aa482b6cfb/content (accessed on 8 January 2025).

- Tayebani, B.; Said, A.; Memari, A. Less carbon producing sustainable concrete from environmental and performance perspectives: A review. Constr. Build. Mater. 2023, 404, 133234. [Google Scholar] [CrossRef]

- European Commission. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe. COM 98; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Skibsted, J.; Snellings, R. Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cem. Concr. Res. 2019, 124, 105799. [Google Scholar] [CrossRef]

- EnDurCrete Project. Available online: http://www.endurcrete.eu/ (accessed on 8 January 2025).

- EN 197-5; Cement-Part 5: Portland-Composite Cement CEM II/C-M and Composite Cement CEM VI. European Committee for Standardization: Brussels, Belgium, 2021.

- Zhao, J.; Li, Z.; Wang, D.; Yan, P.; Luo, L.; Zhang, H.; Zhang, H.; Gu, X. Hydration superposition effect and mechanism of steel slag powder and granulated blast furnace slag powder. Constr. Build. Mater. 2023, 366, 130101. [Google Scholar] [CrossRef]

- Zou, J.; Liu, Z.; Guo, Q. Comprehensive utilisation of blast furnace slag. Can. Metall. Q. 2024, 63, 927–934. [Google Scholar] [CrossRef]

- Divsholi, B.S.; Yang, T.; Lim, D.; Teng, S. Durability Properties and Microstructure of Ground Granulated Blast Furnace Slag Cement Concrete. Int. J. Concr. Struct. Mater. 2014, 8, 157–164. [Google Scholar] [CrossRef]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hanafi, M. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2022, 48, 741–746. [Google Scholar] [CrossRef]

- Han, Y.; Lin, R.; Wang, X. Performance of sustainable concrete made from waste oyster shell powder and blast furnace slag. J. Build. Eng. 2022, 47, 103918. [Google Scholar] [CrossRef]

- Mostazid, I.; Medepalli, S.; Sakai, Y. Effect of thermal treatment on strengthening recycled compacted concrete incorporating iron, steel, and blast furnace slag. Constr. Build. Mater. 2022, 347, 128623. [Google Scholar] [CrossRef]

- Chen, G.; Li, S.; Zhao, Y.; Xu, Z.; Luo, X.; Gao, J. Hydration and microstructure evolution of a novel low-carbon concrete containing recycled clay brick powder and ground granulated blast furnace slag. Constr. Build. Mater. 2023, 386, 131596. [Google Scholar] [CrossRef]

- Azenha, M.; Kanavaris, F.; Schlicke, D.; Je, A.; Fairbairn, J.T.E.M.R.; Pesavento, F.; Philip, N.; Ragalwar, K. Recommendations of RILEM TC 287-CCS: Thermo-chemo- mechanical modelling of massive concrete structures towards cracking risk assessment. Mater. Struct. 2021, 54, 135. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Hou, G.; Yan, P. Preparation of sustainable and green cement-based composite binders with high-volume steel slag powder and ultrafine blast furnace slag powder. J. Clean. Prod. 2021, 289, 125133. [Google Scholar] [CrossRef]

- Majhi, R.K.; Nayak, A.N. Production of sustainable concrete utilising high-volume blast furnace slag and recycled aggregate with lime activator. J. Clean. Prod. 2020, 255, 120188. [Google Scholar] [CrossRef]

- Zeraoui, A.; Maherzi, W.; Benzerzour, M.; Abriak, N.E.; Aouad, G. Development of Flash-Calcined Sediment and Blast Furnace Slag Ternary Binders. Buildings 2023, 13, 333. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Santhanam, M.; Kaladharan, G.; Ramanathan, S. Towards ternary binders involving limestone additions—A review. Cem. Concr. Res. 2021, 143, 106396. [Google Scholar] [CrossRef]

- Wang, X.-Y. Optimal mix design of low-CO2 blended concrete with limestone powder. Constr. Build. Mater. 2020, 263, 121006. [Google Scholar] [CrossRef]

- Rashwan, M.A.; Al Basiony, T.M.; Mashaly, A.O.; Khalil, M.M. Self-compacting concrete between workability performance and engineering properties using natural stone wastes. Constr. Build. Mater. 2022, 319, 126132. [Google Scholar] [CrossRef]

- Scrivener, K.; Avet, F.; Maraghechi, H.; Zunino, F.; Ston, J.; Hanpongpun, W.; Favier, A. Impacting factors and properties of limestone calcined clay cements (LC3). Green Mater. 2019, 7, 3–14. [Google Scholar] [CrossRef]

- Argın, G.; Uzal, B. Enhancement of pozzolanic activity of calcined clays by limestone powder addition. Constr. Build. Mater. 2021, 284, 9–14. [Google Scholar] [CrossRef]

- Souza, A.T.; Barbosa, T.F.; Riccio, L.A.; Jose, W. Effect of limestone powder substitution on mechanical properties and durability of slender precast components of structural mortar. Integr. Med. Res. 2019, 9, 847–856. [Google Scholar] [CrossRef]

- Li, C.; Jiang, L. Utilization of limestone powder as an activator for early-age strength improvement of slag concrete. Constr. Build. Mater. 2020, 253, 119257. [Google Scholar] [CrossRef]

- Shao, Z.; Cao, M.; Zheng, X. Limestone particle sizes and sulfate impact on the early hydration of limestone calcined clay cement. J. Build. Eng. 2024, 97, 110848. [Google Scholar] [CrossRef]

- Hamdadou, M.N.; Bignonnet, F.; Deboucha, W.; Ranaivomanana, H.; Leklou, N.; Arroudj, K. Hydration, mechanical and transfer properties of blended cement pastes and mortars prepared with recycled powder or limestone filler. J. Build. Eng. 2023, 78, 107541. [Google Scholar] [CrossRef]

- Khatib, J.; Ramadan, R.; Ghanem, H.; Elkordi, A. Effect of using limestone fines on the chemical shrinkage of pastes and mortars. Environ. Sci. Pollut. Res. 2023, 30, 25287–25298. [Google Scholar] [CrossRef]

- Ji, G.; Chi, H.; Sun, K.; Peng, X.; Cai, Y. Effect of limestone waste on the hydration and microstructural properties of cement-based materials. Constr. Build. Mater. 2024, 443, 137784. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, J.; Han, K.; Wang, J.; Hu, X. Study on the structural build-up of cement-ground limestone pastes and its micro-mechanism. Constr. Build. Mater. 2020, 263, 120656. [Google Scholar] [CrossRef]

- Hamza, A.; Nune, S.; Liebscher, M.; Köberle, T.; Willomitzer, A.; Noack, I.; Butler, M.; Mechtcherine, V. Exploring the role of dilutive effects on microstructural development and hydration kinetics of limestone calcined clay cement (LC3) made of low-grade raw materials. J. Clean. Prod. 2023, 428, 139438. [Google Scholar] [CrossRef]

- Liu, Y.; Zhuge, Y.; Duan, W.; Huang, G.; Yao, Y. Modification of microstructure and physical properties of cement-based mortar made with limestone and alum sludge. J. Build. Eng. 2022, 58, 105000. [Google Scholar] [CrossRef]

- Briki, Y.; Zajac, M.; Ben, M.; Scrivener, K. Impact of limestone fineness on cement hydration at early age. Cem. Concr. Res. 2021, 147, 106515. [Google Scholar] [CrossRef]

- Zhao, L.; He, T.; Niu, M.; Chang, X.; Wang, L.; Wang, Y. Effect of Limestone Powder Mixing Methods on the Performance of Mass Concrete. Materials 2024, 17, 617. [Google Scholar] [CrossRef]

- Li, X.; Cao, M. Recent Developments on the Effects of Micro- and Nano-Limestone on the Hydration Process, Products, and Kinetics of Cement. Materials 2024, 17, 2133. [Google Scholar] [CrossRef]

- Elkhaldi, I.; Roziere, E.; Turcry, P.; Loukili, A. Towards global indicator of durability performance and carbon footprint of clinker-slag-limestone cement-based concrete exposed to carbonation. J. Clean. Prod. 2022, 380, 134876. [Google Scholar] [CrossRef]

- Cyr, M. Influence of supplementary cementitious materials (SCMs) on concrete durability. In Eco Efficient Concrete; Pacheco-Torgal, F., Jalali, S., Labrincha, J., John, V.M., Eds.; Woodhead Publishing: Sawston, UK, 2013; pp. 153–197. [Google Scholar]

- Blasi, E.; Di Bella, C.; Choorackal, E.; Maqbool, Q.; Tittarelli, F.; Garufi, D.; Schmidt, T. Use of low-grade kaolinite clays in the production of limestone calcined clay cement. J. Sustain. Cem. Mater. 2024, 14, 209–221. [Google Scholar] [CrossRef]

- EN 196-3; Methods of Testing Cement—Part 3: Determination of Setting Times and Soundness. European Committee for Standardization: Brussels, Belgium, 2016.

- EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2016.

- EN 1015-3; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). European Committee for Standardization: Brussels, Belgium, 1999.

- EN 1015-6; Methods of Test for Mortar for Masonry—Part 6: Determination of Bulk Density of Fresh Mortar. European Committee for Standardization: Brussels, Belgium, 1998.

- EN 12504-4; Testing Concrete in Structures—Part 4: Determination of Ultrasonic Pulse Velocity. European Committee for Standardization: Brussels, Belgium, 2021.

- Mobili, A.; Blasi, E.; Maqbool, Q.; Tittarelli, F. Copper mine tailings and metakaolin as precursors for sustainable alkali-activated mortars. J. Build. Eng. 2025, 103, 112134. [Google Scholar] [CrossRef]

- Cosoli, G.; Mobili, A.; Giulietti, N.; Chiariotti, P.; Pandarese, G.; Tittarelli, F.; Bellezze, T.; Mikanovic, N.; Revel, G.M. Performance of concretes manufactured with newly developed low-clinker cements exposed to water and chlorides: Characterization by means of electrical impedance measurements. Constr. Build. Mater. 2021, 271, 121546. [Google Scholar] [CrossRef]

- EN 15801; Conservation of Cultural Property—Test Methods—Determination of Water Absorption by Capillarity. European Committee for Standardization: Brussels, Belgium, 2009.

- EN 12617-4; Products and Systems for the Protection and Repair of Concrete Structures—Test Methods—Part 4: Determination of Shrinkage and Expansion. European Committee for Standardization: Brussels, Belgium, 2002.

- UNI EN 8147; Not Metallic Expansive Agents for Cement Mixings—Determination of Restrained Expansion of mortar. Ente Italiano di Normazione: Milan, Italy, 2017.

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- GCCA EPD Tool. Available online: https://www.concrete-epd-tool.org (accessed on 13 December 2024).

- Courard, L.; Michel, F. Limestone fillers cement based composites: Effects of blast furnace slags on fresh and hardened properties. Constr. Build. Mater. 2014, 51, 439–445. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H.; Ou, Z. A review on use of limestone powder in cement-based materials: Mechanism, hydration and microstructures. Constr. Build. Mater. 2018, 181, 659–672. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H. A review on effects of limestone powder on the properties of concrete. Constr. Build. Mater. 2018, 192, 153–166. [Google Scholar] [CrossRef]

- Collepardi, M. The New Concrete 2010; Tintoretto: Castrette di Villorba, Italy, 2010. [Google Scholar]

- Jeong, D.-G.; Lee, H.-S. The effect of Pozzolanic reaction under different curing temperatures in strength development of RPC. In Proceedings of the International Conference on Sustainable Building Asia, Seoul, Republic of Korea, 8–10 July 2010; pp. 251–256. [Google Scholar]

- Concu, G.; Trulli, N. Concrete Defects Sizing by Means of Ultrasonic Velocity Maps. Buildings 2018, 8, 176. [Google Scholar] [CrossRef]

- Diab, A.M.; Abd Elmoaty, M.; Aly, A.A. Long term study of mechanical properties, durability and environmental impact of limestone cement concrete. Alexandria Eng. J. 2016, 55, 1465–1482. [Google Scholar] [CrossRef]

- Mobili, A.; Belli, A.; Giosuè, C.; Bellezze, T.; Tittarelli, F. Metakaolin and fly ash alkali-activated mortars compared with cementitious mortars at the same strength class. Cem. Concr. Res. 2016, 88, 198–210. [Google Scholar] [CrossRef]

- Zdravkov, B.D.; Čermák, J.J.; Šefara, M.; Janků, J. Pore classification in the characterization of porous materials: A perspective. Cent. Eur. J. Chem. 2007, 5, 385–395. [Google Scholar] [CrossRef]

- Quadri Simões da Silva, M.T.; Perretto, F.; do Rocio Cardoso, M.; Mazer, W. Porosity: Some characterization techniques. Mater. Today Proc. 2024. [Google Scholar] [CrossRef]

- Mobili, A.; Telesca, A.; Marroccoli, M.; Tittarelli, F. Calcium sulfoaluminate and alkali-activated fly ash cements as alternative to Portland cement: Study on chemical, physical-mechanical, and durability properties of mortars with the same strength class. Constr. Build. Mater. 2020, 246, 118436. [Google Scholar] [CrossRef]

- Mobili, A.; Giosuè, C.; Bitetti, M.; Tittarelli, F. Cement mortars and geopolymers with the same strength class. Proc. Inst. Civ. Eng. Constr. Mater. 2015, 169, 3–12. [Google Scholar] [CrossRef]

- Li, C. Relationship between water absorption and porosity in concrete with limestone powder addition. Struct. Concr. 2022, 23, 3284–3293. [Google Scholar] [CrossRef]

- Xu, W.; Tang, Z.; Song, Y.; Xie, Y.; Lei, B.; Yu, H.; Long, G.; Kai, M. Drying shrinkage of geopolymeric recycled aggregate concrete. Constr. Build. Mater. 2023, 395, 132220. [Google Scholar] [CrossRef]

- Collepardi, M. The New Concrete; Tintoretto: Castrette di Villorba, Italy, 2006. [Google Scholar]

| Material | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | TiO2 | SO3 |

|---|---|---|---|---|---|---|---|---|---|

| PC | 17.4 | 4.4 | 3.3 | 68.1 | 1.9 | 0.8 | 0.2 | 0.3 | 3.2 |

| LS | 1.3 | 0.0 | 0.0 | 98.2 | 0.5 | 0.0 | 0.0 | 0.0 | 0.0 |

| BFS | 33.5 | 10.8 | 0.4 | 43.9 | 7.8 | 0.5 | 0.2 | 0.7 | 1.7 |

| Material | Relative Density (g/cm3) | Specific Surface Area (cm2/g) | Mean Particle Size (µm) |

|---|---|---|---|

| PC | 3.48 | 2899 | 12 |

| LS | 2.75 | 3900 | 13 |

| BFS | 2.90 | 4014 | 14 |

| Mortars | PC (g/L) | LS (g/L) | BFS (g/L) | Water (g/L) | Sand (g/L) | w/c 1 | w/b 2 | Flow Value (mm) |

|---|---|---|---|---|---|---|---|---|

| CEM II/B-LL | ||||||||

| REF | 512 | - | - | 256 | 1535 | 0.5 | 0.5 | 170 |

| 15% LS | 433 | 76 | - | 255 | 1529 | 0.6 | 0.5 | 157 |

| 25% LS | 381 | 127 | - | 254 | 1526 | 0.7 | 0.5 | 156 |

| 35% LS | 330 | 177 | - | 254 | 1521 | 0.8 | 0.5 | 171 |

| CEM VI | ||||||||

| REF BFS | 178 | - | 330 | 254 | 1524 | 1.4 | 0.5 | 143 |

| 10% LS 55% BFS | 178 | 51 | 279 | 254 | 1522 | 1.4 | 0.5 | 144 |

| 20% LS 45% BFS | 177 | 101 | 228 | 253 | 1520 | 1.4 | 0.5 | 150 |

| 30% LS 35% BFS | 177 | 152 | 177 | 253 | 1518 | 1.4 | 0.5 | 143 |

| 40% LS 25% BFS | 177 | 202 | 126 | 253 | 1516 | 1.4 | 0.5 | 143 |

| Mortars | Initial Setting Time (min) | Final Setting Time (min) |

|---|---|---|

| CEM II/B-LL | ||

| REF | 205 | 266 |

| 15% LS | 223 | 296 |

| 25% LS | 222 | 362 |

| 35% LS | 278 | 395 |

| CEM VI | ||

| REF BFS | 200 | 417 |

| 10% LS 55% BFS | 205 | 424 |

| 20% LS 45% BFS | 205 | 421 |

| 30% LS 35% BFS | 215 | 417 |

| 40% LS 25% BFS | 219 | 425 |

| Mortars | Ed at 20 °C (GPa) | Ed at 40 °C (GPa) | Ed at 10 °C (GPa) |

|---|---|---|---|

| CEM II/B-LL | |||

| REF | 45 ± 0.9 | 38 ± 1.5 | 44 ± 0.1 |

| 15% LS | 41 ± 0.1 | 35 ± 0.0 | 42 ± 0.0 |

| 25% LS | 39 ± 1.1 | 31 ± 0.0 | 42 ± 0.1 |

| 35% LS | 37 ± 0.1 | 28 ± 0.0 | 39 ± 0.0 |

| CEM VI | |||

| REF BFS | 46 ± 0.3 | 40 ± 1.1 | 42 ± 0.7 |

| 10% LS 55% BFS | 45 ± 0.5 | 40 ± 0.6 | 41 ± 0.3 |

| 20% LS 45% BFS | 44 ± 1.1 | 40 ± 0.9 | 41 ± 0.7 |

| 30% LS 35% BFS | 43 ± 0.7 | 38 ± 0.4 | 40 ± 1.2 |

| 40% LS 25% BFS | 42 ± 1.3 | 35 ± 0.0 | 40 ± 0.1 |

| Mortars | Vp (%) | AC (kg/(m2√s)) |

|---|---|---|

| CEM II/B-LL | ||

| REF | 15 | 0.015 |

| 15% LS | 16 | 0.016 |

| 25% LS | 18 | 0.028 |

| 35% LS | 21 | 0.033 |

| CEM VI | ||

| REF BFS | 17 | 0.013 |

| 10% LS 55% BFS | 18 | 0.014 |

| 20% LS 45% BFS | 21 | 0.015 |

| 30% LS 35% BFS | 21 | 0.020 |

| 40% LS 25% BFS | 21 | 0.024 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blasi, E.; Mobili, A.; Choorackal, E.; Tittarelli, F.; Garufi, D. Valorisation of Limestone in Sustainable Cements. Sustainability 2025, 17, 2402. https://doi.org/10.3390/su17062402

Blasi E, Mobili A, Choorackal E, Tittarelli F, Garufi D. Valorisation of Limestone in Sustainable Cements. Sustainability. 2025; 17(6):2402. https://doi.org/10.3390/su17062402

Chicago/Turabian StyleBlasi, Elisa, Alessandra Mobili, Eldho Choorackal, Francesca Tittarelli, and Davide Garufi. 2025. "Valorisation of Limestone in Sustainable Cements" Sustainability 17, no. 6: 2402. https://doi.org/10.3390/su17062402

APA StyleBlasi, E., Mobili, A., Choorackal, E., Tittarelli, F., & Garufi, D. (2025). Valorisation of Limestone in Sustainable Cements. Sustainability, 17(6), 2402. https://doi.org/10.3390/su17062402