Abstract

Business organisations are working to improve their IT flexibility to gain a competitive advantage in the evolving business landscape. This study aims to assess the influence of IT flexibility in its three dimensions (compatibility, connectivity, modularity) on supply chain resilience in the petroleum products distribution sector. It will also examine the connection between these dimensions and supply chain resilience at both the macro and micro levels. The research population represented the managers of fuel stations in the petroleum products distribution company with 2215 managers. A sample of 327 managers was selected using the G*Power program. The results of the regression analysis indicate that IT flexibility has a significant impact on supply chain resilience. Among the dimensions of IT flexibility, the modularity dimension was found to be the most influential. This research contributes to clarifying the role of IT infrastructure flexibility in enhancing supply chain resilience, which in turn contributes to the continuity and growth of organisations. The research emphasises the importance of focusing on collaboration and knowledge sharing to achieve greater flexibility in facing challenges, as well as investing in opportunities.

1. Introduction

The petroleum products distribution sector is one of the vital sectors that plays a strategic role in supporting the national economy and meeting the energy needs of various economic sectors [1]. As a result of the rapid changes in the business environment, this sector, like other economic sectors, faces many challenges [2], including technological challenges, market fluctuations, and customer needs and desires that vary in diversity and intensity [3,4]. Contemporary business organisations seek to adopt an effective strategic approach that ensures supply chain resilience, maintains the continuity of their operations, and protects them from interruption, considering the dynamic changes witnessed by the contemporary business environment [5]. Many studies have indicated that the effectiveness of supply chain resilience is not limited to being a management responsible for confronting interruptions in the supply chain. Still, it goes beyond that to play a crucial role in improving operational efficiency and enhancing competitiveness [6,7]. IT flexibility is one of the important tools that companies rely on to face challenges and disruptions in the supply chain [8]. It provides the ability to quickly redesign systems, enhance communication between stakeholders, and support decision-making processes in the face of uncertainty [9,10]. In addition to innovative solutions that improve the flow of information across different parts of the supply chain [11]. IT flexibility also plays an important role in enhancing integration between different systems and facilitating rapid response to sudden changes that may occur in the market [12,13]. Despite the literature’s discussion of the concept of IT resilience, the knowledge gap exists in understanding how IT resilience can play a critical role in making the supply chain more resilient, especially in the petroleum products distribution sector, especially in developing economies such as Iraq [14,15,16,17,18,19,20]. Iraq’s petroleum products distribution sector suffers from many complexities in the government-controlled regulatory environment, in addition to the challenges of the petroleum refining industry’s infrastructure and seasonal demand fluctuations [21]. This research aims to analyse the impact of IT flexibility on improving supply chain resilience, focusing on its key dimensions: compatibility, connectivity, and modularity [22,23,24]. The construction of each dimension is presented in Table A1 and Table A2 (Appendix A). Additionally, it seeks to identify the factors that enhance operational performance and enable organisations to respond swiftly to market changes. The research also offers practical recommendations to assist decision-makers in making effective choices in this crucial area.

2. Literature Review

The concept of IT flexibility refers to the ability of an organisation’s IT infrastructure to improve and adapt quickly and effectively to rapid changes in the internal and external environment [25]. IT flexibility provides the ability to support innovation, improve operational efficiency, and enhance integration between systems by reconfiguring IT resources [26]. Additionally, IT flexibility minimises the risk of disruptions and strengthens business continuity, providing organisations with a competitive advantage in rapidly changing environments [27]. Therefore, IT flexibility is one of the key pillars for achieving continuity and sustainability in operational performance and enhancing digital growth processes amid rapid developments in IT [28]. According to Duncan’s classification, IT flexibility is measured by its dimensions: compatibility, connectivity, and modularity [29,30].

Compatibility refers to the effective communication between IT components [31]. Different IT platforms make information exchange available and flow smoothly within an organisation [32]. For example, systems designed using a service-oriented architecture have each layer of the technology stack loosely coupled while adhering to strict industry standards [33]. This approach ensures that technology components with similar features can communicate effectively [22].

Connectivity is the possession of the IT infrastructure for a variety of platforms that enable an organisation to use and benefit from them [22]. Connectivity promotes the effective exchange of information within and outside the organisation [32]. Improving connectivity creates better alignment, allowing organisations to create stronger links between IT and other corporate strategies by improving planning, coordination, and task execution [24]. Enterprise application integration (EAI) illustrates this concept by promoting a more connected environment. It breaks down application and data silos by taking communications and data flows out of the applications themselves [34].

Modularity is a vital element of IT flexibility, referring to the ability of technology systems to adapt quickly to changes by using multiple integrated technologies [35]. Through this capability, the organisation can meet the needs of evolving businesses, which is positively reflected in the adaptation and speed of response to environmental challenges imposed by the technological environment [36]. As with some companies with more adaptable technology infrastructures, they leverage scalable software platforms or cloud computing technologies to accommodate new requirements without modifying their infrastructure [37]. Therefore, IT flexibility must include modularity, which allows companies to respond quickly and effectively [38].

Supply chain resilience is the ability of a supply chain to recover from disruptions and emergencies and to adapt and respond quickly to ensure the continued efficient flow of products and services [39]. That makes resilience essential to ensure business sustainability in complex and evolving environments [40]. The concept of supply chain resilience involves a set of strategic dimensions that contribute to enhancing the supply chain’s ability to resist and withstand the crises and disruptions it faces. Among these dimensions is early risk sensing, which helps provide early warning of risks and disruptions before they occur, which helps in taking the necessary precautions that increase the possibility of quickly adapting to emergency conditions and challenges, thus maintaining the continuity of the chain’s operation and quickly restoring its normal state [41]. Continuous cooperation and information exchange among the various parties in the supply chain help to increase the effectiveness of coordination [42], which in turn has a positive impact on the overall sustainability of the system [43,44]. Together, these dimensions form a strong foundation for building a resilient supply chain that can effectively face future challenges [45]. The literature review indicates that previous studies have advanced our understanding of the dimensions of IT flexibility and their significance in improving supply chain resilience. However, there is still a need for an integrated framework that effectively links these dimensions and clarifies their collective impact on operational performance and an organisation’s ability to adapt to rapid market changes. This research is an important step toward bridging this gap by providing a comprehensive analysis and practical recommendations that enhance decision-making in this critical area. It offers a unique contribution and adds value to the existing literature.

3. Research Model and Hypotheses

Supply chain resilience is of great importance to many companies that are always seeking to adapt to the challenges they face in the business environment [46,47], and these challenges are often of a changing and unpredictable nature [48]. IT flexibility and its dimensions of compatibility, connectivity and modularity play a pivotal role in enhancing companies’ ability to adapt to the rapid and unexpected changes they face through communication and coordination across the parts of the supply chain and its basic components [49,50]. IT flexibility increases the speed of companies’ responses to unexpected disruptions and challenges [51]. IT flexibility is expected to play a positive role in supply chain resilience. Therefore, the first hypothesis will be formulated as follows:

H1.

IT flexibility has a significant impact on supply chain resilience.

IT compatibility is critical to enhance coordination between IT systems within companies; this is reflected in the different parties within the supply chain [52]. The greater the compatibility between these systems, the more efficient the flow of data and information is, and it has the advantage of improving supply chain resilience [53]. Therefore, the second hypothesis can be formulated as follows:

H2.

Compatibility has a significant impact on supply chain resilience.

The rapid and effective exchange of information between the parties that make up the supply chain is very important [54]. Effective connectivity enhances the ability to rapidly make decisions to face changes in the business environment [55], thus increasing the ability of the supply chain to withstand and adapt to challenges [56]. Accordingly, the third hypothesis can be formulated as follows:

H3.

Connectivity has a significant impact on supply chain resilience.

Modularity offers IT greater flexibility, allowing companies to swiftly adjust and modify their systems in response to changes in their environment or market challenges [57,58]. This quick adaptation improves the supply chain’s response to environmental shifts [58]. Based on this understanding, we can formulate the following fourth hypothesis:

H4.

Modularity has a significant impact on supply chain resilience.

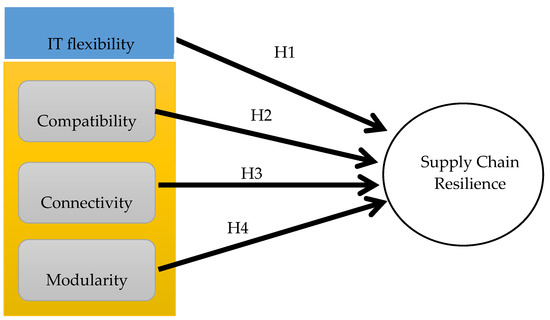

Figure 1 depicts the relationship diagram illustrating the connections between the research variables and their influence based on the research hypotheses. The study focuses on the impact of information technology flexibility on the overall resilience of the supply chain and its dimensions. The independent variable in the study is information technology flexibility, which comprises three dimensions: compatibility (COM), connection (CON), and modularity (MO), as well as supply chain resilience (SCR).

Figure 1.

A conceptual model depicting the relationship between IT flexibility and supply chain resilience and the associated hypotheses.

4. Methodology

To implement the research, a questionnaire consisting of 28 paragraphs was designed and divided into three main sections: the first section dealt with demographic variables, while the second section included the independent variable (IT flexibility) and its three dimensions (compatibility, communication, and modules) [36]. The third section focused on the dependent variable (supply chain flexibility) [37,38]. The questionnaire was designed using a five-point Likert scale (1 = strongly disagree, 5 = completely agree). The study population was determined to include gas station managers working in the oil products distribution company, numbering 2215 managers. The G*Power program was used to determine the total sample size needed, where the total sample size was determined at 327 managers, considering a statistical significance level of 0.05, a statistical power of 0.95, and a medium effect size. To ensure the recovery of a sufficient number of valid questionnaires, 400 questionnaires were distributed, and 350 questionnaires were recovered, of which 334 were valid for statistical analysis after excluding incomplete or invalid questionnaires. The reliability and validity of the questionnaire were evaluated using Cronbach’s alpha coefficient. The results shown in Table 1 show high Cronbach’s alpha coefficients for the different dimensions, indicating the high reliability of the questionnaire. The value of Cronbach’s alpha coefficient for the IT flexibility variable was 0.957, and for the supply chain flexibility variable, 0.963. The sub-dimension coefficients ranged between 0.772 and 0.899, which confirms that the questionnaire has a high and acceptable degree of reliability for all its dimensions.

Table 1.

Study scale concerning survey sections, sources, and Cronbach’s alpha.

The data collected from the survey conducted for this research revealed the demographic details, as shown in Table 2. The survey was comprised of 100% male participants. The largest portion of the sample, 37.13%, fell within the 30–40 age group, followed by the 41–50 age group at 27.84%, the over-50 age group at 23.35%, and the under-30 age group at 11.68%. Regarding academic qualifications, 48.80% of the sample held a diploma, making it the largest group. Holders of a preparatory certificate followed this at 25.75%, a bachelor’s degree at 19.16%, a higher diploma at 5.69%, and a master’s degree at 0.60%. Regarding familiarity with the technologies used in fuel distribution operations, 30% of the participants had a basic level of familiarity, 50% had an intermediate level, and 20% had an advanced level. Regarding participation in supply chain training programs or seminars, 50% had participated in fewer than five programs, while 40% had participated in five or more.

Table 2.

Descriptive results.

5. Results and Discussion

The results indicate that the arithmetic means of all variables are higher than the neutral value (3). In Table 2, the mean arithmetic mean value of IT flexibility was 3.630. Furthermore, the arithmetic mean values of its dimensions were as follows: compatibility 3.635, connectivity 3.639, and modularity 3.615. The arithmetic mean value of supply chain resilience was 3.617. This indicates a relatively positive evaluation by the sample members of these variables compared to the hypothetical average of 3. This evaluation reflects the participants’ interest in the importance of IT flexibility and its role in enhancing the sustainability of logistics operations. Additionally, the standard deviation value of the IT flexibility variable at both the overall and dimensional levels and supply chain resilience was greater than or equal to 0.60, indicating a greater relative homogeneity in the participants’ opinions regarding their supply chain resilience assessment compared to IT flexibility. These results reflect an awareness of the importance of investing in flexible technologies to enhance the supply chain’s ability to adapt to challenges and improve operational efficiency.

Structural equation modelling (SEM) is a statistical technique used to evaluate and examine the causal link between dependent and independent variables [59]. In this study, the measurement model and the structural model were assessed using Smart-PLS 3.0. A measurement model defines the link between the latent variable and the indicator or manifest variable. The Partial Least Squares (PLS) measurement model is analysed using Principal Component Analysis (PCA). Because the study’s variables were reflective, the measurement model was also assessed for internal consistency, indicator reliability, convergent validity, and discriminant validity [60].

Composite reliability is used to gauge internal consistency [61]. To be more precise, according to Hair et al. (2014), it is deemed acceptable if the composite dependability is 0.70 or above [62]. Table 3 displays the composite reliability (CR) statistics. Every CR value was discovered to be more than 0.70. Put another way, all the variables included in this study were deemed reliable since the results met the overall recommendations of Hair et al. (2019) [63].

Table 3.

Results of composite reliability.

Convergent validity is the positive association between a measure and further measurements of the same variable. Validity assessment of the reflective variables is crucial [62]. Table 4 presents the evaluation of the measurement model in terms of factor loadings and AVE. Hair et al. (2014) state that all items should ideally have factor loadings of at least 0.70 [63]. As a result, 12 items with values below 0.70 were eliminated as they could not account for the variable in the specified factor. It may be inferred that the factor takes enough variation from the variable because the other factor saturations were higher than 0.70. The variation that the variable in the given factor represents is explained by factor saturation. Furthermore, every Average Variance Extracted (AVE) value for these items was greater than 0.50, indicating that the variables in this study had convergent validity.

Table 4.

Results of convergent validity.

Discriminant validity evaluates the degree to which items distinguish between ideas or variables [64]. According to Hair et al. (2014), a variable that demonstrates discriminant validity is unique and able to capture the phenomenon of interest that is not reflected by other variables in the same model [62]. This investigation assessed discriminant validity using Fornell and Larcker’s criteria (see Table 5).

Table 5.

Results of Fornell–Larcker ‘s criterion.

5.1. Structural Model Path Coefficients (Model 1)

Hypothesis (H1).

IT flexibility significantly affects supply chain resilience.

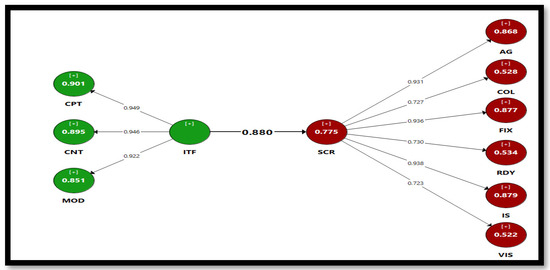

The direct influence of the IT flexibility (ITF) variable, which consists of compatibility, connection, and modularity dimensions, on supply chain resilience (SCR) was examined using a route analysis model, as shown in Figure 2. With a coefficient of β = 0.880 and p < 0.01, Table 6 and the model in Figure 2 show that the IT flexibility variable has a positive influence on supply chain resilience, indicating that increased IT flexibility improves supply chain resilience. The high impact factor shows that investing in IT flexibility is not just a technical improvement but a strategic factor that enhances supply chain resilience, underscoring its critical role in dynamic and complex business environments such as the petroleum products distribution sector.

Figure 2.

Path coefficient Model 3 results for the effect of IT flexibility on supply chain resilience.

Table 6.

Modelling the coefficients of the path model for the effect of IT flexibility on supply chain resilience.

5.2. Model Fit Indices and Statistical Reporting

Structural Equation Modelling (SEM) was employed using Smart-PLS 3.0 to evaluate the model’s explanatory power and goodness of fit, ensuring methodological rigour. The key model fit indices are reported in Table 7.

Table 7.

Model fit indices for IT flexibility and supply chain resilience.

These results indicate that IT flexibility contributes only marginally to variations in supply chain resilience, emphasising the need to consider additional variables that might mediate or moderate this relationship.

5.3. Structural Model Path Coefficients (Model 2)

Hypothesis (H2).

The impact of compatibility on supply chain resilience is significant.

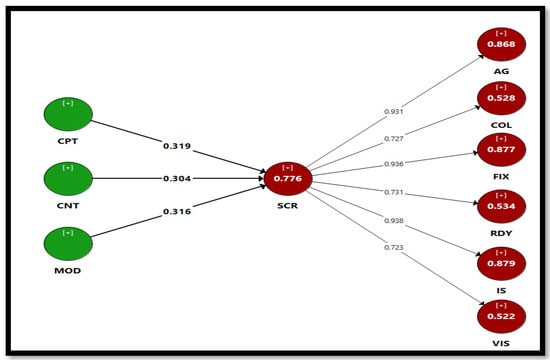

The compatibility variable (CPT) has a positive effect on supply chain resilience (SCR), as demonstrated in Table 7 and illustrated in the model in Figure 3, with β = 0.3019 and p < 0.01. In other words, an improved level of compatibility would lead to increased resilience.

Figure 3.

Path coefficient Model 4 results for the effect of IT flexibility dimensions on supply chain resilience.

Hypothesis (H3).

The impact of connectivity on supply chain resilience is significant.

Table 7 and Figure 3 illustrate that the connectivity variable (CNT) exerts a positive influence on supply chain resilience (SCR), with β = 0.304, p < 0.01. In other words, increased connectivity would lead to a more resilient supply chain.

Hypothesis (H4).

The impact of modularity on supply chain resilience is substantial.

The modularity variable (LC) has a positive effect on supply chain resilience (SCR), as demonstrated in Table 8 and illustrated in the model in Figure 3, with β = 0.316 and p < 0.01. In other words, an increased modularity level would lead to improved supply chain resilience.

Table 8.

Modelling the coefficients of the path model for the effect of IT flexibility dimensions on supply chain resilience.

5.4. Testing of Hypotheses

Geisser and Stone created the bootstrapping method to test the study’s hypotheses. Table 9 shows the outcomes of this study’s hypothesis testing.

Table 9.

Results of hypotheses testing.

The results of the path analysis indicated that IT flexibility has a strong overall effect on supply chain resilience (β = 0.88). However, the effects of its dimensions—compatibility (β = 0.319), modularity (β = 0.3015), and connectivity (β = −0.304)—were found to be weak. This means that IT flexibility significantly enhances the ability of the supply chain to adapt to challenges and disruptions. At the same time, the individual dimensions do not exert the same level of influence. This indicates that IT flexibility at the aggregate level plays a crucial role in increasing the ability of the supply chain to adapt to disruptions and challenges, which enhances its resilience. The current research results are consistent with what was discussed in the previous literature regarding IT flexibility as a concept consisting of several interconnected dimensions, each contributing to improving organisational performance and the ability to coexist and adapt to changes in the business environment [6,31,32]. Although the dimensions of IT flexibility are essential pillars of information systems’ resilience, their impact individually remains limited unless they are effectively integrated. This is confirmed by previous literature, which finds that an integrated technological infrastructure that combines these dimensions is the most efficient and effective in enhancing supply chain resilience [33,34]. The information in Table 7 shows that the overall effect of IT flexibility on supply chain resilience is weak, suggesting the need to explore additional factors. Conversely, Table 9 demonstrates a strong overall impact of IT flexibility; however, when the individual dimensions are evaluated separately, their effects are weak. This highlights the importance of combining the different dimensions of IT flexibility to effectively improve supply chain resilience.

The results indicate that IT flexibility at the aggregate level significantly affects supply chain resilience. However, when its dimensions (compatibility, connectivity, and modularity) are analysed individually, they appear to have a smaller influence. This phenomenon can be attributed to the synergistic interaction between these elements. Compatibility helps systems integration, which enhances connectivity and enables seamless and efficient data exchange. At the same time, modularity allows for rapid adaptation to changes in demand or disruptions within the supply chain. However, compatibility and connectivity are critical to ensuring operational continuity. Ultimately, these dimensions are most effective and impactful when they work together in an integrated manner, enhancing rapid response to challenges, which is the logical explanation for the power of their combined effect.

The accuracy of the analysis of the results does not prevent some limitations from being considered. The most prominent of these limitations is the use of a Likert scale in collecting data, which may lead to biases in the participants’ responses, as these responses are based on self-assessment that may be affected by the respondents’ perceptions or previous experiences in the field of information technology. In addition, the sample used in the research, which was limited to managers of fuel stations in Iraq, limited the process of generalising the results. Therefore, the current research allows for future studies that take different samples in different geographical areas to expand the scope of generalising the results. Moreover, from the management side, companies should focus on integrating the components of IT into a technology strategy that achieves an effective impact that ensures the efficiency of the supply chain and enhances its resilience.

6. Conclusions

This study examined the relationship between IT flexibility and supply chain resilience in Iraq’s petroleum products distribution sector. The three dimensions of IT flexibility, compatibility, modularity, and connectivity were explored to analyse their contribution to improving the ability of supply chains to cope with changes and disruptions. The results indicate that IT flexibility as an overarching factor is critical in enhancing supply chain resilience. At the same time, the individual dimensions showed varying and relatively weak effects, reflecting the need for their integration to achieve greater effectiveness. Theoretically, these results are consistent with previous literature that emphasises the importance of IT flexibility in enhancing operational efficiency and rapid response to market changes. However, the study added a new dimension by testing the effect of each dimension of IT flexibility separately, which contributed to highlighting the limited effectiveness of these dimensions when they are not integrated. The study has several limitations that should be considered. First, the sample was limited to fuel station managers in Iraq, which may limit the possibility of generalising the results to other industrial sectors or geographic regions. Second, the study relied on a Likert scale survey instrument, which may be affected by inaccurate subjective assessments. Finally, the study did not consider the impact of other environmental and organisational factors that may affect supply chain resilience. Based on these limitations, the study recommends future research considering diverse samples covering different sectors and using more comprehensive research methodologies, such as longitudinal studies, to track the impact of IT flexibility on supply chain resilience over time. Studying the impact of environmental and organisational factors, such as mediating or moderating variables, is also suggested. In practical terms according to the research findings, to improve the resilience of the supply chain, companies operating in the oil products distribution sector should rely on practical strategies that focus on developing IT flexibility by first having the company conduct an assessment of its technological infrastructure to identify weaknesses in compatibility and connectivity between different parts, and then work on investing in systems that can compatibility and improve flow such as enterprise resource planning (ERP) systems. In addition, companies can implement standard technology solutions, such as smart and customisable inventory management systems, which allow for rapid adaptation to changes in demand or disruptions in the supply chain. Finally, the company should subject its employees to training courses on how to operate these new systems to ensure maximum benefit from the capabilities available in these systems. This is reflected positively in the efficiency of supply chain operations and their adaptability. By implementing these strategies, the oil products distribution company will be able to build a more resilient and capable supply chain in the face of future challenges.

Author Contributions

Conceptualisation, H.A.M. and M.K.I.; methodology, H.A.M. and M.K.; investigation, H.A.M.; resources, H.A.M. and M.K.I.; data curation, H.A.M.; writing—original draft preparation, H.A.M.; writing—review and editing, M.K.I. and M.K.; visualisation, M.K.; supervision, M.K.I. and M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author(s).

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

Multiple dimensions of IT flexibility.

Table A1.

Multiple dimensions of IT flexibility.

| Dimensions | Questions |

|---|---|

| Compatibility |

|

| |

| Connectivity |

|

| Modularity |

|

Table A2.

Multiple dimensions of supply chain resilience.

Table A2.

Multiple dimensions of supply chain resilience.

| Dimensions | Questions |

|---|---|

| Agility |

|

| Collaboration |

|

| Flexibility |

|

| Redundancy |

|

| Redundancy |

|

| Information Sharing |

|

| visible |

|

References

- Cao, J.; Bo, Y.; Luo, X.; Bhaumik, D.A. A critical assessment of the distribution strategies employed in the marketing of petroleum products. Int. J. Multidiscip. Res. 2023, 45, 102–118. [Google Scholar]

- Egorov, A.S.; Prischepa, O.; Nefedov, Y.; Kontorovich, V.A.; Vinokurov, I.Y. Deep structure, tectonics and petroleum potential of the western sector of the Russian Arctic. J. Mar. Sci. Eng. 2021, 9, 258. [Google Scholar] [CrossRef]

- Shammary, N.A.; Badry, H.S. Effect of organizational ambidexterity in achieving high performance: Exploratory research in a company of the Petroleum Products Distribution Company/Al-Forat Al-Awsat Distribution Corporation/Babel. Transylv. Rev. 2020, 28, 99–114. [Google Scholar]

- Alanagh, S.T.; Aazad, M.A.; Ranjpour, R.; Pourebadolahan, M.; Asali, M. Calculating commission fee for the private sector’s distribution of petroleum products simultaneously with the proposal of changing Iran’s oil products market structure. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 6222–6239. [Google Scholar]

- Al-Qasimi, M.; Khudari, M.; Al Balushi, Z.; Abdullah, A. The logistics performance index in Oman: A comprehensive review through multi-criteria decision-making. J. Ecohumanism 2024, 3, 630–658. [Google Scholar]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Al-Shukri, B.S.; Al-Dulaimi, I.A.H.; Mijbas, H.A. Impact of strategic scenario planning on marketing competitive strategies: Applied study in tourism service in social media. Afr. J. Hosp. Tour. Leis. 2020, 9, 150–168. [Google Scholar]

- Al-Qasimi, M.; Khudari, M.; Al Balushi, Z. A review on mitigating disruptions and improving resilience in supply chain logistics. WSEAS Trans. Bus. Econ. 2024, 21, 2551–2577. [Google Scholar] [CrossRef]

- Mustapić, M.; Trstenjak, M.; Gregurić, P.; Opetuk, T. Implementation and use of digital, green and sustainable technologies in internal and external transport of manufacturing companies. Sustainability 2023, 15, 1025. [Google Scholar] [CrossRef]

- Milovanović, V.; Chong, K.L.; Paunović, M. Benefits from adopting technologies for the hotel’s supply chain management. Menadz. Hotelj. Tur. 2022, 14, 250–265. [Google Scholar] [CrossRef]

- Zhou, Z. Application and benefits of supply chain digitization in traditional manufacturing industries. Ind. Eng. Innov. Manag. 2023, 18, 140–152. [Google Scholar]

- Dolgui, A.; Ivanov, D.A. 5G in digital supply chain and operations management: Fostering flexibility, end-to-end connectivity and real-time visibility through internet-of-everything. Int. J. Prod. Res. 2021, 60, 442–451. [Google Scholar] [CrossRef]

- Meidutė-Kavaliauskienė, I.; Çiğdem, Ş.; Yıldız, B. The effect of supply chain learning on flexibility performance: An empirical study. Indep. J. Manag. Prod. 2022, 19, 225–241. [Google Scholar] [CrossRef]

- Rezaei, G.; Hosseini, S.M.; Sana, S.S. Exploring the relationship between data analytics capability and competitive advantage: The mediating roles of supply chain resilience and organization flexibility. Sustainability 2022, 14, 1580. [Google Scholar] [CrossRef]

- Amico, A.; Verginer, L.; Casiraghi, G.; Vaccario, G.; Schweitzer, F. Adapting to disruptions: Managing supply chain resilience through product rerouting. Sci. Adv. 2024, 10, eadj1194. [Google Scholar] [CrossRef]

- Ivanov, D. Comparative analysis of product and network supply chain resilience. Int. Trans. Oper. Res. 2025, 32, 150–165. [Google Scholar] [CrossRef]

- Suali, A.S.; Srai, J.S.; Tsolakis, N. The role of digital platforms in e-commerce food supply chain resilience under exogenous disruptions. Supply Chain Manag. 2024, 29, 500–518. [Google Scholar] [CrossRef]

- Villar, A.S.; Abowitz, S.; Read, R.L.; Butler, J. Maximizing supply chain resilience: Viability of a distributed manufacturing network platform using the Open Knowledge Resilience Framework. Oper. Res. Forum 2024, 5, 26. [Google Scholar] [CrossRef]

- Al-Saadi, T.; Cherepovitsyn, A.; Semenova, T. Iraq oil industry infrastructure development in the conditions of the global economy turbulence. Energies 2022, 15, 1023. [Google Scholar] [CrossRef]

- Raissouni, R.; Hamiche, M.; Bourekkadi, S.; Raissouni, K. The impact of the integrated supply chain on the operational performance of companies in the Moroccan electric vehicle sector. E3S Web Conf. 2023, 33, 150–165. [Google Scholar] [CrossRef]

- Mijbas, H.A.; Islam, M.K.; Khudari, M. The theoretical and analytical framework of dynamic capabilities in IT flexibility: An exploratory study in the Oil Products Distribution Company. J. Ecohumanism 2025, 5, 75–98. [Google Scholar] [CrossRef]

- Ness, L.R. Assessing the relationships among IT flexibility, strategic alignment, and IT effectiveness: Study overview and findings. J. Inf. Technol. Manag. 2005, 16, 1–17. [Google Scholar]

- Jorfi, S.; Nor, K.M.; Najjar, L. An empirical study of the role of IT flexibility and IT capability in IT-business strategic alignment. J. Syst. Inf. Technol. 2017, 19, 2–21. [Google Scholar] [CrossRef]

- Afandi, W. IT flexibility, capabilities, and IT-business alignment: Do organizational characteristics and context matter? J. Theor. Appl. Inf. Technol. 2020, 98, 3837. [Google Scholar]

- Chen, X.; Siau, K.L. Business analytics/business intelligence and IT infrastructure: Impact on organizational agility. J. Organ. End User Comput. 2020, 32, 138–161. [Google Scholar] [CrossRef]

- Ononiwu, M.I.; Onwuzulike, O.C.; Shitu, K. The role of digital business transformation in enhancing organizational agility. World J. Adv. Res. Rev. 2024, 15, 550–570. [Google Scholar]

- Gao, P.; Zhang, J.; Gong, Y.; Li, H. Effects of technical IT capabilities on organizational agility: The moderating role of IT business spanning capability. Ind. Manag. Data Syst. 2020, 120, 941–961. [Google Scholar] [CrossRef]

- Hou, C.K. The effects of IT infrastructure integration and flexibility on supply chain capabilities and organizational performance: An empirical study of the electronics industry in Taiwan. Inf. Dev. 2019, 36, 576–602. [Google Scholar] [CrossRef]

- Han, J.H.; Wang, Y.; Naim, M. Narrowing the Gaps: Assessment of Logistics Firms’ Information Technology Flexibility for Sustainable Growth. Sustainability 2020, 12, 4342. [Google Scholar] [CrossRef]

- Duncan, N.B. Capturing Flexibility of Information Technology Infrastructure: A Study of Resource Characteristics and their Measure. J. Manag. Inf. Syst. 1995, 12, 37–57. [Google Scholar] [CrossRef]

- Seguin, J.P.; Varghese, D.; Anwar, M.; Bartindale, T.; Olivier, P.L. Co-Designing Digital Platforms for Volunteer-Led Migrant Community Welfare Support. In Proceedings of the 2022 ACM Designing Interactive Systems Conference, Online, 13–17 June 2022; ACM: New York, NY, USA, 2022. [Google Scholar]

- Fasola, O.S.; Abimbola, M.O. Collaborative Technology for Information Sharing, Knowledge Creation and Management in Libraries. Gatew. Inf. J. 2023, 24, 33–46. [Google Scholar]

- Lindgren, R.; Saadatmand, F.; Schultze, U. Compatibility Promotion for Standard Development within Shared Platforms: A Rising Tide Does Not Lift All Boats. Electron. Mark. 2023, 33, 19. [Google Scholar] [CrossRef]

- Schmieder, F.; Habibey, R.; Striebel, J.; Büttner, L.; Czarske, J.W.; Busskamp, V. Tracking Long-Term Functional Connectivity Maps in Human Stem-Cell-Derived Neuronal Networks by Holographic-Optogenetic Stimulation. bioRxiv 2021. [Google Scholar] [CrossRef]

- Selmani, A.; Schoetz, M.D.; Queen, A.E.; Schoenebeck, F. Modularity in the Csp3 Space—Alkyl Germanes as Orthogonal Molecular Handles for Chemoselective Diversification. ACS Catal. 2022, 12, 4833–4839. [Google Scholar] [CrossRef]

- Silva, F.N.; Albeshri, A.; Thayananthan, V.; Alhalabi, W.; Fortunato, S. Robustness Modularity in Complex Networks. Phys. Rev. E 2022, 105, 054308. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Gupta, S.; Licsandru, T.C.; Schoefer, K. Integrating Machine Learning, Modularity, and Supply Chain Integration for Branding 4.0. Ind. Mark. Manag. 2022, 104, 136–149. [Google Scholar] [CrossRef]

- Skiada, P.; Ampatzoglou, A.; Arvanitou, E.; Chatzigeorgiou, A.; Stamelos, I. Exploring the Relationship between Software Modularity and Technical Debt. In Proceedings of the 2018 44th Euromicro Conference on Software Engineering and Advanced Applications (SEAA), Prague, Czech Republic, 29–31 August 2018; pp. 404–407. [Google Scholar]

- Nnaji, U.O.; Benjamin, L.B.; Eyo-Udo, N.L.; Etukudoh, E.A. Strategies for enhancing global supply chain resilience to climate change. Int. J. Manag. Entrep. Res. 2024, 6, 1677–1686. [Google Scholar] [CrossRef]

- Adewusi, A.O.; Komolafe, A.M.; Ejairu, E.; Aderotoye, I.A.; Abiona, O.O.; Oyeniran, O.C. The Role of Predictive Analytics in Optimizing Supply Chain Resilience: A Review of Techniques and Case Studies. Int. J. Manag. Entrep. Res. 2024, 6, 815–837. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef]

- Chowdhury, M.H.; Chowdhury, P.; Quaddus, M.; Rahman, K.W.; Shahriar, S. Flexibility in Enhancing Supply Chain Resilience: Developing a Resilience Capability Portfolio in the Event of Severe Disruption. Glob. J. Flex. Syst. Manag. 2024, 25, 395–417. [Google Scholar] [CrossRef]

- Rashid, A.; Rasheed, R.; Ngah, A.H.; Jayaratne, M.D.R.P.; Rahi, S.; Tunio, M.N. Role of information processing and digital supply chain in supply chain resilience through supply chain risk management. J. Glob. Oper. Strat. Sourc. 2024, 17, 429–447. [Google Scholar] [CrossRef]

- Yang, Z.; Guo, X.; Sun, J.; Zhang, Y.; Wang, Y. What Does Not Kill You Makes You Stronger: Supply Chain Resilience and Corporate Sustainability Through Emerging IT Capability. IEEE Trans. Eng. Manag. 2022, 71, 10507–10521. [Google Scholar] [CrossRef]

- Jurinic, E. A-205 Evaluating the Cost and Importance of Supply Chain Resilience in the Clinical Laboratory. Clin. Chem. 2024, 70, hvae106.203. [Google Scholar] [CrossRef]

- Yamin, M.A.; Almuteri, S.D.; Bogari, K.J.; Ashi, A.K. The Influence of Strategic Human Resource Management and Artificial Intelligence in Determining Supply Chain Agility and Supply Chain Resilience. Sustainability 2024, 16, 2688. [Google Scholar] [CrossRef]

- Haji, M.H.A. Enhancing insulin supply chain resilience: A critical importance for diabetes management. Glob. J. Obes. Diabetes Metab. Syndr. 2023, 10, 9–13. [Google Scholar]

- Romagnoli, G.; Galli, M.; Mezzogori, D.; Zammori, F. Exploratory Research on Adaptability and Flexibility of a Serious Game in Operations and Supply Chain Management. Int. J. Online Biomed. Eng. (iJOE) 2022, 18, 77–98. [Google Scholar] [CrossRef]

- Saad, N.A.; Elgazzar, S.; Kac, S.M. Investigating the impact of supply chain management practices on customer satisfaction through flexibility and technology adoption: Empirical evidence. Bus. Strat. Dev. 2023, 7, e326. [Google Scholar] [CrossRef]

- Hao, Y. Research on the Synergistic Optimization Path of Supply Chain Management and Working Capital in Retail Enterprises. Front. Bus. Econ. Manag. 2024, 17, 1–4. [Google Scholar] [CrossRef]

- Lello, D.S.; Emuze, F.A. Reconceptualizing a Model for Lean Construction Supply Chain. In Proceedings of the 32nd Annual Conference of the International Group for Lean Construction (IGLC 32), Auckland, New Zealand, 3–5 July 2024. [Google Scholar]

- Guo, J.; Wang, G.; Wang, Z.; Liang, C.; Gen, M. Research on remanufacturing closed loop supply chain based on incentive-compatibility theory under uncertainty. Ann. Oper. Res. 2022. [Google Scholar] [CrossRef]

- Tang, K. Research on Information Sharing Among Supply Chain Financial Enterprises Based on Blockchain. Front. Business, Econ. Manag. 2024, 14, 104–110. [Google Scholar] [CrossRef]

- Nguyen, H.; Onofrei, G.; Truong, D. Supply chain communication and cultural compatibility: Performance implications in the global manufacturing industry. Bus. Process. Manag. J. 2020, 27, 253–274. [Google Scholar] [CrossRef]

- Rajaguru, R.; Matanda, M.J. Role of compatibility and supply chain process integration in facilitating supply chain capabilities and organizational performance. Supply Chain Manag. Int. J. 2019, 24, 301–316. [Google Scholar] [CrossRef]

- Wolf, S.; Hofmann, C.; Bahls, T.; Maurenbrecher, H.; Pleintinger, B. Modularity in Humanoid Robot Design for Flexibility in System Structure and Application. In Proceedings of the 2023 IEEE-RAS 22nd International Conference on Humanoid Robots (Humanoids), Austin, TX, USA, 12–14 December 2023; pp. 1–7. [Google Scholar]

- Lukyanenko, R.; Samuel, B.M.; Parsons, J.; Storey, V.C.; Pastor, O.; Jabbari, A. Universal conceptual modeling: Principles, benefits, and an agenda for conceptual modeling research. Softw. Syst. Model. 2024, 23, 1077–1100. [Google Scholar] [CrossRef]

- Bush, A.A.; Tiwana, A.; Rai, A. Complementarities Between Product Design Modularity and IT Infrastructure Flexibility in IT-Enabled Supply Chains. IEEE Trans. Eng. Manag. 2010, 57, 240–254. [Google Scholar] [CrossRef]

- Cepeda-Carrión, G.; Hair, J.F.; Ringle, C.M.; Roldán, J.L.; García-Fernández, J. Guest editorial: Sports management research using partial least squares structural equation modeling (PLS-SEM). Int. J. Sports Mark. Spons. 2022, 23, 229–240. [Google Scholar] [CrossRef]

- Wang, S.; Cheah, J.-H.; Wong, C.Y.; Ramayah, T. Progress in partial least squares structural equation modeling use in logistics and supply chain management in the last decade: A structured literature review. Int. J. Phys. Distrib. Logist. Manag. 2023, 54, 673–704. [Google Scholar] [CrossRef]

- Shuttleworth, M. Internal Consistency Reliability. In The SAGE Encyclopedia of Research Design; Sage Publications: Thousand Oaks, CA, USA, 2022. [Google Scholar]

- Sarstedt, M.; Hopkins, L.; Kuppelwieser, V.G. Partial least squares structural equation modeling (PLS-SEM): An emerging tool in business research. Eur. Bus. Rev. 2014, 26, 106–121. [Google Scholar]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.R.; Sarstedt, M.; Danks, N.P.; Ray, S. Partial Least Squares Structural Equation Modeling (PLS-SEM) Using R; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Lim, W.M. A typology of validity: Content, face, convergent, discriminant, nomological and predictive validity. J. Trade Sci. 2024, 12, 155–179. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).