Optimal Economic Dispatch of Hydrogen Storage-Based Integrated Energy System with Electricity and Heat

Abstract

1. Introduction

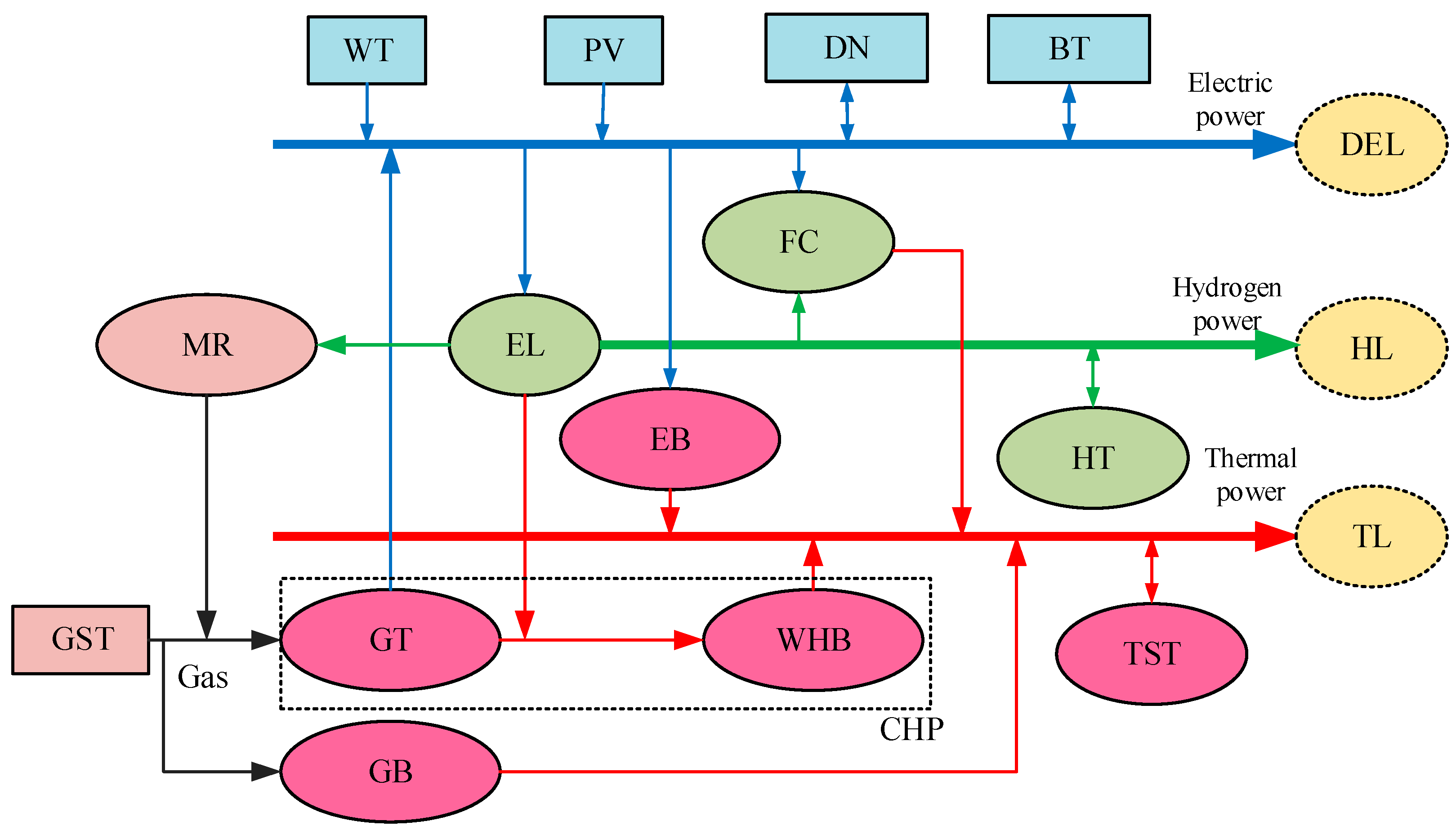

2. Modeling of an Integrated Electro-Thermal Hydrogen Energy System Considering Hydrogen Energy Storage

2.1. Modeling of Electrical Heat Coupling Systems

- (1)

- Gas turbine

- (2)

- Waste heat boiler

- (3)

- Gas boiler

- (4)

- Methane reactor

- (5)

- Thermal storage tank

- (6)

- Battery

- (7)

- Gas storage tank

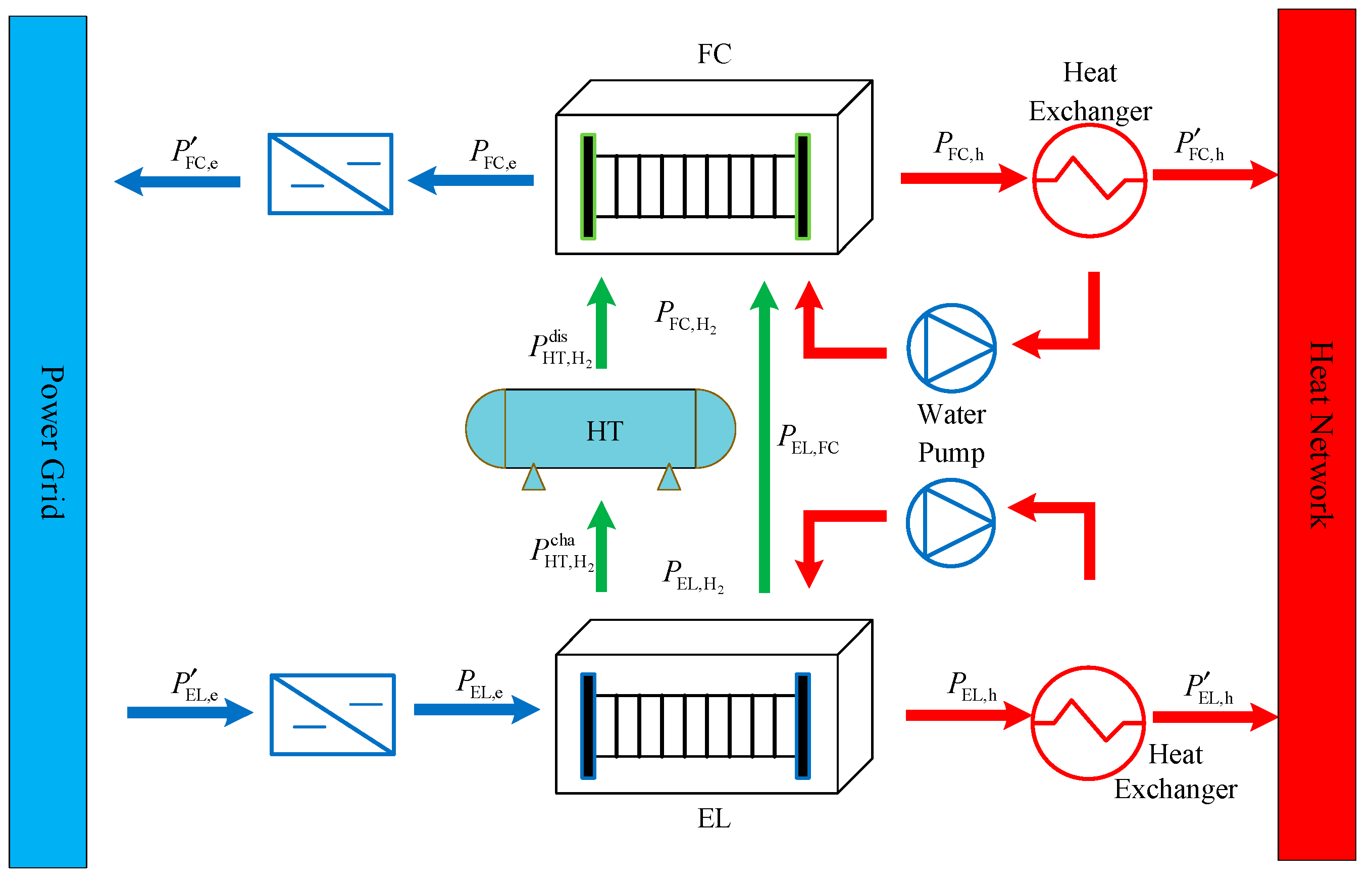

2.2. Modeling of Hydrogen Energy Systems

- (1)

- Modeling of electric hydrogen production

- (2)

- Modeling hydrogen energy storage

- (3)

- Modeling of hydrogen fuel cells

3. Economic Dispatching Model of Electrothermal Hydrogen Integrated Energy System Under Carbon Trading Mechanism

3.1. Tiered Carbon Trading Scheme

3.2. Objective Function

- (1)

- The operation and maintenance cost of each device in the system f1

- (2)

- The purchase cost of the system f2

- (3)

- System of wind, light penalty cost f3

- (4)

- The carbon trading costs of the system are shown in Equation (19) above.

3.3. Constraint Condition

- (1)

- Wind–power constraint

- (2)

- Electric hydrogen production constraints

- (3)

- Hydrogen fuel cell confinement

- (4)

- Methane reactor confinement

- (5)

- Energy storage constraint Energy storage constraint

- (6)

- CHP constraint

- (7)

- Gas boiler confinement

- (8)

- Power balance constraint of the power grid

- (9)

- Power balance constraint of heat supply network

- (10)

- Hydrogen power balance constraints

- (11)

- Power balance constraint of the gas network

3.4. Model Linearization Processing and Solving

- (1)

- Gas turbine linearization process

- (2)

- The actual carbon emission model linearization process

4. Case Study

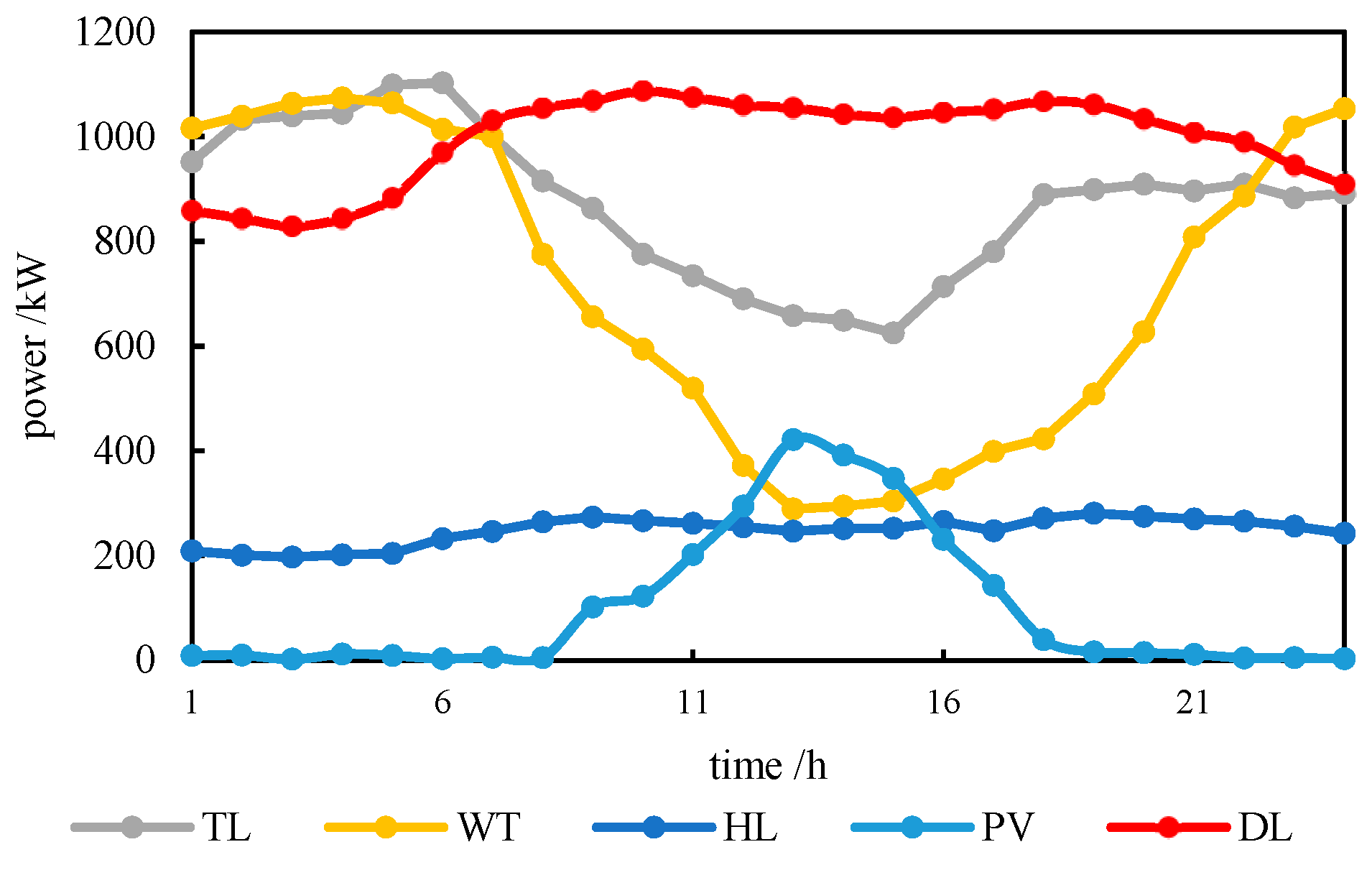

4.1. System Data

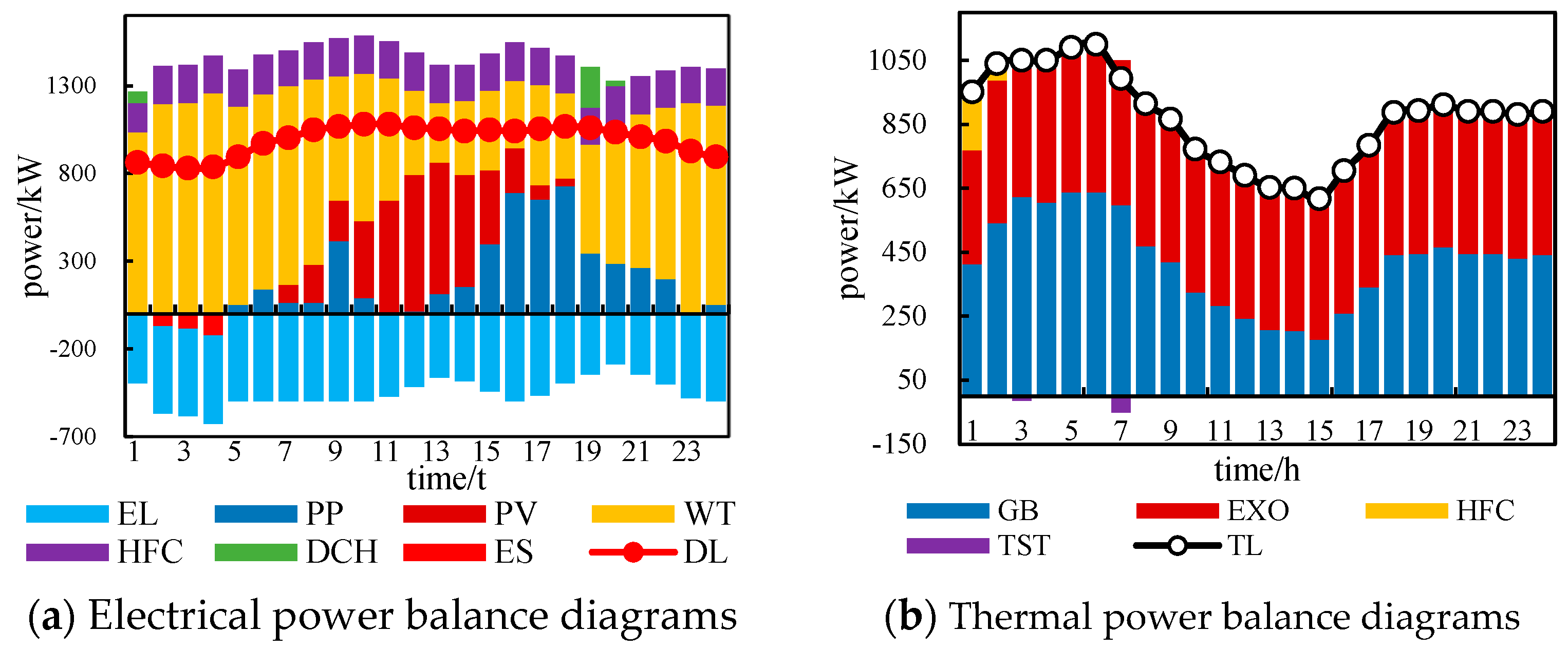

4.2. Case 1: Benefit Analysis of Carbon Trading Mechanism

4.2.1. Scenario Configuration and Analysis of Case 1

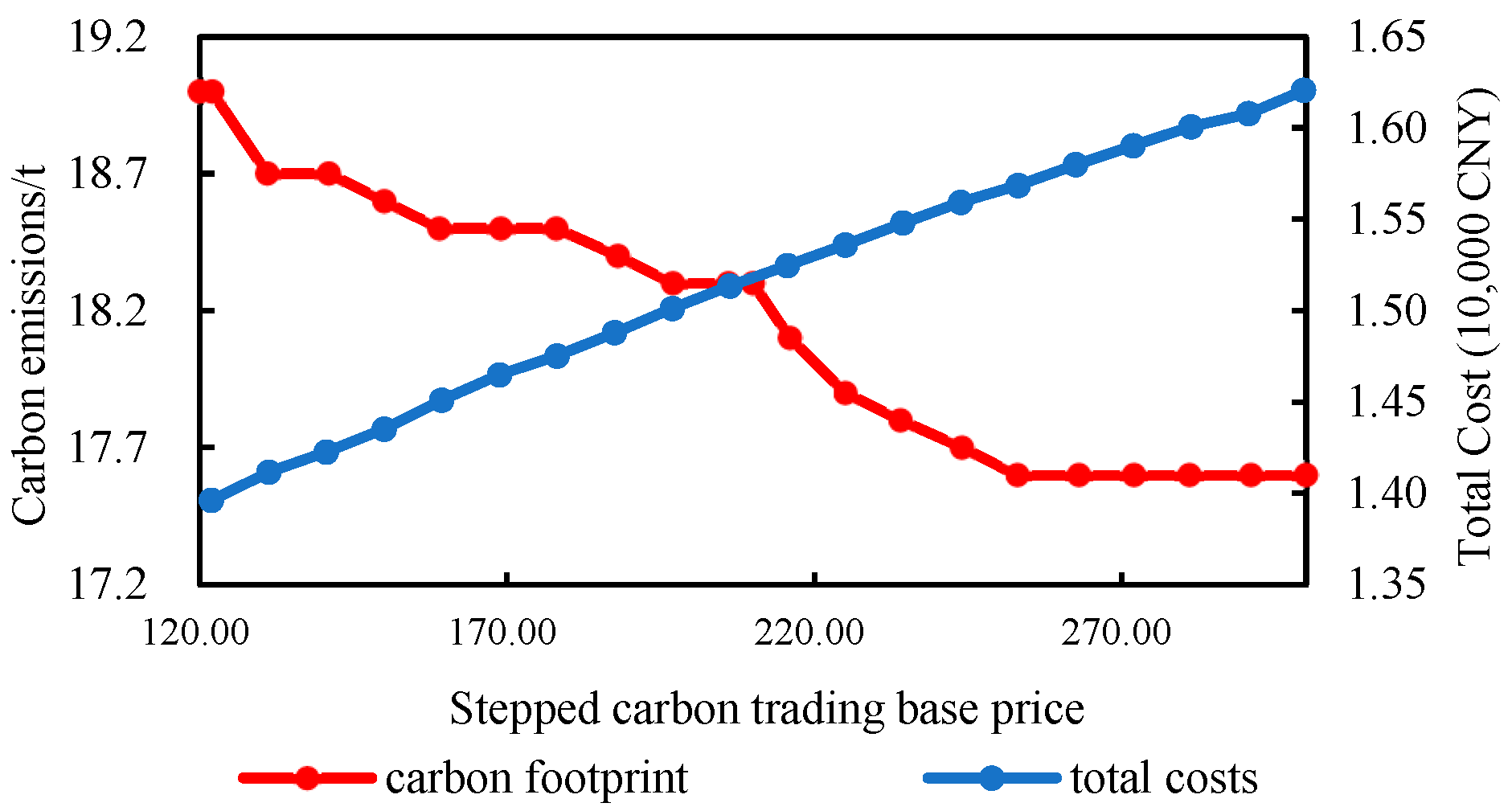

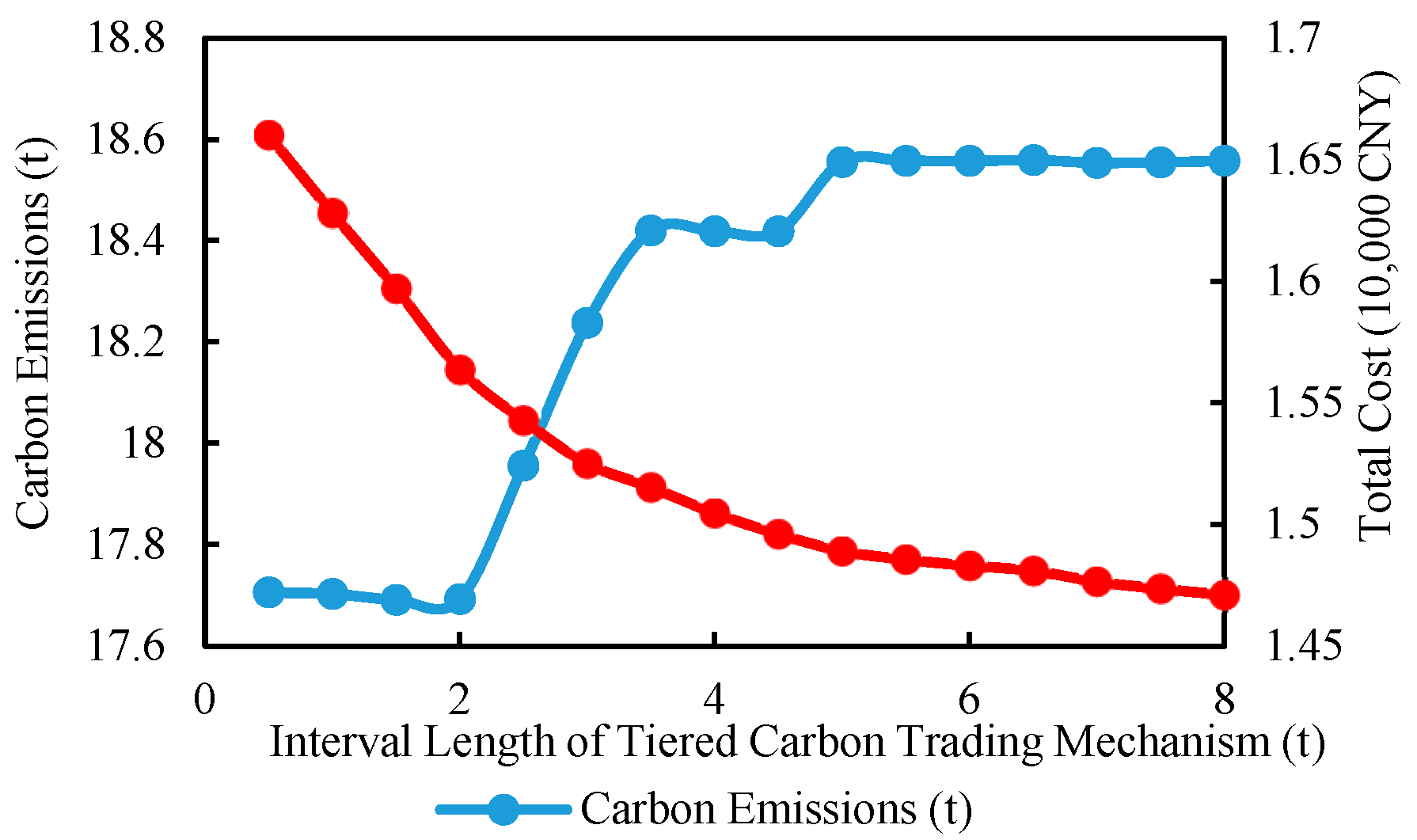

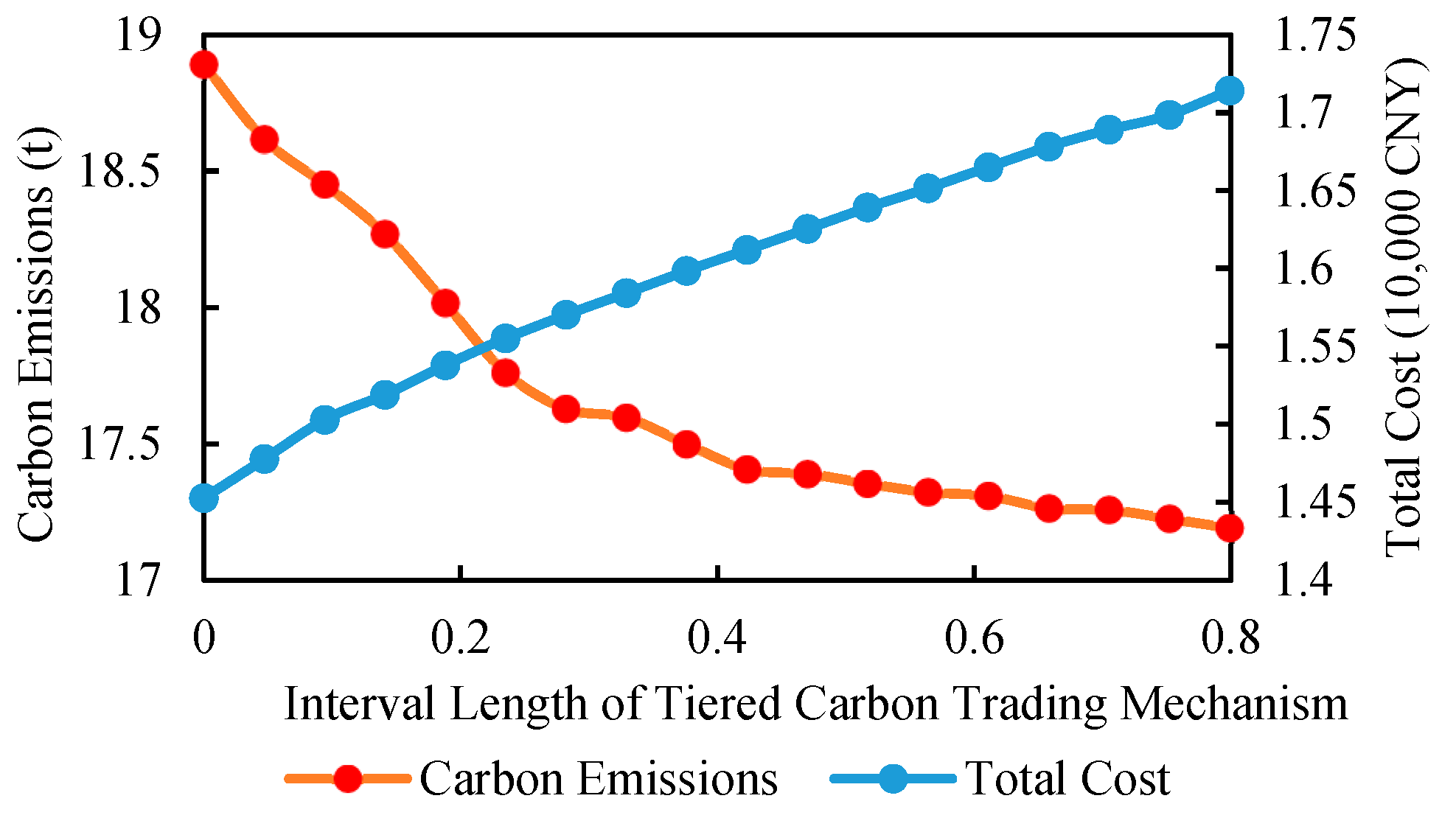

4.2.2. Parameter Sensitivity Analysis of Cascade Carbon Trading Mechanism

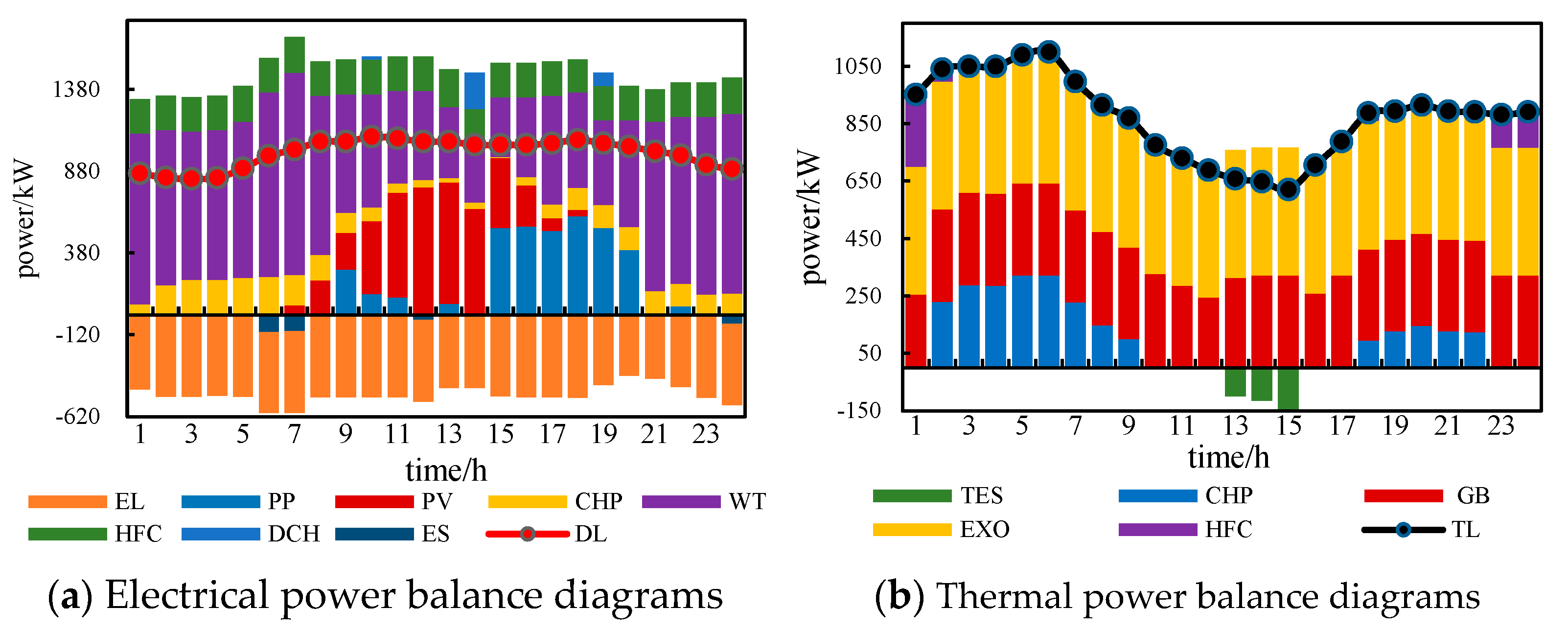

4.3. Case 2: Benefit Analysis of Hydrogen Technology and Cogeneration System

4.3.1. Scenario Configuration and Analysis of Case 2

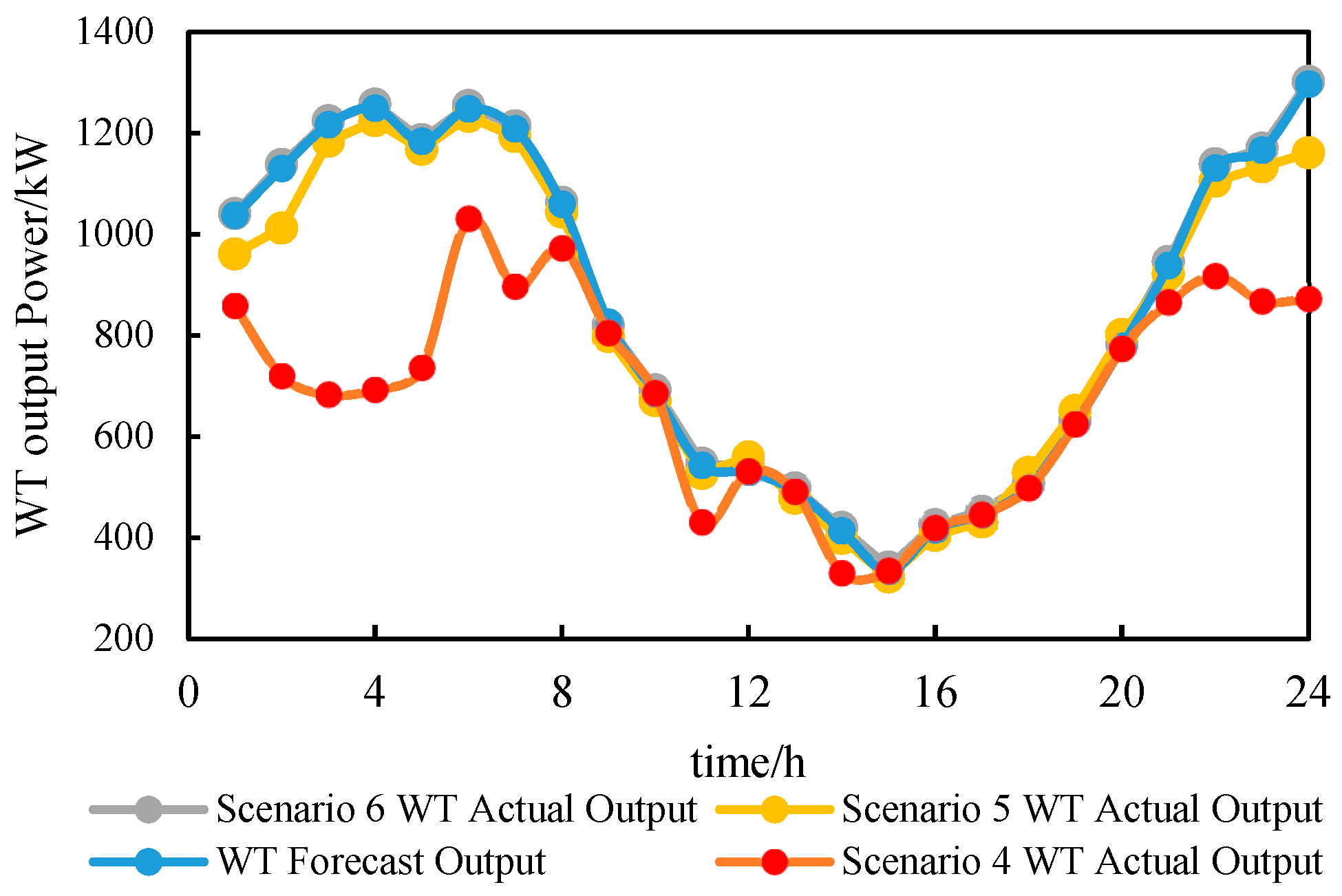

4.3.2. Analysis of Scenery Absorption Ability

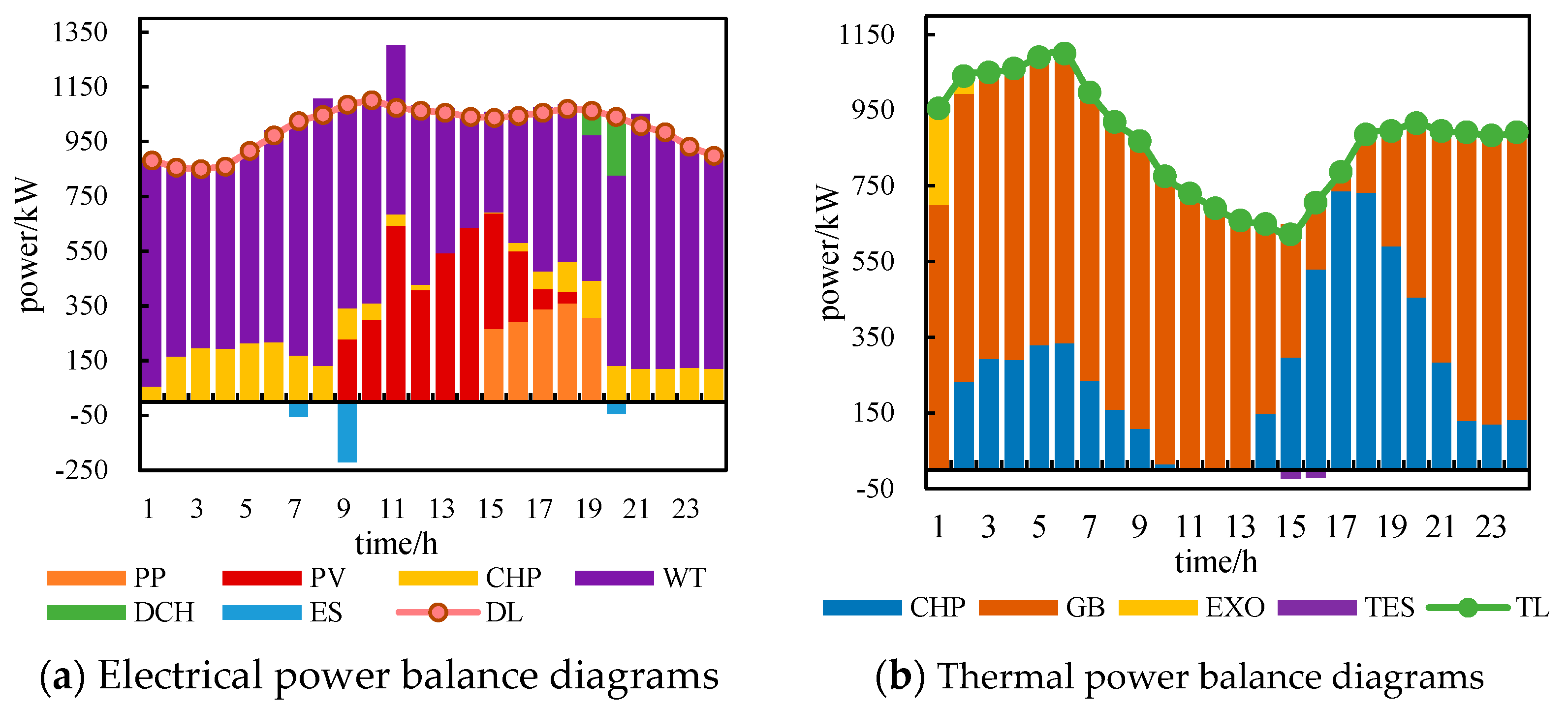

4.3.3. Analysis of System Power Scheduling Results in Different Scenarios

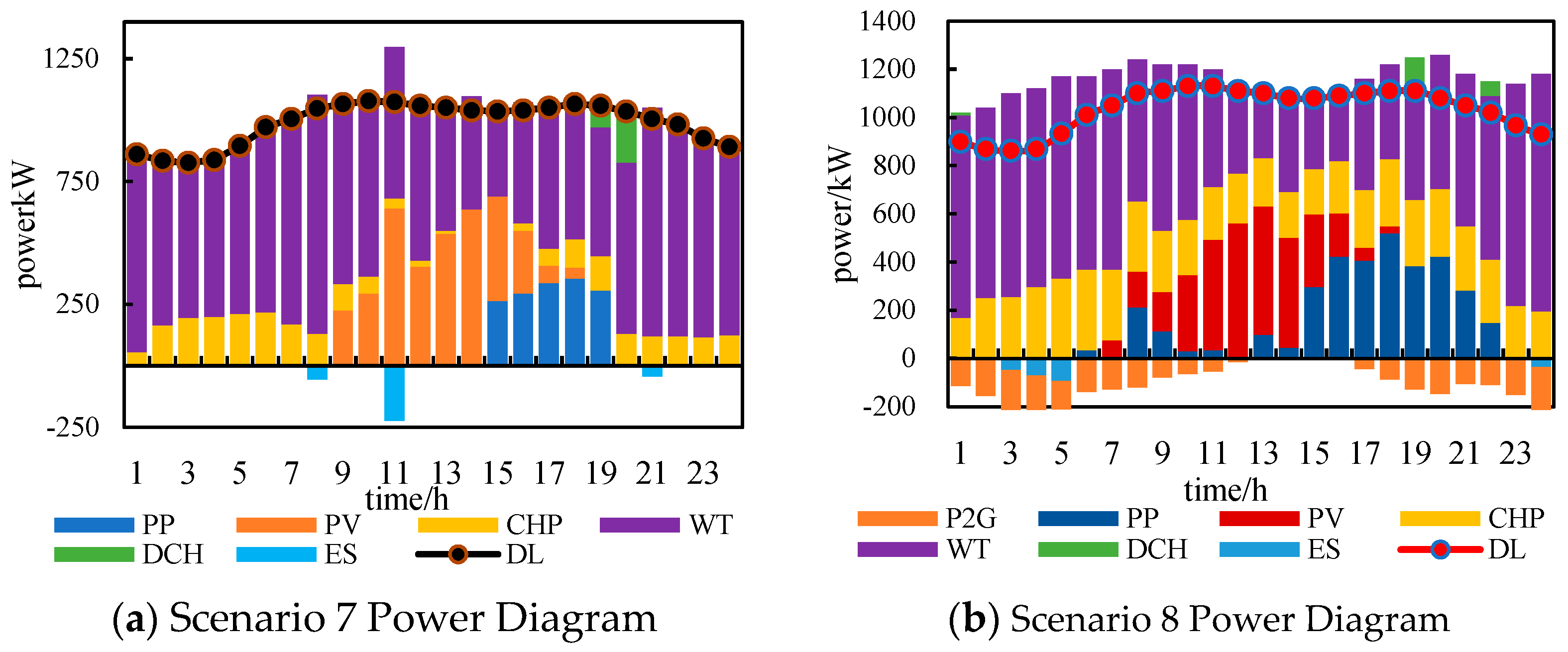

4.4. Case 3: Benefit Analysis of P2G Coupling Elements

4.4.1. Scheduling Results of Each Scenario of Case 3

4.4.2. Analysis of System Power Scheduling Results in Each Scenario

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AST | Air storage tank | HEES | hydrogen energy storage system |

| EL | Electrolyzer | IES | Integrated energy system |

| HST | hydrogen storage tank | DN | Distribution Network |

| HFC | hydrogen fuel cell | TL | Thermal load |

| FC | Fuel cells | HL | Hydrogen load |

| WT | Wind turbine | DEL | Demand electric load |

| PV | Photovoltaic | WP | Water Pump |

| HE | Heat exchangers | P2G | Power-to-Gas |

| MR | Methane reactor | PP | Power Purchase |

| GT | Gas turbine | ES | Energy Storage |

| WHB | Waste heat boiler | DCH | Discharge |

| GB | Gas boiler | TES | Thermal Energy Storage |

| TST | Thermal storage tank | EXO | Exothermic |

| BT | Battery tank | EB | Electric boiler |

| CHP | Combined heat and power | HESS | Hydrogen energy storage system |

| MES | Multi-energy system | GST | Gas storage tank |

| Variables | |||

| Hydrogen energy input to FC at time t | The upper and lower limits of GB ramping | ||

| Total power obtained by FC from HST and EL | The input and output limits for FC hydrogen | ||

| Hydrogen energy input to MR at time t | Upper and lower FC climbing limits | ||

| Input storage power at time t | Upper and lower limits of the FC electrothermal ratio | ||

| Input gas storage power at time t | Upper and lower limits of hydrogen energy input to MR | ||

| The heat of P2G reaction at time t | GB Upper and lower limits of the climb | ||

| Input power of heat storage during the t period | , | Power generation and waste heat power of GT at time t | |

| Input power of hydrogen storage at time t | , | GT power generation and heating efficiency | |

| Electric power generated by FC | Heat input and heat output | ||

| Thermal power generated by FC | , | Natural gas power, thermal power output at time t | |

| Power input from FC bus | Upper and lower limits of natural gas power input to GB | ||

| Thermal power output from the thermal bus | , | Hydrogen-to-methane conversion efficiency at MR | |

| Total power obtained from electric hydrogen production | , | BT charging and discharging efficiency. | |

| Electrical power supplied to the EL from the DC bus | , | BT charging power and discharging power at time t | |

| Electrical power received by EL from the DC busbar | , | Charging and discharging efficiency of TST | |

| Thermal power output from the thermal bus | , | TST total heat storage and release power at time t | |

| The total output power of GT at time t | The upper and lower limits of the electrical energy input to EL | ||

| EL during time t | EL Upper and lower limits of the climb | ||

| EL power used for heat production | , | Charging and discharging efficiency of AST | |

| CO2 consumed in the methanation process at time t | , | AST charging and discharging power at time t | |

| Calculation factor for CO2 | The upper limit of wind and optical output power | ||

| Gas consumption of GT at time t | Hydrogen energy input to MR at time t | ||

| Thermal energy stored by TST at time t | Is a binary variable, indicating the charging and discharging states of the energy storage device in the t period | ||

| The heat generated by GB at time t | Upper and lower limits of the capacity of the energy storage device | ||

| Gas consumption of GB at time t | Carbon credits traded in IES | ||

| Heat storage status of the heat storage equipment at time t | Actual carbon emissions of IES | ||

| Maximum storage capacity of TST | IES carbon credit allowances | ||

| Electric power is stored by an electrical energy storage device in time t | The t period is directly used for the power consumed by FC power generation | ||

| GB heating efficiency | The gas power stored by the gas storage device in the t period | ||

| WHB efficiency | Predicted value of wind and optical power | ||

| ES state of the electrical energy storage device at time t | Unit power operation and maintenance cost of WT and PV | ||

| Maximum storage capacity of BT | Unit power operation and maintenance cost of EL and FC | ||

| EL’s work efficiency | HST, BT, TST, AST charging/discharging operation and maintenance cost per unit power | ||

| Unit abandoned wind, abandoned light penalty cost | Unit power operation and maintenance cost of GT, WHB, GB, and MR | ||

| Efficiency of FC converter | Charging and discharging power of the energy storage device (HST, TES, ES, AST) | ||

| Heat transfer efficiency of FC | The amount of electricity and natural gas purchased during the t period | ||

| AST’s gas storage status at the time of t | WT, PV working power | ||

| Maximum gas storage capacity of AST | EL, FC working power | ||

| Heat transfer efficiency of FC | HST charging/discharging power in t period | ||

| The total operating cost of the system | BT charge/discharge power in t period | ||

| Scheduling cycle | TST charge/discharge power in t period | ||

| PV and WT system operation and maintenance costs | AST charge/discharge power in time t | ||

| Hydrogen energy system operation and maintenance costs | Working power of GT, WHB, GB, and MR | ||

| Energy storage system operation and maintenance costs | Power obtained by FC from HST in time slot t | ||

| Operation and maintenance costs of CHP-related devices | The maximum power of the energy storage device is charged and discharged at one time | ||

| Efficiency of FC | The capacity of the energy storage device in time t | ||

| Efficiency of FC consumption of H2 | Gas power input to GB for time t | ||

| Carbon trading base price | The cost of cascade carbon trading | ||

| Unit carbon price growth rate | The maximum power purchased from the upper power grid | ||

| Carbon emission range | The power input to EL at time t | ||

| The low calorific value of H2 | TL at the time t | ||

| t time to the higher power grid purchase unit price | The unit price of gas from gas shopping | ||

References

- Wang, Y.; Wang, X.; Yu, H.; Huang, Y.; Dong, H.; Qi, C.; Baptiste, N. Optimal Design of Integrated Energy System Considering Economics, Autonomy and Carbon Emissions. J. Clean. Prod. 2019, 225, 563–578. [Google Scholar] [CrossRef]

- Liu, D.; Luo, Z.; Qin, J.; Wang, H.; Wang, G.; Li, Z.; Zhao, W.; Shen, X. Low-Carbon Dispatch of Multi-District Integrated Energy Systems Considering Carbon Emission Trading and Green Certificate Trading. Renew. Energy 2023, 218, 119312. [Google Scholar] [CrossRef]

- Lu, J.; Liu, T.; He, C.; Nan, L.; Hu, X. Robust Day-Ahead Coordinated Scheduling of Multi-Energy Systems with Integrated Heat-Electricity Demand Response and High Penetration of Renewable Energy. Renew. Energy 2021, 178, 466–482. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, F.; Li, Y.; Wang, Y. An Improved Two-Stage Robust Optimization Model for CCHP-P2G Microgrid System Considering Multi-Energy Operation under Wind Power Outputs Uncertainties. Energy 2021, 223, 120048. [Google Scholar] [CrossRef]

- Eladl, A.A.; ElDesouky, A.A. Optimal Economic Dispatch for Multi Heat-Electric Energy Source Power System. Int. J. Electr. Power Energy Syst. 2019, 110, 21–35. [Google Scholar] [CrossRef]

- Haider, J.; Lee, B.; Choe, C.; Abdul Qyyum, M.; Shiung Lam, S.; Lim, H. SNG Production with Net Zero Outflow of CO2 in an Integrated Energy System: An Energy and Economic Aspects. Energy Convers. Manag. 2022, 270, 116167. [Google Scholar] [CrossRef]

- Anand, H.; Narang, N.; Dhillon, J.S. Multi-Objective Combined Heat and Power Unit Commitment Using Particle Swarm Optimization. Energy 2019, 172, 794–807. [Google Scholar] [CrossRef]

- Wang, C.; Chen, S.; Mei, S.; Chen, R.; Yu, H. Optimal Scheduling for Integrated Energy System Considering Scheduling Elasticity of Electric and Thermal Loads. IEEE Access 2020, 8, 202933–202945. [Google Scholar] [CrossRef]

- Kong, X.Q.; Wang, R.Z.; Li, Y.; Huang, X.H. Optimal Operation of a Micro-Combined Cooling, Heating and Power System Driven by a Gas Engine. Energy Convers. Manag. 2009, 50, 530–538. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, H.; Hong, F.; Yang, J.; Chen, Z.; Cui, H.; Feng, J. Modeling and Optimization of Combined Heat and Power with Power-to-Gas and Carbon Capture System in Integrated Energy System. Energy 2021, 236, 121392. [Google Scholar] [CrossRef]

- Shumei, J.; Xuebo, Q.; Yong, L.; Tianyu, Y.; Yijia, C. Joint Optimal Configuration of P2G Equipment and PV Considering Life-Cycle Carbon Emissions and Carbon Trading of IES. Dianli Zidonghua Shebei 2021, 41, 156–163. [Google Scholar]

- Wang, L.; Dai, W.; Zhu, L.; Wang, X.; Yin, C.; Cong, H.; Shi, T.; Qi, X.; Bi, R. Multi-Objective Expansion Planning of Park-Level Integrated Energy System Considering the Volatility Trend of CETP. IET Gener. Transm. Distrib. 2022, 16, 1225–1243. [Google Scholar] [CrossRef]

- Yan, N.; Ma, G.; Li, X.; Guerrero, J.M. Low-Carbon Economic Dispatch Method for Integrated Energy System Considering Seasonal Carbon Flow Dynamic Balance. IEEE Trans. Sustain. Energy 2023, 14, 576–586. [Google Scholar] [CrossRef]

- Groenemans, H.; Saur, G.; Mittelsteadt, C.; Lattimer, J.; Xu, H. Techno-Economic Analysis of Offshore Wind PEM Water Electrolysis for H2 Production. Curr. Opin. Chem. Eng. 2022, 37, 100828. [Google Scholar] [CrossRef]

- Sarrias-Mena, R.; Fernández-Ramírez, L.M.; García-Vázquez, C.A.; Jurado, F. Electrolyzer Models for Hydrogen Production from Wind Energy Systems. Int. J. Hydrogen Energy 2015, 40, 2927–2938. [Google Scholar] [CrossRef]

- Deng, Z.; Jiang, Y. Optimal Sizing of Wind-Hydrogen System Considering Hydrogen Demand and Trading Modes. Int. J. Hydrogen Energy 2020, 45, 11527–11537. [Google Scholar] [CrossRef]

- Kim, M.; Kim, J. An Integrated Decision Support Model for Design and Operation of a Wind-Based Hydrogen Supply System. Int. J. Hydrogen Energy 2017, 42, 3899–3915. [Google Scholar] [CrossRef]

- Recalde Melo, D.F.; Chang-Chien, L.-R. Synergistic Control between Hydrogen Storage System and Offshore Wind Farm for Grid Operation. IEEE Trans. Sustain. Energy 2014, 5, 18–27. [Google Scholar] [CrossRef]

- Abadlia, I.; Hassaine, L.; Beddar, A.; Abdoune, F.; Bengourina, M.R. Adaptive Fuzzy Control with an Optimization by Using Genetic Algorithms for Grid Connected a Hybrid Photovoltaic–Hydrogen Generation System. Int. J. Hydrogen Energy 2020, 45, 22589–22599. [Google Scholar] [CrossRef]

- Lin, J.; Cai, R. Optimal Planning for Industrial Park-Integrated Energy System with Hydrogen Energy Industry Chain. Int. J. Hydrogen Energy 2023, 48, 19046–19059. [Google Scholar] [CrossRef]

- Li, Q.; Li, R.; Pu, Y.; Li, S.; Sun, C.; Chen, W. Coordinated Control of Electric-Hydrogen Hybrid Energy Storage for Multi-Microgrid with Fuel Cell/ Electrolyzer/ PV/ Battery. J. Energy Storage 2021, 42, 103110. [Google Scholar] [CrossRef]

- Wang, J.; Xue, K.; Guo, Y.; Ma, J.; Zhou, X.; Liu, M.; Yan, J. Multi-Objective Capacity Programming and Operation Optimization of an Integrated Energy System Considering Hydrogen Energy Storage for Collective Energy Communities. Energy Convers. Manag. 2022, 268, 116057. [Google Scholar] [CrossRef]

- Aminudin, M.A.; Kamarudin, S.K.; Lim, B.H.; Majilan, B.H.; Masdar, M.S.; Shaari, N. An overview: Current progress on hydrogen fuel cell vehicles. Int. J. Hydrogen Energy 2023, 48, 4371–4388. [Google Scholar] [CrossRef]

- Rahim Malik, F.; Yuan, H.-B.; Moran, J.C.; Tippayawong, N. Overview of Hydrogen Production Technologies for Fuel Cell Utilization. Eng. Sci. Technol. Int. J. 2023, 43, 101452. [Google Scholar] [CrossRef]

- Wang, K.; Wu, X.; Wang, X.; Dang, P. Two-stage stochastic optimal scheduling for multi-microgrid networks with natural gas blending with hydrogen and low carbon incentive under uncertain environment. J. Energy Storage 2023, 72, 108319. [Google Scholar] [CrossRef]

| Equipment | Capacity/kW | Efficiency | Climbing Constraint | O and m Cost Factor Element/(kw·h) |

|---|---|---|---|---|

| Wind turbine | - | - | - | 0.018 |

| Photovoltaic | - | - | - | 0.008 |

| Electrolyser | 500 | 87% | 20% | 0.016 |

| Fuel cell | 250 | 95% | 20% | 0.0128 |

| Electric boiler | 800 | 80% | 20% | 0.011 |

| Gas boiler | 800 | 95% | 20% | 0.025 |

| Combined heat and power | 600 | 92% | 20% | 0.04 |

| Methane reactor | 250 | 60% | 20% | 0.016 |

| Equipment | Capacity/kW | Capacity Lower Bound | Upper Capacity Constraint | Climbing Constraint | O and m Cost Factor Element/(kw·h) |

|---|---|---|---|---|---|

| Hydrogen storage tan | 200 | 10% | 90% | 20% | 0.016 |

| Thermal storage tan | 500 | 10% | 90% | 20% | 0.016 |

| Air storage tank | 150 | 10% | 90% | 20% | 0.016 |

| Battery | 450 | 10% | 90% | 20% | 0.018 |

| Period Type | Time Frame | Electricity Price/ [CNY(kW·h)−1] |

|---|---|---|

| Valley interval | 01:00—07:00, 23:00—24:00 | 0.38 |

| Meantime segment | 08:00—11:00, 15:00—18:00 | 0.68 |

| Peak hour | 12:00—14:00, 19:00—22:00 | 1.20 |

| Power Consumption Type | Gas-Consuming Type | ||||

|---|---|---|---|---|---|

| a1 | b1 | c1 | a2 | b2 | c2 |

| 36 | −0.38 | 0.0034 | 3 | −0.004 | 0.001 |

| Parameter | Numerical Value |

|---|---|

| Carbon trading base price | 250 CNY/t |

| Length of the carbon trading band | 2 t |

| Carbon trading growth rate | 0.25 |

| Cost/CNY | Scenario 1 | Scenario 2 | Scenario 3 |

|---|---|---|---|

| Total cost | 14,757.94 | 12,065.80 | 11,456.83 |

| Operation and maintenance cost | 1087.13 | 1048.20 | 1104.50 |

| Power purchase cost | 1646.50 | 2254.21 | 2514.25 |

| Gas purchase cost | 6170.48 | 6024.92 | 5525.2 |

| Abandonment cost | 0 | 0 | 0 |

| Carbon trading cost | 5853.83 | 2738.47 | 2312.88 |

| Cost/CNY | Scenario 4 | Scenario 5 | Scenario 6 |

|---|---|---|---|

| Total cost | 20,230.94 | 16,521.44 | 15,627.83 |

| Operation and maintenance cost | 1073.05 | 1023.76 | 1104.50 |

| Power purchase cost | 4258.47 | 3941.51 | 3514.25 |

| Gas purchase cost | 5594.44 | 5701.57 | 5696.20 |

| Abandonment cost | 54.55 | 17.55 | 0 |

| Carbon trading cost | 9250.43 | 5837.06 | 5312.88 |

| Cost/CNY | Scenario 7 | Scenario 8 | Scenario 9 |

|---|---|---|---|

| Total cost | 20,230.94 | 19,712.61 | 15,627.83 |

| Operation and maintenance cost | 1073.05 | 1098.28 | 1104.50 |

| Power purchase cost | 4258.47 | 4704.97 | 3514.25 |

| Gas purchase cost | 5594.44 | 5391.30 | 5696.20 |

| Abandonment cost | 54.56 | 0 | 0 |

| Carbon trading cost | 9250.43 | 8518.06 | 5312.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Niu, S.; Dai, G.; Li, Y.; Wang, L.; Jia, R. Optimal Economic Dispatch of Hydrogen Storage-Based Integrated Energy System with Electricity and Heat. Sustainability 2025, 17, 1974. https://doi.org/10.3390/su17051974

Zhu Y, Niu S, Dai G, Li Y, Wang L, Jia R. Optimal Economic Dispatch of Hydrogen Storage-Based Integrated Energy System with Electricity and Heat. Sustainability. 2025; 17(5):1974. https://doi.org/10.3390/su17051974

Chicago/Turabian StyleZhu, Yu, Siyu Niu, Guang Dai, Yifan Li, Linnan Wang, and Rong Jia. 2025. "Optimal Economic Dispatch of Hydrogen Storage-Based Integrated Energy System with Electricity and Heat" Sustainability 17, no. 5: 1974. https://doi.org/10.3390/su17051974

APA StyleZhu, Y., Niu, S., Dai, G., Li, Y., Wang, L., & Jia, R. (2025). Optimal Economic Dispatch of Hydrogen Storage-Based Integrated Energy System with Electricity and Heat. Sustainability, 17(5), 1974. https://doi.org/10.3390/su17051974