Predicting Fuel Consumption by Artificial Neural Network (ANN) Based on the Regular City Bus Lines

Abstract

1. Introduction

- Maneuver-related factors—forced stops and disruptions to traffic flow during the course, such as entering and exiting stops, parking, intersections, traffic congestion, and random events.

- Resistance related to vehicle movement and the route. As the previous research proves, the movement on the route plays a significant role for trucks, i.e., substantial fuel savings of up to 10% by truck platooning [7].

- Thermal stabilization of the engine.

- Technical condition of the vehicle.

- Driver experience and driving techniques.

2. State of the Art

3. Methodology

3.1. Fuel Consumption Factors

3.1.1. Complexities and Methodological Considerations

- Route length;

- Ambient temperature;

- Changes in the vehicle’s potential and kinetic energy;

- Boundary traffic conditions;

- Frequency and magnitude of direction changes;

- Engine thermal state;

- Road surface condition;

- Vehicle load (weight);

- Driving technique;

- Drivetrain efficiency [21];

- Condition and type of vehicle tires;

- The effect of wind speed and direction.

3.1.2. Impact of Driving Constraints on Fuel Consumption

- Passing through manually operated gates;

- Parking and garaging that require multiple maneuvers (forward and reverse movements);

- Operating in tight garage spaces that necessitate reduced maneuvering speed;

- Speed limitations and non-stationary engine conditions caused by speed bumps, curbs, or uneven surfaces;

- Idling the engine for at least 30 s during tasks such as gate closure or passenger boarding;

- Driving at very low speeds (up to 7 km/h) over short distances due to uneven terrain, weather conditions, or traffic congestion;

- Frequent stops, braking, and acceleration at intersections or traffic lights.

3.1.3. Underestimating Fuel Consumption in Urban Routes

- Idling during traffic entry (e.g., from stops or intersections);

- Overcoming resistance during turns and directional changes;

- Non-stationary conditions in difficult scenarios.

- Difficult engine and drivetrain conditions from traffic entry to stop;

- Additional, unforeseen directional changes (e.g., overtaking or obstacle avoidance);

- Differences between calculated consumption from linear models and actual consumption, considering thermal stabilization.

3.1.4. Thermal Stabilization of the Vehicle in Non-Stationary Conditions

- Idle Fuel Consumption: For engines operating under thermal stabilization conditions, 1 min of idling consumes 13 cm3 of fuel [22].

- Cold Start Consumption: At extreme cold temperatures, such as −40 °C and −50 °C, the fuel volume consumed increases by 34 cm3 and 31 cm3, respectively, for the same duration.

- Two-Minute Idling Analysis: For all three operating states, the fuel consumption over 2 min is as follows: 27 cm3 under normal conditions, 61 cm3 at −40 °C, and 53 cm3 at −50 °C. These values vary depending on the vehicle type.

3.1.5. Rolling Resistance and Fuel Consumption

- Road surface: Asphalt.

- Gradient: 0.5 m elevation over a 100 m segment.

- —energy consumption of vehicle movement when coasting for 100 m [J];

- —the difference in the kinetic energy of the car at the boundary points [J];

- —the difference in the potential energy of the car at the boundary points [J].

- —longitudinal road slope angle, [o];

- —aerodynamic drag coefficient 0.36 [m/kg];

- —total vehicle weight [kg];

- —speeds: initial and final vehicle [m/s];

- —arithmetic mean of the squares of the speeds [m/s];

- —travel time [s];

- —length of the measuring section 100 [m];

- —rolling resistance coefficient of the vehicle when driving in a straight line, ;

- —acceleration of gravity [m/s2].

- —correction accounting for coasting [dm3/100 km];

- —correction taking into account the influence of ambient temperature, vehicle thermal condition, and route length [dm3/100 km];

- —correction taking into account mileage fuel consumption based on road share and consumption in selected driving cycles [dm3/100 km];

- —correction for fuel maneuvering volume [dm3/100 km];

- —correction taking into account the change in the vehicle’s potential energy [dm3/100 km].

3.1.6. Technical Condition of the Vehicle

- Spark plugs and high-voltage wires: These should be replaced approximately every 15,000–20,000 km, as the ignition system plays a critical role. Proper maintenance ensures achieving the manufacturer’s stated fuel consumption. Periodically checking connections and replacing worn or dirty spark plugs is advisable.

- Fuel filter [22]: A clogged fuel filter allows impurities to enter the fuel, creating a poor fuel mixture and reducing engine efficiency. The fuel filter should be replaced every 20,000 km.

- Air filter [22]: A dirty air filter reduces system efficiency. It should be replaced as per the manufacturer’s recommendations, typically every 10,000–15,000 km. The mentioned distance is recommended by Polish car services. Regular checks are essential, especially when driving on dusty roads, to prevent a 10% increase in fuel consumption and protect the engine from contaminants.

- Oxygen sensor [22]: Located behind the catalytic converter, this sensor measures oxygen levels in exhaust gases and communicates with the onboard computer to adjust the fuel mixture. Incorrect readings lead to inefficient engine performance.

- Oil [12]: Oil significantly affects engine wear and fuel consumption. Using low-viscosity synthetic oil, such as 0W-30, can reduce fuel consumption by 3–5%. It should always meet the manufacturer’s specifications.

- Braking system [4]: Issues such as seized brake pads or partially engaged handbrakes (even without an active warning light) create friction, converting energy into heat, increasing rolling resistance, and raising fuel consumption by 2–4 dm3/100 km. These issues also pose safety risks by overheating brake fluid, potentially leading to brake failure.

- Tire pressure [23]: Maintaining the manufacturer-recommended tire pressure is crucial. Underinflation by 0.2 bar can increase fuel consumption by 5%, while overinflation by 0.5 bar can save fuel but may reduce ride comfort. Excessive inflation leads to uneven tire wear and reduced grip.

- Aerodynamic resistance [23]: Vehicles are designed for optimal airflow to minimize resistance. Alterations, such as damaged bumpers, bent fenders, or roof-mounted cargo carriers, increase drag and can add 0.5 dm3/100 km to fuel consumption.

3.1.7. Driving Technique Assessment Using a Coefficient

- Kp = 0.8–1.1 for an economical driving style;

- Kp = 1.1–1.3 for normal driving;

- Kp = 1.3–1.6 for dynamic driving.

- Route length;

- Number of stops;

- Number of traffic lights;

- Number of curves;

- Number of speed bumps;

- Route type associated with a corresponding correction coefficient.

- —average driving speed [km/h];

- L—length of the route [km];

- —Arrival time [min];

- —Departure time [min].

- Fuel consumption during idling;

- Fuel consumption for urban and non-urban routes;

- Vehicle curb weight and gross weight;

- Year of manufacture;

- Mileage.

- —fuel consumption correction factor depending on the technical condition of the vehicle;

- —a weighting factor relating to the degree of wear of the vehicle depending on the vehicle’s production date, equal to 0.35, where ;

- —weight factor relating to the degree of wear of the vehicle depending on the number of kilometers traveled, amounting to 0.65, where ;

- —current year;

- —date specifying the year of vehicle production;

- p—Current vehicle mileage [km];

- dy—estimated number of kilometers traveled per year with low intensity of use [km];

- fc—calculation correction factor depending on the technical condition of the vehicle.

- —maneuvering volume [dm3];

- —number of stops;

- —number of traffic lights and subordinate intersections;

- —number of turns;

- —number of speed bumps;

- —the amount of fuel consumed during a one-minute stop [dm3].

- —additional mass [kg];

- —total vehicle weight [kg];

- —vehicle curb weight [kg];

- —sample driver weight, taking value 80 [kg].

- —volume of fuel used on the entire route for driving a loaded vehicle [dm3/km];

- —additional mass [kg];

- L—length of the route [km].

- —a volume of fuel used to drive a loaded vehicle [dm3/km];

- —additional mass [kg].

- —predicted fuel consumption [dm3/km];

- s—vehicle fuel consumption as stated by the manufacturer [dm3/km];

- —correction factor for route type;

- —driver driving style correction factor;

- —fuel consumption correction factor depending on technical conditions;

- —maneuvering volume [dm3];

- —a volume of fuel used to drive a loaded vehicle [dm3/km].

- —new proposed standard [dm3/100 km];

- z—number of courses;

- —actual consumption for the course [dm3/100 km];

- —previous norm [dm3/100 km].

3.2. Input Data

- Vehicles run on the lines for 12 h a day, every 20 min;

- The carrier operates three permanent routes with lengths of 11, 17, and 43 km;

- The route includes request stops, so the number of stops is not constant;

- The routes are operated 7 days a week with the same frequency.

3.3. Model Developed

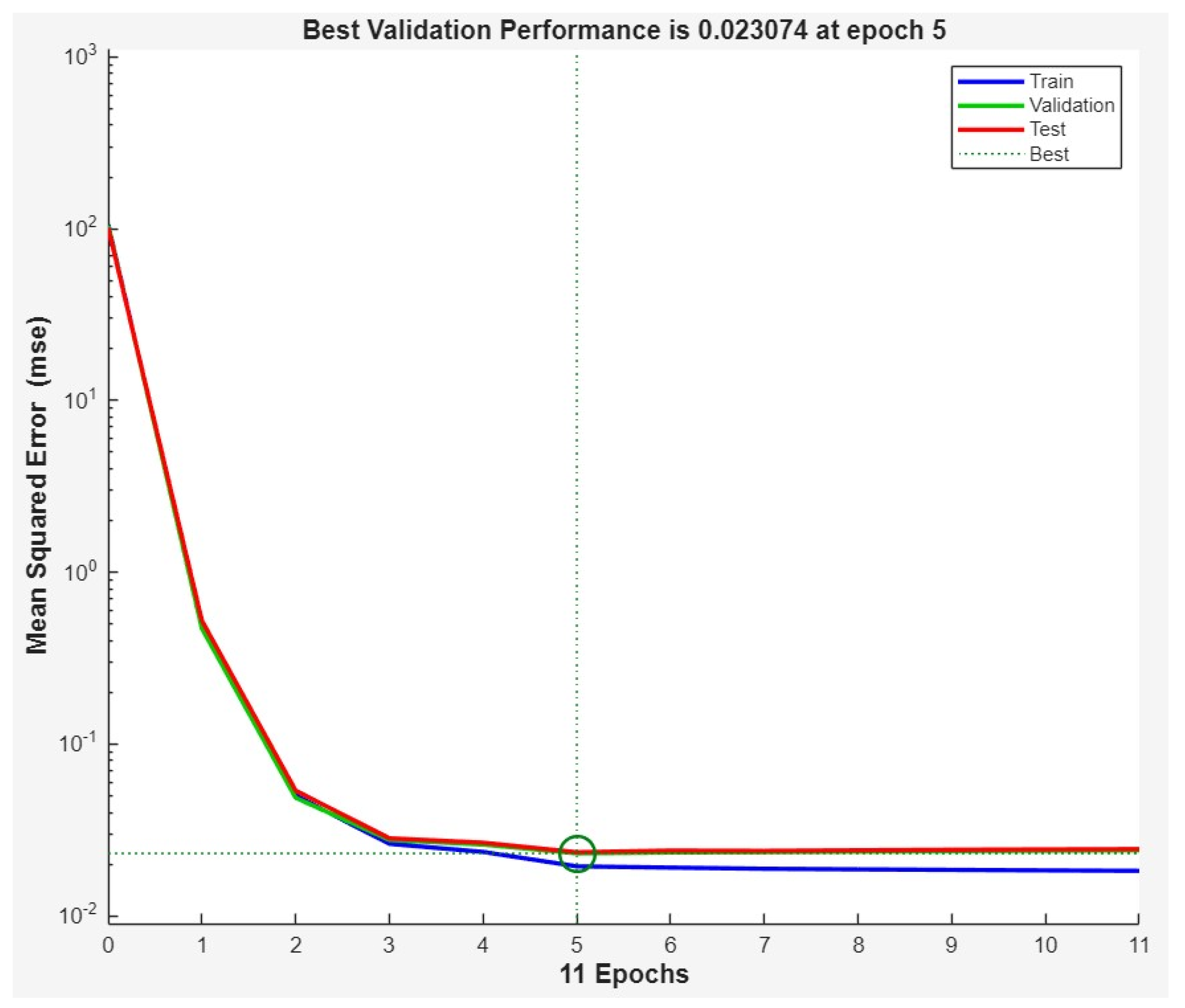

- Analysis of Mean Squared Error (MSE) and Correlation Coefficient (R)

- ○

- The best result in terms of the lowest MSE was obtained using the Levenberg–Marquardt algorithm with 200 neurons (MSE = 0.0194, R = 0.966).

- ○

- MSE values for the other cases were close, ranging between 0.019 and 0.025.

- ○

- The worst result was observed for Scaled Conjugate Gradient with 50 neurons (MSE = 0.0254, R = 0.956).

- ○

- The average R value was 0.964, indicating a very good model fit the data.

- Impact of Training Algorithm

- ○

- The Levenberg–Marquardt (LM) algorithm generally achieved the best results in terms of MSE and R, suggesting that it effectively minimizes network error.

- ○

- The Bayesian Regularization (BR) algorithm was characterized by a high number of stop epochs, indicating its ability to thoroughly regularize models and provide stable training.

- ○

- The Scaled Conjugate Gradient (SCG) algorithm performed worse, especially for smaller layer sizes, which may suggest slower convergence or a greater tendency to fall into local minima.

- Impact of Hidden Layer Size

- ○

- The best results (low MSE, high R) were obtained for models with 200 neurons, particularly when using Levenberg–Marquardt (MSE = 0.0194, R = 0.966) and Bayesian Regularization (MSE = 0.0203, R = 0.964).

- ○

- Networks with 50 and 100 neurons produced similar results, but sometimes exhibited slightly higher error values.

- ○

- The smallest networks (10 neurons) showed slightly higher MSE values (e.g., SCG: MSE = 0.0215), suggesting that too small a hidden layer may limit the model’s ability to accurately fit the data.

- Analysis of Stop Epochs

- ○

- The Bayesian Regularization algorithm often reached a high number of stop epochs, e.g., 953 epochs for 200 neurons, indicating longer training compared to LM and SCG.

- ○

- Levenberg–Marquardt typically stopped within a dozen or so epochs, suggesting rapid convergence (e.g., 11 epochs for 200 neurons).

- ○

- Scaled Conjugate Gradient required a greater number of epochs (e.g., 158 epochs for 10 neurons), confirming its slower learning rate.

- Analysis of Gradient and Mu Parameter

- ○

- Levenberg–Marquardt had relatively high gradient values (e.g., 0.0984 for 80 neurons), suggesting fast weight adjustments.

- ○

- Bayesian Regularization exhibited the smallest gradient values (e.g., 6.89−5 for 10 neurons), indicating stable and slow training.

- ○

- Mu (regularization parameter for LM) remained low in most cases, suggesting a well-optimized training process.

- Training Set—The scatter plot shows the correlation between the target and output values for the training dataset. The regression equation is approximate: Output ≈ 0.93 × Target + 0.95. The coefficient of determination (R = 0.96634) suggests a strong correlation, indicating that the model fits the training data well. The data points align closely with the ideal line Y = T (dashed line), with minor deviations.

- Validation Set—This plot represents the validation dataset. The regression equation: Output ≈ 0.92 × Target + 1.1. The correlation coefficient (R = 0.95993) is slightly lower than in the training set but still indicates a good model fit. The data points closely follow the ideal line, demonstrating that the model generalizes well on unseen validation data.

- Test Set—This scatter plot evaluates the model’s performance on the test dataset. The regression equation: Output ≈ 0.91 × Target + 1.2. The correlation coefficient (R = 0.96024) is similar to the validation set, suggesting that the model maintains performance when tested on unseen data.

- Overall Performance—This plot represents the combined results from all datasets (training, validation, and test). The regression equation: Output ≈ 0.92 × Target + 1. The correlation coefficient (R = 0.96445) suggests that the model performs consistently across all data. The correlation values (R > 0.95) indicate a high degree of accuracy in predictions. There is good generalization across validation and test sets, implying minimal overfitting.

4. Model Implementation and Results

- Route Management Module

- Route Types Section: handles the input of additional correction coefficients for routes. These coefficients go beyond distinguishing between urban and non-urban routes, as the system automatically identifies route types based on average driving speed to match the fuel consumption specified by the manufacturer. The correction coefficient in this section allows for further adjustment of fuel consumption forecasts, accounting for factors such as uphill driving, poor road conditions, and traffic congestion.

- Routes Section: provides a detailed description of routes, including the name, length, number of stops, and additional parameters such as traffic lights, curves, speed bumps, and route type. The route type corresponds to the correction coefficient defined in the previous section.

- Vehicle Management Module

- Vehicle Brands Section: records technical data for groups of vehicles, including brand, fuel consumption at idle, in urban and non-urban cycles, curb weight, and gross weight.

- Vehicles Section: captures individual vehicle details such as year of manufacture, mileage, license plate number, seating and standing capacity, and assigns the vehicle to its corresponding brand.

- Driver Management Module

- Driving Style Section: assigns a correction coefficient based on driving style, which significantly impacts fuel consumption. The correction coefficient ranges from 0.9 to 1.3, underscoring the importance of economical driving skills.

- Driver Data Section: includes personal information such as name, address, license issue date, number of collisions, and the driver’s associated driving style from the previous section.

- Trip Management Module

- Date of trip;

- Departure and arrival times;

- Heating or air conditioning settings;

- Initial and external temperatures (not used in calculations in the current version but prepared for future system enhancements);

- Total idling time;

- Actual fuel consumption.

- Reporting Module

- Route details: name, type, length, number of stops, and additional parameters.

- Selected date or time range, if specified, or a note indicating that the report includes all trips in the database.

- Date, departure, and arrival times;

- Vehicle registration number;

- Driver name;

- Actual fuel consumption for the trip;

- System-calculated fuel consumption;

- User-input standard.

- 0.2% exceedance: light yellow;

- 5% exceedance: dark yellow;

- 10% exceedance: orange;

- 20% exceedance: light red;

- 50% exceedance: dark red.

- Forced stops;

- Traffic congestion;

- Road collisions along the route;

- Overloaded vehicles;

- Excessive use of heating or air conditioning;

- Potential fuel theft.

5. Conclusions

- Identifying vehicles with excessive fuel consumption;

- Determining the most economical configuration of vehicles for a given route;

- Identifying drivers who lack skills in economical driving;

- Highlighting drivers who excel in fuel-efficient driving;

- Pinpointing times of the day with the highest congestion on routes;

- Detecting potential cases of fuel theft.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Flakiewicz, W. Systemy Informacyjne w Zarządzaniu: (Uwarunkowania, Technologie, Rodzaje); Wydawnictwo C.H. Beck: Warsaw, Poland, 2002; Volume 7, ISBN 9772081415. [Google Scholar]

- Jarzmik, K.; Jedynak, M.; Sowa, A. Komputerowy System Wspomagania Gospodarki Paliwami Płynnymi w Przedsiębiorstwie Komunikacyjnym. Probl. Eksploat. 1999, 3, 65–78. [Google Scholar]

- Gazewski, T. Jak Zachować Nominalne Zużycie Paliwa; Wydawnictwa Komunikacji i Łączności: Warsaw, Poland, 1990. [Google Scholar]

- Hebda, M. Eksploatacja Samochodów; Wydaw. Inst. Technologii Eksploatacji-PIB: Radom, Poland, 2005. [Google Scholar]

- Niziński, S.; Michalski, R. Utrzymanie Pojazdów i Maszyn; Wydaw. Inst. Technologii Eksploatacji-PIB: Olsztyn, Poland, 2007. [Google Scholar]

- Ubysz, A. Problem “niedoliczenia” W Programie Eko-Drive’05 Przebiegowego Zużycia Paliwa w Samochodzie Na Krótkich Trasach Przejazdu. Probl. Transp. 2007, 3, 51–61. [Google Scholar]

- Liu, T.; Meidani, H. Neural Network Surrogate Models for Aerodynamic Analysis in Truck Platoons: Implications on Autonomous Freight Delivery. Int. J. Transp. Sci. Technol. 2024, 16, 234–243. [Google Scholar] [CrossRef]

- Mustafa, A.; Faisal, S.; Singh, J.; Rezki, B.; Kumar, K.; Moholkar, V.S.; Kutlu, O.; Aboulmagd, A.; Khamees Thabet, H.; El-Bahy, Z.M.; et al. Converting Lignocellulosic Biomass into Valuable End Products for Decentralized Energy Solutions: A Comprehensive Overview. Sustain. Energy Technol. Assess. 2024, 72, 104065. [Google Scholar] [CrossRef]

- Mobasshir, M.; Pachauri, P.; Kumari, P.; Khan, F.; Equbal, A.; Khan, O.; Parvez, M.; Ahamad, T.; Ahmad, S. Analyzing Vehicle Emissions Using a Hybrid Machine Learning Approach Using Weighted Average Based K-Means Clustering for Sustainable Transportation Decision-Making. Green Technol. Sustain. 2025, 3, 100163. [Google Scholar] [CrossRef]

- Komnos, D.; Smit, R.; Ntziachristos, L.; Fontaras, G. A Comparative Analysis of Car Fleet Efficiency Evolution in Europe and Australia Insights on Policy Influence. J. Environ. Manag. 2025, 373, 123313. [Google Scholar] [CrossRef]

- Ahmat, N.; Christopher, S.; Saputra, J.; Sukemi, M.N.; Nawawi, M.N. The Impact of Energy Consumption, Economic Growth, and Non-Renewable Energy on Carbon Dioxide Emission in Malaysia. Int. J. Energy Econ. Policy 2025, 15, 143–152. [Google Scholar] [CrossRef]

- Sharma, D.; Roul, R.K. Intelligent Traffic Congestion Classification Framework. SN Comput. Sci. 2025, 6, 49. [Google Scholar] [CrossRef]

- Tan, M.; Hu, C.; Chen, J.; Wang, L.; Li, Z. Multi-Node Load Forecasting Based on Multi-Task Learning with Modal Feature Extraction. Eng. Appl. Artif. Intell. 2022, 112, 104856. [Google Scholar] [CrossRef]

- Brand, C.; Marsden, G.; Anable, J.L.; Dixon, J.; Barrett, J. Achieving Deep Transport Energy Demand Reductions in the United Kingdom. Renew. Sustain. Energy Rev. 2025, 207, 114941. [Google Scholar] [CrossRef]

- Oweh, S.O.; Aigba, P.A.; Samuel, O.D.; Oyekale, J.; Abam, F.I.; Veza, I.; Enweremadu, C.C.; Der, O.; Ercetin, A.; Sener, R. Improving Productivity at a Marble Processing Plant Through Energy and Exergy Analysis. Sustainability 2024, 16, 11233. [Google Scholar] [CrossRef]

- Zaręba, M.; Danek, T. Analysis of Air Pollution Migration during COVID-19 Lockdown in Krakow, Poland. Aerosol Air Qual. Res. 2022, 22, 210275. [Google Scholar] [CrossRef]

- Adamović, D.; Adamović, S.; Čepić, Z.; Morača, S.; Mihailović, A.; Mijailović, I.; Stošić, M. Possibilities of Improving the Emission Characteristics of Passenger Cars by Controlling the Concentration Levels of Combustion-Generated BTEX Components. Sustainability 2024, 16, 11033. [Google Scholar] [CrossRef]

- Zhang, C.; Ma, Y.; Li, Z.; Han, L.; Xiang, C.; Wei, Z. Fuel-Economy-Optimal Power Regulation for a Twin-Shaft Turboshaft Engine Power Generation Unit Based on High-Pressure Shaft Power Injection and Variable Shaft Speed. Energy 2024, 309, 133153. [Google Scholar] [CrossRef]

- Pandey, A.; Pandey, G.; Mishra, R.K. Evaluating Exhaust Emissions from Heterogeneous Car Fleet through Real-Time Field-Generated Dataset. Atmos. Pollut. Res. 2024, 15, 102232. [Google Scholar] [CrossRef]

- Mane, V.; Vishal, P.; Nikita, P.; Iyer, N.C.; Ashwini, K. Model-Based Design Technique to Monitor Vehicle Exhaust Emissions. Lect. Notes Netw. Syst. 2023, 401, 797–803. [Google Scholar] [CrossRef]

- Kaczor, G.; Zając, G. Analiza Niezawodności Wtryskiwaczy. Czas. Tech. 2012, 109, 327–334. [Google Scholar]

- Ubysz, A. Prognozowanie Zużycia Paliwa w Samochodzie Osobowym w Ruchu Rzeczywistym. Czas. Tech. 2008, 105, 209–217. [Google Scholar]

- Szypulski, P. Siedem Sposobów Na Niższe Spalanie. Co Działa, Co Nie Działa, a Co Ma Niebezpieczne Skutki Uboczne? Available online: https://www.auto-swiat.pl/porady/eksploatacja/sposoby-na-nizsze-spalanie-jak-jezdzic-taniej-skutki-uboczne-oszczedzania-paliwa/lfplz2v (accessed on 15 January 2025).

- Feng, C.; Shao, L.; Wang, J.; Zhang, Y.; Wen, F. Short-Term Load Forecasting of Distribution Transformer Supply Zones Based on Federated Model-Agnostic Meta Learning. IEEE Trans. Power Syst. 2025, 40, 31–45. [Google Scholar] [CrossRef]

| No. | Complex Route (Number of Routes) | Vm [dm3] | Boundary Conditions Description |

|---|---|---|---|

| 1 | L = 19 km (2) | 0.10 | ΔH = 0 m (parking simplified) |

| 2 | L = 20 km (2) | 0.12 | ΔH = 0 m (garage/parking lot) |

| 3 | L = 21 km (3) | 0.20 | As above + 1.5 h stop on the return route |

| 4 | L = 29 km (4) | 0.25 | As in no. 2 + additional route 2 × 4.5 km |

| 5 | L = 20 km (2) | 0.20 | As in no. 2 but very difficult garage conditions |

| No. | Turning Radius R [m] | 25 km/h 6.94 m/s | 30 km/h 8.33 m/s | 35 km/h 9.72 m/s | 5 km/h 1.4 m/s | ||||

|---|---|---|---|---|---|---|---|---|---|

| a [m/s2] | Vm,ł [cm3] | a [m/s2] | Vm,ł [cm3] | a [m/s2] | Vm,ł [cm3] | a [m/s2] | Vm,ł [cm3] | ||

| 1 | 6 | - | - | - | - | - | - | 0.32 | 0 |

| 2 | 11 | 4.38 | 1.6 | 4.48 | 1.9 | 8.56 | 2.6 | 0.18 | 0 |

| 3 | 15.5 | 3.1 | 1.0 | 4.48 | 1.4 | 6.10 | 2.3 | 1.13 | 0 |

| 4 | 20 | 2.41 | 0.8 | 3.47 | 1.0 | 4.72 | 2.0 | 0.1 | 0 |

| 5 | 63.7 | 0.76 | 0.3 | 1.1 | 0.45 | 1.48 | 1.0 | 0.03 | 0 |

| Route No. | Route Length [km] | Number of Bus Stops | Probability of Traffic Jams | Ambient Temperature [°C] | Technical State of the Vehicle | Type of Petrol | Filling of the Vehicle | Fuel Consumption per 100 km |

|---|---|---|---|---|---|---|---|---|

| 1 | 11 | 6 | 2 | 11 | 1 | 2 | 1 | 12.6 |

| 2 | 17 | 7 | 2 | 22 | 3 | 2 | 4 | 13.2 |

| 2 | 17 | 11 | 1 | 16 | 1 | 2 | 2 | 12.2 |

| 3 | 43 | 22 | 1 | 24 | 3 | 1 | 2 | 12.6 |

| 3 | 43 | 22 | 3 | 14 | 3 | 1 | 4 | 14.1 |

| 1 | 11 | 7 | 2 | 16 | 4 | 1 | 2 | 12.9 |

| 3 | 43 | 24 | 2 | 17 | 1 | 2 | 5 | 13.6 |

| 2 | 17 | 8 | 1 | 7 | 4 | 1 | 4 | 13.2 |

| 2 | 17 | 7 | 1 | 18 | 4 | 1 | 2 | 12.8 |

| 2 | 17 | 7 | 2 | 25 | 2 | 1 | 5 | 13.3 |

| 2 | 17 | 11 | 2 | 17 | 3 | 2 | 3 | 13.3 |

| 3 | 43 | 21 | 3 | 25 | 3 | 1 | 3 | 13.9 |

| 1 | 11 | 5 | 2 | 7 | 2 | 2 | 2 | 13.3 |

| 2 | 17 | 9 | 2 | 22 | 2 | 2 | 4 | 13.1 |

| 1 | 11 | 5 | 3 | 18 | 1 | 2 | 1 | 13.1 |

| 3 | 43 | 19 | 3 | 22 | 1 | 1 | 3 | 13.4 |

| 3 | 43 | 23 | 1 | 16 | 4 | 1 | 5 | 13.1 |

| 2 | 17 | 11 | 2 | 5 | 1 | 1 | 3 | 13.1 |

| 1 | 11 | 7 | 2 | 7 | 2 | 2 | 4 | 13.4 |

| No. | Training Algorithm | Layer Size | Stop Epoch | Performance | Gradient | Mu | Sum Squared Param | Validation Checks | MSE | R |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Bayesian regularization | 100 | 606 | 0.0203 | 9.21−5 | 5.0010 | 26.14 | x | 0.0203 | 0.965 |

| 2 | Levenberg–Marquardt | 100 | 12 | 0.0196 | 0.0134 | 1.00−5 | x | 6 | 0.0204 | 0.964 |

| 3 | Scaled conjugate gradient | 100 | 156 | 0.0233 | 0.032 | x | x | 6 | 0.0234 | 0.959 |

| 4 | Bayesian regularization | 50 | 1000 | 0.02 | 0.000129 | 0.5 | 36.40 | x | 0.02 | 0.965 |

| 5 | Levenberg–Marquardt | 50 | 15 | 0.0206 | 0.00224 | 1.00−5 | x | 6 | 0.021 | 0.963 |

| 6 | Scaled conjugate gradient | 50 | 106 | 0.0253 | 0.0317 | x | x | 6 | 0.0254 | 0.956 |

| 7 | Bayesian regularization | 10 | 326 | 0.0204 | 6.89−5 | 5.00+10 | 23.70 | x | 0.0204 | 0.964 |

| 8 | Levenberg–Marquardt | 10 | 63 | 0.0199 | 0.00172 | 1.00−6 | x | 6 | 0.02 | 0.965 |

| 9 | Scaled conjugate gradient | 10 | 158 | 0.0214 | 0.00518 | x | x | 6 | 0.0215 | 0.963 |

| 10 | Bayesian regularization | 80 | 215 | 0.0203 | 0.000101 | 5.00+10 | 32.70 | x | 0.0203 | 0.964 |

| 11 | Levenberg–Marquardt | 80 | 11 | 0.019 | 0.0984 | 1.00−6 | x | 6 | 0.0204 | 0.964 |

| 12 | Levenberg–Marquardt | 200 | 11 | 0.0183 | 0.0107 | 1.00−5 | x | 6 | 0.0194 | 0.966 |

| 13 | Bayesian regularization | 200 | 953 | 0.0203 | 0.000101 | 5.00+10 | 45,716.00 | x | 0.0203 | 0.964 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lorenc, A. Predicting Fuel Consumption by Artificial Neural Network (ANN) Based on the Regular City Bus Lines. Sustainability 2025, 17, 1678. https://doi.org/10.3390/su17041678

Lorenc A. Predicting Fuel Consumption by Artificial Neural Network (ANN) Based on the Regular City Bus Lines. Sustainability. 2025; 17(4):1678. https://doi.org/10.3390/su17041678

Chicago/Turabian StyleLorenc, Augustyn. 2025. "Predicting Fuel Consumption by Artificial Neural Network (ANN) Based on the Regular City Bus Lines" Sustainability 17, no. 4: 1678. https://doi.org/10.3390/su17041678

APA StyleLorenc, A. (2025). Predicting Fuel Consumption by Artificial Neural Network (ANN) Based on the Regular City Bus Lines. Sustainability, 17(4), 1678. https://doi.org/10.3390/su17041678