Effect of Topographic Condition of Drainage Channel on the Interaction Between Granular Flow and Slit Dams

Abstract

1. Introduction

2. Numerical Simulation

2.1. DEM Theory

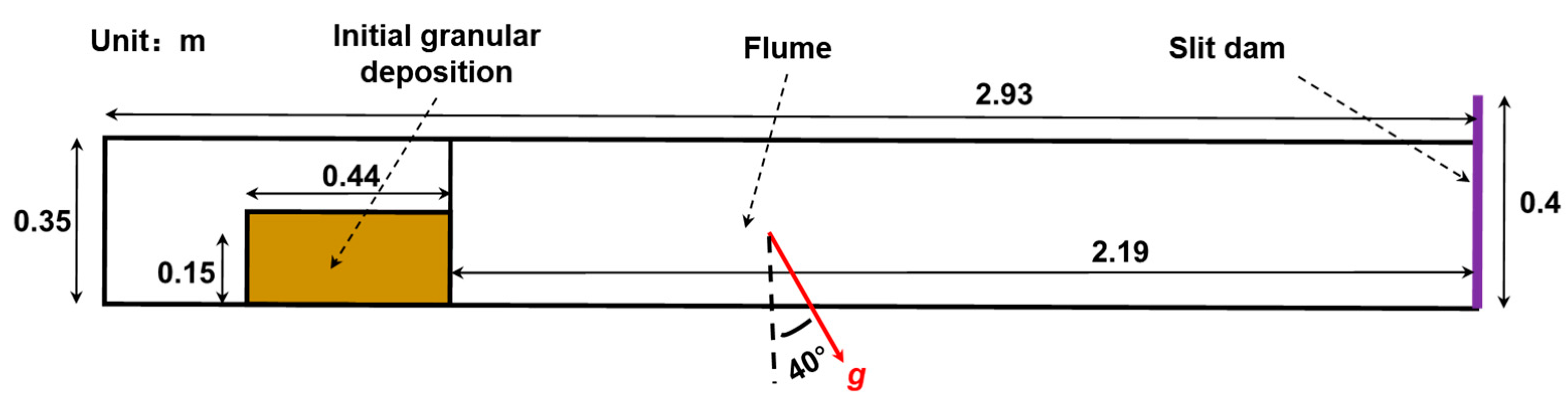

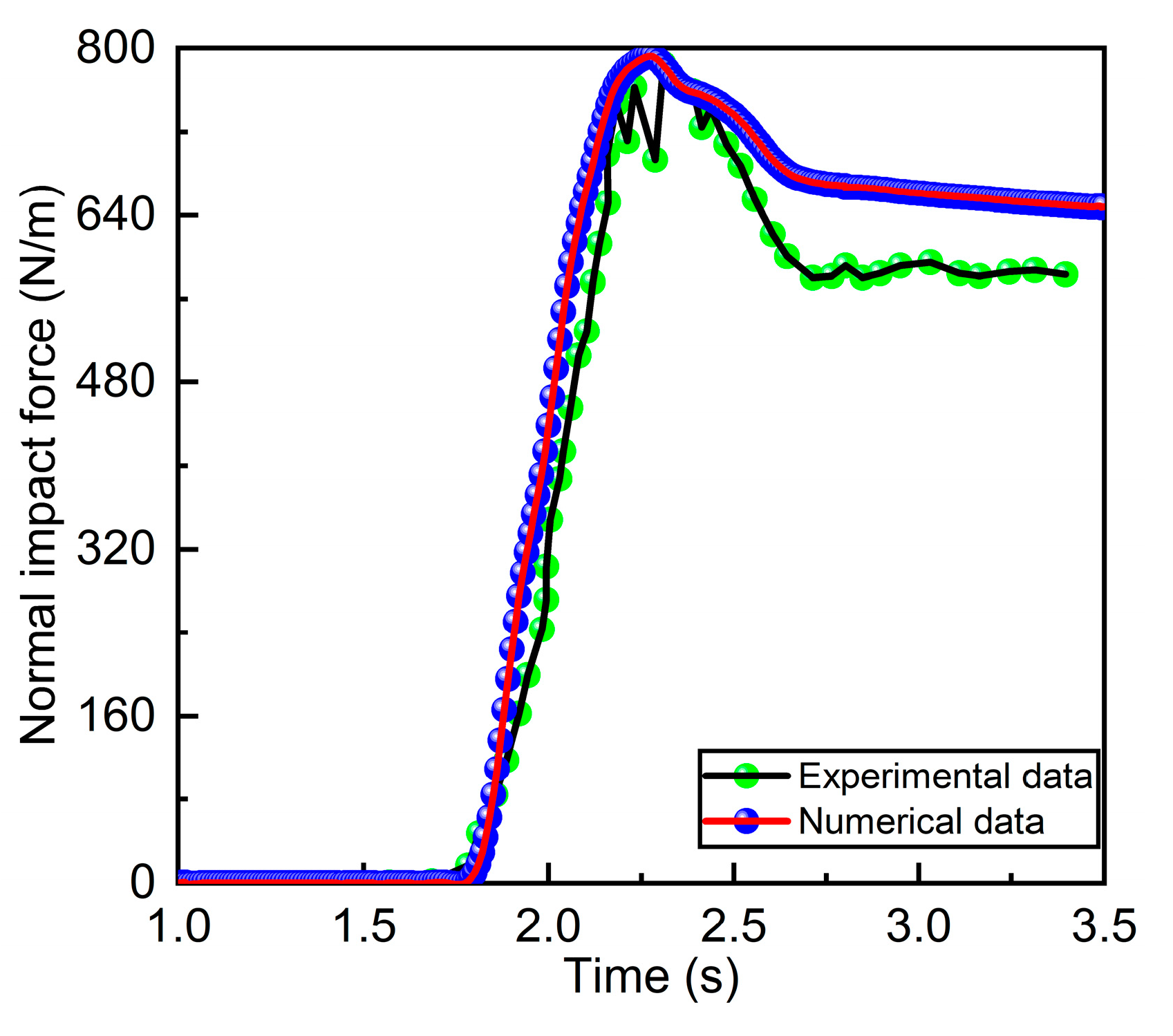

2.2. Model Setup and Validation

2.3. Numerical Simulation Plans

3. Results

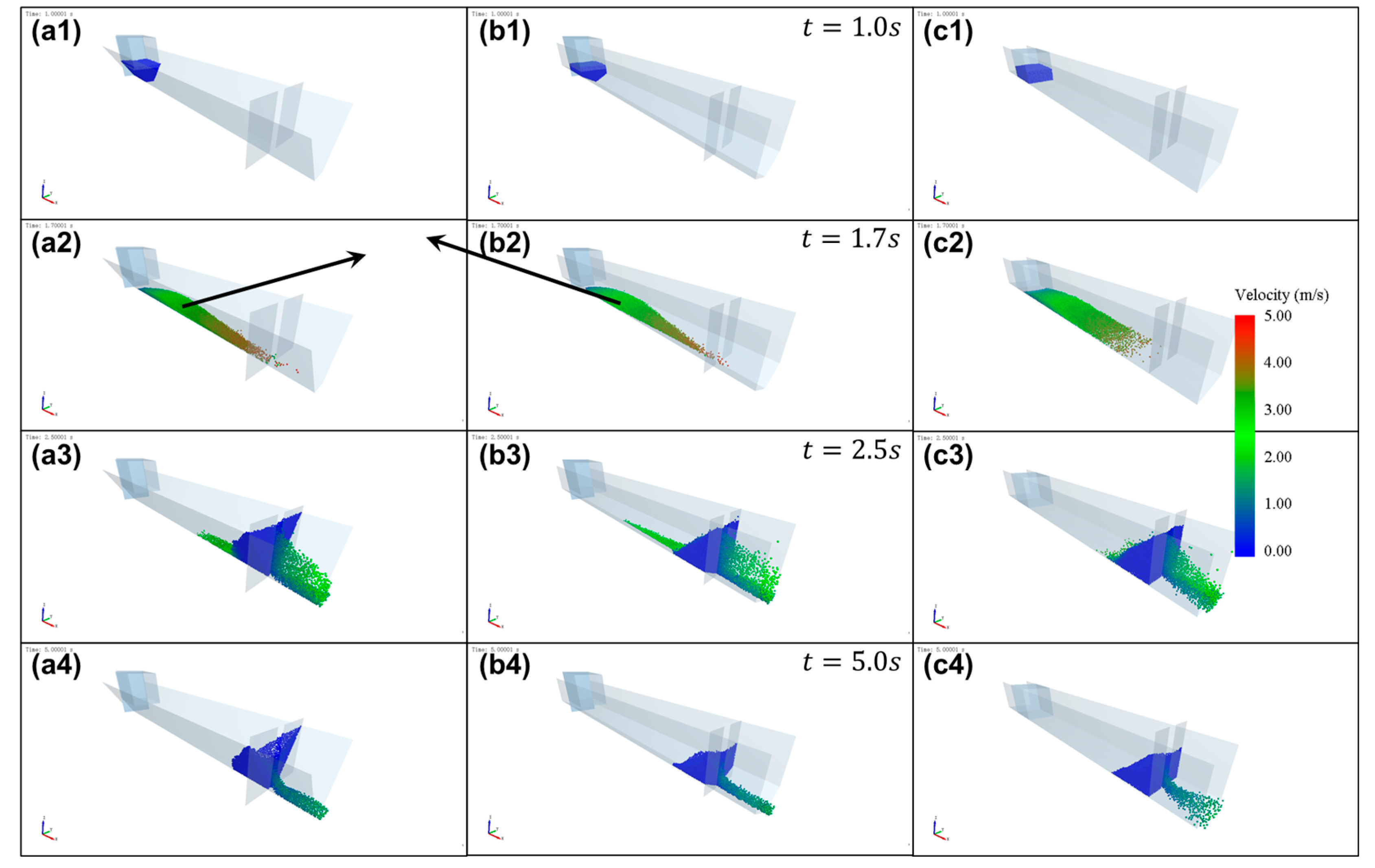

3.1. Flow–Slit Dam Interaction

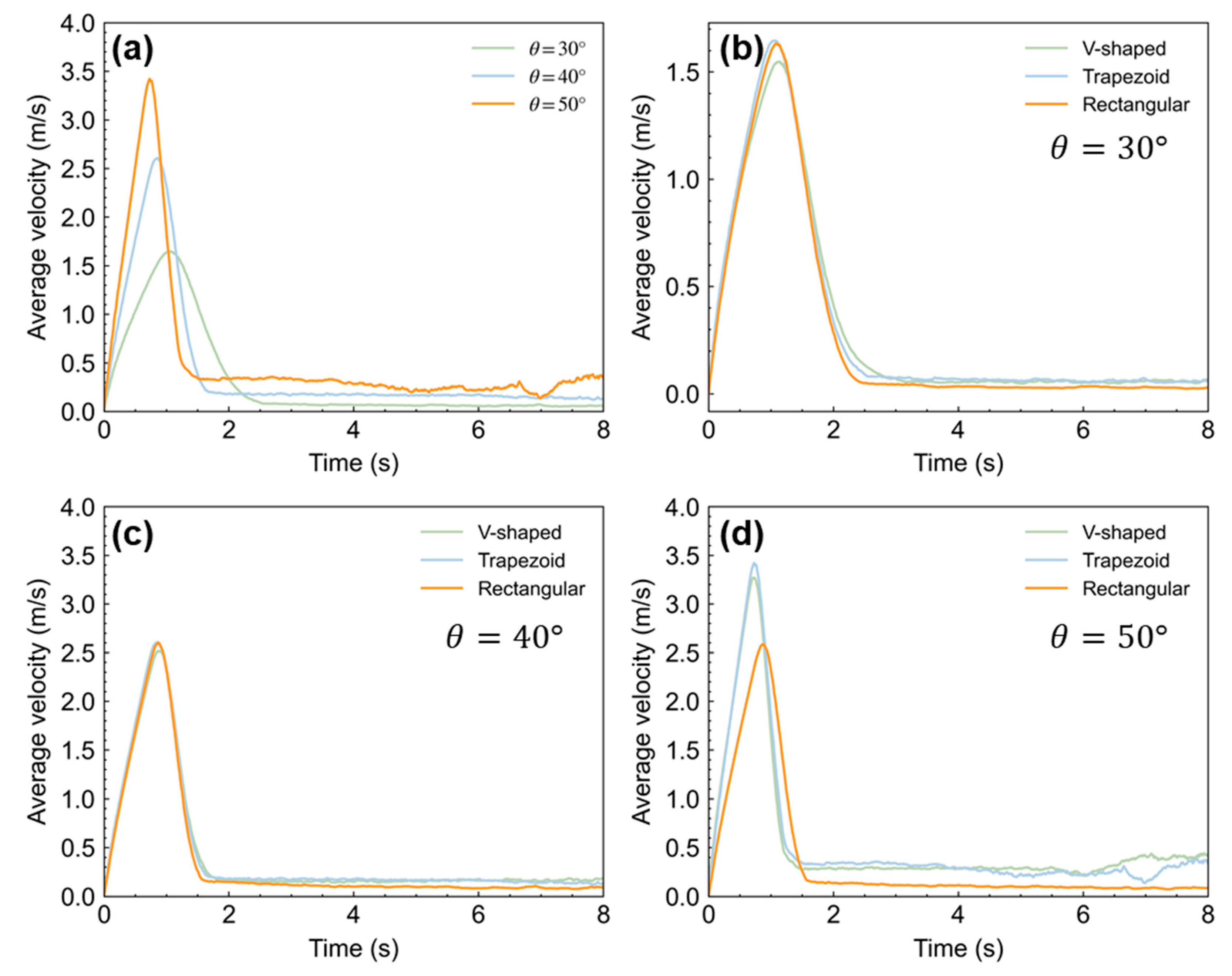

3.2. Average Velocity Evolution

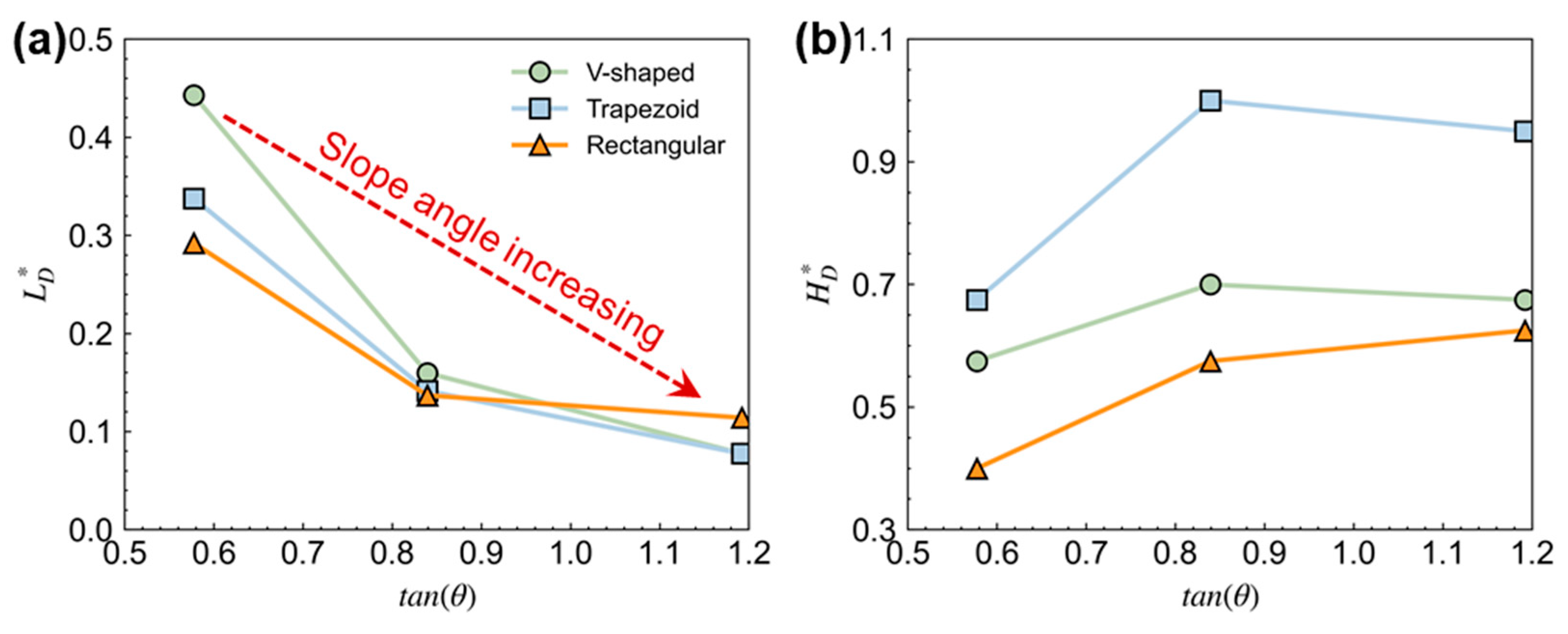

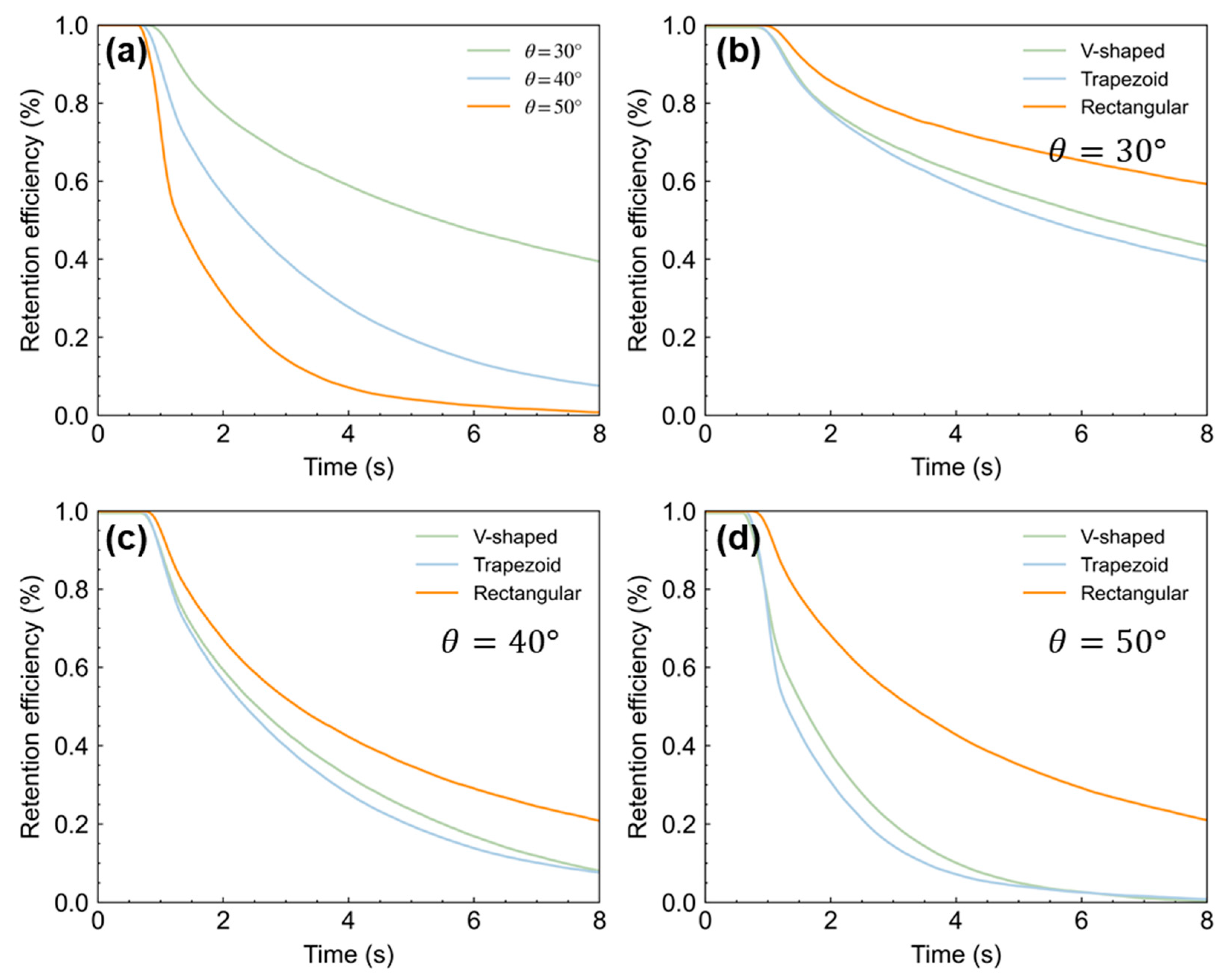

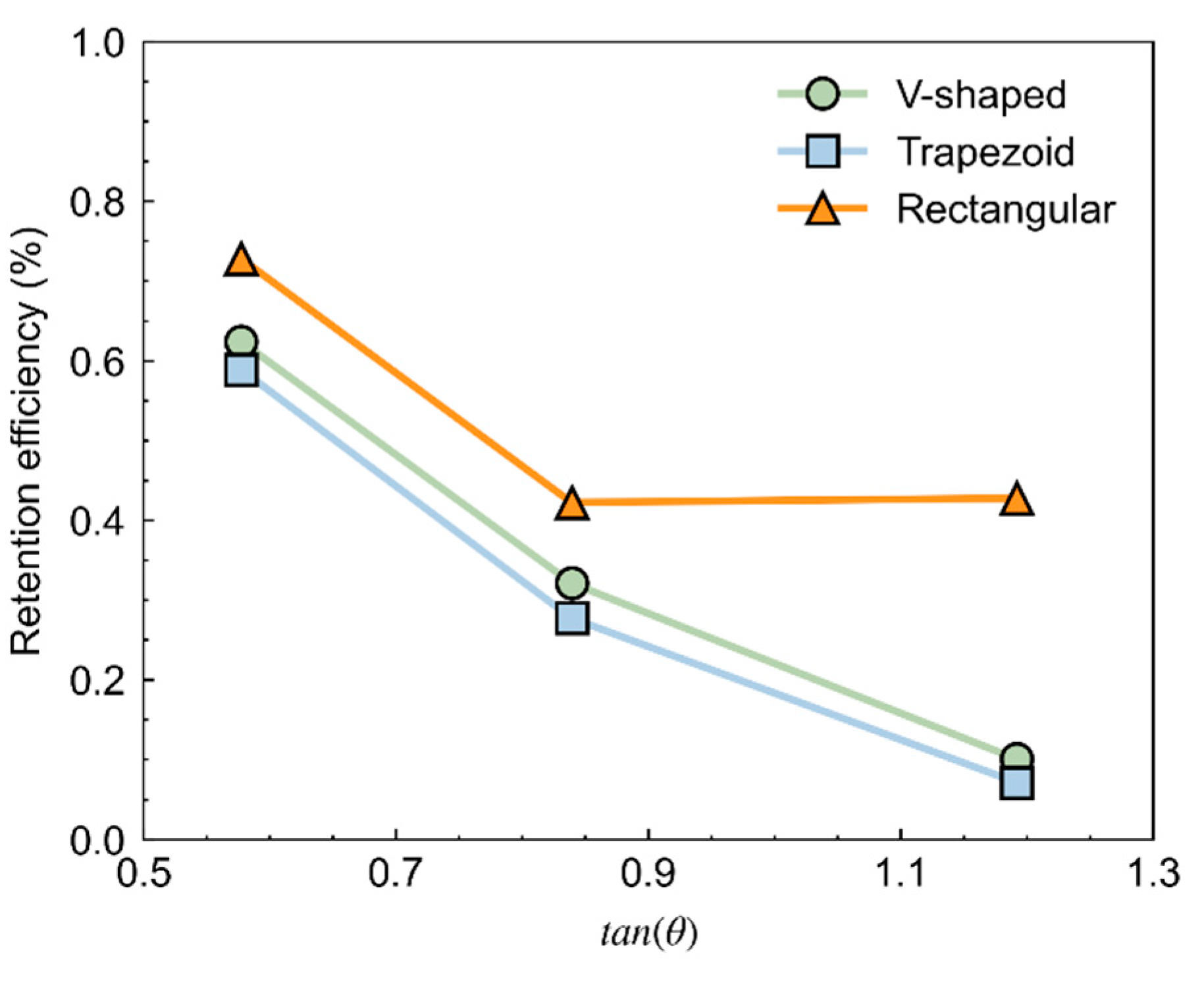

3.3. Retention Efficiency

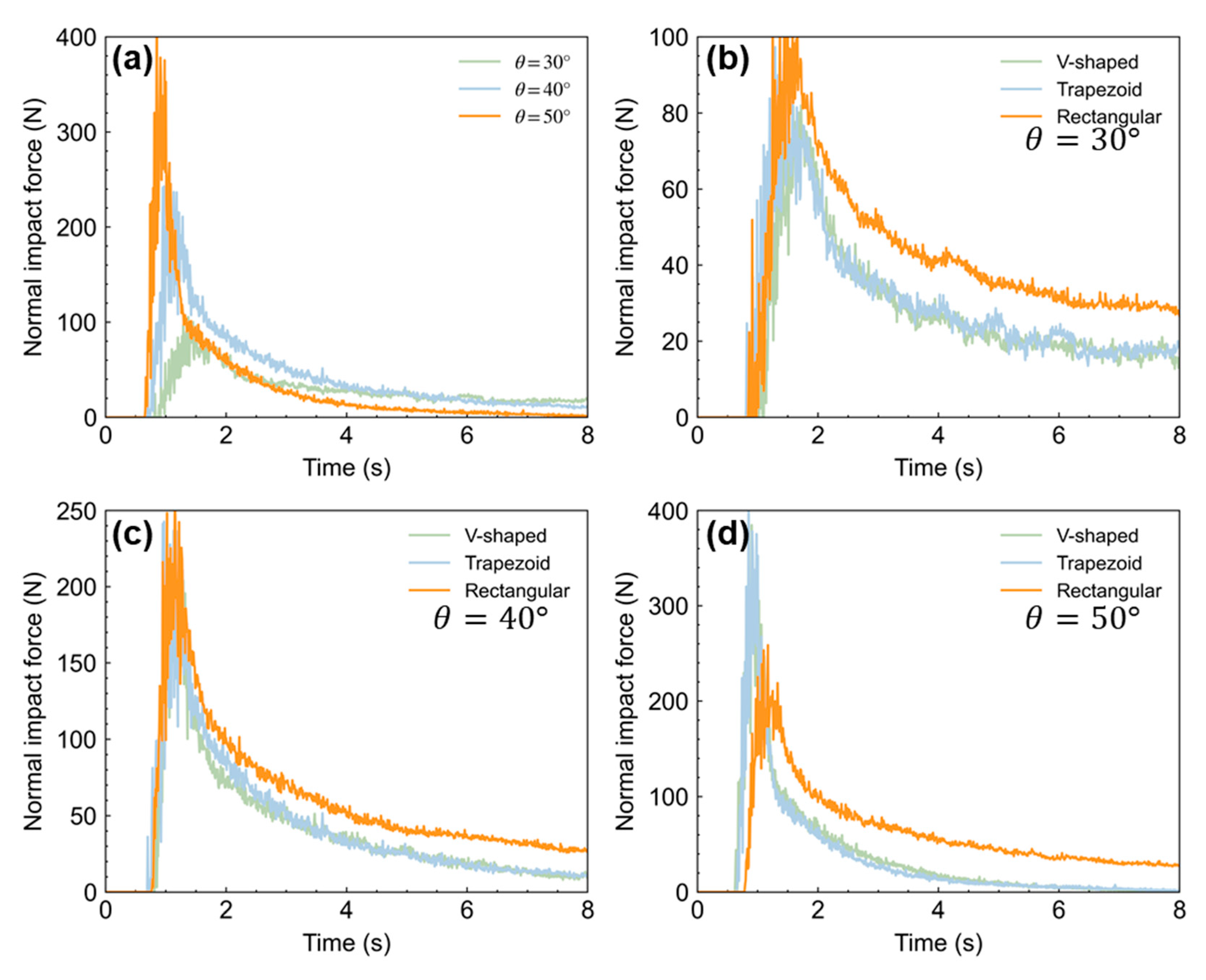

3.4. Impact Force

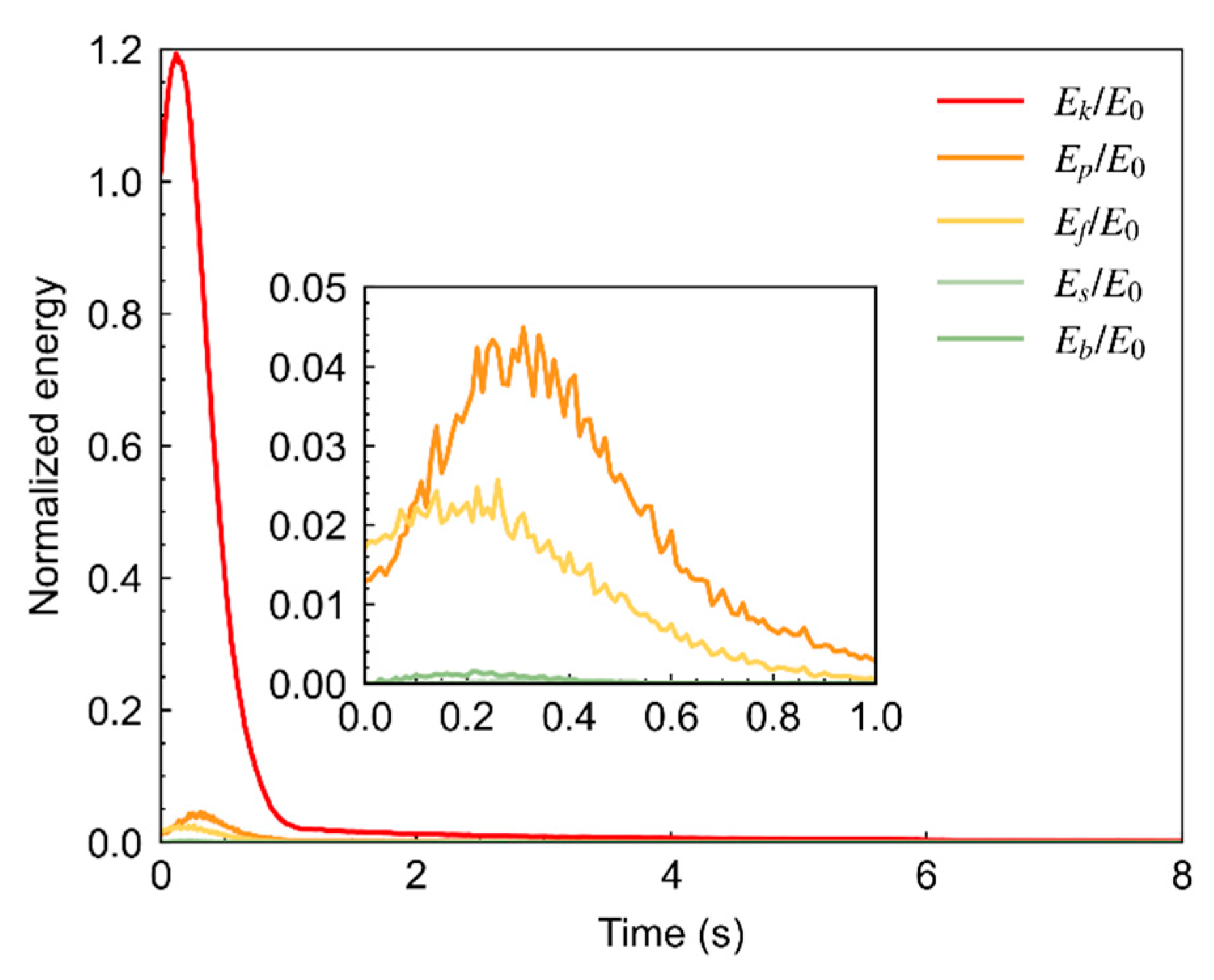

3.5. Energy Evolution

4. Discussion and Conclusions

- Based on numerical results, the dynamics process of flow–slit dam interaction for different-shape cross-sections of the drainage channel, including trapezoid cross-section, V-shaped cross-section, and rectangular cross-section, has been explicitly analyzed and compared. The final pile-up height of trapezoid cross-section is the largest. However, the rectangular cross-section results in a larger final accumulation length;

- The restraint effect of flume inclined side wall and the buffer effect of dead zone jointly influences the dynamics process of flow–slit dam interaction and the retention efficiency;

- From the energy evolution aspect, the friction-induced energy loss by inter-particle interaction consumes most of the energy;

- The cross-section shape of the drainage channel is an important factor that should be considered in the design of barriers, especially the slit dam. The dry granular flow in the drainage channel with a V-shaped cross-section leads to the smallest normal impact force on the slit dam; however, it also intercepts the least particles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Iverson, R.M. The Physics of Debris Flows. Rev. Geophys. 1997, 35, 245–296. [Google Scholar] [CrossRef]

- Iverson, R.M.; Reid, M.E.; Logan, M.; LaHusen, R.G.; Godt, J.W.; Griswold, J.P. Positive Feedback and Momentum Growth during Debris-Flow Entrainment of Wet Bed Sediment. Nat. Geosci. 2011, 4, 116–121. [Google Scholar] [CrossRef]

- Iverson, R.M.; George, D.L.; Logan, M. Debris Flow Runup on Vertical Barriers and Adverse Slopes. J. Geophys. Res. Earth Surf. 2016, 121, 2333–2357. [Google Scholar] [CrossRef]

- Brighenti, R.; Segalini, A.; Ferrero, A.M. Debris Flow Hazard Mitigation: A Simplified Analytical Model for the Design of Flexible Barriers. Comput. Geotech. 2013, 54, 1–15. [Google Scholar] [CrossRef]

- Hungr, O.; Leroueil, S.; Picarelli, L. The Varnes Classification of Landslide Types, an Update. Landslides 2014, 11, 167–194. [Google Scholar] [CrossRef]

- Tang, C.; Rengers, N.; van Asch, T.W.J.; Yang, Y.H.; Wang, G.F. Triggering Conditions and Depositional Characteristics of a Disastrous Debris Flow Event in Zhouqu City, Gansu Province, Northwestern China. Nat. Hazards Earth Syst. Sci. 2011, 11, 2903–2912. [Google Scholar] [CrossRef]

- Li, S.; Chen, X.; Chen, J.; Tang, H.; You, Y.; Chen, H.; Zhao, W.; Geng, X. Small-Scale Flume Investigation of the Performance of Step-Baffle Drainage Channels in Mitigating Debris Flows. Front. Earth Sci. 2022, 10, 921716. [Google Scholar] [CrossRef]

- Chen, H.-X.; Li, J.; Feng, S.-J.; Gao, H.-Y.; Zhang, D.-M. Simulation of Interactions between Debris Flow and Check Dams on Three-Dimensional Terrain. Eng. Geol. 2019, 251, 48–62. [Google Scholar] [CrossRef]

- Faug, T.; Caccamo, P.; Chanut, B. A Scaling Law for Impact Force of a Granular Avalanche Flowing Past a Wall. Geophys. Res. Lett. 2012, 39, 23401. [Google Scholar] [CrossRef]

- Faug, T. Depth-Averaged Analytic Solutions for Free-Surface Granular Flows Impacting Rigid Walls down Inclines. Phys. Rev. E 2015, 92, 062310. [Google Scholar] [CrossRef] [PubMed]

- Albaba, A.; Lambert, S.; Kneib, F.; Chareyre, B.; Nicot, F. DEM Modeling of a Flexible Barrier Impacted by a Dry Granular Flow. Rock Mech. Rock Eng. 2017, 50, 3029–3048. [Google Scholar] [CrossRef]

- Song, D.; Zhou, G.G.D.; Xu, M.; Choi, C.E.; Li, S.; Zheng, Y. Quantitative Analysis of Debris-Flow Flexible Barrier Capacity from Momentum and Energy Perspectives. Eng. Geol. 2019, 251, 81–92. [Google Scholar] [CrossRef]

- Chen, H.-E.; Chen, T.-Y.; Zheng, Y.-L.; Chiu, Y.-Y.; Chen, S.-C. Optimizing Sediment Control by Adjusting the Relative Spacing between Trusses/Beams in an Open-Type Check Dam. Landslides 2024, 22, 551–565. [Google Scholar] [CrossRef]

- Xie, X.; Wang, X.; Liu, Z.; Liu, Z.; Zhao, S. Regulation Effect of Slit-Check Dam against Woody Debris Flow: Laboratory Test. Front. Earth Sci. 2023, 10, 1023652. [Google Scholar] [CrossRef]

- Xiong, H.; Hao, M.; Zhao, D.; Qiu, Y.; Chen, X. Study of the Dynamics of Water-Enriched Debris Flow and Its Impact on Slit-Type Barriers by a Modified SPH–DEM Coupling Approach. Acta Geotech. 2023, 19, 1019–1045. [Google Scholar] [CrossRef]

- Lei, Y.; Cui, P.; Zeng, C.; Guo, Y. An Empirical Mode Decomposition-Based Signal Process Method for Two-Phase Debris Flow Impact. Landslides 2018, 15, 297–307. [Google Scholar] [CrossRef]

- Li, X.; Zhao, J.; Soga, K. A New Physically Based Impact Model for Debris Flow. Géotechnique 2020, 71, 674–685. [Google Scholar] [CrossRef]

- Song, D.; Zhou, G.G.D.; Chen, X.Q.; Li, J.; Wang, A.; Peng, P.; Xue, K.X. General Equations for Landslide-Debris Impact and Their Application to Debris-Flow Flexible Barrier. Eng. Geol. 2021, 288, 106154. [Google Scholar] [CrossRef]

- Vagnon, F.; Ferrero, A.M.; Alejano, L.R. Reliability-Based Design for Debris Flow Barriers. Landslides 2020, 17, 49–59. [Google Scholar] [CrossRef]

- Albaba, A.; Lambert, S.; Faug, T. Dry Granular Avalanche Impact Force on a Rigid Wall: Analytic Shock Solution versus Discrete Element Simulations. Phys. Rev. E 2018, 97, 052903. [Google Scholar] [CrossRef] [PubMed]

- Calvetti, F.; di Prisco, C.G.; Vairaktaris, E. DEM Assessment of Impact Forces of Dry Granular Masses on Rigid Barriers. Acta Geotech. 2017, 12, 129–144. [Google Scholar] [CrossRef]

- Chen, X.; Cui, P.; You, Y.; Chen, J.; Li, D. Engineering Measures for Debris Flow Hazard Mitigation in the Wenchuan Earthquake Area. Eng. Geol. 2015, 194, 73–85. [Google Scholar] [CrossRef]

- Fang, J.; Wang, L.; Hong, Y.; Zhao, J. Influence of Solid–Fluid Interaction on Impact Dynamics against Rigid Barrier: CFD–DEM Modelling. Géotechnique 2021, 72, 391–406. [Google Scholar] [CrossRef]

- Li, K.; Wang, Y.-F.; Lin, Q.-W.; Cheng, Q.-G.; Wu, Y. Experiments on Granular Flow Behavior and Deposit Characteristics: Implications for Rock Avalanche Kinematics. Landslides 2021, 18, 1779–1799. [Google Scholar] [CrossRef]

- Shen, W.; Li, T.; Li, P.; Lei, Y. Numerical Assessment for the Efficiencies of Check Dams in Debris Flow Gullies: A Case Study. Comput. Geotech. 2020, 122, 103541. [Google Scholar] [CrossRef]

- Gong, S.; Zhao, T.; Zhao, J.; Dai, F.; Zhou, G.G.D. Discrete Element Analysis of Dry Granular Flow Impact on Slit Dams. Landslides 2021, 18, 1143–1152. [Google Scholar] [CrossRef]

- Kong, Y.; Guan, M.; Li, X.; Zhao, J.; Yan, H. How Flexible, Slit and Rigid Barriers Mitigate Two-Phase Geophysical Mass Flows: A Numerical Appraisal. J. Geophys. Res. Earth Surf. 2022, 127, e2021JF006587. [Google Scholar] [CrossRef]

- Li, N.; Zhou, G.G.D.; Hu, H.; Cui, K.F.E.; Huang, Y. Influence of Trapping Efficiency on the Pile-up Geometry of Granular Flows behind Slit Dams. Eng. Geol. 2023, 326, 107333. [Google Scholar] [CrossRef]

- Marchelli, M.; Leonardi, A.; Pirulli, M.; Scavia, C. On the Efficiency of Slit-Check Dams in Retaining Granular Flows. Géotechnique 2020, 70, 226–237. [Google Scholar] [CrossRef]

- Ren, S.; Zhang, P.; Man, T.; Galindo-Torres, S.A. Numerical Assessments of the Influences of Soil–Boulder Mixed Flow Impact on Downstream Facilities. Comput. Geotech. 2023, 153, 105055. [Google Scholar] [CrossRef]

- Choi, C.E.; Goodwin, G.R.; Ng, C.W.W.; Cheung, D.K.H.; Kwan, J.S.H.; Pun, W.K. Coarse Granular Flow Interaction with Slit Structures. Géotechnique Lett. 2016, 6, 267–274. [Google Scholar] [CrossRef]

- Goodwin, G.R.; Choi, C.E. Slit Structures: Fundamental Mechanisms of Mechanical Trapping of Granular Flows. Comput. Geotech. 2020, 119, 103376. [Google Scholar] [CrossRef]

- Hu, H.; Zhou, G.G.D.; Song, D.; Cui, K.F.E.; Huang, Y.; Choi, C.E.; Chen, H. Effect of Slit Size on the Impact Load against Debris-Flow Mitigation Dams. Eng. Geol. 2020, 274, 105764. [Google Scholar] [CrossRef]

- Chen, Z.; Rickenmann, D.; Zhang, Y.; He, S. Effects of Obstacle’s Curvature on Shock Dynamics of Gravity-Driven Granular Flows Impacting a Circular Cylinder. Eng. Geol. 2021, 293, 106343. [Google Scholar] [CrossRef]

- Choi, C.E.; Ng, C.W.W.; Law, R.P.H.; Song, D.; Kwan, J.S.H.; Ho, K.K.S. Computational Investigation of Baffle Configuration on Impedance of Channelized Debris Flow. Can. Geotech. J. 2015, 52, 182–197. [Google Scholar] [CrossRef]

- Fang, Y.; Liu, H.; Guo, L.; Li, X. Model Experiment Exploration of the Kinetic Dissipation Effect on the Slit Dam with Baffles Tilted in the Downstream Direction. Water 2022, 14, 2772. [Google Scholar] [CrossRef]

- Kim, B.-J.; Yune, C.-Y. Flume Investigation of Cylindrical Baffles on Landslide Debris Energy Dissipation. Landslides 2022, 19, 3043–3060. [Google Scholar] [CrossRef]

- Li, S.; Wang, J.; Wang, F.; Li, P. Experimental Study on a Debris Flow Water-Sediment Separation Structure of a Funnel-Type Grating and Its Sorting Characteristics. Bull. Eng. Geol. Environ. 2023, 82, 148. [Google Scholar] [CrossRef]

- Shima, J.; Moriyama, H.; Kokuryo, H.; Ishikawa, N.; Mizuyama, T. Prevention and Mitigation of Debris Flow Hazards by Using Steel Open-Type Sabo Dams. Int. J. Eros. Control Eng. 2016, 9, 135–144. [Google Scholar] [CrossRef]

- Choi, C.E.; Ng, C.W.W.; Song, D.; Kwan, J.H.S.; Shiu, H.Y.K.; Ho, K.K.S.; Koo, R.C.H. Flume Investigation of Landslide Debris–Resisting Baffles. Can. Geotech. J. 2014, 51, 540–553. [Google Scholar] [CrossRef]

- Leonardi, A.; Goodwin, G.R.; Pirulli, M. The Force Exerted by Granular Flows on Slit Dams. Acta Geotech. 2019, 14, 1949–1963. [Google Scholar] [CrossRef]

- You, Y.; Pan, H.; Liu, J.; Ou, G. The Optimal Cross-Section Design of the “Trapezoid-V” Shaped Drainage Canal of Viscous Debris Flow. J. Mt. Sci. 2011, 8, 103–107. [Google Scholar] [CrossRef]

- Jiang, Y.-J.; Towhata, I. Experimental Study of Dry Granular Flow and Impact Behavior Against a Rigid Retaining Wall. Rock Mech. Rock Eng. 2013, 46, 713–729. [Google Scholar] [CrossRef]

- Jiang, Y.-J.; Fan, X.-Y.; Li, T.-H.; Xiao, S.-Y. Influence of Particle-Size Segregation on the Impact of Dry Granular Flow. Powder Technol. 2018, 340, 39–51. [Google Scholar] [CrossRef]

- Zhou, G.G.D.; Du, J.; Song, D.; Choi, C.E.; Hu, H.S.; Jiang, C. Numerical Study of Granular Debris Flow Run-up against Slit Dams by Discrete Element Method. Landslides 2020, 17, 585–595. [Google Scholar] [CrossRef]

- Shen, W.; Zhao, T.; Zhao, J.; Dai, F.; Zhou, G.G.D. Quantifying the Impact of Dry Debris Flow against a Rigid Barrier by DEM Analyses. Eng. Geol. 2018, 241, 86–96. [Google Scholar] [CrossRef]

- Nie, Y.-P.; Wang, X.-K.; Yan, X.-F. CFD-DEM-Based Evaluation of Main-Channel Sediment Transport Processes Subject to Supplement from a Steep Tributary. Eng. Geol. 2024, 333, 107498. [Google Scholar] [CrossRef]

- Piton, G.; Recking, A. Design of Sediment Traps with Open Check Dams. I: Hydraulic and Deposition Processes. J. Hydraul. Eng. 2016, 142, 04015045. [Google Scholar] [CrossRef]

- Rossi, G.; Armanini, A. Impact Force of a Surge of Water and Sediments Mixtures against Slit Check Dams. Sci. Total Environ. 2019, 683, 351–359. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.-J.; Zhao, Y.; Towhata, I.; Liu, D.-X. Influence of Particle Characteristics on Impact Event of Dry Granular Flow. Powder Technol. 2015, 270, 53–67. [Google Scholar] [CrossRef]

| Material | |||

|---|---|---|---|

| Particles | 2550 | 0.25 | 100 |

| Flume | 7900 | 0.3 | 2 × 103 |

| Barrier | 7900 | 0.3 | 2 × 103 |

| Parameter | Particle–Particle | Particle–Flume Base | Particle–Slide Wall | Particle–Barrier |

|---|---|---|---|---|

| Contact model | Hertz–Mindlin (no slip) | |||

| Coefficient of restitution | 0.6 | 0.6 | 0.6 | 0.6 |

| Friction coefficient | 1.33 | 0.466 | 0.268 | 0.384 |

| Rolling friction coefficient | 0.06 | 0.01 | 0.01 | 0.01 |

| Test Series | Cross-Section Shape | |||

|---|---|---|---|---|

| 1–5 | , , | V-shaped | 10 | 39.6 |

| 6–10 | , , | Trapezoid | 10 | 39.6 |

| 11–15 | , , | Rectangular | 10 | 39.6 |

| 1–5 | , , | V-shaped | 10 | 39.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, J.; Yang, C.; Bu, C.; Xia, Y.; Zhang, G. Effect of Topographic Condition of Drainage Channel on the Interaction Between Granular Flow and Slit Dams. Sustainability 2025, 17, 1649. https://doi.org/10.3390/su17041649

Feng J, Yang C, Bu C, Xia Y, Zhang G. Effect of Topographic Condition of Drainage Channel on the Interaction Between Granular Flow and Slit Dams. Sustainability. 2025; 17(4):1649. https://doi.org/10.3390/su17041649

Chicago/Turabian StyleFeng, Jiajia, Chengye Yang, Chongyang Bu, Yangyang Xia, and Gen Zhang. 2025. "Effect of Topographic Condition of Drainage Channel on the Interaction Between Granular Flow and Slit Dams" Sustainability 17, no. 4: 1649. https://doi.org/10.3390/su17041649

APA StyleFeng, J., Yang, C., Bu, C., Xia, Y., & Zhang, G. (2025). Effect of Topographic Condition of Drainage Channel on the Interaction Between Granular Flow and Slit Dams. Sustainability, 17(4), 1649. https://doi.org/10.3390/su17041649