Life Cycle Assessment of a Composite Prototype Battery Enclosure for Electric Vehicles

Abstract

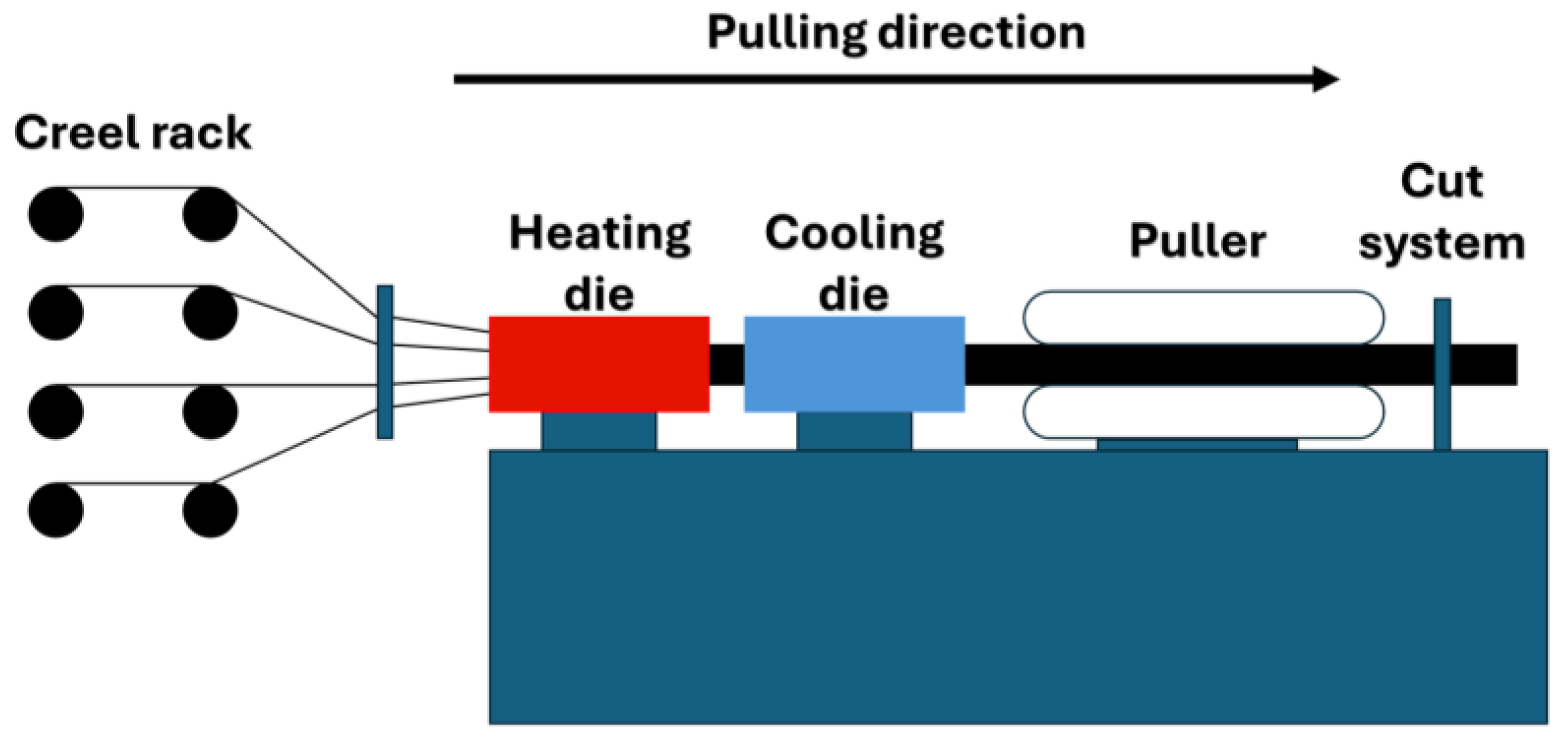

1. Introduction

2. Materials and Methods

2.1. Battery Pack Case Prototype

- Two outer modules (25s1p).

- Two middle modules (28s1p).

- Battery housing, engineered to securely and precisely house the four modules. The internal slots optimize space utilization, minimize voids, and improve manufacturing efficiency.

- Battery cover, designed to provide mechanical and environmental protection by closing the system.

- Structural support, included to ensure the secure attachment of the system to the vehicle’s framework and to guarantee stability and integration during the operation.

2.2. Life Cycle Assessment

- Goal and scope definition;

- Life cycle inventory;

- Impact assessment;

- Result interpretation.

Goal and Scope Definition

- Raw material extraction and transportation: resource extraction for glass fibers and thermoplastics.

- Manufacturing: Enclosure enclosure fabrication using the processes described above.

- Use phase: Enclosure enclosure performance during vehicle operation, focusing on weight and energy consumption.

- End-of-life: Recyclingrecycling, considering the recovery of the whole battery enclosure.

- LCA databases: EuCIA’s Eco Impact Calculator for composites was used for data on raw material extraction and standardized manufacturing processes.

- The scientific literature: additional information regarding the use phase and the environmental impacts of recycling rates was obtained from relevant studies.

2.3. Life Cycle Inventory

2.3.1. Extraction and Production Stage Inventory

2.3.2. Use Stage Inventory

2.3.3. Recycle Stage Inventory

2.4. Impact Assessment Methodology

- Carbon footprint (CF): it calculates the total CO2 and other greenhouse gases (GHGs) associated with an activity or product. In the CF calculation, all GHGs regulated by the Kyoto Protocol (CO2, CH4, N2O, SF6) are considered through the global warming potential (GWP100) of each one, which represents the ratio between the warming caused by the specific GHG in a particular interval of time and the warming caused in the same period by the same amount of CO2 [25].

- Energy consumption: it calculates the total amount of energy used to produce goods and can include different forms of energy, such as electricity, natural gas, oil, coal, and other non-renewable and renewable energy sources (solar, wind, ocean, hydropower, hydrogen from renewable sources, biofuels, geothermal, biomass) [24]. Both primary and secondary energy were included in this study.

3. Results

4. Discussion

4.1. Sensitivity Analysis

Energy Consumption Comparison

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, H.; Balthasar, F.; Tait, N.; Riera-Palou, X.; Harrison, A. A New Comparison between the Life Cycle Greenhouse Gas Emissions of Battery Electric Vehicles and Internal Combustion Vehicles. Energy Policy 2012, 44, 160–173. [Google Scholar] [CrossRef]

- Moradloo, N.; Mahdinia, I.; Khattak, A. Charging into the Future: Unraveling the Factors Shaping Electric Adoption and Addressing Heterogeneity. SAE Int. J. Sustain. Transp. Energy Environ. Policy 2024, 6, 13. [Google Scholar] [CrossRef]

- Silvestri, L.; De Santis, M.; Falcucci, G.; Serao, P.; Bella, G. Evaluation of Battery Power Losses During the LCA Use Phase of Electric Vehicles: An Experimental Analysis of Different Li-Ion Battery Chemistries. SAE Int. J. Adv. Curr. Pract. Mobil. 2023, 6, 2059–2065. [Google Scholar] [CrossRef]

- Pradeep, S.A.; Deshpande, A.M.; Shah, B.; Khan, S.; Farahani, S.; Sternberg, J.; Li, G.; Pilla, S. Advancing Automotive Light-Weighting:Material–Process–Microstructure–Performance (MP2) Relationships of Supercritical Injection of PP–Graphene Nanocomposite Foams and Over-Molding. SAE Int. J. Sustain. Transp. Energy Environ. Policy 2024, 5. [Google Scholar] [CrossRef]

- Azzopardi, B.; Hapid, A.; Kaleg, S.; Sudirja; Onggo, D.; Budiman, A.C. Recent Advances in Battery Pack Polymer Composites. Energies 2023, 16, 6223. [Google Scholar] [CrossRef]

- Khajepour, A.; Fallah, S.; Goodarzi, A. Electric and Hybrid Vehicles: Technologies, Modeling and Control—A Mechatronic Approach; Wiley: Hoboken, NJ, USA, 2014; pp. 1–45. ISBN 978-1-118-34151-3. [Google Scholar]

- Belingardi, G.; Scattina, A. Battery Pack and Underbody: Integration in the Structure Design for Battery Electric Vehicles—Challenges and Solutions. Vehicles 2023, 5, 498–514. [Google Scholar] [CrossRef]

- Ma, Q.; Fan, D.; Qin, X.; Gan, X.; Cai, M. Parallel Optimization of Design and Manufacturing—Carbon Fiber Battery Pack for Electric Vehicles. Mech. Adv. Mater. Struct. 2022, 31, 2289–2306. [Google Scholar] [CrossRef]

- Minchenkov, K.; Vedernikov, A.; Safonov, A.; Akhatov, I. Thermoplastic Pultrusion: A Review. Polymers 2021, 13, 180. [Google Scholar] [CrossRef] [PubMed]

- Choi, C.H.; Cho, J.M.; Kil, Y.; Yoon, Y. Development of Polymer Composite Battery Pack Case for an Electric Vehicle. In Proceedings of the SAE Technical Papers, SAE 2013 World Congress and Exhibition, Detroit, MI, USA, 16 April 2013; Volume 2, pp. 1–8. [Google Scholar]

- Wazeer, A.; Das, A.; Abeykoon, C.; Sinha, A.; Karmakar, A. Composites for Electric Vehicles and Automotive Sector: A Review. Green Energy Intell. Transp. 2023, 2, 100043. [Google Scholar] [CrossRef]

- Liu, Z.; Zhu, C.; Zhu, P.; Chen, W. Reliability-Based Design Optimization of Composite Battery Box Based on Modified Particle Swarm Optimization Algorithm. Compos. Struct. 2018, 204, 239–255. [Google Scholar] [CrossRef]

- Nigel Tesla LFP Model 3. Available online: https://www.batterydesign.net/tesla-lfp-model-3/ (accessed on 10 November 2024).

- Carlone, P.; Baran, I.; Hattel, J.H.; Palazzo, G.S. Computational Approaches for Modeling the Multiphysics in Pultrusion Process. Adv. Mech. Eng. 2013, 5, 301875. [Google Scholar] [CrossRef]

- Stock, S.; Hagemeister, J.; Grabmann, S.; Kriegler, J.; Keilhofer, J.; Ank, M.; Dickmanns, J.L.S.; Schreiber, M.; Konwitschny, F.; Wassiliadis, N.; et al. Cell Teardown and Characterization of an Automotive Prismatic LFP Battery. Electrochim. Acta 2023, 471, 143341. [Google Scholar] [CrossRef]

- ISO 14040 2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006; pp. 1–20.

- ISO 14044 2006; Environmental management—Life cycle assessment—Requirements and guidelines. International Organization for Standardization: Geneva, Switzerland, 2006; pp. 1–46.

- Curran, M.A. Life Cycle Assessment: A Review of the Methodology and Its Application to Sustainability. Curr. Opin. Chem. Eng. 2013, 2, 273–277. [Google Scholar] [CrossRef]

- EuCia. Eco Impact Calculator For Composites. Available online: https://ecocalculator.eucia.eu/ (accessed on 21 November 2024).

- Li, X.; Zhang, Y.; Liao, Y.; Yu, G. Environmental Impact Assessment of Battery Boxes Based on Lightweight Material Substitution. Sci. Rep. 2024, 14, 2594. [Google Scholar] [CrossRef]

- Lunetto, V.; Galati, M.; Settineri, L.; Iuliano, L. Sustainability in the Manufacturing of Composite Materials: A Literature Review and Directions for Future Research. J. Manuf. Process 2023, 85, 858–874. [Google Scholar] [CrossRef]

- TESLA. Consumo Energetico Del Veicolo. Available online: https://www.tesla.com/it_it/support/power-consumption (accessed on 4 December 2024).

- Allgemeine Artikel Model 3 with LFP Cells: The Big Nextmove Winter Test. Available online: https://nextmove.de/model-3-with-lfp-cells-the-big-nextmove-winter-test/ (accessed on 4 December 2024).

- Martin Hirschnitz-Garbers (Ecologic Institute) Tanja Srebotnjak (Ecologic Institute) Ecologic Briefs Integrating Resource Efficiency, Greening of Industrial Production and Green Industries-Scoping of and Recommendations for Effective Indicators. Available online: https://www.ecologic.eu/sites/default/files/project/2013/PolicyBrief_EcologicInstitute_20121018_final_A4.pdf (accessed on 22 November 2024).

- Veleva, V.; Ellenbecker, M. Indicators of Sustainable Production: Framework and Methodology. J. Clean. Prod. 2001, 9, 519–549. [Google Scholar] [CrossRef]

- Istituto Superiore per la Protezione e la Ricerca Ambientale Tabelle per calcolo degli indicatori. Available online: https://www.isprambiente.gov.it/files/emas/tabellepercalcolodegliindicatori.pdf (accessed on 4 December 2024).

- Fonte, R.; Xydis, G. Wind Turbine Blade Recycling: An Evaluation of the European Market Potential for Recycled Composite Materials. J. Environ. Manag. 2021, 287, 112269. [Google Scholar] [CrossRef] [PubMed]

| Component | Mass [kg] | Quantity |

|---|---|---|

| Battery housing | 39.35 | 2 |

| Battery cover | 2.06 | 2 |

| Structural supports | 1.18 | 4 |

| Total | 87.55 | - |

| Stage | Source |

|---|---|

| Raw material | EuCIA Eco Impact Calculator for composites [19] |

| Production | EuCIA Eco Impact Calculator for composites [19] |

| Use | The literature [20] |

| Recycling | The literature [21] |

| Impact Category | Amount | Unit |

|---|---|---|

| Climate change | 3.04 × 102 | kg CO2 eq |

| Ozone depletion | 8.87 × 10⁻6 | kg CFC-11 eq |

| Human toxicity, non-cancer effects | 1.82 × 10⁻5 | CTuh |

| Human toxicity, cancer effects | 3.21 × 10⁻6 | CTuh |

| Particulate matter | 1.15 × 10⁻1 | kg PM2.5 eq |

| Ionizing radiation HH | 1.68 × 101 | kBq U235 eq |

| Ionizing radiation E (interim) | 5.71 × 10⁻5 | CTUe |

| Freshwater ecotoxicity | 5.63 × 102 | CTUe |

| Photochemical ozone formation | 1.68 | kg NMVOC eq |

| Acidification | 9.78 × 10⁻1 | molc H+ eq |

| Terrestrial eutrophication | 2.06 | molc N eq |

| Freshwater eutrophication | 1.43 × 10⁻2 | kg P eq |

| Marine eutrophication | 2.86 × 10⁻1 | kg N eq |

| Land use | 9.89 × 101 | kg C deficit |

| Water resource depletion | −4.77 | m3 water eq |

| Mineral, fossil and ren resource depletion | 2.55 × 10⁻3 | kg Sb eq |

| Method | SEC [MJ/kg] |

|---|---|

| Mechanical Recycling (GFRP) | 0.4–5.0 |

| Pyrolysis | 3–30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Sio, P.; Gaito, M.; Esperto, V.; Cozzolino, E.; Astarita, A.; Tucci, F. Life Cycle Assessment of a Composite Prototype Battery Enclosure for Electric Vehicles. Sustainability 2025, 17, 1579. https://doi.org/10.3390/su17041579

De Sio P, Gaito M, Esperto V, Cozzolino E, Astarita A, Tucci F. Life Cycle Assessment of a Composite Prototype Battery Enclosure for Electric Vehicles. Sustainability. 2025; 17(4):1579. https://doi.org/10.3390/su17041579

Chicago/Turabian StyleDe Sio, Paolo, Marica Gaito, Vitantonio Esperto, Ersilia Cozzolino, Antonello Astarita, and Fausto Tucci. 2025. "Life Cycle Assessment of a Composite Prototype Battery Enclosure for Electric Vehicles" Sustainability 17, no. 4: 1579. https://doi.org/10.3390/su17041579

APA StyleDe Sio, P., Gaito, M., Esperto, V., Cozzolino, E., Astarita, A., & Tucci, F. (2025). Life Cycle Assessment of a Composite Prototype Battery Enclosure for Electric Vehicles. Sustainability, 17(4), 1579. https://doi.org/10.3390/su17041579