Carbon Footprint Comparison of Rapeseed and Palm Oil: Impact of Land Use and Fertilizers

Abstract

1. Introduction

2. Materials and Methods

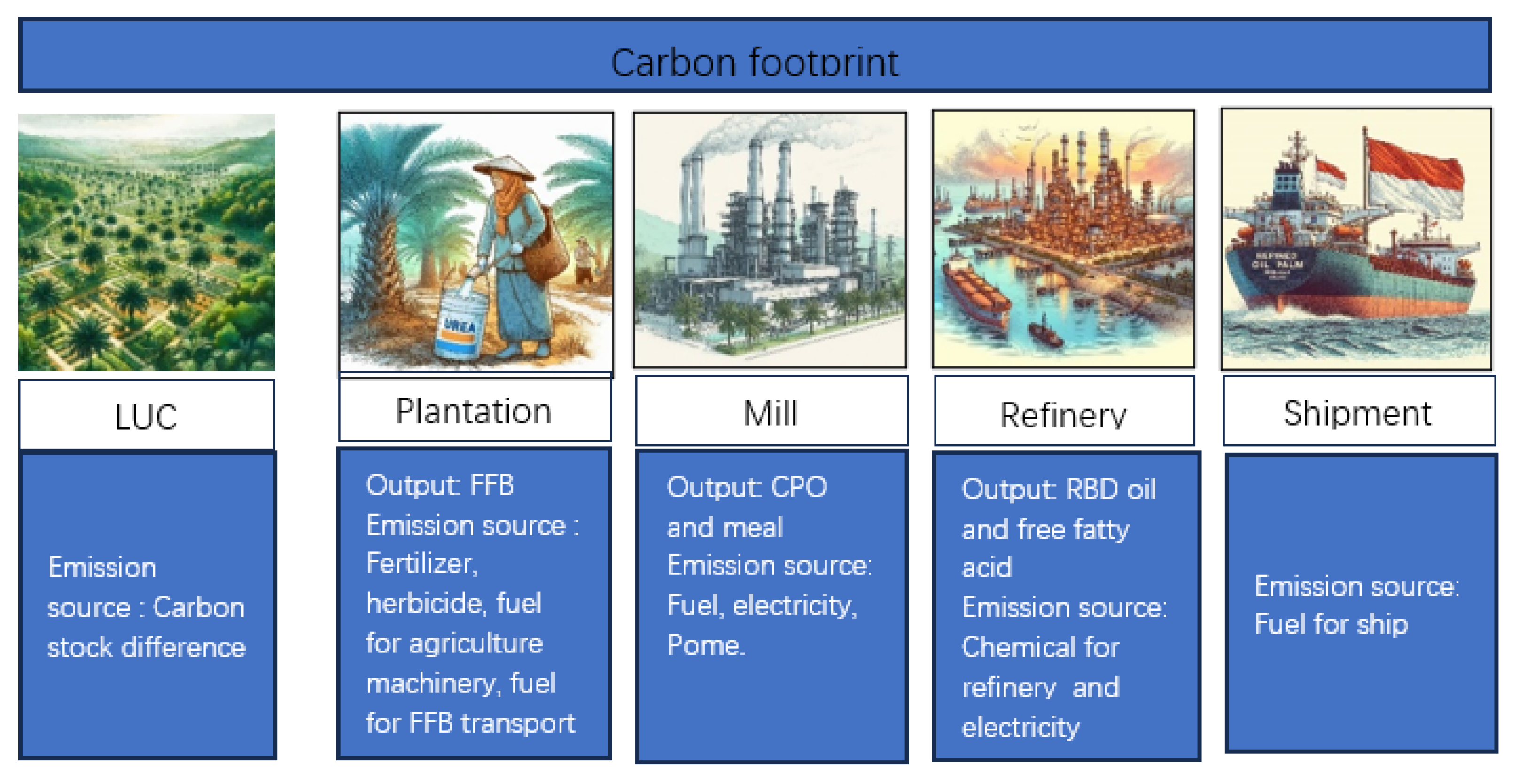

2.1. System Boundary

2.2. LUC Stage

2.3. Plantation and Oil Processing Stages

3. Results

3.1. LUC Stage Carbon Footprint

3.2. Plantation and Oil Processing Stages’ Carbon Footprint

3.2.1. Life-Cycle Inventory

3.2.2. Carbon Footprint Using LCA SIMAPRO

3.3. Sensitivity Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. The State of Food and Agriculture. Making Agrifood Systems More Resilient to Shocks and Stresses; FAO Publishing: Rome, Italy, 2021. [Google Scholar] [CrossRef]

- Schmidt, J.H. Life cycle assessment of five vegetable oils. J. Clean. Prod. 2015, 87, 130–138. [Google Scholar] [CrossRef]

- Uusitalo, V.; Väisänen, S.; Havukainen, J.; Havukainen, M.; Soukka, R.; Luoranen, M. Carbon footprint of renewable diesel from palm oil, jatropha oil, and rapeseed oil. Renew. Energy 2014, 69, 103–113. [Google Scholar] [CrossRef]

- Lukovic, N.; Knezevic-Jugovic, Z.; Bezbradica, D. Biodiesel fuel production by enzymatic transesterification of oils: Recent trends, challenges, and future perspectives. In Alternative Fuel; Manzanera, M., Ed.; Books on Demand: Norderstedt, Germany, 2011; pp. 47–72. [Google Scholar]

- Statista. Production of Major Vegetable Oils Worldwide from 2012/2013 to 2022/2023. 2023. Available online: https://www.statista.com/statistics/263933/production-of-vegetable-oils-worldwide-since-2000/ (accessed on 1 June 2024).

- Singh, B.P. Biofuel Crop Sustainability; Wiley-Blackwel: Hoboken, NJ, USA, 2013; ISBN 978-0-470-96304-3. [Google Scholar]

- Faostat. Available online: http://www.fao.org/faostat/en/#home (accessed on 11 December 2024).

- Van Duren, I.; Voinov, A.; Arodudu, O.; Firrisa, M.T. Where to produce rapeseed biodiesel and why? Mapping European rapeseed energy efficiency. Renew. Energy 2015, 74, 49–59. [Google Scholar] [CrossRef]

- Vijay, V.; Pimm, S.L.; Jenkins, C.N.; Smith, S.J. The Impacts of Oil Palm on Recent Deforestation and Biodiversity Loss. PLoS ONE 2016, 11, e0159668. [Google Scholar] [CrossRef]

- Teng, S.; Khong, K.W.; Norbani, C.H. Palm oil and its environmental impacts: A big data analytics study. J. Clean. Prod. 2020, 274, 122901. [Google Scholar] [CrossRef]

- Meijaard, E.; Garcia-Ulloa, J.; Sheil, D.; Wich, S.A.; Carlson, K.M.; Juffe-Bignoli, D.; Brooks, T.M. (Eds.) Oil Palm and Biodiversity. A Situation Analysis by the IUCN Oil Palm Task Force; IUCN: Gland, Switzerland, 2018; Volume 13, 116p. [Google Scholar]

- Bakhtiar, I.; Suradiredja, D.; Santoso, H.; Saputra, W. Hutan Kita Bersawit; Yayasan KEHATI: South Jakarta, Indonesia, 2019; ISBN 978-623-7041-01-6. [Google Scholar]

- Searchinger, T.D.; Wirsenius, S.; Beringer, T.; Dumas, P. Assessing the efficiency of changes in land use for mitigating climate change. Nature 2018, 564, 249–253. [Google Scholar] [CrossRef]

- Alcock, T.D.; Salt, D.E.; Wilson, P.; Ramsden, S.J. More sustainable vegetable oil: Balancing productivity with carbon storage opportunities. Sci. Total Environ. 2022, 829, 154539. [Google Scholar] [CrossRef]

- Peteru, S.; Komarudin, H.; Brady, M. Sustainability Certifications, Approaches, and Tools for Oil Palm in Indonesia and Malaysia. European Forest Institute 2022. Available online: https://www.cifor-icraf.org/knowledge/publication/8756/ (accessed on 2 June 2024).

- Traction Energy Asia. Greenhouse Gas Emissions from Biodiesel Production in Indonesia Based on Life Cycle Analysis. 2019. Available online: https://tractionenergy.asia/ (accessed on 2 June 2024).

- RSPO. Cultivating Sustainability for People and Planet. 2023. Available online: https://rspo.org/ (accessed on 5 June 2024).

- ISCC. Solutions for Sustainable and Deforestation. 2023. Available online: https://www.iscc-system.org/ (accessed on 8 April 2024).

- GHG. We Set the Standards to Measure and Manage Emissions. 2023. Available online: https://ghgprotocol.org/ (accessed on 6 June 2024).

- Amri, N.N.; Anwar, S.; Jupesta, J.; Sahari, B. Differences in greenhouse gas emission calculation guidelines for palm oil and its implication on mitigation planning. IOP Conf. Ser. Earth Environ. Sci. 2023, 1266, 012066. [Google Scholar] [CrossRef]

- Walker, S.M.; McMurray, A.; Rinaldy, F.; Brown, K.; Karsiwulan, D. Compilation of Best Management Practices to Reduce Total Emissions from Palm Oil Production; Report to: Roundtable on Sustainable Palm Oil (RSPO); Winrock International: Little Rock, AR, USA, 2018. [Google Scholar]

- Fridrihsone, A.; Romagnoli, F.; Cabulis, U. Environmental Life Cycle Assessment of Rapeseed and Rapeseed Oil Produced in Northern Europe: A Latvian Case Study. Sustainability 2020, 12, 5699. [Google Scholar] [CrossRef]

- Malça, J.; Freire, F. Uncertainty analysis in biofuel systems: An application to the life cycle of rapeseed oil. J. Ind. Ecol. 2010, 14, 322–334. [Google Scholar] [CrossRef]

- Poorter, L.; Bongers, F.; Aide, T.M.; Almeyda Zambrano, A.M.; Balvanera, P.; Becknell, J.M.; Boukili, V.; Brancalion, P.H.; Broadbent, E.N.; Chazdon, R.L.; et al. Biomass resilience of neotropical secondary forests. Nature 2016, 530, 211–214. [Google Scholar] [CrossRef] [PubMed]

- Bernal, B.; Murray, L.T.; Pearson, T.R.H. Global carbon dioxide removal rates from forest landscape restoration activities. Carbon Balance Manag. 2018, 13, 22. [Google Scholar] [CrossRef] [PubMed]

- SNI ISO 14040:2016; Code for Environmental Management—Life Cycle Assesment. Guideline for LCA Reporting. Directorate General of Pollution and Environmental Damage Control, Ministry of Environment and Forestry, Indonesia: Jakarta, Indonesia. ISO: Geneva, Switzerland, 2021.

- Guillaume, T.; Kotowska, M.M.; Hertel, D.; Knohl, A.; Krashevska, V.; Murtilaksono, K.; Scheu, S.; Kuzyakov, Y. Carbon costs and benefits of Indonesian rainforest conversion to plantations. Nat. Commun. 2018, 9, 2388. [Google Scholar] [CrossRef] [PubMed]

- Khasanah, N.; van Noordwijk, M.; Ningsih, H. Aboveground carbon stocks in oil palm plantations and the threshold for carbon-neutral vegetation conversion on mineral soils. Cogent Environ. Sci. 2015, 1, 1119964. [Google Scholar] [CrossRef]

- Khasanah, N.; van Noordwijk, M.; Ningsih, H.; Rahayu, S. Carbon neutral? No change in mineral soil carbon stock under oil palm plantations derived from forest or non-forest in Indonesia. Agric. Ecosyst. Environ. 2015, 211, 195–206. [Google Scholar] [CrossRef]

- IPCC (Intergovernmental Panel on Climate Change). N2O emissions from managed soils and CO2 emissions from lime and urea application. In IPCC Guidelines for National Greenhouse Gas Inventories; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Institute for Global Environmental Strategies: Hayama, Japan, 2006; Volume 4. [Google Scholar]

- Thamsiriroj, T.; Murphy, J.D. Is it better to import palm oil from Thailand to produce biodiesel in Ireland than to produce biodiesel from indigenous Irish rape seed? Appl. Energy 2009, 86, 595–604. [Google Scholar] [CrossRef]

- Chase, L.D.C.; Henson, I.E. A detailed greenhouse gas budget for palm oil production. Int. J. Agric. Sustain. 2010, 8, 199–214. [Google Scholar] [CrossRef]

- Choo, Y.M.; Muhamad, H.; Hashim, Z.; Subramaniam, V.; Puah, C.W.; Tan, Y.A. Determination of GHG contributions by subsystems in the oil palm supply chain using the LCA approach. Int. J. Life Cycle Assess. 2011, 16, 669–681. [Google Scholar] [CrossRef]

- Schmidt, J. Life Cycle Assessment of Rapeseed Oil and Palm Oil. Ph.D. Thesis, Department of Planning and Development, Aalborg University, Aalborg, Denmark, 2007. [Google Scholar]

- Aziz, N.I.H.A.; Hanafiah, M.M. Life cycle analysis of biogas production from anaerobic digestion of palm oil mill effluent. Renew. Energy 2019, 145, 847–857. [Google Scholar] [CrossRef]

- Brinkman Consultancy. Greenhouse Gas Emissions from Palm Oil Production Literature Review and Proposals from the RSPO Working Group on Greenhouse Gases; Final Report 2009; RSPO: Kuala Lumpur, Malaysia, 2009. [Google Scholar]

- Hong, W.O. Review on Carbon Footprint of the Palm Oil Industry: Insights into Recent Developments. Int. J. Sustain. Dev. Plan. 2023, 18, 447–455. [Google Scholar] [CrossRef]

- Stiegler, C.; Koebsch, F.; Ali, A.A.; June, T.; Veldkamp, E.; Corre, M.D.; Koks, J.; Tjoa, A.; Knohl, A. Temporal variation in nitrous oxide (N2O) fluxes from an oil palm plantation in Indonesia: An ecosystem-scale analysis. Bioenergy 2023, 15, 1221–1239. [Google Scholar] [CrossRef]

- Iriarte, A.; Rieradevall, J.; Gabarrell, X. Life cycle assessment of sunflower and rapeseed as energy crops under Chilean conditions. J. Clean. Prod. 2010, 18, 336–345. [Google Scholar] [CrossRef]

- El Bassam, N. Handbook of Bioenergy Crops: A Complete Reference to Species, Development, 1st ed.; Earthscan: London, UK, 2010. [Google Scholar]

- Arthey, T. Challenges and Perspectives in Global Rapeseed Production; Agri-Benchmark: Braunschweig, Germany, 2020. [Google Scholar]

- Marinussen, M.; van Kernebeek, H.; Broekema, R.; Groen, E.; Kool, A.; van Zeist, W.J.; Dolman, M.; Blonk, H. LCI Data for the Calculation Tool Feedprint for Greenhouse Gas Emissions of Feed Production and Utilization Cultivation Oil Seeds and Oil Fruits; Crushing Industry: Turkistan, Kazakhstan, 2012; p. 66. [Google Scholar]

- Richter, R. Prozesskosten in Ausgewählten Produktionsverfahren in Sachsen-Anhalt; Landesanstalt für Landwirtschaft und Gartenbau Sachsen-Anhalt: Bernburg, Germany, 2016. [Google Scholar]

- Statistische Ämter des Bundes und der Länder, Deutschland. 2023. Available online: https://www.statistikportal.de/en/node/106 (accessed on 7 April 2024).

- Malça, J.; Coelho, A.; Freire, F. Environmental life-cycle assessment of rapeseed-based biodiesel: Alternative cultivation systems and locations. Appl. Energy 2014, 114, 837–844. [Google Scholar] [CrossRef]

- Lachmann, N. Makronährstoffdüngung im Winterraps; RAPOOL-RING GmbH: Isernhagen, Germany, 2022; Available online: www.rapool.de (accessed on 6 May 2024).

- Dalgaard, R.; Schmidt, J.; Halberg, N.; Christensen, P.; Thrane, M.; Pengue, W.A. LCA of Soybean Meal. Int. J. LCA 2008, 13, 240–254. [Google Scholar] [CrossRef]

- Gupta, R.; McRoberts, R.; Yu, Z.; Smith, C.; Sloan, W.; You, S. Life cycle assessment of biodiesel production from rapeseed oil: Influence of process parameters. Bioresour. Technol. 2022, 360, 127532. [Google Scholar] [CrossRef]

- LfL [Bayerische Landesanstalt für Landwirtschaft]. Anbauempfehlungen für Winterraps; LfL: Freising, Germany, 2011; Available online: www.LfL.bayern.de (accessed on 6 June 2024).

- O’keeffe, S.; Majer, S.; Drache, C.; Franko, U.; Thran, D. Modelling biodiesel production within a regional context—A comparison with RED Benchmark. Renew. Energy 2017, 108, 355–370. [Google Scholar] [CrossRef]

- Poor, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2018, 360, 987–991. [Google Scholar] [CrossRef]

- Queiros, J.; Malça, J.; Freire, F. Environmental life-cycle assessment of rapeseed produced in Central Europe: Addressing alternative fertilization and management practices. J. Clean. Prod. 2015, 99, 266–274. [Google Scholar] [CrossRef]

- Available online: https://www.kws.com/de/de/beratung/bestandesfuehrung/duengung/duengung-raps/ (accessed on 9 April 2024).

- Silalertruksa, T.; Gheewala, S.H. Environmental sustainability assessment of palm biodiesel production in Thailand. Energy 2012, 43, 306–314. [Google Scholar] [CrossRef]

- Larson, E. A review of life-cycle analysis studies on liquid biofuel systems for the transport sector. Energy Sustain. Dev. 2006, 10, 109–126. [Google Scholar] [CrossRef]

- Schmidt, J.; De Rosa, M. Certified palm oil reduces greenhouse gas emissions compared to non-certified. J. Clean. Prod. 2020, 277, 124045. [Google Scholar] [CrossRef]

- Ramirez-Contreras, N.E.; Munar-Florez, D.A.; Garcia-Nunez, J.A.; Mosquera-Montoya, M.; Faaij, A.P.C. The GHG emissions and economic performance of the Colombian palm oil sector; current status and long-term perspectives. J. Clean. Prod. 2020, 258, 120757. [Google Scholar] [CrossRef]

- Tiong, L.G.; Cai, H. Calculating GHG Emission in Oil Palm Using PalmGHG. Planter 2017, 93, 167–276. [Google Scholar]

- Meijide, A.; de la Rua, C.; Guillaume, T.; Röll, A.; Hassler, E.; Stiegler, C.; Knohl, A. Measured greenhouse gas budgets challenge emission savings from palm-oil biodiesel. Nat. Commun. 2020, 11, 1089. [Google Scholar] [CrossRef]

| Area Equivalent (ha) | Biogenic Carbon for an Area Equivalent | C Stock Change from Native to Oil Crop | t CO2eq t−1 Oil (Amortized to 100 Years) | |||

|---|---|---|---|---|---|---|

| Oil Crop (t C) | Native Land Use (t C ha−1) | t C ha−1 | t C t−1 Oil | kg CO2-eq kg−1 Oil | ||

| a | b | c | d = (c − b) × a | e = d/3.6 | f = e × 3.66 | f/100 |

| 1 | 77 g1 (Oil palm) | 34.4 (Shrub) g2 | −42.6 | −11.8 | −43.18 | −0.43 |

| 230 g3 (Tropical forest) | 153 | 42.5 | 155.6 | 1.56 | ||

| 230 g3 + 1200 h (Peat swamp forest) | 1353 | 375.8 | 1375.5 | 13.76 | ||

| 2.6 i | 5 j (Rapeseed) | 84 (Temperate forest) k | 205.4 | 57.1 | 209 | 2.09 |

| 6.8 (Grassland) l | 4.68 | 1.3 | 4.76 | 0.05 | ||

| Component | Description | Average (min–max) | Sources |

|---|---|---|---|

| Yield | FFB | 22,000 (18,000–26,000) | Field survey |

| CPO | 4400 (3760–5320) | Field survey | |

| RPO | 3960 (3380–4790) | Field survey | |

| PKO | 560 (480–680) | Field survey | |

| Pome | 14,960 (1090–15,430) | ||

| Fuel | Plantation machinery | 65 (40–89) | [31] (55 kg); [32] (89 kg); [33] (40 kg) |

| Cultivation | N | 154 (123–185) | Field survey |

| P as P2O5 | 81 (65–97) | Field survey | |

| K as K2O | 190 (152−228) | Field survey | |

| Herbicide | 2.0 (1.6–2.4) | Field survey | |

| Mg as MgO | 52.0(41.6–62.4) | Field survey | |

| Refinery | Bleaching earth | 17.8 | [34] |

| NaOH | 11.5 | [34] | |

| Phosphoric acid | 0.9 | [34] | |

| Heat (steam) | 1298.8 MJ | [34] | |

| Electricity | 138.6 KWh | [34] | |

| Fuel-Product Transport | 10t truck (farm to mill) | 31.6 | [16] |

| 30t truck (mill to refinery) | 5.5 | [16] | |

| 2400t ship to EU | 415 | [31] | |

| Emission to air | CH4 | 122.4 | [33] (11.9 kg CH4/t POME), [35] (9.9 kg CH4/t POME), [36] (625–1467 kg CO2/t CPO), [37] (637–1131 kg CO2/t CPO); [16] (436 kg CO2/t CPO) |

| N2O | 3.2 | [38] |

| Component | Description | Average (min–max) | References |

|---|---|---|---|

| Yield | Seed | 3750 (3000–4500) | (1) [43] (Germany; 3.79 tons seed); (2) [44] (3.98 ton seed) (3) [31] (Ireland: 4.11 ton seed) (4) [45] (3.75 ton seed); |

| CRO | 1500 (1200–1800) | ||

| Meal | 2250 (1800–2700) | [45] (60% meal–40% Oil) | |

| Cultivation | N | 175 (130–220) | (1) Field Survey (Germany; N = 160 kg; K = 40 kg); (2) [46] (Germany; N = 130 kg ha−1. K = 50 kg ha−1, P = 135 kg; S = 30 kg) (3) [43] (Germany; N = 175 kg); (4) [41] (Germany; N = 208 kg); (5) [47] (N = 167 kg, P = 24 kg, K = 77 kg) (6) [22] (Latvia; N = 220 kg ha−1, P2O5 = 61 kg ha−1, K2O ha−1 = 129 kg; S = 59 kg) (7) [22] (Latvia; N = 220 kg/ha, P2O5 = 61 kg ha−1, K2O ha−1 = 129 kg) (8) [48] (UK; N = 135 kg ha−1, P2O5 = 72 kg ha−1, K2O = 62 kg; S = 63 kg) (9) [49] 2011 (N = 210 kg) (10) [45] (Germany; N = 153 kg, P2O5 = 44 kg ha−1, K2O ha−1 = 33 kg) (11) [50] (N = 176 kg, P = 63 kg (12) [51] (2018) (N = 176 kg) (13) [52] (Germany; N = 155 kg, P2O5 = 44 kg ha−1, K2O ha−1 = 92 kg) (14) [53] (15) [34] (N = 140 kg, P = 57 kg, K = 99 kg) |

| P as P2O5 | 71 (24–117) | ||

| K as K2O | 82 (33–130) | ||

| S | 47 (30–63) | ||

| Pesticide | 2.5 (2–3.4) | Field Survey Germany; [22,48] (3.4 L). | |

| Emission to air | N2O | 1.9 (1.7–2.0) | [31] (1.7 kg); [22] (1.73 kg) |

| Fuel (Traction) | Agricultural machinery | 82 (41–122) | [31] (99 kg); [45] (Germany; 80 kg); [52] (57 kg), [22] (41 kg), [48] UK: 122 kg); [52] (70 kg) |

| Mill (drying and pressing) | 37 (18–55) | [31] (55 kg); [48] (24.4 kg); [22] (18 kg); [45] (34 kg); [52] (32 kg); [34] (18 kg) | |

| Transport | 24 t tuck fuel from farm to mill/refinery | 33.7(26.9–40.4) | [22] |

| Material Use Refinery | Bleaching earth | 13.50 | [34] |

| NaOH | 3.2 | [34] | |

| Phosphoric acid | 1.2 | [34] | |

| Sulphuric acid | 2.9 | [34] | |

| Heat | 339 MJ | [34] (MJ) | |

| Electricity | 43.3 | [34] (KWh) | |

| NaoH | 20 (16–24) | [31] (16 kg); [54] (24 kg) | |

| Fuel | 32 |

| Product | Price (US $/t) | One Growing Cycle Oil Yield (t ha−1) | Allocation |

|---|---|---|---|

| Palm oil | 570 | 82 | 82% |

| Palm Kernel oil | 658 | 11 | 12% |

| Palm Kernel meal | 98 | 12 | 2% |

| Palm Fatty acid | 632 | 3.7 | 4% |

| Rapeseed oil | 840 | 0.6 | 70% |

| Rapeseed meal | 247 | 0.9 | 30% |

| LCA Components | Smallholder Palm Oil | Company Palm Oil | Rapeseed | |||||

|---|---|---|---|---|---|---|---|---|

| Non-Allocated | Allocated | Non-Allocated | Allocated | Non-Allocated | Allocated | |||

| Plantation | Fertilizer and herbicide | N | 367 | 300.9 | 370.9 | 304.1 | 1168 | 817.6 |

| N2O | 110 | 90.2 | 75.6 | 62.0 | 99.8 | 69.9 | ||

| P2O5 | 40.1 | 32.9 | 29.4 | 24.1 | 68.5 | 48.0 | ||

| K2O | 53.3 | 43.7 | 56.9 | 46.7 | 24.8 | 17.4 | ||

| Mg and Herbicide | 16.9 | 13.9 | 11.5 | 9.4 | 14.4 | 10.1 | ||

| Fuel | 15.3 | 12.5 | 13.2 | 10.8 | 33.1 | 23.2 | ||

| Sub-Total | 602.6 | 494.1 | 557.5 | 457.2 | 1408.6 | 986.0 | ||

| Mill | Fuel | 4.3 | 3.5 | 1 | 0.8 | 25.4 | 17.8 | |

| POME | CH4 | 436 | 357.5 | 436 | 357.5 | 0 | 0.0 | |

| Sub-Total | 440.3 | 361.0 | 437 | 358.3 | 25.4 | 17.8 | ||

| Refinery | Chemical | 4.5 | 3.7 | 4.4 | 3.6 | 4.1 | 2.9 | |

| Electricity | 36.1 | 29.6 | 36.1 | 29.6 | 29.8 | 20.9 | ||

| Heat | 38.5 | 31.6 | 38.6 | 31.7 | 26.6 | 18.6 | ||

| Sub-Total | 79.1 | 64.9 | 79.1 | 64.9 | 60.5 | 42.4 | ||

| Shipment | 82.9 | 68.0 | 56.5 | 46.3 | 0 | 0.0 | ||

| Total | 1122 | 920 | 1073.6 | 880.4 | 1494.5 | 1046.2 | ||

| Data Input Variation | ||||||

|---|---|---|---|---|---|---|

| Fertilizer N | N2O Emission | |||||

| ±10% | ±15% | ±20% | ±10% | ±15% | ±20% | |

| Smallholder oil palm | ±37 | ±56 | ±74 | ±11 | ±17 | 22 |

| Big company oil palm | ±37 | ±56 | ±74 | ±7 | ±11 | 14 |

| Rapeseed | ±120 | ±175 | ±230 | ±10 | ±15 | 20 |

| Oil Palm Company | Emission (t CO2eq t−1 Oil) | Method | Source |

|---|---|---|---|

| V | 0.49 | PalmGHG Calculator | [16] (p. 12;20;36) |

| W | 0.40 | PalmGHG Calculator | [16] (p. 13;20;36) |

| Y | 0.54 | PalmGHG Calculator | [16] (p. 15;20;36) |

| Z | 0.34 | PalmGHG Calculator | [16] (p. 17;20;36) |

| This study | 0.56 | LCA SIMAPRO | Table 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tarigan, S.; Pradiko, I.; Darlan, N.H.; Kristanto, Y. Carbon Footprint Comparison of Rapeseed and Palm Oil: Impact of Land Use and Fertilizers. Sustainability 2025, 17, 1521. https://doi.org/10.3390/su17041521

Tarigan S, Pradiko I, Darlan NH, Kristanto Y. Carbon Footprint Comparison of Rapeseed and Palm Oil: Impact of Land Use and Fertilizers. Sustainability. 2025; 17(4):1521. https://doi.org/10.3390/su17041521

Chicago/Turabian StyleTarigan, Suria, Iput Pradiko, Nuzul H. Darlan, and Yudha Kristanto. 2025. "Carbon Footprint Comparison of Rapeseed and Palm Oil: Impact of Land Use and Fertilizers" Sustainability 17, no. 4: 1521. https://doi.org/10.3390/su17041521

APA StyleTarigan, S., Pradiko, I., Darlan, N. H., & Kristanto, Y. (2025). Carbon Footprint Comparison of Rapeseed and Palm Oil: Impact of Land Use and Fertilizers. Sustainability, 17(4), 1521. https://doi.org/10.3390/su17041521