Transforming Livestock and Aquaculture Waste into Renewable Energy and Materials—A Review

Abstract

1. Introduction

2. Methods

3. Waste Sources, Quantification, and Characterization

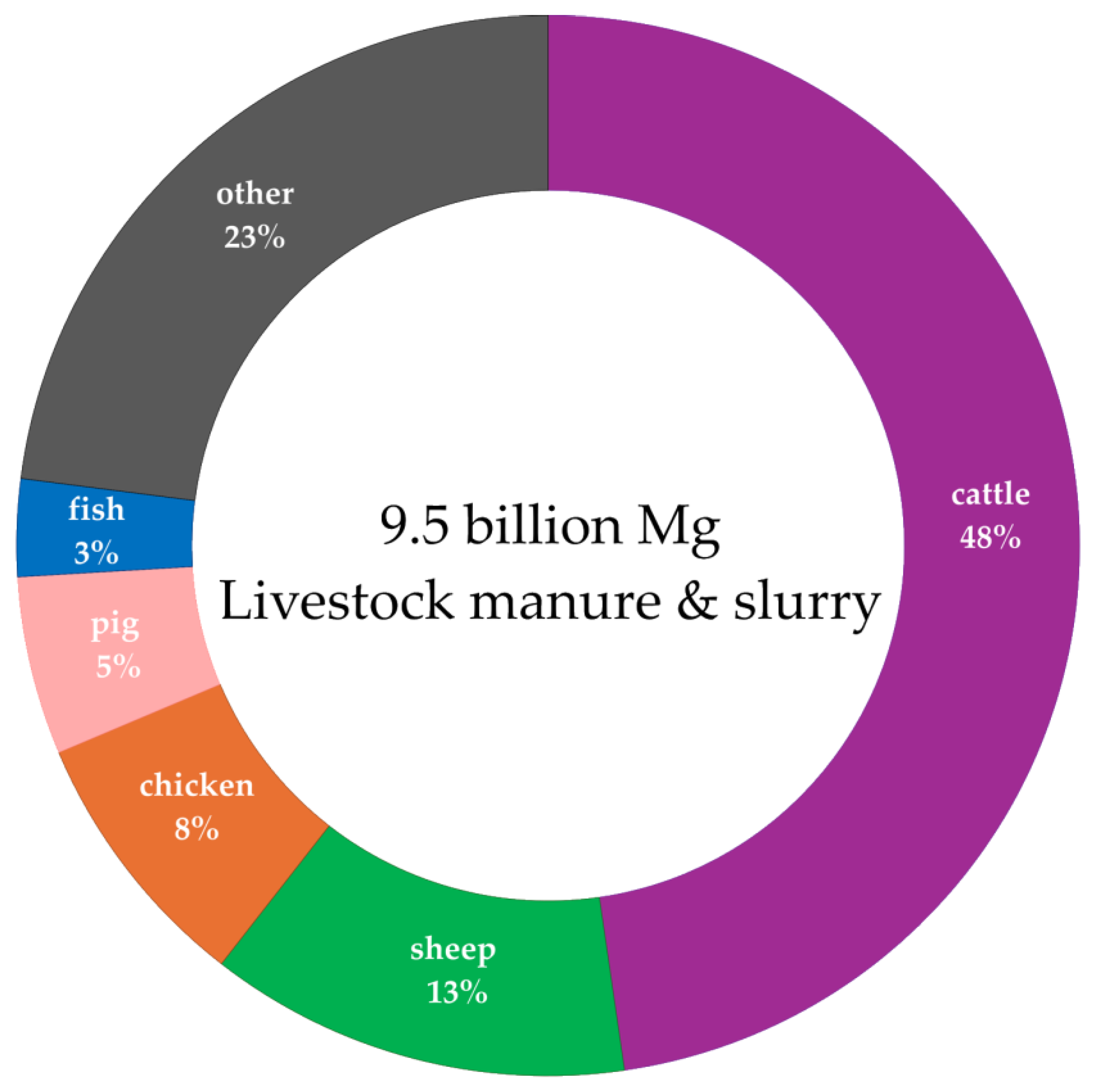

3.1. Manure, Slurry, and Sludge

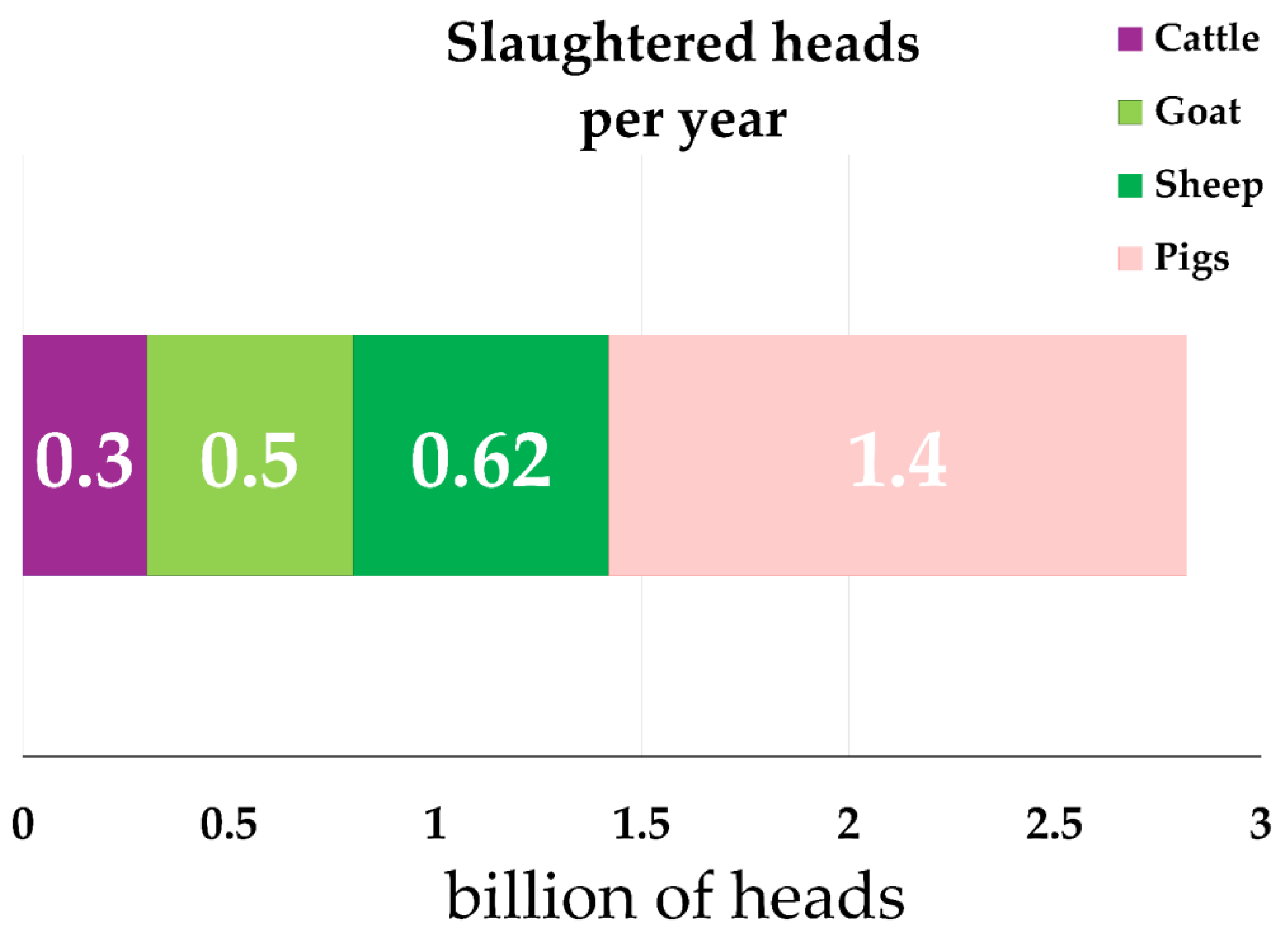

3.2. Waste and Wastewater from Slaughterhouses and Seafood Processing

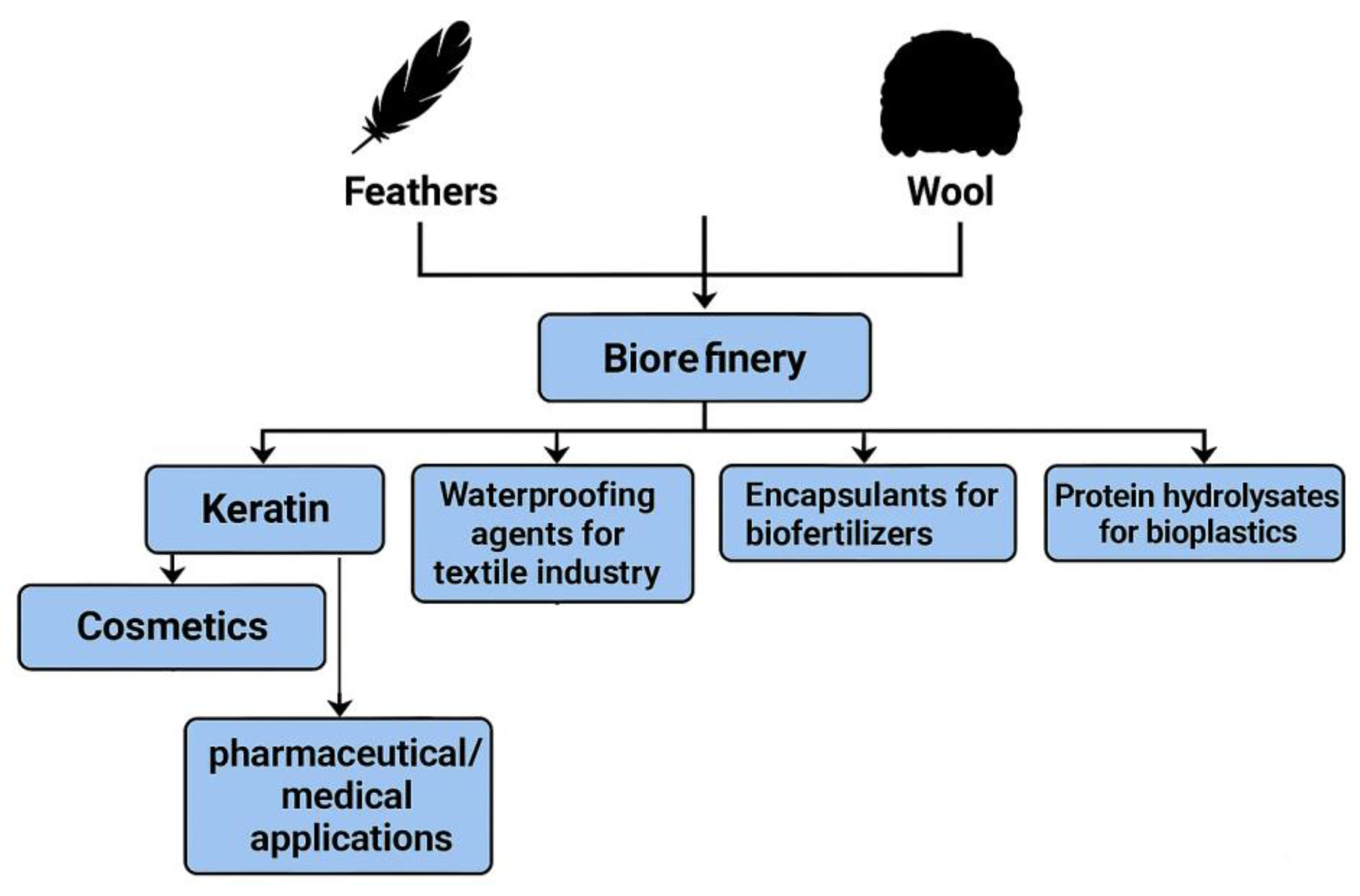

3.3. Feathers and Wool

4. Strategies, Limitations, and Challenges

4.1. Livestock Waste (Manure, Slurry, Sludge, and AWW)

4.2. Slaughterhouse Waste

4.3. Strategies to Produce Energy from Waste

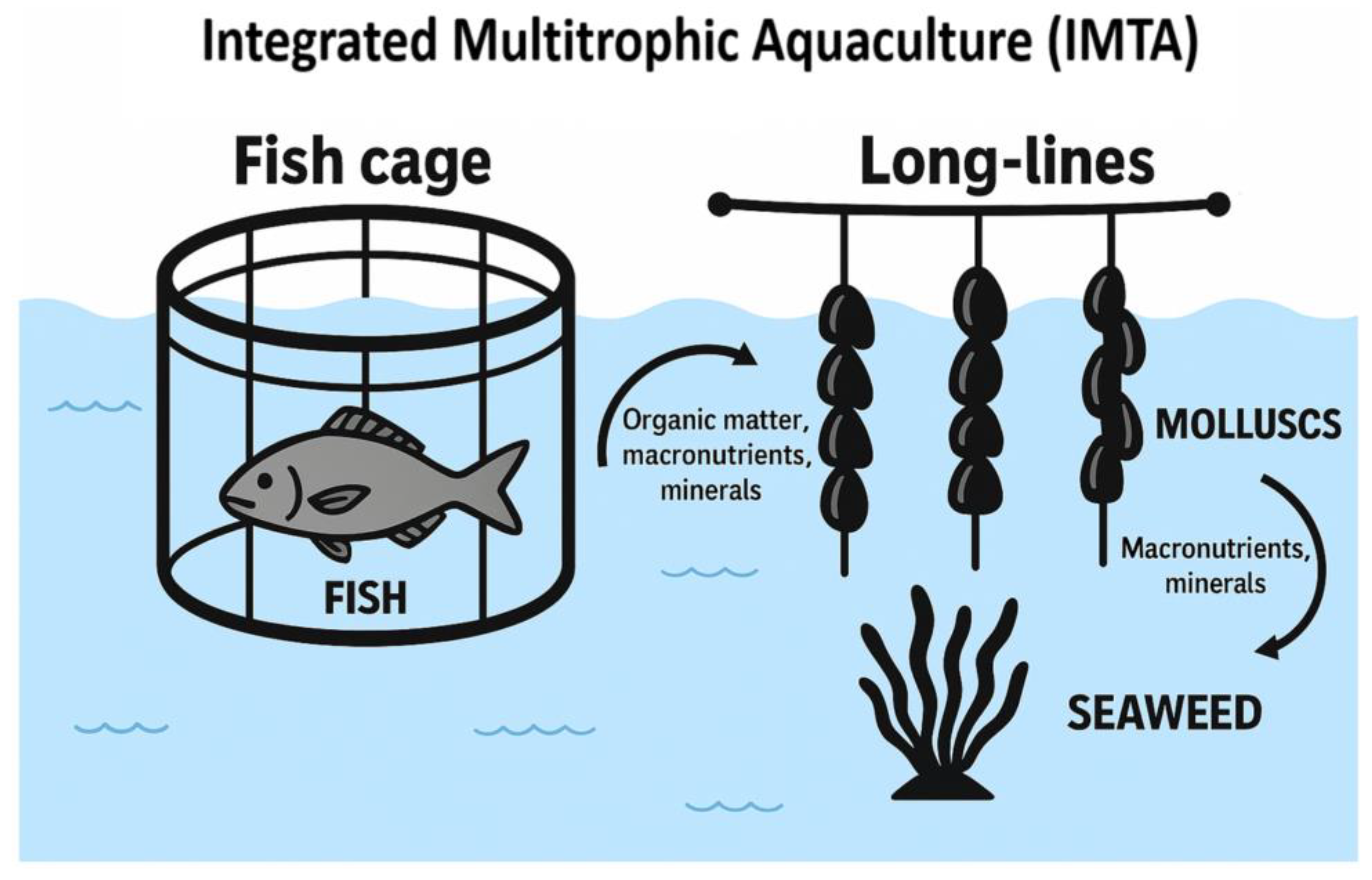

4.4. Strategies to Reduce Waste in Aquaculture

5. Opportunities

5.1. Biorefining of Feathers and Wool

5.2. Rendering and Feed Production

5.3. Microalgae

5.4. Phytoremediation

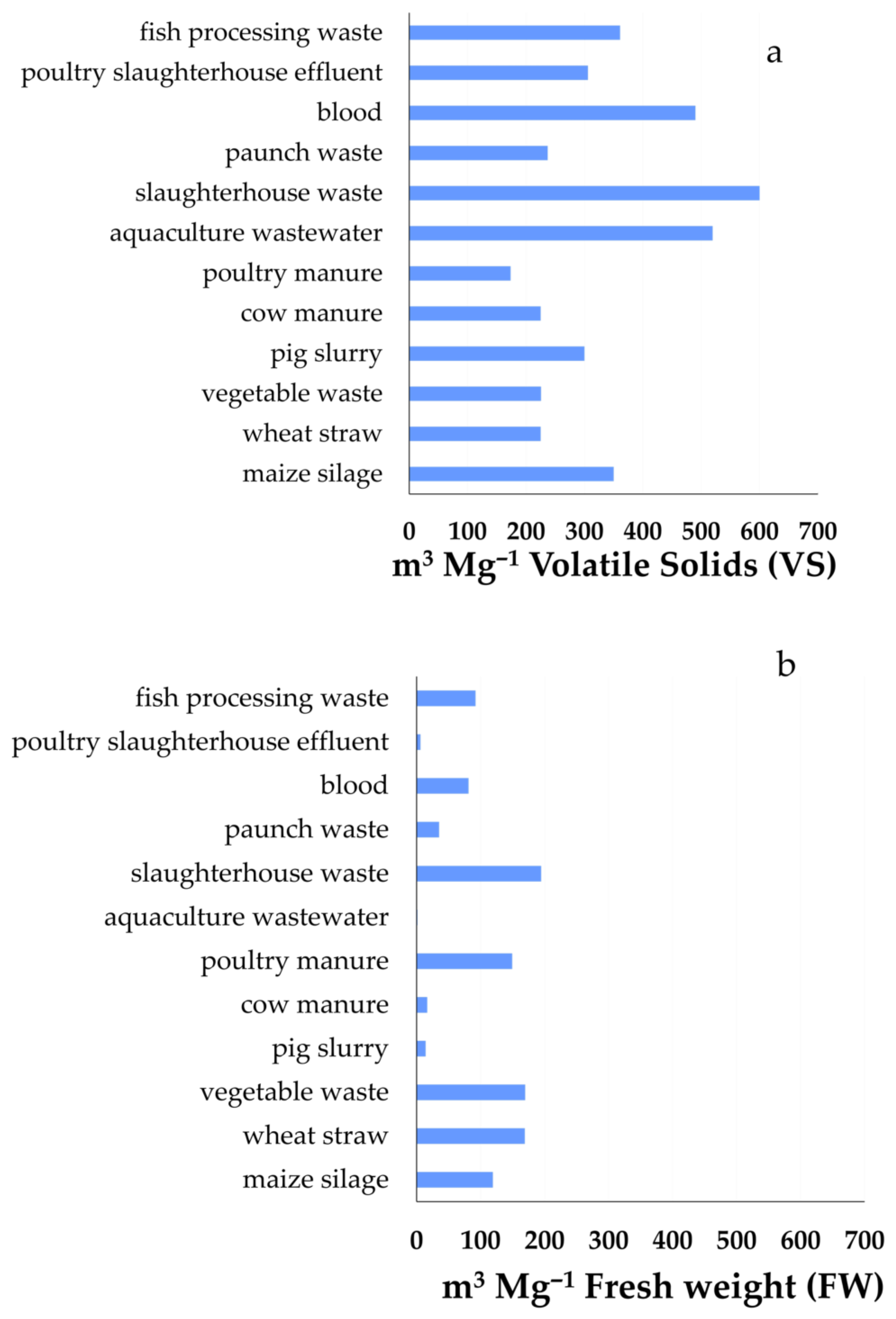

5.5. Anaerobic Digestion

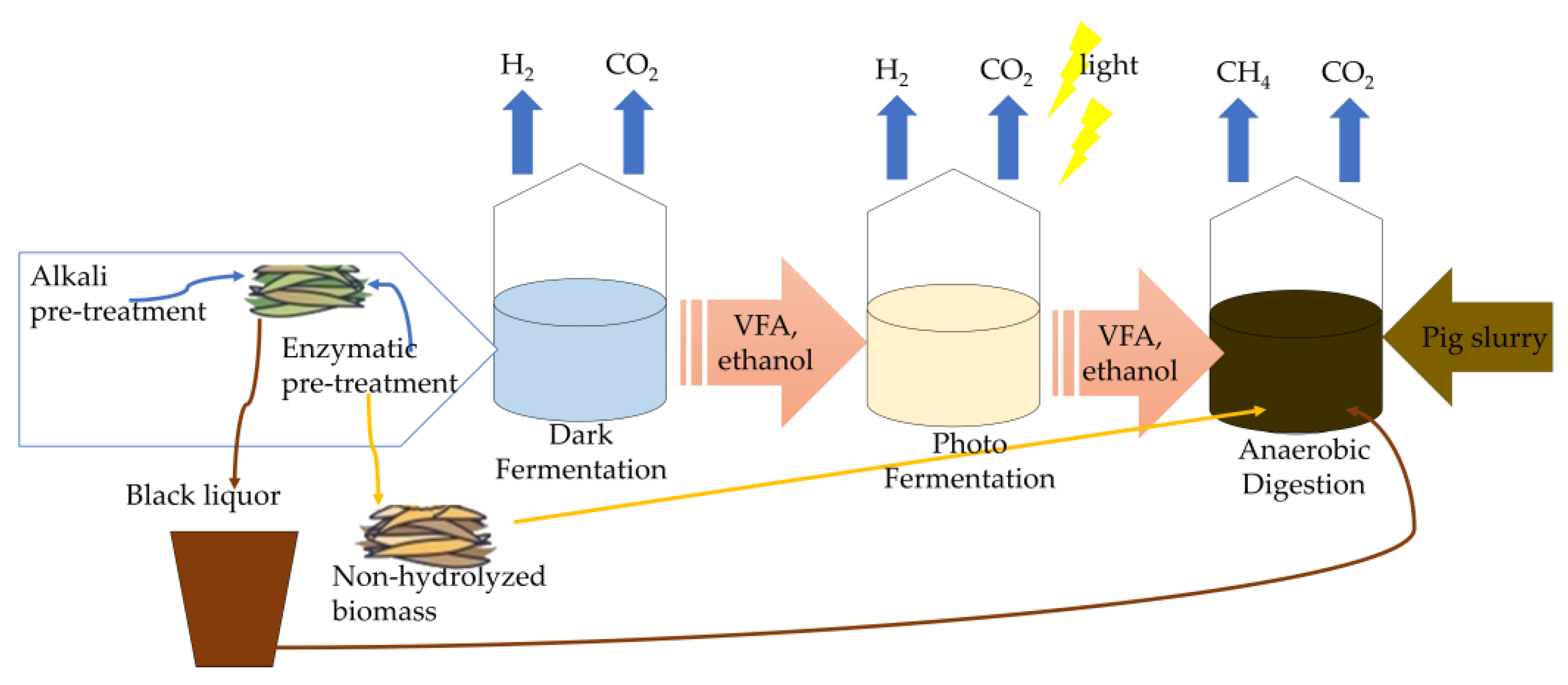

6. Integrated Biorefinery Approach to Enhance Circular Economy

6.1. Digestate Valorization

6.1.1. Membrane Filtration to Recover Renewable NPK

6.1.2. Vermicompost

6.1.3. Insect Compost

6.2. Extracellular Polymeric Substances

6.3. Microcellulose and Nanolignin

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, H.; Li, X.; Wu, S.; Yang, C. Sustainable Livestock Wastewater Treatment via Phytoremediation: Current Status and Future Perspectives. Bioresour. Technol. 2020, 315, 123809. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Mehariya, S.; Bhatia, R.K.; Kumar, M.; Pugazhendhi, A.; Awasthi, M.K.; Atabani, A.E.; Kumar, G.; Kim, W.; Seo, S.O.; et al. Wastewater Based Microalgal Biorefinery for Bioenergy Production: Progress and Challenges. Sci. Total Environ. 2021, 751, 141599. [Google Scholar] [CrossRef]

- Agga, G.E.; Couch, M.; Parekh, R.R.; Mahmoudi, F.; Appala, K.; Kasumba, J.; Loughrin, J.H.; Conte, E.D. Lagoon, Anaerobic Digestion, and Composting of Animal Manure Treatments Impact on Tetracycline Resistance Genes. Antibiotics 2022, 11, 391. [Google Scholar] [CrossRef]

- Ahmad, A.; Sheikh Abdullah, S.R.; Hasan, H.A.; Othman, A.R.; Ismail, N. Aquaculture Industry: Supply and Demand, Best Practices, Effluent and Its Current Issues and Treatment Technology. J. Environ. Manag. 2021, 287, 112271. [Google Scholar] [CrossRef]

- Qi, J.; Yang, H.; Wang, X.; Zhu, H.; Wang, Z.; Zhao, C.; Li, B.; Liu, Z. State-of-the-Art on Animal Manure Pollution Control and Resource Utilization. J. Environ. Chem. Eng. 2023, 11, 110462. [Google Scholar] [CrossRef]

- FAO. The State of World Fisheries and Aquaculture 2024; FAO: Rome, Italy, 2024. [Google Scholar] [CrossRef]

- FAO. Fishery and Aquaculture Statistics—Yearbook 2023; FAO: Rome, Italy, 2025. [Google Scholar] [CrossRef]

- FAO. Estimating Global and Country—Level Employment in Agrifood Systems; FAO: Rome, Italy, 2023. [Google Scholar] [CrossRef]

- Springmann, M.; Clark, M.; Mason-D’Croz, D.; Wiebe, K.; Bodirsky, B.L.; Lassaletta, L.; de Vries, W.; Vermeulen, S.J.; Herrero, M.; Carlson, K.M.; et al. Options for Keeping the Food System within Environmental Limits. Nature 2018, 562, 519–525. [Google Scholar] [CrossRef] [PubMed]

- Tom, A.P.; Jayakumar, J.S.; Biju, M.; Somarajan, J.; Ibrahim, M.A. Aquaculture Wastewater Treatment Technologies and Their Sustainability: A Review. Energy Nexus 2021, 4, 100022. [Google Scholar] [CrossRef]

- Paolacci, S.; Stejskal, V.; Toner, D.; Jansen, M.A.K. Wastewater Valorisation in an Integrated Multitrophic Aquaculture System; Assessing Nutrient Removal and Biomass Production by Duckweed Species. Environ. Pollut. 2022, 302, 119059. [Google Scholar] [CrossRef]

- Gephart, J.A.; Henriksson, P.J.G.; Parker, R.W.R.; Shepon, A.; Gorospe, K.D.; Bergman, K.; Eshel, G.; Golden, C.D.; Halpern, B.S.; Hornborg, S.; et al. Environmental Performance of Blue Foods. Nature 2021, 597, 360–365. [Google Scholar] [CrossRef]

- Poore, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Liu, H.; Zhang, Y.; Zhou, Q.; Wen, X.; Guo, W.; Zhang, Z. A Systematic Review on Aquaculture Wastewater: Pollutants, Impacts, and Treatment Technology. Environ. Res. 2024, 262, 119793. [Google Scholar] [CrossRef] [PubMed]

- Camilli, F.; Focacci, M.; Dal Prà, A.; Bortolu, S.; Ugolini, F.; Vagnoni, E.; Duce, P. Turning Waste Wool into a Circular Resource: A Review of Eco-Innovative Applications in Agriculture. Agronomy 2025, 15, 446. [Google Scholar] [CrossRef]

- Ramirez, J.; McCabe, B.; Jensen, P.D.; Speight, R.; Harrison, M.; Van Den Berg, L.; O’Hara, I. Wastes to Profit: A Circular Economy Approach to Value-Addition in Livestock Industries. Anim. Prod. Sci. 2021, 61, 541–550. [Google Scholar] [CrossRef]

- Jensen, P.D.; Mehta, C.M.; Carney, C.; Batstone, D.J. Recovery of Energy and Nutrient Resources from Cattle Paunch Waste Using Temperature Phased Anaerobic Digestion. Waste Manag. 2016, 51, 72–80. [Google Scholar] [CrossRef]

- Midolo, G.; Porto, S.M.C.; Cascone, G.; Valenti, F. Sheep Wool Waste Availability for Potential Sustainable Re-Use and Valorization: A GIS-Based Model. Agriculture 2024, 14, 872. [Google Scholar] [CrossRef]

- Parlato, M.C.M.; Valenti, F.; Midolo, G.; Porto, S.M.C. Livestock Wastes Sustainable Use and Management: Assessment of Raw Sheep Wool Reuse and Valorization. Energies 2022, 15, 3008. [Google Scholar] [CrossRef]

- Rodríguez-Alegre, R.; Zapata-Jiménez, J.; You, X.; Pérez-Moya, M.; Sanchis, S.; García-Montaño, J. Nutrient Recovery and Valorisation from Pig Slurry Liquid Fraction with Membrane Technologies. Sci. Total Environ. 2023, 874, 162548. [Google Scholar] [CrossRef]

- Gama Pantoja, L.S.; Amante, E.R.; Manoel da Cruz Rodrigues, A.; Meller da Silva, L.H. World Scenario for the Valorization of Byproducts of Buffalo Milk Production Chain. J. Clean. Prod. 2022, 364, 132605. [Google Scholar] [CrossRef]

- Zhuang, M.; Shan, N.; Wang, Y.; Caro, D.; Fleming, R.M.; Wang, L. Different Characteristics of Greenhouse Gases and Ammonia Emissions from Conventional Stored Dairy Cattle and Swine Manure in China. Sci. Total Environ. 2020, 722, 137693. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Xu, R.; Canadell, J.G.; Thompson, R.L.; Winiwarter, W.; Suntharalingam, P.; Davidson, E.A.; Ciais, P.; Jackson, R.B.; Janssens-Maenhout, G.; et al. A Comprehensive Quantification of Global Nitrous Oxide Sources and Sinks. Nature 2020, 586, 248–256. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Available online: https://www.epa.gov/moves/how-do-i-get-carbon-dioxide-equivalent-co2e-results-nonroad-equipment (accessed on 14 November 2025).

- European Environment Agency. Available online: https://www.eea.europa.eu/en/analysis/indicators/greenhouse-gas-emissions-from-agriculture?activeAccordion=309c5ef9-de09-4759-bc02-802370dfa366 (accessed on 14 November 2025).

- Al-Wabel, M.I.; Almutari, M.M.; Ahmad, M.; Al-Swadi, H.A.; Ahmad, J.; Al-Farraj, A.S.F. Impacts of Aquaculture Wastewater Irrigation on Soil Health, Nutrient Availability, and Date Palm Fruit Quality. Sci. Rep. 2024, 14, 18634. [Google Scholar] [CrossRef]

- Prado, J.; Ribeiro, H.; Alvarenga, P.; Fangueiro, D. A Step towards the Production of Manure-Based Fertilizers: Disclosing the Effects of Animal Species and Slurry Treatment on Their Nutrients Content and Availability. J. Clean. Prod. 2022, 337, 130369. [Google Scholar] [CrossRef]

- Ackefors, H.; Enell, M. The Release of Nutrients and Organic Matter from Aquaculture Systems in Nordic Countries. J. Appl. Ichthyol. 1994, 10, 225–241. [Google Scholar] [CrossRef]

- Coêlho, Y.R.; Silva, S.d.Q.; Aquino, S.F.d. Anaerobic Co-Digestion of Poultry Litter and Poultry Slaughterhouse Effluent in an Anaerobic Sequencing Fed-Batch Reactor. J. Environ. Chem. Eng. 2025, 13, 118677. [Google Scholar] [CrossRef]

- Piedrahita, R.H. Reducing the Potential Environmental Impact of Tank Aquaculture Effluents through Intensification and Recirculation. Aquaculture 2003, 226, 35–44. [Google Scholar] [CrossRef]

- Dalbem Barbosa, A.P.; Kosten, S.; Muniz, C.C.; Oliveira-Junior, E.S. From Feed to Fish—Nutrients’ Fate in Aquaculture Systems. Appl. Sci. 2024, 14, 6056. [Google Scholar] [CrossRef]

- Kadam, R.; Jo, S.; Lee, J.; Khanthong, K.; Jang, H.; Park, J. A Review on the Anaerobic Co-Digestion of Livestock Manures in the Context of Sustainable Waste Management. Energies 2024, 17, 546. [Google Scholar] [CrossRef]

- Carpanez, T.G.; Moreira, V.R.; Silva, J.B.G.; Otenio, M.H.; Amaral, M.C.S. Membranes for Nutrient Recovery from Waste and Production of Organo-Mineral Fertilizer in the Context of Circular Economy. Water Res. 2025, 288, 124560. [Google Scholar] [CrossRef]

- Chuenchart, W.; Timilsina, A.P.; Ge, J.; Shah, A. Advances in Biorefinery of Cattle Manure for Value-Added Products. Fermentation 2024, 10, 568. [Google Scholar] [CrossRef]

- Babaee, A.; Shayegan, J.; Roshani, A. Anaerobic Slurry Co-Digestion of Poultry Manure and Straw: Effect of Organic Loading and Temperature. J. Environ. Health Sci. Eng. 2013, 11, 15. [Google Scholar] [CrossRef]

- Vasmara, C.; Marchetti, R. Biogas Production from Biodegradable Bioplastics. Environ. Eng. Manag. J. 2016, 15, 2041–2048. [Google Scholar] [CrossRef]

- Marchetti, R.; Vasmara, C. Co-Digestion of Deproteinized Dairy Waste with Pig Slurry: Effect of Recipe and Initial PH on Biogas and Volatile Fatty Acid Production. Bioenergy Res. 2020, 13, 643–658. [Google Scholar] [CrossRef]

- Marchetti, R.; Vasmara, C.; Florio, G.; Borin, M. Biomethanation Potential of Wetland Biomass in Codigestion with Pig Slurry. Waste Biomass Valorization 2016, 7, 1081–1089. [Google Scholar] [CrossRef]

- Marchetti, R.; Vasmara, C.; Orsi, A. Inoculum Production from Pig Slurry for Potential Use in Agricultural Biogas Plants. Sustain. Energy Technol. Assess. 2022, 52, 102310. [Google Scholar] [CrossRef]

- Marchetti, R.; Vasmara, C.; Fiume, F. Pig Slurry Improves the Anaerobic Digestion of Waste Cooking Oil. Appl. Microbiol. Biotechnol. 2019, 103, 8267–8279. [Google Scholar] [CrossRef] [PubMed]

- Vasmara, C.; Cianchetta, S.; Marchetti, R.; Galletti, S. Biogas Production from Wheat Straw Pre-Treated with Ligninolytic Fungi and Co-Digestion with Pig Slurry. Environ. Eng. Manag. J. 2015, 14, 1751–1760. [Google Scholar] [CrossRef]

- Vasmara, C.; Marchetti, R. Spent Coffee Grounds from Coffee Vending Machines as Feedstock for Biogas Production. Environ. Eng. Manag. J. 2018, 17, 2401–2408. [Google Scholar] [CrossRef]

- Vasmara, C.; Marchetti, R.; Cianchetta, S.; Galletti, S.; Ceotto, E. Enhancing Methane Yield From Giant Reed (Arundo donax L.) Through Thermo-Alkaline Pre-Treatment and Co-Digestion with Pig Slurry. In Proceedings of the 28th European Biomass Conference and Exhibition, Virtual, 28–30 April 2020. [Google Scholar] [CrossRef]

- Vasmara, C.; Orsi, A.; Bochicchio, D.; Ceotto, E. Multi-Feedstock Anaerobic Digestion to Enhance 2nd Generation Methane Production. In Proceedings of the 31st European Biomass Conference and Exhibition, Bologna, Italy, 5 June 2023. [Google Scholar] [CrossRef]

- da Borso, F.; Chiumenti, A.; Fait, G.; Mainardis, M.; Goi, D. Biomethane Potential of Sludges from a Brackish Water Fish Hatchery. Appl. Sci. 2021, 11, 552. [Google Scholar] [CrossRef]

- Mozhiarasi, V.; Natarajan, T.S. Slaughterhouse and Poultry Wastes: Management Practices, Feedstocks for Renewable Energy Production, and of Value Recovery Added Products. Biomass Convers. Biorefin. 2025, 15, 1705–1728. [Google Scholar] [CrossRef]

- Limeneh, D.Y.; Tesfaye, T.; Ayele, M.; Husien, N.M.; Ferede, E.; Haile, A.; Mengie, W.; Abuhay, A.; Gelebo, G.G.; Gibril, M.; et al. A Comprehensive Review on Utilization of Slaughterhouse By-Product: Current Status and Prospect. Sustainability 2022, 14, 6469. [Google Scholar] [CrossRef]

- Hejnfelt, A.; Angelidaki, I. Anaerobic Digestion of Slaughterhouse By-Products. Biomass Bioenergy 2009, 33, 1046–1054. [Google Scholar] [CrossRef]

- Pettersen, K.S.; Sele, V.; Araujo, P.; Belghit, I.; Benestad, S.L.; Bernhoft, A.; Booth, A.M.; Eriksen, G.S.; Farkas, J.; Handå, A.H.; et al. Fish Sludge as Feed in Circular Bioproduction: Overview of Biological and Chemical Hazards in Fish Sludge and Their Potential Fate via Ingestion by Invertebrates. Rev. Aquac. 2025, 17, e12996. [Google Scholar] [CrossRef]

- Dowd, B.; McDonnell, D.; Tuohy, M.G. Current Progress in Optimising Sustainable Energy Recovery from Cattle Paunch Contents, a Slaughterhouse Waste Product. Front. Sustain. Food Syst. 2022, 6, 722424. [Google Scholar] [CrossRef]

- FAOSTAT. Available online: https://www.fao.org/faostat/en/?#data/QCL/ (accessed on 14 November 2025).

- Al-Zohairi, S.; Knudsen, M.T.; Mogensen, L. Utilizing Animal By-Products in European Slaughterhouses to Reduce the Environmental Footprint of Pork Products. Sustain. Prod. Consum. 2023, 37, 306–319. [Google Scholar] [CrossRef]

- Li, J.P.; Healy, M.G.; Zhan, X.M.; Rodgers, M. Nutrient Removal from Slaughterhouse Wastewater in an Intermittently Aerated Sequencing Batch Reactor. Bioresour. Technol. 2008, 99, 7644–7650. [Google Scholar] [CrossRef]

- Gürel, L.; Büyükgüngör, H. Treatment of Slaughterhouse Plant Wastewater by Using a Membrane Bioreactor. Water Sci. Technol. 2011, 64, 214–219. [Google Scholar] [CrossRef]

- El Salamony, D.H.; Salah Eldin Hassouna, M.; Zaghloul, T.I.; Moustafa Abdallah, H. Valorization of Chicken Feather Waste Using Recombinant Bacillus Subtilis Cells by Solid-State Fermentation for Soluble Proteins and Serine Alkaline Protease Production. Bioresour. Technol. 2024, 393, 130110. [Google Scholar] [CrossRef] [PubMed]

- Islam, J.; Yap, E.E.S.; Krongpong, L.; Toppe, J.; Peñarubia, O.R. Fish waste management—An assessment of the potential production and utilization of fish silage in Bangladesh, Philippines and Thailand. FAO Fish. Aquac. Circ. 2021, 1216. [Google Scholar] [CrossRef]

- Duncan, S. National Programme of Action Atlantic Regional Team Management of Wastes from Atlantic Seafood Processing Operations-Final Report Re: FINAL REPORT-Management of Wastes from Atlantic Seafood Processing Operations National Programme of Action-Atlantic Regional Team. 2003. Available online: https://p2infohouse.org/ref/42/41590.pdf (accessed on 14 November 2025).

- Arvanitoyannis, I.S.; Kassaveti, A. Fish Industry Waste: Treatments, Environmental Impacts, Current and Potential Uses. Int. J. Food Sci. Technol. 2008, 43, 726–745. [Google Scholar] [CrossRef]

- Love, D.C.; Fry, J.P.; Milli, M.C.; Neff, R.A. Wasted Seafood in the United States: Quantifying Loss from Production to Consumption and Moving toward Solutions. Glob. Environ. Change 2015, 35, 116–124. [Google Scholar] [CrossRef]

- Ingabire, H.; M’arimi, M.M.; Kiriamiti, K.H.; Ntambara, B. Optimization of Biogas Production from Anaerobic Co-Digestion of Fish Waste and Water Hyacinth. Biotechnol. Biofuels Bioprod. 2023, 16, 110. [Google Scholar] [CrossRef]

- Martínez-Alvarez, O.; Chamorro, S.; Brenes, A. Protein Hydrolysates from Animal Processing By-Products as a Source of Bioactive Molecules with Interest in Animal Feeding: A Review. Food Res. Int. 2015, 73, 204–212. [Google Scholar] [CrossRef]

- Sachindra, N.M.; Mahendrakar, N.S. Process Optimization for Extraction of Carotenoids from Shrimp Waste with Vegetable Oils. Bioresour. Technol. 2005, 96, 1195–1200. [Google Scholar] [CrossRef]

- Akhtar, N.A.; Kyzy, K.K.; Kobya, M.; Gengec, E. Operating cost and treatment analysis of cattle slaughterhouse wastewater by coagulation-flocculation and electrooxidation processes. Clean Technol. Environ. Policy 2025, 27, 3999–4014. [Google Scholar] [CrossRef]

- Donoso-Bravo, A.; Bindels, F.; Gerin, P.A.; Vande Wouwer, A. Anaerobic Biodegradability of Fish Remains: Experimental Investigation and Parameter Estimation. Water Sci. Technol. 2015, 71, 922–928. [Google Scholar] [CrossRef]

- Mahatmanto, T.; Estiningtyas, N.R.; Maharani, S.K.; Shalahuddin, A.S.; Agustian, M.Y.D.; Murdiyatmo, U. Feather Waste Biorefinery Using Chryseobacterium Sp. A9.9 Adapted to Feathers as Its Sole Carbon and Nitrogen Source. Waste Biomass Valorization 2022, 13, 4137–4146. [Google Scholar] [CrossRef]

- Petek, B.; Marinšek Logar, R. Management of Waste Sheep Wool as Valuable Organic Substrate in European Union Countries. J. Mater. Cycles Waste Manag. 2021, 23, 44–54. [Google Scholar] [CrossRef]

- Ravanan, P.; Gurrala, K.K.; Preethi, M.; Roy, C.L.; Liz, T.A.; Divya, S.; Kannan, M.; Banu, J.R. Biogas Production from Chicken Feathers via Pretreatment with Keratinolytic Protease Secreting Bacteria. Biomass Convers. Biorefin. 2025, 15, 19429–19438. [Google Scholar] [CrossRef]

- Saputra, S.A.; Zain, N.; Ardhani, K.; Pratiwi, N. Valorization of Chicken Feather Waste in West Java into Bokashi Fertilizer Using Anaerobic Fermentation to Support Circular Agriculture: A Review. J. Clean. Technol. 2025, 2, 28957. [Google Scholar] [CrossRef]

- Ula, N.M.; Le, T.M.; Lin, Y.; van Loosdrecht, M.C.M.; Bhattacharyya, D.; Jayaraman, K.; Kim, N.K. Flammability and Mechanical Performance of Fibreboards Based on Wool Fibres and Extracellular Polymeric Substances Recovered from Wastewater Sludge. Mater. Today Sustain. 2025, 31, 101210. [Google Scholar] [CrossRef]

- Zoccola, M.; Montarsolo, A.; Mossotti, R.; Patrucco, A.; Tonin, C. Green Hydrolysis as an Emerging Technology to Turn Wool Waste into Organic Nitrogen Fertilizer. Waste Biomass Valorization 2015, 6, 891–897. [Google Scholar] [CrossRef]

- Abdallah, A.; Ugolini, F.; Baronti, S.; Maienza, A.; Camilli, F.; Bonora, L.; Martelli, F.; Primicerio, J.; Ungaro, F. The Potential of Recycling Wool Residues as an Amendment for Enhancing the Physical and Hydraulic Properties of a Sandy Loam Soil. Int. J. Recycl. Org. Waste Agric. 2019, 8, 131–143. [Google Scholar] [CrossRef]

- Visca, A.; Caracciolo, A.B.; Grenni, P.; Patrolecco, L.; Rauseo, J.; Massini, G.; Miritana, V.M.; Spataro, F. Anaerobic Digestion and Removal of Sulfamethoxazole, Enrofloxacin, Ciprofloxacin and Their Antibiotic Resistance Genes in a Full-Scale Biogas Plant. Antibiotics 2021, 10, 502. [Google Scholar] [CrossRef]

- Kung, C.C.; Hu, S.; Lee, T.J.; Li, J. An Economic and Environmental Evaluation of Taiwan’s Manure to Energy Applications. iScience 2025, 28, 113492. [Google Scholar] [CrossRef]

- Tomasi, I.T.; Santos, I.; Gozubuyuk, E.; Santos, O.; Boaventura, R.A.R.; Botelho, C.M.S. A Sustainable Solution for Aquaculture Wastewater Treatment: Evaluation of Tannin-Based and Conventional Coagulants. Chemosphere 2025, 377, 144320. [Google Scholar] [CrossRef] [PubMed]

- Overmeyer, V.; Trimborn, M.; Clemens, J.; Hölscher, R.; Büscher, W. Acidification of Slurry to Reduce Ammonia and Methane Emissions: Deployment of a Retrofittable System in Fattening Pig Barns. J. Environ. Manag. 2023, 331, 117263. [Google Scholar] [CrossRef]

- Mutegoa, E.; Hilonga, A.; Njau, K.N. Approaches to the Mitigation of Ammonia Inhibition during Anaerobic Digestion–A Review. Water Pract. Technol. 2020, 15, 551–570. [Google Scholar] [CrossRef]

- Yellezuome, D.; Zhu, X.; Wang, Z.; Liu, R. Mitigation of Ammonia Inhibition in Anaerobic Digestion of Nitrogen-Rich Substrates for Biogas Production by Ammonia Stripping: A Review. Renew. Sustain. Energy Rev. 2022, 157, 112043. [Google Scholar] [CrossRef]

- Kim, E.J.; Kim, H.; Lee, E. Influence of Ammonia Stripping Parameters on the Efficiency and Mass Transfer Rate of Ammonia Removal. Appl. Sci. 2021, 11, 441. [Google Scholar] [CrossRef]

- Hou, Y.; Velthof, G.L.; Lesschen, J.P.; Staritsky, I.G.; Oenema, O. Nutrient Recovery and Emissions of Ammonia, Nitrous Oxide, and Methane from Animal Manure in Europe: Effects of Manure Treatment Technologies. Environ. Sci. Technol. 2017, 51, 375–383. [Google Scholar] [CrossRef]

- Vasmara, C.; Galletti, S.; Cianchetta, S.; Ceotto, E. Hydrogen Production from Renewable and Non-Renewable Sources with a Focus on Bio-Hydrogen from Giant Reed (Arundo donax L.), a Review. Energies 2025, 18, 709. [Google Scholar] [CrossRef]

- Dowd, B.; O’Donovan, A.; Gupta, V.K.; O’Flaherty, V.; Tuohy, M.G. Enhancing Biodegradability and Biomethane Potential of Cattle Paunch Contents during Anaerobic Digestion through Pre-Treatment with the Secretome of Deep-Sea Talaromyces Stollii and Rumen Fluid. Bioresour. Technol. Rep. 2025, 30, 102165. [Google Scholar] [CrossRef]

- Vasmara, C.; Cianchetta, S.; Marchetti, R.; Ceotto, E.; Galletti, S. Co-Digestion of Pig Slurry and KOH Pre-Treated Giant Reed (Arundo donax L.) Enhances Methane Yield and Digestate Characteristics. Environ. Technol. Innov. 2023, 31, 103204. [Google Scholar] [CrossRef]

- Hagos, K.; Zong, J.; Li, D.; Liu, C.; Lu, X. Anaerobic Co-Digestion Process for Biogas Production: Progress, Challenges and Perspectives. Renew. Sustain. Energy Rev. 2017, 76, 1485–1496. [Google Scholar] [CrossRef]

- Pedullà, A.; Bonaccorsi, L.M.; Limonti, C.; Paone, E.; Siciliano, A.; Calabrò, P.S. Advancing the Circular Economy: A Zero-Waste Valorisation Approach for the de-Oiled Fish Waste through Anaerobic Co-Digestion and Fertilisers Production. J. Environ. Chem. Eng. 2025, 13, 117322. [Google Scholar] [CrossRef]

- Mahari, W.A.W. Aquaculture Wastes as a Resource: An Overview. Planet. Sustain. 2024, 2, 51–60. [Google Scholar] [CrossRef]

- Dauda, A.B.; Ajadi, A.; Tola-Fabunmi, A.S.; Akinwole, A.O. Waste Production in Aquaculture: Sources, Components and Managements in Different Culture Systems. Aquac. Fish 2019, 4, 81–88. [Google Scholar] [CrossRef]

- Zhu, H.; Gu, Z.J.; Cheng, G.F.; Liu, X.G.; Tang, R. Facilities Pond Aquaculture System Construction and the Ecological Economy Analyzed. Aquac. Eng. 2024, 106, 102435. [Google Scholar] [CrossRef]

- Chiquito-Contreras, R.G.; Hernandez-Adame, L.; Alvarado-Castillo, G.; Martínez-Hernández, M.d.J.; Sánchez-Viveros, G.; Chiquito-Contreras, C.J.; Hernandez-Montiel, L.G. Aquaculture—Production System and Waste Management for Agriculture Fertilization—A Review. Sustainability 2022, 14, 7257. [Google Scholar] [CrossRef]

- Gallego-Alarcón, I.; Fonseca, C.R.; García-Pulido, D.; Díaz-Delgado, C. Proposal and Assessment of an Aquaculture Recirculation System for Trout Fed with Harvested Rainwater. Aquac. Eng. 2019, 87, 102021. [Google Scholar] [CrossRef]

- Chen, P.; Kim, H.J.; Thatcher, L.R.; Hamilton, J.M.; Alva, M.L.; Zhou, Z.; Brown, P.B. Maximizing Nutrient Recovery from Aquaponics Wastewater with Autotrophic or Heterotrophic Management Strategies. Bioresour. Technol. Rep. 2023, 21, 101360. [Google Scholar] [CrossRef]

- Ximenes, J.; Siqueira, A.; Kochańska, E.; Łukasik, R.M. Valorisation of Agri-and Aquaculture Residues via Biogas Production for Enhanced Industrial Application. Energies 2021, 14, 2519. [Google Scholar] [CrossRef]

- Serra, V.; Pastorelli, G.; Tedesco, D.E.A.; Turin, L.; Guerrini, A. Alternative Protein Sources in Aquafeed: Current Scenario and Future Perspectives. Veter. Anim. Sci. 2024, 25, 100381. [Google Scholar] [CrossRef]

- Bertocci, F.; Mannino, G. Can Agri-Food Waste Be a Sustainable Alternative in Aquaculture? A Bibliometric and Meta-Analytic Study on Growth Performance, Innate Immune System, and Antioxidant Defenses. Foods 2022, 11, 1861. [Google Scholar] [CrossRef]

- Randazzo, B.; Di Marco, P.; Zarantoniello, M.; Daniso, E.; Cerri, R.; Finoia, M.G.; Capoccioni, F.; Tibaldi, E.; Olivotto, I.; Cardinaletti, G. Effects of Supplementing a Plant Protein-Rich Diet with Insect, Crayfish or Microalgae Meals on Gilthead Sea Bream (Sparus aurata) and European Seabass (Dicentrarchus labrax) Growth, Physiological Status and Gut Health. Aquaculture 2023, 575, 739811. [Google Scholar] [CrossRef]

- Ibrahim, L.A.; Shaghaleh, H.; El-Kassar, G.M.; Abu-Hashim, M.; Elsadek, E.A.; Alhaj Hamoud, Y. Aquaponics: A Sustainable Path to Food Sovereignty and Enhanced Water Use Efficiency. Water 2023, 15, 4310. [Google Scholar] [CrossRef]

- Martini, A.; Napolitano, R.; Capoccioni, F.; Martinoli, M.; Tonachella, N.; Aguiari, L.; Piva, P.; Rossetti, E.; Pulcini, D. Prefacing the challenge–Assessment of the environmental efficiency of Manila clam (Ruditapes philippinarum) production based on hatchery-produced and wild seed. Aquaculture 2025, 595, 741474. [Google Scholar] [CrossRef]

- Martini, A.; Calì, M.; Capoccioni, F.; Martinoli, M.; Pulcini, D.; Buttazzoni, L.; Moranduzzo, T.; Pirlo, G. Environmental performance and shell formation-related carbon flows for mussel farming systems. Sci. Total Environ. 2022, 831, 154891. [Google Scholar] [CrossRef]

- Ferreira, J.G.; Saurel, C.; Ferreira, J.M. Cultivation of Gilthead Bream in Monoculture and Integrated Multi-Trophic Aquaculture. Analysis of Production and Environmental Effects by Means of the FARM Model. Aquaculture 2012, 358–359, 23–34. [Google Scholar] [CrossRef]

- Kovács, F.; Papdi, E.; Veres, A.; Mohay, P.; Szegő, A.; Juhos, K. More Efficient Nitrogen Utilization through Wool Pellet and Soil Inoculation. Agrosystems Geosci. Environ. 2024, 7, e20534. [Google Scholar] [CrossRef]

- Marczak, D.; Lejcuś, K.; Grzybowska-Pietras, J.; Biniaś, W.; Lejcuś, I.; Misiewicz, J. Biodegradation of Sustainable Nonwovens Used in Water Absorbing Geocomposites Supporting Plants Vegetation. Sustain. Mater. Technol. 2020, 26, e00235. [Google Scholar] [CrossRef]

- Haque, A.N.M.A.; Naebe, M.; Mielewski, D.; Kiziltas, A. Waste Wool/Polycaprolactone Filament towards Sustainable Use in 3D Printing. J. Clean. Prod. 2023, 386, 135781. [Google Scholar] [CrossRef]

- Dong, W.; Yang, Y.; Liu, C.; Zhang, J.; Pan, J.; Luo, L.; Wu, G.; Awasthi, M.K.; Yan, B. Caproic Acid Production from Anaerobic Fermentation of Organic Waste—Pathways and Microbial Perspective. Renew. Sustain. Energy Rev. 2023, 175, 113181. [Google Scholar] [CrossRef]

- Iglesias-Iglesias, R.; Portela-Grandío, A.; Treu, L.; Campanaro, S.; Kennes, C.; Veiga, M.C. Co-Digestion of Cheese Whey with Sewage Sludge for Caproic Acid Production: Role of Microbiome and Polyhydroxyalkanoates Potential Production. Bioresour. Technol. 2021, 337, 125388. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, H.; Liu, Y.; Bowden, J.A.; Townsend, T.G.; Solo-Gabriele, H.M. Evaluation of Per- and Polyfluoroalkyl Substances (PFAS) in Landfill Liquids from Pennsylvania, Colorado, and Wisconsin. Chemosphere 2024, 355, 141719. [Google Scholar] [CrossRef]

- Zhang, C.; Xia, L.; Zhang, J.; Liu, X.; Xu, W. Utilization of Waste Wool Fibers for Fabrication of Wool Powders and Keratin: A Review. J. Leather Sci. Eng. 2020, 2, 15. [Google Scholar] [CrossRef]

- S, R.; Sabumon, P.C. A Critical Review on Slaughterhouse Waste Management and Framing Sustainable Practices in Managing Slaughterhouse Waste in India. J. Environ. Manag. 2023, 327, 116823. [Google Scholar] [CrossRef] [PubMed]

- Abasubong, K.P.; Amin, A.B.; Uwem, G.U.; Desouky, H.E. A Review of Fish Waste and Byproducts in Poultry Production: Effects on Growth, Egg Quality, Carcass Traits, and Broader Knowledge beyond Physiological Response. Anim. Adv. 2025, 2, e021. [Google Scholar] [CrossRef]

- Rana, S.; Singh, A.; Surasani, V.K.R.; Kapoor, S.; Desai, A.; Kumar, S. Fish Processing Waste: A Novel Source of Non-Conventional Functional Proteins. Int. J. Food Sci. Technol. 2023, 58, 2637–2644. [Google Scholar] [CrossRef]

- Abun, A.; Rusmana, D.; Haetami, K.; Widjastuti, T. Evaluation of the Nutritional Value of Fermented Pangasius Fish Waste and Its Potential as a Poultry Feed Supplement. Veter. World 2025, 18, 355–366. [Google Scholar] [CrossRef]

- Tian, X.; Lin, X.; Xie, Q.; Liu, J.; Luo, L. Effects of Temperature and Light on Microalgal Growth and Nutrient Removal in Turtle Aquaculture Wastewater. Biology 2024, 13, 901. [Google Scholar] [CrossRef]

- Perazzoli, S.; Bruchez, B.M.; Michelon, W.; Steinmetz, R.L.R.; Mezzari, M.P.; Nunes, E.O.; da Silva, M.L.B. Optimizing Biomethane Production from Anaerobic Degradation of Scenedesmus Spp. Biomass Harvested from Algae-Based Swine Digestate Treatment. Int. Biodeterior. Biodegrad. 2016, 109, 23–28. [Google Scholar] [CrossRef]

- Daneshvar, E.; Zarrinmehr, M.J.; Hashtjin, A.M.; Farhadian, O.; Bhatnagar, A. Versatile Applications of Freshwater and Marine Water Microalgae in Dairy Wastewater Treatment, Lipid Extraction and Tetracycline Biosorption. Bioresour. Technol. 2018, 268, 523–530. [Google Scholar] [CrossRef]

- Rossi, S.; Mantovani, M.; Marazzi, F.; Bellucci, M.; Casagli, F.; Mezzanotte, V.; Ficara, E. Microalgal Cultivation on Digestate: Process Efficiency and Economics. Chem. Eng. J. 2023, 460, 141753. [Google Scholar] [CrossRef]

- Ruales, E.; Gómez-Serrano, C.; Morillas-España, A.; Garfí, M.; González-López, C.V.; Ferrer, I. Microalgae-Based Biorefinery for Biostimulant and Biogas Production: An Integrated Approach for Resource Recovery. Algal. Res. 2025, 91, 104323. [Google Scholar] [CrossRef]

- Ciani, M.; Vargas-Estrada, L.; Adessi, A.; Muñoz, R. Digestate Dilution Shapes Carbohydrate and Pigment Production during Microalgal and Cyanobacterial-Based Biogas Upgrading. Algal. Res. 2025, 91, 104290. [Google Scholar] [CrossRef]

- Montero-Martínez, M.J.; del Refugio Castañeda-Chávez, M.; Lango-Reynoso, F.; Navarrete-Rodríguez, G.; Martínez-Cárdenas, L. Removal of Pathogenic Bacteria in a Horizontally Fed Subsurface Constructed Wetland Hybrid System. J 2023, 6, 492–507. [Google Scholar] [CrossRef]

- Březinová, T.; Vymazal, J. Competition of Phragmites Australis and Phalaris Arundinacea in Constructed Wetlands with Horizontal Subsurface Flow–Does It Affect BOD5, COD and TSS Removal? Ecol. Eng. 2014, 73, 53–57. [Google Scholar] [CrossRef]

- Parde, D.; Patwa, A.; Shukla, A.; Vijay, R.; Killedar, D.J.; Kumar, R. A Review of Constructed Wetland on Type, Treatment and Technology of Wastewater. Environ. Technol. Innov. 2021, 21, 101261. [Google Scholar] [CrossRef]

- Idris, S.M.; Jones, P.L.; Salzman, S.A.; Croatto, G.; Allinson, G. Evaluation of the Giant Reed (Arundo donax) in Horizontal Subsurface Flow Wetlands for the Treatment of Recirculating Aquaculture System Effluent. Environ. Sci. Pollut. Res. 2012, 19, 1159–1170. [Google Scholar] [CrossRef] [PubMed]

- Shilpi, S.; Lamb, D.; Bolan, N.; Seshadri, B.; Choppala, G.; Naidu, R. Waste to Watt: Anaerobic Digestion of Wastewater Irrigated Biomass for Energy and Fertiliser Production. J. Environ. Manag. 2019, 239, 73–83. [Google Scholar] [CrossRef] [PubMed]

- Vasmara, C.; Galletti, S.; Cianchetta, S.; Ceotto, E. Advancements in Giant Reed (Arundo donax L.) Biomass Pre-Treatments for Biogas Production: A Review. Energies 2023, 16, 949. [Google Scholar] [CrossRef]

- Hurtig, O.; Buffi, M.; Besseau, R.; Scarlat, N.; Carbone, C.; Agostini, A. Mitigating Biomethane Losses in European Biogas Plants: A Techno-Economic Assessment. Renew. Sustain. Energy Rev. 2025, 210, 115187. [Google Scholar] [CrossRef]

- Fusi, M.; Pirlo, G. Environmental Impact of Milk and Electricity Production from Dairy Farms with Biogas Plants of Different Size and Feeding System. J. Clean. Prod. 2023, 383, 135445. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and Perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Bai, X.; Grassino, M.; Jensen, P.D. Effect of Alkaline Pre-Treatment on Hydrolysis Rate and Methane Production during Anaerobic Digestion of Paunch Solid Waste. Waste Manag. 2023, 171, 303–312. [Google Scholar] [CrossRef]

- Bai, X.; Rebosura, M.J.; Jensen, P.D. Enhanced Anaerobic Digestion of Lignocellulosic Paunch Waste Using Potassium Hydroxide Pre-Treatment. Bioresour. Technol. 2025, 425, 132323. [Google Scholar] [CrossRef] [PubMed]

- Rana, M.S.; Nandi, R.; Brown, P.B.; Huang, J.Y.; Ni, J.Q. Optimizing Feedstocks Mixing Ratio and Hydraulic Retention Time for Biogas Production from Anaerobic Codigestion of Dairy Manure and Aquaculture Sludge. GCB Bioenergy 2025, 17, e70079. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; Majeed, H.H.; Jwaid, T.A.; Silas, K. Advancements in Anaerobic Digestion of Organic Waste for Sustainable Biogas Production. Environ. Sci. Pollut. Res. 2025, 32, 17916–17930. [Google Scholar] [CrossRef]

- Dyksma, S.; Jansen, L.; Gallert, C. Syntrophic Acetate Oxidation Replaces Acetoclastic Methanogenesis during Thermophilic Digestion of Biowaste. Microbiome 2020, 8, 105. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, S.; Hu, Y.; Du, B.; Meng, J.; Wu, G.; Liu, H.; Zhan, X. Distinguishing Responses of Acetoclastic and Hydrogenotrophic Methanogens to Ammonia Stress in Mesophilic Mixed Cultures. Water Res. 2022, 224, 119029. [Google Scholar] [CrossRef]

- Fan, Q.; Fan, X.; Fu, P.; Sun, Y.; Li, Y.; Long, S.; Guo, T.; Zheng, L.; Yang, K.; Hua, D. Microbial Community Evolution, Interaction, and Functional Genes Prediction during Anaerobic Digestion in the Presence of Refractory Organics. J. Environ. Chem. Eng. 2022, 10, 107789. [Google Scholar] [CrossRef]

- Rodrigues Oliveira, H.; Mendes Anacleto, T.; Carraro, G.; Abreu, F.; Enrich-Prast, A. A Novel Approach to Estimate Methanogenic Pathways in Biogas Reactors via Stable Carbon Isotope Analysis. Biomass Bioenergy 2024, 183, 107167. [Google Scholar] [CrossRef]

- Kouzuma, A.; Tsutsumi, M.; Ishii, S.; Ueno, Y.; Abe, T.; Watanabe, K. Non-Autotrophic Methanogens Dominate in Anaerobic Digesters. Sci. Rep. 2017, 7, 1510. [Google Scholar] [CrossRef]

- Marchetti, R.; Vasmara, C.; Bertin, L.; Fiume, F. Conversion of Waste Cooking Oil into Biogas: Perspectives and Limits. Appl. Microbiol. Biotechnol. 2020, 104, 2833–2856. [Google Scholar] [CrossRef] [PubMed]

- Nesse, A.S.; Aanrud, S.G.; Lyche, J.L.; Sogn, T.; Kallenborn, R. Confirming the Presence of Selected Antibiotics and Steroids in Norwegian Biogas Digestate. Environ. Sci. Pollut. Res. 2022, 29, 86595–86605. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Kosaki, Y.; Watanabe, N. Higher Load Operation by Adoption of Ethanol Fermentation Pretreatment on Methane Fermentation of Food Waste. Bioresour. Technol. 2020, 297, 122475. [Google Scholar] [CrossRef] [PubMed]

- Vasmara, C.; Marchetti, R.; Carminati, D. Wastewater from the Production of Lactic Acid Bacteria as Feedstock in Anaerobic Digestion. Energy 2021, 229, 120740. [Google Scholar] [CrossRef]

- Sun, J.; Kosaki, Y.; Kawamura, K.; Watanabe, N. Operational Load Enhancement for an Anaerobic Membrane Bioreactor through Ethanol Fermentation Pretreatment of Food Waste. Energy Convers. Manag. 2021, 249, 114840. [Google Scholar] [CrossRef]

- Yu, Q.; Yang, Y.; Wang, M.; Zhu, Y.; Sun, C.; Zhang, Y.; Zhao, Z. Enhancing Anaerobic Digestion of Kitchen Wastes via Combining Ethanol-Type Fermentation with Magnetite: Potential for Stimulating Secretion of Extracellular Polymeric Substances. Waste Manag. 2021, 127, 10–17. [Google Scholar] [CrossRef]

- Arsic, M.; Abdalla, A.L.; Dong, H.; Loyon, L.; Packer, A.P.C.; Saha, C.K.; Si, B.; Meo Zilio, D.; Amon, B.R. Circular Bioeconomy Approaches for Livestock Manure and Post-Consumer Wastes: Opportunities for Biofertilizers and Bioenergy. Anim. Front. 2025, 15, 54–64. [Google Scholar] [CrossRef]

- Finzi, A.; Ferrari, O.; Riva, E.; Provolo, G. Nitrogen Recovery from Intensive Livestock Farms Using a Simplified Ammonia Stripping Process. Front. Sustain. Food Syst. 2024, 8, 1406962. [Google Scholar] [CrossRef]

- Nowak, M.; Bojarski, W.; Czekała, W. Economic and Energy Efficiency Analysis of the Biogas Plant Digestate Management Methods. Energies 2024, 17, 3021. [Google Scholar] [CrossRef]

- Yazan, D.M.; Cafagna, D.; Fraccascia, L.; Mes, M.; Pontrandolfo, P.; Zijm, H. Economic Sustainability of Biogas Production from Animal Manure: A Regional Circular Economy Model. Manag. Res. Rev. 2018, 41, 605–624. [Google Scholar] [CrossRef]

- Martín-Sanz-Garrido, C.; Revuelta-Aramburu, M.; Santos-Montes, A.M.; Morales-Polo, C. A Review on Anaerobic Digestate as a Biofertilizer: Characteristics, Production, and Environmental Impacts from a Life Cycle Assessment Perspective. Appl. Sci. 2025, 15, 8635. [Google Scholar] [CrossRef]

- Jabłoński, S.; Łukaszewicz, M.; Kułażyński, M. Manure Processing as Energy Efficient Fertilizer Production Technology. Clean Technol. Environ. Policy 2025, 27, 3573–3587. [Google Scholar] [CrossRef]

- Kavanagh, I.; Fenton, O.; Healy, M.G.; Burchill, W.; Lanigan, G.J.; Krol, D.J. Mitigating Ammonia and Greenhouse Gas Emissions from Stored Cattle Slurry Using Agricultural Waste, Commercially Available Products and a Chemical Acidifier. J. Clean. Prod. 2021, 294, 126251. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Duan, N.; Tsapekos, P.; Awasthi, M.K.; Liu, Z.; Mohammadi, A.; Angelidaki, I.; Tsang, D.C.W.; Zhang, Z.; Pan, J.; et al. A Critical Review on Livestock Manure Biorefinery Technologies: Sustainability, Challenges, and Future Perspectives. Renew. Sustain. Energy Rev. 2021, 135, 110033. [Google Scholar] [CrossRef]

- Köninger, J.; Lugato, E.; Panagos, P.; Kochupillai, M.; Orgiazzi, A.; Briones, M.J.I. Manure Management and Soil Biodiversity: Towards More Sustainable Food Systems in the EU. Agric. Syst. 2021, 194, 103251. [Google Scholar] [CrossRef]

- Oyedun, A.O.; Salami, H.A.; Odewole, M.M.; Lawal, L.O.; Akpenpuun, T.D.; Adebayo, H.O. A Review of Emerging Trends in Circular Manure Management and the Role of Digital Solutions. J. Saudi Soc. Agric. Sci. 2025, 24, 21. [Google Scholar] [CrossRef]

- Cheng, H.; Liu, Y.; Deng, Z.; Yang, C.; Xie, X.; Baloch, H.; Xu, W.; Zhang, H.; Gao, J.; Qin, Z.; et al. The Potential Microalgae-Based Strategy for Attaining Carbon Neutrality and Mitigating Climate Change: A Critical Review. Front. Mar. Sci. 2025, 12, 1644390. [Google Scholar] [CrossRef]

- Kowalska, A.; Biczak, R. Phytoremediation and Environmental Law: Harnessing Biomass and Microbes to Restore Soils and Advance Biofuel Innovation. Energies 2025, 18, 1860. [Google Scholar] [CrossRef]

- O’Connor, D.; Zheng, X.; Hou, D.; Shen, Z.; Li, G.; Miao, G.; O’Connell, S.; Guo, M. Phytoremediation: Climate Change Resilience and Sustainability Assessment at a Coastal Brownfield Redevelopment. Environ. Int. 2019, 130, 104945. [Google Scholar] [CrossRef]

- Halim, M.A.; Aziz, D.; Arshad, A.; Nur, N.L.; Nabi, M.M.; Islam, M.A.; Syukri, F. A Systematic Analysis of Recirculating Aqua culture Systems (RAS) and Biofloc Technology (BFT) for White Leg Shrimp (Litopenaeus vannamei) in the Indoor Farming System. Aquac. Eng. 2025, 110, 102544. [Google Scholar] [CrossRef]

- Ashilenje, D.; Ashour, F.; Barz, M.; Belandria, V.; Borello, A.; Bostyn, S.; Boushaki, T.; Branciari, R.; Bwapwa, J.K.; Cerza, E.; et al. A Literature Review of Slaughterhouse Waste Valorisation: Techniques, Environmental, and Economic Implications. Resour. Conserv. Recycl. 2026, 224, 108571. [Google Scholar] [CrossRef]

- Ali, A.M.; Nawaz, A.M.; Al-Turaif, H.A.; Shahzad, K. The Economic and Environmental Analysis of Energy Production from Slaughterhouse Waste in Saudi Arabia. Environ. Dev. Sustain. 2021, 23, 4252–4269. [Google Scholar] [CrossRef]

- Regulation (EU) 2023/857. Available online: https://eur-lex.europa.eu/eli/reg/2023/857/oj (accessed on 14 November 2025).

- Vasmara, C.; Cianchetta, S.; Marchetti, R.; Ceotto, E.; Galletti, S. Hydrogen Production from Enzymatic Hydrolysates of Alkali Pre-Treated Giant Reed (Arundo donax L.). Energies 2022, 15, 4876. [Google Scholar] [CrossRef]

- Vasmara, C.; Marchetti, R. Initial PH Influences In-Batch Hydrogen Production from Scotta Permeate. Int. J. Hydrogen Energy 2017, 42, 14400–14408. [Google Scholar] [CrossRef]

- Vasmara, C.; Pindo, M.; Micheletti, D.; Marchetti, R. Initial PH Influences Microbial Communities Composition in Dark Fermentation of Scotta Permeate. Int. J. Hydrogen Energy 2018, 43, 8707–8717. [Google Scholar] [CrossRef]

- Meo Zilio, D.; Vasmara, C. Circular Bioeconomy in Dairy Production: Ricotta Cheese Exhausted Whey, from a Byproduct to Bioproducts, a Case Study. Anim. Front. 2025, 15, 38–43. [Google Scholar] [CrossRef] [PubMed]

- Gurmessa, B.; Milanovic, V.; Foppa Pedretti, E.; Corti, G.; Ashworth, A.J.; Aquilanti, L.; Ferrocino, I.; Rita Corvaglia, M.; Cocco, S. Post-Digestate Composting Shifts Microbial Composition and Degrades Antimicrobial Resistance Genes. Bioresour. Technol. 2021, 340, 125662. [Google Scholar] [CrossRef]

- Cocolo, G.; Curnis, S.; Hjorth, M.; Provolo, G. Effect of Different Technologies and Animal Manures on Solid-Liquid Separation Efficiencies. J. Agric. Eng. 2012, 43, 9. [Google Scholar] [CrossRef]

- Chanakya, H.N.; Malayil, S.; Vijayalakshmi, C. Cultivation of Pleurotus Spp. on a Combination of Anaerobically Digested Plant Material and Various Agro-Residues. Energy Sustain. Dev. 2015, 27, 84–92. [Google Scholar] [CrossRef]

- Randazzo, B.; Zarantoniello, M.; Gioacchini, G.; Cardinaletti, G.; Belloni, A.; Giorgini, E.; Faccenda, F.; Cerri, R.; Tibaldi, E.; Olivotto, I. Physiological Response of Rainbow Trout (Oncorhynchus mykiss) to Graded Levels of Hermetia illucens or Poultry by-Product Meals as Single or Combined Substitute Ingredients to Dietary Plant Proteins. Aquaculture 2021, 538, 736550. [Google Scholar] [CrossRef]

- Baderuddin, S.H.; David, L.S.; Wester, T.J.; Morel, P.C.H. Influence of Different Levels of Black Soldier Fly Larvae Meal on Growth Performance and Carcass Quality of Broiler Chickens. Livest. Sci. 2024, 290, 105588. [Google Scholar] [CrossRef]

- La Mantia, M.C.; Calì, M.; Petrocchi Jasinski, L.; Contò, M.; Meo Zilio, D.; Renzi, G.; Guarino Amato, M. Black Soldier Meal in Feed Could Adversely Affect Organic Broiler Meat Quality When Used for the Total or Half Replacement of Diet Proteins. Poultry 2024, 3, 66–84. [Google Scholar] [CrossRef]

- Tahamtani, F.M.; Ivarsson, E.; Wiklicky, V.; Lalander, C.; Wall, H.; Rodenburg, T.B.; Tuyttens, F.A.M.; Hernandez, C.E. Feeding Live Black Soldier Fly Larvae (Hermetia illucen) to Laying Hens: Effects on Feed Consumption, Hen Health, Hen Behavior, and Egg Quality. Poult. Sci. 2021, 100, 101400. [Google Scholar] [CrossRef]

- Chae, H.J.; Ahn, J.H. Optimization of Rice Bran and Food Waste Compost Contents in Mushroom Culture Medium to Maximize Mycelial Growth Rate and Fruit Body Yield of Pleurotus ostreatus. Int. Biodeterior. Biodegrad. 2013, 80, 66–70. [Google Scholar] [CrossRef]

- Hilali, S.; Stierlin, E.; Tello Martín, M.L.; Amaral, D.; Pérez-Clavijo, M.; Girão, M.; Carvalho, M.d.F.; Pérez Bonilla, A.M.; de Diego, S.; Ramírez, P.; et al. From Waste to Value: Investigating Mushroom Stems from Pleurotus ostreatus Grown on Mealworm Frass as a Nutritional Source for Aquaculture Feed. Sustainability 2025, 17, 6496. [Google Scholar] [CrossRef]

- Törős, G.; El-Ramady, H.; Béni, Á.; Peles, F.; Gulyás, G.; Czeglédi, L.; Rai, M.; Prokisch, J. Pleurotus ostreatus Mushroom: A Promising Feed Supplement in Poultry Farming. Agriculture 2024, 14, 663. [Google Scholar] [CrossRef]

- Adams, S.; Che, D.; Hailong, J.; Zhao, B.; Rui, H.; Danquah, K.; Qin, G. Effects of Pulverized Oyster Mushroom (Pleurotus ostreatus) on Diarrhea Incidence, Growth Performance, Immunity, and Microbial Composition in Piglets. J. Sci. Food Agric. 2019, 99, 3616–3627. [Google Scholar] [CrossRef]

- Atmakuri, A.; Yadav, B.; Tiwari, B.; Drogui, P.; Tyagi, R.D.; Wong, J.W.C. Nature’s Architects: A Comprehensive Review of Extracellular Polymeric Substances and Their Diverse Applications. Waste Dispos. Sustain. Energy 2024, 6, 529–551. [Google Scholar] [CrossRef]

- Wei, Z.; Niu, S.; Wei, Y.; Liu, Y.; Xu, Y.; Yang, Y.; Zhang, P.; Zhou, Q.; Wang, J.J. The Role of Extracellular Polymeric Substances (EPS) in Chemical-Degradation of Persistent Organic Pollutants in Soil: A Review. Sci. Total Environ. 2024, 912, 168877. [Google Scholar] [CrossRef]

- Wei, X.; Chen, Z.; Liu, A.; Yang, L.; Xu, Y.; Cao, M.; He, N. Advanced Strategies for Metabolic Engineering of Bacillus to Produce Extracellular Polymeric Substances. Biotechnol. Adv. 2023, 67, 108199. [Google Scholar] [CrossRef] [PubMed]

- Hansen, B.B.; Spittle, S.; Chen, B.; Poe, D.; Zhang, Y.; Klein, J.M.; Horton, A.; Adhikari, L.; Zelovich, T.; Doherty, B.W.; et al. Deep Eutectic Solvents: A Review of Fundamentals and Applications. Chem. Rev. 2021, 3, 1232–1285. [Google Scholar] [CrossRef] [PubMed]

- Chutturi, M.; Kelkar, B.U.; Yadav, S.M.; Wibowo, E.S.; Bhuyar, P.; Naik, B.P.; Sinha, A.; Lee, S.H. Exploring Nanolignin as a Sustainable Biomacromolecule in Polymer Composites: Synthesis, Characterization, and Applications: A Review. Int. J. Biol. Macromol. 2025, 304, 140881. [Google Scholar] [CrossRef] [PubMed]

- Gorgun, E.; Ali, A.; Islam, M.S. Biocomposites of Poly(Lactic Acid) and Microcrystalline Cellulose: Influence of the Coupling Agent on Thermomechanical and Absorption Characteristics. ACS Omega 2024, 9, 11523–11533. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Z.; Wang, S.; Cai, X.; Li, K.; Feng, J.; Li, S.; Tong, Y.W. Bioinspired Chitosan Coatings Enhanced with Bacterial Cellulose Nanocrystals and Apple Polyphenols for Preservation of Perishable Fruits. Food Chem. 2025, 495, 146481. [Google Scholar] [CrossRef]

- Sharkawy, A.; Barreiro, M.F.; Rodrigues, A.E. Chitosan-Based Pickering Emulsions and Their Applications: A Review. Carbohydr. Polym. 2020, 250, 116885. [Google Scholar] [CrossRef]

- Cazaudehore, G.; Guyoneaud, R.; Vasmara, C.; Greuet, P.; Gastaldi, E.; Marchetti, R.; Leonardi, F.; Turon, R.; Monlau, F. Impact of Mechanical and Thermo-Chemical Pretreatments to Enhance Anaerobic Digestion of Poly(Lactic Acid). Chemosphere 2022, 297, 133986. [Google Scholar] [CrossRef]

- Vasmara, C.; Cianchetta, S.; Marchetti, R.; Ceotto, E.; Galletti, S. Potassium Hydroxyde Pre-Treatment Enhances Methane Yield from Giant Reed (Arundo donax L.). Energies 2021, 14, 630. [Google Scholar] [CrossRef]

- Vasmara, C.; Cazaudehore, G.; Ceotto, E.; Marchetti, R.; Sambusiti, C.; Monlau, F. Alkali, Thermal, or Thermo-Alkali Pre-Treatment to Improve the Anaerobic Digestion of Poly(Lactic Acid)? Water Res. 2024, 258, 121744. [Google Scholar] [CrossRef] [PubMed]

| Type of Waste | Parameters | Range | Reference |

|---|---|---|---|

| Cattle manure and slurry | Total Solids (g kg−1 FW) | 72–310 | [27,32,33,34] |

| Organic Matter (% TS) COD (g kg−1) Total N (% TS) Ammonium N (% TS) Total P (% TS) Total K (% TS) pH | 75–89 291–1082 1.77–4.56 0.25–2.37 0.3–1.84 1.06–6.95 6.8–8.6 | ||

| Poultry manure | Total Solids (g kg−1 FW) | 132–849 | [27,29,32,35] |

| Organic Matter (% TS) COD (g kg−1) Total N (% TS) Ammonium N (% TS) Total P (% TS) Total K (% TS) pH | 32–85 35.9–945 2.34–5.45 0.42 1.58–6.13 2.66 6.9–9.0 | ||

| Pig slurry | Total Solids (g kg−1 FW) | 12–124 | [2,20,27,32,33,36,37,38,39,40,41,42,43,44] |

| Organic Matter (% TS) COD (g L−1) Total N (% TS) Ammonium N (% TS) Total P (% TS) Total K (% TS) pH | 66–90 1.3–135 4.96–12.2 2.32–4.6 0.45–3.60 5.1 6.7–7.7 | ||

| Aquaculture sludge | Total Solids (g L−1) | 14.3 | [45] |

| Organic Matter (% TS) COD (g L−1) Total N (% TS) Ammonium N (% TS) Total P (% TS) Total K (% TS) pH | 33 4 1.4 0.08 N.A. N.A. 5.9 |

| Category | Risk Level | Types of Waste | Treatment Requirements |

|---|---|---|---|

| Category 1 | Very High | Parts of infected animals, international catering waste. | Prohibited composting or biogas plants. |

| Category 2 | High | Sick animals, intestinal contents, manure | Sterilization at 133 °C, 300 kPa for 20 min. |

| Category 3 | Low | Food waste, meat, pre-cooked foods, by-products from the fish processing | Treatment at 70 °C for 1 h in a closed system. |

| Type of Waste | Parameters | Range | Reference |

|---|---|---|---|

| Cattle slaughterhouse solid waste | Total Solids (g kg−1 FW) | 117–158 | [17,46] |

| Organic Matter (% TS) COD (g kg−1) Total N (% TS) Ammonium N (% TS) Total P (% TS) Total K (% TS) pH | 90–93 111 1.79–10 N.A. 0.6–7.38 N.A. N.A. | ||

| Cattle slaughterhouse wastewater | Total Solids (g L−1) | 7.5 | [17,63] |

| Organic Matter (% TS) COD (g L−1) Total N (% TS) Ammonium N (% TS) Total P (% TS) Total K (% TS) pH | 75 5–18 2.67 0.21 1.44 N.A. 7.1–7.8 | ||

| Pig slaughterhouse solid waste | Total Solids (g kg−1 FW) | 458 | [48] |

| Organic Matter (% TS) COD (g kg−1) Total N (% TS) Ammonium N (% TS) Total P (% TS) Total K (% TS) pH | 82 N.A. 5.28 0.44 N.A. N.A. N.A. | ||

| Pig slaughterhouse blood | Total Solids (g L−1) | 179 | [48] |

| Organic Matter (% TS) COD (g L−1) Total N (% TS) Ammonium N (% TS) Total P (% TS) Total K (% TS) pH | 94 N.A. 15.1 0.95 N.A. N.A. N.A. | ||

| Poultry slaughterhouse effluent | Total Solids (g L−1) | 2.03 | [29] |

| Organic Matter (% TS) COD (g L−1) Total N (% TS) Ammonium N (% TS) Total P (% TS) Total K (% TS) pH | 76 2.4 11.3 N.A. N.A. N.A. 6.9 | ||

| Seafood processing solid waste | Total Solids (g kg−1 FW) | 301–350 | [64] |

| Organic Matter (% TS) COD (g kg−1) Total N (% TS) Ammonium N (% TS) Total P (% TS) Total K (% TS) pH | 82–89 470–530 7.67–7.94 N.A. N.A. N.A. N.A. | ||

| Seafood processing wastewater | Total Solids (g L−1) | 2–25 | [57,58] |

| Organic Matter (% TS) COD (g L−1) Total N (% TS) Ammonium N (% TS) Total P (% TS) Total K (% TS) pH | N.A. 1.4–25 2.48 0.8–1.4 N.A. N.A. N.A. |

| Farm Animal | Manure/Sludge (Mg) | Processing (Mg) | Total (Mg) |

|---|---|---|---|

| Ruminants | 5.8 × 109 | 8.6 × 107 | 5.9 × 109 |

| Pigs | 4.8 × 108 | 6.4 × 106 | 4.8 × 108 |

| Poultry | 7.6 × 108 | 7.7 × 1010 | 7.8 × 1010 |

| Aquaculture | 2.8 × 108 | 9.1 × 106 | 2.9 × 108 |

| Traditional Treatment | Pros | Cons | Total Emission Reduction Efficiency (kg CO2 eq Mg−1 Animal Waste) | Net Economic Benefit ($ Mg−1) | Alternative Treatment | Pros | Cons | Total Emission Reduction Efficiency (kg CO2 eq Mg−1 Animal Waste) | Net Economic Benefit ($ Mg−1) |

|---|---|---|---|---|---|---|---|---|---|

| Direct land application | Low CAPEX and OPEX, low technological level required | Uncontrolled GHG emission, risk of N and P pollution, high salinity, storage cost, high energy demand for transport and application, health risk, antibiotic resistance spread | N.A. | 5.8 | Anaerobic digestion and digestate | Electricity and biofuel production, reduced GHG emission, N and P recovery, volume effluent reduction, biofertilizer | High CAPEX and OPEX, large reactors, technological equipment, potential presence of heavy metals | 94–524 | 63–321 |

| Composting | Low CAPEX and OPEX, low technological level required, reduction in synthetic fertilizer utilization, pathogen removal | Uncontrolled GHG emission, storage cost | 4.1–4.9 | 4–20 | Anaerobic digestion + digestate composting | Electricity and biofuel production, reduced GHG emission, N and P recovery, volume effluent reduction, biofertilizer, pathogen removal, cost-effectiveness and wide applicability, and significant increase in crop yields compared to inorganic fertilizers, reduction of NH3 volatilization, reduced eutrophication and acidification potential | High CAPEX and OPEX, large reactors, technological equipment, potential presence of heavy metals | 98–529 | 76–361 |

| Ammonia stripping | Transforming ammonia into fertilizer | High OPEX cost, corrosion of equipment, chemical and energetic input, lack of P and K recovery | ~0 | 0–174 | Physicochemical (flocculation, bioflocculation, advanced oxidation, photocatalysis, coagulation) | Nutrient recovery, volume reduction, high COD removal efficiency, profitable | Energy intensive, high OPEX, 1–20% N2O increased emission, catalyst dispersion, presence of heavy metals and inorganic ash, chemical input, Cl- and O3 emission, potential risk of water quality degradation | N.A. | N.A. |

| Incineration | Pathogen destruction, waste volume reduced | GHG emissions, presence of heavy metals, formation of toxic compounds, high OPEX | 0 | N.A. | Membrane filtration | High N and P recovery efficiency, volume reduction, water recovery | Pre-treatment steps, membrane fouling, high OPEX | ||

| Landfill | cost- effective | groundwater contamination, GHG emissions, limited space | 0 | 0 | Microalgae cultivation | CO2 utilization for biosynthesis, high N and P removal | High OPEX, large photoreactors, dilution needs, high water demand, low efficiency biomass recovery | N.A. | N.A. |

| Rendering | displacement of fossil fuels, energy intensive, low conversion yield | Nutrient recovery, sanification, pathogen control, biofertilizer and animal feed production, biomolecule recovery | N.A. | N.A. | Phytoremediation | CO2 sequestration, highly effective for heavy metals, cost-effective, high N and P removal, erosion control, preventing dispersion of pollutants into aquatic and atmospheric environments, biomass production | long time required to achieve remediation effects, seasonal dependence, reduced effectiveness at very high contaminant concentrations | N.A. | N.A. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasmara, C.; Martini, A. Transforming Livestock and Aquaculture Waste into Renewable Energy and Materials—A Review. Sustainability 2025, 17, 10590. https://doi.org/10.3390/su172310590

Vasmara C, Martini A. Transforming Livestock and Aquaculture Waste into Renewable Energy and Materials—A Review. Sustainability. 2025; 17(23):10590. https://doi.org/10.3390/su172310590

Chicago/Turabian StyleVasmara, Ciro, and Arianna Martini. 2025. "Transforming Livestock and Aquaculture Waste into Renewable Energy and Materials—A Review" Sustainability 17, no. 23: 10590. https://doi.org/10.3390/su172310590

APA StyleVasmara, C., & Martini, A. (2025). Transforming Livestock and Aquaculture Waste into Renewable Energy and Materials—A Review. Sustainability, 17(23), 10590. https://doi.org/10.3390/su172310590