Low-Carbon Design Strategies for Transparent Building Envelopes in Hot-Summer–Cold-Winter Climate Zones—Experimental and Numerical Simulation Study Based on the High-Performance Sunroom Laboratory in Central-Southern Anhui

Abstract

1. Introduction

2. Thermal Performance Analysis of Transparent Building Envelopes

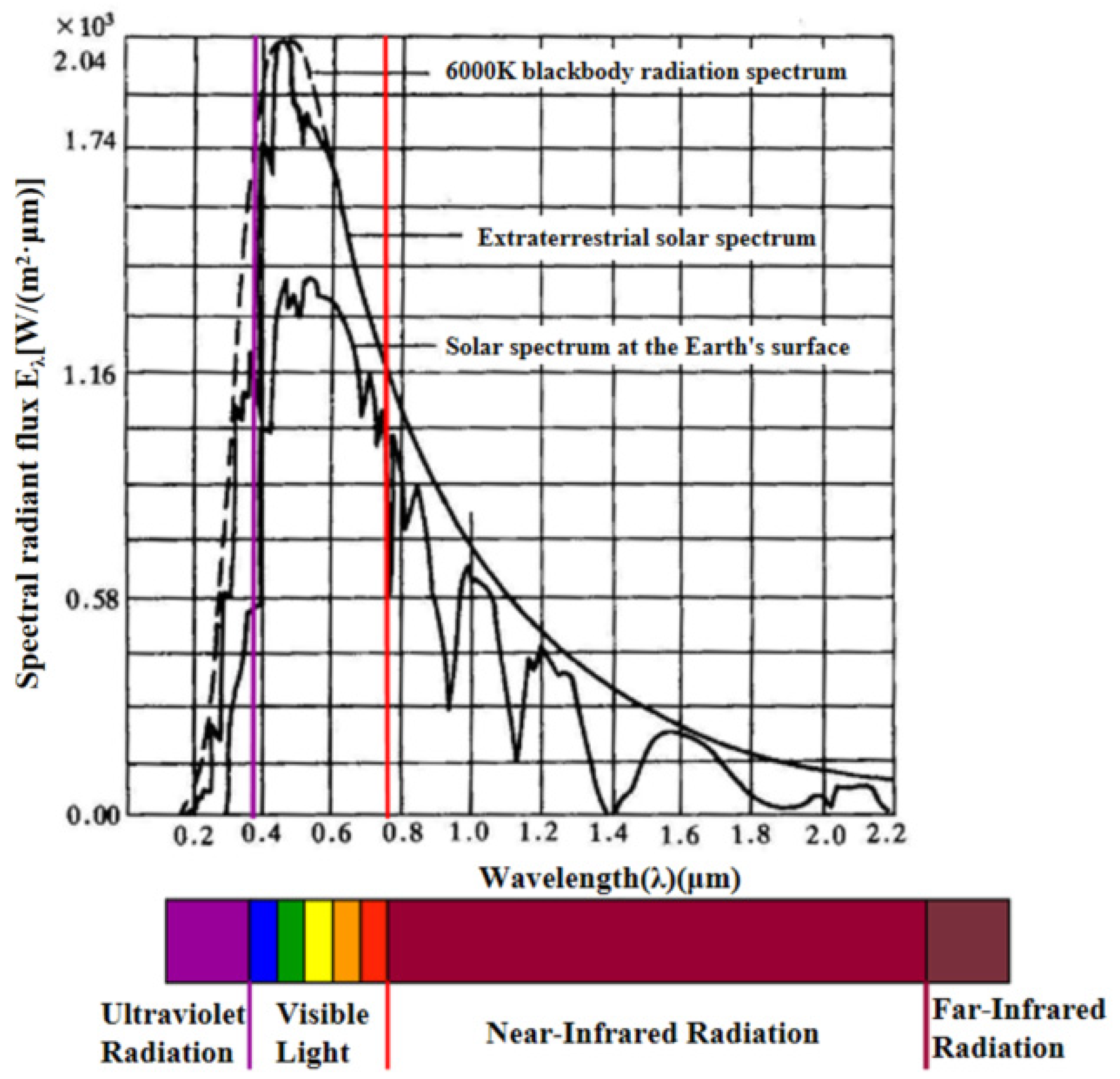

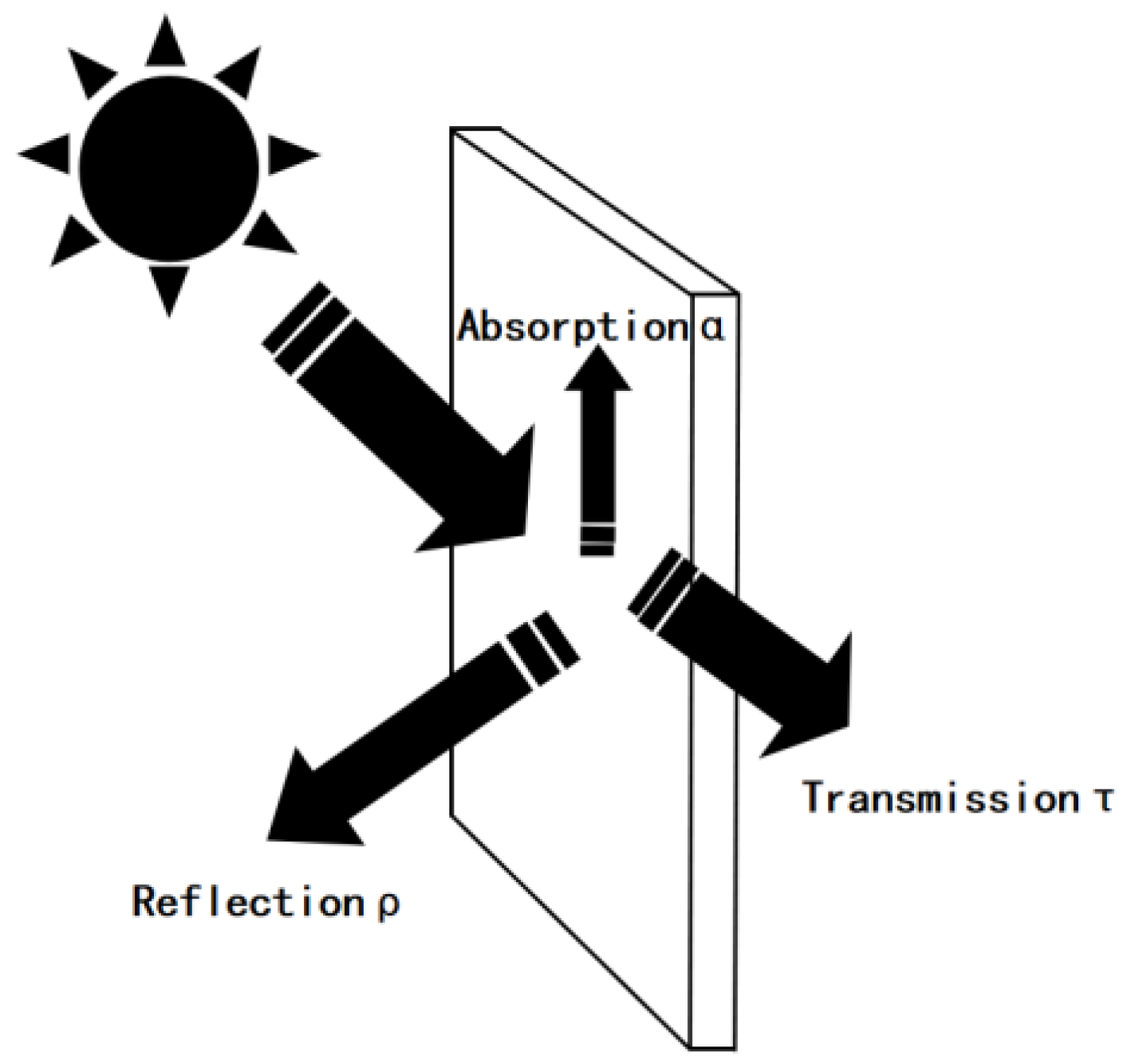

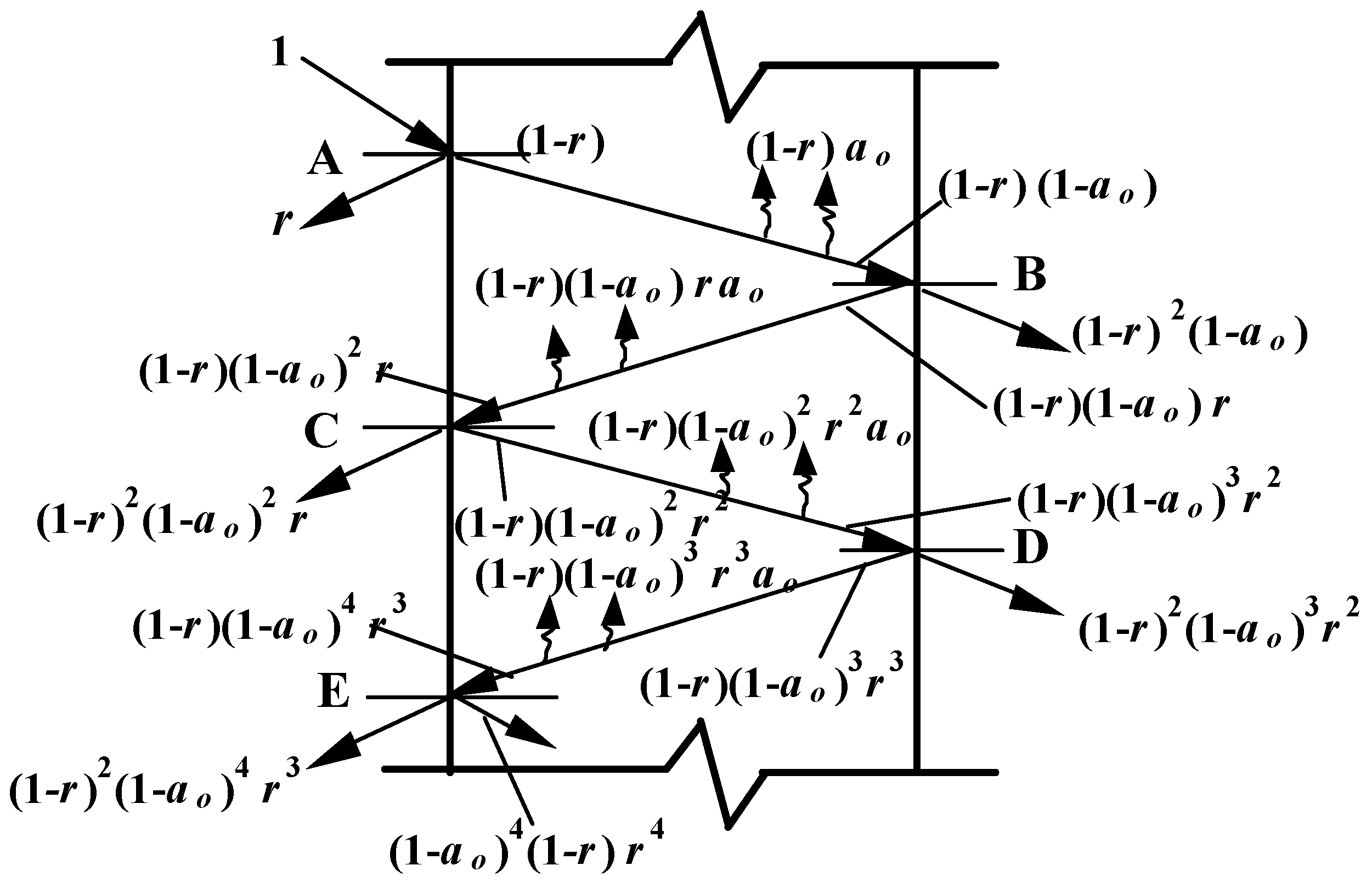

2.1. Mechanisms of Glass Daylighting and Heat Transfer

2.2. Solar Heat Gain Coefficient and Shading Coefficient

2.3. Evaluation Method for Natural Daylighting

3. Experimental Study on Thermal Performance of the High-Performance Sunroom Laboratory

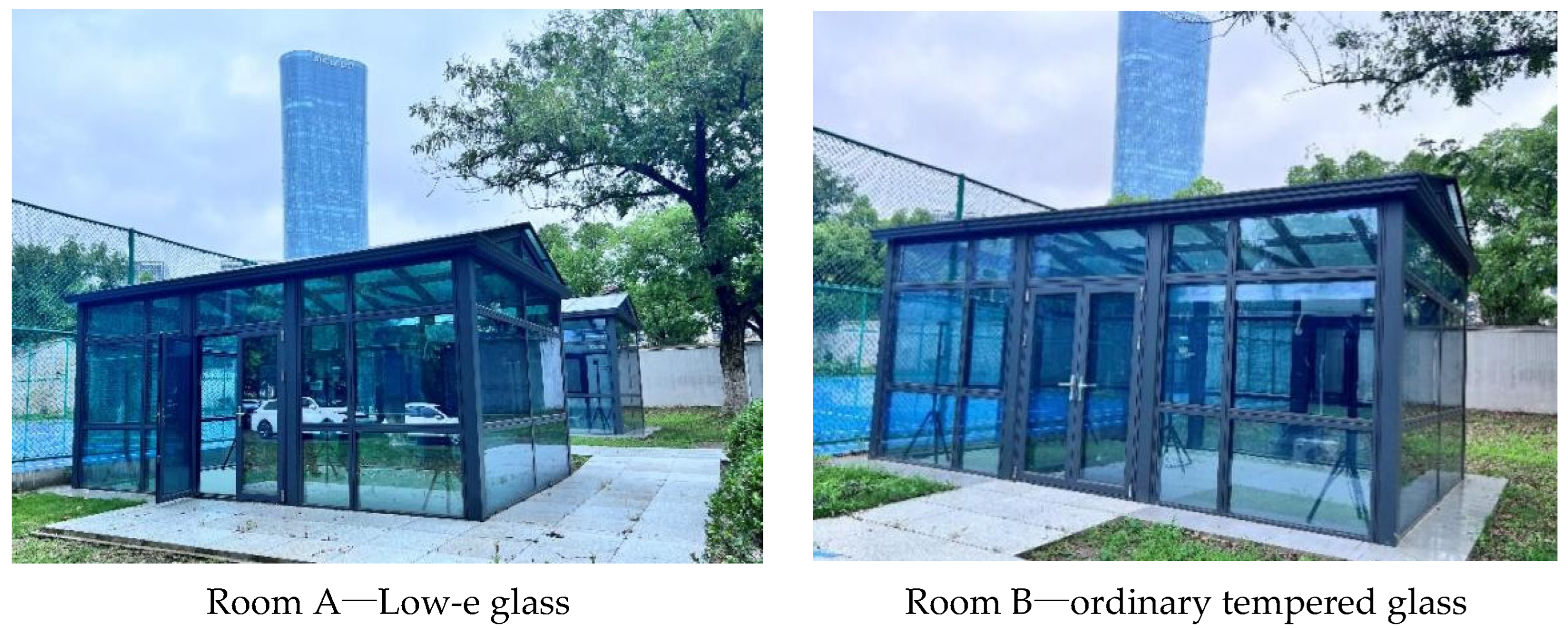

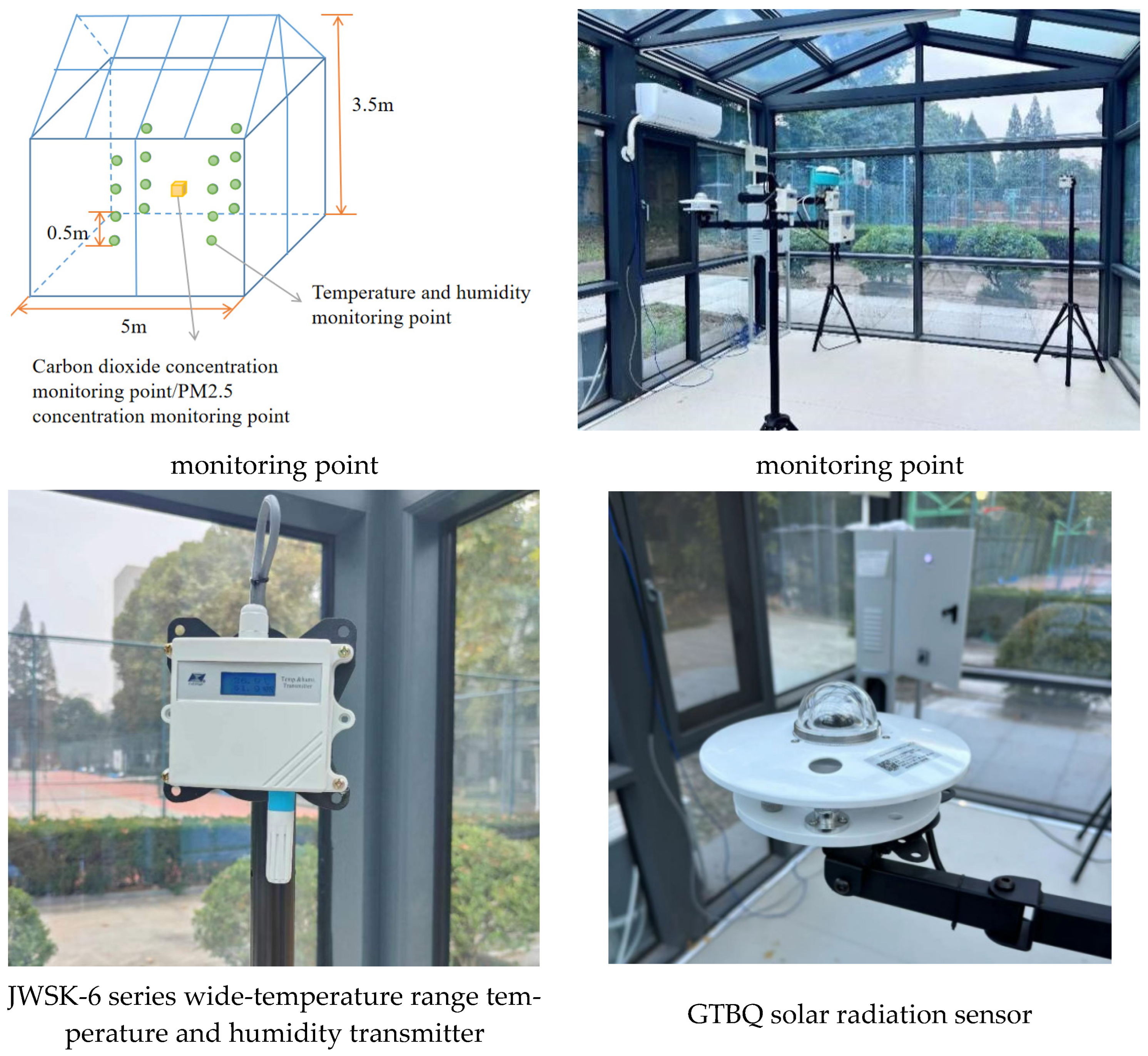

3.1. Experimental Objectives and Arrangement

3.2. Measured Analysis of Sunrooms with Different Glazing

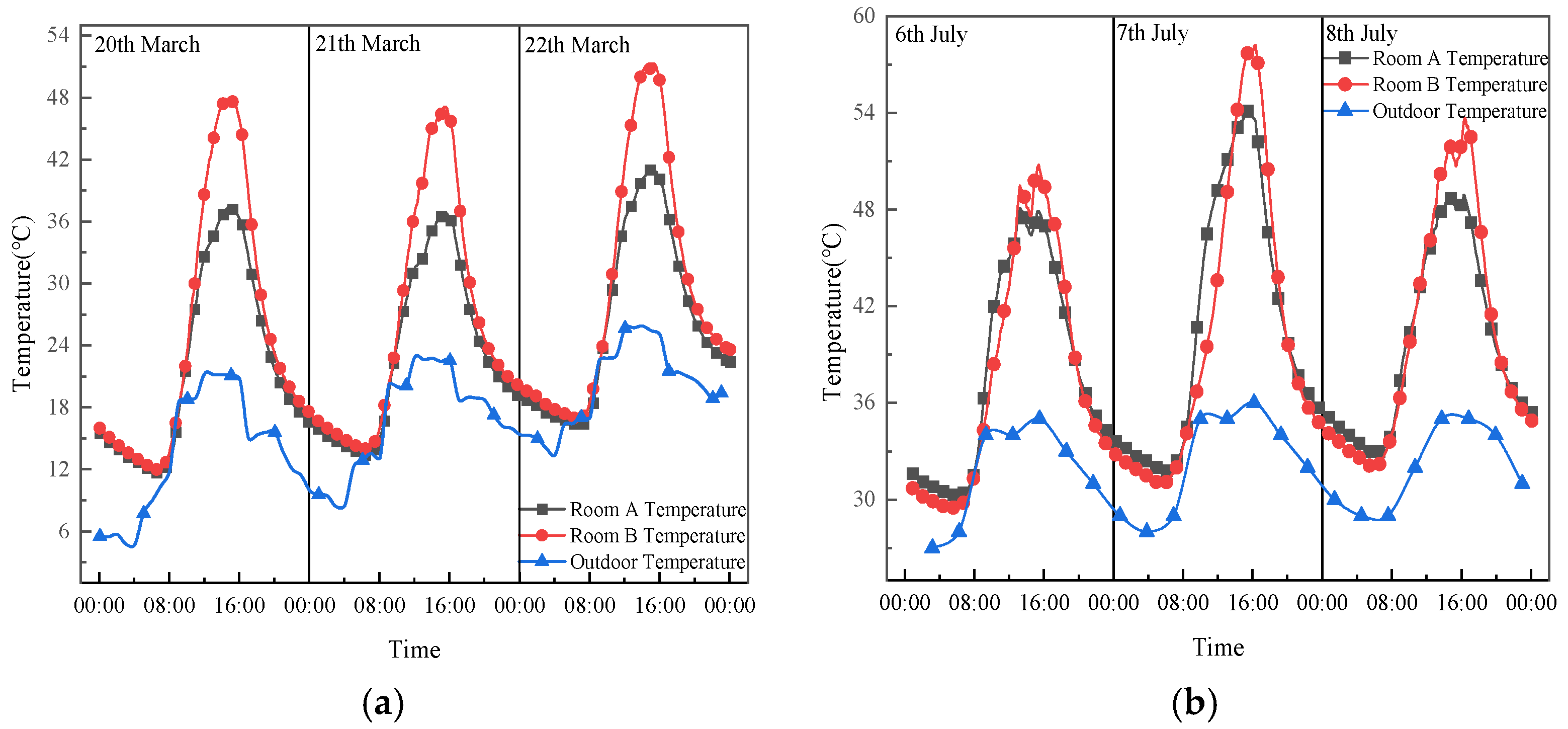

3.2.1. Comparative Analysis of Indoor Temperature

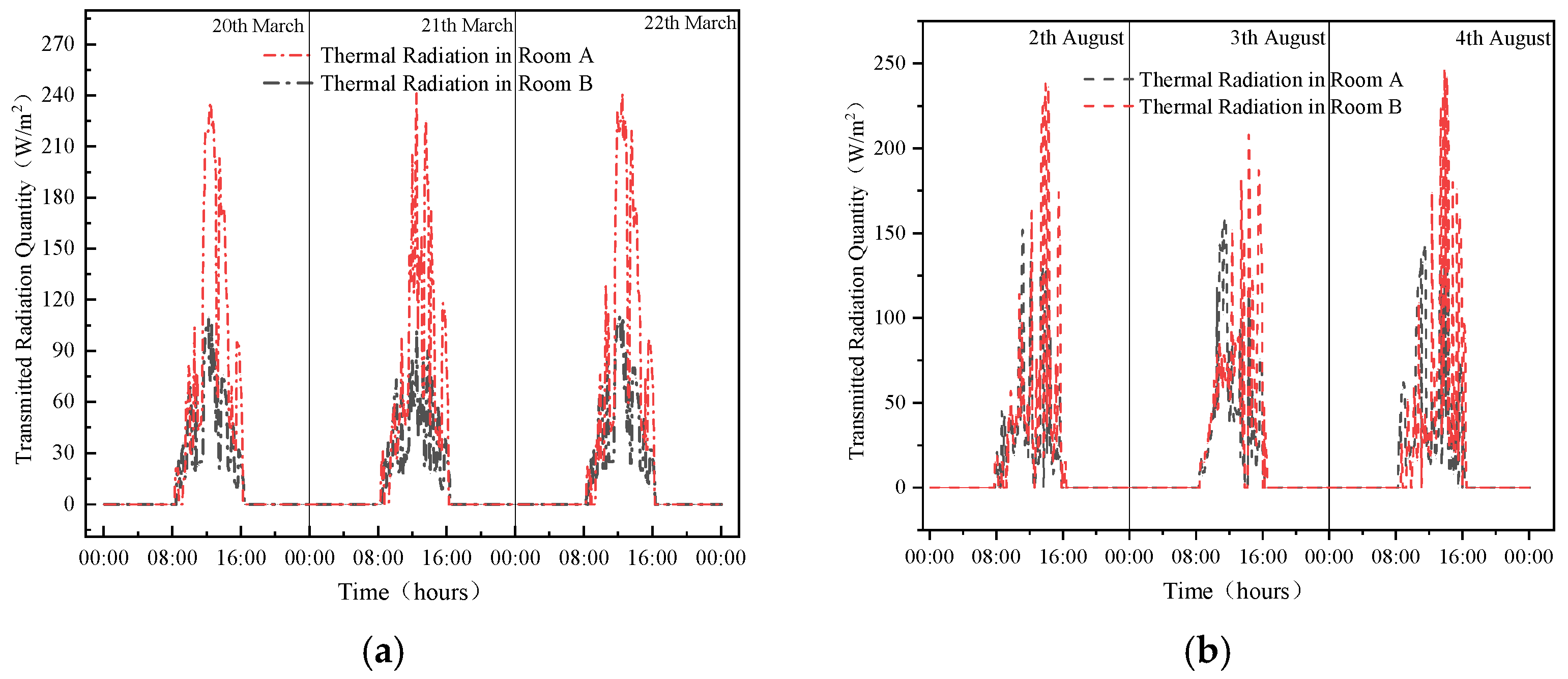

3.2.2. Comparative Analysis of Indoor Thermal Radiation

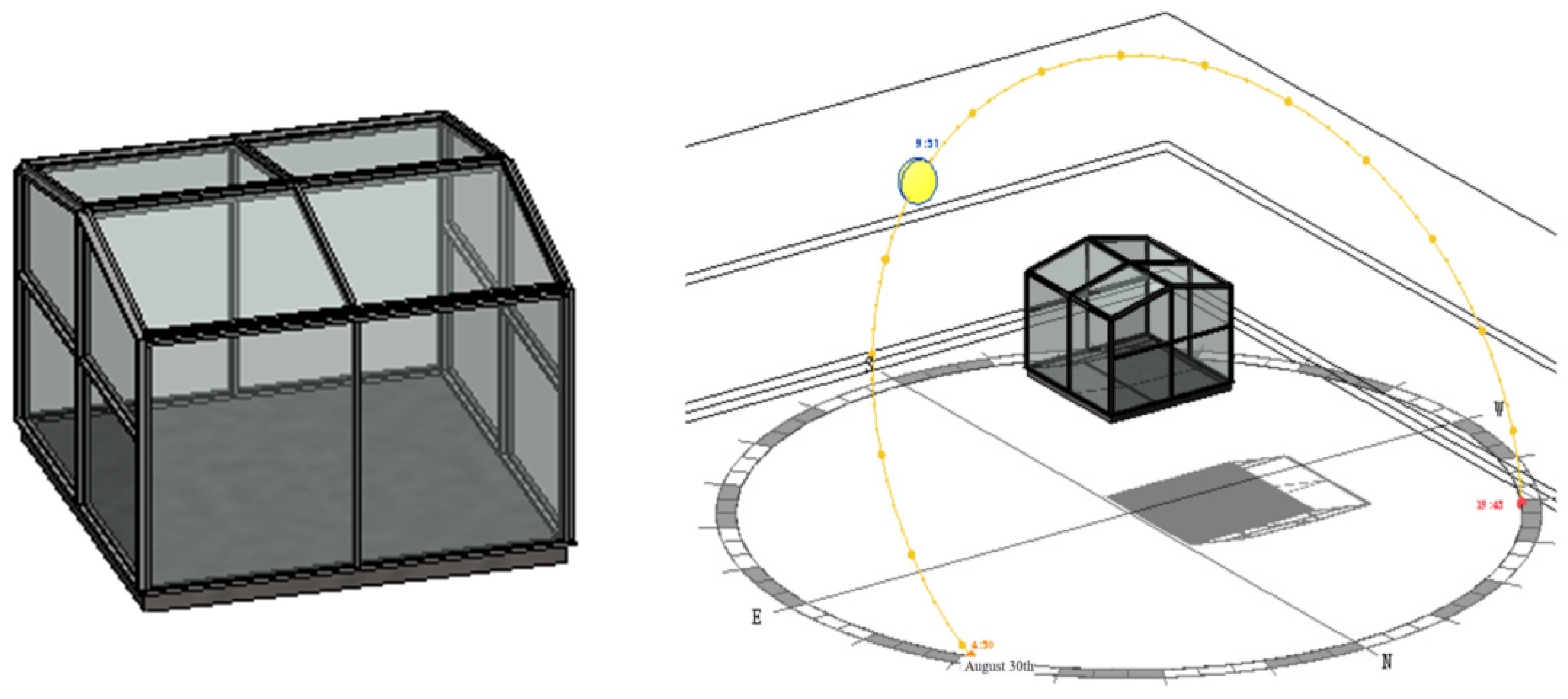

4. Simulation Study of Glass Performance in the High-Performance Sunroom Laboratory

4.1. Selection of Simulation Software

4.2. Model Building and Parameter Settings

4.3. Daylighting and Illuminance Simulation

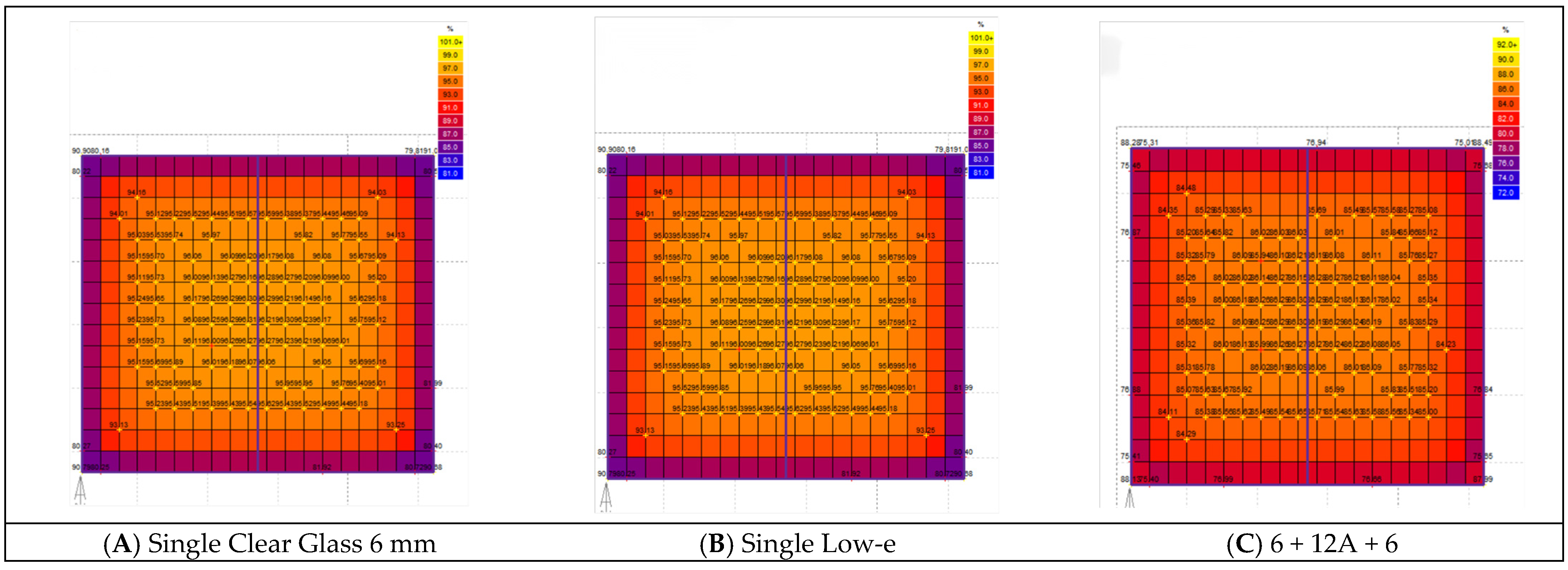

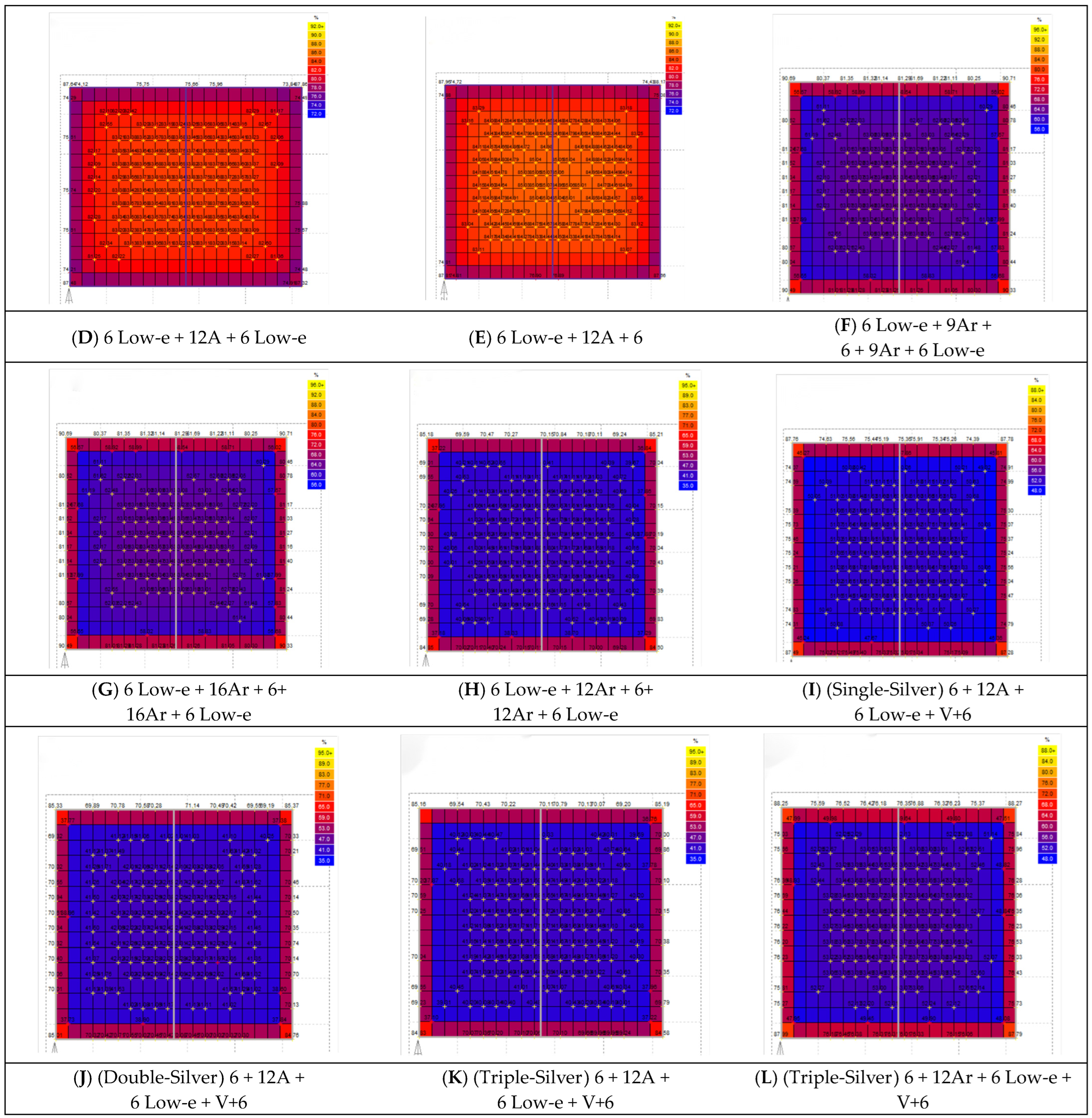

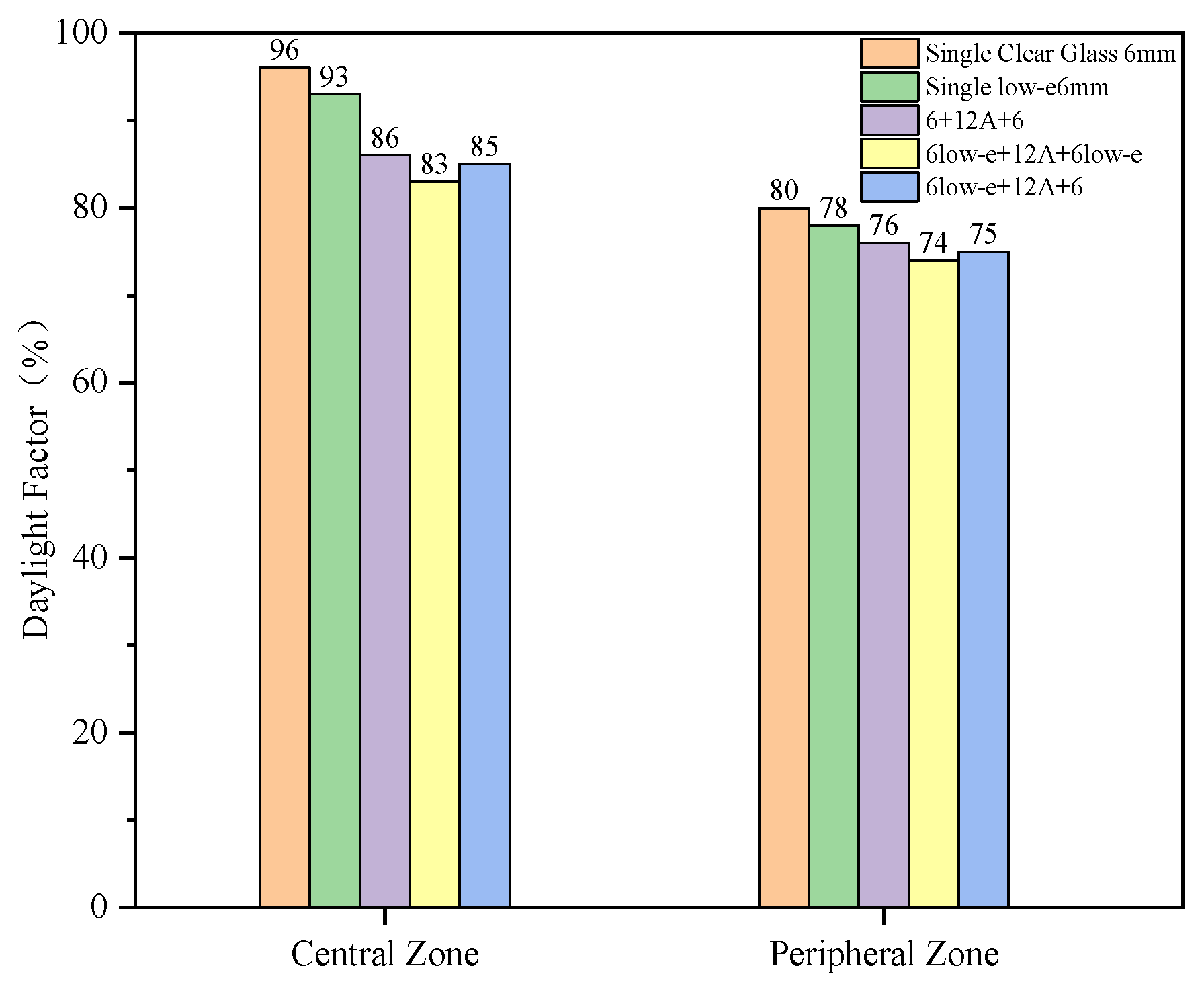

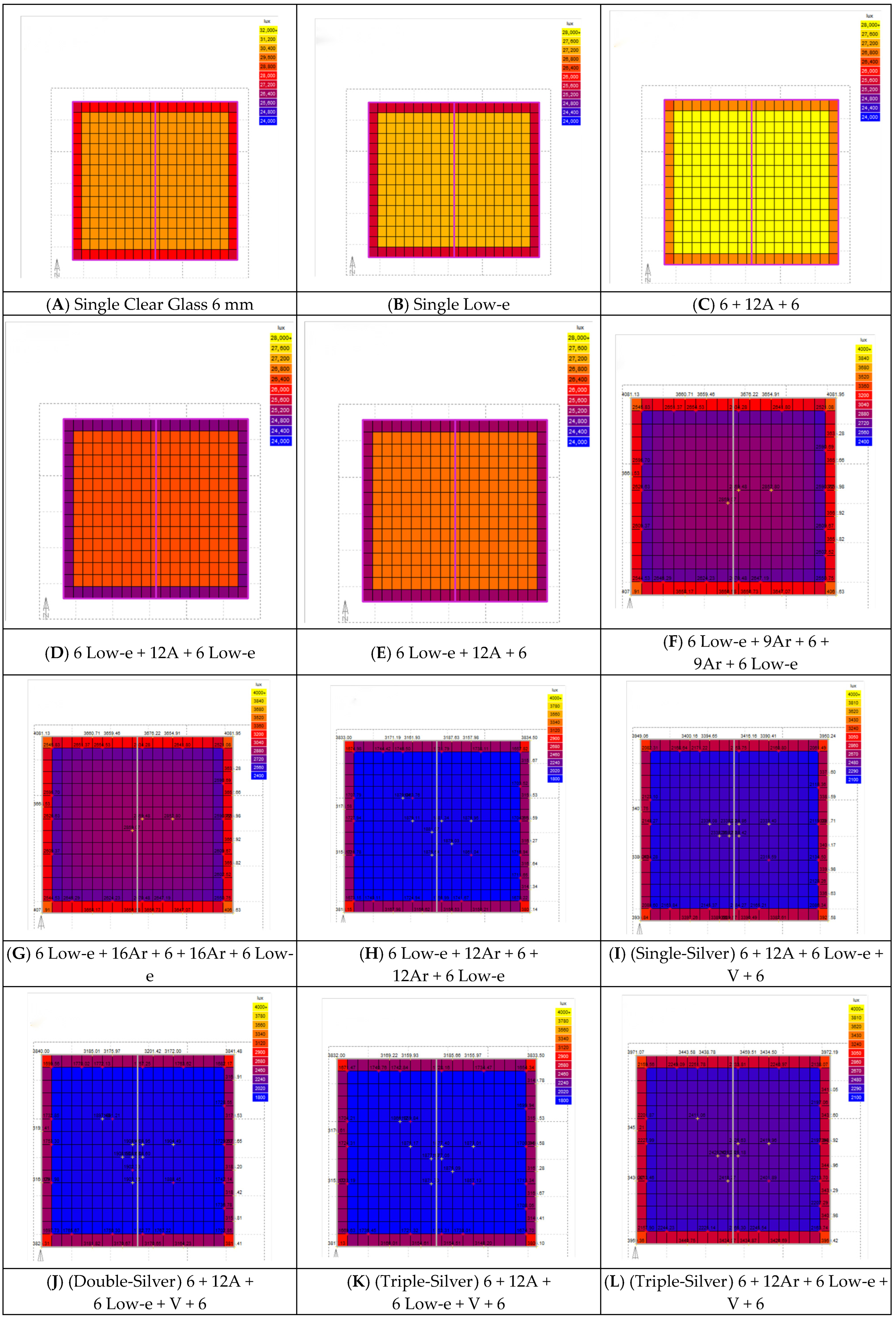

4.3.1. Daylight Factor Analysis for Different Glazings

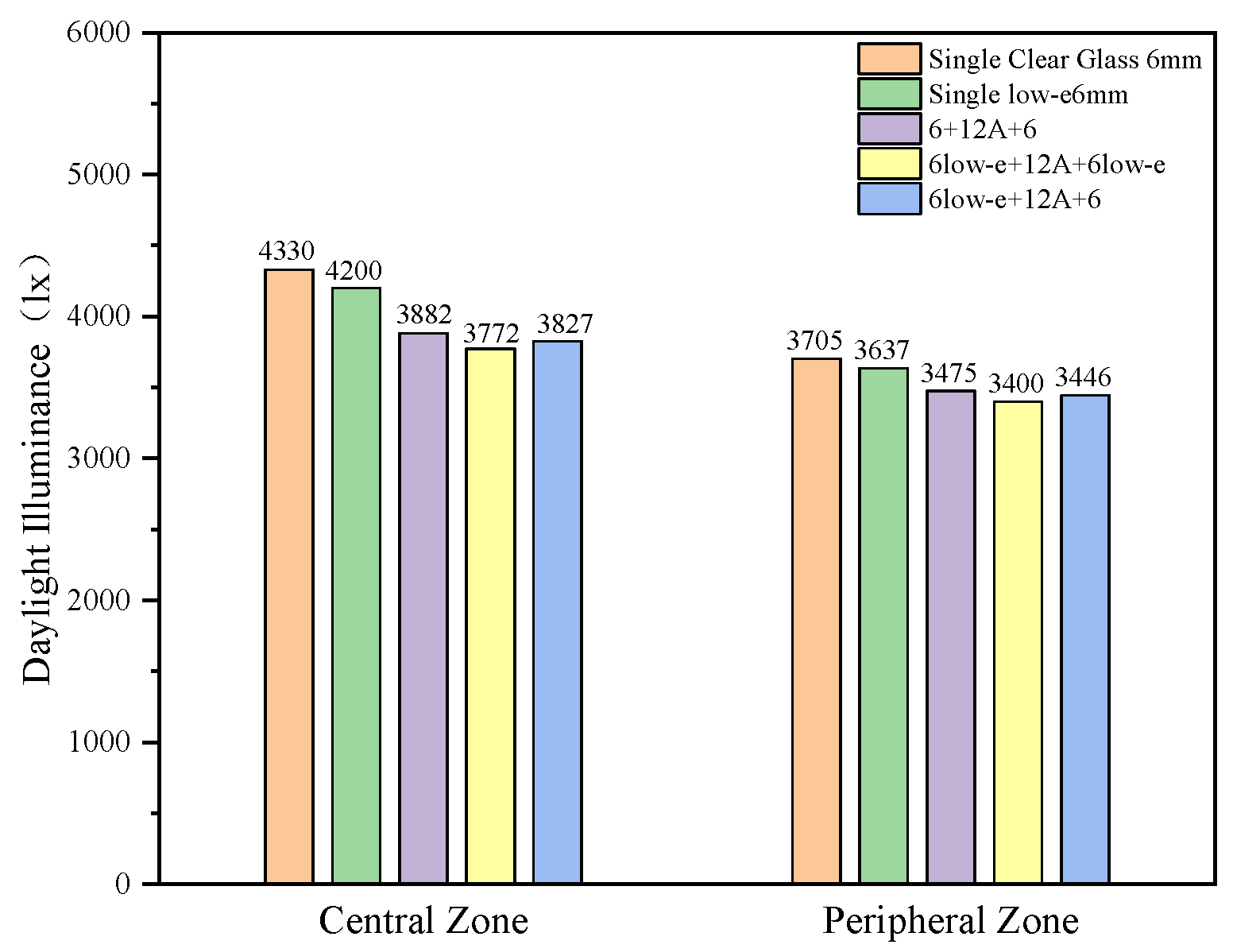

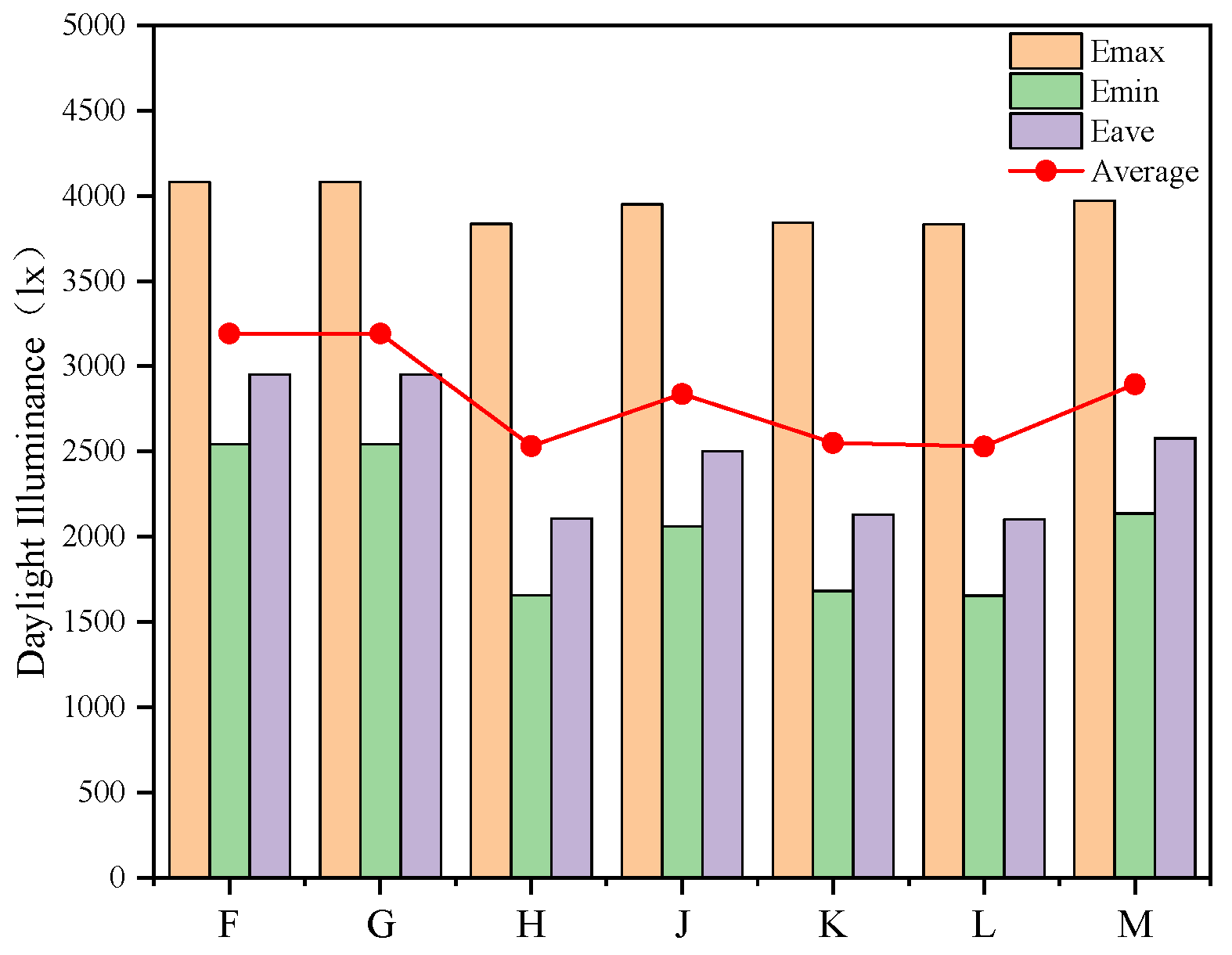

4.3.2. Illuminance Analysis of Sunrooms with Different Glazings

4.4. Simulation Analysis of Solar Radiation

4.4.1. Analysis of Solar Radiation for Common Glazing

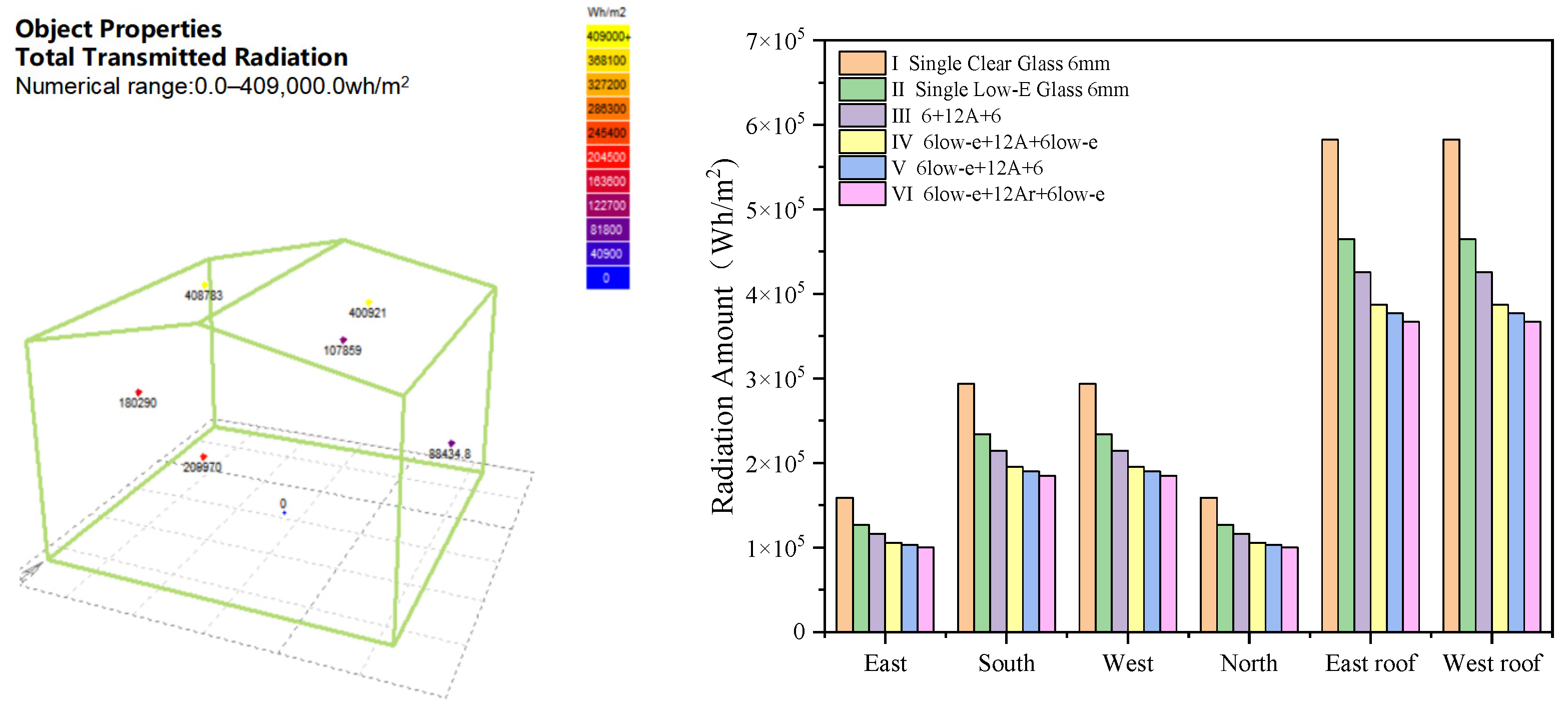

- (1)

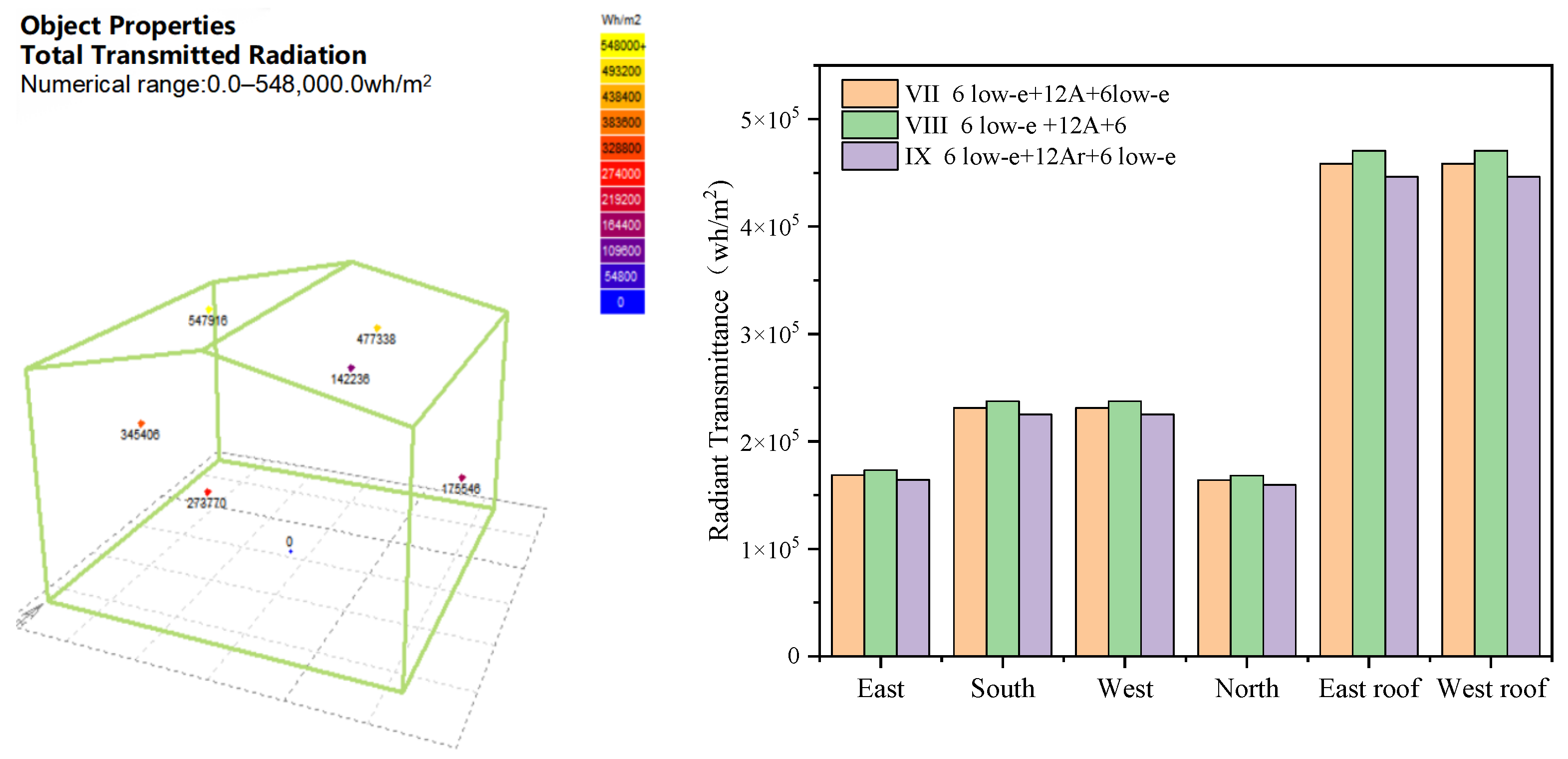

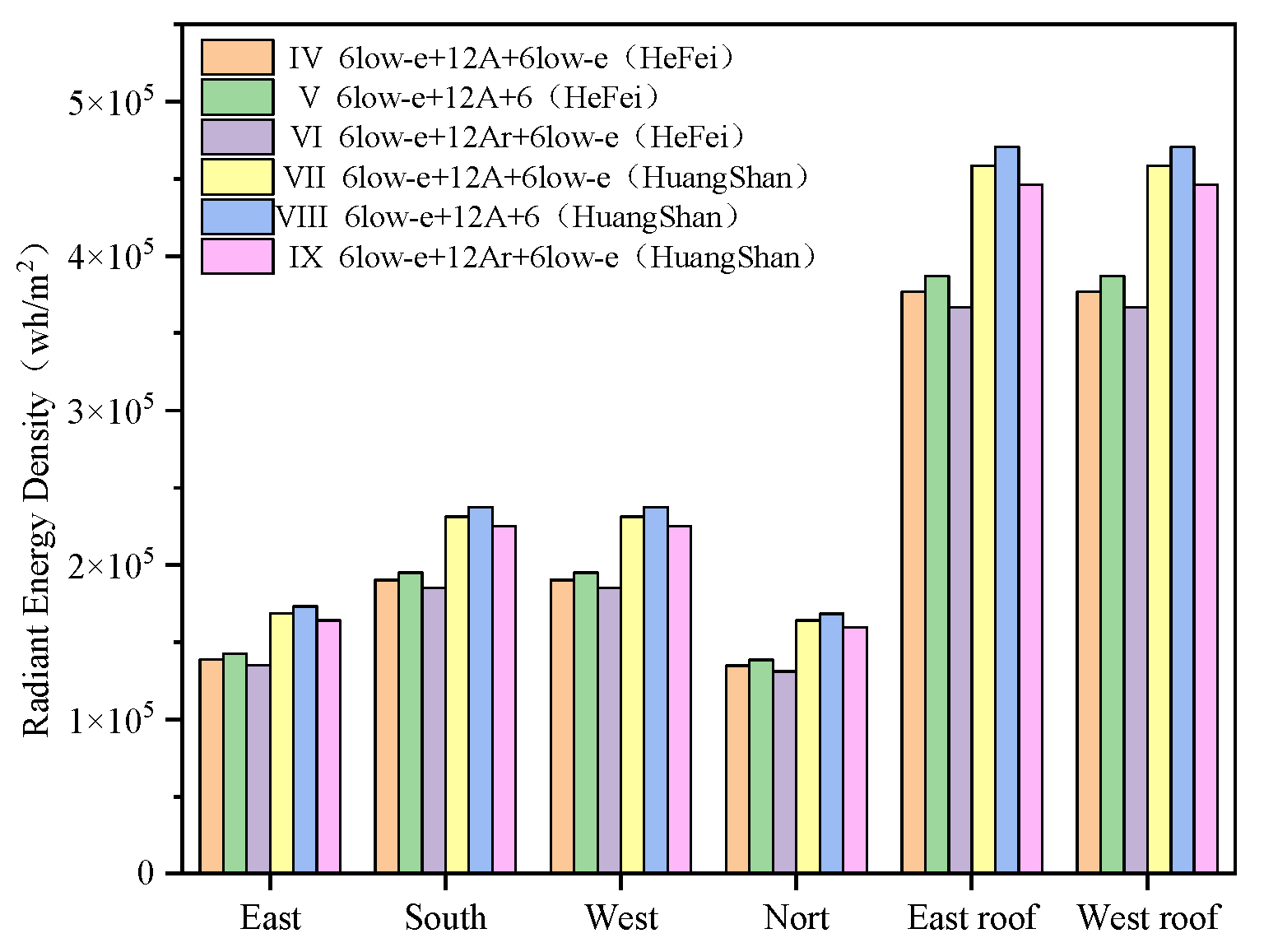

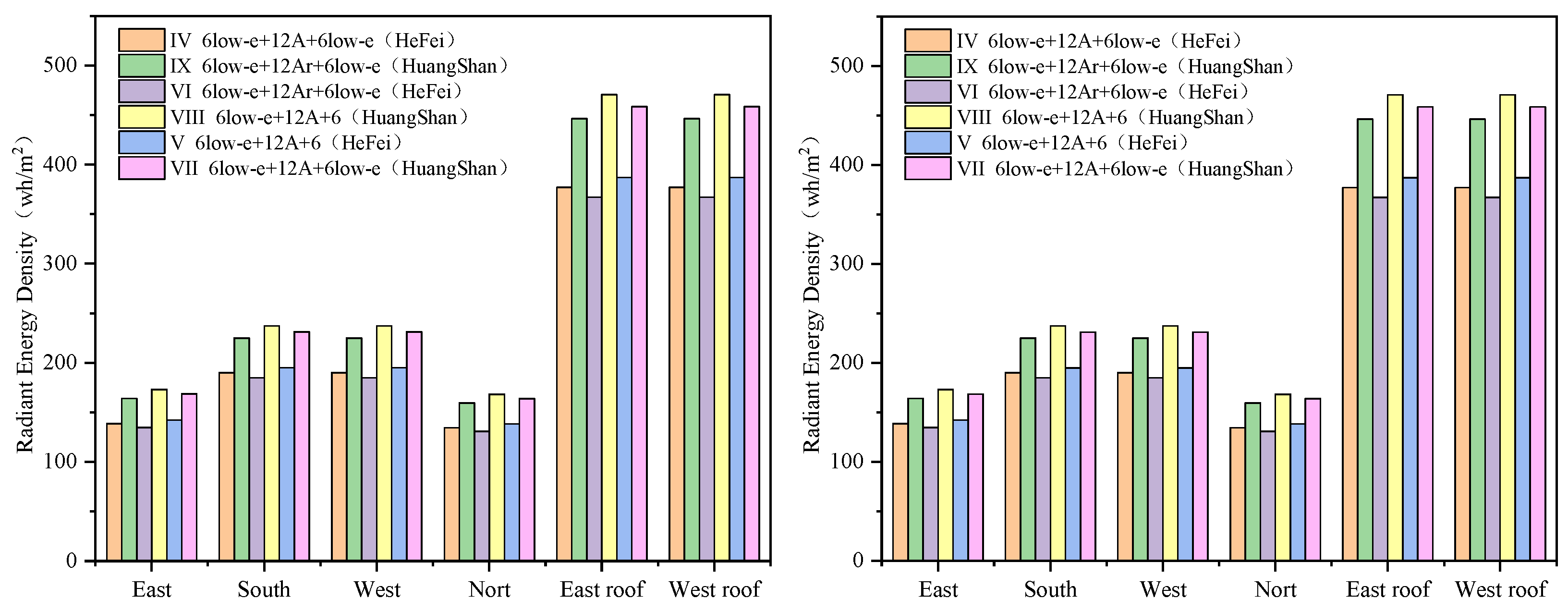

- Analysis of Transmitted Radiation by Orientation. We analyzed cases I-IX for transmitted radiation to compare orientations.

- (2)

- Analysis of Annual Transmitted Radiation in Different Regions

- (3)

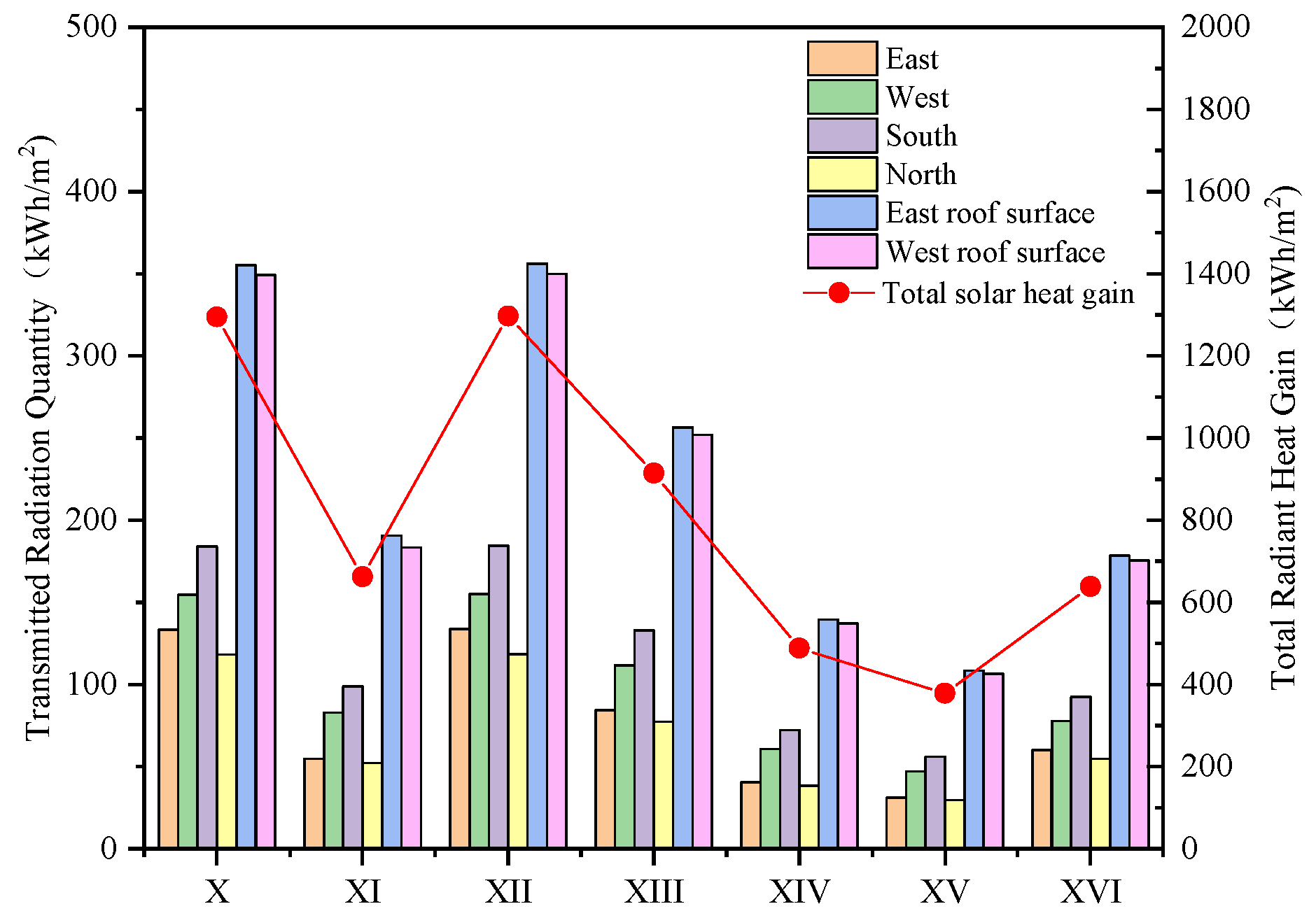

- Analysis of Transmitted Radiation on the Hottest and Coldest Days

4.4.2. Analysis of Solar Radiation for High-Performance Glazing

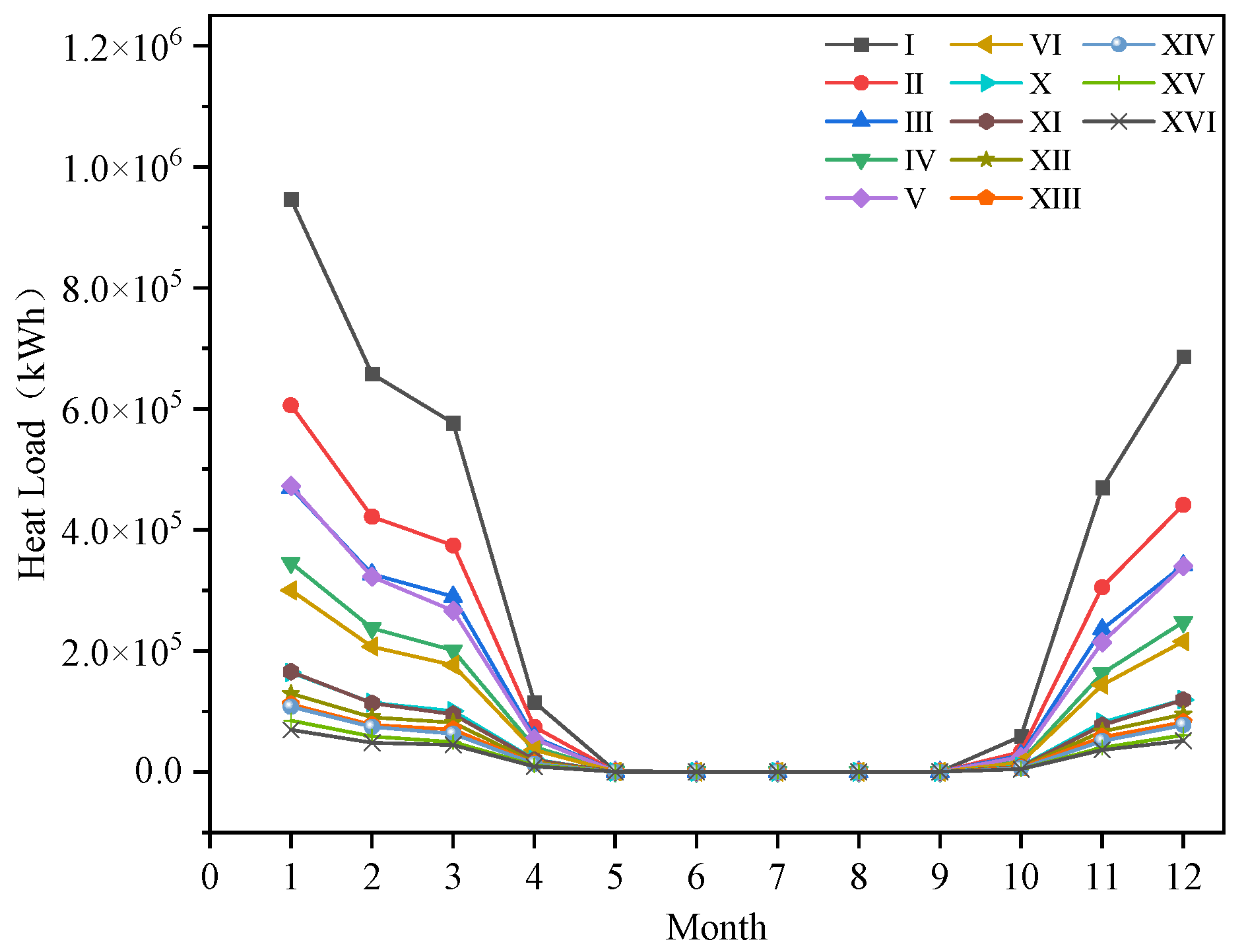

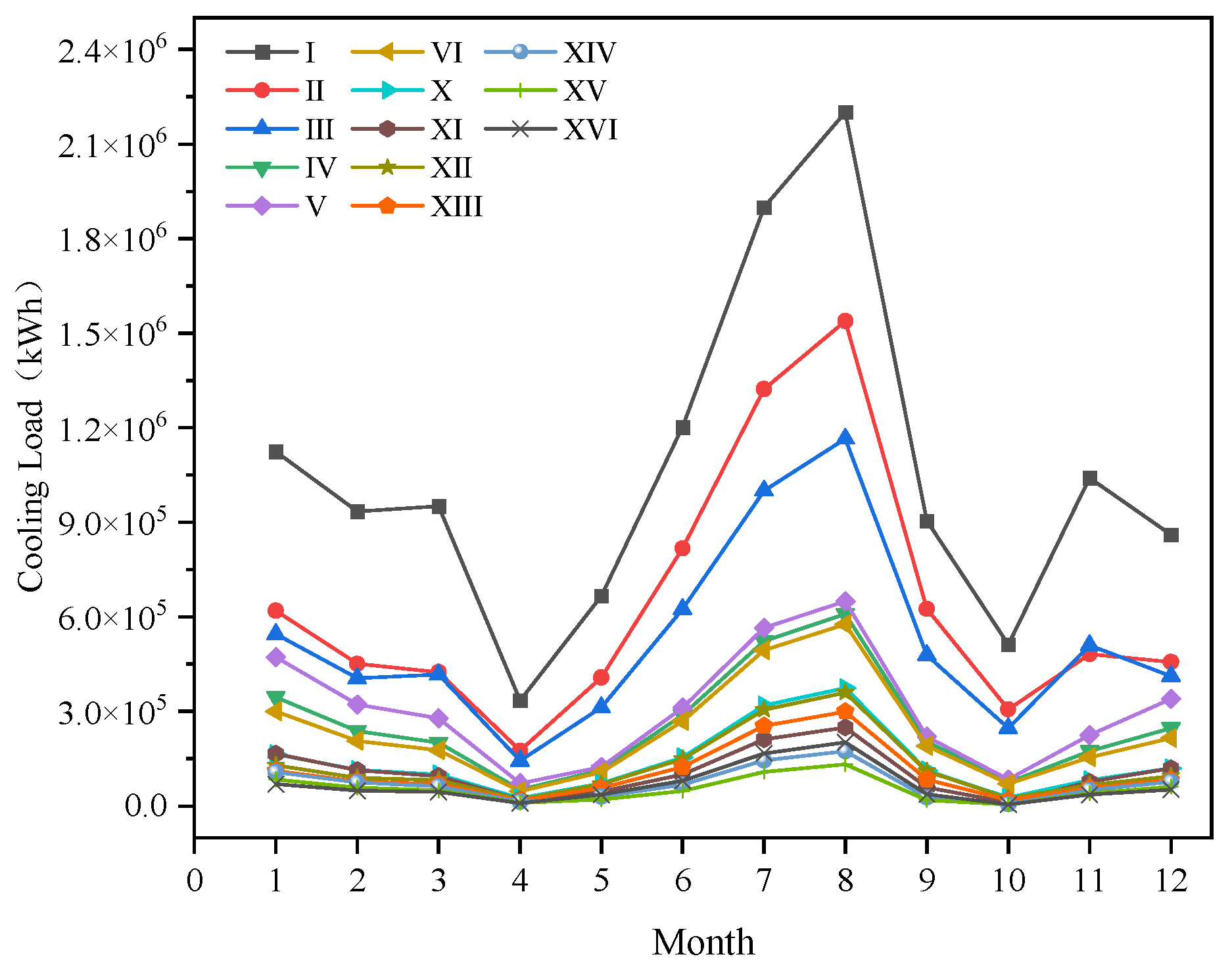

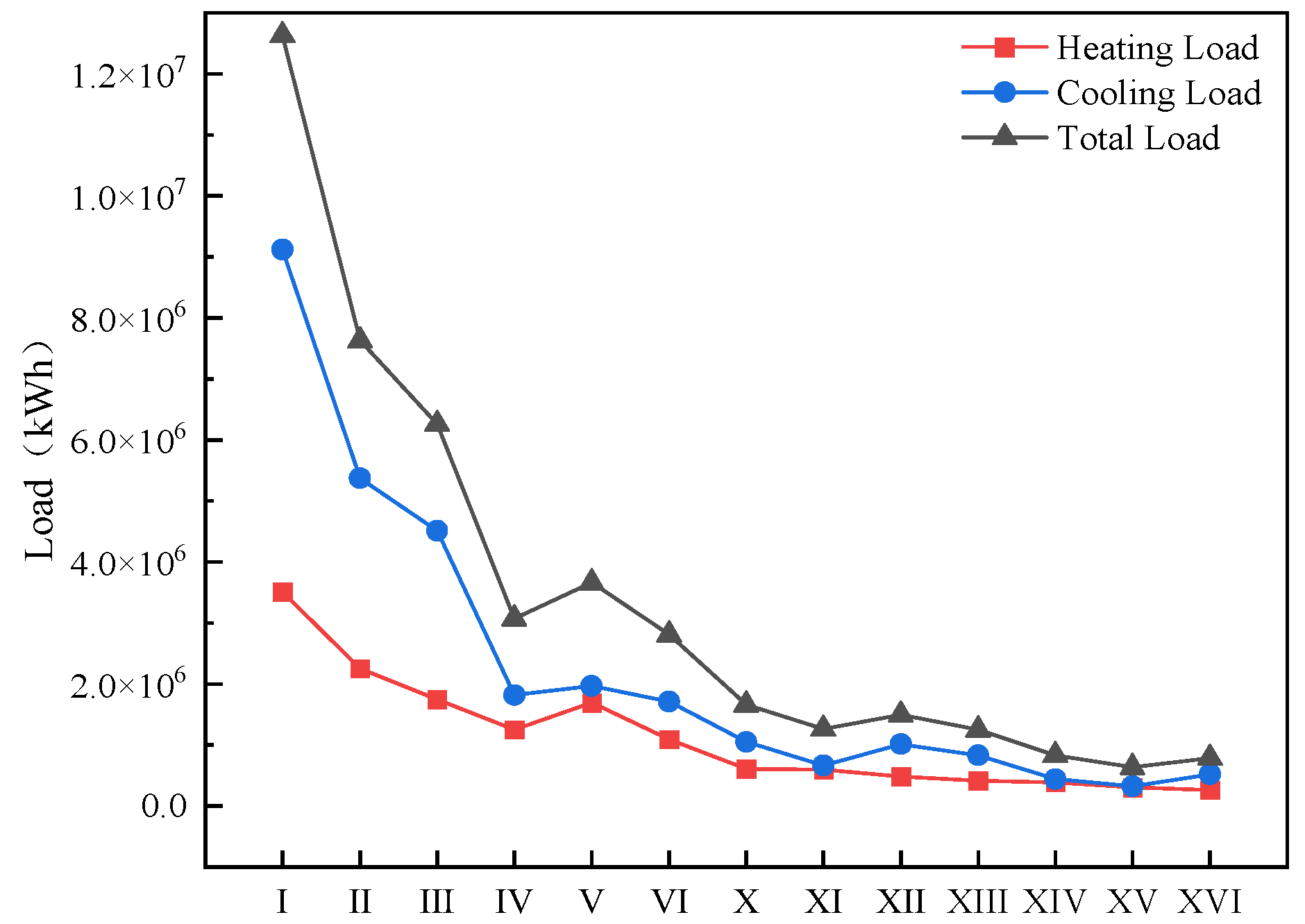

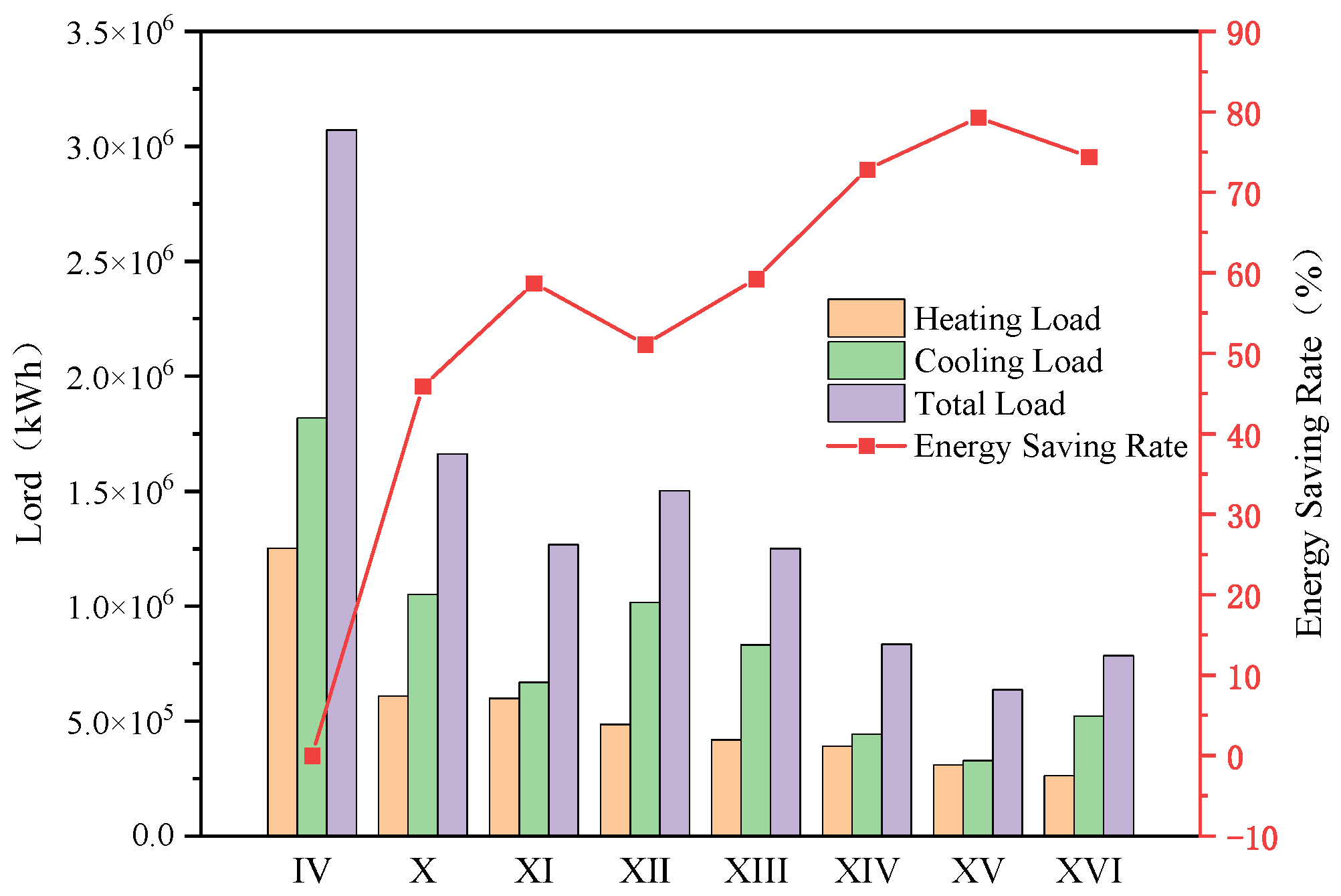

4.5. Energy Simulation Analysis of the Sunrooms

4.6. Collaborative Validation and Complementarity Between Experiments and Simulations

5. Conclusions

- (1)

- Based on the climatic characteristics of central-southern Anhui, measured comparisons between Low-e glazing and ordinary tempered glass sunrooms show that the solar radiation transmittance of Low-e glass is only 45.31% of that of ordinary tempered glass, with indoor temperature peaks reduced by about 6–7 °C and smaller nighttime temperature fluctuations, verifying the excellent thermal insulation performance and thermal stability of Low-e glazing.

- (2)

- Using Ecotect software to simulate the daylighting performance of 12 glazing types and transmitted radiation under 19 conditions shows that vacuum composite Triple-Silver glazing has about 10% lower transmittance than argon-filled triple glazing, but a significantly lower shading coefficient, making it suitable for summer shading. Single-silver-coated glass has the best daylighting performance, while Triple-Silver coatings combined with high-transmittance substrates can increase the daylight factor by 10.55%. East–west orientations have the highest annual transmitted radiation; argon-filled IGUs reduce radiation by 6.5% compared with ordinary IGUs, making them more suitable for the climate of central-southern Anhui. At the same time, the simulated values of temperature and radiation indicators matched well with the measured data points, verifying the reliability of the model and demonstrating the practical applicability of Ecotect in the optimization design of transparent building envelopes.

- (3)

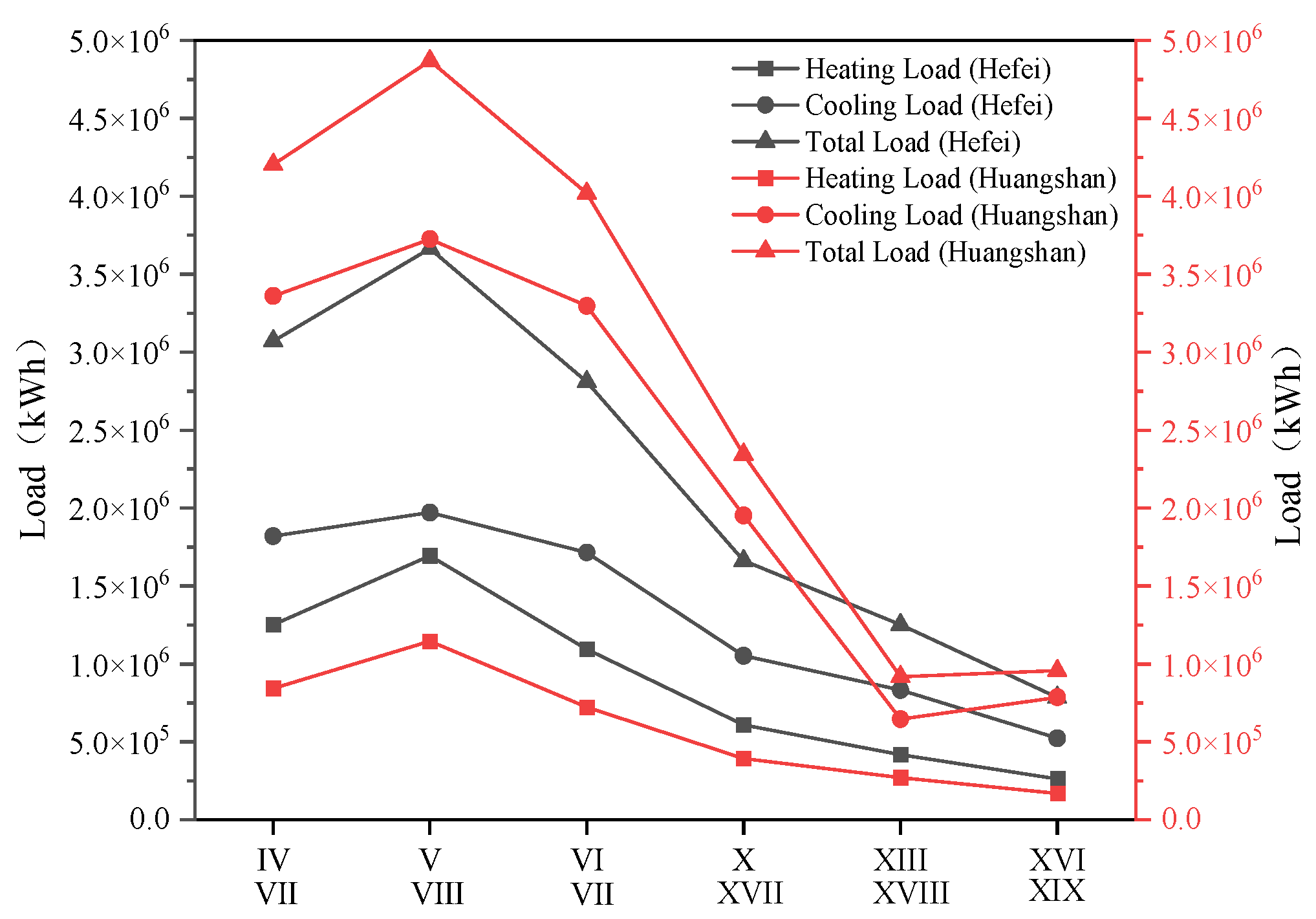

- Experiments indicate that the climatic characteristics of hot, humid summers and cold, damp winters in central-southern Anhui require dynamic adaptation from glazing. The measured performance of Low-e glazing in transitional seasons and summer already meets basic energy-saving requirements. Simulations further quantify optimized strategies by region: Huangshan has lower heating loads and is better suited to vacuum Triple-Silver Low-e glazing that strengthens summer shading; Hefei needs to balance winter and summer, for which argon-filled triple glazing with two cavities can balance heating and cooling energy consumption. Together these show that optimization of transparent envelopes should be based on experimentally measured regional climate parameters and determined via iterative multi-scenario simulations of glazing thermal parameters.

- (4)

- This study has several limitations. It does not yet cover winter operating conditions or year-round dynamic control, reducing applicability under extreme low temperatures. Long-term degradation and contamination of glass and components were not considered, potentially underestimating future energy use and comfort risks. In addition, parameters such as window-to-wall ratio, shading, and ventilation were not jointly optimized, introducing possible bias in trade-offs. Future work will involve annual and extreme weather simulations, accelerated aging tests, and on-site calibration to enhance reliability. Further studies will focus on the dynamic adaptability and integrated optimization of transparent envelopes in central-southern Anhui, with pilot projects to validate the proposed strategies. The ultimate goal is to build a full-chain low-carbon design framework—from material selection to building operation—for transparent envelope innovation in near-zero energy buildings in hot-summer–cold-winter regions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- The Research Center for Building Energy Conservation of Tsinghua University. Annual Development Research Report on Building Energy Conservation in China 2022: Public Building Special Topic; China Architecture & Building Press: Beijing, China, 2022; Volume 146. (In Chinese) [Google Scholar]

- Lai, X. Innovation and Development of Green Building Technologies under the “Dual Carbon” Goal. Resour. Conserv. Environ. Prot. 2025, 5, 113–117. (In Chinese) [Google Scholar] [CrossRef]

- Yang, Q.; Wang, J.; Liu, X.; Fu, L.-M.; Duan, Z.-L.; Wu, C.-Y. Crisis Transformation of Coupling Effects in China’s Building Carbon Emission Reduction-Environmental Protection-Economic Development System. Environ. Sci. 2025, 46, 2035–2046. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Z. Study on Improvement of Human Thermal Comfort Under High Indoor Solar Heat Gain. Ph.D. Thesis, Chang’an University, Xi’an, China, 2024. (In Chinese) [Google Scholar] [CrossRef]

- Song, Z. Analysis and Optimization of Indoor Temperature Fluctuations in Glass Curtain Wall (Office) Buildings in Cold Regions. Ph.D. Thesis, Shandong Jianzhu University, Jinan, China, 2024. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, Y. Study on Building Energy Efficiency Evaluation in Hot-Summer-Cold-Winter Regions Under the Background of Dual Carbon. Ph.D. Thesis, Zhongyuan University of Technology, Zhengzhou, China, 2024. (In Chinese) [Google Scholar] [CrossRef]

- Du, F.; Meng, Q. Study on Indoor Light Pollution and Thermal Environment of Glass Curtain Wall Buildings. Build. Sci. 2011, 27, 61–65. (In Chinese) [Google Scholar] [CrossRef]

- Ren, J.; Yuan, J.; Sui, X.; Zhang, J. Impact of Secondary Heat Transfer of Shading-Transparent Envelope Composites on Human Thermal Comfort. Heating. Vent. Air Cond. 2022, 52, 395–401. (In Chinese) [Google Scholar]

- Zhao, K.; Gui, X.; Ge, J. Influence of Solar Radiation on Thermal Comfort in Large Spaces and Design of Indoor Parameters. Acta Energiae Solaris Sin. 2019, 40, 2655–2662. (In Chinese) [Google Scholar]

- Ascione, F. Energy conservation and renewable technologies for buildings to face the impact of the climate change and minimize the use of cooling. Sol. Energy 2017, 154, 34–100. [Google Scholar] [CrossRef]

- Ahn, H.; Rim, D.; Pavlak, G.S.; Freihaut, J.D. Uncertainty analysis of energy and economic performances of hybrid solar photovoltaic and combined cooling, heating, and power (CCHP + PV) systems using a Monte-Carlo method. Appl. Energy 2019, 255, 113753. [Google Scholar] [CrossRef]

- Sun, F.; Jiang, Q.; Qi, Z.; Ye, X.; Chen, D. Research and Application of Standards for Energy-Saving Evaluation Methods of Building Thermal Insulation Coatings. New Build. Mater. 2025, 52, 26–30+41. (In Chinese) [Google Scholar]

- Husin, S.N.S.; Harith, Z.Y.H. The performance of daylight through various windows for residential buildings. Asian J. Environ.-Behav. Stud. 2018, 6, 169–178. [Google Scholar] [CrossRef]

- Missoum, M.; Hamidat, A.; Loukarfi, L.; Abdeladim, K. Impact of rural housing energy performance improvement on the energy balance in the North-West of Algeria. Energy Build. 2014, 85, 374–388. [Google Scholar] [CrossRef]

- Xu, L.; Ojima, T. Field experiments on natural energy utilization in a residential house with a double skin façade system. Build. Environ. 2007, 42, 2014–2023. [Google Scholar] [CrossRef]

- Baldinelli, G. Double skin façades for warm climate regions: Analysis of a solution with an integrated movable shading system. Build. Environ. 2009, 44, 1107–1118. [Google Scholar] [CrossRef]

- Zaller, A.; Winter, E.R.F.; Viskanta, R. Experimental studies of combined heat transfer in turbulent mixed convection fluid flows in double-skin facades. Int. J. Heat Mass Transf. 2002, 45, 4401–4408. [Google Scholar] [CrossRef]

- Shaik, S.; Maduru, V.R.; Kontoleon, K.J.; Arıcı, M.; Gorantla, K.; Afzal, A. Building glass retrofitting strategies in hot and dry climates: Cost savings on cooling, diurnal lighting, color rendering, and payback timeframes. Energy 2022, 243, 123106. [Google Scholar] [CrossRef]

- Bokel, R.M.J. The Effect of Window Position and Window Size on the Energy Demand for Heating, Cooling and Electric Lighting. In Proceedings of the 10th International Building Performance Simulation Association Conference & Exhibition, Tsinghua University, Beijing, China, 3–6 September 2007; Jiang, Y., Zhu, Y., Yang, X., Li, X., Eds.; IBPSA/Tsinghua University: Beijing, China, 2007; pp. 117–121. [Google Scholar]

- Li, Q.; Zhang, L.; Wang, X.; Su, X. Daylighting and energy performance of window with transparent insulation slats combined with building shading in the hot-summer and cold-winter zone. Sustain. Cities Soc. 2024, 114, 105772. [Google Scholar] [CrossRef]

- Ning, Q.; Chen, Z. Study on Energy-Saving Optimization of Opaque Envelopes for Rural Residences in Cold Regions. Build. Technol. 2023, 54, 1711–1716. (In Chinese) [Google Scholar]

- Song, S.; Sun, H.; Long, J.; Tan, X.; Li, J. Light-thermal environment of vertical translucent enclosure structures under solar radiation and method of internal shading adjustment. Energy 2024, 289, 130036. [Google Scholar] [CrossRef]

- Saroglou, T.; Theodosiou, T.; Givoni, B.; Meir, I.A. Studies on the optimum double-skin curtain wall design for high-rise buildings in the Mediterranean climate. Energy Build. 2020, 208, 109641. [Google Scholar] [CrossRef]

- Chow, T.T.; Pei, G.; Chan, L.S.; Lin, Z.; Fong, K.F. A comparative study of PV glazing performance in warm climate. Indoor Built Environ. 2009, 18, 32–40. [Google Scholar] [CrossRef]

- Chan, A.L.S.; Chow, T.T.; Fong, K.F.; Lin, Z. Investigation on energy performance of double skin façade in Hong Kong. Energy Build. 2009, 41, 1135–1142. [Google Scholar] [CrossRef]

- Pérez-Grande, I.; Meseguer, J.; Alonso, G. Influence of glass properties on the performance of double-glazed facades. Appl. Therm. Eng. 2005, 25, 3163–3175. [Google Scholar] [CrossRef]

- Yu, J.; Liu, Y.; Xiong, C.; Huang, J.C. Study on daylighting and energy conservation design of transparent envelope for office building in hot summer and cold winter zone. Procedia Eng. 2015, 121, 1642–1649. [Google Scholar] [CrossRef]

- Liu, M.; Han, S.; Yang, W.; Li, R. Study on Building Energy Consumption of External Circulation DSF in Hot-Summer-Cold-Winter Regions. Power Gener. Air Cond. 2017, 38, 62–66. (In Chinese) [Google Scholar]

- Li, S.; Chen, S. Field monitoring and prediction on temperature distribution of glass curtain walls of a super high-rise building. Eng. Struct. 2022, 250, 113405. [Google Scholar] [CrossRef]

- Yuan, J. Study on Energy-Saving Characteristics of Double-Skin Glass Curtain Walls in Severe Cold Regions. Ph.D. Thesis, Shenyang Jianzhu University, Shenyang, China, 2012. (In Chinese). [Google Scholar]

- Van Moeseke, G.; Gratia, E.; Reiter, S.; De Herde, A. Wind pressure distribution influence on natural ventilation for different incidences and environment densities. Energy Build. 2005, 37, 878–889. [Google Scholar] [CrossRef]

- Yao, S.; Jiang, Z.; Yuan, J.; Wang, Z.; Huang, L. Multi-objective optimization of transparent building envelope of rural residences in cold climate zone, China. Case Stud. Therm. Eng. 2022, 34, 102052. [Google Scholar] [CrossRef]

- Koçlar Oral, G. Appropriate window type concerning energy consumption for heating. Energy Build. 2000, 32, 95–100. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, T. Multi-objective optimization of energy, visual, and thermal performance for building envelopes in China’s hot summer and cold winter climate zone. J. Build. Eng. 2022, 59, 105034. [Google Scholar] [CrossRef]

- Schultz, J.M.; Svendsen, S. WinSim: A simple simulation program for evaluating the influence of windows on heating demand and risk of overheating. Sol. Energy 1998, 63, 251–258. [Google Scholar] [CrossRef]

- Misiopecki, C.; Grynning, S.; Gustavsen, A. Thermal improvements of box-window using shading attachments. Hot-Box measurements. Dev. Built Environ. 2023, 16, 100185. [Google Scholar] [CrossRef]

- Huang, J.; Liu, S.; Tang, X.; Peng, C.; Wang, L.; Zhang, X. Analysis of Thermal Performance and Energy-Saving Effects of External Windows in Office Buildings in Hot-Summer-Cold-Winter Regions. Build. Energy Conserv. 2019, 47, 88–92. (In Chinese) [Google Scholar]

- Hou, X. Comparative Study on Energy Consumption and Economy Between Existing Buildings and Near-Zero Energy Buildings. Ph.D. Thesis, North China University of Technology, Beijing, China, 2021. (In Chinese). [Google Scholar]

- Liu, S.; Qiang, W.; Zhang, Z.; Liu, C.; Sun, C.; Li, G. Economic Sensitivity Analysis of Opaque Envelopes in Near-Zero Energy Buildings in Severe Cold Regions. Build. Technol. 2020, 51, 1385–1388. (In Chinese) [Google Scholar]

- Zhang, Q. Study on Energy-Saving Adaptability of Low-E Glass in Chongqing Area. Ph.D. Thesis, Chongqing University, Chongqing, China, 2007. (In Chinese). [Google Scholar]

- Yu, Z. Study on Energy Consumption Simulation of Glass Film in Existing Office Buildings. Ph.D. Thesis, Hebei University of Technology, Tianjin, China, 2020. (In Chinese). [Google Scholar]

- Zhu, Y. Building Environment Science. Ph.D. Thesis, China Architecture & Building Press, Beijing, China, 2016. (In Chinese). [Google Scholar]

- Daylight Factor. In Wikipedia, The Free Encyclopedia. Available online: https://en.wikipedia.org/wiki/Daylight_factor (accessed on 29 October 2025).

- Carlos, J.S.; Corvacho, H. Evaluation of the performance indices of a ventilated double window through experimental and analytical procedures: SHGC-values. Energy Build. 2015, 86, 886–897. [Google Scholar] [CrossRef]

- Ochoa, C.E.; Capeluto, I.G. Evaluating visual comfort and performance of three natural lighting systems for deep office buildings in highly luminous climates. Build. Environ. 2006, 41, 1128–1135. [Google Scholar] [CrossRef]

- Bourgeois, D.; Reinhart, C.F.; Ward, G. Standard daylight coefficient model for dynamic daylighting simulations. Build. Res. Inf. 2008, 36, 68–82. [Google Scholar] [CrossRef]

- Lin, R.; Zhao, J. Analysis of Main Technical Features of the New Edition of “Code for Design of Building Daylighting”. China Illum. Eng. J. 2013, 24, 5–11. (In Chinese) [Google Scholar]

- ISO 9001; Quality Management Systems—Requirements. International Organization for Standardization (ISO): Geneva, Switzerland, 2015.

| Lighting Class | Side Daylighting | Top Daylighting | ||

|---|---|---|---|---|

| Daylight Factor Standard (%) | Indoor Natural Illuminance (lx) | Daylight Factor Standard (%) | Indoor Natural Illuminance (lx) | |

| I | 5 | 750 | 5 | 750 |

| II | 4 | 600 | 4 | 450 |

| III | 3 | 450 | 3 | 300 |

| IV | 2 | 300 | 2 | 150 |

| V | 1 | 150 | 1 | 75 |

| Daylighting Grade | Visual Task Category | Side Daylighting | Top Daylighting | |||

|---|---|---|---|---|---|---|

| Task Precision | Minimum Identifiable Object Size d (mm) | Indoor Critical Illuminance (l×) | Minimum Daylight Factor Cmin (%) | Indoor Critical Illuminance (l×) | Average Daylight Factor Cmin (%) | |

| I | Extremely high precision | d ≤ 0.15 | 250 | 5 | 350 | 7 |

| II | High precision | 0.15 < d ≤ 0.3 | 150 | 3 | 225 | 1.5 |

| III | Medium precision | 0.3 < d ≤ 1.0 | 100 | 2 | 150 | 3 |

| IV | Standard precision | 1.0 < d ≤ 5.0 | 50 | 1 | 75 | 1.5 |

| V | Low precision | d > 5.0 | 25 | 0.5 | 35 | 0.7 |

| Glass Type | Glass Model | K-Value | Shading Coefficient | Visible Transmittance |

|---|---|---|---|---|

| Clear Tempered Glass | 5T + 12A + 5T | 2.72 | 0.87 | 0.8 |

| Triple-Silver Low-e Tempered Glass | 6Low-e Triple-Silver + 12A + 6T | 1.5 | 0.3 | 0.48 |

| No. | Monitoring Content | Measurement Height (m) |

|---|---|---|

| 1 | Temperature and Humidity Sensors | 0.5 m, 1 m, 1.5 m, 2 m |

| 2 | CO2 Concentration Sensor | 1.5 m |

| 3 | PM2.5 Concentration Sensor | 1.5 m |

| 4 | Radiant Heat Flux Sensor | 1.5 m |

| Equipment Name | Model | Technical Parameters | Manufacturer |

|---|---|---|---|

| Industrial Wide-Temperature Range Temperature and Humidity Transmitter | JWSK-6 | Humidity: ±2% RH (5% RH–95% RH, 25 °C); Temperature: ±0.5 °C (25 °C) | Beijing Kunlun Coast Sensing Technology Co., Ltd. (Beijing, China) |

| Solar Radiation Sensor | RK200-03 | Total Solar Radiation Range: 0–2000 W/m2; Spectral Range: 300–3200 nm; Temperature Influence: ±2% (−10–40 °C) | Hunan Ruikate Electronic Technology Co., Ltd. (Changsha, China) |

| Light Climate Zone | I | II | III | IV | V |

|---|---|---|---|---|---|

| K-value | 0.85 | 0.90 | 1.00 | 1.1 | 1.2 |

| Outdoor natural critical illuminance E | 6000 | 5500 | 5000 | 4500 | 4000 |

| Case | Glazing Type and Thickness | Low-e Emissivity ε | Visible Reflectance | Visible Transmittance | Solar Heat Gain Coefficient | Value W/m2·K | Shading Coefficient Sc |

|---|---|---|---|---|---|---|---|

| A | Single Clear Glass 6 mm | - | 0.081 | 0.897 | 0.94 | 5.360 | 0.98 |

| B | Single Low-e 6 mm | 0.18 | 0.077 | 0.787 | 0.75 | 3.497 | 0.799 |

| C | 6 + 12A + 6 | - | 0.146 | 0.811 | 0.81 | 2.710 | 0.866 |

| D | 6 Low-e + 12A + 6 Low-e | 0.18 | 0.127 | 0.720 | 0.75 | 1.8 | 0.716 |

| E | 6 Low-e + 12A + 6 | 0.18 | 0.130 | 0.730 | 0.77 | 2.3 | 0.650 |

| F | 6 Low-e + 9Ar + 6 + 9Ar + 6 Low-e | 0.072 | 0.158 | 0.725 | 0.510 | 0.92 | 0.587 |

| G | 6 Low-e + 16Ar + 6 + 16Ar + 6 Low-e (High Transmission) | 0.072 | 0.158 | 0.725 | 0.511 | 0.76 | 0.587 |

| H | 6 Low-e + 12Ar + 6 + 12Ar | 0.103 | 0.152 | 0.477 | 0.416 | 0.83 | 0.416 |

| J | 6 + 12A + 6 Low-e + V + 6 (Single-Silver) | 0.103 | 0.193 | 0.593 | 0.450 | 0.65 | 0.517 |

| K | 6 + 12A + 6 Low-e + V + 6 (Double-Silver) | 0.065 | 0.177 | 0.484 | 0.300 | 0.55 | 0.344 |

| L | 6 + 12A + 6 Low-e + V + 6 (Triple-Silver) | 0.024 | 0.171 | 0.476 | 0.237 | 0.43 | 0.273 |

| M | 6 + 12Ar + 6 Low-e + V + 6 (Triple-Silver) | 0.021 | 0.179 | 0.615 | 0.302 | 0.41 | 0.348 |

| Case | Glazing Type and Thickness | Low-e Emissivity ε | Visible Reflectance | Visible Transmittance | Solar Heat Gain Coefficient | U-Value W/m2·K (Thermal Transmittance) | Shading Coefficient (Sc) | Climate Zone |

|---|---|---|---|---|---|---|---|---|

| I | Single Clear Glass 6 mm | - | 0.081 | 0.897 | 0.94 | 5.360 | 0.98 | Hefei |

| II | Single Low-e Glass 6 mm | 0.18 | 0.077 | 0.787 | 0.75 | 3.497 | 0.799 | Hefei |

| III | 6 + 12A + 6 | - | 0.146 | 0.811 | 0.81 | 2.710 | 0.866 | Hefei |

| IV | 6 Low-e + 12A + 6 Low-e | 0.18 | 0.127 | 0.720 | 0.75 | 1.8 | 0.716 | Hefei |

| V | 6 Low-e + 12A + 6 | 0.18 | 0.130 | 0.730 | 0.77 | 2.3 | 0.650 | Hefei |

| VI | 6 Low-e + 12Ar + 6 Low-e | 0.13 | 0.111 | 0.720 | 0.75 | 1.60 | 0.648 | Hefei |

| VII | 6 Low-e + 12A + 6 Low-e | 0.13 | 0.111 | 0.720 | 0.75 | 1.8 | 0.716 | Huangshan |

| VIII | 6 Low-e + 12A + 6 | 0.18 | 0.130 | 0.730 | 0.77 | 2.3 | 0.650 | Huangshan |

| IX | 6 Low-e + 12Ar + 6 Low-e | 0.13 | 0.111 | 0.720 | 0.75 | 1.60 | 0.648 | Huangshan |

| X | 6 Low-e + 9Ar + 6 + 9Ar + 6 Low-e | 0.072 | 0.158 | 0.725 | 0.510 | 0.92 | 0.587 | Hefei |

| XI | 6 Low-e + 12Ar + 6 + 12Ar | 0.103 | 0.152 | 0.477 | 0.416 | 0.83 | 0.416 | Hefei |

| XII | 6 Low-e + 16Ar+ 6 + 16Ar + 6 Low-e (High Transmission) | 0.072 | 0.158 | 0.725 | 0.511 | 0.76 | 0.587 | Hefei |

| XIII | 6 + 12A + 6 Low-e + V + 6 (Single-Silver) | 0.103 | 0.193 | 0.593 | 0.450 | 0.65 | 0.517 | Hefei |

| XIV | 6 + 12A + 6 Low-e + V + 6 (Double-Silver) | 0.065 | 0.177 | 0.484 | 0.300 | 0.55 | 0.344 | Hefei |

| XV | 6 + 12A + 6 Low-e + V + 6 (Triple-Silver) | 0.024 | 0.171 | 0.476 | 0.237 | 0.43 | 0.273 | Hefei |

| XVI | 6 + 12Ar + 6 Low-e + V + 6 (Triple-Silver) | 0.021 | 0.179 | 0.615 | 0.302 | 0.41 | 0.348 | Hefei |

| XVII | 6 Low-e + 9Ar + 6 + 9Ar + 6 Low-e | 0.072 | 0.158 | 0.725 | 0.510 | 0.92 | 0.587 | Huangshan |

| XVIII | 6 + 12A + 6 Low-e + V + 6 (Single-Silver) | 0.065 | 0.177 | 0.484 | 0.300 | 0.55 | 0.344 | Huangshan |

| XIX | 6 + 12Ar + 6 Low-e + V + 6 (Triple-Silver) | 0.021 | 0.179 | 0.615 | 0.302 | 0.41 | 0.348 | Huangshan |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, H.; Zhu, Y.; Cheng, M.; Zhu, S.; Zhu, G.; Xu, J. Low-Carbon Design Strategies for Transparent Building Envelopes in Hot-Summer–Cold-Winter Climate Zones—Experimental and Numerical Simulation Study Based on the High-Performance Sunroom Laboratory in Central-Southern Anhui. Sustainability 2025, 17, 10544. https://doi.org/10.3390/su172310544

Hu H, Zhu Y, Cheng M, Zhu S, Zhu G, Xu J. Low-Carbon Design Strategies for Transparent Building Envelopes in Hot-Summer–Cold-Winter Climate Zones—Experimental and Numerical Simulation Study Based on the High-Performance Sunroom Laboratory in Central-Southern Anhui. Sustainability. 2025; 17(23):10544. https://doi.org/10.3390/su172310544

Chicago/Turabian StyleHu, Haowei, Yukun Zhu, Mingzuo Cheng, Shuguang Zhu, Guotao Zhu, and Jun Xu. 2025. "Low-Carbon Design Strategies for Transparent Building Envelopes in Hot-Summer–Cold-Winter Climate Zones—Experimental and Numerical Simulation Study Based on the High-Performance Sunroom Laboratory in Central-Southern Anhui" Sustainability 17, no. 23: 10544. https://doi.org/10.3390/su172310544

APA StyleHu, H., Zhu, Y., Cheng, M., Zhu, S., Zhu, G., & Xu, J. (2025). Low-Carbon Design Strategies for Transparent Building Envelopes in Hot-Summer–Cold-Winter Climate Zones—Experimental and Numerical Simulation Study Based on the High-Performance Sunroom Laboratory in Central-Southern Anhui. Sustainability, 17(23), 10544. https://doi.org/10.3390/su172310544