Ecological Paradox in the Reuse of Internal Combustion Engines from Scrapped Vehicles for Electric Power Generation—Circular Economy Potential Versus Emission Certification Barriers

Abstract

1. Introduction

2. A Review of Aspects Related to the Reuse of ICEs from Scrapped Vehicles

2.1. Technical Aspect

2.2. Economic Aspect

2.3. Environmental Aspect

2.4. Scientific and Research Aspect

2.5. Analysis of Risks Associated with Using Engines from ELV in Electricity Generators

2.6. Comparison of Carbon Footprint: New Low-Emission Engines vs. Reused Engines Recovered from ELVs

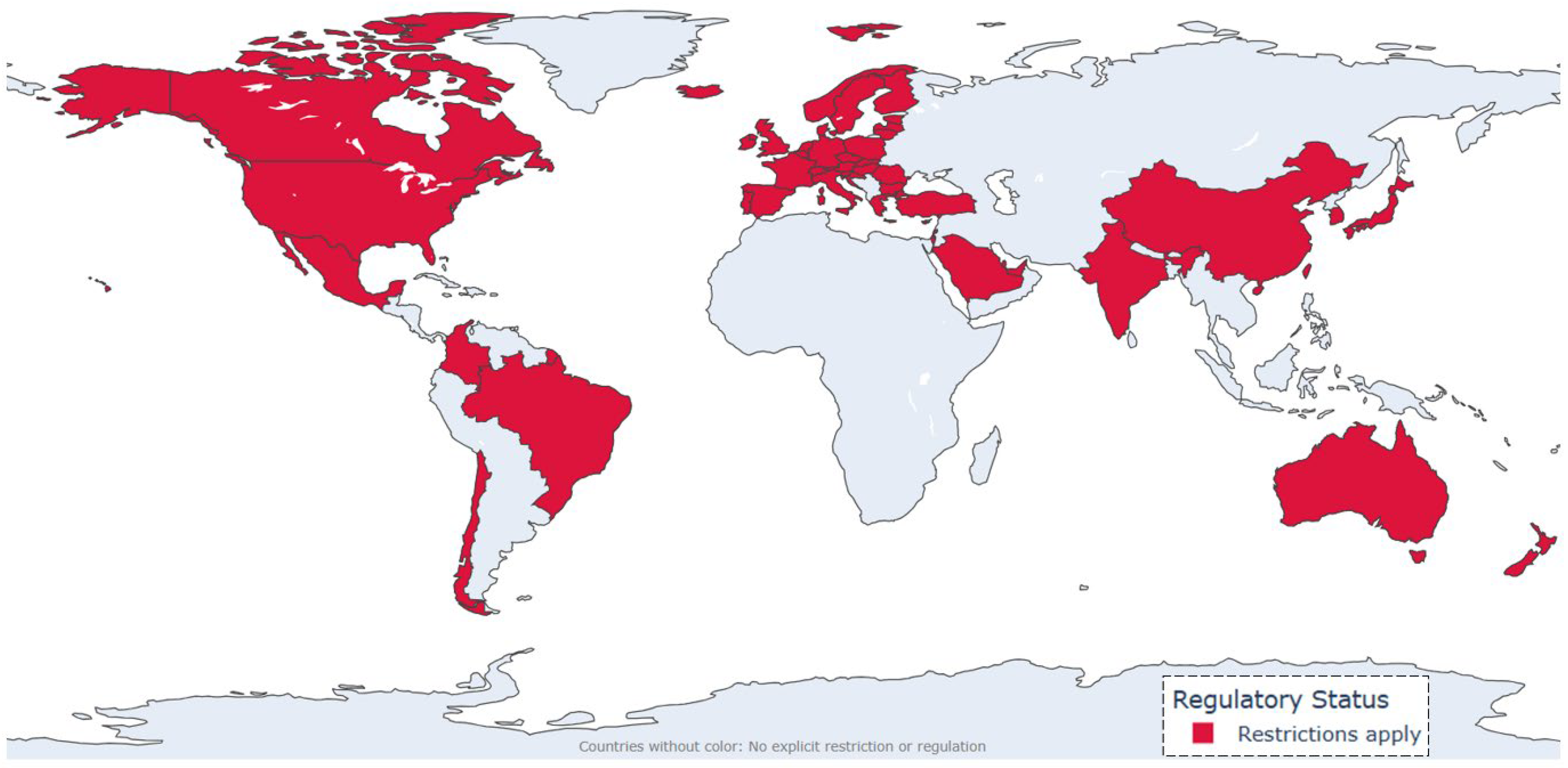

3. Review of Homologation Regulations for Passenger Cars, Trucks, and Electric Power Generators—Their Occurrence in Selected Countries Worldwide

4. Engines from Scrapped Vehicles in the EU and Their Application in Electric Power Generators in the Context of Machine Homologation Focused on Exhaust Emission Limits

5. Limitations on the Applicability of Engines from Scrapped Vehicles in Power Generators—A Global Review

6. Comparison of Homologation Procedures for Engines Intended for Vehicles and Power Generators (Discrepancies Preventing Direct Comparison of Emission Limit Values)

7. Proposed Homologation Procedure for ELV Engines Intended for Power Generator Applications

8. Policy Paradox in Engine Reuse: Local Emission Limits Versus Global Environmental Gains

9. Proposed Guidelines for New Homologation Tests That Should Be Simple, Low-Cost, and Accessible—Supporting the Applicability of the Concept

10. Academic Justification for Reviewing Legal Regulations and Guidelines

11. Differences Between SI and CI Engines in the Context of Recycling Through Reuse

12. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CARB | California Air Resources Board |

| CCSU | Certificate of Conformity for Secondary Use |

| CEV | Construction Equipment Vehicles |

| CI | compression-ignition |

| CNG | compressed natural gas |

| CO2 | carbon dioxide |

| CO | carbon monoxide |

| DfU | Design for Upgradability |

| DME | Dimethyl ether |

| DPF | Diesel Particulate Filter |

| EAEU | Eurasian Economic Union |

| ECU | engine control unit |

| EEA | European Economic Area |

| EFTA | European Free Trade Association |

| EGR | Exhaust Gas Recirculation |

| ELV | End-of-life vehicle |

| EPA | Environmental Protection Agency |

| ETC | European Transient Cycle |

| EU | European Union |

| GDI | gasoline direct injection |

| HC | hydrocarbons |

| ICE | Internal combustion engine |

| KMOE | Korean Ministry of Environment |

| LCA | Life Cycle Assessment |

| LPG | liquefied petroleum gas |

| MCP | Medium Combustion Plant |

| METI | Ministry of Economy, Trade and Industry |

| MLIT | Ministry of Land, Infrastructure, Transport and Tourism |

| NEDC | New European Driving Cycle |

| NESHAP | National Emission Standards for Hazardous Air Pollutants |

| NOx | nitrogen oxides |

| NRMM | non-road machinery |

| NRSC | Non-Road Steady Cycle |

| NRTC | Non-Road Transient Cycle |

| NSPS | New Source Performance Standards |

| PM | particulate matter |

| PN | particle number |

| RDE | Real Driving Emissions |

| SCR | Selective Catalytic Reduction |

| SI | spark-ignition |

| TREM | Tractor, Earth Moving and Material Handling Equipment |

| UAE | United Arab Emirates |

| WHSC | World Harmonized Stationary Cycle |

| WHTC | World Harmonized Transient Cycle |

| WLTC | Worldwide Harmonized Light vehicles Test Cycle |

| WLTP | Worldwide Harmonized Light Vehicles Test Procedure |

References

- Moriarty, P.; Honnery, D. The Global Environmental Crisis of Transport. In Transforming Urban Transport: From Automobility to Sustainable Transport; Low, N., Ed.; Taylor and Francis: Oxfordshire, UK, 2012; pp. 39–53. ISBN 978-1-136-18791-9. [Google Scholar]

- Lee, H.; Kim, K.; Jeon, H.; Baek, S. Feasibility Study of ASR (Automotive Shredder Residue) Recycling Based on the Analysis of Separation Process. In Proceedings of the EARTH—International Symposium on East Asian Resources Recycling Technology, Pattaya, Thailand, 1–4 November 2015; pp. 1108–1111. [Google Scholar]

- Liu, Y.; Guo, F.; Li, L.; Zheng, J. Simulation Analysis and Diagnosis Method of Series Fault Arc in Mine Power Supply System. Meitan Xuebao/J. China Coal Soc. 2019, 44, 1265–1273. [Google Scholar] [CrossRef]

- Karikalan, M.; Eswaran, A.; Krishnaswamy Raman, S. Systematic Approach to Estimate Vehicle Cost at End-of-Life and Different Time Intervals. In Proceedings of the FISITA World Automotive Congress FISITA, Chennai, India, 2–5 October 2018. [Google Scholar]

- Simic, V.; Dimitrijevic, B. Production Planning for Vehicle Recycling Factories in the EU Legislative and Global Business Environments. Resour. Conserv. Recycl. 2012, 60, 78–88. [Google Scholar] [CrossRef]

- Humelnicu, C.; Mereuta, E.; Amortila, V.; Gingarasu, M. Reducing the Air Pollution Impact of the Recycled Auto Vehicles. In Proceedings of the International Multidisciplinary Scientific GeoConference Surveying Geology Mining Ecology Management, SGEM, Albena, Bulgaria, 28 June–6 July 2019; Volume 19, pp. 1053–1060. [Google Scholar]

- Čabalová, I.; Krilek, J.; Bubeníková, T.; Ružiak, I.; Nemec, M.; Lee, S.H.; Lubis, M.A.R.; Darabošová, A.; Mancel, V.; Kristak, L.; et al. Utilization of Waste Tire and Rubber from Automobiles in the Manufacturing of Particleboards and Evaluation of Its Properties. Eur. J. Wood Prod. 2025, 83, 67. [Google Scholar] [CrossRef]

- Kalhor, A.; Dykas, J.; Rodak, K.; Grajcar, A. Materials and Constructional Design for Electric Vehicles: A Review. Adv. Sci. Technol. Res. J. 2025, 19, 178–196. [Google Scholar] [CrossRef] [PubMed]

- Mohelský, L. Impact of the Car Scrapping Scheme on Consumer Behaviour and Aggregate Consumption. Prague Econ. Pap. 2011, 268–287. [Google Scholar] [CrossRef]

- Darekar, R.; Gawande, N.; Karkaria, V.; Karandikar, P.B. Analysis of Critical Issues in Retrofitting of ICE Vehicles. In Proceedings of the Journal of Physics: Conference Series, Second International Conference on Advances in Physical Sciences and Materials 2021 (ICAPSM 2021), Online, 12–13 August 2021; IOP Publishing Ltd.: Bristol, UK, 2021; Volume 2070. [Google Scholar]

- Matuszewska, A.; Wieczorek, P.; Samson-Bręk, I. Bulky Vehicles Recycling. Part 1—Conditions for Recycling. Stud. Ecol. Bioethicae 2020, 18, 85–93. [Google Scholar] [CrossRef]

- Xiao, L.; Zhou, H.; Wang, C.; Liu, X. Influencing factors of vehicle damage degree in vehicle-vehicle collision accident at intersection. J. Automot. Saf. Energy 2023, 14, 23–30. [Google Scholar] [CrossRef]

- Berzi, L.; Delogu, M.; Giorgetti, A.; Pierini, M. On-Field Investigation and Process Modelling of End-of-Life Vehicles Treatment in the Context of Italian Craft-Type Authorized Treatment Facilities. Waste Manag. 2013, 33, 892–906. [Google Scholar] [CrossRef]

- Sahil; Sarmah, S.P.; Shukla, M. Exploration of vehicle scrappage intentions using the theory of planned behavior. In Proceedings of the Computers and Industrial Engineering CIE, Sharjah, United Arab Emirates, 30 October–2 November 2023; Volume 2, pp. 831–836. [Google Scholar]

- Wuschke, L.; Jäckel, H.-G.; Leißner, T.; Peuker, U.A. Crushing of Large Li-Ion Battery Cells. Waste Manag. 2019, 85, 317–326. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Kanciak, W.; Barczewski, M.; Barczewski, R.; Regulski, R.; Sędziak, D.; Jędryczka, C. Recycling of Plastics from Cable Waste from Automotive Industry in Poland as an Approach to the Circular Economy. Polymers 2021, 13, 3845. [Google Scholar] [CrossRef]

- Lyskawinski, W.; Baranski, M.; Jedryczka, C.; Mikolajewicz, J.; Regulski, R.; Sedziak, D.; Netter, K.; Rybarczyk, D.; Czarnecka-Komorowska, D.; Barczewski, M. Tribo-Electrostatic Separation Analysis of a Beneficial Solution in the Recycling of Mixed Poly(Ethylene Terephthalate) and High-Density Polyethylene. Energies 2021, 14, 1755. [Google Scholar] [CrossRef]

- Krawiec, P.; Warguła, Ł.; Małozięć, D.; Kaczmarzyk, P.; Dziechciarz, A.; Czarnecka-Komorowska, D. The Toxicological Testing and Thermal Decomposition of Drive and Transport Belts Made of Thermoplastic Multilayer Polymer Materials. Polymers 2020, 12, 2232. [Google Scholar] [CrossRef] [PubMed]

- Warguła, Ł.; Kaczmarzyk, P.; Wieczorek, B.; Małozięć, D.; Dziechciarz, A. Assessment of the Hazards Occurring During the Thermal Decomposition and Combustion Process in a Toothed Belt Transmission. Materials 2025, 18, 1637. [Google Scholar] [CrossRef]

- Kalargaris, I.; Tian, G.; Gu, S. The Utilisation of Oils Produced from Plastic Waste at Different Pyrolysis Temperatures in a DI Diesel Engine. Energy 2017, 131, 179–185. [Google Scholar] [CrossRef]

- Zogg, R.; Lawrence, T.; Roth, K.; Brodrick, J. Residential Emergency Power Systems. ASHRAE J. 2006, 48, 68–70. [Google Scholar]

- Burrel, I.G.; Leballois, S.; Monmasson, E.; Prévond, L. Energy Performance and Stability of Stirling Micro-Cogeneration System. In Proceedings of the 2006 12th International Power Electronics and Motion Control Conference, Portoroz, Slovenia, 30 August 2006–1 September 2006; pp. 2057–2063. [Google Scholar]

- Fitzgerald, J. Resilient Homes: Worth the Investment? Int. J. Crit. Infrastruct. 2014, 10, 39–51. [Google Scholar] [CrossRef]

- Prochatzki, G.; Mayer, R.; Haenel, J.; Schmidt, A.; Götze, U.; Ulber, M.; Fischer, A.; Arnold, M.G. A Critical Review of the Current State of Circular Economy in the Automotive Sector. J. Clean. Prod. 2023, 425, 138787. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Nazzal, M.A.; Darras, B.M.; Deiab, I.M. A Comprehensive Sustainability Assessment of Battery Electric Vehicles, Fuel Cell Electric Vehicles, and Internal Combustion Engine Vehicles through a Comparative Circular Economy Assessment Approach. Sustainability 2023, 15, 171. [Google Scholar] [CrossRef]

- Kozłowski, E.; Rimkus, A.; Zimakowska-Laskowska, M.; Matijošius, J.; Wiśniowski, P.; Traczyński, M.; Laskowski, P.; Madlenak, R. Energy and Environmental Impacts of Replacing Gasoline with LPG Under Real Driving Conditions. Energies 2025, 18, 5522. [Google Scholar] [CrossRef]

- Milojević, S.; Stopka, O.; Orynycz, O.; Tucki, K.; Šarkan, B.; Savić, S. Exploitation and Maintenance of Biomethane-Powered Truck and Bus Fleets to Assure Safety and Mitigation of Greenhouse Gas Emissions. Energies 2025, 18, 2218. [Google Scholar] [CrossRef]

- Warguła, Ł.; Waluś, K.J.; Wieczorek, B.; Zakaria, R. The Impact of the Modernization of the Ignition and Injection System in the Dniepr MT 11 Motorcycle on the Frequency of Service Operations. Mater. Mech. Eng. Technol. 2023, 2023, 15–22. [Google Scholar] [CrossRef]

- Yesbossynov, K.; Buyalich, G.; Каbikеnоv, S.; Sembayev, N.; Jailaubekov, M. Mathematical Interpretation of Open-Pit Dump Trucks Diesel Engine Durability. In Proceedings of the E3S Web Conference, 5th International Innovative Mining Symposium, Kemerovo, Russia, 19–21 October 2020; EDP Sciences: Les Ulis, France, 2020; Volume 174. [Google Scholar]

- Van Dam, W.; Miller, T.; Narasaki, K.; Parsons, G.; Rele, I.R.T. Low Viscosity Lubricants for Improved Fuel Economy in Heavy Duty Engines While Maintaining Lubricant and Engine Durability. Tribol. Schmier. Tech. 2012, 59, 24–31. [Google Scholar]

- Chen, G.; Wang, G.; Liu, S.; Zhu, J.; Niu, X.; Wang, Y. The Development of a Fillet Design Tool Based on Light-Weight Marine Diesel Engine Crankshafts. J. Mar. Sci. Eng. 2024, 12, 1806. [Google Scholar] [CrossRef]

- Song, S.; Qiu, Q.; Bu, J.; Ke, Q. Predecisional remanufacturing timing selection of crankshaft based on fatigue and wear. Jisuanji Jicheng Zhizao Xitong 2020, 26, 279–287. [Google Scholar] [CrossRef]

- Richards, P.; Kalischewski, W. Results from a 1/4 Million Km, Heavy-Duty Truck Trail, Using FBC Regenerated Dpfs. In Proceedings of the SAE Technical Paper, Detroit, MI, USA, 8–11 March 2004; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Lokachari, S.; Leng, K.; Rincon Romero, A.; Curry, N.; Brewster, G.; Norton, A.; Hussain, T. Processing-Microstructure-Properties of Columns in Thermal Barrier Coatings: A Study of Thermo-Chemico-Mechanical Durability. ACS Appl. Mater. Interfaces 2024, 16, 10646–10660. [Google Scholar] [CrossRef] [PubMed]

- Himabindu, M.; Ravikrishna, R.V. Performance Assessment of a Small Biogas-Fuelled Power Generator Prototype. J. Sci. Ind. Res. 2014, 73, 781–785. [Google Scholar]

- Warguła, Ł.; Wieczorek, B.; Gierz, Ł.; Karwat, B. Critical Concerns Regarding the Transition from E5 to E10 Gasoline in the European Union, Particularly in Poland in 2024—A Theoretical and Experimental Analysis of the Problem of Controlling the Air–Fuel Mixture Composition (AFR) and the λ Coefficient. Energies 2025, 18, 852. [Google Scholar] [CrossRef]

- Pedrazzi, S.; Allesina, G.; Morselli, N.; Puglia, M.; Rinaldini, C.A.; Savioli, T.; Mattarelli, E.; Giorgini, L.; Tartarini, P. Modified Diesel Engine Fueled by Syngas: Modeling and Experimental Validation. In Proceedings of the European Biomass Conference and Exhibition Proceedings, ETA-Florence Renewable Energies, Amsterdam, The Netherlands, 6–9 June 2016; Volume 2016, pp. 880–883. [Google Scholar]

- Elsebaay, A.; Abuadma, M.A.; Ramadan, M. Analyzing the Effect of Motor Loads and Introducing a Method for Selection of Electric Generator Power Rating. In Proceedings of the International Middle East Power Systems Conference MEPCON, Cairo, Egypt, 18–20 December 2018; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2018; pp. 7–12. [Google Scholar]

- Lang, M.; Ilhan, Z.; Franco, T.; Szabo, P.; Cinque, S.; Schiller, G. Development and Characterization of Vacuum Plasma Sprayed Planar Solid Oxide Fuel Cells and Short Stacks under Dynamic Operating Conditions. In Proceedings of the European Fuel Cell Technology and Applications Conference Book Abstract, Rome, Italy, 14–16 December 2005; Volume 2005, p. 40. [Google Scholar]

- Matijošius, J.; Orynycz, O.; Kovbasenko, S.; Simonenko, V.; Shuba, Y.; Moroz, V.; Gutarevych, S.; Wasiak, A.; Tucki, K. Testing the Indicators of Diesel Vehicles Operating on Diesel Oil and Diesel Biofuel. Energies 2022, 15, 9263. [Google Scholar] [CrossRef]

- Szpica, D.; Czaban, J. Investigating of the Combustion Process in a Diesel Engine Fueled with Conventional and Alternative Fuels. In Proceedings of the Transport Means 2019, Palanga, Lithuania, 2–4 October 2019. [Google Scholar]

- Hunicz, J.; Matijošius, J.; Rimkus, A.; Kilikevičius, A.; Kordos, P.; Mikulski, M. Efficient Hydrotreated Vegetable Oil Combustion under Partially Premixed Conditions with Heavy Exhaust Gas Recirculation. Fuel 2020, 268, 117350. [Google Scholar] [CrossRef]

- Rayapureddy, S.M.; Matijošius, J.; Rimkus, A.; Caban, J.; Słowik, T. Comparative Study of Combustion, Performance and Emission Characteristics of Hydrotreated Vegetable Oil–Biobutanol Fuel Blends and Diesel Fuel on a CI Engine. Sustainability 2022, 14, 7324. [Google Scholar] [CrossRef]

- Orynycz, O.; Świć, A. The Effects of Material’s Transport on Various Steps of Production System on Energetic Efficiency of Biodiesel Production. Sustainability 2018, 10, 2736. [Google Scholar] [CrossRef]

- Orliński, P.; Laskowski, P.; Zimakowska-Laskowska, M.; Mazuruk, P. Assessment of the Impact of the Addition of Biomethanol to Diesel Fuel on the Coking Process of Diesel Engine Injectors. Energies 2022, 15, 688. [Google Scholar] [CrossRef]

- Sundarapandian, S.; Devaradjane, G. Theoretical Analysis of the Performance and Emission of Vegetable Oil Ester Operated C.I Engine for Various Injection Timing. J. Chem. Pharm. Sci. 2015, 7, 308–311. [Google Scholar]

- Markov, V.; Kamaltdinov, V.; Bykovskaya, L.; Sa, B. Performance of a Diesel Engine Running on Mixed Biofuels with the Addition of Gasoline. In Proceedings of the E3S Web Conference, the International Scientific Conference on Energy, Environmental and Construction Engineering (EECE-2019), St. Petersburg, Russia, 19–20 November 2019; EDP Sciences: Les Ulis, France, 2019; Volume 140. [Google Scholar]

- Sundarapandian, S. Experimental Performance and Emission Analysis of Vegetable Oil Ester Operated C.I Engine for Various Injection Pressure. In Proceedings of the SAE Technical Paper, Detroit, MI, USA, 12–14 April 2011; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- No, S.-Y. Inedible Vegetable Oils and Their Derivatives for Alternative Diesel Fuels in CI Engines: A Review. Renew. Sustain. Energy Rev. 2011, 15, 131–149. [Google Scholar] [CrossRef]

- Sinuka, Y.; Omar, I.; Makhomo, S. Comparative Effects on Fuel and Exhaust Back Pressure for a Diesel Engine Fuelled with Biodiesel and Biofuel Blends. In Proceedings of the Industrial and Commercial Use of Energy ICU, Cape Town, South Africa, 19–20 August 2014; IEEE Computer Society: Los Alamitos, CA, USA, 2014. [Google Scholar]

- Ivanov, I.; Kirov, S.; Uzuntonev, T.; Petrov, P. Characteristic Defects of the Basic Components or Parts of an IC Engine during Prolonged Operational Performance. In Proceedings of the AIP Conference Proceedings, Transport, Ecology-Sustainable Development, Varna, Bulgaria, 19–21 May 2022; American Institute of Physics: College Park, MD, USA, 2023; Volume 2868. [Google Scholar]

- Álvarez-Flórez, J.; Egusquiza, E. Analysis of Damage Caused by Siloxanes in Stationary Reciprocating Internal Combustion Engines Operating with Landfill Gas. Eng. Fail. Anal. 2015, 50, 29–38. [Google Scholar] [CrossRef]

- Öztürk, U.E.; Yanarocak, R. An Application of Early Fault Detection for the Crankshaft and Piston of an Internal Combustion Engine. Vibroeng. Procedia 2016, 9, 7–12. [Google Scholar]

- Agape, I.; Gaiginschi, L.; Ianuş, G.; Cimpoeşu, N. The Analysis of an Internal Combustion Engine Breakdown-Case Study. In Proceedings of the IOP Conference Series: Materials Science and Engineering, International Conference on Innovative Research—ICIR Euroinvent 2017, Iasi, Romania, 25–26 May 2017; Institute of Physics Publishing: Bristol, UK, 2017; Volume 209. [Google Scholar]

- Bezyukov, O.K.; Zhukov, V.A.; Pulyaev, A.A. Criteria for Calculating Cavitation Erosion in Cooling Systems for Internal Combustion Engines. In Proceedings of the AIP Conference Proceedings, 2th International Scientific Conference on Advances in Science, Engineering and Digital Education, Krasnoyarsk, Russia, 28 October 2021; American Institute of Physics Inc.: College Park, MD, USA, 2022; Volume 2647. [Google Scholar]

- Plaksin, A.; Gritsenko, A.; Glemba, K. Modernization of the Turbocharger Lubrication System of an Internal Combustion Engine. Procedia Eng. 2015, 129, 857–862. [Google Scholar] [CrossRef]

- Jafari, S.M.; Mehdigholi, H.; Behzad, M. Valve Fault Diagnosis in Internal Combustion Engines Using Acoustic Emission and Artificial Neural Network. Shock Vib. 2014, 2014, 823514. [Google Scholar] [CrossRef]

- Mohamed, E.S. Fault Diagnosis of ICE Valve Train for Abnormal Clearance and Valve Head Crack Using Vibration Signals. Int. J. Veh. Noise Vib. 2015, 11, 18–38. [Google Scholar] [CrossRef]

- Petrauskienė, K.; Tverskytė, R.; Dvarionienė, J. Environmental and Economic Benefits of Electric, Hybrid and Conventional Vehicle Treatment: A Case Study of Lithuania. Waste Manag. 2022, 140, 55–62. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Ma, M.; Ma, Y.; Liu, H.; Ma, Q. A Nonlinear Model between Life Cycle Cost, Service Time and Recycling Quality Level of Waste Engine Parts under Uncertain Environment. J. Phys. Conf. Ser. 2021, 1885, 042032. [Google Scholar] [CrossRef]

- Pascovici, D.S.; Colmenares, F.; Ogaji, S.O.T.; Pilidis, P. An Economic and Risk Analysis Model for Aircrafts and Engines. In Proceedings of the ASME Turbo Expo, Montreal, QC, Canada, 14–17 May 2007; Volume 3, pp. 103–116. [Google Scholar]

- Kraft, J.; Sethi, V.; Singh, R. Optimization of Aero Gas Turbine Maintenance Using Advanced Simulation and Diagnostic Methods. J. Eng. Gas Turbines Power 2014, 136, 111601. [Google Scholar] [CrossRef]

- Fachrie, Y. Arviansyah Supplier Evaluation in Industrial Power Services: A Case Study in Gas-Turbine Maintenance, Repair, and Overhaul. In Proceedings of the E3S Web Conference, 5th International Conference on Energy, Environmental and Information System (ICENIS 2020), Semarang, Indonesia, 12–13 August 2020; EDP Sciences: Les Ulis, France, 2020; Volume 202. [Google Scholar]

- Bregant, L.; Spagnol, M.; Caizzi, G. Internal Combustion Engine Analysis Using EngineEnvelope (EE). In Proceedings of the ISMA—International Conference on Noise and Vibration Engineering USD—International Conference on Uncertainty in Structural Dynamics, Leuven, Belgium, 15–17 September 2014; KU Leuven: Leuven, Belgium, 2014; pp. 2787–2794. [Google Scholar]

- Ntantis, E.L.; Botsaris, P.N. Diagnostic Methods for an Aircraft Engine Performance. J. Eng. Sci. Technol. Rev. 2015, 8, 64–72. [Google Scholar] [CrossRef]

- Kraft, J.; Kuntzagk, S. Engine Fleet-Management—The Use of Digital Twins from a Mro Perspective. In Proceedings of the ASME Turbo Expo, Turbomachinery Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017; American Society of Mechanical Engineers (ASME): New York, NY, USA, 2017; Volume 1. [Google Scholar]

- De Campos, V.A.F.; Cantagallo, J.P.T.; Llerena-Pizarro, O.R.; Silveira, J.L. Internal Combustion Engine Fueled with Biogas: Energetic, Economic and Environmental Analyses. IEEE Lat. Am. Trans. 2019, 17, 1873–1878. [Google Scholar] [CrossRef]

- Dillitzer, M.; Issle, P.; Schwarz, J.; Sohn, T.S.; Auerbach, M.; Gruel, W. Repurposing Alternators as Motors: Promoting Sustainability and Circular Economy in Low-Cost Mobility Systems. In Proceedings of the International Conference on Smart Cities and Green ICT Systems, SMARTGREENS—Proceedings; Science and Technology Publications, Lda, Porto, Portugal, 2–3 April 2025; pp. 77–86. [Google Scholar]

- Nwaokocha, C.N.; Giwa, S.O.; Layeni, A.T.; Akinyemi, O.O.; Kuye, S.I. An Experimental Investigation of LPG as an Alternative Fuel for a Retrofitted Spark Ignition Engine. Int. J. Energy Environm. Econ. 2016, 24, 121–130. [Google Scholar]

- Bembenek, M.; Melnyk, V.; Karwat, B.; Rokita, T.; Hnyp, M.; Mosora, Y.; Warguła, Ł. Study of the Technical and Operational Parameters of Injectors Using Biogas Fuel. Energies 2024, 17, 5445. [Google Scholar] [CrossRef]

- Szpica, D. The Influence of Selected Adjustment Parameters on the Operation of LPG Vapor Phase Pulse Injectors. J. Nat. Gas Sci. Eng. 2016, 34, 1127–1136. [Google Scholar] [CrossRef]

- Szpica, D. Research on the Influence of LPG/CNG Injector Outlet Nozzle Diameter on Uneven Fuel Dosage. Transport 2018, 33, 186–196. [Google Scholar] [CrossRef]

- Szaryszová, P.; Nováková, A.; Weiss, E.; Kopčáková, J. Modelling Trends in Sustainable Fuel Consumption of Compressed Natural Gas Vehicles. Adv. Sci. Technol. Res. J. 2025, 19, 81–90. [Google Scholar] [CrossRef]

- Warguła, Ł.; Kukla, M.; Krawiec, P.; Wieczorek, B. Reduction in Operating Costs and Environmental Impact Consisting in the Modernization of the Low-Power Cylindrical Wood Chipper Power Unit by Using Alternative Fuel. Energies 2020, 13, 2995. [Google Scholar] [CrossRef]

- Mei, X.; Li, T.; Zhang, H. Standard adaptability and environmental performance analysis: Remanufactured engines. Dalian Ligong Daxue Xuebao 2021, 61, 237–245. [Google Scholar] [CrossRef]

- Sikora, M.; Orliński, P. Hydrotreated Vegetable Oil Fuel within the Fit for 55 Package. Combust. Engines 2023, 63, 3–8. [Google Scholar] [CrossRef]

- Carmona, L.G.; Whiting, K.; Cullen, J. Circularity Index: Performance Assessment of a Low-Carbon and Circular Economy. In Technology Innovation for the Circular Economy: Recycling, Remanufacturing, Design, System Analysis and Logistics; Nasr, N., Ed.; Wiley: Hoboken, NJ, USA, 2024; pp. 17–28. ISBN 978-1-394-21429-7. [Google Scholar]

- Peng, S.; Yang, Y.; Li, T.; Smith, T.M.; Tan, G.Z.; Zhang, H.-C. Environmental Benefits of Engine Remanufacture in China’s Circular Economy Development. Environ. Sci. Technol. 2019, 53, 11294–11301. [Google Scholar] [CrossRef]

- Bobba, S.; Tecchio, P.; Ardente, F.; Mathieux, F.; dos Santos, F.M.; Pekar, F. Analysing the Contribution of Automotive Remanufacturing to the Circularity of Materials. Procedia CIRP 2020, 90, 67–72. [Google Scholar] [CrossRef]

- Liu, Z.; Li, T.; Jiang, Q.; Zhang, H. Life Cycle Assessment-Based Comparative Evaluation of Originally Manufactured and Remanufactured Diesel Engines. J. Ind. Ecol. 2014, 18, 567–576. [Google Scholar] [CrossRef]

- Steinbiß, K. The Principle of Remanufacture in Circular Economy: Same as New Product. In CSR, Sustainability, Ethics and Governance; Springer Nature: Berlin/Heidelberg, Germany, 2024; Volume Part F4058, pp. 103–108. [Google Scholar]

- Ma, Y.; Du, G.; Jiao, R.J. Design for Product Upgradability Considering Remanufacturing Outsourcing: A Three-Level Joint Optimization Approach. Int. J. Prod. Econ. 2024, 272, 109233. [Google Scholar] [CrossRef]

- Aguilar Esteva, L.C.; Kasliwal, A.; Kinzler, M.S.; Kim, H.C.; Keoleian, G.A. Circular Economy Framework for Automobiles: Closing Energy and Material Loops. J. Ind. Ecol. 2021, 25, 877–889. [Google Scholar] [CrossRef]

- Zhang, Z.; Takeyama, K.; Ohno, H.; Matsubae, K.; Nakajima, K.; Nagasaka, T. An Estimation of the Amount of Dissipated Alloy Elements in Special Steel from Automobile Recycling. Mater. Tech. 2019, 107, 105. [Google Scholar] [CrossRef]

- Laskowski, P.; Zimakowska-Laskowska, M. Simulation Study of the Effect of Ethanol Content in Fuel on Petrol Engine Performance and Exhaust Emissions. Combust. Engines 2025, 201, 129–135. [Google Scholar] [CrossRef]

- Kurzydym, D. CFD Simulations and NEDC Tests for the Original and Replacement Selective Catalytic Reduction System. Combust. Engines 2025, 201, 58–71. [Google Scholar] [CrossRef]

- Fuć, P.; Sokolnicka-Popis, B.; Ziółkowski, A.; Bednarek, M.; Jagielski, A.; Michałowska, A. Technology for Manufacturing Catalytic Systems Using a Pilot Line for Precious Metal Recovery. Combust. Engines 2023, 193, 89–96. [Google Scholar] [CrossRef]

- Kindler, O.; Królak, S.; Warguła, Ł.; Wieczorek, B. Research on the Design of a Non-Commercial Impulse Compressed Air Supply System for the Turbocharger of a Spark-Ignition Internal Combustion Engine. Combust. Engines 2025, 202, 11–19. [Google Scholar] [CrossRef]

- Nurkusheva, S.; Bembenek, M.; Berdychowski, M.; Gajdzik, B.; Wolniak, R. An Analysis of the Correct Frequency of the Service Inspections of German Passenger Cars—A Case Study on Kazakhstan and Poland. Vehicles 2024, 6, 553–570. [Google Scholar] [CrossRef]

- Castellano, J.; Chaudhari, A.; Bromham, J. Adaptive Temperature Control for Diesel Particulate Filter Regeneration. In Proceedings of the SAE Technical Paper, SAE 2013 World Congress & Exhibition, Detroit, MI, USA, 16–18 April 2013; SAE International: Warrendale, PA, USA, 2013; Volume 2. [Google Scholar]

- Tan, P.-Q.; Yin, Y.-F.; Hu, Z.-Y.; Lou, D.-M.; Liu, Y.; Zhang, X.; Feng, W.-L.; Liu, K.; Rao, Z.-H.; Huang, C.-J. Effects of Catalyst Physicochemical Properties on the Catalytic Activity of Cu Zeolite Selective Catalytic Reduction at Different Inlet Gas Conditions. Energy Fuels 2021, 35, 18653–18663. [Google Scholar] [CrossRef]

- Lance, M.J.; Storey, J.; Lewis, S.; Sluder, C.S. Analysis of Lacquer Deposits and Plugging Found in Field-Tested EGR Coolers. In Proceedings of the SAE Technical Paper, SAE 2014 World Congress & Exhibition, Detroit, MI, USA, 8–10 April 2014; SAE International: Warrendale, PA, USA, 2014; Volume 1. [Google Scholar]

- Kinoshita, K.; Takeda, Y.; Abe, Y.; Oguma, M.; Konno, M.; Tanaka, K.; Sakaida, S.; Mori, S.; Kodama, S. Elucidation of Exhaust Gas Recirculation Deposit Formation Mechanism Based on Chemical Analysis of Components. Fuel 2023, 337, 127197. [Google Scholar] [CrossRef]

- Kozina, A.; Radica, G.; Nižetić, S. Emission of Diesel Powered Vehicle under Real Operating Conditions-Impact of Emissions Control System Failure. In Proceedings of the International Conference on Smart and Sustainable Technologies (SpliTech), Split, Croatia, 23–26 September 2020; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2020. [Google Scholar]

- Adamkiewicz, A.; Drzewieniecki, J. The Influence of Fuels Quality on Tribological Wear in Slow Speed Diesel Engines. Solid State Phenom. 2016, 252, 1–10. [Google Scholar] [CrossRef]

- Osipowicz, T.; Grzejda, R. Influence of Wear on Precision Pair Components in Modern Fuel Injectors on the Operating and Environmental Performance of a Compression-Ignition Engine. Int. J. Automot. Mech. Eng. 2025, 22, 12614–12626. [Google Scholar] [CrossRef]

- Watzenig, D.; Sommer, M.S.; Steiner, G. Engine State Monitoring and Fault Diagnosis of Large Marine Diesel Engines. Elektr. Inf. Tech. 2009, 126, 173–179. [Google Scholar] [CrossRef]

- Pilková, M.; Jamrichová, Z.; Kopecký, I. Assessment of Diesel Fuel Injection Systems. In Proceedings of the Transport Means—Proceedings International Conference, Kaunas, Lithuania, 23–24 October 2014; Kaunas University of Technology: Kaunas, Lithuania, 2014; pp. 95–98. [Google Scholar]

- Karamangil, M.I.; Erkus, B.; Kaynakli, O.; Surmen, A. Technical and Economic Analysis of the Problems Observed in Diesel Engines with Common Rail Injection Systems in Turkey. Energy Educ. Sct. Technol. Part A Energy Sci. Res. 2012, 28, 563–576. [Google Scholar]

- Chen, Y.; Liu, C. Research on Adaptive Diagnosis Algorithm for Fuel Injection Failure System of Construction Machinery Diesel Engine. Int. J. Wirel. Mob. Comput. 2022, 22, 23–28. [Google Scholar] [CrossRef]

- Asraf Rahim, K.; Al-Humairi, S.N.S. Influence of Lubrication Technology on Internal Combustion Engine Performance: An Overview. In Proceedings of the Proceeding—IEEE Conference on Systems, Process Control, ICSPC, Melaka, Malaysia, 11–12 December 2020; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2020; pp. 184–189. [Google Scholar]

- Vong, C.; Wong, P. Case-Based Adaptation for Automotive Engine Electronic Control Unit Calibration. Expert Syst. Appl. 2010, 37, 3184–3194. [Google Scholar] [CrossRef]

- Vong, C.M.; Huang, H.; Wong, P.K. Case-Based Reasoning for Automotive Engine Performance Tune-Up. In Proceedings of the AIP Conference Proceedings, 2nd International Symposium on Computational Mechanics and the 12th International Conference on the Enhancement and Promotion of Computational Methods in Engineering and Science, Hong Kong-Macau, China, 30 November–3 December 2009; Volume 1233, pp. 185–190. [Google Scholar]

- Szymlet, N.; Kamińska, M.; Ziółkowski, A.; Sobczak, J. Analysis of Non-Road Mobile Machinery Homologation Standards in Relation to Actual Exhaust Emissions. Energies 2024, 17, 3624. [Google Scholar] [CrossRef]

- Ericson, C.; Westerberg, B.; Egnell, R. Transient Emission Predictions with Quasi Stationary Models. In Proceedings of the SAE Technical Paper, Powertrain & Fluid Systems Conference & Exhibition, San Antonio, TX, USA, 24–27 October 2005; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Mologni, J.F.; Goto, F.K.; Capanema, V.D.S. Coupled Thermal-Mechanical Numerical Analysis of a Wiring Harness Structure Affected by Random Engine Vibration. In Proceedings of the SAE Technical Paper, SAE Brasil 2007 Congress and Exhibition, Paulo, Brazil, 7–8 October 2025; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Gritsenko, A.V.; Almetova, Z.V.; Rudnev, V.V. Monitoring Engine Toxicity Parameters and Selective Control of Its System Operation. In Proceedings of the 5th International Conference on Industrial Engineering (ICIE 2019), Sochi, Russia, 25–29 March 2019; pp. 829–838. [Google Scholar]

- Siano, D.; Viscardi, M.; Chimenti, M.; Panza, M.A.; Molaro, A.; Lanzillo, S. Experimental Analysis of Innovative Acoustic Materials for Engine Noise Control in Vehicles. In Proceedings of the International Congress on Sound and Vibration, ICSV, Montreal, QC, Canada, 7–11 July 2019; Canadian Acoustical Association: Ottawa, ON, Canada, 2019. [Google Scholar]

- Frad, A.; Revnic, I. Prodtect Automotive—Meeting the Requirements of ELV. In Proceedings of the 16th International Conference on Engineering Design, Paris, France, 28–31 July 2007; Volume DS 42. [Google Scholar]

- McGuire, J.; Tett, D.; Patterson, A. Electric-Turbocompounding on Heavy Duty Diesel Engines. VDI Ber. 2009, 211–214. [Google Scholar]

- Patterson, A.T.C.; Tett, R.J.; McGuire, J. Exhaust Heat Recovery Using Electro-Turbogenerators; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2009. [Google Scholar]

- Kodaboina, R.V.; Vorraro, G.; Turner, J.W.G. Using Turbogenerators for Energy Recovery in Turbocharged Hybrid Powertrains; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2025. [Google Scholar]

- Smith, V.M.; Keoleian, G.A. The Value of Remanufactured Engines: Life-Cycle Environmental and Economic Perspectives. J. Ind. Ecol. 2004, 8, 193–221. [Google Scholar] [CrossRef]

- Zhao, Q.; Chen, M. A Comparison of ELV Recycling System in China and Japan and China’s Strategies. Resour. Conserv. Recycl. 2011, 57, 15–21. [Google Scholar] [CrossRef]

- Simic, V.; Dimitrijevic, B. Risk Explicit Interval Linear Programming Model for Long-Term Planning of Vehicle Recycling in the EU Legislative Context under Uncertainty. Resour. Conserv. Recycl. 2013, 73, 197–210. [Google Scholar] [CrossRef]

- Malagrinò, G.; Accardo, A.; Costantino, T.; Pensato, M.; Spessa, E. Life Cycle Assessment of a State-of-the-Art Diesel Powered Engine and Preliminary Evaluation of Its Conversion into a Novel Hydrogen Powered Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2024. [Google Scholar]

- Burchart-Korol, D.; Folęga, P. Comparative Life Cycle Impact Assessment of Chosen Passenger Cars with Internal Combustion Engines. Transp. Probl. 2019, 14, 69–76. [Google Scholar] [CrossRef]

- Lisienko, V.G.; Chesnokov, Y.N.; Lapteva, A.V. Application of the Triad of Blast Furnace, Oxygen Converter, and Electric Arc Furnace for Reducing of Carbon Footprint. Steel Transl. 2017, 47, 523–527. [Google Scholar] [CrossRef]

- Lisienko, V.G.; Chesnokov, Y.N.; Lapteva, A.V. The use of triad of blast furnace, oxygen converter and electric arc furnace for carbon footprint reduction. Izv Ferr. Metall. 2017, 60, 623–628. [Google Scholar] [CrossRef]

- Senthil Raja, T.; Barathi Raja, K.; Kumar, A. Improving the Gearbox Efficiency by Reducing Drag Loss in Automotive Manual Transmission; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2023. [Google Scholar]

- Robeyn, T.; Verhelst, S.; Vinke, I.; Latine, H.; Turner, J. Investigation of Naphtha-Type Biofuel from a Novel Refinery Process; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2022. [Google Scholar]

- Wilby, I.; Bardasz, E.; Chai, J. Low SAPS Engine Oils for Future Diesel Engines—Challenges and Solution. In Proceedings of the 9th Annual Fuels & Lubes Asia Conference and Exhibition, Singapore, January 2003; F+L Asia: Hong Kong, China, 2003; Volume 9. [Google Scholar]

- Yanagisawa, Y.; Fujitsu, T. High Performance Low Ash Lubricant Development for Construction and Mining Equipment. In Proceedings of the 17th Annual Fuels and Lubes Asia Conference and Exhibition, Singapore, March 2011; F+L Asia: Hong Kong, China, 2011; p. 27. [Google Scholar]

- Barrie, D.; Wall, R. Burning Issues. Aviat. Week Space Technol. 2006, 165, 140–142. [Google Scholar]

- Mayanti, B. Life Cycle Assessment of Reciprocating Engine Component in Finland: A Case Study. Int. J. Environ. Stud. 2023, 80, 989–1001. [Google Scholar] [CrossRef]

- Fronk, B.M.; Burton, L.; Garimella, S. Sustainability Impacts of a Program of Decommissioning Older Automobiles for Replacement with Newer, More Efficient Vehicles. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Seattle, WA, USA, 11–15 November 2007; American Society of Mechanical Engineers (ASME): New York, NY, USA, 2007; Volume 6, pp. 373–378. [Google Scholar]

- Ranasinghe, K.; Guan, K.; Gardi, A.; Sabatini, R. Review of Advanced Low-Emission Technologies for Sustainable Aviation. Energy 2019, 188, 115945. [Google Scholar] [CrossRef]

- Gao, W.; Li, T.; Tang, Z.; Peng, S.; Zhang, H.-C. Investigation on the Comparative Life Cycle Assessment between Newly Manufacturing and Remanufacturing Turbochargers. Procedia CIRP 2017, 61, 750–755. [Google Scholar] [CrossRef]

- Yadav, P.K.; Gupta, S.; Kumar, D. Consideration of Environmental Factor in Dumper Performance Calculation of Coal Mines. Indian J. Environ. Prot. 2019, 39. Available online: https://www.e-ijep.co.in/07-july19/ (accessed on 20 October 2025).

- Kyando, M.J.; Ntalikwa, J.W.; Kivevele, T. Influence of Engine Mileage on Emissions of an Aged Retrofitted Spark Ignition Engine Fueled with Gasoline and Compressed Natural Gas. Emiss. Control Sci. Technol. 2025, 11, 15. [Google Scholar] [CrossRef]

- Numfor, S.A.; Takahashi, Y.; Matsubae, K. Energy Recovery from End-of-Life Vehicle Recycling in Cameroon: A System Dynamics Approach. J. Clean. Prod. 2022, 361, 132090. [Google Scholar] [CrossRef]

- Orfale, E.O.; Luiz, A.; Serigiolle, L.; Marcial, M. End-of-Life Vehicle Recycling: Processes, Legislations and Benefits; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2016; Volume Part F127082. [Google Scholar]

- Numfor, S.A.; Omosa, G.B.; Zhang, Z.; Matsubae, K. A Review of Challenges and Opportunities for End-of-life Vehicle Recycling in Developing Countries and Emerging Economies: A Swot Analysis. Sustainability 2021, 13, 4918. [Google Scholar] [CrossRef]

- Kim, H.C.; Ross, M.H.; Keoleian, G.A. Optimal Fleet Conversion Policy from a Life Cycle Perspective. Transp. Res. Part D Transp. Environ. 2004, 9, 229–249. [Google Scholar] [CrossRef]

- Spitzley, D.V.; Grande, D.E.; Keoleian, G.A.; Kim, H.C. Life Cycle Optimization of Ownership Costs and Emissions Reduction in US Vehicle Retirement Decisions. Transp. Res. Part D Transp. Environ. 2005, 10, 161–175. [Google Scholar] [CrossRef]

- Zimakowska-Laskowska, M.; Kozłowski, E.; Laskowski, P.; Wiśniowski, P.; Świderski, A.; Orynycz, O. Vehicle Exhaust Emissions in the Light of Modern Research Tools: Synergy of Chassis Dynamometers and Computational Models. Combust. Engines 2025, 200, 145–154. [Google Scholar] [CrossRef]

- Rymaniak, L.; Ziolkowski, A.; Gallas, D. Particle Number and Particulate Mass Emissions of Heavy Duty Vehicles in Real Operating Conditions. MATEC Web Conf. 2017, 118, 00025. [Google Scholar] [CrossRef]

- Szymlet, N.; Rymaniak, Ł.; Lijewski, P. Two-Wheeled Urban Vehicles—A Review of Emissions Test Regulations and Literature. Energies 2024, 17, 586. [Google Scholar] [CrossRef]

- Ranjan, S.; Saragur Madanayak, S.N. Exploratory Real-World Emission Modal Assessment of Three-Wheeled Autorickshaws in Urban Road Networks. Transp. Res. Part D Transp. Environ. 2025, 148, 105006. [Google Scholar] [CrossRef]

- Warguła, Ł.; Lijewski, P.; Kukla, M. Effects of Changing Drive Control Method of Idling Wood Size Reduction Machines on Fuel Consumption and Exhaust Emissions. Croat. J. For. Eng. (Online) 2023, 44, 137–151. [Google Scholar] [CrossRef]

- Warguła, Ł.; Lijewski, P.; Kukla, M. Influence of Non-Commercial Fuel Supply Systems on Small Engine SI Exhaust Emissions in Relation to European Approval Regulations. Environ. Sci. Pollut. Res. 2022, 29, 55928–55943. [Google Scholar] [CrossRef]

- Santos, T.B.; Ferreira, V.P.; Torres, E.A.; da Silva, J.A.M.; Ordonez, J.C. Energy Analysis and Exhaust Emissions of a Stationary Engine Fueled with Diesel–Biodiesel Blends at Variable Loads. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3237–3247. [Google Scholar] [CrossRef]

- Sobczak, J.; Kamińska, M.; Ziółkowski, A.; Rymaniak, Ł.; Szymlet, N. Analysis of Pollutant Emissions of a Railbus Based on Real Train Emissions Measurements. Combust. Engines 2025, 201, 22–33. [Google Scholar] [CrossRef]

- Kamińska, M.; Rymaniak, Ł.; Lijewski, P.; Szymlet, N.; Daszkiewicz, P.; Grzeszczyk, R. Investigations of Exhaust Emissions from Rail Machinery during Track Maintenance Operations. Energies 2021, 14, 3141. [Google Scholar] [CrossRef]

- Rymaniak, L.; Pielecha, J.; Brzeziński, L. Determining the NOx Emission from an Auxiliary Marine Engine Based on Its Operating Conditions. E3S Web Conf. 2018, 44, 00155. [Google Scholar] [CrossRef]

- Regulation (EU) 2016/1628; On Requirements Relating to Gaseous and Particulate Pollutant Emission Limits and Type-Approval for Internal Combustion Engines for Non-Road Mobile Machinery. European Parliament and the Council: Brussels, Belgium, 2016.

- Directive (EU) 2015/2193; On the Limitation of Emissions of Certain Pollutants into the Air from Medium Combustion Plants. European Parliament and the Council: Brussels, Belgium, 2015.

- Laskowski, P.; Kozłowski, E.; Zimakowska-Laskowska, M.; Wiśniowski, P. Assessment of Methods for Determining Vehicle Emission Characteristics. Eng. Trans. 2025, 73, 407–420. [Google Scholar] [CrossRef]

- ISO 8528-10:2019; Reciprocating Internal Combustion Engine Driven Alternating Current Generating Sets—Part 10: Measurement and Evaluation of Vibration of Generating Sets. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO/IEC 17025:2017; General Requirements for the Competence of Testing and Calibration Laboratories. International Organization for Standardization and International Electrotechnical Commission: Geneva, Switzerland, 2017.

- Álvarez García, V. Normative instruments regulating technical specifications in the European Union: A brief attempt to identify new sources of law. Rev. Gen. Derecho Adm. 2023, 2023. Available online: https://www.iustel.com/v2/revistas/detalle_revista.asp?id_noticia=426418&d=1 (accessed on 20 October 2025).

- Rostovska, K.; Hryshyna, N.; Pakhomova, I.; Liubchyk, V.; Koval, M. Role and implementation of legal principles in the context of digital legal regulation: Comparative analysis of European Union (EU). Syariah 2024, 24, 73–87. [Google Scholar] [CrossRef]

- Robles-Elorza, D.; San-Jose, L.; Urionabarrenetxea, S. Regulation of CSR from International, European, and Spanish Viewpoints. In The Palgrave Handbook of Corporate Social Responsibility; Crowther, D., Seifi, S., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2021; pp. 887–909. ISBN 978-3-030-42465-7. [Google Scholar]

- Álvarez García, V.J. The European concept of technical regulation in the framework of the information system provided for by Directive (EU) 2015/1535. Rev. Derecho Comunitario Eur. 2024, 2024, 99–134. [Google Scholar] [CrossRef]

- Reinikainen, J.; Bouhoulle, E.; Sorvari, J. Inconsistencies in the EU Regulatory Risk Assessment of PFAS Call for Readjustment. Environ. Int. 2024, 186, 108614. [Google Scholar] [CrossRef]

- Anderson, C. Contrasting Models of Euadministration in Judicial Review of Risk Regulation. Common Mark. Law Rev. 2014, 51, 425–454. [Google Scholar] [CrossRef]

- Gryllos, G. Discretion and Judicial Review in EU Competition Law: A Technical Analysis on Sources of Discretion, Judicial Review and Implications for the Litigants. Concurrences 2016, 2016, 81687. [Google Scholar] [CrossRef]

- Schumacher, K. Large-Scale Renewable Energy Project Barriers: Environmental Impact Assessment Streamlining Efforts in Japan and the EU. Environ. Impact Assess. Rev. 2017, 65, 100–110. [Google Scholar] [CrossRef]

- Bozzini, E. Pesticide Policy and Politics in the European Union: Regulatory Assessment, Implementation and Enforcement; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; ISBN 978-3-319-52736-9. [Google Scholar]

- Van Scharen, A.; Deneyer, M.; Cornu, P. Ethics Review or Compliance Check? An Empirical Analysis of 6740 Requests for Information in Belgian Clinical Trial Evaluations (2017–2024). BMC Med. Ethics 2025, 26, 129. [Google Scholar] [CrossRef]

- Waluś, K.J.; Warguła, Ł.; Krawiec, P.; Adamiec, J.M. Legal Regulations of Restrictions of Air Pollution Made by Non-Road Mobile Machinery—the Case Study for Europe: A Review. Environ. Sci. Pollut. Res. 2018, 25, 3243–3259. [Google Scholar] [CrossRef]

- Warguła, Ł.; Kaczmarzyk, P. Legal Regulations of Restrictions of Air Pollution Made by Mobile Positive Pressure Fans—The Case Study for Europe: A Review. Energies 2022, 15, 7672. [Google Scholar] [CrossRef]

- Romero, C.A.; Ramírez, J.D.; Henao Castañeda, E.D.J. Experimental Characterization of the Mechanical Loss Components of a Single-Cylinder Spark-Ignition Engine by Progressive Disassembly Method; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2023. [Google Scholar]

- Ding, F.J. Piston Engine Connecting Rod Transient Dynamic Finite Element Analysis and Maintenance Strategy. Appl. Mech. Mater. 2014, 484–485, 272–276. [Google Scholar] [CrossRef]

- Ali, H.M.M.; Haneef, M. Analysis of Fatigue Stresses on Connecting Rod Subjected to Concentrated Loads At The Big End. Mater. Today Proc. 2015, 2, 2094–2103. [Google Scholar] [CrossRef]

- Rajesh Prabha, N.; Edwin Raja Dhas, J.; Ramanan, G. Finite Element Structural Analysis of Connecting Rod of Aa7075-Tic Composite Using Ansys. Int. J. Mech. Eng. Technol. 2017, 8, 1102–1110. [Google Scholar]

- Kumari, E.; Lal, S.; Choudhary, M.; Gurjar, B.K. Static, Vibrational, and Thermo-Mechanical Design and Analysis of Piston Pin of IC Engine Using ANSYS. J. Mach. Manuf. Reliab. 2025, 54, 99–116. [Google Scholar] [CrossRef]

- Mohanakrishnan, R.; Iniyan, K.; Sabarish Kumar, P.; Arun Vasantha Geethan, K. Design and Analysis of Connecting Rod Using Composite Materials (AL7075, AL6061, AL7075+SiC, AL6061+SiC). IOP Conf. Ser. Mater. Sci. Eng. 2020, 923, 012001. [Google Scholar] [CrossRef]

- Kumar, C.A.; Bhaskar, S.U.; Rajneesh, N.S. Fatigue Analysis of Four Cylinder Engine Crank Shaft. AIP Conf. Proc. 2021, 2358, 050017. [Google Scholar]

- Kliemt, C.; Wilhelm, F.; Hammer, J. Lifetime Improvement of Alsi6cu4 Cylinder Head Alloy. Adv. Mater. Res. 2014, 891–892, 1627–1632. [Google Scholar] [CrossRef]

- Namasivayam, A.M.; Crookes, R.J.; Korakianitis, T.; Olsen, J. Assessment of Combustion in Natural Gas Dual-Fuelled Compression Ignition Engines with Dimethyl Ether and Rapeseed Methyl Ester Pilot Ignition. Int. J. Engine Res. 2009, 10, 165–174. [Google Scholar] [CrossRef]

- Namasivayam, A.M.; Crookes, R.J.; Korakianitis, T.; Bob-Manuel, K.D.H. Combustion Characteristics of Dual-Fuel Diesel Engine Using Emulsified Bio-Fuel for Pilot Ignition; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2009. [Google Scholar]

- Ashok, B.; Kumar, A.N.; Jacob, A.; Vignesh, R. Emission Formation in IC Engines. In NOx Emission Control Technologies in Stationary and Automotive Internal Combustion Engines: Approaches Toward NOx Free Automobiles; Ashok, B., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–38. ISBN 978-0-12-823955-1. [Google Scholar]

- Di Iorio, S.; Mancaruso, E.; Sementa, P.; Vaglieco, B.M. A Comprehensive Analysis of the Impact of Biofuels on the Performance and Emissions from Compression and Spark-Ignition Engines. Int. J. Engine Res. 2015, 16, 680–690. [Google Scholar] [CrossRef]

- Feng, G.; Zhou, M. Assessment of heavy fuel aircraft piston engine types. Qinghua Daxue Xuebao 2016, 56, 1114–1121. [Google Scholar] [CrossRef]

- Bhaskar, D.; Reddy, C.S.S.; Reddy, J.N.; Pavan, M.; Shreenath, J. Study of Diesel Fuel Emissions in HCCI Technology. Int. J. Mech. Eng. Technol. 2017, 8, 510–514. [Google Scholar]

- Basas, M.E.; Khalefa, R.A. Enhancing Compression Ignition Engine Performance and Exhaust Emissions through Fuel Additives: A Comprehensive Review. AIP Conf. Proc. 2024, 3122, 100011. [Google Scholar] [CrossRef]

- Galloni, E.; Fontana, G.; Palmaccio, R. Numerical Analyses of EGR Techniques in a Turbocharged Spark-Ignition Engine. Appl. Therm. Eng. 2012, 39, 95–104. [Google Scholar] [CrossRef]

- Cogo, V.V.; Lanzanova, T.D.M.; Dalla Nora, M.; Martins, M.E.S.; Zhao, H. Study of Exhaust Re-Breathing Application on a Di SI Engine at Partial Load Operation; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Elgin, R.; Turner, C.; Hagen, C.L. Combustion Chamber Design Considerations for a Compression Ignition Engine to Spark Ignited Natural Gas Engine Conversion. In Proceedings of the Fall Technical Meeting of the Western States Section of the Combustion Institute, WSS/CI Fall Meeting, Fort Collins, CO, USA, 7–8 October 2013; pp. 461–466. [Google Scholar]

| Component | Type of Damage | Reason for Disqualification |

|---|---|---|

| Cylinder head | Cracks, burnt valves, corrosion | Loss of structural integrity and sealing |

| Combustion chamber | Deposits, knocking-related damage | Local overheating and secondary component failure |

| Pistons and cylinder walls | Melting, scoring, severe wear | Irreparable deformation and loss of tolerances |

| Crankshaft and bearings | Metal-to-metal contact, fatigue | Catastrophic bearing or journal failure |

| Connecting rods | Fatigue cracks, deformation | Structural failure risk |

| Cylinder liners | Cavitation erosion–corrosion | Damage beyond repair |

| Turbocharger | Thermal overload, bearing failure | High failure probability, short remaining lifespan |

| Valves | Cracks, notches, edge burning | Leakage and loss of operating efficiency |

| General engine parts | Maintenance-related failures | Multiple unpredictable defects |

| Generator Application | Applicable Emission Standard | Compliance of Used Automotive Engine | Remarks |

|---|---|---|---|

| Mobile (Stage V) | Stage V (Reg. 2016/1628/EU) [146] | No | No NRMM type approval, different test cycles |

| Stationary (MCP) | MCP Directive 2015/2193/EU [147] | No | No conformity declaration or certified emission data |

| Emergency (<500 h/year) | Partial exemption under MCP | Conditional | Possible only after notification and technical assessment |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Warguła, Ł.; Kadirov, A.; Aimukhanov, D.; Ulbrich, D.; Kaczmarzyk, P.; Bąk, D.; Wieczorek, B. Ecological Paradox in the Reuse of Internal Combustion Engines from Scrapped Vehicles for Electric Power Generation—Circular Economy Potential Versus Emission Certification Barriers. Sustainability 2025, 17, 10435. https://doi.org/10.3390/su172310435

Warguła Ł, Kadirov A, Aimukhanov D, Ulbrich D, Kaczmarzyk P, Bąk D, Wieczorek B. Ecological Paradox in the Reuse of Internal Combustion Engines from Scrapped Vehicles for Electric Power Generation—Circular Economy Potential Versus Emission Certification Barriers. Sustainability. 2025; 17(23):10435. https://doi.org/10.3390/su172310435

Chicago/Turabian StyleWarguła, Łukasz, Adil Kadirov, Damir Aimukhanov, Dariusz Ulbrich, Piotr Kaczmarzyk, Damian Bąk, and Bartosz Wieczorek. 2025. "Ecological Paradox in the Reuse of Internal Combustion Engines from Scrapped Vehicles for Electric Power Generation—Circular Economy Potential Versus Emission Certification Barriers" Sustainability 17, no. 23: 10435. https://doi.org/10.3390/su172310435

APA StyleWarguła, Ł., Kadirov, A., Aimukhanov, D., Ulbrich, D., Kaczmarzyk, P., Bąk, D., & Wieczorek, B. (2025). Ecological Paradox in the Reuse of Internal Combustion Engines from Scrapped Vehicles for Electric Power Generation—Circular Economy Potential Versus Emission Certification Barriers. Sustainability, 17(23), 10435. https://doi.org/10.3390/su172310435