Abstract

This study examines how Zero-Waste Management (ZWM) and Green Innovative Supply Chain Management (GISCM) influence environmental and operational performance through the mediating role of Green Dynamic Capabilities (GDCs). Building on the Resource-Based View (RBV) and Dynamic Capabilities Theory (DCT), the study develops a model that explains how firms translate green practices into superior performance outcomes. Using survey data from 132 manufacturing firms in Oman and covariance-based structural equation modeling (CB-SEM), the results demonstrate that both ZWM and GISCM significantly enhance sustainable performance, with GISCM exerting the stronger overall effect. Moreover, GDC fully mediates the relationship between ZWM and operational performance and partially mediates the GISCM–performance links. These findings highlight that sustainability-driven outcomes depend on firms’ abilities to sense, seize, and reconfigure resources for continuous environmental innovation. The study advances theory by integrating RBV and DCT within the green operations context and provides practical insights for managers in emerging economies on developing dynamic and learning-based capabilities to achieve sustainable manufacturing competitiveness.

1. Introduction

Sustainable manufacturing has become a strategic imperative for firms seeking to balance economic competitiveness with environmental stewardship. Global industrial sectors are under increasing pressure to reduce waste, conserve resources, and innovate toward green operations in response to tightening environmental regulations and societal expectations [1,2]. Within this context, Zero-Waste Management (ZWM) and Green Innovative Supply Chain Management (GISCM) have emerged as two critical pathways for firms to achieve sustainability-driven performance gains. While ZWM aims to contain all potential waste at all stages of a product’s lifecycle, GISCM orients all supply chain stakeholders towards sustainability goals, which reflect green procurement, green logistics, eco-design, clean production, green packaging, eco-labelling, and reverse logistics. However, while these approaches have been individually studied, their integrative effects and underlying capability mechanisms remain insufficiently explored, particularly in developing and resource-constrained economies.

Existing research grounded in the Resource-Based View (RBV) has established that firms’ internal resources and green practices contribute to sustainable competitive advantage [3,4]. Yet, RBV alone provides a static lens that overlooks how organizations adapt and reconfigure these resources in dynamic environmental contexts [5,6]. To overcome this limitation, the Dynamic Capabilities Theory (DCT) emphasizes the firm’s ability to sense opportunities, seize them through innovation, and transform internal processes to sustain long-term performance. Despite its relevance, few empirical studies have explicitly integrated DCT into green operations frameworks to explain how firms convert environmental practices into measurable performance improvements.

Previously, scholars have taken different approaches to examine ZWM and GISCM viz. perspectives on ZWM approach to sustainable waste management [7], zero-waste index for assessing waste management performance [8], review of ZWM development [9], employment of zero-waste index for assessing waste management [10], factors affecting zero waste [11], impact of organizational dynamic capabilities on overall performance via green supply chain management [12], interactive impact of green dynamic capabilities, green supply chain performance, green supply chain innovativeness on organizational sustainable performance [13], effect of sustainable supply chain management practices on environmental performance via eco-innovation and dynamic capabilities [14], impact of firms’ dynamic capabilities on GSCM practices to determine economic and environmental performance [15], independent effects of SSCM practices and dynamic organizational capabilities on competitive advantage [16], achieving sales growth through sustainability oriented dynamic capabilities [17], environmental performance through green innovation and ZWM [18], and environmental and operational performance through ZWM via GISCM [19]. However, neither of them examined how ZWM and GISCM independently affect environmental and operational performance of organizations nor investigated alternative pathways (e.g., through GDC) to assess their joint impact. Likewise, an integrative perspective explained via multi-theoretic approach is also missing.

This study bridges this gap by integrating RBV and DCT to explain how ZWM and GISCM jointly influence sustainable performance through GDC. GDCs represent the higher-order abilities of firms to learn, innovate, and reconfigure operational processes in response to sustainability challenges [20]. While prior studies have acknowledged the role of green capabilities, they often treat them as static operational routines rather than dynamic mechanisms that drive adaptive performance outcomes. This research therefore conceptualizes GDC as a mediating construct that explains how and why firms translate zero-waste and innovative supply chain practices into enhanced environmental and operational results.

Furthermore, this study responds to the empirical call for more evidence from emerging economies, where resource constraints, institutional pressures, and regulatory diversity present distinct challenges for sustainability transformation [21]. The Omani manufacturing sector, characterized by its rapid industrialization and growing emphasis on environmental compliance, offers an ideal context to examine the dynamic interplay between waste reduction, innovation, and capability building. By focusing on this setting, the study contributes context-specific insights into how capability development can enhance sustainable manufacturing in developing economies.

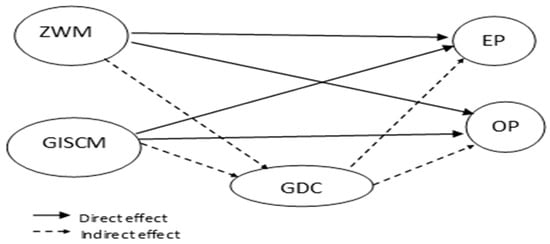

In summary, this research makes three key contributions. First, it extends the RBV–DCT integration by demonstrating how dynamic capabilities mediate the effect of ZWM and GISCM on performance. Second, it offers empirical validation using data from 132 manufacturing firms analyzed via covariance-based structural equation modeling (CB-SEM). Third, it provides actionable guidance for managers and policymakers on building dynamic and learning-oriented mechanisms that foster both environmental and operational excellence. Through this theoretical and practical synthesis, and as illustrated in our conceptual model (Figure 1), the study advances understanding of capability-driven pathways to sustainable manufacturing.

Figure 1.

The conceptual model.

The remainder of this paper is structured as follows. Section 2 reviews the relevant literature, develops the study’s hypotheses, and describes the methodology including data collection procedures. Section 3 presents empirical results. Section 4 discusses these results, draws theoretical and practical implications, and outlines key limitations and recommendations for future research. Finally, Section 5 concludes the whole study.

2. Materials and Methods

2.1. ZWM and Sustainability Performance

ZWM emphasizes the elimination of waste generation through prevention, reuse, and recycling strategies that minimize environmental burden and operational inefficiency. Prior studies affirm that ZWM contributes to resource conservation, process efficiency [18] and improved firm reputation. By redesigning production processes to minimize input–output imbalances, firms can simultaneously reduce costs and enhance environmental compliance. From the RBV perspective, such waste-minimizing practices reflect valuable, rare, and inimitable internal resources that drive competitive advantage [3,4]. Accordingly, the following hypotheses are proposed:

H1a.

ZWM positively influences environmental performance.

H1b.

ZWM positively influences operational performance.

2.2. GISCM and Sustainability Performance

GISCM extends traditional GSCM by embedding innovation into supplier collaboration, eco-design, and technology adoption. From the RBV lens [4], GISCM represents a strategic resource base comprising tangible (technology, infrastructure) and intangible (knowledge, trust, green culture) assets. Through continuous improvement and green-oriented innovation [2], GISCM enables firms to develop adaptive supply networks that are environmentally efficient and competitively agile [14]. Generally, GISCM enhances both environmental and operational outcomes by fostering learning, knowledge sharing, and digital integration across the supply chain. Thus, the following hypotheses are proposed:

H2a.

GISCM positively influences environmental performance.

H2b.

GISCM positively influences operational performance.

2.3. The Mediating Role of Dynamic Capabilities in Achieving Sustainability Outcomes

The RBV posits that firms achieve superior performance by effectively deploying unique, valuable, and inimitable resources [4]. Yet, their sustained impact depends on their dynamic capabilities to integrate and reconfigure these resources under evolving environmental pressures. As markets and technologies evolve rapidly, DCT extends this perspective by emphasizing a firm’s ability to sense environmental changes, seize new opportunities, and transform internal processes to sustain competitiveness [5,6]. Therefore, firms that innovate within their supply networks can improve responsiveness to regulatory and market shifts, achieving superior sustainable performance. However, without inter-organizational collaboration, knowledge-sharing, and absorptive capacity, these innovations may fail to translate into measurable performance gains [22].

ZWM and GISCM represent strategic resource-based initiatives that embed environmental objectives within production and supply processes. Implementing ZWM allows firms to minimize waste generation, enhance resource utilization, and reduce environmental impact [8]. Likewise, with GISCM values, supply chain stakeholders strive to attain their sustainability goals via green procurement, green logistics, eco-design, clean production, green packaging, eco-labelling, and reverse logistics practices. However, performance impact of ZWM as well as GISCM is not automatic; it requires firms to continuously adapt and learn from waste-reduction processes to transform these practices into long-term operational and environmental gains. Within the sustainability domain, GDC represent a firm’s higher-order competencies that enable it to integrate, build, and reconfigure green resources and practices to achieve improved environmental and operational outcomes [23]. However, according to DCT, the benefits of such green initiatives depend on the firm’s ability to dynamically convert these resources into performance outcomes through continuous learning, adaptation, and innovation [20,24]. In this context, among other potential mediating variables viz. digital adoption and technological deployment, strategic orientation, sustainability orientation, organizational culture etc., GDC are expected to serve as a critical mediator that enables firms to absorb, adopt and institutionalize ZWM and GISCM. Firms with strong GDC can better sense waste-related inefficiencies, seize opportunities for material recovery or reuse, and transform production routines into closed-loop systems, thereby amplifying the benefits of ZWM and GISCM [6,23]. Thus, GDC functions as a transformational mechanism through which ZWM and GISCM exert their effects on sustainability performance. Accordingly, the following hypotheses are proposed:

H3.

GDC mediates the relationship between ZWM and environmental (H3a) and operational performance (H3b).

H4.

GDC mediates the relationship between GISCM and environmental (H4a) and operational performance (H4b).

2.4. Theoretical Integration

This study integrates two theoretical lenses to offer a more comprehensive explanation of sustainability outcomes. On one hand, RBV identifies ZWM and GSCM as valuable, rare, and potentially inimitable resources; on the other hand, DCT conceptualizes GDC as the fundamentals that convert resources into sustained advantage under dynamic environmental conditions [25,26].

By combining these perspectives, this study addresses a critical gap in existing research related to understanding not only whether but how sustainability practices create performance value. This integrated framework is especially vital in emerging economies, where firms face severe resource constraints and institutional pressures, making the role of GDC in enabling the translation of ZWM and GISCM into tangible outcomes highly impactful.

2.5. Methodology

This study adopts a quantitative, cross-sectional survey design to empirically test the relationships among ZWM, GISCM, GDC, and sustainable performance (environmental and operational). This design enables systematic examination of theoretical linkages within a real-world manufacturing context. Although cross-sectional designs limit causal inferences, the study mitigates this concern through a strong theoretical foundation and robust statistical testing.

Covariance-based structural equation modeling (CB-SEM) was employed in this study to analyze the data, as it allows simultaneous estimation of multiple relationships among latent constructs and provides a rigorous assessment of overall model fit and construct validity. CB-SEM was selected because the study aims to confirm and validate a theoretically grounded model derived from the RBV and DCT, rather than to maximize prediction, which aligns with the confirmatory orientation of CB-SEM [27,28,29]. This approach enables the estimation of direct, indirect, and mediating effects among complex organizational constructs such as the sensing, seizing, and transforming processes embedded within GDC [20,30]. Moreover, CB-SEM provides comprehensive global goodness-of-fit indices (e.g., χ2/df, CFI, TLI, RMSEA), allowing rigorous evaluation of how well the hypothesized model reproduces the observed covariance structure and enhancing the robustness and credibility of results. The method is also appropriate for the current study’s sample size (N = 132), which exceeds the recommended threshold for model complexity and normally distributed data [27,31]. Therefore, CB-SEM offers both theoretical rigor and statistical precision, making it the most suitable analytical technique for the present research objectives. The methodology of this study is detailed in the next subsections.

2.5.1. Instrument Development and Survey Approach

The survey instrument was developed using a rigorous multi-stage process. All constructs were measured using validated scales adopted from the literature (see Table 1) to ensure both theoretical alignment, strong validity, and contextual relevance. ZWM was associated with items capturing mainly waste minimization, recycling practices and processes redesign [3,9], while GISCM included items addressing eco-design, green procurement, energy efficiency, and reverse logistics [32]. Environmental and operational performances were operationalized using indicators that measured emissions reduction, resource efficiency, process quality, delivery reliability, and cost efficiency, representing both environmental and operational dimensions of firm performance [3,33,34]. GDC were measured using six items adapted from established studies [6,20,23] which conceptually reflect the three foundational dimensions of sensing, seizing, and transforming proposed in DCT [6]. While these dimensions underpin the theoretical structure of GDC [35], many empirical studies in operations and sustainability management have modeled GDC as a single, unidimensional construct to represent a firm’s overall ability to integrate, build, and reconfigure resources toward environmental improvement [23]. Following this approach, the present study operationalizes GDC as one latent factor, with all items directly loading onto a single construct that captures the firm’s aggregate capability to identify environmental opportunities, implement green innovations, and adapt internal processes for sustainability. The adapted scale effectively encompasses these behavioral manifestations—green knowledge management, innovation, and process reconfiguration—offering a parsimonious yet comprehensive representation of GDC. This unidimensional conceptualization maintains theoretical coherence while reducing survey complexity and respondent burden, ensuring both conceptual validity and practical feasibility in sustainability research.

Table 1.

Measurement items and sources.

All survey items measuring the level of ZWM, GISCM and GDC implemented by firms employed a five-point Likert scale ranging from 1 (strongly disagree) to 5 (Strongly agree). A similar five-point scale was used to assess the performance constructs, where respondents evaluated the extent to which their firm’s performance had improved over the past year. The measurement model ensured that the observed indicators adequately captured latent constructs, thereby allowing for robust assessment of internal consistency, convergent validity, and discriminant validity [36]. To ensure conceptual clarity, linguistic accuracy, and contextual relevance, the survey instrument went through several rounds of review and refinement. Table 1 summarizes the measurement items and their respective sources.

2.5.2. Control Variables

We controlled for the effects of firm size (number of full-time employees) and firm age (total years in business) in this study. Larger firms may have easier access to financial and managerial resources [23], making it easier for larger firms to invest in environmental initiatives and adopt advanced management systems [37]. Firm age can also influence environmental and operational performance in some contexts [38]. Older firms often possess established routines and accumulated knowledge that support environmental management [39], whereas younger firms tend to be more flexible and innovative, allowing faster adoption of green and digital practices [40].

The control variables were incorporated in the structural equation models as dummy variables. Based on the median values of the number of full-time employees and the total years in business, firms with ≤137 employees were coded as 0 and those with >137 employees as 1. Similarly, firms with ≤15 years in operation were coded as 0, and those with >15 years as 1. Although firm size can be measured through various financial indicators, data on employment are more readily available and widely used as a proxy in green supply chain and sustainability research [41,42,43,44].

2.5.3. Translation and Pilot Testing

To accommodate the bilingual context of Oman, the survey was developed in English and then translated into Arabic using a rigorous back-translation procedure to ensure linguistic equivalence to the target audience and conceptual equivalence [45]. Pilot testing was then conducted with 20 managers from several firms, which confirmed the clarity and relevance of the items used in the survey. Minor adjustments to wording were made to enhance interpretability and minimize potential measurement error.

2.5.4. Study Sample and Data Collection

The study targeted manufacturing firms from different sectors in Oman. As our unit of analysis is an individual firm, a total of 500 online invitations were distributed to the targeted firms via e-mail, with an emphasis that they should be responded to by managers/individuals responsible for sustainability, supply chain, or operations management. A non-probability purposive sampling approach was used to ensure the inclusion of respondents with direct knowledge of environmental practices. Participation in the survey was voluntary and confidential, reducing the risk of social desirability bias.

After two follow-ups, a total of 132 usable responses were obtained, yielding a response rate of around 26.4%, which is consistent with response rates in comparable green supply chain studies [22,24]. Respondents were top-level executives (CEO, general, supply chain, operations, or production managers), most with over nine years of firm experience. Industry distribution was as follows: chemical & plastic production (24.2%), engineering/metal (22.0%), food/agro-processing (20.6%), oil & gas (9.1%) and others- including electricity production and distribution, publishing, and wood & paper products (24.2%) (see Table 2). This composition enhances the generalizability of the findings while situating them within the framework of Oman’s Vision 2040 for sustainable industries development.

Table 2.

Respondent’s demographics (N = 132).

2.5.5. Data Screening and Controlling for Bias

Prior to our structural analysis, data were screened for missing values, normality, and multicollinearity. Skewness and kurtosis values were within ±2.0, indicating approximate normality. Variance inflation factors (VIFs) were all below 3.0, confirming no multicollinearity concerns [27]. Additionally, ensuring the validity and robustness of empirical findings is critical when investigating the complex relationship between ZWM, GSC, GDC, and environment and operational performance. Given that data were collected via self-reported surveys from managerial respondents, the potential for common method bias (CMB) and non-response bias was carefully addressed using both procedural and statistical strategies recommended by previous empirical studies (e.g., [46,47]).

Non-response bias was first assessed through a comparative analysis of early and late respondents. Independent t-tests of firm size, firm age, and a randomly selected subset of ten measurement items of the constructs under investigation revealed no statistically significant differences, suggesting that non-response bias is not a concern. To further validate this conclusion, follow-up phone interviews were conducted with a random selection of non-respondent firms, revealing that non-participation was primarily due to time constraints or internal policies, confirming the representativeness of the sample.

CMB was addressed through both design and statistical approaches. Procedurally, the survey separated measures of independent and dependent variables into different sections and employed varied response formats to reduce the risk of consistency biases. Respondents were selected as key informants with extensive operational knowledge and managerial experience, averaging fifteen years in middle to senior management positions, ensuring informed and reliable responses. Additionally, dummy items were embedded in the questionnaire to detect inconsistent or invalid responses, and cases failing two or more dummy items were excluded from the analysis.

Statistically, Harman’s single-factor test [46] was conducted by performing an un-rotated exploratory factor analysis on all measurement items. Five different factors emerged, with the first factor accounting for only 24.8% of the variance, well below thresholds indicative of CMB. To further verify the absence of CMB, a common latent factor was incorporated into the measurement model. The latent factor accounted for only 5.7% of the total variance, and all construct loadings remained significant and consistent, confirming that the observed relationships were not substantially inflated by CMB. Collectively, these results confirm that CMB is unlikely to pose a significant threat to the validity of the findings, thereby providing a robust foundation for the subsequent structural analysis [48,49,50].

3. Results

Data analysis proceeded in two stages. First, the measurement model was assessed using Confirmatory Factor Analysis (CFA) in AMOS 22 to establish convergent validity, discriminant validity, and reliability. Convergent validity was confirmed with standardized factor loadings exceeding 0.70, Average Variance Extracted (AVE) above 0.50, and Composite Reliability (CR) values above 0.70 [35]. Discriminant validity was assessed via the Fornell–Larcker criterion, ensuring that each construct’s AVE square root exceeded its correlations with other constructs. Cronbach’s alpha values for all constructs were above 0.70, indicating satisfactory internal consistency [35].

The mediation of GDC between ZWM, GISCM, and performance was examined using the Baron & Kenny (1986) procedures [49], commonly used in previous studies (e.g., [25]) through path analysis within SEM to assess organizational mechanisms mediating the effect of sustainability practices. First, the direct effect of ZWM and GISCM on GDC was tested, followed by the effects of GDC on environmental and operational performance. Next, the direct effects of ZWM and GISCM on performance outcomes were examined in both the presence and absence of GDC. Mediation was identified when the inclusion of GDC reduced the magnitude of the direct effect, with full mediation indicated when the direct effect became non-significant and partial mediation if it decreased but remained significant. This procedure enables the identification of precise mechanisms through which green practices and translated into operational and environmental performance, highlighting the role of GDC as a critical enabler of effective green practices adoption.

This SEM-based path approach is particularly suitable for studying complex organizational phenomena where mediation represents latent organizational processes, such as the absorption, integration and transformation of green practices into performance gains [25,50]. By explicitly modeling the relationships between ZWM, GISCM, GDC, and performance outcomes, this methodology provides a theoretical rigorous framework that aligns with the micro-functional logic or DCT and the RBV while simultaneously addressing practical sustainability challenges in emerging economies. Structural model evaluation and hypothesis testing employed SEM to estimate path coefficients, significance levels, and model fit indices (e.g., CFI, TLI, RMSEA), consistent with those suggested by previous [35].

3.1. Measurement Model Analysis: Construct Validity and Reliability

The results of the confirmatory factor analysis (CFA) presented in Table 3 provide strong evidence of the reliability and validity of the measurement model. All standardized factor loadings exceed the recommended minimum threshold of 0.70 [27], ranging from 0.71 to 0.90 (p < 0.001), thereby demonstrating satisfactory indicator reliability and convergent validity. The Average Variance Extracted (AVE) values for all constructs fall between 0.631 and 0.658, surpassing the benchmark value of 0.50 [30], indicating that a substantial portion of variance in the indicators is explained by their corresponding latent constructs.

Table 3.

Measurement properties and descriptive statistics.

The internal consistency of the constructs was further confirmed through Cronbach’s α and Composite Reliability (CR). Both measures exceeded the conventional criterion of 0.70 [51], with Cronbach’s α values ranging from 0.873 to 0.904 and CR values ranging from 0.873 to 0.910, thereby confirming robust internal reliability and construct consistency across all measurement items.

Discriminant validity was assessed following the Fornell and Larcker (1981) criterion [52], which requires the square root of each construct’s AVE to be greater than its inter-construct correlations. As shown in Table 4, the diagonal elements (square roots of AVE) are consistently higher than the corresponding off-diagonal correlation coefficients, verifying that each construct is empirically distinct from the others. Furthermore, all correlations among the constructs were statistically significant and within acceptable limits (p < 0.01), suggesting no issues with multicollinearity or construct overlap.

Table 4.

Discriminate Validity and Inter-Construct Correlations.

The model fit indices presented in Table 5 indicate that both the direct-effects model and the mediation model demonstrate satisfactory fit to the data, meeting widely accepted criteria [53]. Specifically, the direct-effects model achieved values of CFI = 0.90, TLI = 0.896, RMSEA = 0.078, and SRMR = 0.066, all within recommended thresholds. The mediation model showed improved fit indices (χ2/df = 2.325, CFI = 0.93, TLI = 0.91, RMSEA = 0.072, SRMR = 0.053), confirming a stronger overall fit and greater theoretical robustness than the direct effect model. These results collectively reveal that the measurement model demonstrates satisfactory reliability, convergent validity, and discriminant validity, providing a sound basis for testing the structural relationships in the subsequent analysis.

Table 5.

Goodness-of-fit indices of the two models.

3.2. Results of the Structural Model Analysis

3.2.1. Direct Effect Results

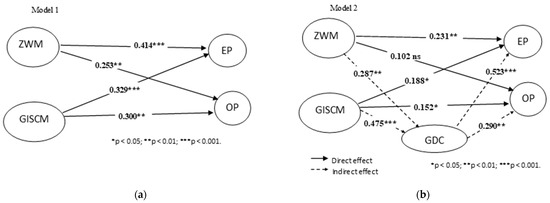

The results of the structural equation modeling presented in Table 6 (Column 1) and Figure 2a indicate that ZWM has a positive and significant effect on both environmental and operational performance in the direct-effect model. Specifically, ZWM significantly influences environmental performance (β = 0.414, p ≤ 0.001) and operational performance (β = 0.253, p ≤ 0.01). These findings suggest (H1a and H1b), emphasizing that the implementation of zero-waste practices contributes meaningfully to improved environmental outcomes and moderately enhances operational results.

Table 6.

Results of Structural Equation Modelling.

Figure 2.

(a) Direct effect results. (b) Indirect effect results. Notes: * p < 0.05; ** p < 0.01; *** p < 0.001, ns not significant.

Similarly, GISCM shows a significant positive relationship with both performance dimensions. The results indicate significant effects on environmental performance (β = 0.329, p ≤ 0.001) and operational performance (β = 0.300, p ≤ 0.01). This provides support for (H2a and H2b), implying that green innovation efforts embedded within supply chain processes yield tangible improvements in both environmental and operational aspects of organizational performance. Overall, both ZWM and GISCM demonstrate substantial direct contributions to firm performance outcomes, confirming their strategic importance as drivers of environmental and operational excellence prior to considering the mediating role of GDC.

3.2.2. Mediation Effects Results

When GDCs are introduced into the model, the results reveal several important mediation patterns. The model fit improves notably (CFI = 0.931; RMSEA = 0.072), indicating a satisfactory overall structure.

As can be seen in Table 6 (Column 2) and Figure 2b, ZWM shows a significant positive path to GDC (β = 0.287, p ≤ 0.01), suggesting that zero-waste practices contribute to the development of dynamic and adaptive organizational capabilities. Similarly, GISCM strongly predicts GDC (β = 0.475, p ≤ 0.001), indicating that innovation-oriented supply chain practices foster higher levels of learning and reconfiguration capabilities.

When GDC is included, the direct path from ZWM to environmental performance decreases but remains significant (β = 0.231, p ≤ 0.01), indicating a partial mediation effect. However, the path from ZWM to operational performance becomes nonsignificant (β = 0.102, ns), confirming full mediation. This means that, while ZWM continues to directly influence environmental outcomes, its effect on operational performance operates entirely through the development of GDC, which provides support for H3.

For GISCM, both mediated paths remain significant but weaker in magnitude. GISCM → Environmental Performance shows β = 0.188 (p ≤ 0.01), and GISCM → Operational Performance shows β = 0.152 (p ≤ 0.05), demonstrating partial mediation in both cases. Hence, GISCM contributes to performance both directly and indirectly through GDC, which supports H4.

Furthermore, the mediating variable itself exhibits strong direct effects on both outcomes: GDC → Environmental Performance (β = 0.523, p ≤ 0.001) and GDC → Operational Performance (β = 0.290, p ≤ 0.01). These results indicate that the presence of robust dynamic capabilities substantially enhances overall organizational performance in green operational contexts.

3.2.3. Effects of Control Variables

Firm size exhibited a marginally significant positive effect on environmental performance in the direct model (β = 0.200, p < 0.05) but became nonsignificant in the mediated model (β = 0.098, ns), suggesting that its influence operates primarily through GDC. Firm age showed no significant effect on either environmental or operational performance, and both variables were nonsignificant predictors of operational outcomes. These results are consistent with prior empirical evidence indicating that structural attributes such as firm size and age are often weak predictors of sustainability-related outcomes [41]. Overall, the findings suggest that the effects of ZWM, GISCM, and GDC on performance are largely independent of firm demographics, underscoring that dynamic capabilities and strategic environmental practices are more influential drivers of sustainable performance than organizational size or maturity. This pattern may be explained by the fact that sustainability outcomes depend less on structural endowments and more on a firm’s capacity to learn, innovate, and reconfigure processes in response to environmental pressures [5,6]. In dynamic market contexts, smaller or younger firms can be equally agile and responsive as larger or more established ones, enabling them to achieve comparable environmental and operational results through effective capability development [54]. This observation aligns with recent studies emphasizing that in rapidly transforming industrial contexts, such as Oman’s manufacturing sector, firms of varying sizes and ages can achieve similar sustainability outcomes when they effectively cultivate and deploy GDC [55].

4. Discussion

The findings of this study offer important insights into how ZWM, GISCM, and GDC contribute to environmental and operational performance in industrial firms operating in Oman. The results confirm H1a and H1b, demonstrating that ZWM exerts a positive and significant influence on both environmental and operational performance. These results align with prior empirical findings emphasizing the role of waste reduction and resource efficiency in enhancing ecological outcomes and process effectiveness [18,56,57]. Such outcomes suggest that firms implementing ZWM practices can simultaneously minimize environmental impacts and improve internal efficiency through systematic waste elimination and recycling initiatives [18].

Similarly, H2a and H2b are supported, as GISCM shows significant positive relationships with both environmental and operational performance. These findings highlight that innovation-oriented green practices embedded within supply chain functions—such as eco-design, cleaner production, and sustainable logistics—enhance both environmental stewardship and operational responsiveness. With silo approach, a study [17] reported that internal green supply chain management capabilities (i.e., eco-design, eco-innovation, and environmental management etc.) positively influence firms’ growth, whereas external green supply chain management capabilities (i.e., green procurement, customer cooperation in reverse logistics, and investment recovery etc.) had no significant influence. In a similar study, scholars reported having established a positive relationship between internal GSCM and firms’ environmental performance [58]. It reinforces the significance of integrated efforts in leveraging green innovative solutions for achieving desired sustainability outcomes. Furthermore, it confirms that GISCM not only contributes to reducing ecological footprints but also strengthens firms’ ability to achieve process flexibility, cost efficiency, and quality improvements through environmentally innovative approaches.

When the mediating variable GDC is introduced, several nuanced mediation patterns emerge. The results confirm that ZWM has a significant positive influence on GDC, and GISCM shows an even stronger effect, suggesting that both practices contribute to capability building but through different mechanisms. Specifically, ZWM fosters adaptive routines related to process optimization and resource recirculation, while GISCM develops higher-level learning and innovation capabilities across the supply chain.

With respect to mediation, H3a is supported, indicating partial mediation between ZWM and environmental performance. The direct effect of ZWM on environmental outcomes weakens but remains significant after including GDC. ZWM had relatively weaker direct impact on firms’ sustainability outcomes; the introduction of GDC has further weakened it. It indicates that either the ZWM practices are yet to achieve maturity, or there is a disproportionate match between resources and capabilities across majority of the surveyed organizations. Conversely, H3b is fully supported, showing full mediation of the ZWM–operational performance relationship, as the direct path becomes nonsignificant. As operational performance reflects in terms of energy efficiency, resource optimization, inventory reduction, scrap reduction, cost containment, and waste reduction [33], even ZWM practices with certain degree of dynamism may help firms attain these metrics. This implies that operational efficiency gains from zero-waste initiatives are realized primarily through dynamic mechanisms of sensing, learning, and reconfiguration that enhance productivity and process reliability [20].

ZWM is an operational-level practice emphasizing waste minimization and process efficiency. Its operational gains are realized only through capability renewal and learning routines (GDC), thus explaining the full mediation. In contrast, GISCM involves innovation and inter-firm collaboration, which generate direct performance impacts with its in-built mechanism of sensing, seizing, and reconfiguration. These mechanisms are otherwise required to produce the desired sustainability outcomes. Hence, even without strong dynamic capability development, the existing GISCM can attain sustainability targets. This logic aligns with [20], who noted that the scope and integration intensity of green initiatives determine the extent to which they depend on dynamic capabilities for performance realization.

For GISCM, the results confirm H4a and H4b, both indicating partial mediation through GDC. The direct paths from GISCM to environmental and operational performance remain significant, though reduced in strength, while GDC shows substantial direct effects on both environmental and operational performance. These findings suggest that while GISCM directly enhances performance through technological and process innovations, its full potential is realized when supported by dynamic learning and adaptive integration across supply chain networks. Thus, firms that actively cultivate GDC are better positioned to translate green innovations into enduring environmental and operational advantages.

Collectively, these results extend the dynamic capabilities view (DCV) [6,20] by demonstrating that sustainable performance outcomes depend not merely on the adoption of environmental practices, but on the firm’s ability to develop and leverage dynamic capabilities that support continuous learning, integration, and transformation. The stronger mediation observed for GISCM underscores its capability-intensive nature, where performance gains rely on iterative learning and innovation across supply chain functions. This is particularly relevant for manufacturing contexts in emerging economies, where dynamic reconfiguration of resources is essential to overcome institutional and environmental constraints [59].

Interestingly, the control variables—firm size and age—showed weak or nonsignificant effects on performance, suggesting that organizational maturity alone does not ensure sustainability success. These findings are consistent with prior research (e.g., [59]), which argues that strategic intent, leadership orientation, and capability development outweigh structural firm characteristics. This observation aligns with studies indicating that in rapidly transforming industrial contexts such as Oman’s manufacturing sector, firms of varying sizes and ages can achieve comparable sustainability outcomes when they effectively cultivate and deploy GDC [55].

4.1. Theoretical Implications

This study makes several important contributions to sustainability and operations management literature. First, it integrates ZWM and GISCM within DCV, extending prior research that examined these constructs in isolation. By demonstrating that both ZWM and GISCM influence performance through GDC, the study underscores the centrality of capability-building, learning, and reconfiguration mechanisms in translating environmental practices into measurable outcomes. This advances theoretical understanding beyond the traditional practice–performance paradigm toward a more systemic, capability-based perspective [20].

Second, the differentiation between partial and full mediation patterns contributes to theory by clarifying how distinct green practices operate. ZWM emphasizes internal efficiency and process-oriented learning, whereas GISCM leverages inter-firm collaboration and innovation networks. These mediation results are somewhat in tandem with the RBV, which establishes that firms’ internal resources and green practices contribute to sustainable competitive advantage. However, while dealing with environmental dynamism, organizations learn, adapt and reconfigure their resources over time to realize the full potential of these resources [5,6]. While viewing these results from DCT perspective, this conceptual distinction supports emerging theoretical arguments that sustainability practices differ in their dependence on dynamic capabilities according to their scope, complexity, and degree of integration [59]. The results therefore enrich our understanding of how various environmental strategies (in the light of RBV) interact with dynamic capabilities (from DCT perspective) to produce differentiated performance outcomes.

Third, the study provides new empirical evidence that structural firm attributes—such as size and age—exert limited influence on sustainability outcomes once dynamic capabilities are accounted for. This reinforces the notion that strategic agility and learning orientation, rather than demographic characteristics, are the key determinants of sustainable competitiveness. In emerging markets, where institutional and technological conditions are still evolving, this finding highlights the importance of coupling operational efficiency with dynamic adaptability to build long-term resilience and innovation capacity.

Overall, this study contributes to the integration of the RBV and DCT by illustrating how green-oriented resources are converted into performance advantages through dynamic capability mechanisms. These findings expand the theoretical boundary of DCT by demonstrating its explanatory power in sustainability-oriented operations within emerging manufacturing contexts.

4.2. Practical Implications

From a managerial standpoint, the findings underscore that achieving sustainable performance requires firms to develop and institutionalize GDC as strategic enablers rather than treating them as secondary operational outcomes. Managers should recognize ZWM and GISCM as two distinct yet similar transformation pathways that demand continuous learning, cross-functional integration, and strategic alignment. Firms that cultivate such capabilities are better positioned to institutionalize circular practices, anticipate environmental regulations, and adapt proactively to shifting market and technological conditions.

Building a learning-oriented and experimentation-friendly culture is vital to encourage innovation and empower employees to design and implement zero-waste and green supply chain initiatives. In practical terms, this entails embedding digital monitoring and data integration tools (viz. circular design software, AI-powered drones, IoT, IIoT etc.) that enable real-time visibility across supply chain operations, facilitating early detection of waste sources and performance inefficiencies. Integrating supplier and customer data, especially through AI-powered digital platforms, enhances material traceability, stimulates eco-innovation, and drives both environmental and operational gains.

Managers should also prioritize the development of knowledge-management systems and organizational learning routines that capture, codify, and disseminate sustainability-related best practices. Such systems enhance adaptive learning, reduce knowledge loss due to employee turnover, and ensure the long-term retention of environmental expertise. Hence, top management commitment and leadership engagement become equally important to attain sustainability outcomes. Executives must treat capability development as a strategic investment that aligns environmental goals with business objectives. In practice, this involves allocating resources to continuous training, fostering interdepartmental collaboration, and aligning performance incentives with sustainability objectives.

For managers in emerging economies such as Oman, leveraging partnerships and inter-firm collaborations can compensate for institutional and resource limitations. Joint initiatives with suppliers, customers, and industry associations can facilitate shared learning, accelerate the diffusion of green innovations, and enhance collective resilience. Firms engaged in national industrial modernization programs can especially benefit from such collaborative frameworks, as they enhance competitiveness while supporting broader sustainability transitions.

Beyond the firm level, the results hold significant policy implications. Government agencies and regulators can act as catalysts by designing incentive schemes, sustainability certification programs, and digital infrastructure platforms that encourage firms to adopt zero-waste and green supply chain practices. Policymakers should also foster knowledge-sharing networks and training programs that build firms’ absorptive capacities and dynamic learning mechanisms, thereby strengthening the overall sustainability ecosystem. These measures can enhance national industrial performance and contribute directly to achieving long-term environmental policy goals.

Collectively, these insights reaffirm that building GDC is not merely a technical requirement or compliance activity—it is a core strategic imperative. Firms that systematically integrate ZWM and GISCM within a capability-driven management framework will be better equipped to achieve sustainable operational excellence, strengthen innovation performance, and secure long-term competitive advantage in increasingly dynamic and environmentally conscious markets.

4.3. Limitations and Recommendations for Future Research

Despite its theoretical and practical contributions, this study has several limitations that open valuable opportunities for future investigation. One key limitation relates to its cross-sectional design, which, while widely adopted in sustainability and operations research, constrains causal inference. Future research employing longitudinal or multi-wave designs could capture how GDCs evolve over time and how the maturity of zero-waste and green supply chain practices affects long-term performance. Such temporal insights would provide a deeper understanding of how firms sustain and renew their dynamic capabilities under changing market and environmental conditions.

Another consideration concerns the study’s focus on Oman’s manufacturing sector. While these findings offer significant implications for similar emerging economies contexts, they may limit the generalizability of findings to other regions or industries. Comparative studies across different countries, sectors, or institutional contexts could test the robustness of the proposed relationships and reveal how variations in policy frameworks, technological readiness, or cultural settings influence the effectiveness of GDC in linking environmental practices to performance.

In addition, this study conceptualized GDC as a unidimensional construct, a choice grounded in methodological parsimony and supported by prior empirical work that treats GDC as an overarching capability to integrate, build, and reconfigure resources toward environmental innovation [23]. This approach reduces survey complexity and enhances response reliability. Nevertheless, future research could adopt a multi-dimensional modeling framework that explicitly captures the sensing, seizing, and transforming capabilities proposed in DCT [6,20]. Such a design would allow for a more nuanced understanding of how each dimension uniquely and collectively drives sustainability outcomes.

Moreover, although this study controlled for firm size and age—variables commonly included in sustainability and operations management research [35,40]—other contextual factors, including industry type, regulatory intensity, and ownership structure, were not incorporated due to limited sample representation across specific subgroups. Future studies with larger and more stratified samples could include these variables to capture sectoral and institutional differences that may moderate the examined relationships. Incorporating such controls would improve the external validity and contextual richness of future analyses.

In addition to broader contextual and structural extensions, future research should explore additional mediating mechanisms that may operate alongside or instead of GDC. Potential mediators include green knowledge sharing, organizational environmental culture, leadership orientation toward sustainability, absorptive capacity, and digital maturity. Examining these factors—individually and in combination—would clarify alternative pathways through which ZWM and GISCM affect environmental and operational performance and would help identify which mechanisms are most salient under different industry or institutional conditions.

Finally, the data were collected through a single-source survey design, and although statistical tests indicated no serious common-method bias, future research could strengthen validity by employing multi-source, longitudinal, or mixed-method approaches. Combining survey data with case studies, archival records, or longitudinal field observations could reveal the micro-processes through which dynamic capabilities and other mediators are developed and enacted across organizational levels and supply chain tiers.

5. Conclusions

This study advances understanding of how ZWM and GISCM jointly enhance firms’ sustainability outcomes through the development of GDC. While prior studies have examined direct and isolated effects of ZWM and GISCM on firms’ sustainability outcomes, empirical investigations exploring the indirect mechanisms via GDC are missing. Thus, the current study fills this void by proposing and empirically examining a conceptual framework that places GDC as a variable mediating the links of ZWM and GDC with firm’s sustainability outcomes. This framework is innovatively rationalized in the light of integrated RBV-DCT paradigm. The outcomes of this study demonstrate that sustainability-oriented performance emerges not solely from implementing environmental practices but from the underlying dynamic capability to integrate, learn, and adapt those practices to evolving market and ecological conditions.

The findings reaffirm that capability development lies at the heart of sustainable competitiveness—particularly within the manufacturing context of emerging economies, where adaptability, learning, and innovation are essential to achieving both environmental and operational excellence. By empirically validating the mediating role of GDC, this research highlights the strategic importance of internal capability renewal as a pathway to circular and resilient operations.

Beyond its empirical contribution, the study provides a conceptual foundation for future inquiry into capability-driven sustainability transitions. Longitudinal and cross-contextual studies could further illuminate how GDC evolves over time and interacts with contextual factors such as digital maturity, regulatory pressure, or leadership orientation. Such investigations would enrich theoretical understanding and guide managers and policymakers in designing interventions that foster dynamic, capability-based sustainability.

In conclusion, the evidence presented here underscores that true sustainability performance is not fully achieved through isolated green initiatives but through the dynamic capabilities that enable firms to continuously transform them into enduring strategic advantages.

Author Contributions

Conceptualization, A.A. and H.A.; methodology, A.A.; software, A.A.; validation, A.A., H.A. and A.B.; formal analysis, A.A.; investigation, A.A. and A.S.; resources, A.B.; data curation, A.A.; writing—original draft preparation, A.A.; writing—review and editing, H.A. and A.S.; visualization, A.A.; supervision, A.B.; project administration, A.A.; funding acquisition, none. All authors have read and agreed to the published version of the manuscript.

Funding

This work received funding from the University of Technology and Applied Sciences, Oman.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by the Research Ethics Committee, University of Technology and Applied Sciences (Rustaq College of Education) (protocol code GEN072025 and date of approval 12 March 2025).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study. Participation was voluntary and anonymous, and participants provided consent by proceeding with the online survey after reading the information page. No identifying personal or organizational information was collected.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors acknowledge the use of ChatGPT-5 for formatting assistance only, specifically to adjust citations and references to meet Sustainability journal guidelines. The authors have reviewed and approved the final content in full.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| ZWM | Zero-Waste Management |

| GISCM | Green Innovative Supply Chain Management |

| GDC | Green Dynamic Capabilities |

| RBV | Resource-Based View |

| DCT | Dynamic Capabilities Theory |

| DCV | Dynamic Capabilities View |

| SEM | Structural Equation Modeling |

| CFA | Confirmatory Factor Analysis |

| AVE | Average Variance Extracted |

| CR | Composite Reliability |

| CFI | Comparative Fit Index |

| TLI | Tucker–Lewis Index |

| RMSEA | Root Mean Square Error of Approximation |

| SRMR | Standardized Root Mean Square Residual |

References

- Rashid, A.; Rasheed, R.; Altay, N. Greening manufacturing: The role of institutional pressure and collaboration in operational performance. J. Manuf. Technol. Manag. 2025, 36, 455–478. [Google Scholar] [CrossRef]

- Borah, P.S.; Dogbe, C.S.K.; Marwa, N. Green dynamic capability and green product innovation for sustainable development: Role of green operations, green transaction, and green technology development capabilities. Corp. Soc. Responsib. Environ. Manag. 2025, 32, 911–926. [Google Scholar] [CrossRef]

- Hart, S.L. A natural-resource-based view of the firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar] [CrossRef]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Eisenhardt, K.M.; Martin, J.A. Dynamic capabilities: What are they? Strateg. Manag. J. 2000, 21, 1105–1121. [Google Scholar] [CrossRef]

- Teece, D.J. Explicating dynamic capabilities: The nature and microfoundations of (sustainable) enterprise performance. Strateg. Manag. J. 2007, 28, 1319–1350. [Google Scholar] [CrossRef]

- Suryawan, I.W.K.; Lee, C.H. Achieving zero waste for landfills by employing adaptive municipal solid waste management services. Ecol. Indic. 2024, 165, 112191. [Google Scholar] [CrossRef]

- Zaman, A.U.; Lehmann, S. The zero waste index: A performance measurement tool for waste management systems in a ‘zero waste city’. J. Clean. Prod. 2013, 50, 123–132. [Google Scholar] [CrossRef]

- Zaman, A.U. A comprehensive review of the development of zero waste management: Lessons learned and guidelines. J. Clean. Prod. 2015, 91, 12–25. [Google Scholar] [CrossRef]

- Zaman, A.U. Measuring waste management performance using the ‘Zero Waste Index’: The case of Adelaide, Australia. J. Clean. Prod. 2014, 66, 407–419. [Google Scholar] [CrossRef]

- Coskun, S. Zero waste management behavior: Conceptualization, scale development and validation—A case study in Turkey. Sustainability 2022, 14, 12654. [Google Scholar] [CrossRef]

- Al Mamun, A.; Reza, M.N.H.; Yang, Q.; Aziz, N.A. Dynamic capabilities in action: The synergy of big data analytics, supply chain ambidexterity, green supply chain and firm performance. J. Enterp. Inf. Manag. 2025, 38, 636–659. [Google Scholar] [CrossRef]

- Li, W.; Waris, I.; Bhutto, M.Y. Understanding the nexus among big data analytics capabilities, green dynamic capabilities, supply chain agility and green competitive advantage: The moderating effect of supply chain innovativeness. J. Manuf. Technol. Manag. 2024, 35, 119–140. [Google Scholar] [CrossRef]

- Siddiqi, R.A.; Codini, A.P.; Ishaq, M.I.; Jamali, D.R.; Raza, A. Sustainable supply chain, dynamic capabilities, eco-innovation, and environmental performance in an emerging economy. Bus. Strategy Environ. 2025, 34, 338–350. [Google Scholar] [CrossRef]

- Song, B.; Choi, D. Dynamic capability of the firm as driver of green supply chain management implementation. Sustainability 2018, 10, 2539. [Google Scholar] [CrossRef]

- Uddin, M.H.; Razzak, M.R.; Rahman, A.A. Sustainable supply chain management practices, dynamic capabilities and competitive advantage: Evidence from Bangladesh ready-made garments industry. Bus. Strategy Dev. 2023, 6, 176–188. [Google Scholar] [CrossRef]

- Yi, Y.; Demirel, P. The impact of sustainability-oriented dynamic capabilities on firm growth: Investigating the green supply chain management and green political capabilities. Bus. Strategy Environ. 2023, 32, 5873–5888. [Google Scholar] [CrossRef]

- Liu, D.; Yousaf, Z.; Rosak-Szyrocka, J. Environmental Performance Through Green Supply Chain Management Practices, Green Innovation, and Zero Waste Management. Sustainability 2024, 16, 11173. [Google Scholar] [CrossRef]

- Serrano-García, J.; Arbelaez-Toro, J.J.; Cardona-Cárdenas, J.D.; Marimon, F. Green research and development capability and corporate environmental responsibility: A bibliometric analysis on green product innovation and financial sustainability in manufacturing companies. Int. J. Inf. Manag. Data Insights 2025, 5, 100367. [Google Scholar]

- Teece, D.J. Dynamic capabilities as (workable) management systems theory. J. Manag. Organ. 2018, 24, 359–368. [Google Scholar] [CrossRef]

- Díaz-Arancibia, J.; Hochstetter-Diez, J.; Bustamante-Mora, A.; Sepúlveda-Cuevas, S.; Albayay, I.; Arango-López, J. Navigating digital transformation and technology adoption: A literature review from small and medium-sized enterprises in developing countries. Sustainability 2024, 16, 5946. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J. The role of big data and predictive analytics in green supply chain management. J. Clean. Prod. 2017, 180, 220–232. [Google Scholar]

- Chen, Y.S.; Chang, C.H. The determinants of green product development performance: Green dynamic capabilities, green transformational leadership, and green creativity. J. Bus. Ethics 2013, 116, 107–119. [Google Scholar] [CrossRef]

- Wu, G.C.; Ding, J.H.; Chen, P.S. The effects of GSCM drivers and institutional pressures on GSCM practices in Taiwan’s textile and apparel industry. Int. J. Prod. Econ. 2012, 135, 618–636. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K.H. An organizational theoretic review of green supply chain management. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Abbas, J. Does the nexus of corporate social responsibility and green dynamic capabilities drive firms toward green technological innovation? The moderating role of green transformational leadership. Technol. Forecast. Soc. Change 2024, 208, 123698. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R.L. Multivariate Data Analysis; Cengage Learning Hampshire: Andover, UK, 2019. [Google Scholar]

- Kline, R.B. Principles and Practice of Structural Equation Modeling; Guilford Publications: New York, NY, USA, 2023. [Google Scholar]

- Byrne, B.M. Structural Equation Modeling with Mplus: Basic Concepts, Applications, and Programming; Routledge: Abingdon, UK, 2013. [Google Scholar]

- Anderson, J.C.; Gerbing, D.W. Structural equation modeling in practice: A review and recommended two-step approach. Psychol. Bull. 1988, 103, 411–423. [Google Scholar] [CrossRef]

- West, S.G.; Taylor, A.B.; Wu, W. Model fit and model selection in structural equation modeling. In Handbook of Structural Equation Modeling; Guilford Press: New York, NY, USA, 2012; pp. 209–231. [Google Scholar]

- Chen, Y.S.; Lai, S.B.; Wen, C.T. The influence of green innovation performance on corporate advantage in Taiwan. J. Bus. Ethics 2006, 67, 331–339. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Green supply chain management innovation diffusion and its relationship to organizational improvement: An ecological modernization perspective. J. Eng. Technol. Manag. 2012, 29, 168–185. [Google Scholar] [CrossRef]

- Kump, B.; Engelmann, A.; Kessler, A.; Schweiger, C. Toward a dynamic capabilities scale: Measuring organizational sensing, seizing, and transforming. Strateg. Manag. J. 2019, 40, 1392–1418. [Google Scholar] [CrossRef]

- Hair, J.F. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); Sage: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Alvarez Gil, M.J.; Jimenez, J.B.; Lorente, J.C. An analysis of environmental management, organizational context and performance of Spanish hotels. Omega 2001, 29, 457–471. [Google Scholar] [CrossRef]

- Sharma, S.; Vredenburg, H. Proactive corporate environmental strategy and the development of competitively valuable organizational capabilities. Strateg. Manag. J. 1998, 19, 729–753. [Google Scholar] [CrossRef]

- Theyel, G. Management practices for environmental innovation and performance. Int. J. Oper. Prod. Manag. 2000, 20, 249–266. [Google Scholar] [CrossRef]

- López-Gamero, M.D.; Molina-Azorín, J.F.; Claver-Cortés, E. The whole relationship between environmental variables and firm performance: Competitive advantage and firm resources as mediator variables. J. Environ. Manag. 2009, 90, 3110–3121. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Institutional-based antecedents and performance outcomes of internal and external green supply chain management practices. J. Purch. Supply Manag. 2013, 19, 106–117. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Green project partnership in the supply chain: The case of the package printing industry. J. Clean. Prod. 2006, 14, 661–671. [Google Scholar] [CrossRef]

- Vachon, S. Green supply chain practices and the selection of environmental technologies. Int. J. Prod. Res. 2007, 45, 4357–4379. [Google Scholar] [CrossRef]

- Brislin, R.W. The wording and translation of research instruments. In Field Methods in Cross-Cultural Research; Lonner, W.J., Berry, J.W., Eds.; Sage Publications: Beverly Hills, CA, USA, 1986; pp. 137–164. [Google Scholar]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef]

- Armstrong, J.S.; Overton, T.S. Estimating nonresponse bias in mail surveys. J. Mark. Res. 1977, 14, 396–402. [Google Scholar] [CrossRef]

- Fuller, C.M.; Simmering, M.J.; Atinc, G.; Atinc, Y.; Babin, B.J. Common methods variance detection in business research. J. Bus. Res. 2016, 69, 3192–3198. [Google Scholar] [CrossRef]

- Baron, R.M.; Kenny, D.A. The moderator–mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Pers. Soc. Psychol. 1986, 51, 1173–1182. [Google Scholar] [CrossRef]

- Al-Sheyadi, A.; Muyldermans, L.; Kauppi, K. The complementarity of green supply chain management practices and the impact on environmental performance. J. Environ. Manag. 2019, 242, 186–198. [Google Scholar] [CrossRef]

- Malhotra, N.K.; Nunan, D.; Birks, D.F. Marketing Research; Pearson UK: London, UK, 2020. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Hu, L.T.; Bentler, P.M. Cutoff criteria for fit indexes in covariance structure analysis: Conventional criteria versus new alternatives. Struct. Equ. Model. 1999, 6, 1–55. [Google Scholar] [CrossRef]

- Aragón-Correa, J.A.; Sharma, S. A contingent resource-based view of proactive corporate environmental strategy. Acad. Manag. Rev. 2003, 28, 71–88. [Google Scholar] [CrossRef]

- Javed, S.; Al-Mulali, U. Navigating the Innovation–Sustainability Paradox: The Strategic Role of Leadership and Industry 4.0 in Oman’s Manufacturing Sector. Sustainability 2025, 17, 2595. [Google Scholar] [CrossRef]

- Abdulrahman, M.D.; Gunasekaran, A.; Subramanian, N. Critical barriers to reverse logistics practices in Chinese manufacturing sectors. Int. J. Prod. Econ. 2014, 147, 460–471. [Google Scholar] [CrossRef]

- Nadeem, M.; Khalid, R.; Shahbaz, M. Waste minimization and green innovation as enablers of sustainable operations. J. Clean. Prod. 2020, 258, 120859. [Google Scholar]

- Saeed, A.; Jun, Y.; Nubuor, S.A.; Priyankara, H.P.R.; Jayasuriya, M.P.F. Institutional pressures, green supply chain management practices on environmental and economic performance: A two theory view. Sustainability 2018, 10, 1517. [Google Scholar] [CrossRef]

- Singh, S.K.; Giudice, M.D.; Chierici, R.; Graziano, D. Green innovation and environmental performance: The role of green transformational leadership and green human resource management. Technol. Forecast. Soc. Change 2020, 150, 119762. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).