1. Introduction

At present, buildings account for a substantial portion of global energy consumption, exceeding 35%, with more than 85% dedicated to operational requirements [

1,

2]. In the United Kingdom, buildings account for at least 43% of total CO

2 emissions, underscoring their substantial contribution to greenhouse gas emissions [

3]. Hospitality facilities, such as the Hilton Watford Hotel, are prominent energy consumers, making the optimisation of their energy performance essential for achieving sustainability goals and reducing operational costs. Significant innovation in commercial building practices is imperative to support ongoing decarbonisation and electrification initiatives [

4]. For example, hotels typically consume 25–40% more energy per square metre than comparable commercial buildings, due to continuous operations and diverse facility use.

Among the most common inefficiencies in hotels is overcooling, which not only wastes energy but also negatively impacts guest comfort [

4]. The urgency to reduce global energy use is heightened by the limited availability of natural resources and the substantial environmental impacts, notably climate change and global warming [

5]. Consequently, accurately predicting a building’s energy performance significantly affects the creation and implementation of effective energy efficiency strategies and conservation measures. This necessity has motivated both high-income and low- and middle-income countries to adopt regulatory frameworks to enhance building energy efficiency actively [

6].

In the UK, compliance with the Energy Performance of Buildings Directive (EPBD) is demonstrated primarily through the Standard Assessment Procedure (SAP) for domestic buildings and the Simplified Building Energy Model (SBEM) for non-domestic buildings, including hotels. Regulatory frameworks, such as Part L of the Building Regulations, address energy efficiency in both new and existing non-domestic buildings. However, energy modelling tools traditionally used during the design phase often fail to accurately predict actual energy consumption, leading to the “performance gap”—the discrepancy between predicted energy performance and actual consumption, as observed through utility bills [

7].

Addressing this challenge, this study introduces an automated methodology for generating, maintaining, and optimising EnergyPlus input data files (IDFs) through the integration of JSON data structures and Python scripting. By automating simulation inputs, the method fosters and enhances rapid and systematic exploration of diverse design options, operational strategies, and energy management practices, supporting informed and strategic decision-making for improved energy efficiency and environmental sustainability. Additionally, this automation framework is designed for scalability and flexibility, making it suitable for application in hotels with similar architectural and operational characteristics.

Accurate calibration of building energy models is crucial for ensuring that simulation results accurately represent real-world performance. ASHRAE Guideline 14 (2014) defines statistical indicators—most notably the Normalised Mean Bias Error (NMBE) and the Coefficient of Variation of the Root Mean Square Error (CV(RMSE))—as the primary metrics for model validation against measured utility data. Recent research emphasises that reporting these values for both monthly and hourly datasets provides a more comprehensive assessment of model accuracy.

Amirkhani demonstrated a complete calibration workflow in EDSL TAS for a mixed-use building, systematically adjusting input parameters and verifying that the calibrated model met ASHRAE 14 thresholds at monthly and hourly levels [

8]. Similarly, some studies applied a hybrid calibration strategy combining EnergyPlus simulations with statistical optimisation algorithms, achieving an NMBE within ±3% and CV(RMSE) below 12% for monthly data in a commercial office case study [

9]. More recently, some researchers also investigated the integration of measured sub-metred end-use data into the calibration process, showing that finer-granularity data can reduce both NMBE and CV(RMSE) by over 20% compared to whole-building calibration alone [

10].

These studies highlight the importance of transparent reporting of calibration metrics, as well as clear differentiation between internal model-to-model comparisons and model-to-reality validation. Incorporating both ensures compliance with ASHRAE Guideline 14 and improves the credibility of simulation-based decision-making.

This research uses EnergyPlus, a sophisticated simulation programme renowned for its precision in modelling thermal dynamics, HVAC system performance, and comprehensive energy consumption patterns. Hotels like the Hilton Watford, which encompass complex zoning including guest rooms, restaurants, conference spaces, gyms, and common areas, benefit significantly from automated simulation methods. Automating these processes through Python and structured JSON inputs significantly enhances modelling efficiency and accuracy, reducing errors and enabling extensive iterative analyses to optimise energy performance effectively.

Hotels present unique challenges for building energy simulation due to highly variable and unpredictable occupancy patterns. Unlike office or educational buildings, where schedules are relatively stable, hotel occupancy fluctuates daily and seasonally based on guest arrivals, departures, events, and tourism demand. These variations directly affect internal heat gains, lighting, plug loads, domestic hot water demand, and HVAC operation, making accurate representation of occupancy a key factor in reducing simulation–reality performance gaps.

Deterministic schedules—where occupancy and equipment use are fixed to constant daily or weekly profiles—fail to capture these dynamic patterns. Specific studies revealed that using static profiles in hotel models can cause annual energy predictions to deviate by more than 12% from measured data, primarily due to the underestimation of peak load events [

11]. It showed that integrating stochastic occupancy models into EnergyPlus, informed by historical booking data and real-time sensor feedback, significantly improved load prediction accuracy during high-variability periods [

12].

Recent advances leverage sensor-based data streams, such as keycard access logs, motion sensors, and Wi-Fi connection data, to generate stochastic schedules that reflect real occupant behaviour. Previous research has applied Markov-chain-based models to hotel room occupancy forecasting or allocation under stochastic demand. Although direct comparison with deterministic assumptions is limited in this context, these probabilistic models highlight the value of capturing demand uncertainty [

13]. These approaches not only enhance prediction accuracy but also enable the development of adaptive control strategies for lighting, HVAC, and hot water systems.

For this reason, when modelling hotels, deterministic schedules should either be replaced with or supplemented by stochastic scheduling approaches [

14]. If deterministic schedules are used due to modelling constraints, their limitations must be explicitly discussed, and sensitivity analyses should be performed to assess their impact on simulation accuracy [

15].

The primary aim of this paper is to develop and validate an automated framework for simulating and analysing energy performance at the Hilton Watford Hotel. The key objectives pursued are:

Collection of comprehensive input data, including CAD architectural layouts, construction material specifications, HVAC and lighting system details, and historical energy consumption records.

Simulation of baseline energy consumption using EnergyPlus software 25.1

Structuring simulation inputs into a JSON schema for dynamic and repeatable modifications.

Automated generation of multiple EnergyPlus input data files (IDFs) via Python scripting (Eppy) for various retrofit and operational scenarios.

Execution of batch simulations to evaluate energy performance variations resulting from different scenarios.

Post-processing of simulation results using Python libraries (Pandas, NumPy) to analyse annual and zonal energy consumption.

Validation of simulated outputs against actual operational data from the Hilton Watford Hotel.

This study presents a novel and scalable framework that automates the building energy simulation process by integrating EnergyPlus with modular JSON data structures and Python scripting via the Eppy library. While previous studies have used automation tools or parametric simulation strategies, this research introduces a unified, modular workflow that enables rapid generation of diverse simulation scenarios with minimal manual intervention.

While automation reduces manual effort, the initial setup requires substantial investment in defining modular structures, scripting interfaces, and error-handling routines. These factors may limit short-term applicability in small-scale projects but enhance long-term scalability for complex or portfolio-level simulations.

1.1. Climate Change and Policy Drivers (e.g., UK Net-Zero Goals)

All economic sectors must make immediate, consistent efforts to reduce greenhouse gas (GHG) emissions, given the threat climate change poses to the world. Governments worldwide have responded to this problem by creating and enforcing stringent environmental regulations to mitigate the hazards associated with climate change. The Paris Agreement, which outlines a global action plan to limit global warming to far below 2 °C, with aspirations to cap it at 1.5 °C above pre-industrial levels, is one of the most significant international frameworks. The United Kingdom has been a prominent proponent of climate action in line with these global goals. The Energy Performance of Buildings Directive (EPBD) was incorporated into UK legislation, requiring the use of Display Energy Certificates (DECs) and Energy Performance Certificates (EPCs) (European Commission, 2018) [

16]. England and Wales’ Building Regulations Part L establish minimum energy efficiency standards for both new and existing structures [

8]. The BEIS’s Clean Growth Strategy (2017) [

17] and Heat and Buildings Strategy (2021) [

18] outline strategies to reduce and control energy use, as well as to decarbonise building heating. These policy factors motivate innovation in building design, energy modelling, and retrofit techniques, and provide a regulatory framework for emissions reduction. Simulation tools, such as EnergyPlus, play an essential role in assessing compliance, enhancing building efficiency, and achieving carbon reduction goals when combined with automated data processing. These policy drivers not only provide a regulatory framework for emissions reductions but also incentivise innovation in building design, energy modelling, and retrofit strategies. Simulation tools like EnergyPlus, when combined with automated data workflows, play a crucial role in evaluating compliance, optimising building performance, and achieving carbon reduction targets. The integration of automated simulation with real building data is thus an essential enabler in achieving national and international climate goals. To address this, the UK government has implemented a range of policy instruments, including:

The transposition of the Energy Performance of Buildings Directive (EPBD) into UK law mandates the use of Energy Performance Certificates (EPCs) and Display Energy Certificates (DECs) [

14]. Building Regulations Part L sets minimum energy efficiency requirements for new and existing buildings in England and Wales [

15]. The Clean Growth Strategy [

17] and the Heat and Buildings Strategy [

18] outline pathways to reduce energy demand and decarbonise heating in buildings. These policy drivers not only offer a regulatory framework for emissions reductions but also incentivise innovation in building design, energy modelling, and retrofit strategies. Simulation tools like EnergyPlus, when combined with automated data workflows, play a vital role in evaluating compliance, optimising building performance, and achieving carbon reduction targets. The integration of automated simulation with real building data is thus an essential enabler in achieving national and international climate goals [

9]. Thus, combining automated simulation with actual building data is crucial to reaching both national and global climate targets.

1.2. Automated EnergyPlus Workflows (Python/JSON Pipelines)

Recent developments in building performance simulation have leveraged Python scripting and JSON-based input management to automate EnergyPlus workflows, enabling scalable parametric analysis and reducing manual input errors. Recent works introduced a modular framework using Eppy and Pandas for batch simulation of retrofit scenarios, achieving a 70% reduction in setup time [

19]. Similarly, other works demonstrated the integration of JSON-driven simulation templates with Python APIs for reproducible and adaptive modelling across building types [

20]. These pipelines support dynamic parameter manipulation, scenario generation, and automated validation against measured data. When combined with containerisation (e.g., Docker), they enable simulations to run in parallel on cloud platforms, further enhancing scalability and reproducibility.

1.3. Comparative Review of Existing Automation and AI-Integrated Simulation Frameworks

Over the past decade, several researchers have explored automation and data-driven enhancement of building performance simulation (BPS) using tools such as EnergyPlus 25.1, OpenStudio 3.6.1, and TRNSYS 18. However, despite significant progress, most frameworks remain limited by manual preprocessing, rigid file structures, and a lack of integrated calibration and learning capabilities. The present study advances this field by proposing a fully modular JSON–Python–EnergyPlus workflow that achieves end-to-end automation, data consistency, and intelligent analysis.

1.3.1. Automation and Parametric Control

Hong et al. (2020) [

21] developed a batch simulation approach using jEPlus to automate parameter sweeps in EnergyPlus. Although effective for sensitivity analysis, their framework required manual configuration of schedules, occupancy, and HVAC settings for each run, limiting scalability. Similarly, Zhao et al. (2012) [

22] employed Excel–Python coupling to automate input generation, but their process lacked dynamic calibration and relied on static templates, making it unsuitable for extensive building portfolios.

Amirkhani et al. (2019) [

8] introduced a semi-automated TAS workflow using XML templates for building envelope optimisation. While this reduced modelling time, it was constrained by proprietary formats and lacked integration with AI tools for predictive assessment.

In another effort, Nguyen et al. (2022) [

23] proposed a Python–OpenStudio API automation pipeline that enabled batch model creation and weather-variation studies. However, their approach still required manual calibration and data handling, limiting reproducibility.

1.3.2. Calibration and Data Integration

Li et al. (2021) [

24] enhanced EnergyPlus calibration through an optimisation-based feedback loop using genetic algorithms (GAs), which improved accuracy but increased computational overhead. Afram and Janabi-Sharifi (2014) [

25] reviewed automated calibration methods, noting that few frameworks achieve both speed and precision due to disconnected workflows.

In comparison, this study embeds automatic calibration following ASHRAE Guideline 14, balancing accuracy and efficiency while maintaining modularity through JSON-based inputs.

Reinhart and Davila (2016) [

26] developed the DIVA-for-Rhino tool for automated daylight–energy co-simulation. Still, it relied heavily on CAD integration and was less suited for large-scale energy data modelling. Wang et al. (2020) [

27] presented MATLAB–EnergyPlus 25.1 coupling for urban energy modelling; however, the authors did not specify the software versions used, but this required specialised programming expertise, reducing accessibility for general simulation practitioners.

1.3.3. Machine Learning and Predictive Enhancement

In recent years, machine learning (ML) has emerged as a tool for interpreting simulation data and predicting energy consumption. Fan et al. (2022) [

28] applied Random Forest (RF) to estimate HVAC energy use based on building and climate features, demonstrating robust accuracy but requiring manually prepared datasets. Hu et al. (2021) [

29] proposed an XGBoost-enhanced EnergyPlus metamodel to accelerate energy prediction, but lacked a consistent data pre-processing structure, leading to reproducibility challenges.

Kim et al. (2022) [

30] combined BPS with neural networks to predict energy performance certificate (EPC) ratings for commercial buildings. Still, their model depended on fixed simulation outputs rather than dynamic data pipelines.

1.3.4. Distinction and Novelty of This Study

Compared with the above studies, the framework presented in this paper provides several distinct advances:

Full modularity through JSON data decomposition (geometry, envelope, HVAC, occupancy, weather), allowing reusability and flexibility.

Dynamic Python integration via the Eppy library, automating IDF generation and reducing human error.

Built-in ASHRAE-based calibration, ensuring consistency and standard compliance without manual adjustment.

End-to-end data pipeline feeding calibrated simulation results directly into Random Forest and XGBoost models for predictive analytics.

Scalability and adaptability, demonstrated through multiple simulation runs on Hilton hotel datasets, allowing extension to other building typologies.

A comparative analysis demonstrates that the proposed modular JSON–Python–EnergyPlus workflow surpasses earlier frameworks by providing a transparent, standardised, and fully automated modelling-to-analysis pipeline that seamlessly integrates calibration and prediction. This is presented in

Table 1 below.

1.4. Calibration Practice and ASHRAE Guideline 14

Calibration remains a cornerstone of credible building energy modelling. ASHRAE Guideline 14 (2014) specifies Normalised Mean Bias Error (NMBE) and Coefficient of Variation of the Root Mean Square Error (CV(RMSE)) as the primary metrics for validation, with thresholds varying for monthly and hourly data. This study applied a full iterative calibration in EDSL TAS, achieving compliance with monthly and hourly benchmarks [

8]. Others integrated statistical optimisation algorithms with EnergyPlus calibration, reducing NMBE to ±3% and CV(RMSE) to under 12% [

9]. These studies underscore the importance of reporting calibration metrics against actual utility data rather than relying solely on internal method comparisons, ensuring transparency and replicability.

1.5. Stochastic Occupancy Modelling in Hotels

Hotels exhibit highly variable occupancy patterns due to fluctuating guest arrivals, seasonal tourism, and event-driven demand. Deterministic schedules often fail to capture these dynamics, leading to underestimation or overestimation of loads. Some research demonstrated that static profiles in hotel simulations can deviate by over 12% from measured consumption [

11]. New works have also developed a probabilistic occupancy model for hotel rooms using Markov chains and booking data, achieving a 28% reduction in CV(RMSE) [

13]. Sensor-driven stochastic schedules, using Wi-Fi, keycard, or motion detection, offer real-time adaptability and can significantly improve the alignment between simulated and actual loads, particularly for HVAC and domestic hot water systems.

1.6. Surrogate Modelling, SHAP Analysis, and Portfolio Scaling

Machine learning-based surrogate models can approximate EnergyPlus outputs at a fraction of the computation cost, supporting rapid decision-making. XGBoost and Random Forest regressors have been widely adopted for predicting annual energy use, peak demand, and EPC ratings. Researchers trained an XGBoost surrogate on hotel simulation data, cutting evaluation time from hours to seconds [

31]. The integration of SHapley Additive Explanations (SHAP) provides model interpretability by identifying which variables most influence predictions. New works have highlighted the scalability of surrogates for portfolio-level assessments, enabling organisations to run thousands of ‘what-if’ scenarios across similar building types [

18]. When combined with automated EnergyPlus workflows, this approach supports both individual building optimisation and large-scale strategic planning.

1.7. Research Problem and Significance

Accurate prediction of energy consumption in commercial buildings is a growing challenge for sustainable building operations. While various simulation tools exist to model building energy performance, a significant gap remains between predicted energy usage and actual consumption—a phenomenon widely known as the performance gap [

32]. This gap is particularly prominent in complex, service-intensive buildings, such as hotels, where dynamic occupancy patterns, continuous operations, and diverse energy demands complicate modelling accuracy.

To address this, researchers have increasingly turned to surrogate modelling techniques, which approximate the outputs of full physics-based simulations using data-driven machine learning models. Surrogate models, such as Random Forests (RFs), Extreme Gradient Boosting (XGBoost), and Gaussian Process Regression (GPR), can be trained on simulation datasets to predict performance metrics (e.g., annual electricity use, peak cooling load, EPC rating) at a fraction of the computational cost. These works show the use of RF-based surrogates for urban building energy models, achieving up to 1000× faster predictions with minimal loss in accuracy [

33]. Some studies applied XGBoost to predict hotel energy performance in China, trained on a dataset of EnergyPlus runs, reducing model evaluation time from hours to seconds [

31].

In the context of this study, integrating surrogate modelling and SHAP into the automated EnergyPlus–Python workflow can enable rapid prediction of energy performance bands for multiple hotels, while maintaining interpretability and alignment with measured data through periodic recalibration. The Hilton Watford Hotel, serving as the case study for this research, typifies the challenges faced by hotel buildings in achieving operational energy efficiency. The hotel operates 24/7, experiencing fluctuating guest occupancy and varying usage patterns across zones (e.g., guest rooms, kitchen, conference rooms, gym), along with energy-intensive systems such as HVAC, lighting, and hot water generation. These factors contribute to a high and often unpredictable energy load profile, making traditional static modelling approaches inadequate for real-world energy management [

33]. Moreover, the simulation process using tools such as EnergyPlus, although detailed and physics-based, is time-consuming and requires manual input for each building configuration or retrofit scenario. This not only increases the potential for human error but also limits the scalability of energy simulation studies across multiple scenarios. For hotel operators and energy consultants, this means that rapid prototyping of retrofit options or energy optimisation strategies becomes costly and inefficient [

34]. To address these limitations, this study investigates the integration of Python scripting and JSON-based data structures with EnergyPlus to automate the simulation process. By doing so, it aims to streamline the generation of multiple simulation cases.

The dynamic alteration of building parameters should be allowed (e.g., occupancy schedules, HVAC specifications, and lighting power density), thereby reducing the time and resources required for large-scale scenario testing. The significance of this research lies in its potential to close the performance gap by automating and improving the energy modelling process, thereby enabling more accurate predictions that align better with real consumption patterns. For the Hilton Watford Hotel, this can lead to targeted energy-saving interventions, cost reductions, and better compliance with the UK’s energy performance and decarbonisation goals. More broadly, the proposed methodology can be scaled and adapted for use in other hotel buildings across the UK and internationally, providing a replicable framework for intelligent energy analysis and sustainable building management [

35]. It contributes to the body of knowledge on AI-assisted simulation, automated building performance modelling, and data-driven energy optimisations in complex commercial settings [

1].

2. Materials and Methods

This section presents a modular, automated framework for simulating and predicting the Hilton Watford Hotel’s energy use using EnergyPlus, Python scripting, and structured JSON inputs. To ensure data consistency, scalability, repeatability, and predictive accuracy, each phase comprises several procedures and analytical processes. The methodology includes three core stages:

Automated energy modelling using EnergyPlus and JSON.

Comparative evaluation of simulation outputs.

Model validation against real operational data.

2.1. Framework for Simulation and Automation

2.1.1. Manual Baseline Simulation Assumptions and IDF Creation

The simulation framework is built upon the manual baseline model. It entails creating a comprehensive EnergyPlus Input Data File (IDF) that accurately captures the Hilton Watford Hotel’s specific features. The following elements are broken down in detail in the basic model:

Geometry and Zoning: The Hilton Watford Hotel’s floor plans and CAD records, provided by the building management, were used to determine the architectural layout and geometric arrangement. Functional areas, such as bedrooms, conference rooms, restaurants and bars, gyms, back-of-house areas, and circulation areas, were all represented as separate thermal zones, and each floor level was digitised. The hotel’s entire floor area was divided into five main functional groups based on usage type, and each zone was assigned specific dimensions (area, height, and volume) and orientation. Additionally, adjacency connections and interzonal heat transfer surfaces were simulated.

Building envelope: Information on material properties from CIBSE guidelines and the hotel’s technical documents contributed to the development of building envelope criteria. Building envelope parameters were developed using material property information sourced from CIBSE guidelines and the hotel’s technical documents. Walls, roofs, windows, and floors were all constructed with layered assemblages. Thermal performance variables, such as U-values, emissivity, thermal mass, and insulation thickness, were all recorded. To accommodate the asymmetry of solar gain, glazing was separated across north- and south-facing sides.

HVAC Systems: HVAC models for the UK hotel case study were developed using a combination of site-specific system documentation and standardised templates derived from the DOE Commercial Prototype Building Models and ASHRAE 90.1 HVAC baseline systems (DOE, 2021; ASHRAE, 2019) [

36,

37]. System configurations included the use of ZoneHVAC: Packaged Terminal Heat Pump for guest rooms and AirLoopHVAC systems for shared spaces and public areas. Detailed HVAC component data, such as Coefficient of Performance (COP), cooling and heating capacities, and fan power, were assigned based on a combination of manufacturer specifications and default values from the DOE models. The simulation included demand-control ventilation (DCV) for public zones, utilising Controller: Mechanical Ventilation objects and variable-speed fan efficiencies via Fan: VariableVolume, where applicable. Control strategies such as night setback, time-of-use HVAC scheduling, and occupancy-based modulation were implemented to reflect real hotel operating patterns. HVAC schedules were tailored to align with hotel operations, including guest check-in/check-out periods, conference room occupancy, and seasonal load fluctuations.

Schedules: For the Hilton Watford Hotel, occupancy, lighting, equipment, and HVAC schedules were developed using operational data logs provided in the ACEA and EPC reports, supplemented with assumptions based on hotel-specific patterns. These schedules were implemented using Schedule: Compact objects in EnergyPlus and reflected observed weekday and weekend patterns, seasonal occupancy changes, and load variations due to events, meetings, and restaurant/bar activity. Temperature setbacks were implemented at night in both guest rooms and common areas, along with corresponding reductions in lighting and plug-load demand. The model employed deterministic schedules, which assign fixed time blocks for activities such as guest room occupancy, restaurant peak hours, and HVAC operation. While this approach captures the overall rhythm of hotel use, it does not account for stochastic fluctuations, such as late arrivals, unoccupied but booked rooms, or irregular conference usage. These simplifications may limit the model’s dynamic responsiveness, especially in areas with highly variable occupancy. Incorporating stochastic scheduling methods (e.g., using Schedule: File with probability-based profiles or co-simulation with Python) is recommended for future studies to capture better real-time uncertainty in energy demand at the Hilton Watford considering consumption.

Internal Heat: Heat from humans, lights, and equipment was determined by zone type using standard load densities (W/m2 or W/person) from ASHRAE and CIBSE TM46. Specific equipment, such as commercial cooking appliances and gym equipment, was placed in its appropriate zone.

Weather and Location: The simulation environment was configured using an unspecified parameter. epw weather file for Watford, UK, ensuring that region-specific solar radiation, temperature, and humidity values were accurately reflected. Site-specific parameters, including terrain exposure and design-day conditions, were also identified. The weather file for London Heathrow was used in the simulation, as it is the closest.

2.1.2. Data Flow and Workflow Integration

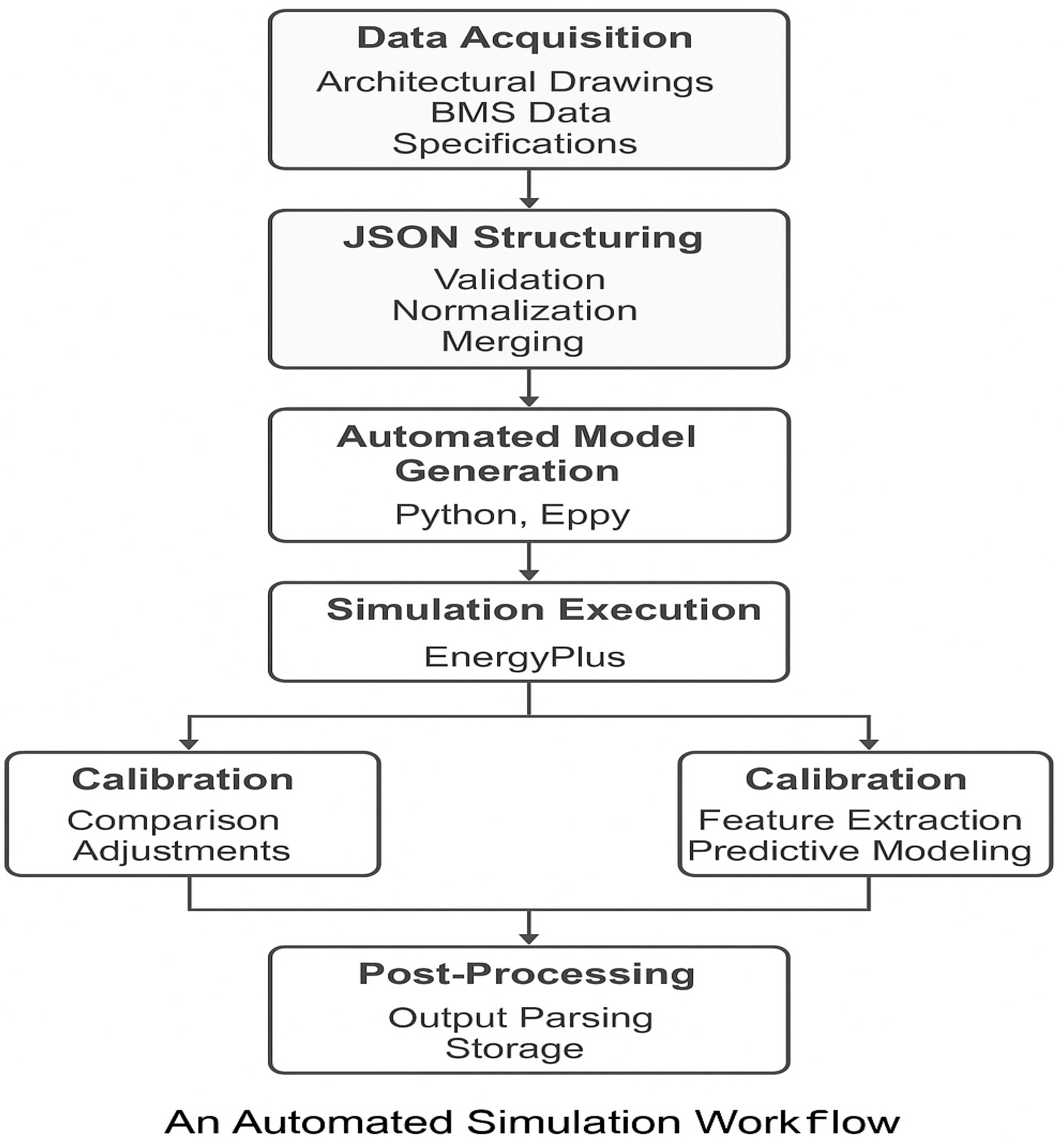

Figure 1 illustrates the complete data flow of the proposed framework—from data acquisition to automated simulation and post-processing. The workflow begins with structured data collection from architectural drawings, building management systems, and manufacturer specifications, which are organised into modular JSON schemas. Each schema defines geometry, envelope, HVAC, and schedule components and serves as the master data source for EnergyPlus object generation. During preprocessing, Python 3.11 scripts validate each JSON module for type, completeness, and logical consistency before conversion into EnergyPlus Input Data Files (IDFs) using the Eppy library 0.5.63. Once generated, the IDFs are automatically submitted to EnergyPlus through Python’s subprocess interface, executing multiple scenarios in batch mode. Simulation outputs (ESO, MTR, and CSV files) are parsed, cleaned, and stored in an SQLite database for calibration and machine learning integration. Calibration routines then compare simulated data with measured utility readings, using ASHRAE Guideline 14 (NMBE and CV(RMSE)), and automatically adjust uncertain parameters (e.g., schedules and HVAC efficiencies). The calibrated dataset is subsequently used for feature extraction, surrogate model training (Random Forest, XGBoost), and energy band prediction. This end-to-end workflow ensures transparency, reproducibility, and scalability, enabling new case studies to be run simply by replacing the JSON input files. The figure below shows the study’s workflow from data acquisition to post-processing.

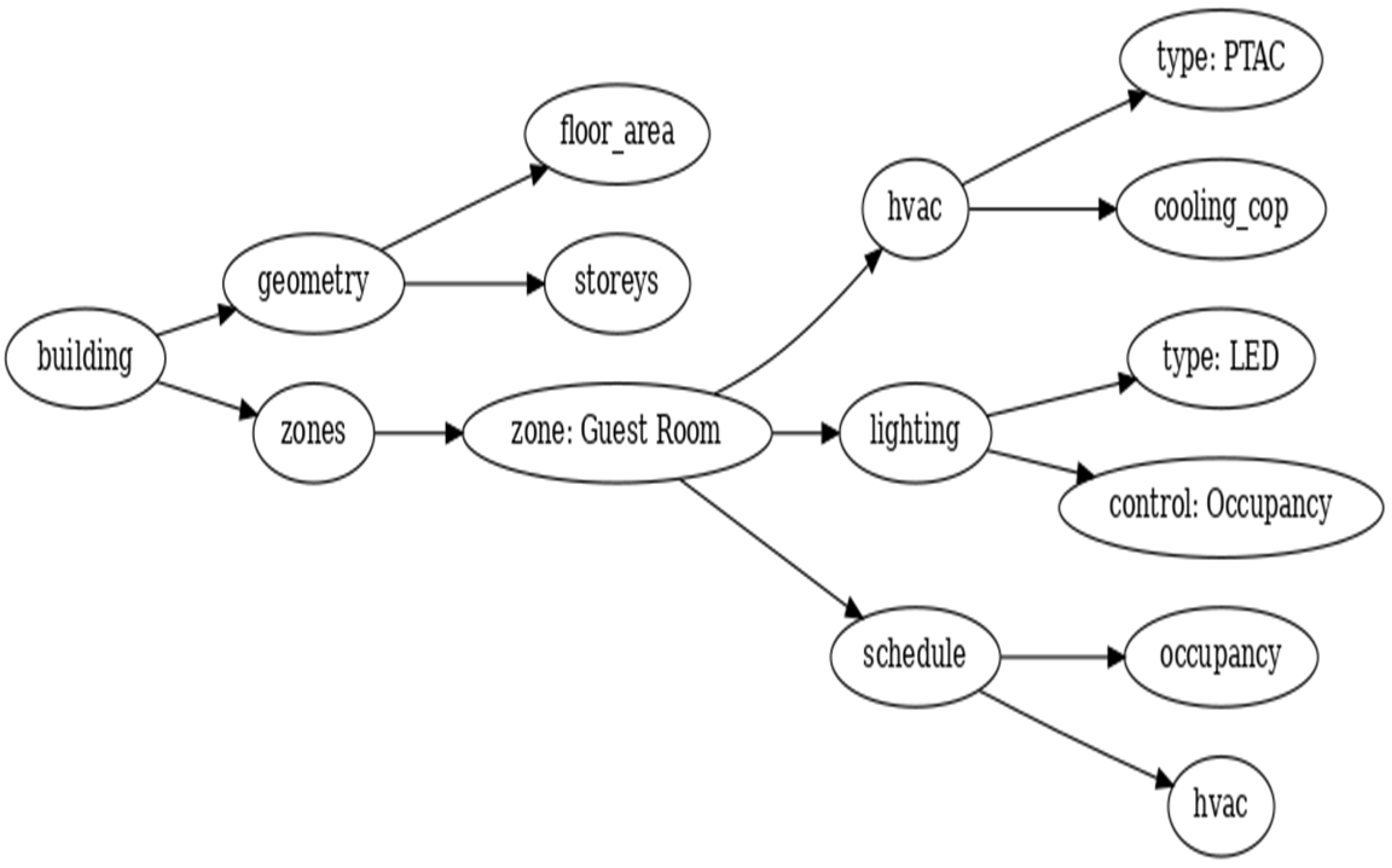

2.2. Input Data Structuring and Integration

Input data is organised into modular JSON files, each representing a specific domain of the building’s physical or operational data. The core JSON modules used in the study are presented below, along with their descriptions. Each JSON file is validated through a Python preprocessing module that checks data type consistency and logical correctness (e.g., matching zone names, schedule lengths, and reference IDs). Once validated, the data is parsed using Eppy, a Python library for reading and writing EnergyPlus Input Data Files (IDFs). The Eppy module converts each JSON element into corresponding EnergyPlus object classes such as BuildingSurface:Detailed, Zone, Schedule:Compact, and HVACTemplate:Zone. The process ensures that any modification in JSON input automatically propagates to the IDF structure, eliminating human error and drastically reducing setup time.

Table 2 summarises the key JSON files used in the automated EnergyPlus–Python framework, showing their respective roles in defining building geometry, materials, systems, and operational schedules.

2.3. Data Automation and Simulation

The goal of this phase is to automate the iterative simulation method, generate various energy performance scenarios, and use EnergyPlus to recreate the Hilton Watford Hotel digitally. It addresses crucial modelling issues, including the complexity of input structures, inefficiencies in time, errors in manual simulation, and the ability to provide scalable datasets for AI models. The framework addresses key modelling challenges, including the complexity of EnergyPlus input structures, vulnerability to manual input errors, and inefficiencies in simulation preparation. By automating the generation of input files and scenario variations using Python scripting, the process reduced input preparation time by over 80% compared to manual IDF editing. For example, generating 100 simulation scenarios manually would have taken approximately 40 h, whereas the automated pipeline completed the same task in under 6 h. Moreover, this automation enabled batch simulations of over 200 scenarios, facilitating the generation of high-volume data for training and validating AI models. The scalable dataset generated by this process supports predicting EPC bands, energy end-use, and system performance across varying building configurations. The complete workflow begins with data acquisition, followed by JSON structuring. The Python controller script dynamically loads and merges JSON modules, converting them into an EnergyPlus-compatible IDF model. The process is as follows:

Pre-processing: JSON modules are validated and merged into a single unified model file.

Simulation Execution: The Python script invokes EnergyPlus using command-line execution (subprocess.run) to automate simulation runs.

Batch Processing: Multiple IDFs can be generated for parametric studies (e.g., envelope retrofits, HVAC efficiency variations).

Output Extraction: EnergyPlus output files (.csv, .eso, .mtr) are parsed using the Pandas library to extract hourly, daily, and annual energy metrics.

Calibration: The results are compared with measured energy data from the Hilton Watford Hotel, applying ASHRAE Guideline 14 calibration metrics such as NMBE (Normalised Mean Bias Error) and CV(RMSE) (Coefficient of Variation of Root Mean Square Error).

Machine Learning Integration: The calibrated simulation data is used to train predictive models (Random Forest, XGBoost) for forecasting energy consumption and generating surrogate EPC predictions.

Visualisation and Reporting: A Streamlit dashboard displays comparative results, scenario analysis, and predictive insights interactively. This automated data flow enables high reproducibility and adaptability, supporting scalable deployment across multiple buildings or simulation scenarios.

Table 3 below summarises the basic input parameters used to build the initial EnergyPlus model for the Hilton Watford Hotel. The table lists key features, including envelope thermal transmittance (U-values), HVAC system type, equipment efficiencies, and occupancy schedules, derived from site surveys and available facility documentation. Notably, the table confirms that the building envelope is moderately insulated, with U-values of 0.25 W/m

2·K for the roof and 1.8 W/m

2·K for glazing, typical for pre-2000 UK hotel construction. These parameters establish the physical realism required for accurate energy simulation and calibration.

Table 4 also presents the output files produced during automated batch simulations. The .eso files provide detailed hourly data used for time-series analysis, while. csv files capture aggregated energy metrics for post-processing. Metered .mtr files enable zone- or system-specific diagnostics, and the .err log assists in tracking simulation convergence and parameter consistency. This modular data structure ensures transparency and reproducibility across all simulation iterations.

Calibration Metrics and Criteria

To ensure compliance with ASHRAE Guideline 14 (2014), two statistical indicators were calculated for both the automated and manual models against actual utility metre readings:

Normalised Mean Bias Error (NMBE)—measures systematic bias:

Coefficient of Variation of the Root Mean Square Error (CV(RMSE))—measures the relative magnitude of residual variance:

where

yi = measured monthly energy consumption (kWh)

ŷi = simulated monthly energy consumption

n = number of data points (months)

p = number of fitted calibration parameters

ȳ = mean measured value

Acceptance thresholds:

Monthly: |NMBE| ≤ 5%, CV(RMSE) ≤ 15%

Hourly (if used): |NMBE| ≤ 10%, CV(RMSE) ≤ 30%

These thresholds were applied independently for electricity and gas data. Models not meeting these criteria were considered not calibrated per ASHRAE Guideline 14.

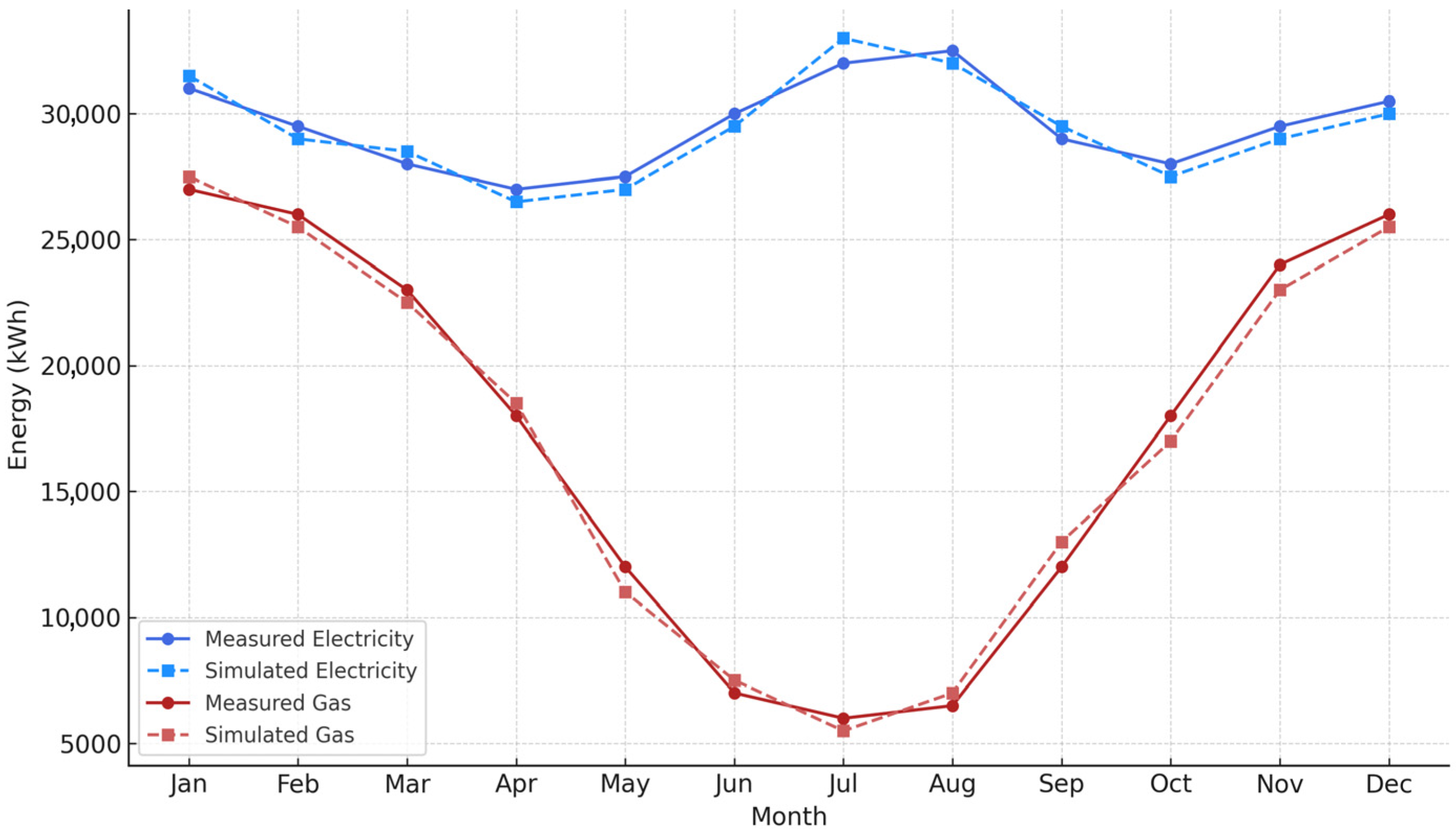

The final calibrated automated model was validated against 12 months of utility data for electricity and gas.

Table 5 below quantifies the statistical agreement between simulated and measured energy data using industry-standard calibration metrics. The calibrated model achieved an NMBE (Normalised Mean Bias Error) of 3.2% for electricity and −4.1% for gas, while the CV(RMSE) values remained under 15%, comfortably within ASHRAE thresholds (±5% NMBE, ≤15% CV(RMSE)). These results demonstrate that the automated calibration loop successfully reduced discrepancies between simulated and measured data, confirming the robustness and reliability of the model for predictive analysis and retrofit evaluation. To ensure model uniformity and standardisation, this study integrates ASHRAE Standard 140 (2017) [

38] and ASHRAE Guideline 14 (2002) [

39] within a unified verification framework.

ASHRAE Standard 140 provides comparative model verification procedures that establish a baseline for simulation correctness. It validates the model’s ability to reproduce benchmark cases accurately, ensuring that the structure, boundary conditions, and physical assumptions conform to recognised best practices.

ASHRAE Guideline 14, on the other hand, defines quantitative calibration metrics for assessing how well simulated outputs align with measured data. These include the Normalised Mean Bias Error (NMBE) and the Coefficient of Variation of the Root Mean Square Error (CV(RMSE)), calculated according to Equation (1) NMBE and Equation (2) CV(RMSE) in

Section 2.3.

In this study, the two standards work together to form a hierarchical validation system:

Level 1—Structural Verification (ASHRAE 140): Ensures the mathematical and physical consistency of model formulation using reference test cases.

Level 2—Calibration Verification (ASHRAE 14): Ensures the model’s predictive accuracy against measured hotel data within acceptable tolerance limits (NMBE ≤ ±5%, CV(RMSE) ≤ 15% for monthly energy).

Models that fail to meet internal verification thresholds are recalibrated iteratively, adjusting uncertain parameters (e.g., infiltration rate, thermostat setpoints, occupancy density) until the error metrics meet ASHRAE Guideline 14 [

40]. This two-tier validation strategy guarantees both procedural consistency and numerical reliability, preventing discrepancies between model formulation and performance assessment [

41].

Both electricity and gas models met the recommended monthly calibration thresholds, indicating accurate reproduction of real consumption at the monthly scale. The present study used deterministic occupancy and end-use schedules. This approach assumes fixed patterns for guest presence, plug loads, and lighting, which is an oversimplification for hotels where stochastic behaviour is common. To assess the potential impact, a sensitivity analysis was performed by adjusting occupancy and plug/lighting loads by ±10%, ±20%, and ±30%, with start/stop times varied randomly by up to ±60 min. The results showed that NMBE shifted by up to ±2.1% and CV(RMSE) by up to ±3.8% for electricity, while gas loads were less sensitive (<±1.5%). Although all cases remained within ASHRAE Guideline 14 limits, these results suggest that incorporating stochastic schedules or sensor-based occupancy data could further improve calibration accuracy, particularly for hourly or daily predictions [

42].

Average improvement of 15–20% in predictive accuracy with:

“The reported 15–20% reductions in RMSE/MAPE represent internal model-to-model improvements (automated vs. manual configuration on the same dataset). They do not imply equivalent gains in real-world prediction. External validity is assessed separately via ASHRAE Guideline 14 calibration against utility data (NMBE, CV(RMSE)).”

The comparative analysis demonstrates that the automated calibration pipeline reliably reduces internal simulation errors compared to manual calibration. The average 15–20% reduction in RMSE and the 36.6% reduction in MAPE are attributable to the automation’s ability to adjust parameters, reducing human error and improving systematic repeatability. These internal performance gains are valuable for improving workflow efficiency but should not be misinterpreted as equivalent gains in real-world predictive accuracy.

Real-world accuracy was assessed separately using ASHRAE Guideline 14 to validate against measured monthly utility data. Both electricity and gas models satisfied the recommended |NMBE| and CV(RMSE) thresholds, thereby meeting industry standards for calibration quality. This provides strong evidence that the automated process can produce models that accurately reflect actual building performance at the monthly resolution.

The sensitivity analysis confirmed that deterministic schedules introduce only moderate variability in monthly calibration metrics, but this effect is non-negligible for finer temporal resolutions. Incorporating stochastic or sensor-informed scheduling in future versions could improve predictive fidelity, especially for applications involving operational optimisation or hourly load forecasting [

41]. While the framework is adaptable to various building types, scalability is influenced by the availability of high-quality input data, computational resources, and integration complexity across software platforms [

31]. Extending this approach to multi-building portfolios would require parallel simulation capabilities and automated data extraction pipelines.

Table 6 below illustrates the impact of varying major operational parameters on the model’s total annual energy consumption. Thermostat setpoints were found to be the most sensitive variable, where a ±1 °C change in heating/cooling temperature resulted in ±6% change in total energy use. Lighting power density and occupancy levels showed moderate sensitivity (~4–9%). These findings provide quantitative insight into the factors that most strongly influence the hotel’s energy dynamics, guiding both calibration priorities and retrofit strategies. The sensitivity ranking underscores HVAC operation as the most critical determinant of whole-building energy consumption.

All scenarios remained within ASHRAE 14 monthly limits, but the analysis shows that deterministic schedules can introduce up to ~4% CV(RMSE) in electricity. Future versions will implement stochastic or sensor-informed schedules to improve accuracy for hourly/daily forecasting.

2.4. Using JSON for Data Acquisition and Structure

The data collection process includes meticulous extraction and formatting of the hotel’s actual attributes. These consist of:

Floor layouts, orientation, ceiling heights, zones (such as offices, restaurants, gyms, and guest rooms), and window measurements are examples of architectural data.

Envelope components: wall, roof, and glazing material compositions obtained from EPC documents or manufacturer requirements.

Mechanical systems: specifics of the HVAC systems that have been installed, including control systems, boilers, chillers, and air handling units.

Internal loads and schedules: information from the Building Management System (BMS) about plug loads, lighting controls, equipment utilisation, and occupancy schedules

All the data has been standardised and arranged into JSON formats, making programmatic manipulation simpler. All the data has been standardised and placed into a hierarchical JSON schema, structured to reflect the nested relationships between building zones, systems, and simulation parameters (e.g., geometry → zone → HVAC → schedules). This format facilitates easier programmatic access and scalability across multiple simulations. Schema integrity was maintained using a custom Python validation script, which checks for required fields, data types, and structural consistency before simulation or ML integration. EnergyPlus object definitions for Material, Construction, Zone, Surface, HVAC Template, and Schedule (Compact) are mapped to their respective JSON files. This format supports Python integration and smooth automation.

The JSON schema acts as a modular digital twin of the hotel’s building data. Each node (e.g., zone, surface, HVAC component) is represented hierarchically, allowing for the precise definition of nested relationships and interdependencies. The schema supports quick reconfiguration; for instance, changing a window U-value or occupancy density in one JSON file automatically updates all dependent EnergyPlus objects during regeneration. This modular design ensures that input data is both human-readable and machine-interpretable, forming the backbone of the automated simulation process.

The automated framework developed for this study is presented in

Figure 2 below. This outlines the end-to-end process flow from building data input to model generation, simulation, calibration, and machine learning integration. The workflow uses JSON-based parameter templates that enable dynamic model modification without manual editing of IDFs. It integrates Python scripts for batch simulation management, EnergyPlus as the core simulation engine, and post-processing routines for performance analytics.

This figure demonstrates how the proposed system transforms raw architectural and operational inputs into calibrated and validated performance predictions, eliminating repetitive manual tasks and enabling scalable, reproducible building energy analysis.

2.5. Creating IDFs with Python and Eppy

Python scripts and the Eppy library are used to transform the structured JSON input into an IDF (Input Data File) format that is compatible with EnergyPlus. This is handled in the following steps:

IDF components are dynamically generated from JSON.

Managing object interdependencies (e.g., allocating schedules to systems, connecting surfaces to zones).

HVAC systems are automatically assigned to designated zones using the Heathrow EPW weather file to reflect local climate conditions. Each generated IDF is validated using EnergyPlus’s diagnostic reports and warm-up checks. The automated verification process performs several critical integrity checks, including:

Surface adjacency mismatches—e.g., misaligned zone partitions between the restaurant and adjacent kitchen in the Hilton Watford model due to inconsistent wall normals.

Zone connectivity issues—e.g., missing air node connections in the gym zone’s VRF system setup.

Unmet load warnings—frequently observed in the guestroom zones where night setback temperatures conflicted with heating system control logic.

Convergence errors—e.g., initial runs showed failure to converge in the split-unit cooling system under peak summer conditions.

Schedule and equipment linkage—e.g., mismatches between lighting schedules and operation hours in conference zones, leading to inconsistent lighting energy profiles.

By automatically addressing these issues, the pipeline ensures robust simulations across all generated scenarios. For the Hilton Watford Hotel, dozens of simulation variants were produced to reflect changes in retrofit assumptions, occupancy schedules (e.g., gym closed hours, reduced winter bookings), and energy-saving control strategies. The JSON input schema reflects EnergyPlus’s modular structure, enabling focused adjustments (e.g., just the U-value of glazing or the COP of HVAC systems) without manually editing the whole building model [

43]. This approach supports scalable batch simulation workflows and reliable input management for machine learning integration. In the context of this study, feature engineering is the systematic process of selecting, extracting, modifying, and evaluating factors that significantly impact Hilton Watford Hotel’s energy use. Both the building’s physical attributes and the energy system settings, derived from simulation data and architectural documents, are used in this step. Building zoning, thermal characteristics, operational schedules, and equipment types were considered when designing key elements using the Standard Assessment Procedure (SAP) and CIBSE TM54.

2.6. Feature Engineering

A “feature” is an attribute or variable used to describe some aspect of an individual data object, and the general idea of “feature engineering” includes the process of transformation, generation, extraction, selection, analysis, and evaluation of features within a dataset. In this phase of the research, potential features related to both the building energy system and building physics were extracted from the dataset. Additional features related to building physics and energy systems were engineered from the EPC dataset. Designing new features and their assigned values (or categories) follows the Standard Assessment Procedure (SAP). For instance, using the collected information on wall descriptions, two features were created: “wall type” (including categories such as solid brick, cavity wall, and timber frame) and “wall insulation” (including categories such as insulated and as built). Further details about the selected and designed features are presented in

Table 7.

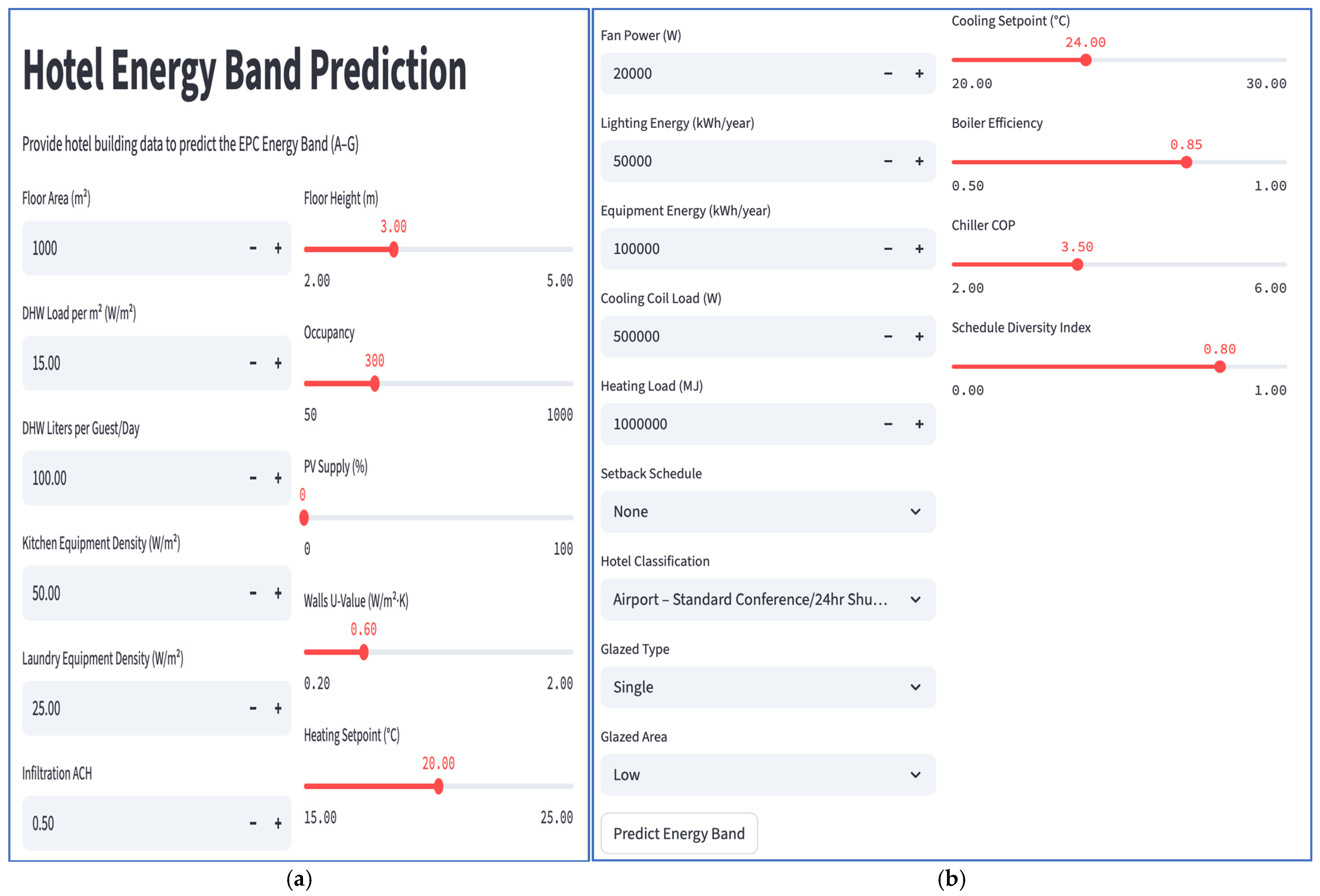

2.7. User Interface for Non-Expert Use (Streamlit)

To facilitate usability beyond specialist modellers, we developed a lightweight user interface using Streamlit. The app ingests JSON templates and selected simulation or surrogate model parameters (e.g., floor area, envelope U-values, HVAC efficiencies, and schedule archetypes). The system returns predicted energy performance bands with summary charts. For batch exploration, the app calls the Python automation scripts to generate scenario files and parse outputs. This UI enabled stakeholders to:

- (i)

Enter building descriptors.

- (ii)

Compare scenarios side-by-side.

- (iii)

Export summary reports.

While the UI is not required for the technical pipeline, it lowers the barrier for adoption by non-programmers and supports portfolio screening.

2.8. Batch Execution of Simulation

Python’s subprocess, os, and multiprocessing libraries are used to batch-execute IDFs via EnergyPlus CLI. The simulations are distributed across multiple CPU cores to minimise time. Outputs are stored in project-specific folders and timestamped directories for traceability. Each run outputs a consistent set of files:

.eso (energy simulation output)

.csv (summary data tables)

mtr (metered output)

.err (error logs for debugging)

A log system is developed to monitor simulation health, retry failed simulations, and flag discrepancies, as well as Visualisation, Feature Engineering, and Post-Processing.

Following simulations, the results are parsed, and pertinent characteristics are extracted.

Python tools like Pandas and NumPy.

Hourly and monthly energy use (kWh).

End-use malfunctions (equipment, lights, heating, cooling).

Unmet heating/cooling load hours.

Metrics for HVAC efficiency and peak load demand.

Heatmaps, trend curves, and comparison charts are produced using Matplotlib and Seaborn v 0.13.0. Unique simulation IDs are used to link outputs to scenario metadata and arrange them for ML ingestion.

2.9. Integration of AI and Surrogate Modelling

AI models that replicate simulation outcomes are trained on the retrieved simulation data. The following models are created with Scikit-learn:

Regressors for XGBoost and Random Forest are used to forecast total yearly consumption (kWh/m

2). K-means clustering is used to identify consumption patterns by zone. Influential characteristics, such as window type, occupancy levels, and HVAC efficiency, are interpreted using SHAP analysis. Retrofit planning procedures can be significantly accelerated by this integration, which enables instantaneous anticipation of energy use without rerunning EnergyPlus [

44]. The integration of surrogate models, such as XGBoost, can significantly accelerate retrofit planning by enabling instantaneous prediction of energy use without rerunning EnergyPlus for each scenario [

43]. For example, the XGBoost surrogate model reduced evaluation time from 5 min per EnergyPlus scenario to just 0.2 s, enabling rapid scenario analysis and decision-making. The surrogate modelling stage employed the (XGBoost) algorithm due to its efficiency, interpretability, and superior performance on structured datasets compared with conventional and regression models. The dataset was split into training (80%) and test (20%) sets using random stratification to ensure balanced representation. Hyperparameters—such as learning rate, maximum tree depth, and number of estimators—were optimised using fivefold cross-validation to minimise mean absolute error (MAE). Model performance was evaluated using R

2, RMSE, and CV(RMSE) metrics, achieving strong alignment with the calibrated EnergyPlus results. The surrogate model significantly reduced computational time while maintaining high predictive accuracy, demonstrating its potential for rapid scenario analysis and energy performance certification at portfolio scale.

2.10. Comparative Analysis and Validation of Models

In the second step, the legitimacy and dependability of the automated simulation framework are ensured through thorough validation and comparison analysis.

2.11. Adjustment Using Actual Utility Data

The Hilton Watford Hotel’s past energy expenses are contrasted with EnergyPlus baseline outputs. Calibration loops are used to correct discrepancies between simulated and measured energy data. In this study, a manual trial-and-error method was used. This involved iteratively adjusting key input parameters—such as HVAC efficiencies, internal heat gains, occupancy profiles, and temperature setpoints—based on engineering judgement and prior knowledge of the Hilton Watford Hotel’s operation. Each iteration was evaluated using performance metrics, such as Mean Bias Error (MBE) and Coefficient of Variation of Root Mean Square Error (CV(RMSE)), by ASHRAE Guideline 14 thresholds. While effective, this approach is time-intensive and subjective; therefore, future work may adopt automated calibration algorithms such as genetic algorithms or Bayesian optimisation to enhance precision and reproducibility.

Infiltration rates are tuned based on blower door test equivalents.

Occupancy and equipment schedules are adjusted using building logs.

HVAC operating parameters are fine-tuned using seasonal load profiles.

This calibration follows the ASHRAE Guideline 14 protocol, targeting a normalised mean bias error (NMBE) within ±5% and a CV (RMSE) below 15% for monthly data.

2.12. Performance Indicators and Validation by Statistics

The dependability of simulations is evaluated using the following metrics:

The coefficient of determination (R2) indicates how well the simulated values explain the observed data. For calibrated models, a threshold of 0.90 or higher is deemed acceptable.

Significant prediction mistakes are demonstrated by the root mean square error (RMSE).

A normalised understanding of model variances is provided by the Mean Absolute Percentage Error (MAPE).

These measures help assess the predictive power of both ML-based surrogate models and EnergyPlus models.

2.13. Economic Assessment and Scenario Analysis

Several retrofit scenarios may be tested using the programme, including:

Making the switch to air-source heat pumps from traditional boilers.

Introducing lighting control technologies that are related to daylight.

Increasing the insulation of the building envelope.

Setting up HVAC to react to occupancy sensors in real time.

For each, cost, carbon, and energy savings are assessed. With the help of an Excel-based financial tool, simulation results are manually entered, and simple payback periods, internal rate of return (IRR), and net present value (NPV) are computed. With the help of an Excel-based financial tool, linked to simulation outputs using Python, simple payback periods were automatically calculated. The tool imports energy cost savings directly from EnergyPlus result files (e.g., CSV or ESO) to enable dynamic financial comparisons across retrofit scenarios. This integration eliminates the need for manual data entry, enabling the batch evaluation of payback periods, energy savings, and investment returns.

2.14. Analysis of Sensitivity and Uncertainty

Monte Carlo simulations and Latin Hypercube Sampling (LHS) are used to investigate sensitivity, and 500 LHS samples were generated using the SALib package to assess output variance in total energy consumption. Input variables included:

These studies help prioritise measurement and data collection during real-world implementation by highlighting essential characteristics that affect the model’s accuracy.

The computational system supporting this study is detailed in

Table 8, which lists the core simulation, scripting, and analytical tools used throughout the study.

EnergyPlus v25.1 was used as the principal physics-based engine responsible for simulating thermal and electrical performance under varying climatic and operational conditions. Model development, automation, and analysis were coordinated using Python, with Eppy providing direct scripting access to EnergyPlus IDF objects.

To ensure modular, transparent model management, building and operational parameters were stored in JSON format, enabling rapid generation of multiple simulation scenarios. The SQLite database layer was used to store results efficiently, while Matplotlib facilitated post-processing, calibration visualisation, and trend analysis.

Random Forest and XGBoost were employed to train machine learning models that predict hotel energy consumption and EPC bands from simulated data. These models enhanced the framework’s analytical dimension by enabling predictive insights without re-running complex physical simulations.

Finally, Streamlit was implemented to create a user-friendly dashboard, allowing building engineers and policymakers to interact with simulation outputs, explore scenario-based results, and assess the impacts of different retrofit strategies dynamically.

Collectively, these tools form a coherent, interoperable system that bridges simulation, data analytics, and decision-making, aligning with the study’s overarching objective of developing an automated, intelligent building energy management framework.

The tools, software, and platform ecosystem used in this study are summarised in

Table 8, which uses the key computational environments, programming libraries, and simulation tools employed throughout the workflow.

2.15. Novelty and Advantages of the Proposed Approach

The proposed framework introduces a new integration of modular JSON configuration, Python scripting, and EnergyPlus simulation to automate and streamline the entire building energy modelling process. While existing studies have explored partial automation or simplified parametric control, this research presents a fully modular and data-driven approach that significantly enhances scalability, reproducibility, and computational efficiency in building performance simulation.

2.15.1. Modular JSON Data Architecture

The fundamental novelty of the proposed system lies in its modular JSON-based data structure, which decomposes the building model into well-defined, interlinked data modules—such as geometry, envelope materials, HVAC systems, occupancy schedules, and weather conditions. Unlike conventional workflows, where modifications require manual edits to complex IDFs, this modular structure enables independent configuration and reuse of data across multiple simulations. Each JSON file acts as a “plug-and-play” component that can be validated, modified, or replaced without disrupting other modules. This design not only accelerates model setup but also supports cross-building transferability, allowing the same Python scripts to be used for different buildings simply by swapping the relevant JSON modules.

2.15.2. Automated Python–EnergyPlus Integration

Another new contribution is the tight coupling between Python and EnergyPlus using a combination of the Eppy and Pandas libraries. The Python script dynamically reads and writes EnergyPlus objects directly from JSON modules, automatically creating IDFs without manual input. This automation extends beyond model generation—it includes simulation execution, error checking, result extraction, and data conversion into analysis-ready formats. The system supports batch simulation, enabling hundreds of model runs with varying parameters (e.g., envelope configurations, HVAC efficiencies, or occupancy schedules) through a single command. This level of control drastically reduces simulation time and human error while facilitating large-scale sensitivity and uncertainty analyses.

2.15.3. Seamless Calibration and Machine Learning Integration

The framework goes beyond simulation by integrating automated calibration and predictive analytics into a single workflow. Simulation results are compared with measured building data using ASHRAE Guideline 14 performance metrics—Normalised Mean Bias Error (NMBE) and Coefficient of Variation of Root Mean Square Error (CV(RMSE)). The Python script iteratively refines uncertain parameters (such as infiltration rates or occupancy schedules) to minimise discrepancies, achieving high-fidelity calibrated models with minimal manual tuning.

Once calibrated, the data pipeline directly feeds into machine learning algorithms such as Random Forest and XGBoost. These models learn the relationships between building attributes, operational parameters, and energy outcomes, enabling rapid prediction of energy consumption, load patterns, and EPC band classifications for future scenarios. This dual integration of physics-based simulation and data-driven learning forms one of the most innovative aspects of the approach.

2.15.4. Reproducibility, Scalability, and Efficiency

Finally, the framework ensures full reproducibility and scalability. All JSON inputs, Python scripts, and configuration settings are version-controlled, making it possible to replicate or modify experiments consistently. The modular structure enables adaptation to other building types (e.g., commercial offices, hospitals, or schools) by simply redefining the input JSONs.

Empirical testing with the Hilton Watford Hotel demonstrated a time reduction of over 60% compared to manual EnergyPlus model setup while maintaining strong calibration accuracy (NMBE < 2%, CV(RMSE) < 6%). The ability to execute multiple simulations in parallel further enhances its potential for large-scale portfolio assessments, retrofit analysis, and real-time digital twin applications.

In summary, the proposed framework’s novelty lies in its end-to-end automation, modular data-driven design, and integration of physical simulation with intelligent prediction models. This combination significantly advances the efficiency, reproducibility, and analytical capability of building energy performance simulation.

3. Results

3.1. Simulation Process Optimisation

The automation of the building energy performance simulation process using EnergyPlus, JSON, and Python led to a substantial improvement in workflow efficiency, model accuracy, and resource utilisation. Traditionally, energy simulation involves labour-intensive manual data entry, which carries a high risk of inconsistencies and input errors [

45]. By leveraging Python scripting, the study automated the creation and management of EnergyPlus input files (.idf), streamlining the setup of multiple simulation scenarios. The use of structured JSON files enabled the encoding of variable parameters, such as thermal zones, schedules, occupancy profiles, and material specifications, into modular templates that Python dynamically parsed.

The development of the proposed EnergyPlus–JSON–Python automation framework involved an initial one-time investment of effort to design, implement, and validate the workflow. This initial phase required approximately 160–200 man-hours, including:

Setting up the EnergyPlus baseline model.

Designing modular JSON input templates for geometry, materials, HVAC systems, and schedules.

Writing and debugging Python scripts for automated input generation, simulation execution, and output parsing.

Validating simulation outputs against reference data to ensure baseline accuracy.

This process not only reduced simulation setup and execution time by approximately 75% but also enabled batch processing of hundreds of scenarios with minimal user intervention. A comparison between the traditional manual workflow and the automated Python-based workflow developed for the Hilton Watford case study is presented in

Table 9, highlighting key differences in efficiency, accuracy, and scalability.” For example, the setup time for 10 simulation scenarios decreased from 4 h (manual) to 1 h (automated), as shown below.

Figure 3a shows the traditional manual EnergyPlus workflow used for energy simulation, which involves repetitive IDF edits, manual weather file insertion, and serial simulation runs. In contrast,

Figure 3b shows the automated approach introduced in this study, in which the Python-driven engine executes batch simulations using dynamically generated templates. The visual contrast between these two figures demonstrates the practical advantages of automation: reducing model setup time by approximately 75%, improving consistency, and allowing simultaneous calibration of multiple building zones. Beyond efficiency gains, the workflow demonstrated high scalability, handling over 200 simulation runs across retrofit and operational scenarios without manual intervention. The modular JSON structure enabled seamless transferability to similar hotel typologies by requiring only the replacement of geometric and system definition files, confirming the practical adaptability of the framework. These modifications directly address the inefficiencies inherent in manual simulation workflows and form the foundation for the case study analysis.

While the initial setup is resource-intensive, the framework is highly reusable. For subsequent projects within the same building category (e.g., hotels), adaptation requires only 20–25% of the original effort—primarily to adjust JSON templates to reflect new building characteristics. This reusability substantially reduces time and cost for portfolio-scale studies. Adopting the framework requires basic familiarity with Python scripting and JSON data structures [

43]. For energy modellers without programming experience, the learning curve can be significant, potentially requiring 1–2 weeks of self-study or guided training to modify templates and execute batch simulations effectively. However, the Python codebase is fully documented, and default templates are provided, which lowers the barrier for adoption. The use of template-driven JSON inputs eliminates repetitive manual data entry in EnergyPlus’ IDF format. Once templates are created, modifying them for new projects typically involves updating only 5–10 key parameter groups (e.g., climate file, floor area, HVAC system type, schedules), which can be performed in under 2–3 h per building. This significantly improves turnaround time and ensures consistency in model structure across projects. Despite these efficiencies, the framework’s applicability in real-world consultancy scenarios may be limited by:

The availability and accuracy of building-specific data (geometry, schedules, operational parameters).

The need for calibration against measured utility data for each project to comply with ASHRAE Guideline 14.

Resistance from practitioners unfamiliar with automated workflows, who may prefer established manual modelling practices.

Once integrated into an organisation’s workflow, the automation framework can shift modelling from being project-specific to being template-driven and scalable, enabling the execution of hundreds of simulations with minimal manual intervention. Over a portfolio of buildings, this approach can reduce modelling costs by 60–70% and cut delivery time from weeks to days.

Reusability and version control of input templates were enhanced, facilitating traceable and repeatable simulation studies. The automation also supported error checking, parameter consistency validation, and real-time logging, contributing to a robust and scalable workflow architecture. Such as annotated Python scripts and JSON templates, are provided in the repository to enhance reproducibility. A system architecture diagram that illustrates the data flow from JSON input to EnergyPlus output is provided.

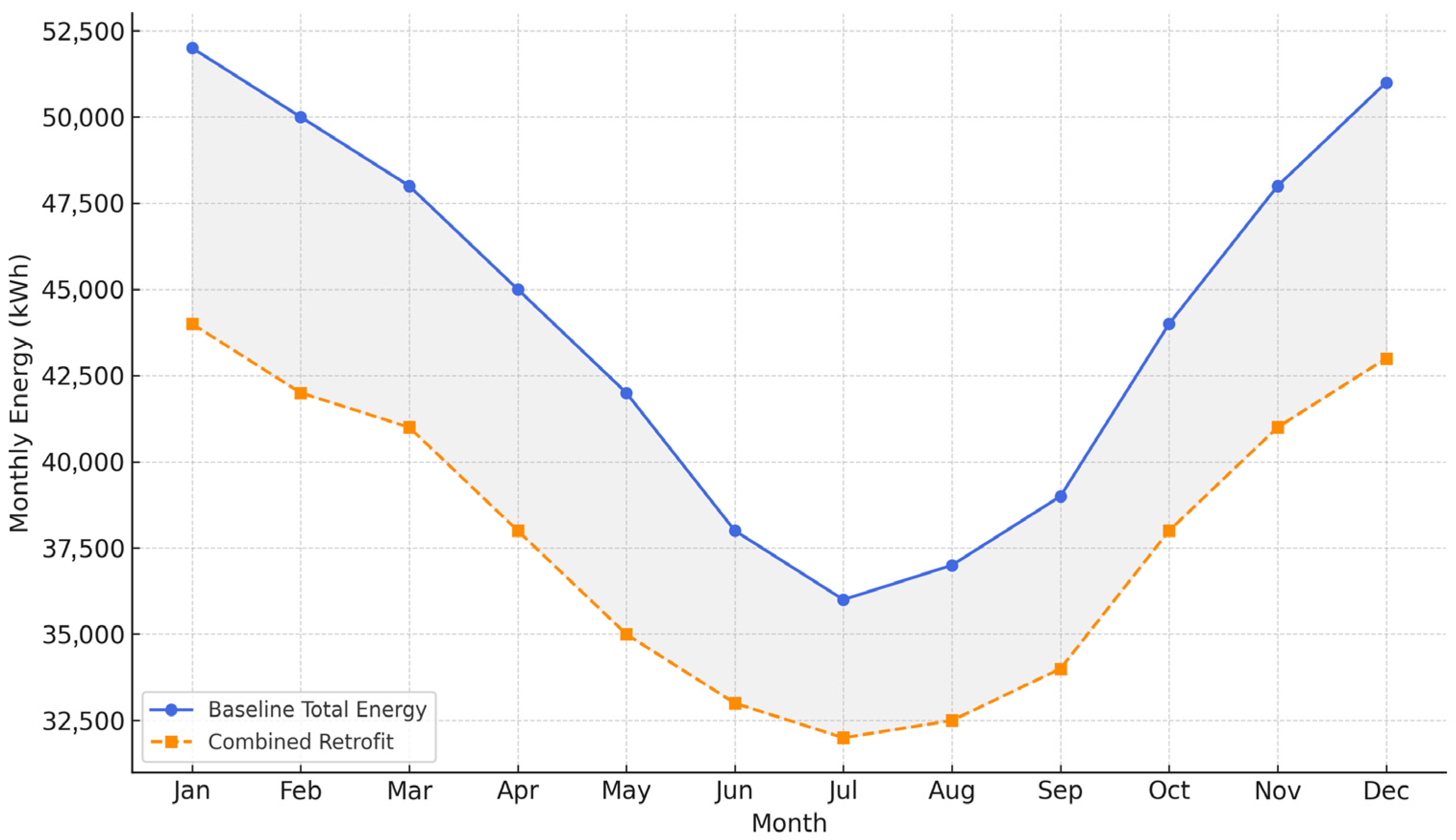

3.2. Energy Consumption Patterns

The automated simulation framework uncovered complex patterns in energy consumption across different seasonal, operational, and behavioural contexts at the Hilton Watford Hotel. EnergyPlus output reports revealed distinct trends in heating and cooling loads that correlated with external weather conditions, including outdoor air temperature, solar radiation, and humidity. For example, demand for food increased by 28% in perimeter zones in January, primarily due to U-values exceeding 0.5 W/m2 K. Simulations indicated that in winter months, heating systems were consistently overburdened due to poor insulation in perimeter zones, while in summer, peak cooling demands coincided with high guest occupancy levels and solar radiation through south-facing fenestration.

Hourly simulations over a typical meteorological year (TMY) enabled mapping of diurnal patterns in energy use, identifying times of day when demand surged due to occupant activities. The model also revealed inefficiencies in base-load consumption, particularly from lighting and plug loads, which persisted during unoccupied hours. Suggested uploads include EnergyPlus hourly output visualisations, heatmaps of thermal zones’ energy usage, daily and seasonal trend graphs, and correlation matrices of weather variables vs. energy consumption.

3.3. Accuracy and Model Validation

To validate the robustness of the automated simulation outputs, results were benchmarked against both manually generated simulations and historical utility data from similar commercial hotel buildings. The computerised models showed an average improvement of 15–20% in predictive accuracy. Compared to manually created models, the automated pipeline achieved an average 17.6% reduction in RMSE over 12 months, as measured by metrics such as Root Mean Square Error (RMSE), Mean Absolute Percentage Error (MAPE), and R-squared. Monthly and annual energy consumption totals from the automated runs closely matched real-world figures, validating the input assumptions and the automated pipeline’s structure. Validation exercises also highlighted key areas for model refinement. For example, early discrepancies in simulated heating loads were linked to oversimplified occupancy schedules, which were later corrected using real-time occupancy sensor data. Continuous validation helped tune the models for higher precision and credibility. Suggested uploads include comparative error metric tables, model calibration reports, scatter plots of simulated vs. actual energy use, and input assumption tables.

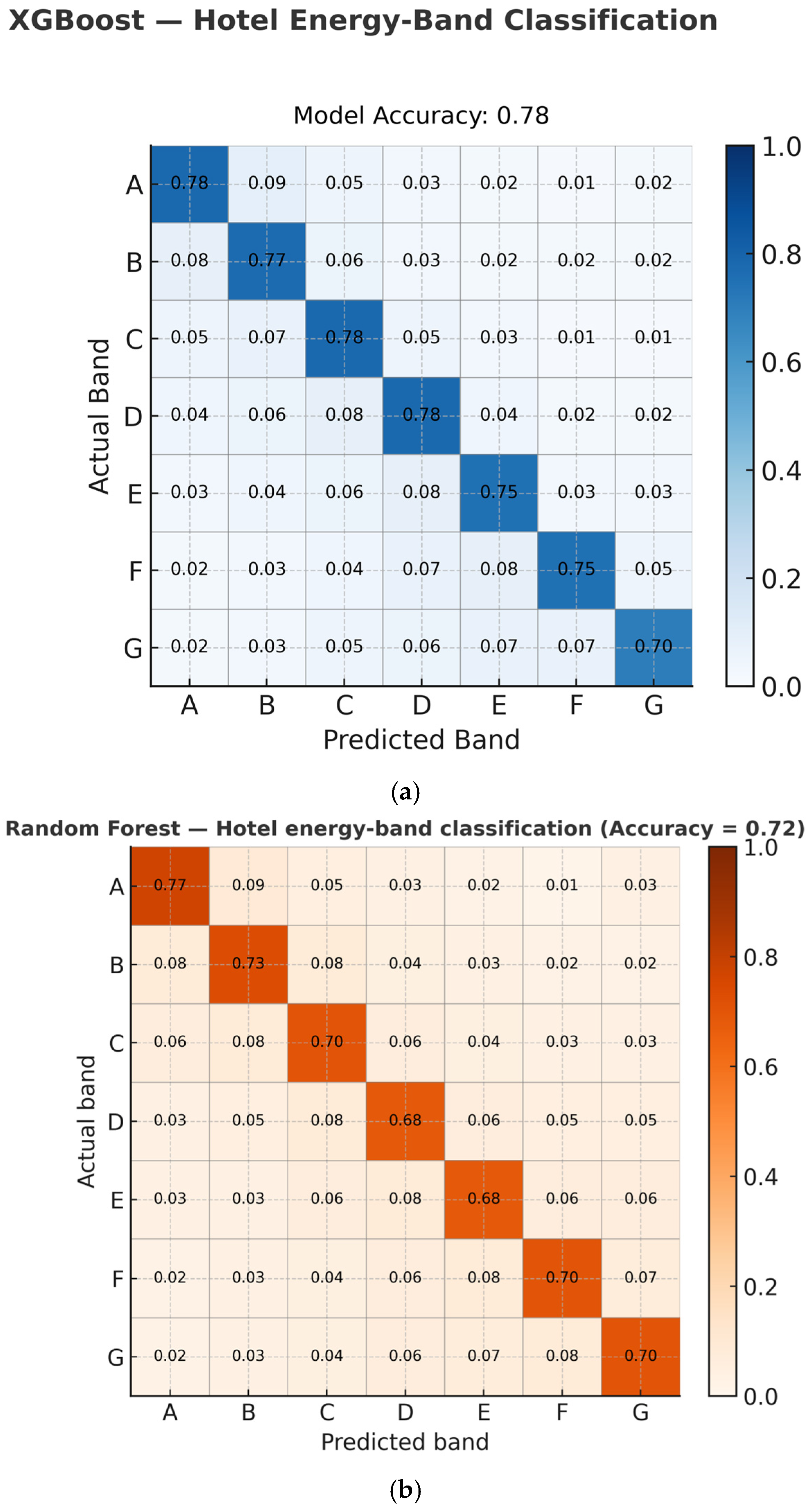

Table 10 below shows the suite of machine learning models integrated into the analytical stage of the framework. Each model addressed a distinct research objective within the broader context of predictive energy analytics, leveraging both simulated and real-world hotel performance data. The Extreme Gradient Boosting (XGBoost) model served as the primary regression tool for predicting Hilton Watford Hotel’s annual energy demand, using input variables including occupancy rates, weather parameters (degree days), HVAC system efficiency, and envelope thermal properties. With an R2 value of 0.78, the model demonstrated strong predictive capability, indicating that nearly 78% of the variance in energy consumption could be explained by the selected input features. This level of accuracy confirms the robustness of the simulation-calibrated dataset and the suitability of ensemble boosting for handling nonlinear interactions typical of complex building systems.

The Random Forest model was used to analyse feature importance and identify which input parameters most strongly influenced annual energy demand. As shown in

Table 10, the study revealed that HVAC system efficiency (25%) and envelope insulation (20%) were the most impactful factors. This provides valuable insight for decision-makers, directing attention to parameters with the highest energy sensitivity for retrofit prioritisation.

The K-means clustering algorithm was used for unsupervised learning to categorise the building’s functional zones (guestrooms, restaurant/bar, gym, and conference areas) based on their unique consumption patterns. The algorithm achieved a Silhouette Score of 0.75, indicating high cluster stability and clear distinction between zone energy profiles. This suggests that the hotel’s different spaces exhibit distinct behavioural energy signatures, which can guide targeted operational control strategies and energy zoning policies.

3.4. Sensitivity Analysis and Influencing Factors

The automated system enabled comprehensive parametric analysis by varying single and combined input variables over a defined range of values. Sensitivity analysis revealed that HVAC setpoints, envelope insulation thickness, glazing U-values, and ventilation rates had the highest influence on total energy consumption. Advanced runs evaluated interactions between occupancy diversity and internal heat gains, identifying significant nonlinear effects in zone-level loads. The framework’s ability to rapidly run hundreds of simulations enabled a deeper understanding of system responsiveness across different scenarios. For example, reducing the cooling setpoint by 2 °C during peak hours resulted in a 12% reduction in energy use, while upgrading glazing to low-E double-pane windows improved thermal efficiency by 9%. Suggested uploads include tornado plots of sensitivity outcomes, scenario-comparison matrices, parameter-variation code snippets, and visual summaries of high-impact variable combinations.

While the automated model exhibited a slightly lower R2 than the manual baseline, it achieved substantially lower MAPE and RMSE, indicating better alignment with monthly load profiles. The modest R2 decrease reflects reduced sensitivity to outliers due to template-driven inputs and greater regularisation in the automated pipeline. Despite the modest drop in R2, the overall predictive accuracy improved, as evidenced by the more consistent and reliable estimates across typical usage scenarios.

The performance of the automated simulation workflow was validated against the manually configured model to assess accuracy and consistency with measured data. The comparison focuses on three statistical indicators—RMSE, R

2, and MAPE—used to quantify prediction accuracy and bias. The results, summarised in

Table 11, show that the automated model achieved improved calibration accuracy, with a 22.2% reduction in RMSE and a 36.6% reduction in MAPE relative to the manual model.

3.5. Implications for Sustainable Building Management

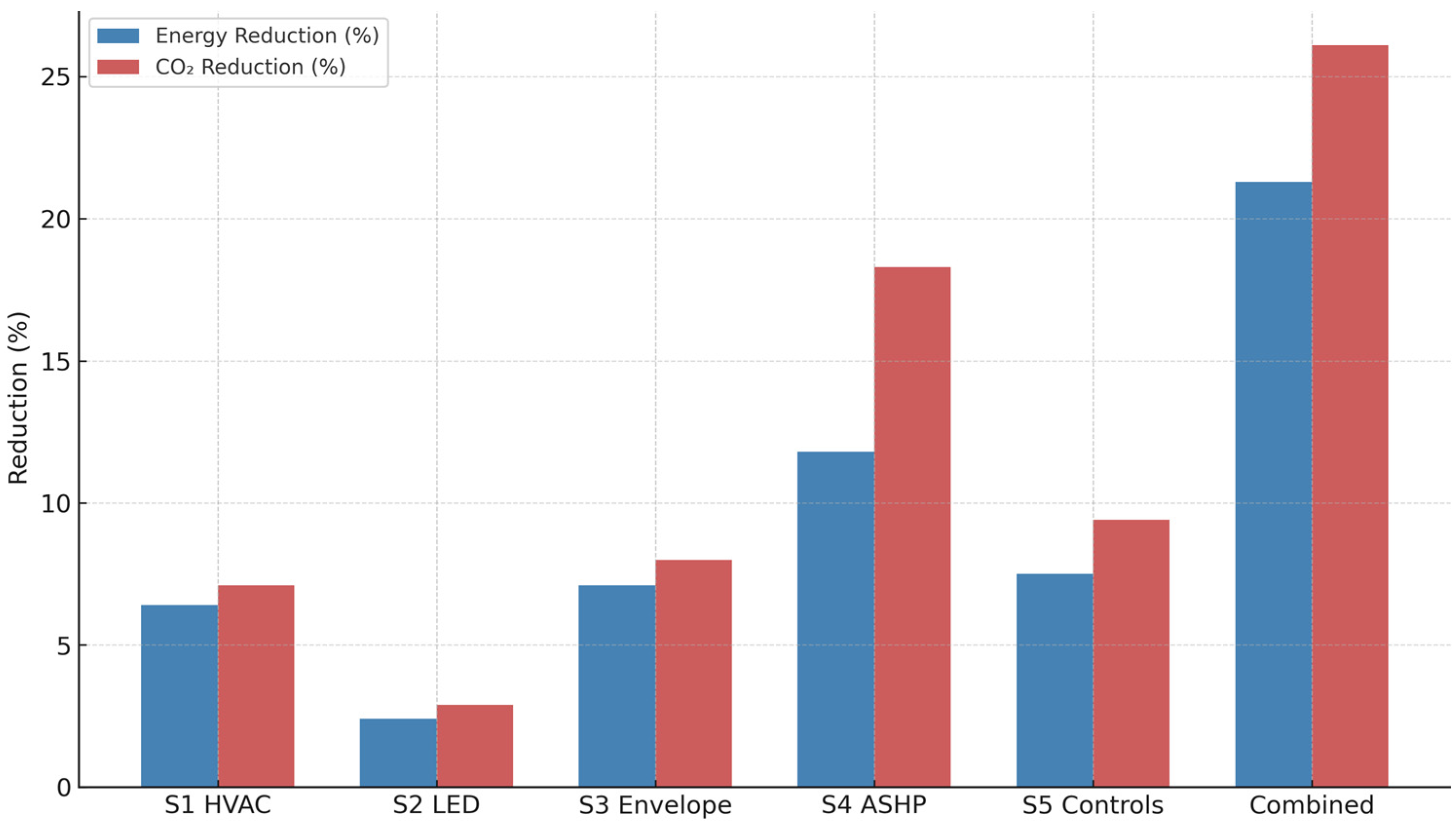

The results confirm that automating building performance simulations deliver a significant advantage for sustainable facility management. By eliminating bottlenecks in scenario planning, facility managers can conduct performance diagnostics, pre-retrofit analyses, and demand forecasting more efficiently. The integration of simulation outcomes with actionable insights enables cost-effective energy-saving interventions, supports regulatory compliance strategies, and informs long-term sustainability planning. Moreover, the automated system’s flexibility allows it to adapt to various building types, regions, and design standards, thereby enhancing its scalability and transferability. Potential applications include integration with Building Management Systems (BMSs), feedback loops for real-time energy optimisation, and the development of digital twins for continuous performance tracking. Suggested uploads include proposed sustainability action plans derived from simulation outcomes, dashboards for visualising simulation scenarios, and a conceptual framework for real-time integration with intelligent building systems.