1. Introduction

A capillary barrier cover (CBC) is a geotechnical structure that consists of two layers, in which the fine-grained layer is placed on top of the coarse-grained layer. Under unsaturated conditions, when water migrates to the interface between the fine-grained layer and the coarse-grained layer (hereafter referred to as the “interface”), due to the abrupt change in pore size between the two layers—specifically, the pores of the coarse-grained layer are significantly larger than those of the fine-grained layer—according to the Young–Laplace equation, the matric suction required for the coarse-grained layer to maintain the same water content as the fine-grained layer is much lower. However, constrained by the continuity of suction at the interface, water cannot directly and smoothly enter the coarse-grained layer; instead, it accumulates in the fine-grained layer on the side adjacent to the interface. Infiltration water is intercepted, stored, or laterally drained within the fine-grained layer. If evaporation, transpiration, and lateral drainage exceed the infiltration amount, water flow will not leak into the coarse-grained layer [

1,

2,

3]. In recent years, three-layer CBCs with an unsaturated drainage layer [

4,

5,

6,

7], clay interlayer CBCs [

8] (referred to as the functional layer), and four-layer (fine-coarse-fine-coarse) CBCs [

9] have been proposed to improve the water storage capacity and lateral diversion performance of CBCs. Therefore, CBCs can be used in a wider range of engineering projects, such as landfill cover [

10,

11,

12,

13], farmland water storage [

14,

15,

16,

17], and the slope drainage layer [

18,

19,

20].

The water storage capacity and lateral diversion performance of CBCs are primarily controlled by the unsaturated hydraulic characteristics of the interface between the fine-grained layer and the coarse-grained layer. Specifically, the greater the difference in water-entry values between the fine-grained layer and the coarse-grained layer, the stronger the water storage capacity and lateral diversion of CBCs. However, during transportation, stockpiling, and handling processes, the coarse-grained layer will inevitably mix with various fine-grained materials. Additionally, uneven settlement of CBCs during construction and service, as well as agricultural activities and erosion by plants and animals, may damage the isolation layer between different particle layers [

21,

22], leading to the mixture of fine particles into the coarse-grained layer, causing capillary barrier performance to fail to meet design requirements or even become ineffective. Hotton [

23] argues that quality control during the construction process exerts a significant influence on the capillary barrier performance when the fine-grained layer is composed of silt. The migration of silt from the fine-grained layer into the coarse-grained layer—either during construction or service life—will lead to degradation in capillary barrier performance. Brink [

24] found that the capillary barrier effect decreased by 34% after one year of operation due to sand in the fine-grained layer entering the coarse-grained layer. From the above, it can be concluded that the entry of fine particles into the coarse-grained layer will affect the capillary barrier’s performance. From the aforementioned studies, it is evident that the entry of fine particles into the coarse-grained layer indeed exerts an adverse effect on capillary barrier performance, with the degree of influence being related to the properties of the fine particles. However, there remains a lack of systematic research and data support regarding which specific properties of fine particles affect the performance of capillary barrier layers and the respective extent of their impacts. To address this, the authors [

25] focused on investigating the influence of incorporating fine particles of different sizes into the coarse-grained layer on the water storage capacity of CBCs. They used a single type of quartz sand for the fine-grained layer (aiming to eliminate interference from differences in water storage capacity on test comparisons) and proposed a method for rapidly judging capillary barrier performance based on the variation pattern of water content at the fine–coarse layer interface during breakthrough under different admixture ratios. Nevertheless, the study has obvious limitations: it failed to consider the impact of the variable “incorporating fine particles of the same size but different properties into the coarse-grained layer” on water storage capacity, which restricts the applicability of the proposed rapid judgment method. In light of this, the present study adopts an experimental scheme that involves “incorporating fine particles of the same size but different properties into the coarse-grained layer.” Meanwhile, drawing on the research conclusion from [

25]—“when the size of the incorporated fine particles is smaller than that of the particles in the fine-grained layer, the impact on the performance of the capillary barrier cover is the most significant”—fine particles with a size smaller than those in the fine-grained layer were selected as the test materials.

In the present study, three types of fine-grained materials, silt, quartz sand (0.075–0.1 mm), and diatomite, each featuring particle sizes similar to one another and smaller than those of the fine-grained layer, were admixed into the coarse-grained layer. This approach aims to further investigate how the material characteristics of the admixed fine particles affect the water storage capacity of the coarse-grained layer.

2. Test Materials and Methods

2.1. Test Materials

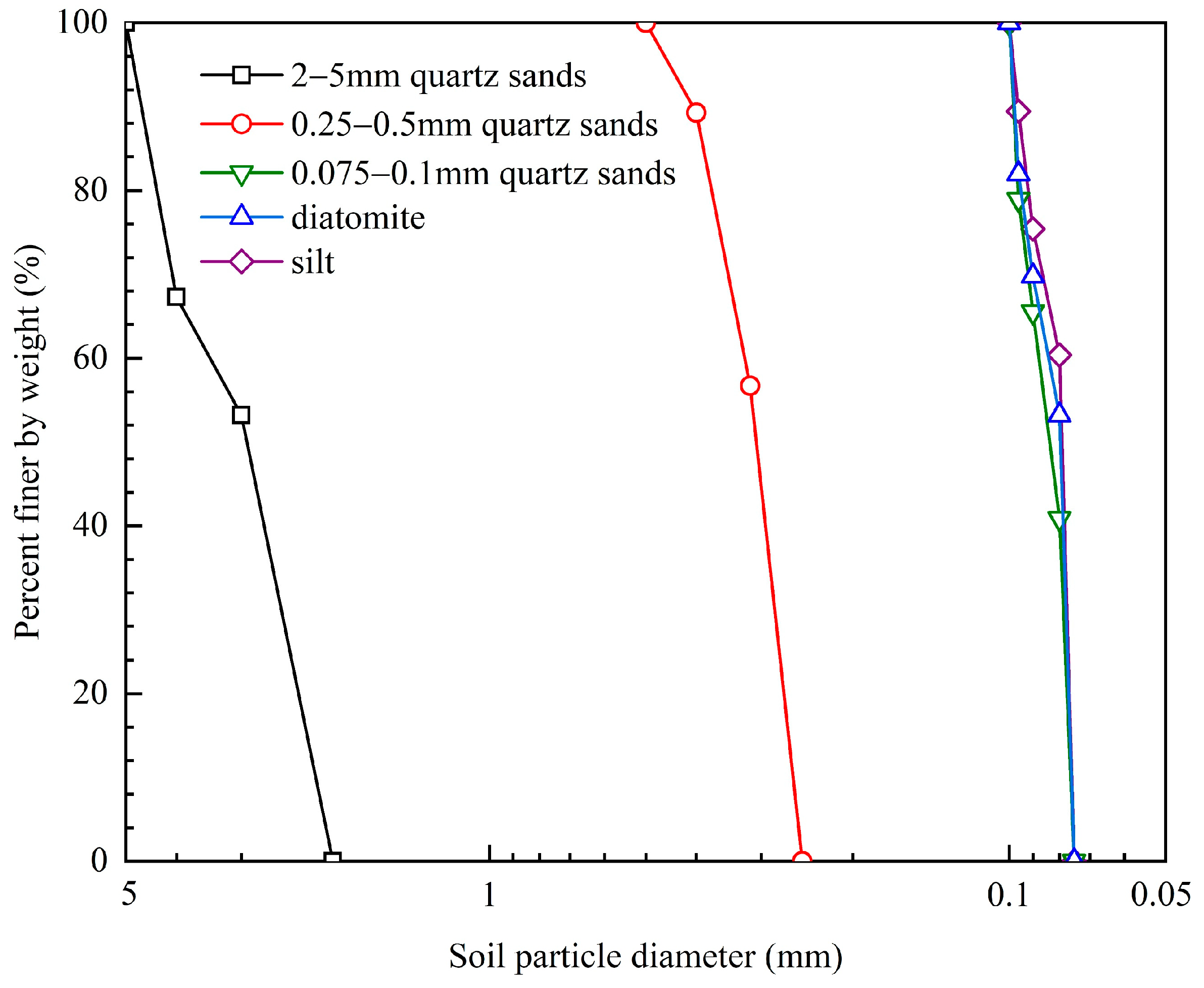

In this paper, 0.25–0.5 mm quartz sand was used as the fine-grained layer, and 2–5 mm quartz sand was used as the coarse-grained layer’s base material. The fine particles mixed into the coarse-grained layer’s base material included 0.075–0.1 mm quartz sand, silt from the Yellow River Delta (silt), and AG800 diatomite (diatomite). All these materials had similar particle sizes and had sizes smaller than those of the fine-grained layer (

Figure 1). The test materials’ basic physical properties are summarized in

Table 1.

2.2. Unsaturated Hydraulic Characteristics

The soil–water characteristic curves (SWCCs) and unsaturated permeability coefficient curves for the test materials used are shown in

Figure 2. The SWCCs were measured using the capillary rise method, while the unsaturated permeability coefficient curves were fitted by the van Genuchten–Mualem model.

2.3. Experiment Apparatus

The 1D infiltration test apparatus, as shown in

Figure 3, is composed of three integral components: an acrylic glass column, a water supply system, and a data acquisition system.

The acrylic glass column has an inner diameter of 14.4 cm and a height of 50 cm. Five circular holes are symmetrically positioned on each side of the column wall (totaling ten holes) for the installation of moisture meters and tensiometers. However, due to the large particle size of the coarse-grained layer, which could potentially damage the ceramic tips of the tensiometers, the tensiometers were not installed in this layer. Instead, the holes designated for tensiometers in the coarse-grained layer were sealed with waterproof tape. The moisture meters utilized are the SM150T from Delta-T (Cambridge, UK), while the tensiometers are the T5x from METER (Munchen, Germany). The specific performance indicators of the moisture meters and tensiometers are detailed in

Table 2. The soil moisture meter was calibrated by fitting the measured water content (from the meter) with the actual water content. This calibration used the same soil material as that used in the experiment and involved preparing five water content gradients. The tensiometer’s cavity was ensured to be free of air bubbles and fully filled with deaerated water.

The water supply system consists of a Mariotte bottle, a test bench, and a collection tank connected to the drainage outlet at the bottom of the acrylic glass column. The seepage velocity is controlled by adjusting the height of the test bench and the degree of valve opening. Water flows uniformly into the soil column through the permeable stone and porous plate at the top of the column, and it eventually drains into the collection tank via the drainage outlet at the bottom of the acrylic glass column.

The data acquisition system utilizes the GP2 data logger from Delta-T to automatically collect data on volumetric water content (VWC) and matric suction. The moisture meters and tensiometers are secured in the circular holes on both sides of the acrylic glass column using a neutral silicone sealant. The GP2 data logger is connected to a computer to enable real-time monitoring of the experimental data.

For the convenience of data processing and analysis in the following paper, the bottom of the soil column is taken as the reference plane, and the heights of the moisture meters and tensiometers (for each profile) in the fine-grained layer from the reference plane are 15 cm, 25 cm, 35 cm, and 45 cm, referred to as the 15 cm profile, 25 cm profile, 35 cm profile, and 45 cm profile. Since the 15 cm profile is located 5 cm above the interface between the fine-grained and coarse-grained layers, the VWC and matric suction measured at this profile can be considered representative of the conditions at the fine–coarse-grained layer interface. The moisture meter in the coarse-grained layer is located 5 cm below the interface between the fine-grained layer and the coarse-grained layer. The measurement range of the SM150T moisture meter is 3 cm around the probe, so the time when the moisture meter detects the VWC is considered the breakthrough time (Tbt) of the CBC.

2.4. Experiment Methods

In this paper, three types of admixtures were used: 0.075–0.1 mm quartz sand, silt, and diatomite. The three admixtures had similar particle sizes, all ranging from 0.075 to 0.1 mm. For each admixture, the coarse-grained layer’s base material with four mixing ratios (by volume) was prepared as follows: 1:0.1, 1:0.3, 1:0.6, and 1:1. Additionally, two control groups were set up: a CBC column (CB) using 2–5 mm quartz sand as the coarse-grained layer and a homogeneous column (H) using 0.25–0.5 mm quartz sand. The objective was to investigate the impact of mixing different types and proportions of fine particles into the coarse-grained layer on CBC water storage capacity. The specific experimental design is detailed in

Table 3.

The fundamental physical properties of the coarse-grained layer after admixing the base material with the admixtures are presented in

Table 4. After the admixtures were added to the base material in the specified proportions, the saturated permeability coefficient decreased as the proportion of admixtures increased. The most significant reduction in saturated permeability coefficient is observed when silt is added. The maximum compaction density increases with the proportion of added 0.075–0.1 mm quartz sand and silt. In contrast, the maximum compaction density decreases with the proportion of added diatomite. This is attributed to the fact that the density of diatomite is approximately one-third that of quartz sand and silt, leading to a decrease in maximum compaction density as the proportion of diatomite increases.

3. Influence of Different Admixture Proportions on Volumetric Water Content Changes and Distribution

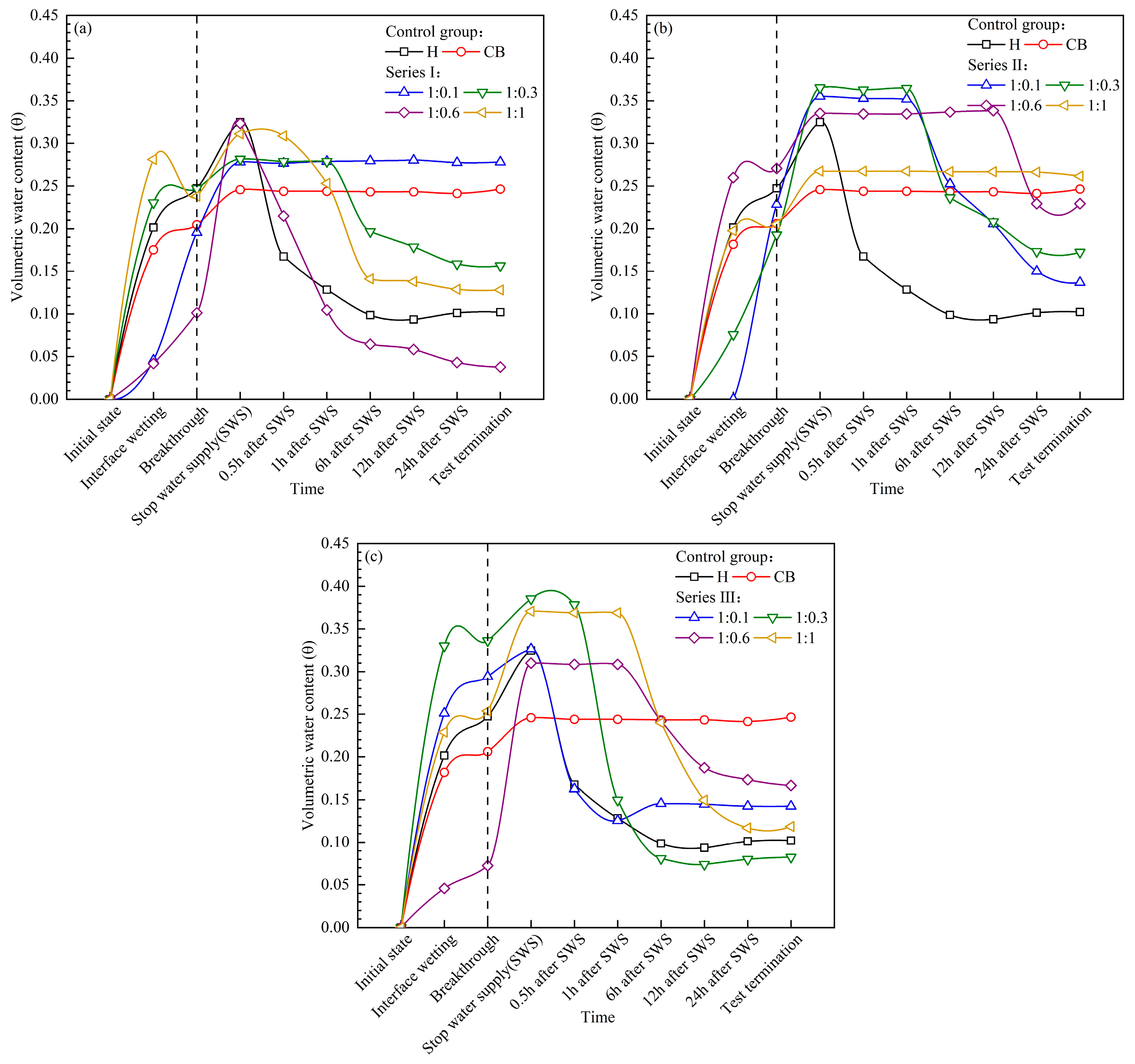

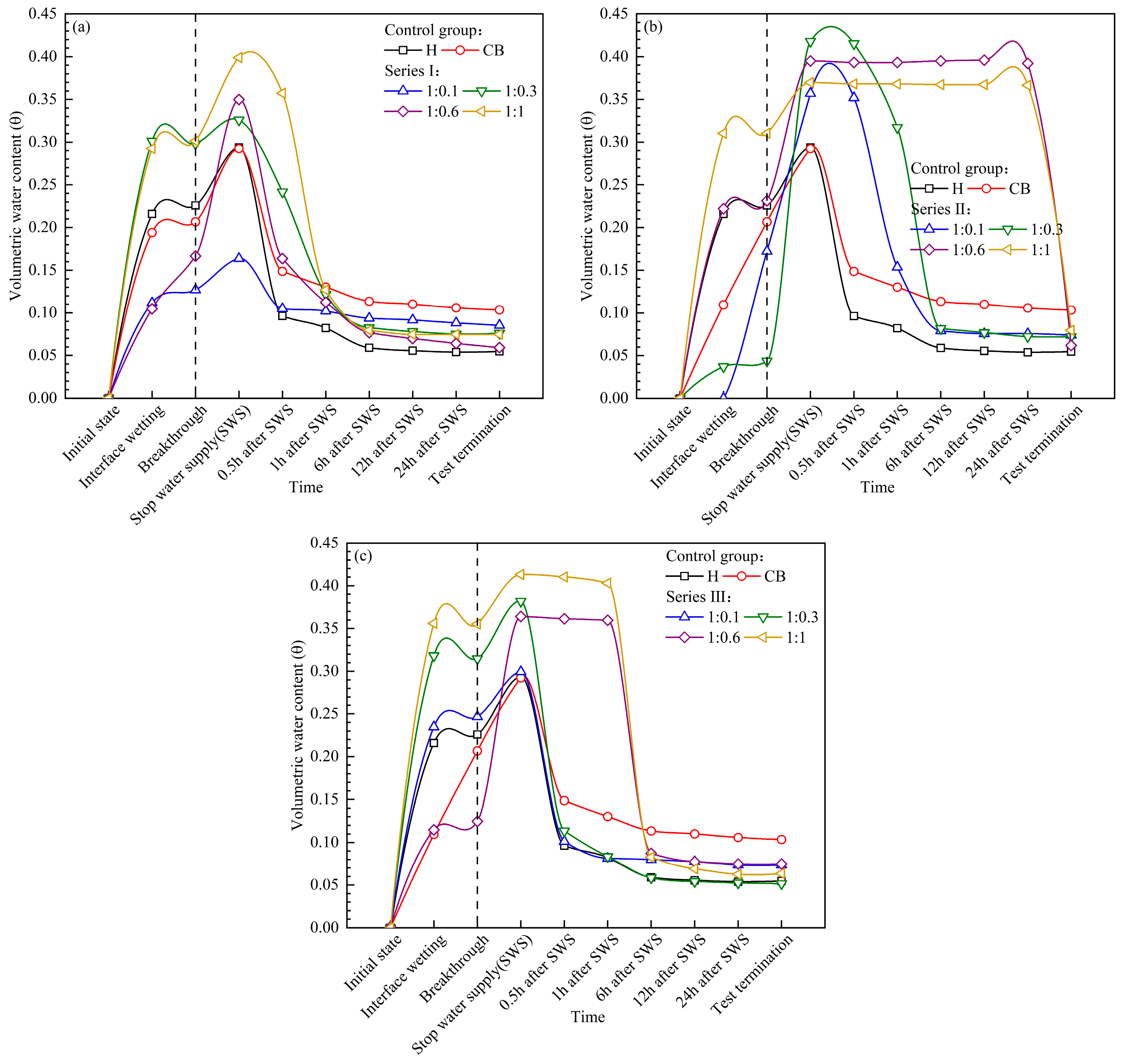

Figure 4 shows the variation in VWC within the coarse-grained layer (5 cm profile) during the infiltration test, as influenced by the admixture with different proportions of 0.075–0.1 mm quartz sand, silt, and diatomite in the coarse-grained layer. As the proportion of these three admixtures in the coarse-grained layer increases, so does the VWC of the layer. When the admixtures are 0.075–0.1 mm quartz sand and silt, the VWC lies between that of the CB column and the H column. However, when the admixture is diatomite and the admixture ratio reaches 1:1, the VWC of the CB column surpasses that of the H column.

Figure 4 shows the variation in VWC at the fine–coarse-grained layer interface of the CBC. At the moment of breakthrough, the CB column interface VWC reached a steady state, whereas the H column did not achieved a stable VWC at breakthrough, which is one of the significant indicators of the presence of CBC effects. When the proportion of 0.075–0.1 mm quartz sand, silt, and diatomite mixed into the coarse-grained layer is less than or equal to 1:0.3, the interface VWC reaches a steady state at the breakthrough time, but this stable VWC is less than that of the CB column, indicating that the CBC effect is weakened due to the admixtures in the coarse-grained layer. However, when the admixture ratio of 0.075–0.1 mm quartz sand, silt, and diatomite exceeds 1:0.3, the interface VWC fails to reach a steady state at the time of breakthrough, signifying the disappearance of the CBC effect.

We found that when 0.075–0.1 mm quartz sand is admixed into the coarse-grained layer at a ratio of 1:0.6 (

Figure 5a), the time variation in VWC differs from that in silt (

Figure 5b) and diatomite (

Figure 5c). This is because the saturated permeability coefficient of the coarse-grained layer admixed with 0.075–0.1 mm quartz sand (

Table 2 and

Table 4) is 2.22 × 10

−3 cm/s, while that of the fine-grained layer is 4.11 × 10

−2 cm/s. Although the coarse-grained layer’s coefficient is smaller, the difference is within one order of magnitude, failing to form an effective hydraulic barrier [

2]. However, after adding silt and diatomite, the saturated permeability coefficients of the coarse-grained layer admixed with silt and diatomite are 4.11 × 10

−4 cm/s and 3.21 × 10

−4 cm/s, respectively, which are two orders of magnitude less than the saturated permeability coefficients of the fine-grained layer, forming an effective hydraulic barrier and also having the effect of increasing the VWC of the fine-grained layer.

Figure 6,

Figure 7 and

Figure 8 are show the variation in VWC at the 25 cm, 35 cm, and 45 cm profiles of the CBC. As the profile location gradually moves away from the fine–coarse-grained layer interface, the difference in stable VWC between the CB column and the H column progressively diminishes until it reaches the 45 cm profile, where the VWC of both essentially becomes the same, indicating the complete disappearance of the CBC effect. The influence range of the capillary barrier effect is limited, and the farther away from the fine–coarse interface, the smaller the effect. The stable VWC of the CBC with the admixture of 0.075–0.1 mm quartz sand, silt, and diatomite into the coarse-grained layer lies between that of the H column and the CB column. The time required to reach stable VWC is longest for the admixture of silt, followed by diatomite, and it is shortest for the admixture of 0.075–0.1 mm quartz sand. This is because the saturated permeability coefficient is the smallest after the silt is admixed into the coarse-grained layer, requiring a longer drainage time after the permeation test, whereas the saturated permeability coefficient remains relatively large after the admixture of 0.075–0.1 mm quartz sand, necessitating a shorter drainage time (

Table 4).

In summary, the stabilization of VWC at the fine–coarse-grained layer interface at the breakthrough time is a critical characteristic indicative of the presence of the CBC effect. When the size of the fine particles admixed into the coarse-grained layer is smaller than that of the fine-grained layer and the admixture ratio exceeds 1:0.3, the CBC effect is invariably eliminated. The scope of the CBC effect is confined to a certain distance from the fine–coarse-grained layer interface, and the closer it is to this interface, the more pronounced the CBC effect becomes.

4. The Influence of the Admixture Mixed into the Coarse-Grained Layer on the Matric Potential Distribution of the Fine-Grained Layer

According to Stormont and Morris [

1], the CBC enhances the water content of the fine-grained layer, resulting in a matric potential distribution in the fine-grained layer that forms an angle of approximately 45° with the X-axis (matric potential), which we refer to as the CBC linear type. However, the water content distribution of the homogeneous soil column is solely influenced by gravity, leading to a matric potential distribution that is almost perpendicular to the X-axis, which we term the homogeneous linear type.

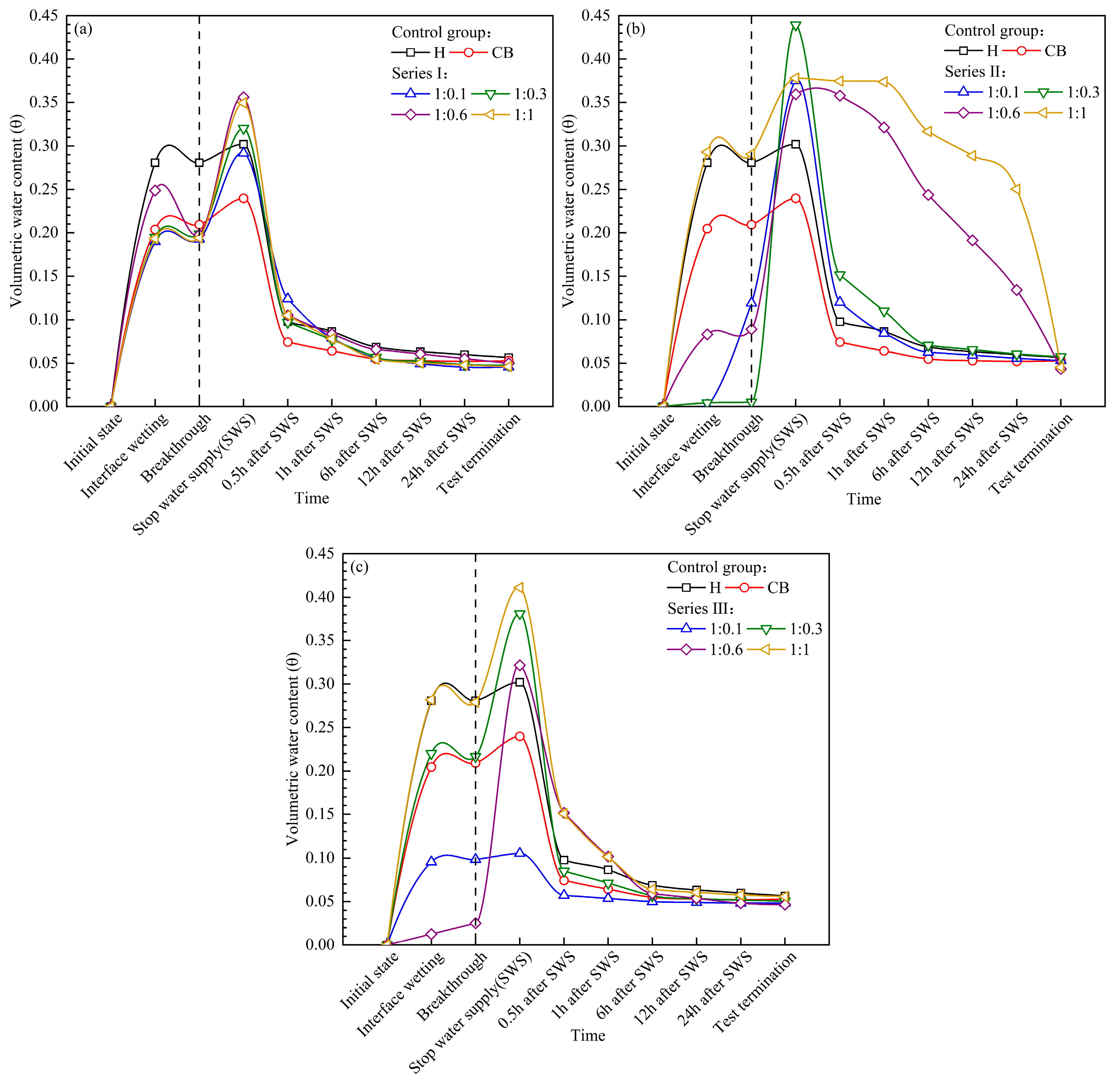

Figure 9 shows the matric potential distribution pattern in the fine-grained layer when the coarse-grained layer is admixed with 0.075–0.1 mm quartz sand, silt, and diatomite (admixture ratios of 1:0.1, 1:0.3, 1:0.6, and 1:1). The matric potential distribution in the fine-grained layer of the H column forms a nearly vertical line (homogeneous linear type) with a large angle to the X-axis, indicating a relatively uniform distribution of VWC within the soil column. In contrast, the matric potential distribution in the fine-grained layer of the CB column forms a line at an approximate 45° angle to the X-axis (CBC linear type), suggesting that VWC is concentrated at the fine–coarse-grained layer interface, consistent with the matric potential distribution pattern observed by Stormont and Morris [

1] in their study of CBC systems at steady state.

When 0.075–0.1 mm quartz sand is admixed into the coarse-grained layer (

Figure 9a), the matric potential distribution in the fine-grained layer at steady state transitions from CBC linear to homogeneous linear and back to CBC linear as the admixture ratio increases. At admixture ratios less than 1:0.3, the matric potential distribution is of the CBC linear type. When the admixture ratio reaches 1:0.6, it presents a homogeneous linear distribution, and the steady-state matric potential is significantly lower than that of the H column because the saturated permeability coefficient is closest to that of the fine-grained layer, so neither an effective capillary barrier nor an effective hydraulic barrier can be formed; therefore, it has the greatest impact on the CBC effect. As the admixture ratio further increases to 1:1, the steady-state matric potential distribution reverts to the CBC linear type. As shown in

Figure 5a, the CBC effect disappears when the admixture ratio exceeds 1:0.3. When the admixture ratio reaches 1:1, the saturated permeability coefficient of the coarse-grained layer (1.06 × 10

−4 cm/s) is two orders of magnitude lower than that of the fine-grained layer (4.11 × 10

−2 cm/s), forming a hydraulic barrier [

2]. The hydraulic barrier also serves to enhance water storage capacity, and its matric potential distribution exhibits a CBC linear type.

When silt (

Figure 9b) and diatomite (

Figure 9c) are admixed into the coarse-grained layer, the matric potential distribution in the fine-grained layer at steady state remains of the CBC linear type as the admixture ratio increases. This is because, at admixture ratios greater than 1:0.3, the saturated permeability coefficient of the coarse-grained layer with silt or diatomite is more than two orders of magnitude lower than that of the fine-grained layer (

Table 2 and

Table 4), forming a hydraulic barrier. Unlike the case with 0.075–0.1 mm quartz sand, there is no scenario where the coarse-grained layer’s saturated permeability coefficient becomes similar to that of the fine-grained layer. Therefore, the matric potential distribution in the fine-grained layer at steady state remains of the CBC linear type when silt or diatomite is admixed into the coarse-grained layer.

In summary, as the admixture ratio increases, the saturated permeability coefficient of the coarse-grained layer decreases. When the coarse-grained layer’s saturated permeability coefficient is similar to that of the fine-grained layer, the matric potential distribution in the fine-grained layer at steady state exhibits a homogeneous linear type. When the saturated permeability coefficient of the coarse-grained layer is either greater or less than that of the fine-grained layer by one order of magnitude, the matric potential distribution in the fine-grained layer at steady state exhibits a CBC linear type.

5. Variation in Water Storage Capacity

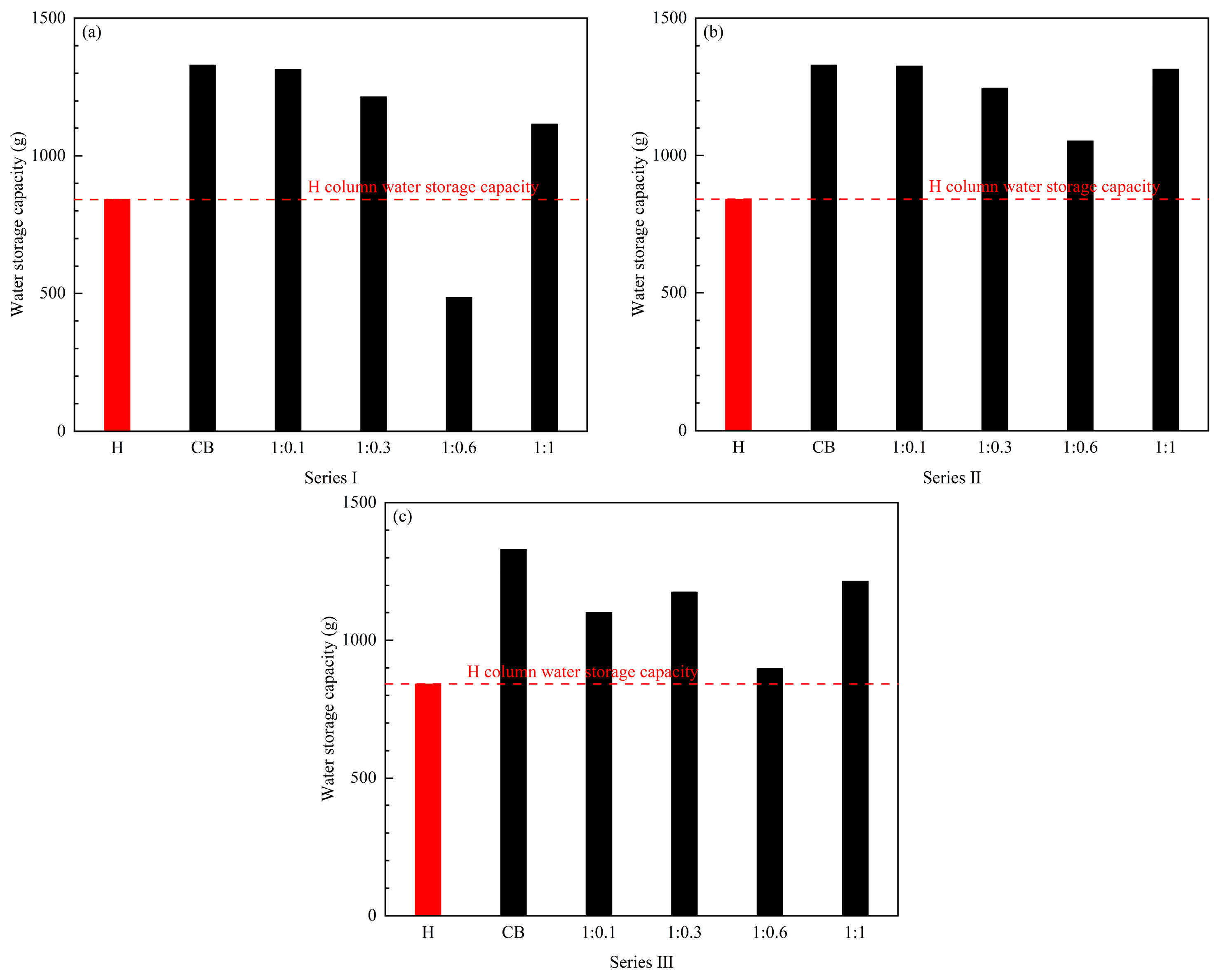

Figure 10 shows the impact of admixing 0.075–0.1 mm quartz sand, silt, and diatomite into the coarse-grained layer on the water storage capacity of the CBC. As the admixture ratio increases, the water storage capacity initially decreases and then increases, reaching its minimum at an admixture ratio of 1:0.6. This indicates the existence of a most unfavorable admixture ratio, at which the water storage capacity of the CBC is minimized. As demonstrated in this study, the minimum water storage capacity of the coarse-grained layer is consistently achieved at a volume admixture ratio of 1:0.6, regardless of whether quartz sand, silt, or diatomite is incorporated. Furthermore, research by author [

25] has shown that when fine particles of different particle sizes are admixed into the coarse-grained layer, the minimum water storage capacity also occurs at a volume admixture ratio of 1:0.6. Therefore, it can be concluded that this most unfavorable admixture ratio is independent of the properties of the admixtures. When the admixture ratio increases to 1:1, the water storage capacity rises to near that of the CB column. At this point, the saturated permeability coefficient of the mixed coarse-grained layer is lower than that of the fine-grained layer, forming a hydraulic barrier. The best CBC for water storage capacity is the one with no fine particle admixture in the coarse-grained layer.

When 0.075–0.1 mm quartz sand is admixed into the coarse-grained layer (

Figure 10a), the water storage capacity at an admixture ratio of 1:0.6 is less than that of the H column. At this point, the saturated permeability coefficient of the coarse-grained layer is similar to that of the fine-grained layer, and the matric potential distribution in the fine-grained layer at steady state is the homogeneous linear type (

Figure 9a). At this stage, neither an effective CBC nor a hydraulic barrier has been formed, resulting in the worst water storage capacity. Additionally, the matric potential of the CB column is lower than that of the H column, leading to a water storage capacity less than that of the homogeneous soil column.

When silt (

Figure 10b) and diatomite (

Figure 10c) are admixed into the coarse-grained layer, the water storage capacity is always greater than that of the homogeneous soil column. This is because, after the admixture ratio exceeds 1:0.3, the saturated permeability coefficient of the coarse-grained layer rapidly decreases to more than one order of magnitude lower than that of the fine-grained layer, forming a hydraulic barrier. Since the hydraulic barrier also serves to enhance water storage capacity, the water storage capacity with the admixture of silt and diatomite is always greater than that of the homogeneous soil column.

6. Conclusions

This paper investigates the impact of admixing fine particles of different soil types into a coarse-grained layer on the water storage capacity of the CBC through one-dimensional infiltration experiments. The main conclusions drawn are as follows:

(1) A rapid assessment method for the failure of CBC has been proposed, based on the variation pattern of VWC at the fine–coarse-grained layer interface. The strength of the CBC effect can be quickly determined by observing the VWC changes at this interface upon breakthrough. If the VWC in the fine-grained layer within a 5 cm range above the interface does not change over time post-breakthrough, the CBC effect is present, and its strength is proportional to the VWC. This scenario occurs when the admixture ratio is less than 1:0.3.

(2) A method for selecting materials for CBCs based on the saturated permeability coefficient has been introduced. An effective CBC can be formed when the saturated permeability coefficient of the coarse-grained layer is at least one order of magnitude greater than that of the fine-grained layer.

(3) When the admixed fine particles’ saturated permeability coefficient in the coarse-grained layer is smaller than 10−5 cm/s, as the admixture ratio increases, the matric potential distribution in the fine-grained layer remains the CBC linear type. When the admixed fine particles’ saturated permeability coefficient in the coarse-grained layer is larger than 10−5 cm/s and the admixture ratio increases, the matric potential distribution in the fine-grained layer appears as the homogeneous linear type (admixture ratio 1:0.6). This is because, at admixture ratios greater than 1:0.3, the saturated permeability coefficient of the coarse-grained layer with silt or diatomite is more than two orders of magnitude lower than that of the fine-grained layer, forming a hydraulic barrier. When 0.075–0.1 mm quartz sand is admixed into the coarse-grained layer, the saturated permeability coefficient of the coarse-grained layer is close to that of the fine-grained layer at a ratio of 1:0.6, forming a matric potential distribution similar to that of a homogeneous soil column (homogeneous linear type).

(4) When the admixed fine particle size in the coarse-grained layer is smaller than the fine-grained layer’s particle size, the CBC’s water storage performance is only affected by the proportion of fine particles added and is independent of the type of fine particle. The particle sizes of 0.075–0.1 mm quartz sand, Yellow River Delta silt, and AG800 diatomite are similar, so the effect of mixing them in the coarse-grained layer on the CBC water storage capacity is also similar.

In summary, the VWC variation at the fine–coarse-grained layer interface can be used to quickly determine whether a CBC has failed. The CBC fails when the particle size of the fine particles in the coarse-grained layer is smaller than that in the fine-grained layer and the volume admixture ratio exceeds 1:0.3. If the absolute difference in saturated permeability coefficient between the fine-grained and coarse-grained layers is less than one order of magnitude under these conditions, the matric potential distribution in the fine-grained layer at stability resembles that of a homogeneous soil column (homogeneous linear type). As the fine particle content in the coarse-grained layer further increases (an admixture ratio greater than 1:0.6), the saturated permeability coefficient of the coarse-grained layer becomes more than one order of magnitude less than that of the fine-grained layer, forming a hydraulic barrier.

7. Limitations and Considerations

This paper investigates the impact of adding different types and proportions of admixtures into the coarse-grained layer on the water storage capacity of CBCs. However, the indoor 1D infiltration test did not consider the influence of factors such as scale effects, field variability, lateral diversion, and climatic conditions. Further research is needed through field experiments in the future. For more precise quantitative research conclusions, follow-up studies should include replicate tests to conduct rigorous verification.

Author Contributions

Conceptualization, C.S. and Q.L.; Methodology, C.S.; Validation, C.S.; Formal analysis, C.S.; Investigation, C.S.; Resources, C.S.; Writing—original draft, C.S.; Writing—review & editing, C.S., J.Y., Q.L. and Y.W.; Visualization, C.S.; Supervision, J.Y., Q.L., Y.W. and J.M.; Project administration, J.Y., Q.L., Y.W. and J.M.; Funding acquisition, J.Y. and Q.L. All authors have read and agreed to the published version of the manuscript.

Funding

The authors thank the National Natural Science Foundation of China (Grant Nos. 52378380, 52078474 and 51779235) and the Natural Science Foundation of Shandong Province (Grant No.: ZR2021MD021) for their support and assistance.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Stormont, J.C.; Morris, C.E. Method to Estimate Water Storage Capacity of Capillary Barriers. J. Geotech. Geoenviron. Eng. 1998, 124, 297–302. [Google Scholar] [CrossRef]

- Li, X.; Chang, S.; Salifu, F. Soil texture and layering effects on water and salt dynamics in the presence of a water table: A review. Environ. Rev. 2014, 22, 41–50. [Google Scholar] [CrossRef]

- Zhan, L.T.; Qiu, Q.W.; Xu, W.J.; Chen, Y.M. Field measurement of gas permeability of compacted loess used as an earthen final cover for a municipal solid waste landfill. J. Zhejiang Univ.-Sci. A 2016, 17, 541–552. [Google Scholar] [CrossRef]

- Morris, C.E.; Stormont, J.C. Parametric Study of Unsaturated Drainage Layers in a Capillary Barrier. J. Geotech. Geoenviron. Eng. 1999, 125, 1057–1065. [Google Scholar] [CrossRef]

- Yang, H.; Rahardjo, H.; Leong, E.C.; Fredlund, D.G. A study of infiltration on three sand capillary barriers. Can. Geotech. J. 2004, 41, 629–643. [Google Scholar] [CrossRef]

- Deng, L.H.; Zhan, L.T.; Chen, Y.M.; Jia, G.W. Model tests on capillary-barrier cover with unsaturated drainage layer. Yantu Gongcheng Xuebao/Chin. J. Geotech. Eng. 2012, 34, 75–80. [Google Scholar]

- Li, X.; Li, X.; Wu, Y.; Gao, L. A novel unsaturated drainage layer in capillary barrier cover for slope protection. Bull. Eng. Geol. Environ. 2023, 82, 108. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Liu, J.; Chen, R.; Xu, J. Physical and numerical modeling of an inclined three-layer (silt/gravelly sand/clay) capillary barrier cover system under extreme rainfall. Waste Manag. 2015, 38, 210–221. [Google Scholar] [CrossRef] [PubMed]

- Harnas, F.R.; Rahardjo, H.; Leong, E.C.; Wang, J.Y. Experimental study on dual capillary barrier using recycled asphalt pavement materials. Can. Geotech. J. 2014, 51, 1165–1177. [Google Scholar] [CrossRef]

- Kämpf, M.; Montenegro, H. On the performance of capillary barriers as landfill cover. Hydrol. Earth Syst. Sci. 1997, 1, 925–930. [Google Scholar] [CrossRef]

- Bussière, B.; Aubertin, M.; Zhan, G. Design of Inclined Covers with Capillary Barrier Effect by S.-E. Parent and A. Cabral. Geotech. Geol. Eng. 2007, 25, 673–678. [Google Scholar] [CrossRef]

- Rahardjo, H.; Satyanaga, A.; Harnas, F.R.; Leong, E.C. Use of Dual Capillary Barrier as Cover System for a Sanitary Landfill in Singapore. Indian Geotech. J. 2016, 46, 228–238. [Google Scholar] [CrossRef]

- Hey, C.; Simms, P. Preliminary assessment of biosolids in covers with capillary barrier effects. Eng. Geol. 2021, 280, 105973. [Google Scholar] [CrossRef]

- Ityel, E.; Ben-Gal, A.; Silberbush, M.; Lazarovitch, N. Increased root zone oxygen by a capillary barrier is beneficial to bell pepper irrigated with brackish water in an arid region. Agric. Water Manag. 2014, 131, 108–114. [Google Scholar] [CrossRef]

- Miyake, M.; Otsuka, M.; Fujimaki, H.; Inoue, M.; Saito, H. Evaluation of an Artificial Capillary Barrier to Control Infiltration and Capillary Rise at Root Zone Areas. J. Arid. Land Stud. 2015, 25, 117–120. [Google Scholar]

- Menezes-Blackburn, D.; Al-Ismaily, S.; Al-Mayahi, A.; Al-Siyabi, B.; Al-Kalbani, A.; Al-Busaid, H.; Al-Naabi, I.; Al-Mazroui, M.; Al-Yahyai, R. Impact of a Nature-Inspired Engineered Soil Structure on Microbial Diversity and Community Composition in the Bulk Soil and Rhizosphere of Tomato Grown Under Saline Irrigation Water. J. Soil Sci. Plant Nutr. 2021, 21, 173–186. [Google Scholar] [CrossRef]

- Noguchi, K.; Saito, H.; Saefuddin, R.; Šimůnek, J. Evaluation of Subsurface Drip Irrigation Designs in a Soil Profile with a Capillary Barrier. Water 2021, 13, 1300. [Google Scholar] [CrossRef]

- Rahardjo, H.; Krisdani, H.; Leong, E.C. Application of Unsaturated Soil Mechanics in Capillary Barrier System. In Proceedings of the 3rd Asian Conference on Unsaturated Soils, Nanjing, China, 21–23 April 2007. [Google Scholar]

- Satyanaga, A.; Zhai, Q.; Rahardjo, H.; Gitirana, G.; Moon, S.-W.; Kim, J. Performance of capillary barrier as a sustainable slope protection. MATEC Web Conf. 2021, 337, 03021. [Google Scholar] [CrossRef]

- Ma, S.-K.; He, B.-F.; Ma, M.; Huang, Z.; Chen, S.-J.; Yue, H. Novel protection systems for the improvement in soil and water stability of expansive soil slopes. J. Mt. Sci. 2023, 20, 3066–3083. [Google Scholar] [CrossRef]

- Albright, W.H.; Benson, C.H.; Gee, G.W.; Roesler, A.C.; Abichou, T.; Apiwantragoon, P.; Lyles, B.F.; Rock, S.A. Field Water Balance of Landfill Final Covers. J. Environ. Qual. 2005, 33, 2317–2332. [Google Scholar] [CrossRef]

- Benson, C.H. Final Coves for Waste Containment Systems: A North American Perspective. In Proceedings of the XVII Conference of Geotechnics of Torino, Control and Management of Subsoil Pollutants, Torino, Italy, 23–25 November 1999. [Google Scholar]

- Hotton, G.; Bussière, B.; Pabst, T.; Bresson, É.; Roy, P. Influence of climate change on the ability of a cover with capillary barrier effects to control acid generation. Hydrogeol. J. 2020, 28, 763–779. [Google Scholar] [CrossRef]

- Brink, J.M.V.D.; Scharff, H.; Steinert, B.; Melchior, S.; Hrachowitz, M.; Heimovaara, T.J.; Gebert, J. Long-term observations on the hydraulic performance of a combined capillary barrier-methane oxidation landfill cover system. Waste Manag. 2024, 187, 109–118. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Yang, J.; Liu, Q.; Wu, Y.; Miao, J. A Laboratory Investigation into the Effect of Coarse-Grained Layer Mixing with Fine Particles on the Water Storage Capacity of a Capillary Barrier Cover. Water 2025, 17, 183. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).