Meeting Sustainable Development Challenges at the Enterprise Level

Abstract

1. Introduction

2. Literature Review

2.1. Integration of Modern Management Concepts for Sustainable Development

- In the economic dimension—long time needed to implement the concept itself, inadequate resource allocation, administrative costs;

- In the environmental dimension—problematic waste disposal, pollution;

- In the social dimension—routine activities, lack of trust on the part of employees, compromises in the range of operational efficiency.

2.2. Standardized Management Systems

2.3. Sustainable Development Assessment Methods at the Enterprise Level

3. Methodology

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Waas, T.; Hugé, J.; Block, T.; Wright, T.; Benitez-Capistros, F.; Verbruggen, A. Sustainability assessment and indicators: Tools in a decision-making strategy for sustainable development. Sustainability 2014, 6, 5512–5534. [Google Scholar] [CrossRef]

- Marczak, Ł. Problem wieloznaczności pojęcia “zrównoważony rozwój”. Stud. Gdańskie 2015, 36, 167–180. [Google Scholar]

- Czaja, S.; Becla, A. Wybrane informacyjne problemy definiowania zrównoważonego i trwałego rozwoju–ujęcie teoretyczne. Optim. Stud. Ekon. 2016, 1, 14–35. [Google Scholar] [CrossRef]

- Elkington, J. The triple bottom line. Environ. Manag. Read. Cases 1997, 2, 49–66. [Google Scholar]

- GRI Standards. Available online: https://www.globalreporting.org/standards (accessed on 24 November 2024).

- Liu, H.; Zhao, H. Upgrading models, evolutionary mechanisms and vertical cases of service-oriented manufacturing in SVC leading enterprises: Product-development and service-innovation for industry 4.0. Humanit. Soc. Sci. Commun. 2022, 9, 387. [Google Scholar] [CrossRef]

- Arvidsson, S.; Dumay, J. Corporate ESG reporting quantity, quality and performance: Where to now for environmental policy and practice? Bus. Strategy Environ. 2022, 31, 1091–1110. [Google Scholar] [CrossRef]

- Sun, Y. The real effect of innovation in environmental, social, and governance (ESG) disclosures on ESG performance: An integrated reporting perspective. J. Clean. Prod. 2024, 460, 142592. [Google Scholar] [CrossRef]

- Imperiale, F.; Pizzi, S.; Lippolis, S. Sustainability reporting and ESG performance in the utilities sector. Util. Policy 2023, 80, 101468. [Google Scholar] [CrossRef]

- Hamrol, A. Strategie i Praktyki Sprawnego Działania; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2015. [Google Scholar]

- Shah, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Bortolotti, T.; Boscari, S.; Danese, P. Successful lean implementation: Organizational culture and soft lean practices. Int. J. Prod. Econ. 2015, 160, 182–201. [Google Scholar] [CrossRef]

- Negrão, L.L.L.; Godinho Filho, M.; Marodin, G. Lean practices and their effect on performance: A literature review. Prod. Plan. Control 2017, 28, 33–56. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; Santos, F.C.A.; Fonseca, S.A.; Nagano, M.S. Green teams: Understanding their roles in the environmental management of companies located in Brazil. J. Clean. Prod. 2013, 46, 58–66. [Google Scholar] [CrossRef]

- Piercy, N.; Rich, N. The relationship between lean operations and sustainable operations. Int. J. Oper. Prod. Manag. 2015, 35, 282–315. [Google Scholar] [CrossRef]

- Resta, B.; Dotti, S.; Gaiardelli, P.; Boffelli, A. How lean manufacturing affects the creation of sustainable value: An integrated model. Int. J. Autom. Technol. 2017, 11, 542–551. [Google Scholar] [CrossRef]

- Resta, B.; Dotti, S.; Gaiardelli, P.; Boffelli, A. Lean manufacturing and sustainability: An integrated view. In Advances in Production Management Systems. Initiatives for a Sustainable World: IFIP WG 5.7 International Conference, APMS 2016, Iguassu Falls, Brazil, 3–7 September 2016, Revised Selected Papers; Springer International Publishing: Cham, Switzerland, 2016; pp. 659–666. [Google Scholar]

- Jasiulewicz-Kaczmarek, M.; Gola, A. Maintenance 4.0 technologies for sustainable manufacturing–an overview. IFAC-PapersOnLine 2019, 52, 91–96. [Google Scholar] [CrossRef]

- Afum, E.; Agyabeng-Mensah, Y.; Sun, Z.; Frimpong, B.; Kusi, L.Y.; Acquah, I.S.K. Exploring the link between green manufacturing, operational competitiveness, firm reputation and sustainable performance dimensions: A mediated approach. J. Manuf. Technol. Manag. 2020, 31, 1417–1438. [Google Scholar] [CrossRef]

- Bour, K.B.; Asafo, A.J.; Kwarteng, B.O. Study on the effects of sustainability practices on the growth of manufacturing companies in urban Ghana. Heliyon 2019, 5, e01903. [Google Scholar] [CrossRef]

- Baah, C.; Jin, Z.; Tang, L. Organizational and regulatory stakeholder pressures—Friends or foes to green logistics practices and financial performance: Investigating corporate reputation as a missing link. J. Clean. Prod. 2020, 247, 119125. [Google Scholar] [CrossRef]

- Cherrafi, A.; Elfezazi, S.; Hurley, B.; Garza-Reyes, J.A.; Kumar, V.; Anosike, A.; Batista, L. Green and lean: A Gemba–Kaizen model for sustainability enhancement. Prod. Plan. Control 2019, 30, 385–399. [Google Scholar] [CrossRef]

- Teixeira, P.; Coelho, A.; Fontoura, P.; Sá, J.C.; Silva, F.J.; Santos, G.; Ferreira, L.P. Combining lean and green practices to achieve a superior performance: The contribution for a sustainable development and competitiveness—An empirical study on the Portuguese context. Corp. Soc. Responsib. Environ. Manag. 2022, 29, 887–903. [Google Scholar] [CrossRef]

- Leong, W.D.; Lam, H.L.; Ng, W.P.Q.; Lim, C.H.; Tan, C.P.; Ponnambalam, S.G. Lean and green manufacturing—A review on its applications and impacts. Process Integr. Optim. Sustain. 2019, 3, 5–23. [Google Scholar] [CrossRef]

- Teixeira, P.; Sá, J.C.; Silva, F.J.G.; Ferreira, L.P.; Santos, G.; Fontoura, P. Connecting lean and green with sustainability towards a conceptual model. J. Clean. Prod. 2021, 322, 129047. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A. Lean and green—A systematic review of the state of the art literature. J. Clean. Prod. 2015, 102, 18–29. [Google Scholar] [CrossRef]

- Larinina, T.; Djoldosheva, T.; Mottaeva, A. A study on the convergence of lean and green management goals. BIO Web Conf. 2024, 145, 04035. [Google Scholar] [CrossRef]

- Siegel, R.; Antony, J.; Govindan, K.; Garza-Reyes, J.A.; Lameijer, B.; Samadhiya, A. A framework for the systematic implementation of Green-Lean and sustainability in SMEs. Prod. Plan. Control 2022, 35, 71–89. [Google Scholar] [CrossRef]

- Cherrafi, A.; Elfezazi, S.; Govindan, K.; Garza-Reyes, J.A.; Benhida, K.; Mokhlis, A. A framework for the integration of Green and Lean Six Sigma for superior sustainability performance. Int. J. Prod. Res. 2017, 55, 4481–4515. [Google Scholar] [CrossRef]

- Ghasemibojd, F.; Franchetti, M.J.; George, B. Green lean six sigma for sustainable development: A systematic review of evolution, challenges, and future pathways. Clean Technol. Environ. Policy 2025, 1–24. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A. Green lean and the need for Six Sigma. Int. J. Lean Six Sigma 2015, 6, 226–248. [Google Scholar] [CrossRef]

- Banawi, A.; Bilec, M.M. A framework to improve construction processes: Integrating Lean, Green and Six Sigma. Int. J. Constr. Manag. 2014, 14, 45–55. [Google Scholar] [CrossRef]

- Gaikwad, L.M.; Sunnapwar, V.K. Integrated Lean-Green-Six Sigma Practices to Improve the Performance of the Manufacturing Industry. In Concepts, Applications and Emerging Opportunities in Industrial Engineering; IntechOpen: London, UK, 2021. [Google Scholar]

- Venugopal, V.; Saleeshya, P.G. Manufacturing system sustainability through lean and agile initiatives. Int. J. Sustain. Eng. 2019, 12, 159–173. [Google Scholar] [CrossRef]

- Singh, S.; Olugu, E.U.; Musa, S.N. Development of sustainable manufacturing performance evaluation expert system for small and medium enterprises. Procedia CIRP 2016, 40, 608–613. [Google Scholar] [CrossRef]

- Shah, R.; Ward, P.T. Lean manufacturing: Context, practice bundles, and performance. J. Oper. Manag. 2003, 21, 129–149. [Google Scholar] [CrossRef]

- Lawrence, E.; Andrews, D.; Ralph, B.; France, C. Applying organizational environmental tools and techniques. Corp. Soc. Responsib. Environ. Manag. 2002, 9, 116–125. [Google Scholar] [CrossRef]

- Herrmann, C.; Schmidt, C.; Kurle, D.; Blume, S.; Thiede, S. Sustainability in manufacturing and factories of the future. Int. J. Precis. Eng. Manuf.-Green Technol. 2014, 1, 283–292. [Google Scholar] [CrossRef]

- Salleh, N.A.M.; Kasolang, S.; Jaffar, A. Green lean total quality information management in Malaysian automotive companies. Procedia Eng. 2012, 41, 1708–1713. [Google Scholar] [CrossRef]

- Sung, J.; Ashton, D.N. High Performance Work Practices: Linking Strategy and Skills to Performance Outcomes; Department of Trade and Industry: London, UK, 2005.

- Höglund, L.; Holmgren Caicedo, M.; Mårtensson, M.; Svärdsten, F. Strategic management in the public sector: How tools enable and constrain strategy making. Int. Public Manag. J. 2018, 21, 822–849. [Google Scholar] [CrossRef]

- Eswaramoorthi, M.; Kathiresan, G.R.; Prasad, P.S.S.; Mohanram, P.V. A survey on lean practices in Indian machine tool industries. Int. J. Adv. Manuf. Technol. 2011, 52, 1091–1101. [Google Scholar] [CrossRef]

- Kovilage, M.P. Influence of lean–green practices on organizational sustainable performance. J. Asian Bus. Econ. Stud. 2021, 28, 121–142. [Google Scholar] [CrossRef]

- Nunhes, T.V.; Bernardo, M.; Oliveira, O.J. Guiding principles of integrated management systems: Towards unifying a starting point for researchers and practitioners. J. Clean. Prod. 2019, 210, 977–993. [Google Scholar] [CrossRef]

- Poltronieri, C.F.; Ganga, G.M.D.; Gerolamo, M.C. Maturity in management system integration and its relationship with sustainable performance. J. Clean. Prod. 2019, 207, 236–247. [Google Scholar] [CrossRef]

- Nunhes, T.V.; Bernardo, M.; Oliveira, O.J. Rethinking the way of doing business: A reframe of management structures for developing corporate sustainability. Sustainability 2020, 12, 1177. [Google Scholar] [CrossRef]

- Gueorguiev, T.; Kostadinova, I. ISO Standards Do Good: A New Perspective on Sustainable Development Goals. In Proceedings of the 13th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2021)—Volume 3: KMIS, Virtual Event, 25–27 October 2021; pp. 133–137. [Google Scholar]

- Martínez, S.; Ortiz, I.; Juan, J.; Lázaro, F. Using Certification as a Tool to Develop Sustainability in Project Management. Sustainability 2018, 10, 1408. [Google Scholar] [CrossRef]

- Bravi, L.; Santos, G.; Pagano, A.; Murmura, F. Environmental management system according to ISO 14001:2015 as a driver to sustainable development. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 2599–2614. [Google Scholar] [CrossRef]

- Hassan, H.; Bushagour, A.; Layton, A. Resilient Circularity in Manufacturing: Synergies Between Circular Economy and Reconfigurable Manufacturing. J. Manuf. Sci. Eng. 2024, 146, 110902. [Google Scholar] [CrossRef]

- Kornelius, H. Linking occupational health and safety management to sustainable competitive advantage of the firm. J. Econ. Bus. 2018, 1, 577–583. [Google Scholar] [CrossRef]

- Siva, V.; Gremyr, I.; Bergquist, B.; Garvare, R.; Zobel, T.; Isaksson, R. The support of Quality Management to sustainable development: A literature review. J. Clean. Prod. 2016, 138, 148–157. [Google Scholar] [CrossRef]

- Rebelo, M.F.; Santos, G.; Silva, R. A generic model for integration of quality, environment and safety management systems. TQM J. 2014, 26, 143–159. [Google Scholar] [CrossRef]

- Bernardo, M.; Gotzamani, K.; Vouzas, F.; Casadesus, M. A qualitative study on integrated management systems in a non-leading country in certifications. Total Qual. Manag. Bus. Excell. 2018, 29, 453–480. [Google Scholar] [CrossRef]

- Asif, M.; Searcy, C.; Zutshi, A.; Ahmad, N. An integrated management systems approach to corporate sustainability. Eur. Bus. Rev. 2011, 23, 353–367. [Google Scholar] [CrossRef]

- Merlin, F.K.; Pereira, V.L.D.V.; Pacheco, W. Sustainable development induction in organizations: A convergence analysis of ISO standards management tools’ parameters. Work 2012, 41 (Suppl. S1), 2736–2743. [Google Scholar] [CrossRef]

- Poltronieri, C.F.; Gerolamo, M.C.; Dias, T.C.M.; Carpinetti, L.C.R. Instrument for evaluating IMS and sustainable performance. Int. J. Qual. Reliab. Manag. 2018, 35, 373–386. [Google Scholar] [CrossRef]

- Cierpioł, A.; Wąsikiewicz-Rusnak, U. Znormalizowane Systemy Zarządzania w Organizacjach Przemysłowych; Wydawnictwo Naukowe Akademii WSB: Wrocław, Poland, 2021. [Google Scholar]

- Nunhes, T.V.; Campos, T.L.R.; Francisco, F.E.; Oliveira, O.J.D. Contributions of Annex SL to Corporate Sustainability. Front. Sustain. 2021, 2, 745350. [Google Scholar] [CrossRef]

- Silva, C.; Magano, J.; Moskalenko, A.; Nogueira, T.; Dinis, M.A.P.; Pedrosa e Sousa, H.F. Sustainable management systems standards (SMSS): Structures, roles, and practices in corporate sustainability. Sustainability 2020, 12, 5892. [Google Scholar] [CrossRef]

- Gianni, M.; Gotzamani, K.; Tsiotras, G. Multiple perspectives on integrated management systems and corporate sustainability performance. J. Clean. Prod. 2017, 168, 1297–1311. [Google Scholar] [CrossRef]

- de Nadae, J.; Carvalho, M.M.; Vieira, D.R. Integrated management systems as a driver of sustainability performance: Exploring evidence from multiple-case studies. Int. J. Qual. Reliab. Manag. 2021, 38, 800–821. [Google Scholar] [CrossRef]

- Gibson, R.B.; Hassan, S.; Holtz, S.; Tansey, J.; Whitelaw, G. Sustainability Assessment: Criteria and Processes; Earthscan: London, UK, 2005. [Google Scholar]

- Pope, J. What’s so special about sustainability assessment? J. Environ. Assess. Policy Manag. 2006, 8, v–x. [Google Scholar] [CrossRef]

- Sari, Y.; Hidayatno, A.; Suzianti, A.; Hartono, M. A systematic literature review for developing sustainability assessment tool: Formulating the state of the art and future direction. IOP Conf. Ser. Mater. Sci. Eng. 2019, 703, 012018. [Google Scholar] [CrossRef]

- Gibson, R.B. Beyond the pillars: Sustainability assessment as a framework for effective integration of social, economic and ecological considerations in significant decision-making. J. Environ. Assess. Policy Manag. 2006, 8, 259–280. [Google Scholar] [CrossRef]

- Madanchi, N. A Rapid Assessment Tool to Assess Factory Sustainability. Master’s Thesis, University of Rhode Island, Kingston, RI, USA, 2013. [Google Scholar]

- Subic, A.; Shabani, B.; Hedayati, M.; Crossin, E. Performance analysis of the capability assessment tool for sustainable manufacturing. Sustainability 2013, 5, 3543–3561. [Google Scholar] [CrossRef]

- Popovic, T.; Barbosa-Póvoa, A.; Kraslawski, A.; Carvalho, A. Quantitative indicators for social sustainability assessment of supply chains. J. Clean. Prod. 2018, 180, 748–768. [Google Scholar] [CrossRef]

- Chen, D.; Schudeleit, T.; Posselt, G.; Thiede, S. A state-of-the-art review and evaluation of tools for factory sustainability assessment. Procedia CIRP 2013, 9, 85–90. [Google Scholar] [CrossRef]

- Steinkellner, H.; Domenik, K. Strengthen Social Sustainability in Parcel Hubs: A Theoretical Exploration and the Potential Role of Discrete Event Simulation. In Proceedings of the XXV International Conference MHCL, Vienna, Austria, 18–19 September 2024. [Google Scholar]

- Wu, L.; Subramanian, N.; Abdulrahman, M.D.; Liu, C.; Lai, K.H.; Pawar, K.S. The impact of integrated practices of lean, green, and social management systems on firm sustainability performance—Evidence from Chinese fashion auto-parts suppliers. Sustainability 2015, 7, 3838–3858. [Google Scholar] [CrossRef]

- Jonker, J.; Rudnicka, A.; Reichel, J. Nowe Horyzonty. Przewodnik po Społecznej Odpowiedzialności i Rozwoju Zrównoważonym; Centrum Strategii/Rozwoju Impact: Łódź, Poland, 2011. [Google Scholar]

- Benitez, B. Corporate Sustainability Self-Assessment; Harvard Division of Continuing Education: Cambridge, MA, USA, 2018. [Google Scholar]

- Nicholls, J.; Lawlor, E.; Neitzert, E.; Goodspeed, T. A Guide to Social Return on Investment; Office of the Third Sector, Cabinet Office: London, UK, 2009. [Google Scholar]

- Shahbazi, S.; Kurdve, M.; Zackrisson, M.; Jönsson, C.; Kristinsdottir, A.R. Comparison of four environmental assessment tools in Swedish manufacturing: A case study. Sustainability 2019, 11, 2173. [Google Scholar] [CrossRef]

- Karnib, A. A methodological approach for sustainability assessment: Application to the assessment of the sustainable water resources withdrawals. Int. J. Sustain. Dev. 2016, 19, 402–417. [Google Scholar] [CrossRef]

- Moldavska, A.; Welo, T. Development of manufacturing sustainability assessment using systems thinking. Sustainability 2015, 8, 5. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Bradley, R. Technological elements of circular economy and the principles of 6R-based closed-loop material flow in sustainable manufacturing. Procedia CIRP 2016, 40, 103–108. [Google Scholar] [CrossRef]

- Eslami, Y. A Modelling-Based Sustainability Assessment in Manufacturing Organizations. Ph.D. Dissertation, Politecnico di Bari, Bari, Italy, 2019. [Google Scholar]

- Jing, W.; Alias, A.H. Key factors for BIM Implementation in the Context of ESG and SDGs Integration: A Systematic Literature Review. Sustainability 2024, 16, 9504. [Google Scholar] [CrossRef]

- Tehrani, M.; Rathgeber, A.; Dougherty, E.; Fulton, L.; Fournier, J. Dow Jones Sustainability Indices and ESG Scores: Do They Tell the Same Story? Sustainability 2024, 16, 6110. [Google Scholar] [CrossRef]

- Khamisu, M.S.; Paluri, R.A. Emerging trends of environmental social and governance (ESG) disclosure research. Clean. Prod. Lett. 2024, 7, 100079. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, W.; Liu, Y.; Cherubini, F.; Fu, B.; Pereira, P. Prioritizing sustainable development goals and linking them to ecosystem services: A global expert’s knowledge evaluation. Geogr. Sustain. 2020, 1, 321–330. [Google Scholar] [CrossRef]

- Chomać-Pierzecka, E.; Dyrka, S.; Kokiel, A.; Urbańczyk, E. Sustainable HR and employee psychological well-being in shaping the performance of a business. Sustainability 2024, 16, 10913. [Google Scholar] [CrossRef]

- Peretz, H. Sustainable human resource management and employees’ performance: The impact of national culture. Sustainability 2024, 16, 7281. [Google Scholar] [CrossRef]

- ISO 37000:2021; Governance of Organizations—Guidance. International Organization for Standardization: Geneva, Switzerland, 2021.

- Elidrisy, A. Comparative Review of ESG Reporting Standards: ESRS European Sustainability Reporting Standards “versus ISSB” International Sustainability Standards Board (Comparative Analysis of ESG Reporting Standards). Int. Multiling J. Sci. Technol. 2024, 9, 7191–7198. [Google Scholar]

- ISO 26000:2010; Guidance on Social Responsibility. International Organization for Standardization: Geneva, Switzerland, 2010.

- Du Toit, E. Thirty years of sustainability reporting: Insights, gaps and an agenda for future research through a systematic literature review. Sustainability 2024, 16, 10750. [Google Scholar] [CrossRef]

- Leal Filho, W.; Wall, T.; Williams, K.; Dinis, M.A.P.; Martin, R.M.F.; Mazhar, M.; Gatto, A. European sustainability reporting standards: An assessment of requirements and preparedness of EU companies. J. Environ. Manag. 2025, 380, 125008. [Google Scholar] [CrossRef]

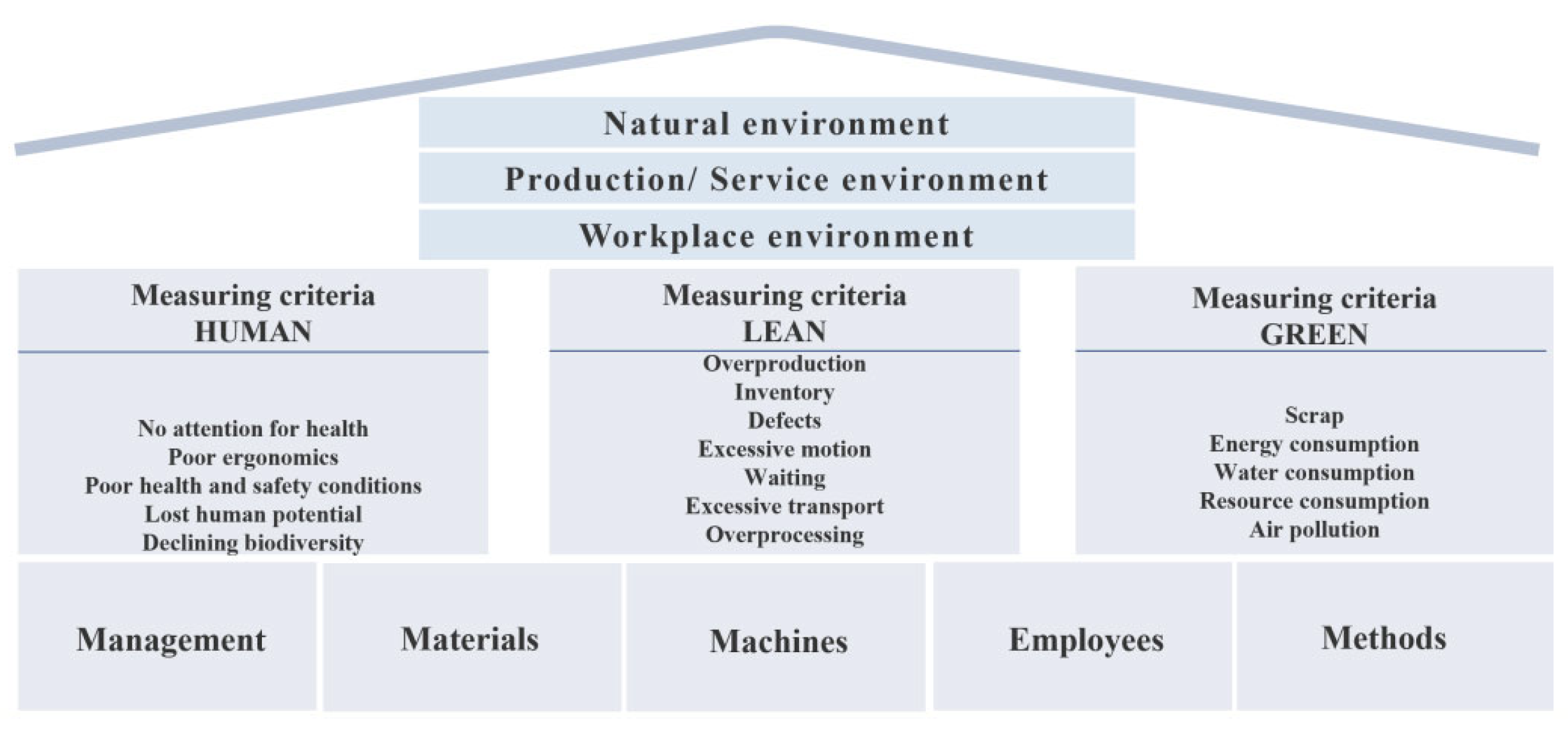

- Starzyńska, B.; Bryke, M.; Diakun, J. Human lean green method—A new approach toward auditing manufacturing & service companies. Sustainability 2021, 13, 10789. [Google Scholar] [CrossRef]

- Abualfaraa, W.; Salonitis, K.; Al-Ashaab, A.; Ala’raj, M. Lean-green manufacturing practices and their link with sustainability: A critical review. Sustainability 2020, 12, 981. [Google Scholar] [CrossRef]

| No. | Method/Tool for Assessing the Sustainability of an Enterprise | Useful for Companies? | Comprehensive? | Quick Assessment? |

|---|---|---|---|---|

| 1 | Barometer of Sustainability | – | – | + |

| 2 | Dow Jones Sustainability Index | + | o | – |

| 3 | Global Reporting Initiative Framework (GRI) | + | + | – |

| 4 | IChemE Sustainability Metrics | + | + | – |

| 5 | Rapid Plant Assessment Tool | + | – | + |

| 6 | Sustainability Assessment in Mining and Minerals Industry) | o | + | – |

| 7 | Composite Sustainable Development Index) | + | + | + |

| 8 | ITT Flygt Sustainability Index | + | + | + |

| 9 | Ford of Europe’s Product Sustainability Index | – | + | – |

| 10 | GM Metrics for Sustainable Manufacturing | + | + | + |

| 11 | Sustainable Development Framework (SDF) | – | + | – |

| 12 | Rapid Basin-wide Hydropower Sustainability Assessment Tool | – | + | + |

| Evaluation Criteria | Evaluation Elements | ||||

|---|---|---|---|---|---|

| Mgt. | Material | Machine | Man | Method | |

| HUMAN | Question 1 | Question 1 | Question 1 | Question 1 | Question 1 |

| Question 2 | Question 2 | Question 2 | Question 2 | Question 2 | |

| … | … | … | … | … | |

| Question k | Question k | Question k | Question k | Question k | |

| LEAN | Question 1 | Question 1 | Question 1 | Question 1 | Question 1 |

| Question 2 | Question 2 | Question 2 | Question 2 | Question 2 | |

| … | … | … | … | … | |

| Question l | Question l | Question l | Question l | Question l | |

| GREEN | Question 1 | Question 1 | Question 1 | Question 1 | Question 1 |

| Question 2 | Question 2 | Question 2 | Question 2 | Question 2 | |

| … | … | … | … | … | |

| Question m | Question m | Question m | Question m | Question m | |

| Company Name | Human Indicator [%] | Lean Indicator [%] | Green Indicator [%] | Human Indicator Deviation [%] | Lean Indicator Deviation [%] | Green Indicator Deviation [%] | Total Deviation [%] | Average Deviation/3 [%] |

|---|---|---|---|---|---|---|---|---|

| Company 1 | 82.95 | 70.00 | 71.74 | 7.95 | −5.00 | −3.26 | −0.31 | −0.10 |

| Company 2 | 73.00 | 73.57 | 53.00 | −2.00 | −1.43 | −22.00 | −25.43 | −8.48 |

| Company 3 | 57.00 | 57.86 | 65.00 | −18.00 | −17.14 | −10.00 | −45.14 | −15.05 |

| Company 4 | 53.00 | 44.52 | 19.00 | −22.00 | −30.48 | −56.00 | −108.48 | −36.16 |

| Company 5 | 64.13 | 61.43 | 53.75 | −10.87 | −13.57 | −21.25 | −45.69 | −15.23 |

| Company 6 | 74.00 | 48.57 | 33.33 | −1.00 | −26.43 | −41.67 | −69.10 | −23.03 |

| Company 7 | 83.00 | 86.43 | 64.00 | 8.00 | 11.43 | −11.00 | 8.43 | 2.81 |

| Company 8 | 93.00 | 85.29 | 77.00 | 18.00 | 10.29 | 2.00 | 30.29 | 10.10 |

| Company 9 | 76.00 | 46.43 | 59.21 | 1.00 | −28.57 | −15.79 | −43.36 | −14.45 |

| Company 10 | 28.00 | 44.29 | 35.87 | −47.00 | −30.71 | −39.13 | −116.84 | −38.95 |

| Company 11 | 62.50 | 65.63 | 66.30 | −12.50 | −9.37 | −8.70 | −30.57 | −10.19 |

| Company 12 | 24.00 | 29.29 | 23.91 | −51.00 | −45.71 | −51.09 | −147.80 | −49.27 |

| Company 13 | 73.00 | 60.00 | 45.65 | −2.00 | −15.00 | −29.35 | −46.35 | −15.45 |

| Company 14 | 87.50 | 74.29 | 84.38 | 12.50 | −0.71 | 9.38 | 21.17 | 7.06 |

| Company 15 | 85.00 | 70.59 | 69.00 | 10.00 | −4.41 | −6.00 | −0.41 | −0.14 |

| Company 16 | 75.00 | 78.57 | 54.35 | 0.00 | 3.57 | −20.65 | −17.08 | −5.69 |

| Company 17 | 34.00 | 43.57 | 29.35 | −41.00 | −31.43 | −45.65 | −118.08 | −39.36 |

| Company 18 | 59.38 | 65.44 | 65.63 | −15.62 | −9.56 | −9.37 | −34.55 | −11.52 |

| Company 19 | 93.00 | 69.29 | 96.74 | 18.00 | −5.71 | 21.74 | 34.03 | 11.34 |

| Company 20 | 92.00 | 90.71 | 97.00 | 17.00 | 15.71 | 22.00 | 54.71 | 18.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Starzyńska, B.; Bryke, M. Meeting Sustainable Development Challenges at the Enterprise Level. Sustainability 2025, 17, 10275. https://doi.org/10.3390/su172210275

Starzyńska B, Bryke M. Meeting Sustainable Development Challenges at the Enterprise Level. Sustainability. 2025; 17(22):10275. https://doi.org/10.3390/su172210275

Chicago/Turabian StyleStarzyńska, Beata, and Mariusz Bryke. 2025. "Meeting Sustainable Development Challenges at the Enterprise Level" Sustainability 17, no. 22: 10275. https://doi.org/10.3390/su172210275

APA StyleStarzyńska, B., & Bryke, M. (2025). Meeting Sustainable Development Challenges at the Enterprise Level. Sustainability, 17(22), 10275. https://doi.org/10.3390/su172210275