Collaborative Low-Carbon Scheduling Strategy for Microgrid Groups Based on Green Certificate Incentives and Energy Demand Response

Abstract

1. Introduction

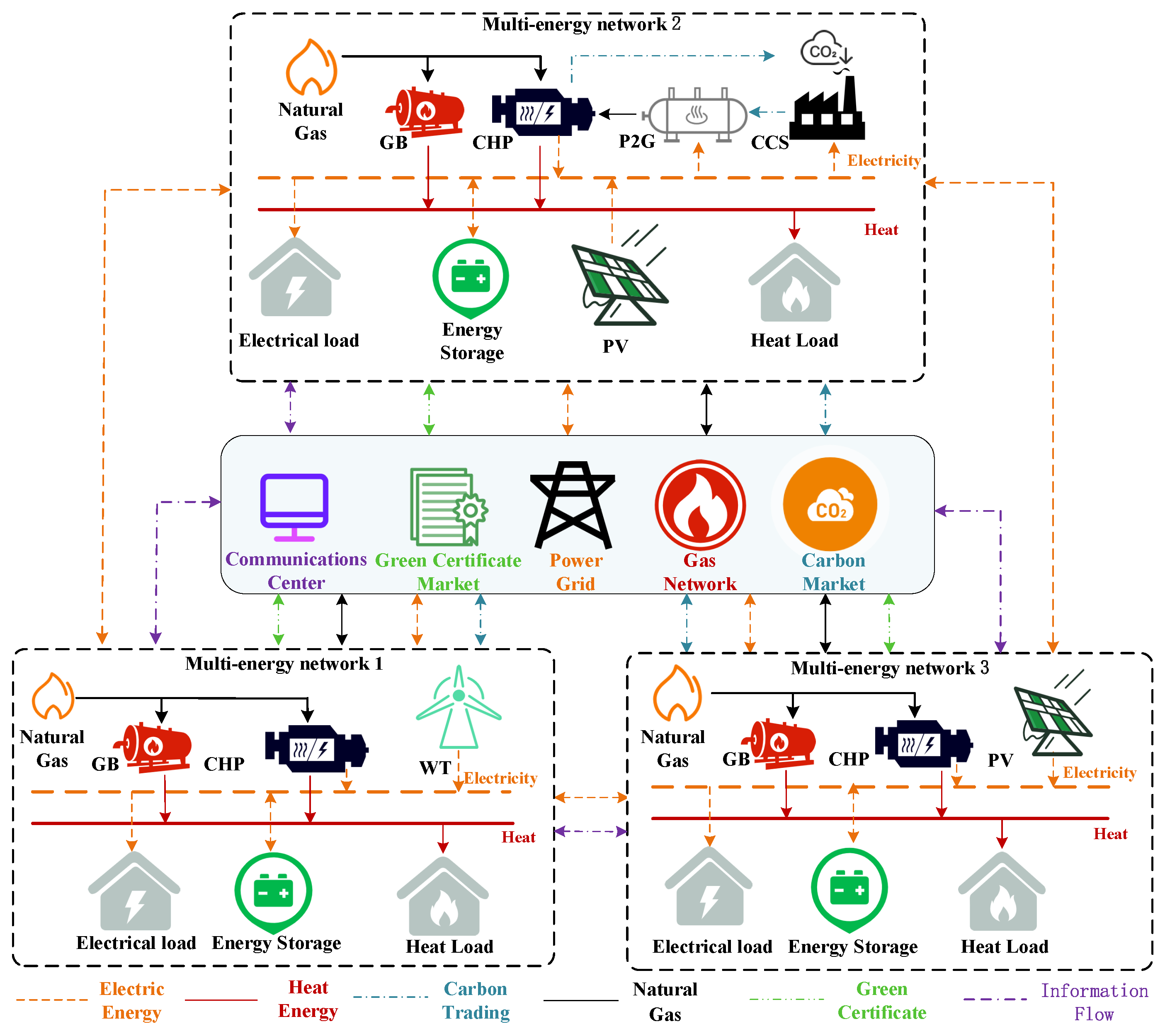

2. Integrated Energy Multi-Microgrid Architecture with CCS-P2G

2.1. System Model Establishment

2.1.1. Gas Turbine Model

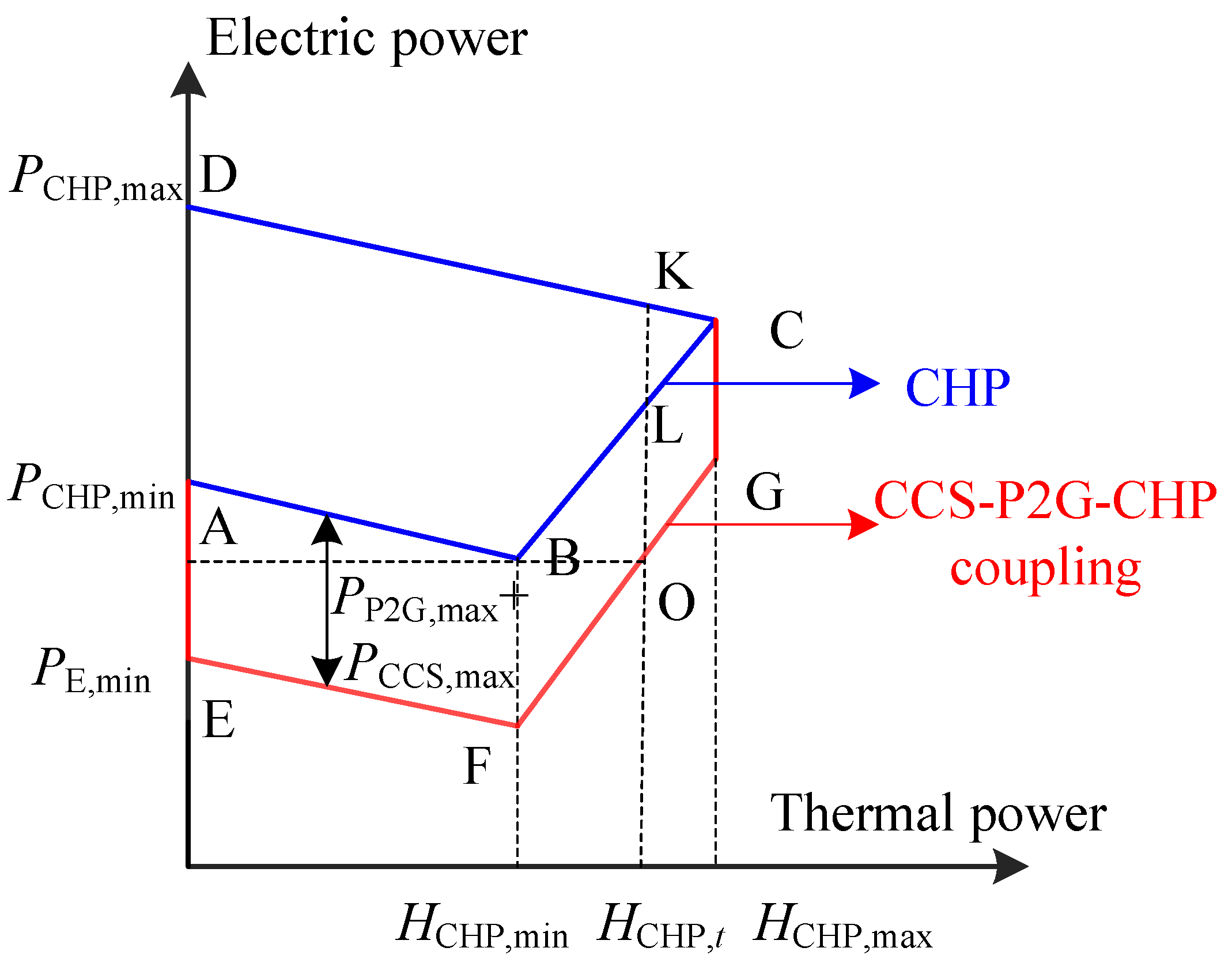

2.1.2. CCS-P2G-CHP Coupling Model

2.2. Integrated Demand Response Mechanism

2.2.1. Load Classification and Modeling Basis

2.2.2. Shiftable Load Model

2.2.3. Load Reduction Model

2.3. Cost Model

- (1)

- Operating costs of CHP units

- (2)

- Operation and maintenance costs of energy storage devices

- (3)

- External Interaction Costs

- (4)

- Carbon Trading Costs

- (5)

- Demand response cost

- (6)

- Green certificate trading costs

2.4. Synergistic Relationship Between Green Certificate Trading and Carbon Trading Mechanisms

2.5. Constraints

2.5.1. Electric Power Balance Constraint

2.5.2. Thermal Power Balance Constraint

2.5.3. Gas Power Balance Constraints

2.5.4. CCS-P2G-CHP Power Upper and Lower Limit Constraints

2.5.5. Renewable Energy Power Constraints

2.5.6. Energy Storage Device Constraints

2.5.7. Green Certificate Quota Constraints

2.5.8. Demand Response Constraints

2.5.9. Power Interaction Constraints Between Microgrid and Main Grid

2.6. Applicability Analysis of the Model Construction

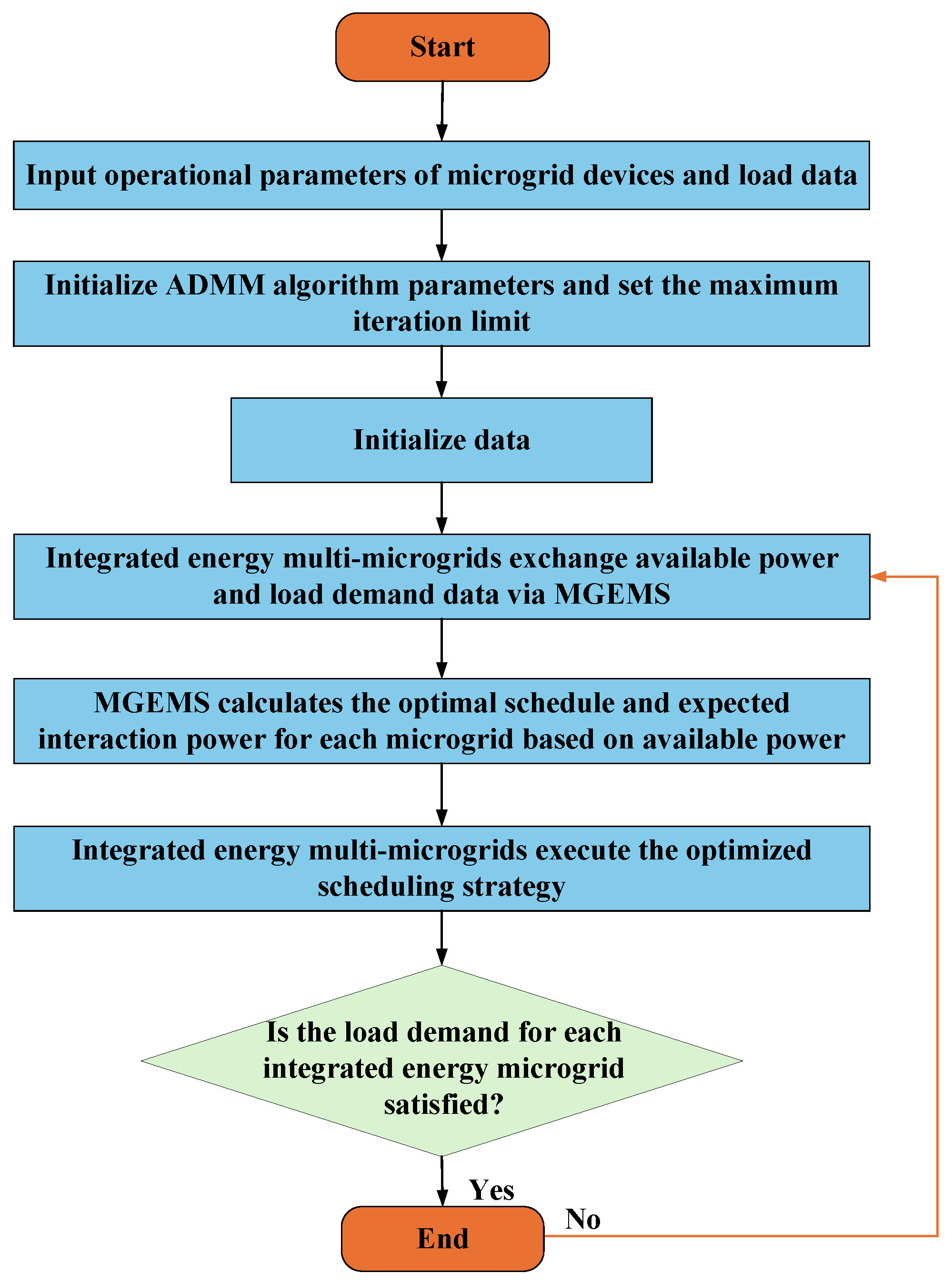

3. Solution of Distributed Dispatch of Integrated Energy Multi-Microgrid Based on Alternating Direction Method of Multipliers (ADMM)

- (1)

- Input the operating parameters of equipment, including CHP units, CCS systems, power-to-gas units, and energy storage devices, along with the output data from the distributed power sources of each microgrid and the corresponding load data. Additionally, include the original data, such as Lagrange multipliers and penalty coefficients.

- (2)

- The microgrid MGEMS system analyzes the previous data of each microgrid and formulates an initial dispatch plan for the microgrid.

- (3)

- Each microgrid communicates its available power and load demand information through the MGEMS. The MGEMS then derives the optimal dispatch strategy and expected interactive power for each microgrid through distributed solution iteration. Since the microgrids only exchange information related to power purchase and sales plans, without sharing power generation outputs, the internal privacy of each microgrid is preserved.

- (4)

- The MGEMS of each microgrid collectively forms an integrated energy management system for the multi-microgrid network, designed to meet the load demand of each microgrid while minimizing the operating cost and ensuring the efficient utilization of energy across the system.

4. Case Analysis

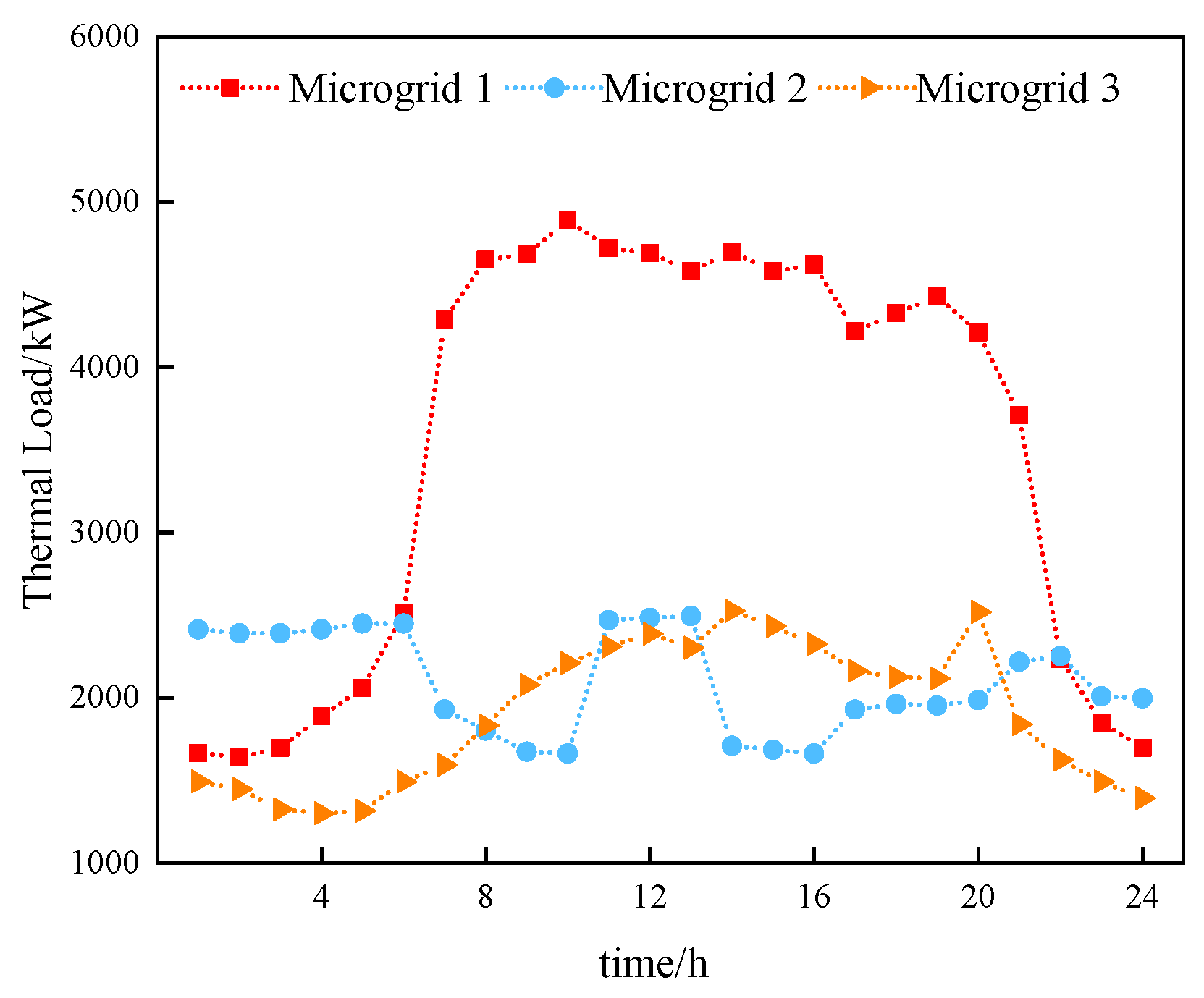

4.1. Case Parameters

4.2. Scenario Configuration

4.3. Convergence Analysis

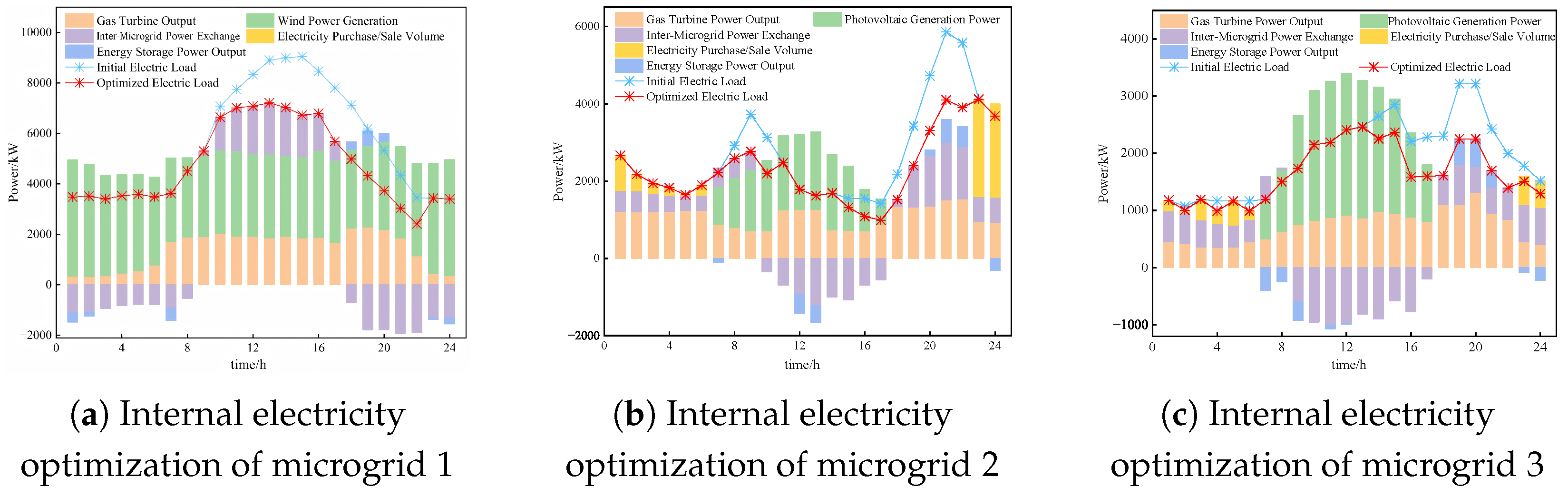

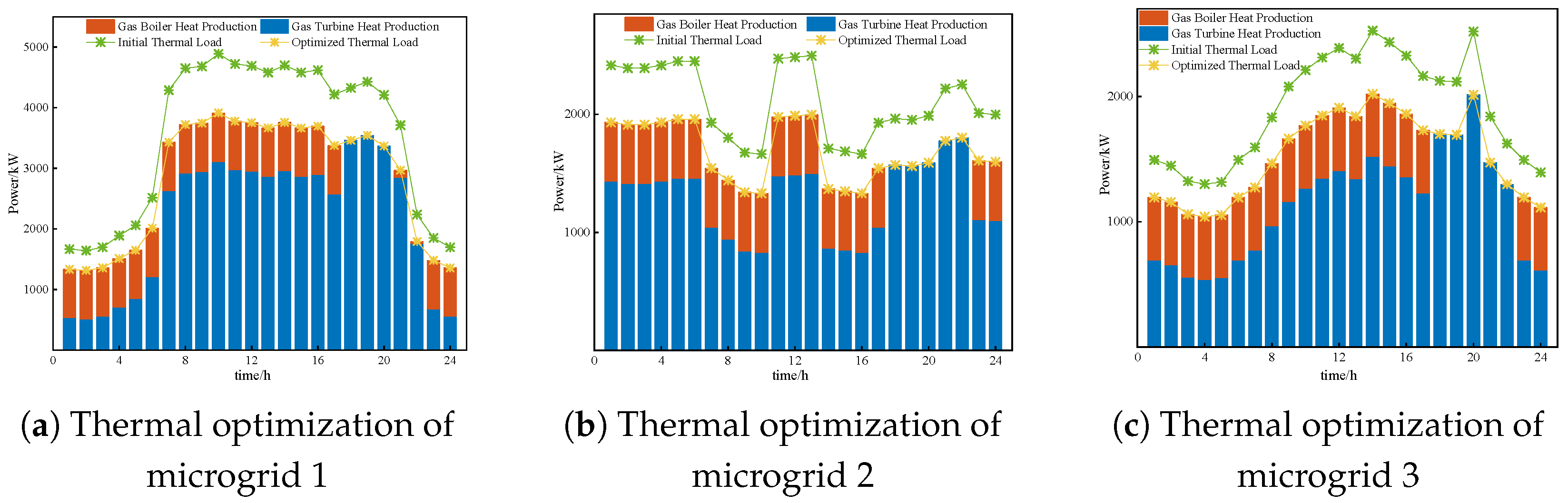

4.4. Analysis of Optimization Dispatch Results of Each Energy Microgrid

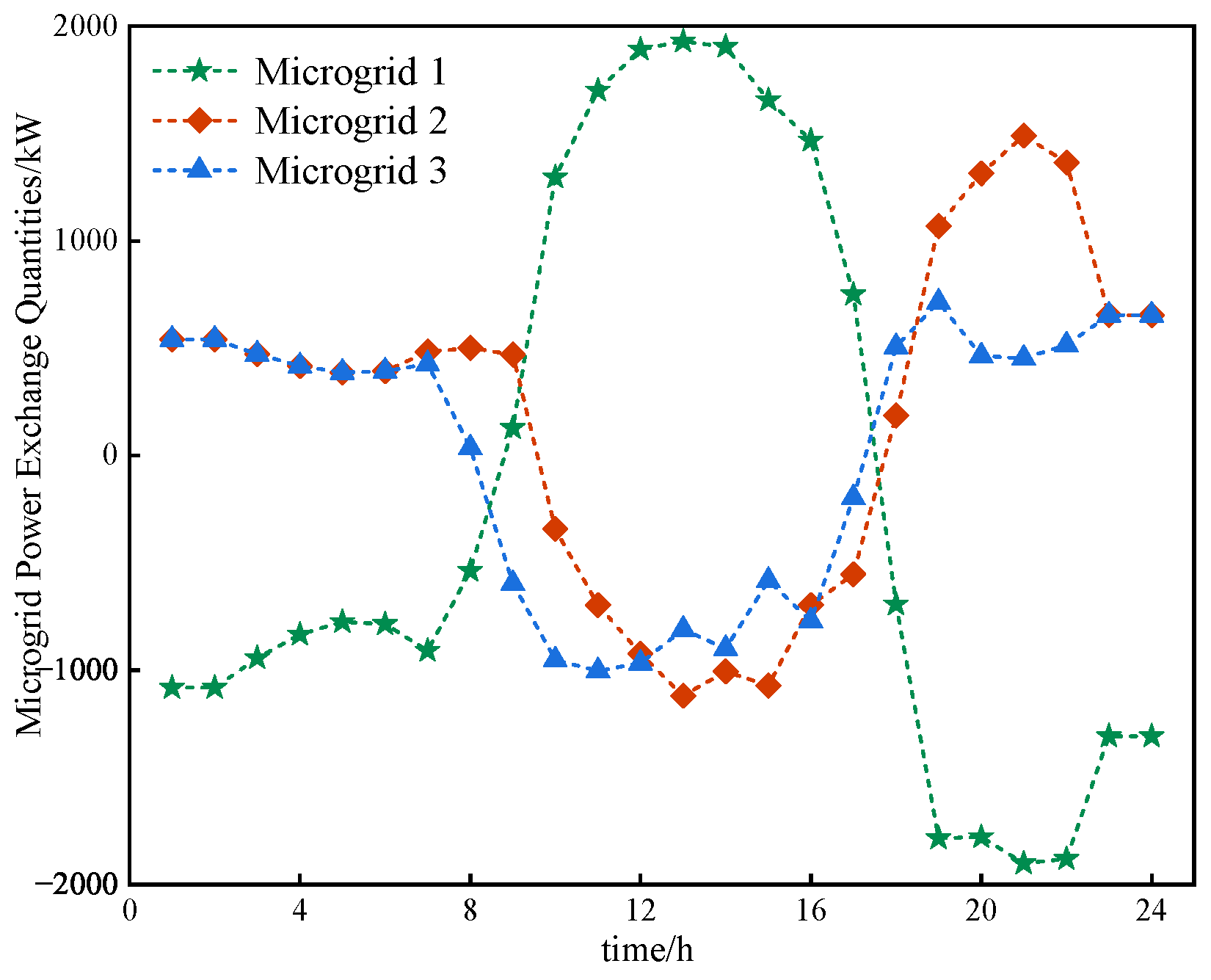

4.5. Analysis of the Results of Power Interaction Between Multiple Microgrids

4.6. Analysis of Multi-Microgrid Dispatch Results Under Different Schemes

5. Conclusions

- (1)

- This paper proposes a low-carbon dispatch model for IEM containing CCS-P2G, which enhances conventional CHP units by integrating CCS and P2G technologies. The coupled operation of CCS-P2G-CHP significantly reduces carbon dioxide emissions during microgrid operation, enhances the energy dispatch management capability, and effectively promotes low-carbon system operation.

- (2)

- A multi-microgrid distributed energy management strategy is proposed, leveraging the energy sharing framework of the MM-IES. By enabling energy exchange among microgrids, this strategy significantly reduces the operating costs and carbon dioxide emissions of each microgrid compared to independent operation, while enhancing the renewable energy absorption rate and improving the economy of the system.

- (3)

- A distributed model for the MM-IES based on the ADMM is proposed. The system’s operating cost is optimized iteratively using the alternating multiplier method, requiring only a few iterations to achieve convergence. This approach enables rapid convergence, facilitates distributed dispatch, and ensures the protection of transaction information for each participating microgrid.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liang, H.; Xu, L.; Zhao, Y.; Zhang, S.; Chen, C.; Tang, J.; Yang, L.; Lin, Z. Day-Ahead Joint Scheduling of Multiple Park-Level Integrated Energy Systems Considering Coupling Uncertainty of Electricity-Carbon-Gas Prices. Int. J. Electr. Power Energy Syst. 2024, 158, 109933. [Google Scholar] [CrossRef]

- Li, X.; Yang, J.; Du, D.; Bu, S.; Wu, L.; Chung, C.Y.; Li, K. A Review of Optimal Scheduling and Distributed Cooperative control for Smart Grids Integrated with Electric Vehicles. J. Mod. Power Syst. Clean Energy 2025. [Google Scholar] [CrossRef]

- Bracco, S.; Dentici, G.; Siri, S. Economic and Environmental Optimization Model for the Design and Operation of a Combined Heat and Power Distributed Generation System in an Urban Area. IEEE Trans. Sustain. Energy 2013, 55, 1014–1024. [Google Scholar] [CrossRef]

- Xu, D.; Hu, A.; Lam, C.-S.; Yang, X.; Jin, X. Cooperative Planning of Multi-Energy System and Carbon Capture, Utilization and Storage. IEEE Trans. Sustain. Energy 2024, 15, 2718–2732. [Google Scholar] [CrossRef]

- Dong, W.; Lu, Z.; He, L.; Geng, L.; Guo, X.; Zhang, J. Low-Carbon Optimal Planning of an Integrated Energy Station Considering Combined Power-to-Gas and Gas-Fired Units Equipped With Carbon Capture Systems. Int. J. Electr. Power Energy Syst. 2022, 138, 107966. [Google Scholar] [CrossRef]

- Zhou, R.; Li, Y.; Sun, J.; Zhang, H.; Liu, D. Low-Carbon Economic Dispatch Considering Carbon Capture Unit and Demand Response Under Carbon Trading. In Proceedings of the Low-Carbon Economic Dispatch Considering Carbon Capture Unit and Demand Response Under Carbon Trading, Xi’an, China, 25–28 October 2016; pp. 1435–1439. [Google Scholar]

- Guo, W.; Xu, X. Comprehensive Energy Demand Response Optimization Dispatch Method Based on Carbon Trading. Energies 2022, 15, 3128. [Google Scholar] [CrossRef]

- Yang, D.; Wang, M. Optimal Operation of an Integrated Energy System by Considering the Multi-Energy Coupling, AC-DC Topology, and Demand Responses. Int. J. Electr. Power Energy Syst. 2021, 129, 106826. [Google Scholar] [CrossRef]

- Li, X.; Wang, W.; Wang, H.; Wu, J.; Fan, X.; Xu, Q. Dynamic Environmental Economic Dispatch of Hybrid Renewable Energy Systems Based on Tradable Green Certificates. IEEE Trans. Smart Grid 2020, 193, 116699. [Google Scholar] [CrossRef]

- Yang, D.; Xu, Y.; Liu, X.; Jiang, C.; Nie, F.; Ran, Z. Economic-Emission Dispatch Problem in Integrated Electricity and Heat System Considering Multi-Energy Demand Response and Carbon Capture Technologies. Energy 2022, 253, 124153. [Google Scholar] [CrossRef]

- Ma, T.; Pei, W.; Xiao, H.; Yang, Y.; Ma, L. A Joint Power and Renewable Energy Certificate Trading Method in the Peer-to-Peer Market. IEEE Trans. Smart Grid 2025, 16, 1604–1618. [Google Scholar] [CrossRef]

- Liu, Z.; Zheng, W.; Qi, F.; Wang, L.; Zou, B.; Wen, F.; Xue, Y. Optimal Dispatch of a Virtual Power Plant Considering Demand Response and Carbon Trading. Energies 2018, 11, 1488. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, N.; Kang, C.; Li, M.; Huo, M. From Demand Response to Integrated Demand Response: Review and Prospect of Research and Application. Prot. Control Mod. Power Syst. 2019, 4, 12. [Google Scholar] [CrossRef]

- Li, C.; Yan, Z.; Yao, Y.; Deng, Y.; Shao, C.; Zhang, Q. Coordinated Low-Carbon Dispatching on Source-Demand Side for Integrated Electricity-Gas System Based on Integrated Demand Response Exchange. IEEE Trans. Power Syst. 2024, 39, 1287–1303. [Google Scholar] [CrossRef]

- Zheng, S.; Sun, Y.; Qi, B.; Li, B. Incentive-Based Integrated Demand Response Considering S&C Effect in Demand Side with Incomplete Information. IEEE Trans. Smart Grid 2022, 13, 4465–4482. [Google Scholar]

- Shao, C.; Ding, Y.; Siano, P.; Song, Y. Optimal Scheduling of the Integrated Electricity and Natural Gas Systems Considering the Integrated Demand Response of Energy Hubs. IEEE Syst. J. 2021, 15, 4545–4553. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, X.; Li, Y.; Sun, Q.; Xu, X.; Zhang, Y. Distributed Robust Model Predictive Control-Based Energy Management Strategy for Islanded Multi-Microgrids Considering Uncertainty. IEEE Trans. Smart Grid 2022, 15, 2107–2120. [Google Scholar] [CrossRef]

- Du, Y.; Li, F. A Hierarchical Real-Time Balancing Market Considering Multi-Microgrids with Distributed Sustainable Resources. IEEE Trans. Sustain. 2020, 11, 72–83. [Google Scholar] [CrossRef]

- Nikmehr, N.; Najafi-Ravadanegh, S. Probabilistic Optimal Power Dispatch in Multi-microgrids Using Heuristic Algorithms. In Proceedings of the 2014 Smart Grid Conference (SGC), Tehran, Iran, 9–10 December 2014; pp. 1–6. [Google Scholar]

- Dong, Z.; Mao, S.; Perc, M.; Du, W.; Tang, Y. A Distributed Dynamic Event-Triggered Algorithm with Linear Convergence Rate for the Economic Dispatch Problem. IEEE Trans. Netw. Sci. Eng. 2023, 10, 500–513. [Google Scholar] [CrossRef]

- Qiu, H.; You, F. Decentralized-distributed Robust Electric Power Scheduling for Multi-microgrid Systems. CSEE J. Power Energy Syst. 2019, 269, 115146. [Google Scholar] [CrossRef]

- Qiu, H.; Gu, W.; Xu, Y.; Wu, Z.; Zhou, S.; Pan, G. Robustly Multi-microgrid Scheduling: Stakeholder-parallelizing Distributed Optimization. IEEE Trans. Sustain. Energy 2020, 11, 988–1001. [Google Scholar] [CrossRef]

- Mohiti, M.; Monsef, H.; Anvari-moghaddam, A.; Guerrero, J.; Lesani, H. A Decentralized Robust Model for Optimal Operation of Distribution Companies with Private Microgrids. Int. J. Electr. Power Energy Syst. 2019, 106, 105–123. [Google Scholar] [CrossRef]

- Fang, X.; Hodge, B.-M.; Jiang, H.; Zhang, Y. Decentralized Wind Uncertainty Management: Alternating Direction Method of Multipliers based Distributionally-robust Chance Constrained Optimal Power Flow. Appl. Energy 2019, 239, 938–947. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, W.; Zhang, T. ADMM-based Distributed State Estimation for Integrated Energy System. CSEE J. Power Energy Syst. 2019, 5, 275–283. [Google Scholar] [CrossRef]

- Ma, W.-J.; Wang, J.; Gupta, V.; Chen, C. Distributed Energy Management for Networked Microgrids Using online ADMM with Regret. IEEE Trans. Smart Grid 2018, 9, 847–856. [Google Scholar] [CrossRef]

- Wang, S.; Wu, W.; Lin, C.; Chen, B. A Dynamic Equivalent Energy Storage Model of Natural Gas Networks for Joint Optimal Dispatch of Electricity-Gas Systems. IEEE Trans. Sustain. Energy 2024, 15, 621–632. [Google Scholar] [CrossRef]

- Zhao, Y. Optimal Dispatch and Pricing of Industrial Parks Considering CHP Mode Switching and Demand Response. CSEE J. Power Energy Syst. 2024, 10, 2174–2185. [Google Scholar] [CrossRef]

- Shi, R.; Yan, X.; Fan, Z. Multi-Objective Scheduling Method for Integrated Energy System Containing CCS+ P2G System Using Q-Learning Adaptive Mutation Black-Winged Kite Algorithm. Sustainability 2025, 17, 5709. [Google Scholar] [CrossRef]

- Fan, J.; Zhang, J.; Yuan, L. Deep Low-carbon Economic Optimization Using CCUS and Two-Stage P2G with Multiple Hydrogen Utilizations for an Integrated Energy System with a High Penetration Level of Renewables. Sustainability 2024, 16, 5722. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Li, Y.; Xin, H. Multi-Agent Based Optimal Scheduling and Trading for Multi-Microgrids Integrated with Urban Transportation Networks. IEEE Trans. Power Syst. 2021, 36, 2197–2210. [Google Scholar] [CrossRef]

- Liang, S.; Lou, S.; Wu, Y.; Peng, Y. Generation Expansion Planning for Solvent-Storaged Carbon Capture Power Plants Considering the Internalization of the Carbon Emission Effects. IEEE Trans. Power Syst. 2024, 39, 2653–2667. [Google Scholar] [CrossRef]

- Li, X.; Zhang, T.; Zhou, Z. A Balanced Partitioning Method and Its Application on Distributed State Estimation in Power Grids. IEEE Trans. Power Syst. 2025. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, H.; Luo, X. A Novel Optimal Dispatch Strategy for Hybrid Energy Ship Power System Based on the Improved NSGA-II Algorithm. Electr. Power Syst. Res. 2024, 232, 110385. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, P.; Ji, X.; Wen, F.; Yang, M.; Ye, P. Low-Carbon Economic Dispatch of Integrated Energy Systems Considering Extended Carbon Emission Flow. J. Mod. Power Syst. Clean Energy 2024, 12, 1798–1809. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| 0.35 | /kW | 600 | (kg/kW) | 18.20 | |

| 0.90 | 0.5 | 0.01 | |||

| 0.15 | 0.5 | 0.01329 | |||

| 0.20 | 1.02 | 0.031 | |||

| 0.85 | 0.95 | 0.031 | |||

| (MJ/m3) | 35 | 0.95 | |||

| /kW | 300 | /kW | 500 | 0.3 | |

| /kW | 1200 | /kW | 600 | 0.15 | |

| /kW | 3000 | 0.2 | 0.01 | ||

| /kW | 300 | 0.8 | 0.424 | ||

| /kW | 2100 | (kW·h) | 2000 | 0.798 | |

| /kW | 0 | 0.15 | 1.08 | ||

| /kW | 300 | (kg/kW) | 0.55 | c (yuan/kg) | 0.25 |

| /kW | 0 | (kg/kW) | 0.65 | (yuan/kW·h) | 100 |

| Main Body | Time | Price (Yuan/(kW·h)) |

|---|---|---|

| Electricity Prices | Off-Peak Period | 0.40 |

| Electricity Prices | Mid-Peak Period | 0.75 |

| Electricity Prices | Peak Period | 1.20 |

| Natural gas | Full Day | 3.50 (yuan/m3) |

| Scenario | Main Body | Operating Cost/Yuan | Carbon Emissions /kg | Carbon Trading Amount/Yuan | Renewable Energy Generation Share/% |

|---|---|---|---|---|---|

| Scheme 1 | Microgrid 1 | 59,866.59 | 77,887.87 | 702.58 | 26.2 |

| Microgrid 2 | 55,749.48 | 41,841.09 | −14.28 | 30.5 | |

| Microgrid 3 | 38,197.34 | 43,383.92 | 2912.78 | 45.6 | |

| Scheme 2 | Microgrid 1 | 32,950.24 | 49,838.68 | −2296.27 | 70.0 |

| Microgrid 2 | 40,533.86 | 32,398.91 | −48.35 | 35.9 | |

| Microgrid 3 | 27,020.15 | 32,331.15 | 1611.97 | 51.6 | |

| Scheme 3 | Microgrid 1 | 47,262.72 | 63,419.44 | −330.34 | 64.7 |

| Microgrid 2 | 50,091.11 | 33,266.62 | −577.32 | 30.0 | |

| Microgrid 3 | 33,156.39 | 35,968.20 | 2592.21 | 44.6 | |

| Scheme 4 | Microgrid 1 | 27,439.50 | 46,049.51 | −3058.86 | 71.2 |

| Microgrid 2 | 32,021.36 | 23,351.22 | −1322.18 | 39.2 | |

| Microgrid 3 | 22,942.00 | 27,100.94 | 1153.21 | 53.1 |

| Main Body | Operating Cost of the Scheduling Stage/Yuan | Carbon Emissions of the Scheduling Stage/kg |

|---|---|---|

| Microgrid 1 | 27,439.50 | 46,049.51 |

| Microgrid 2 | 32,021.36 | 23,351.22 |

| Microgrid 3 | 22,942.00 | 27,100.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Xia, K.; Nie, C.; Yang, J.; Hu, Z.; Wang, Z. Collaborative Low-Carbon Scheduling Strategy for Microgrid Groups Based on Green Certificate Incentives and Energy Demand Response. Sustainability 2025, 17, 10274. https://doi.org/10.3390/su172210274

Zhu Y, Xia K, Nie C, Yang J, Hu Z, Wang Z. Collaborative Low-Carbon Scheduling Strategy for Microgrid Groups Based on Green Certificate Incentives and Energy Demand Response. Sustainability. 2025; 17(22):10274. https://doi.org/10.3390/su172210274

Chicago/Turabian StyleZhu, Yongsheng, Kaifei Xia, Caijing Nie, Junlin Yang, Zefei Hu, and Zikang Wang. 2025. "Collaborative Low-Carbon Scheduling Strategy for Microgrid Groups Based on Green Certificate Incentives and Energy Demand Response" Sustainability 17, no. 22: 10274. https://doi.org/10.3390/su172210274

APA StyleZhu, Y., Xia, K., Nie, C., Yang, J., Hu, Z., & Wang, Z. (2025). Collaborative Low-Carbon Scheduling Strategy for Microgrid Groups Based on Green Certificate Incentives and Energy Demand Response. Sustainability, 17(22), 10274. https://doi.org/10.3390/su172210274