Artificial Intelligence, Energy Consumption Intensity, and Supply Chain Resilience in China’s ICT Manufacturing Industry

Abstract

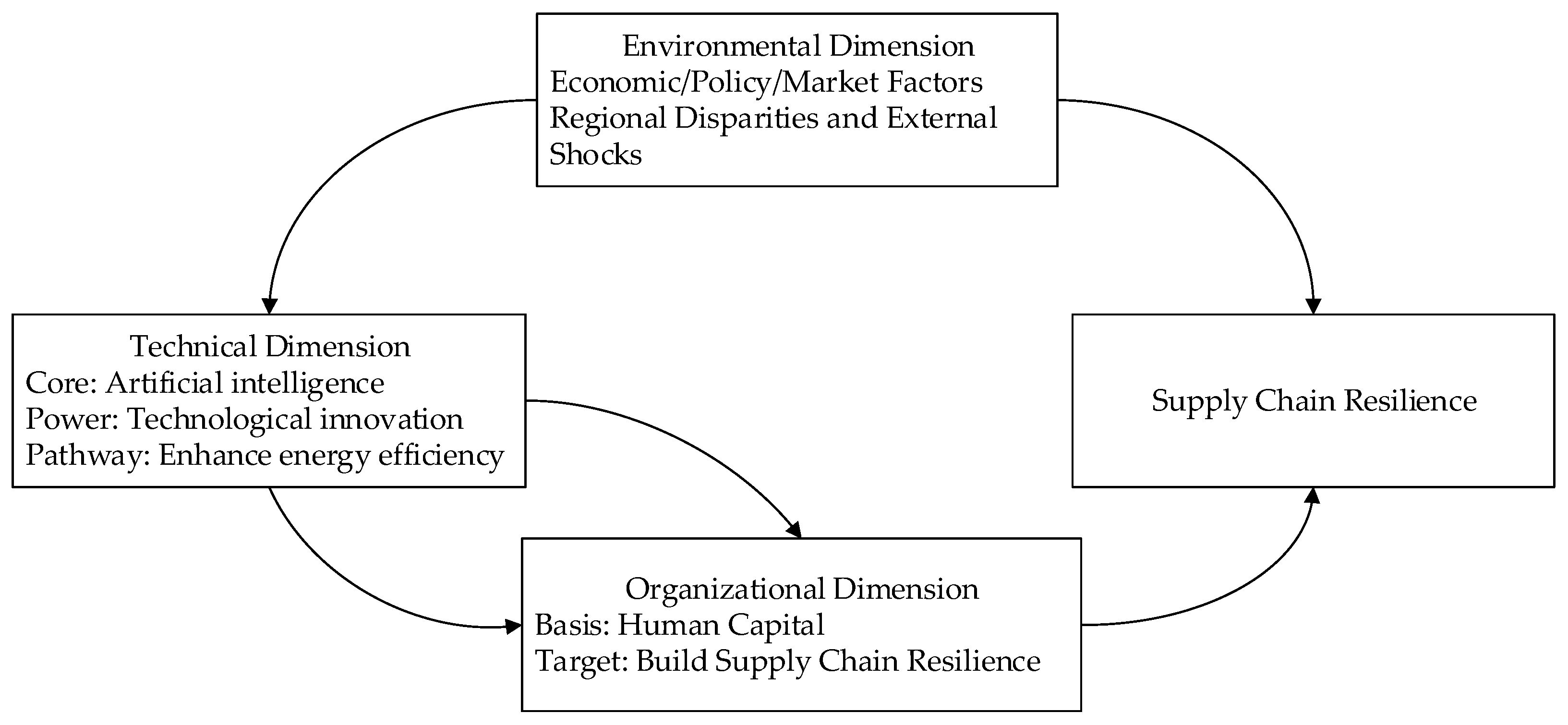

1. Introduction

- (1)

- Can the application of artificial intelligence technology effectively enhance the resilience of China’s ICT manufacturing supply chain?

- (2)

- Can energy intensity optimization effectively improve the resilience of the ICT manufacturing supply chain? If so, what role does technological innovation capability play?

- (3)

- Is the impact of AI technology application and energy intensity on the resilience of the ICT manufacturing supply chain heterogeneous?

2. Theoretical Analysis and Research Hypothesis

3. Research Design

3.1. Model Establishment

3.2. Variable Selection

3.2.1. Dependent Variable: ICT Manufacturing Supply Chain Resilience (SCR)

- Adaptability [46];

- Innovation capability [20].

3.2.2. Core Explanatory Variable: Artificial Intelligence (AI)

3.2.3. Mediating Variable

3.2.4. Moderating Variable

3.2.5. Control Variables

- Level of economic development;

- 2.

- Human capital development level;

- 3.

- Market size;

- 4.

- Government intervention level;

- 5.

- Level of knowledge flow.

3.3. Data Selection

4. Empirical Research

4.1. Empirical Results and Analysis

4.2. Endogeniety Concerns

4.3. Robustness Test

5. Further Analysis

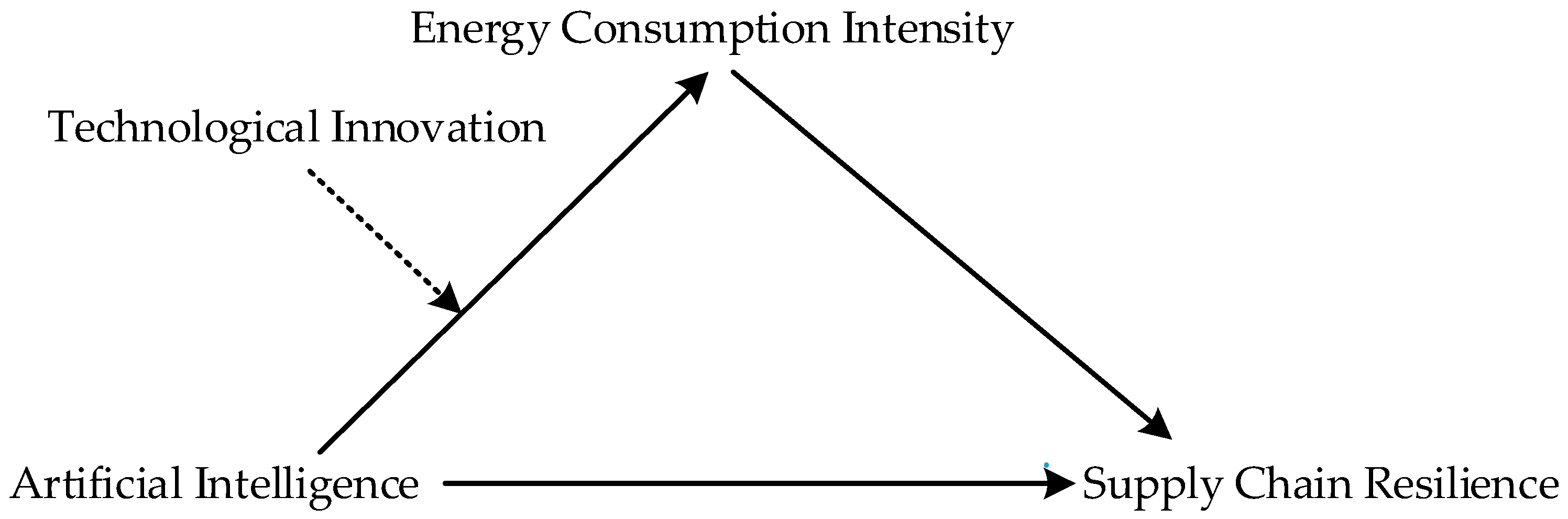

5.1. Impact Mechanism Testing

5.2. Heterogeneity Analysis

5.2.1. Analysis of Heterogeneity at the Regional Level

5.2.2. Heterogeneity Analysis Based on Time

6. Conclusions and Policy Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Analysis of the Current Development Status and Future Prospects of the Semiconductor Industry in 2025. Available online: https://www.chinairn.com/scfx/20250606/173932934.shtml (accessed on 26 July 2025).

- McKinsey & Company. Risks, Resilience, and Rebalancing of Global Value Chains. Available online: https://www.mckinsey.com/capabilities/operations/our-insights/risk-resilience-and-rebalancing-in-global-value-chains (accessed on 26 July 2025).

- Wang, B.; He, J.; Wang, H. The Macroeconomic Effects of Decoupling in the Information and Communication Technology Industry: A Perspective from Production Networks. Econ. Theory Econ. Manag. 2024, 44, 143–162. [Google Scholar]

- Song, H. AI-based Intelligent Supply Chain: Theoretical Exploration and Prospects. China Circ. Econ. 2024, 38, 44–54. [Google Scholar] [CrossRef]

- Chen, J.-K.; Huang, T.-Y. The Multi-Level Hierarchical Structure of the Enablers for Supply Chain Resilience Using Cloud Model-DEMATEL–ISM Method. Sustainability 2022, 14, 12116. [Google Scholar] [CrossRef]

- Rahman, S.; Hossain, N.U.I.; Govindan, K.; Nur, F.; Bappy, M. Assessing Cyber Resilience of Additive Manufacturing Supply Chain Leveraging Data Fusion Technique: A Model to Generate Cyber Resilience Index of a Supply Chain. CIRP J. Manuf. Sci. Technol. 2021, 35, 911–928. [Google Scholar] [CrossRef]

- Barhmi, A.; Hajaji, O. Multidisciplinary Approach to Supply Chain Resilience: Conceptualization and Scale Development. Cent. Eur. Bus. Rev. 2023, 12, 43–69. [Google Scholar] [CrossRef]

- Pettit, T.J.; Fiksel, J.; Croxton, K.L. Ensuring Supply Chain Resilience: Development of a Conceptual Framework. J. Bus. Logist. 2010, 31, 1–21. [Google Scholar] [CrossRef]

- Kazemian, I.; Torabi, S.A.; Zobel, C.W.; Li, Y.; Baghersad, M. A Multi-Attribute Supply Chain Network Resilience Assessment Framework Based on SNA-Inspired Indicators. Oper. Res. 2022, 22, 1853–1883. [Google Scholar] [CrossRef]

- Li, R.; Dong, Q.; Jin, C.; Kang, R. A New Resilience Measure for Supply Chain Networks. Sustainability 2017, 9, 144. [Google Scholar] [CrossRef]

- Sezer, M.D.; Ozbiltekin-Pala, M.; Kazancoglu, Y.; Garza-Reyes, J.A.; Kumar, A.; Kumar, V. Investigating the Role of Knowledge-Based Supply Chains for Supply Chain Resilience by Graph Theory Matrix Approach. Oper. Manag. Res. 2023, 16, 1220–1230. [Google Scholar] [CrossRef]

- Singh, C.S.; Soni, G.; Badhotiya, G.K. Performance Indicators for Supply Chain Resilience: Review and Conceptual Framework. J. Ind. Eng. Int. 2019, 15, 105–117. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, W.; Wang, D.; Dou, S.; Xu, D. Resilience evaluation of China’s copper resources industrial chain and supply chain. Resour. Sci. 2023, 45, 1761–1777. [Google Scholar] [CrossRef]

- Luo, X.; Kang, K.; Lu, L.; Yu, C.; Li, C.; Li, B.; Hu, S.; Qi, X.; Zhou, Y. Resilience Evaluation of Low-Carbon Supply Chain Based on Improved Matter-Element Extension Model. PLoS ONE 2024, 19, e0301390. [Google Scholar] [CrossRef]

- Ruel, S.; El Baz, J.; Ivanov, D.; Das, A. Supply Chain Viability: Conceptualization, Measurement, and Nomological Validation. Ann. Oper. Res. 2024, 335, 1107–1136. [Google Scholar] [CrossRef]

- Tsolakis, N.; Zissis, D.; Tjahjono, B. Scrutinising the Interplay between Governance and Resilience in Supply Chain Management: A Systems Thinking Framework. Eur. Manag. J. 2023, 41, 164–180. [Google Scholar] [CrossRef]

- Chen, J. AI-Driven Supply Chain Transformation: Platform Reconfiguration, Ecology Reinvention and Advantage Reconstruction. Contemp. Econ. Manag. 2023, 45, 50–63. [Google Scholar] [CrossRef]

- Song, H.; Han, M.; Shen, L. How Does AI Play a Role in Shaping Supply Chain Resilience: A Case Study Based on Maitrox’s Global After-Sales Supply Chain Management Practice. China Ind. Econ. 2024, 5, 174–192. [Google Scholar] [CrossRef]

- Lyu, Y.; Zhang, H.; Gao, K. On Extension of China’s Industrial Chain in the Era of Artificial Intelligence: Evidence from Firms’ Imports of Industrial Intelligent Equipment. China Ind. Econ. 2024, 20, 56–74. [Google Scholar] [CrossRef]

- Liu, X.; Han, X. Artificial Intelligence and Manufacturing Resilience: Intrinsic Mechanisms and Empirical Tests. Econ. Manag. 2023, 45, 48–67. [Google Scholar] [CrossRef]

- Zhang, R. Digital Technology and Supply Chain Efficiency: Theoretical Mechanism and Empirical Evidence. Res. Econ. Manag. 2022, 43, 60–76. [Google Scholar] [CrossRef]

- Lyu, Y.; Zhang, J. Artificial Intelligence and Improving the Resilience of the Industrial Chain. J. Xi’an Jiaotong Univ. Soc. Sci. 2024, 44, 29–38. [Google Scholar] [CrossRef]

- Xu, W.; Mu, Y.; Zhou, J.; Liu, C. The Impact and Mechanism of Artificial Intelligence Technology Innovation on Industrial Chain Modernization. Sci. Technol. Prog. Policy 2025, 42, 14–24. [Google Scholar]

- Gu, C.; Zhang, S. Digital Economy Development and Industry Chain Resilience Improvement. Commer. Res. 2023, 65, 1–11. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Z. The Impact of New Production Factors on the Resilience of ICT Manufacturing Supply Chain. Sci. Technol. Prog. Policy 2025, 42, 32–43. [Google Scholar]

- Lü, Y. Risk Prevention of Resilience in China’s Industrial and Supply Chains and Mechanism Pathways for Empowering New Quality Productive Forces. Acad. Forum. 2025, 48, 25–37. [Google Scholar] [CrossRef]

- Kocabasoglu-Hillmer, C.; Roden, S.; Vanpoucke, E.; Son, B.; Lewis, M.W. Radical Innovations as Supply Chain Disruptions? A Paradox between Change and Stability. J. Supply Chain Manag. 2023, 59, 3–19. [Google Scholar] [CrossRef]

- Scholten, K.; Schilder, S. The Role of Collaboration in Supply Chain Resilience. Supply Chain Manag. Int. J. 2015, 20, 471–484. [Google Scholar] [CrossRef]

- Fattahi, M.; Govindan, K.; Maihami, R. Stochastic Optimization of Disruption-Driven Supply Chain Network Design with a New Resilience Metric. Int. J. Prod. Econ. 2020, 230, 107755. [Google Scholar] [CrossRef]

- Vali-Siar, M.M.; Shekarabi, H.; Roghanian, E. A Novel Multi-Objective Stochastic Model and a Novel Hybrid Metaheuristic for Designing Supply Chain Network under Disruption Risks to Enhance Supply Chain Resilience. Decis. Sci. Lett. 2024, 13, 921–950. [Google Scholar] [CrossRef]

- Syntetos, A.A.; Babai, Z.; Boylan, J.E.; Kolassa, S.; Nikolopoulos, K. Supply Chain Forecasting: Theory, Practice, Their Gap and the Future. Eur. J. Oper. Res. 2016, 252, 1–26. [Google Scholar] [CrossRef]

- Zamani, E.D.; Smyth, C.; Gupta, S.; Dennehy, D. Artificial Intelligence and Big Data Analytics for Supply Chain Resilience: A Systematic Literature Review. Ann. Oper. Res. 2023, 327, 605–632. [Google Scholar] [CrossRef]

- Yamin, M.A.; Almuteri, S.D.; Bogari, K.J.; Ashi, A.K. The Influence of Strategic Human Resource Management and Artificial Intelligence in Determining Supply Chain Agility and Supply Chain Resilience. Sustainability 2024, 16, 2688. [Google Scholar] [CrossRef]

- Kim, Y.; Chen, Y.; Linderman, K. Supply Network Disruption and Resilience: A Network Structural Perspective. J. Oper. Manag. 2015, 33–34, 43–59. [Google Scholar] [CrossRef]

- Chao, X.; Lian, Y.; Yuan, R.; Chen, S. Digital Infrastructure Construction and Industrial Chain Resilience: Empirical Analysis Based on Industrial Chain Recovery Capability Data. J. Quant. Technol. Econ. 2024, 41, 112–131. [Google Scholar] [CrossRef]

- Ge, X.; Xie, J.; Yang, H. Digital Transformation and the Resilience of Enterprise Supply Chain: Evidence from Chinese Listed Companies and Suppliers. J. Zhongnan Univ. Econ. Law 2024, 3, 136–150. [Google Scholar] [CrossRef]

- Tao, F.; Wang, X.; Xu, Y.; Zhu, P. Digital Transformation, Resilience of Industrial Chain and Supply Chain, and Enterprise Productivity. China Ind. Econ. 2023, 5, 118–136. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Yu, H. A New Way to Alleviate Bullwhip Effect: An Intelligent Decision-making Robot Based on Man-robot Cooperation. Chin. J. Manag. Sci. 2024, 32, 113–120. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S. Supply Chain Management for Improved Energy Efficiency: Review and Opportunities. Energies 2017, 10, 1618. [Google Scholar] [CrossRef]

- Chen, J.; Wen, H. The Application of Complex Network Theory for Resilience Improvement of Knowledge-Intensive Supply Chains. Oper. Manag. Res. 2023, 16, 1140–1161. [Google Scholar] [CrossRef]

- Li, L.; Zhou, Y. Can Technological Progress Improve Energy Efficiency? An Empirical Examination Based on China’s Industrial Sector. Manag. World 2006, 1, 82–89. [Google Scholar] [CrossRef]

- Chen, X.; Xu, S.; Lian, Y. Factor Substitution Elasticity and Biased Technology’s Effects on Industrial Energy Intensity. J. Quant. Tech. Econ. 2015, 32, 58–76. [Google Scholar] [CrossRef]

- Acemoglu, D.; Aghion, P.; Bursztyn, L.; Hemous, D. The Environment and Directed Technical Change. Am. Econ. Rev. 2012, 102, 131–166. [Google Scholar] [CrossRef] [PubMed]

- Sheffi, Y.; Rice, J.B., Jr. A Supply Chain View of the Resilient Enterprise. MIT Sloan Manag. Rev. 2005, 47, 41–48. [Google Scholar]

- Martin, R.; Sunley, P.; Gardiner, B.; Tyler, P. How Regions React to Recessions: Resilience and the Role of Economic Structure. Reg. Stud. 2016, 50, 561–585. [Google Scholar] [CrossRef]

- Han, X.; Fu, L.; Lyu, C.; Peng, J. Improving Resilience with Intelligent Manufacturing: Mechanism and Evidence for Intelligent Manufacturing to Enhance Industrial Resilience. R D Manag. 2023, 35, 46–59. [Google Scholar] [CrossRef]

- Huang, X.; Wan, S.; Gong, M. Can Regional Trade Agreements Strengthen the Resilience of China’s Manufacturing Industry Chain? An Empirical Study of the China—ASEAN Free Trade Area. Comp. Econ. Soc. Syst. 2025, 1, 41–53. [Google Scholar]

- Yang, H.; Fu, Q.; Li, L. Research on the mechanism and effect of digital transformation on the resilience of industrial chain —Comparison of resilience dimensions of manufacturing industrial chain. Stud. Sci. Sci. 2025, 14, 3481–3488. [Google Scholar] [CrossRef]

- Wang, X.; Fan, G.; Hu, L. Zhongguo Fen Shengsheng Shichanghua Zhishu Baogao (2021). In China Provincial Marketization Index Report (2021); Social Sciences Academic Press: Beijing, China, 2021. [Google Scholar]

- Chen, N.; Cai, Y. The Development Quality and Regional Characteristics of China’s ICT Manufacturing Industry in the Digital Economy Boom: An Empirical Analysis Based on Provincial Data. J. Grad. Sch. Chin. Acad. Soc. Sci. 2019, 5, 23–39. [Google Scholar]

- Hötte, K.; Tarannum, T.; Verendel, V.; Bennett, L. Measuring Artificial Intelligence: A Systematic Assessment and Implications for Governance 2024. arXiv 2022, arXiv:2204.10304. [Google Scholar]

- Xu, N.; Mao, J.; Mao, X.; Wang, Y. Computility Deployment, Cross-Domain Data Flow and Enterprise Total Factor Productivity: Evidence from Intelligent Computing Centers. China Ind. Econ. 2025, 4, 61–79. [Google Scholar] [CrossRef]

- Autor, D.H. Why Are There Still so Many Jobs? The History and Future of Workplace Automation. J. Econ. Perspect. 2015, 29, 3–30. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. Robots and Jobs: Evidence from US Labor Markets. J. Polit. Econ. 2020, 128, 2188–2244. [Google Scholar] [CrossRef]

- Danmaraya, I.A.; Hassan, S. Electricity Consumption and Manufacturing Sector Productivity in Nigeria: An Autoregressive Distributed Lag-Bounds Testing Approach. Int. J. Energy Econ. Policy 2016, 6, 195–201. [Google Scholar]

- Xu, Y.; Zhang, Q. Decomposition Effects of Energy Consumption in China’s Manufacturing Industry: A Study Based on the LMDI Model. J. Southeast Univ. (Philos. Soc. Sci.) 2011, 13, 55–60+127. [Google Scholar] [CrossRef]

- Norelli IV, M.A. Reducing Energy Usage in a Manufacturing Facility Through a Behavior Change Based Approach. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2010. [Google Scholar]

- Gelenbe, E. Electricity Consumption by ICT: Facts, Trends, and Measurements. Ubiquity 2023, 2023, 1–15. [Google Scholar] [CrossRef]

- Huang, L.; Lin, Z.; Wang, X. Industrial Robot Application and Global Value Chain Reconstruction—Based on the Perspective of Bargaining Power of Export Products. China Ind. Econ. 2023, 2, 74–92. [Google Scholar] [CrossRef]

- Klimek, P.; Poledna, S.; Thurner, S. Quantifying Economic Resilience from Input–Output Susceptibility to Improve Predictions of Economic Growth and Recovery. Nat. Commun. 2019, 10, 1677. [Google Scholar] [CrossRef]

- Li, M.; Wang, X. How Regions React to Economic Crisis: Regional Economic Resilience in a Chinese Perspective. Sage Open 2022, 12, 21582440221142507. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, H.; Huang, S. The influence and path identification of the national unified large market on the resilience of manufacturing industry. Chongqing Soc. Sci. 2024, 54–72. [Google Scholar] [CrossRef]

- Zhang, J.; Fan, Y. Innovation Input and Enterprise Resilience: Internal Mechanism and Industrial Chain Cooperation. Econ. Manag. 2024, 46, 51–71. [Google Scholar] [CrossRef]

- Li, L.; Liu, R. Producer Services Agglomeration and the Resilience of Urban Manufacturing Industry. Financ. Econ. 2021, 11, 64–79. [Google Scholar]

- Zhang, W.; Li, H.; Zhang, T. Measuring the Resilience of China’s Manufacturing Industry Chain and Its Spatial-temporal Differentiation. Econ. Geogr. 2023, 43, 134–143. [Google Scholar] [CrossRef]

- Cui, L.; Weng, S.; Mo, J.; Song, M.; Xia, Y. Embargo Alliance, Supply Chain Disruption and China’s Macroeconomic Vulnerability: Taking Chips as an Example. J. Financ. Econ. Res. 2022, 48, 92–105+165. [Google Scholar] [CrossRef]

- Han, D. The Growth of Service Sectors, Institutional Environment and Quality Development in China’s Manufacturing. Systems 2023, 11, 128. [Google Scholar] [CrossRef]

- Kassa, A. Artificial Intelligence Techniques for Enhancing Supply Chain Resilience: A Systematic Literature Review, Holistic Framework, and Future Research. Ind. Eng. 2023, 186, 109714. [Google Scholar] [CrossRef]

- Xie, W.; Lin, M.; Zheng, D.; Qin, L.; Yu, J. What Mechanisms Does Artificial Intelligence Technology Employ to Foster the Transformation and Upgrading of Manufacturing Firms: A Chain-mediated Role of Data Element and Internal Control. Technol. Econ. 2025, 44, 72–88. [Google Scholar]

- Jiang, T. Mediating Effects and Moderating Effects in Causal Inference. China Ind. Econ. 2022, 5, 100–120. [Google Scholar] [CrossRef]

- Li, Y.; Lin, Y.; Li, D. How Does the Application of AI Technologies Affect Firm Innovation. China Ind. Econ. 2024, 10, 155–173. [Google Scholar] [CrossRef]

- Wen, W.; Xiao, Y.; Niu, Y. Artificial Intelligence Technology Level and Corporate Investment Efficiency. Econ. Manag. 2025, 47, 103–122. [Google Scholar] [CrossRef]

- Masood, T.; Israr, A.; Zubair, M.; Qazi, U.W. Assessing Challenges to Sustainability and Resilience of Energy Supply Chain in Pakistan: A Developing Economy from Triple Bottom Line and UN SDGs’ Perspective. Int. J. Sustain. Energy 2023, 42, 268–288. [Google Scholar] [CrossRef]

- Brandon-Jones, E.; Squire, B.; Autry, C.W.; Petersen, K.J. A Contingent Resource-based Perspective of Supply Chain Resilience and Robustness. J. Supply Chain Manag. 2014, 50, 55–73. [Google Scholar] [CrossRef]

- Hald, K.S.; Coslugeanu, P. The Preliminary Supply Chain Lessons of the COVID-19 Disruption—What Is the Role of Digital Technologies? Oper. Manag. Res. 2022, 15, 282–297. [Google Scholar] [CrossRef]

| First-Level Indicators | Second-Level Indicators | Third-Level Indicators | Basic Indicators |

|---|---|---|---|

| Resilience of the ICT manufacturing supply chain | Resistance capacity [46,47,48] | risk prevention capabilities [20] | total assets of industrial enterprises above designated size [48] |

| average number of employees [48] | |||

| risk control capabilities | debt-to-equity ratio | ||

| current assets | |||

| Recovery capability [46,48] | industrial benefits | cost-to-income ratio [48] | |

| return on assets [47] | |||

| industrial support [13] | education expenditure [46] | ||

| number of Internet broadband access ports per capita [46,48] | |||

| average road mileage per capita [48] | |||

| Adaptability [46] | external dependencies | imports | |

| foreign ownership ratio | |||

| adjustability | ICT main business revenue/total manufacturing revenue | ||

| inventory composition ratio | |||

| Innovation capability [20] | innovation investment | full-time equivalent R&D personnel in high-tech enterprises [48] | |

| internal expenditure on R&D by high-tech enterprises [48] | |||

| innovative output | number of invention patents held by high-tech enterprises [47] | ||

| new product sales |

| Variables | Model 1 | Model 2 | Model 3 | Model 4 |

|---|---|---|---|---|

| AI | 0.320 *** (5.647) | 0.311 * (1.772) | 0.295 *** (2.328) | 0.380 ** (2.128) |

| eco | 0.099 (0.575) | 0.087 (0.421) | ||

| gov | 0.143 ** (2.430) | 0.125 ** (2.184) | ||

| size | 0.110 ** (2.313) | 0.096 (1.329) | ||

| edu | 0.145 * (1.719) | 0.170 (1.414) | ||

| tech | −0.680 * (−1.717) | −0.768 * (−1.921) | ||

| Provincial fixed effects | Yes | Yes | Yes | Yes |

| Time fixed effects | No | Yes | No | Yes |

| N | 348 | 348 | 348 | 348 |

| Adj.R2 | 0.556 | 0.087 | 0.617 | 0.203 |

| Variables | Model 1 | Model 2 | Model 3 |

|---|---|---|---|

| AI | 0.289 *** (4.995) | 0.241 *** (3.525) | 0.271 *** (5.964) |

| L.SCR | 0.307 ** (1.862) | ||

| control variables | Yes | Yes | Yes |

| First stage F statistic | 13.283 *** | 10.612 *** | |

| Cragg-Donald Wald F statistic | 189.931 *** | 121.264 *** | |

| AR(1) | 0.002 *** | ||

| AR(2) | 0.246 | ||

| Hansen | 0.586 |

| Variables | Model 1 | Model 2 | Model 3 | Model 4 | Model 5 |

|---|---|---|---|---|---|

| AI | 0.3763 ** (2.055) | 0.315 * (2.116) | 0.467 *** (2.700) | 0.380 ** (2.128) | 0.467 *** (8.683) |

| control variables | Yes | Yes | Yes | Yes | Yes |

| fixed effects | Yes | Yes | Yes | Yes | Yes |

| N | 348 | 232 | 300 | 342 | 348 |

| Adj.R2 | 0.293 | 0.117 | 0.287 | 0.203 | 0.287 |

| Variables | (1) SCR | (2) EC | (3) EC | (4) EC |

|---|---|---|---|---|

| AI | 0.380 ** (2.128) | −0.077 ** (−2.249) | −0.082 * (−1.747) | −0.102 * (−1.875) |

| TI | −0.007 (0.298) | −0.056 ** (−2.474) | ||

| eco | 0.087 (0.421) | −0.571 *** (−4.585) | −0.571 *** (−4.556) | −0.562 *** (−4.454) |

| gov | 0.125 ** (2.184) | −0.022 (−0.632) | −0.023 (−0.651) | −0.022 (−0.623) |

| size | 0.096 (1.329) | 0.014 (0.363) | 0.014 (0.366) | 0.015 (0.399) |

| edu | 0.170 (1.414) | 0.001 (−0.002) | −0.002 (−0.036) | −0.002 (−0.039) |

| tech | −0.768 * (−1.921) | 0.213 (0.858) | 0.219 (0.873) | 0.262 (1.042) |

| AI TI | 0.096 ** (2.001) | |||

| Bootstrap Test | [0.0990, 0.3858] | |||

| fixed effects | Yes | Yes | Yes | Yes |

| N | 348 | 348 | 348 | 348 |

| Variables | Regional Heterogeneity | Time Heterogeneity | ||

|---|---|---|---|---|

| (1) | (2) | (3) | (4) | |

| Eastern | Central | Western | Public Health Emergency | |

| AI | 0.665 *** (5.084) | 0.041 (0.303) | 0.223 *** (3.292) | 0.397 ** (2.081) |

| eco | 0.176 (0.223) | 0.015 (0.068) | 0.341 (0.923) | 0.079 (0.466) |

| gov | 0.198 (1.360) | −0.146 (−0.986) | 0.165 *** (4.649) | 0.125 ** (2.189) |

| size | −0.121 (−0.610) | 0.150 *** (3.473) | 0.072 (1.087) | 0.098( 1.314) |

| edu | 0.282 (0.913) | 0.080 (0.474) | 0.241 ** (2.553) | 0.170 (1.287) |

| tech | −2.256 (−2.290) | 0.003 (0.008) | −0.468 *** (−3.187) | −0.760 * (−1.893) |

| AI cov | −0.020 (−0.386) | |||

| fixed effects | Yes | Yes | Yes | Yes |

| N | 348 | 348 | 348 | 348 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, D.; Jiao, D.; Tu, Y. Artificial Intelligence, Energy Consumption Intensity, and Supply Chain Resilience in China’s ICT Manufacturing Industry. Sustainability 2025, 17, 10253. https://doi.org/10.3390/su172210253

Han D, Jiao D, Tu Y. Artificial Intelligence, Energy Consumption Intensity, and Supply Chain Resilience in China’s ICT Manufacturing Industry. Sustainability. 2025; 17(22):10253. https://doi.org/10.3390/su172210253

Chicago/Turabian StyleHan, Dechao, Dongliang Jiao, and Yayi Tu. 2025. "Artificial Intelligence, Energy Consumption Intensity, and Supply Chain Resilience in China’s ICT Manufacturing Industry" Sustainability 17, no. 22: 10253. https://doi.org/10.3390/su172210253

APA StyleHan, D., Jiao, D., & Tu, Y. (2025). Artificial Intelligence, Energy Consumption Intensity, and Supply Chain Resilience in China’s ICT Manufacturing Industry. Sustainability, 17(22), 10253. https://doi.org/10.3390/su172210253