Abstract

A very important issue in urban agglomerations is the proper management of green waste while reducing its negative impact on the environment. One potential solution is the utilization of green biomass—originating from the maintenance of parks, squares, and home gardens—for the production of compost and compost-based pellets as organic fertilizers. The aim of this study was to produce compost-based pellets intended for fertilization purposes from compost derived from green waste and conifer sawdust, and to analyze their mechanical and chemical properties. Ten variants of pellets with different compost-to-sawdust ratios were evaluated. Compost-based pellets exhibited the highest initial mechanical strength; however, their resistance to external loads decreased over time, whereas the best long-term stability was observed in pellets containing 50% sawdust. The seasoning process influenced the stabilization or improvement of the mechanical properties of certain mixtures. Chemical analyses showed that compost-based pellets contained the highest concentrations of nutrients (N, P, K), while increasing the proportion of sawdust reduced their fertilizing value. No exceedances of permissible heavy metal limits were detected. The results confirm the suitability of compost-based pellets made from green biomass as a sustainable alternative to mineral fertilizers, supporting the principles of the circular economy.

1. Introduction

Modern agriculture faces numerous challenges associated with the need to maintain high production efficiency while simultaneously minimizing its negative environmental impact. Reviews indicate that intensive systems, characterized by high mineral fertilizer inputs and monoculture practices, contribute to soil degradation, loss of biodiversity, acidification, and the deterioration of surface and groundwater quality [1,2].

In the era of agrotechnical intensification and progressing climate change, practices that promote the sustainable management of natural resources are gaining increasing importance. One of the key issues in this context is the effective utilization of organic waste, particularly green biomass, the quantity of which continues to increase as a result of horticultural, municipal, and agricultural activities [3]. Green biomass—including plant residues, mown grass, leaves, and pruned branches—can be processed through composting, leading to the formation of valuable organic fertilizers [4].

Compost obtained from green biomass is a rich source of organic matter and essential macro- and microelements necessary for plant growth and development. Moreover, it improves soil structure, enhances water retention capacity, and stimulates the activity of soil microorganisms [5]. For instance, a meta-analysis demonstrated that the application of green waste compost significantly increased soil organic carbon, total nitrogen, and available potassium contents [6]. Due to these properties, green waste compost represents a viable alternative to mineral fertilizers, whose long-term use contributes to soil degradation and water contamination. Studies also emphasize that composts play a key role in the circular economy and in improving resource use efficiency in agriculture [7].

Although the topic of compost-based pellets derived from green biomass has been gaining attention, the literature indicates that there is still a relatively limited number of studies comprehensively addressing both the mechanical properties of such materials (e.g., durability, resistance to disintegration during transport) and their chemical properties (macro- and microelement content and heavy metal profiles) in the context of their potential use as alternative fertilizers [8].

Environmental safety is also of particular concern, as the content of heavy metals in composts, compost-based pellets, and organic fertilizers remains a critical factor limiting their agricultural application. Literature reviews indicate that proper quality control, raw material selection, and processing technology are essential to ensure compliance with regulatory standards for heavy metals and other potential contaminants [9].

Furthermore, Svensson et al. [8] highlighted that while many studies have focused on the use of agricultural residues for pelletization, the aspects of the mechanical and chemical properties of organic fertilizers derived from green biomass still require further exploration. Recently, increasing attention has also been devoted to the form of fertilizer application—including granulation and pelletization technologies—which improve product usability, facilitate storage and application, and reduce odor emissions and nutrient losses. Studies have shown that granulated organic fertilizers derived from compost exhibit greater chemical and microbiological stability compared with their loose counterparts. For example, a study evaluating compost-based pellets confirmed their compliance with heavy metal safety standards [10].

In view of the above, the present study aimed to produce compost-based pellets from waste generated during the maintenance of green areas (green biomass) and to perform a detailed assessment of their mechanical and chemical properties, including heavy metal content, with regard to their potential use as alternative fertilizers. The analysis covered both the effect of mixture composition (the proportion of compost and coniferous sawdust) and the biomass collection period on the properties of the resulting material. This study, therefore, seeks to fill an existing research gap concerning the utilization of compost-based pellets derived from green biomass by providing an integrated evaluation of their mechanical, chemical, and environmental characteristics.

2. Materials and Methods

2.1. Research Material

In this study, compost-based pellets were produced and analyzed, originating from waste generated during the maintenance and care of green areas in the city of Rzeszów (Podkarpackie Voivodeship, Poland). Plant biomass used for compost production included leaves, branches from parks and squares, and plant-derived waste from households within the city. Additionally, conifer sawdust obtained from a local sawmill was used as a binding agent during pellet production. The research material consisted of 6 mm diameter compost-based pellets with varying compost-to-sawdust ratios, produced in the laboratory of the University of Rzeszów.

The composting process was carried out at the Municipal Waste Management Company in Rzeszów. Upon completion of substrate production, random samples of the compost were collected and used for pellet manufacturing. Since compost at this facility is produced in six-month cycles, the material for the study was collected in June and December 2024. Due to the challenge of managing large amounts of compost generated from green waste, the analysis aimed to assess its suitability for use as a fertilizer for cultivated plants.

The first stage of the study involved collecting and air-drying the material, followed by grinding it in an Essa CM 1000 shredder (Atest Sp. z o.o., Kielce, Poland). Conifer sawdust was used as an additional component for pellet production. The next step involved producing five types of compost-based pellets using a Prime-200 pelletizing machine (Techno-MaszBud, Ciemne, Poland). Before pelletization, all feedstock materials were conditioned to a moisture content of 10 ± 1% (w.b.), determined using the oven-drying method at 105 °C. The pellets were formed using a Prime-200 pelletizer (Techno-MaszBud, Ciemne, Poland) equipped with a flat die of 6 mm hole diameter. During operation, the die temperature was maintained at 90–100 °C, and the roller pressure was approximately 200–250 MPa, with a production capacity of 80 kg·h−1. The resulting pellets had an average length of 15–25 mm. The following pellet types (Table 1) were used for further analysis.

Table 1.

Composition and coding of pellets produced from compost and conifer sawdust collected in different periods of 2024.

2.2. Mechanical Testing of Pellets

The mechanical properties of the pellets were evaluated based on uniaxial compression tests of individual 6 mm diameter pellets along the horizontal axis, using a Zwick/Roell Z010 testing machine (Zwick Roell Polska Sp. z o.o. Sp. K., Wrocław, Poland), in accordance with the methodology described by Gorzelany et al. [11].

2.3. Chemical Analyses

The aim of this study was to determine selected chemical parameters of the analyzed pellets, including the concentrations of copper (Cu), cadmium (Cd), lead (Pb), zinc (Zn), and nickel (Ni), using inductively coupled plasma–atomic emission spectroscopy (ICP-AES). Total trace metal concentrations were determined after the digestion of samples with aqua regia in a microwave system. The concentrations of Cu, Cd, Pb, Zn, and Ni in the digested samples were then measured using ICP-AES (iCAP 7400, Thermo Fisher Scientific, Waltham, MA, USA).

In addition, total nitrogen content was determined using the Kjeldahl method, while sodium (Na) and potassium (K) were measured by flame atomic emission spectrometry (FAES), and magnesium (Mg) and calcium (Ca) were analyzed using atomic absorption spectrometry (AAS). Total phosphorus (P) was determined spectrophotometrically using the ammonium molybdate method. Furthermore, the contents of mineral and organic matter were assessed gravimetrically using an SNOL 8.2/1100 LZM 01 furnace (AB UMEGA Group, Utena, Lithuania).

2.4. Statistical Analysis

Statistical analyses were performed using STATISTICA 12.5 PL software (StatSoft Tulsa, OK, USA). For all analyses, the significance level was set at p ≤ 0.05. Data were analyzed separately for each type of pellet. To assess the significance of the effect of different waste mixtures on the quality parameters of the pellets, analysis of variance (ANOVA) was applied.

A factorial or mixed-effects analysis (mixture × storage time × season) was not applied due to the experimental design (independent batches, limited replication, and partial confounding between season and batch).

3. Results and Discussion

3.1. Measurement of Mechanical Properties

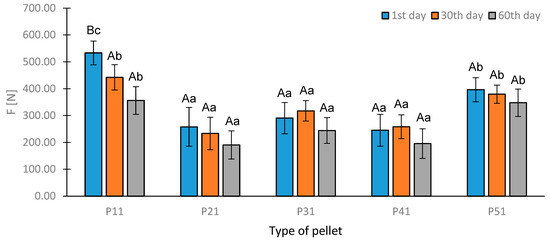

Mechanical parameters determine the resistance of compost-based pellets to external loads, and their appropriate values are crucial for ensuring the durability of individual granules and preventing disintegration during transport and storage (Figure 1).

Figure 1.

Mean crushing force values of individual pellets produced from compost collected in the first half of 2024 and sawdust during uniaxial compression (horizontal axis) on the 1st, 30th, and 60th day of storage. Lowercase letters indicate significant differences between pellets within the same testing period, whereas uppercase letters denote significant differences between different testing periods. Bars represent mean ± SD, n = 3, p < 0.05.

This study presents the results of quasi-static strength tests performed on six types of compost-based pellets to assess the quality of the biomass used for their production. Tests were conducted on the 1st, 30th, and 60th day of storage. The analysis of mechanical properties was carried out for pellets produced from compost obtained in June and December 2024, with varying proportions of sawdust.

On the 1st day of storage, pellets composed entirely of compost (P11) exhibited the highest resistance to damage (~533 N), confirming the good mechanical strength of compost-based pellets made from pure compost. As the proportion of sawdust in the mixture increased, the crushing strength decreased (P21—~257 N, P31—~290 N, P41—~245 N), whereas a noticeable increase was observed for sample P51 (~396 N).

On the 30th day of storage, a reduction in strength was recorded for P11 (~442 N) and P21 (~240 N), indicating a partial loss of cohesion. In contrast, a slight increase for P31 and P41 (to ~317 N and ~258 N, respectively) may have resulted from additional drying and material stabilization. The consistently high values for P51 (~379 N) confirm the good stability of this mixture.

After 60 days of storage, all samples showed a decrease in crushing force, though to varying degrees: P11 dropped to ~356 N yet retained the highest resistance among all variants; P21 decreased further to ~190 N, the lowest value observed; P31 declined to ~250 N; P41 to ~195 N; and P51 to ~347 N, slightly below P11.

Overall, pellets made from pure compost (P11) initially demonstrate the greatest mechanical strength but lose it over time. The addition of sawdust generally reduces crushing force; however, in certain proportions (P51), it appears to stabilize the pellet structure. Pellets with moderate sawdust content (P31, P41) show temporary improvement due to stabilization effects. Sample P51 exhibited the best long-term mechanical stability, suggesting that a 50:50 compost-to-sawdust ratio may be optimal for pellet durability.

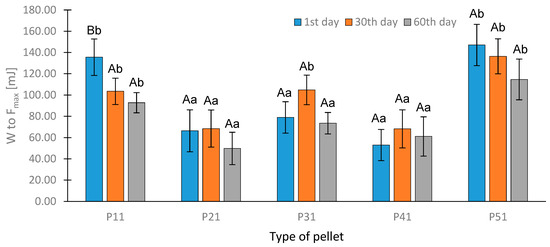

Figure 2 illustrates the changes in work to maximum force (W to Fₘₐₓ, [mJ]) for the five analyzed compost-based pellet types (P11, P21, P31, P41, P51), produced from green biomass compost obtained during the maintenance of urban green areas in the winter–spring period (first half of 2024). The analysis was performed at three storage intervals: 1, 30, and 60 days after pellet production.

Figure 2.

Mean values of energy (W to Fmax) required to crush individual pellet samples made from compost collected in the first half of 2024, with the addition of sawdust, during uniaxial compression (horizontal axis) on the 1st, 30th, and 60th day of storage. Lowercase letters indicate significant differences between pellets within the same testing period, whereas uppercase letters denote significant differences between different testing periods. Bars represent mean ± SD, n = 3, p < 0.05.

On the 1st day of storage, the highest energy value (W to Fₘₐₓ) was recorded for sample P51 (~147 mJ), followed by P11 (~135 mJ), which may indicate the beneficial effect of a higher proportion of conifer sawdust on pellet strength. For P21, P31, and P41, an increase in W to Fₘₐₓ between the 1st and 30th day suggests an improvement in mechanical performance resulting from the seasoning process.

By the 60th day, W to Fₘₐₓ values had decreased compared with earlier measurements, indicating partial structural degradation during storage. Increasing the sawdust content to 50% improved the initial strength of the pellets; however, this effect diminished over time. The seasoning process affected different mixtures in varying ways, emphasizing the importance of monitoring mechanical property changes throughout storage.

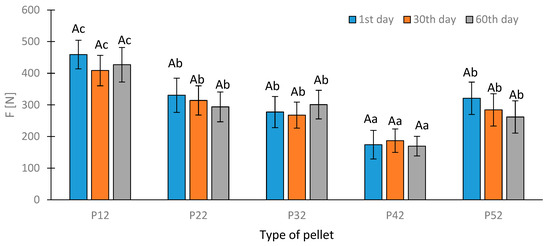

On the 1st day of storage, the highest crushing force was recorded for compost-based pellets (P12, 459.21 N), composed entirely of compost (Figure 3). As the proportion of sawdust in the mixture increased, a systematic decrease in mechanical strength was noted: P22 (~330 N), P32 (~277 N), and P42 (~174 N). Pellets containing 50% compost (P52) exhibited a slightly higher value (~320 N) compared to P32 and P42.

Figure 3.

Mean crushing force values of the tested pellet samples produced from compost collected in the second half of 2024, with the addition of sawdust, during uniaxial compression (horizontal axis) on the 1st, 30th, and 60th day of storage. Lowercase letters indicate significant differences between pellets within the same storage period, whereas uppercase letters denote significant differences between different storage periods. Bars represent mean ± SD, n = 3, p < 0.05.

On the 30th day of storage, an overall decrease in strength was observed across all analyzed compost-based pellets. The greatest reduction occurred for P12 (to approximately 410 N), whereas the strength of P22 and P32 decreased only slightly or remained similar to previous values. The crushing force of P52 (284 N) also confirmed this downward trend.

After 60 days of storage, the crushing force of P12 increased compared with the 30th day, reaching approximately 426 N, which may indicate further stabilization of the pellet structure. In contrast, P22 showed a slight decrease in crushing force, while P42 and P52 continued to decline, reaching approximately 169 N and 261 N, respectively.

Pellets composed entirely of compost (P12) exhibited the highest mechanical strength throughout the entire storage period. Increasing the proportion of conifer sawdust generally led to reduced resistance to mechanical damage, likely due to lower material density and reduced compactibility. Pellets containing 75% compost and 25% sawdust (P32) demonstrated relatively good mechanical stability during storage, suggesting a favorable balance between structural integrity and mechanical strength. After 60 days, strength values varied depending on composition, with some mixtures showing further decreases, stabilization, or—in the case of P12—a slight improvement in mechanical performance.

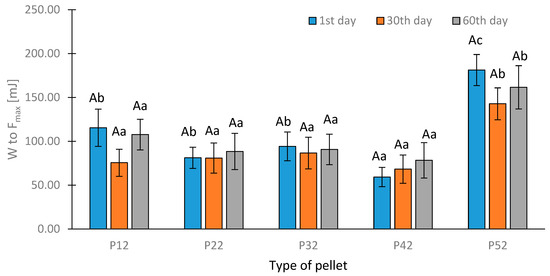

Figure 4 illustrates the changes in mean energy values (W to Fₘₐₓ, [mJ]) for five types of compost-based pellets (P12, P22, P32, P42, P52) produced from green biomass compost obtained during the maintenance of urban green areas in the summer period (second half of 2024), with varying proportions of sawdust. The assessment of this parameter was performed at three storage intervals: the 1st, 30th, and 60th day after pellet production.

Figure 4.

Mean values of energy (W to Fmax) required to crush the tested pellet samples produced from compost collected in the second half of 2024, with varying proportions of sawdust, during uniaxial compression (horizontal axis) on the 1st, 30th, and 60th day of storage. Lowercase letters indicate significant differences between pellets within the same storage period, whereas uppercase letters denote significant differences between different storage periods. Bars represent mean ± SD, n = 3, p < 0.05.

On the 1st day of storage, the highest W to Fₘₐₓ value was recorded for P52 (~181 mJ), indicating the beneficial effect of a high sawdust content (50%) on mechanical strength. Lower values were obtained for P12 (~115 mJ), P22 (~80 mJ), P32 (~92 mJ), and P42 (~60 mJ).

For P42, a notable increase in W to Fₘₐₓ was recorded between the 1st and 60th day of storage (from ~60 mJ to ~78 mJ), which may indicate an improvement in mechanical properties due to seasoning. A similar, though less pronounced, trend was observed for P22 and P32, where the parameter remained relatively stable or increased slightly. In contrast, P12 and P52, despite their initially high energy values, showed a decrease after 30 days of storage, followed by an increase by the 60th day, though not reaching the initial level.

The greatest reduction in mechanical strength occurred in P52—from approximately 180 mJ on the 1st day to about 145 mJ on the 30th day, followed by a slight increase to around 160 mJ after 60 days. P12 also showed a significant drop after 30 days of storage (to approximately 75 mJ), then increased to around 107 mJ by the 60th day.

Increasing the proportion of conifer sawdust in the pellet composition positively affects the initial mechanical strength; however, these parameters may deteriorate during storage. The seasoning process can improve the mechanical properties of certain mixtures, as exemplified by P42. These findings emphasize the importance of monitoring mechanical property changes during storage, particularly when varying the proportions of the analyzed raw materials.

The mechanical strength of pellets is determined based on two main parameters: the quasi-static strength of individual granules (the maximum force or energy required to crush them) and mechanical durability, assessed dynamically using the tumbling method [12]. The quality requirements for minimum durability (≥ 96.5%) are specified in the ISO 17225-2:2021 standard [13].

The literature emphasizes that the addition of lignin-rich materials increases pellet strength [14,15]. Hettiarachchi et al. [16] reported an increase in crushing force after the use of additives such as rice flour or lime, while Butler et al. [17] highlighted the role of lignin as a natural binder, which improves pellet hardness when added up to approximately 30%, whereas higher amounts may cause brittleness.

The obtained results are consistent with the following observations. The pellets containing 50% conifer sawdust (P52) exhibited greater mechanical strength, which can be attributed to the presence of lignin that was not fully depolymerized during pelletization and acted as an effective binder.

Pellet strength is also influenced by factors such as particle size, degree of grinding, pressing temperature and pressure, and feedstock moisture content. Excessive moisture (>20%) reduces pellet quality, while too low a moisture level (5–8%) results in brittleness [18,19]. Compost-based materials, characterized by a fibrous–granular structure and lower lignin content compared with wood, show a reduced self-binding capacity [20]. Therefore, the use of additives that enhance cohesion, such as technical lignin, starch [21], or sawdust [22], is justified.

The measurement of single-pellet strength in the compression test provided valuable insights into their structural integrity; however, further research, including dynamic durability tests [23], is necessary to fully evaluate their mechanical properties in terms of storage stability and applicability in mechanized fertilization processes.

3.2. Assessment of Selected Chemical Properties of Pellets

Table 2 presents the mean values of macronutrients (nitrogen, phosphorus, potassium, sodium, calcium, and magnesium) in pellets produced from compost (green biomass from the maintenance of green areas) and sawdust.

Table 2.

Mean values of macronutrients in pellets produced from compost and sawdust.

The nitrogen (N) content in the analyzed compost-based pellet samples ranged from 11,891.14 mg·kg−1 (P52; containing 50% summer compost and 50% sawdust) to 20,620.44 mg·kg−1 (P12; made from pure summer compost). The highest values were recorded in pellets produced exclusively from compost (P11, P12), confirming the high nitrogen levels typical of plant-derived organic materials. Literature data indicate that nitrogen content in reed biomass usually ranges from 0.5–1.5% of dry matter (5000–15,000 mg·kg−1) [24]. Filipek-Mazur and Gondek [25] reported nitrogen levels of approximately 20,800 mg·kg−1 in compost derived from green waste, consistent with the present results. The nitrogen concentration in green plants depends on the harvest time. Plants collected in spring contain significantly less nitrogen than those harvested in autumn due to mineral leaching by precipitation [26]. Other studies confirm that biomass harvested in late autumn exhibits higher nitrogen levels [27,28]. The obtained results indicate that increasing the proportion of sawdust in the mixture leads to a decrease in nitrogen content, consistent with the findings of Bello et al. [29], who reported that coniferous sawdust contains only about 0.04% nitrogen (approximately 400 mg·kg−1 of dry matter).

The total phosphorus (P) content in the analyzed pellets ranged from 1394.20 to 2416.00 mg·kg−1, with the highest values found in samples containing the largest proportion of compost. Compost obtained from biomass collected in the first half of 2024 contained approximately 30% more phosphorus than compost from the second half of the year, indicating the significance of raw material seasonality. Filipek-Mazur and Gondek [25] reported a phosphorus content of 4900 mg·kg−1 in compost made from urban green waste, while other studies [30] confirmed values around 2400 mg·kg−1. The addition of sawdust reduced the phosphorus content of the pellets, reflecting the low mineral content of wood [31].

The potassium (K) content in the compost-based pellets varied significantly depending on the type of biomass. In samples P11–P51, values ranged from 6770 to 8715 mg·kg−1, whereas in P12–P52, K content reached up to 20,314 mg·kg−1. Higher potassium concentrations were observed in pellets with a greater compost proportion, confirming the high fertilizing potential of plant biomass. An increase in sawdust content corresponded to a systematic decrease in potassium, consistent with previous studies [31]. Research by Buneviciene et al. [32] demonstrated that composts produced from autumn biomass contain substantially more potassium due to its accumulation in plant tissues at the end of the growing season. Similar trends were reported by Rao et al. [33] and Heinsoo et al. [34], confirming that harvest time strongly influences potassium concentration in biomass.

Sodium (Na) occurred in much smaller amounts than other macronutrients, ranging from 540.15 to 896.47 mg·kg−1, with the highest value in P12. The lower sodium content in mixtures containing sawdust results from its limited mineral composition. According to literature data, agricultural composts contain 0.06–0.80% Na (600–8000 mg·kg−1) [35], while an analysis of green waste compost from the University of Minnesota showed a range of 36–921 mg·kg−1 [36], confirming consistency with the present results.

Calcium (Ca) content varied depending on the biomass collection period, with the highest values recorded in pellets produced from material harvested in the second half of 2024. Calcium in plants is a poorly mobile element. Once incorporated into tissues, it does not easily translocate; therefore, accumulation in woody parts increases during autumn. These findings are consistent with Ujj et al. [37], who reported that garden composts contain between 13,200 and 50,000 mg·kg−1 of Ca. Higher calcium levels in autumn biomass may also result from a more advanced compost maturation process [38]. Heinsoo et al. [34] confirmed that autumn-harvested biomass, especially grasses, contains higher macronutrient concentrations, including calcium, compared with spring-harvested material. Conversely, the reduction in Ca content in pellets with sawdust addition results from the considerably lower calcium levels in coniferous wood [31].

The magnesium (Mg) content in the analyzed pellets ranged from 2514.19 mg·kg−1 (P52) to 8290.14 mg·kg−1 (P11). Higher values were found in samples produced from biomass collected in the first half of 2024, while lower values were recorded in pellets from autumn biomass. This pattern is due to the mobility of magnesium in plant tissues and its susceptibility to leaching during periods of intense rainfall [30]. As a component of chlorophyll, Mg undergoes degradation during leaf senescence, leading to its depletion in autumn biomass [39]. Furthermore, limited mineral uptake from the soil in the late phase of the growing season may further reduce Mg levels, particularly in soils poor in this element [40].

Based on the conducted analyses, it can be concluded that compost-based pellets produced from green biomass represent a valuable source of essential nutrients—nitrogen, phosphorus, potassium, calcium, and magnesium—and can serve as effective organic fertilizers. The addition of conifer sawdust reduced the concentrations of these elements, reflecting its low mineral content. However, compost–sawdust mixtures may function as materials that improve soil physicochemical properties. According to Olejarski [41], the application of compost and sawdust enhances soil fertility and microbial activity. Jourgholami et al. [42] demonstrated the effectiveness of sawdust in reducing surface runoff and soil erosion after harvesting, while compost-based fertilizers can be successfully applied in organic farming, horticulture, and soil reclamation as sustainable alternatives to conventional fertilizers [43,44].

Table 3 presents the percentage composition of mineral and organic substances in the analyzed compost-based pellets, produced from green biomass compost collected during the maintenance of urban green areas in two periods of 2024: the winter–spring season (first half of the year) and the summer season (second half of the year), with varying proportions of conifer sawdust in the mixture.

Table 3.

Average values of mineral and organic matter in pellets produced from compost and sawdust.

The analysis showed that with an increasing proportion of sawdust in the pellet composition, the share of organic substances increased, accompanied by a simultaneous decrease in mineral substances. For example, pellets made entirely from compost (P11) contained 43.45% mineral and 56.55% organic substances, whereas pellets containing 50% sawdust (P51) had 28.96% mineral and 71.04% organic content. Similar patterns were observed for pellets produced from summer compost. In the case of P12 (100% compost), the mineral substance content was 43.20% and the organic content 56.80%, while for P52 (50% compost and 50% sawdust), these values were 32.60% and 67.40%, respectively.

A comparison between pellets produced from composts collected in the two periods revealed that summer biomass pellets (P12–P52) contained slightly less mineral and more organic substances than those made from winter–spring compost (P11–P51) at identical mixture ratios. This difference may result from seasonal variations in biomass composition, consistent with studies reporting fluctuations in lignin, cellulose, and mineral compound contents throughout the growing season [45].

The results clearly demonstrate that increasing the proportion of conifer sawdust in the mixture leads to a marked rise in organic matter content at the expense of mineral components. This trend agrees with literature findings showing that conifer sawdust is characterized by high organic content [46] and low mineral levels [47]. Pellets made exclusively from compost (P11, P12) exhibited the highest mineral content—43.45% and 43.20%, respectively—while samples with 50% sawdust (P51, P52) showed reduced values of 28.96% and 32.60%. These findings correspond with reports indicating that plant biomass contains relatively higher levels of mineral compounds, such as silicates and carbonates [48], compared with coniferous sawdust [49].

Although the differences between pellets produced from winter–spring and summer composts were relatively minor, a consistent trend toward lower mineral content in composts obtained in the latter half of the year was observed. This may be attributed to seasonal variations in mineral composition influenced by environmental conditions and plant developmental stages.

From the perspective of fertilizer application, a key parameter characterizing compost-based pellets is the mineral substance content, as it determines the supply of macro- and micronutrients that enhance soil properties and support plant growth [50,51]. The use of pellets made entirely from compost aligns with the principles of the circular economy: converting green waste into valuable fertilizing products reduces biowaste sent to landfills, limits the need for mineral fertilizers, and promotes the sustainable development of agricultural systems [52,53].

The content of heavy metals in organic materials intended for fertilization is a crucial indicator of environmental safety and market authorization (Table 4. In the analyzed pellet samples (P11–P52), five heavy metals were detected: copper (Cu), cadmium (Cd), lead (Pb), zinc (Zn), and nickel (Ni). Their concentrations varied depending on the raw material composition—specifically, the compost-to-sawdust ratio—and the season during which the biomass was collected.

Table 4.

Average contents of heavy metals in the analyzed pellets produced from compost and coniferous sawdust.

The analysis of heavy metal content in the examined compost-based pellets revealed the highest cadmium (Cd) concentration—1.36 mg·kg−1—in sample P12, produced entirely from summer compost. Compost obtained in the second half of 2024 contained significantly higher cadmium levels than that from the first half of the year, likely due to seasonal variations in green biomass composition or environmental contamination of the feedstock [54]. According to the Regulation of the Minister of Agriculture and Rural Development of 18 June 2008 [55], the permissible Cd content in mineral fertilizers in Poland is 50 mg·kg−1 of dry matter. The obtained results indicate that cadmium concentrations in all compost-based pellets were well below this limit, confirming their environmental safety.

Lead (Pb) content ranged from 5.21 to 9.41 mg·kg−1, remaining far below the contamination threshold for organic fertilizers established by the European Union (120 mg·kg−1) [56]. Similarly, nickel (Ni) concentrations, ranging from 11.06 to 40.19 mg·kg−1, did not exceed the permissible value of 50 mg·kg−1 specified in the same regulations [57]. In the analyzed samples, copper (Cu) content ranged from 17.92 to 44.34 mg·kg−1 and zinc (Zn) from 79.25 to 279.20 mg·kg−1. Although Cu and Zn levels were higher than those of Cd or Pb, they remained well below the threshold values defined by EU standards [56]. Both elements are essential micronutrients for plant growth; thus, their presence in organic materials can enhance soil fertility, provided that excessive accumulation is avoided [57].

Based on these findings, pellets produced from pure compost (P11, P12) and compost–sawdust mixtures (P21–P52) can be considered environmentally safe for agricultural use. The heavy metal concentrations remained within the limits of current environmental regulations, confirming their suitability for organic fertilizer applications. Studies by Wang et al. [58] demonstrated that compost enhances root development and transpiration efficiency of maize under water stress, while Kamal et al. [59] reported that compost mitigates salinity stress by protecting photosynthetic pigments, maintaining ionic balance, and enhancing plant tolerance to oxidative stress.

In recent years, the key role of compost in advancing the principles of the circular economy has been increasingly recognized. The composting of biowaste—such as kitchen residues and garden waste—enables its transformation into valuable fertilizer products, thereby reducing the amount of waste sent to landfills or incineration. This process facilitates nutrient recovery, lowers greenhouse gas emissions, and decreases the demand for mineral fertilizers. The present results confirm that utilizing green biomass for compost production provides tangible environmental and economic benefits: reducing waste generation, improving soil quality, and mitigating CO2 and other greenhouse gas emissions [60,61].

4. Conclusions

The conducted research demonstrated that the composition of compost and conifer sawdust mixtures significantly influences both the fertilizing value and mechanical properties of the resulting pellets. Pellets made entirely from green biomass compost exhibited the highest nutrient content (N, P, K, Ca, Mg) and proved suitable for use in organic farming and soil reclamation. The addition of conifer sawdust enhanced mechanical strength and storage stability due to the presence of lignin, but simultaneously reduced the mineral content and, consequently, the fertilizing efficiency. The concentrations of heavy metals (Cd, Pb, Ni, Cu, Zn) in all analyzed samples were well below the permissible limits defined by EU Regulation 2019/1009, confirming the environmental safety of the produced materials. These compost-based pellets represent a sustainable and environmentally friendly solution consistent with the principles of the circular economy by reducing biowaste generation and decreasing the reliance on mineral fertilizers. The obtained results confirm that pellets with favorable mechanical properties and high nutrient content can be effectively used as organic fertilizers. Future studies should include germination and pot experiments to assess nutrient release dynamics and potential phytotoxic effects under field conditions. This approach supports the development of the circular bioeconomy by enabling the conversion of green waste into valuable organic fertilizers. The use of such materials can facilitate the gradual replacement of mineral fertilizers, particularly in urban and peri-urban agricultural systems, contributing to more sustainable and resource-efficient food production.

Author Contributions

Conceptualization, M.Z. and J.G.; methodology, M.Z., K.S., and D.G.; software, M.Z.; validation, M.Z. and B.S.; formal analysis, M.Z. and M.B.; investigation, M.Z. and T.R.S.; resources, M.Z., B.S., and M.B.; data curation, M.Z. and D.G.; writing—original draft preparation, M.Z.; writing—review and editing, J.G., D.G., and K.S.; visualization, M.Z. and T.R.S.; supervision, M.Z. and B.S.; project administration, M.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Țopa, D.-C.; Căpșună, S.; Calistru, A.-E.; Ailincăi, C. Sustainable practices for enhancing soil health and crop quality in modern agriculture: A Review. Agriculture 2025, 15, 998. [Google Scholar] [CrossRef]

- Vitousek, P.M.; Naylor, R.; Crews, T.; David, M.B.; Drinkwater, L.E.; Holland, E.; Johnes, P.J.; Katzenberger, J.; Martinelli, L.A.; Matson, P.A.; et al. Nutrient imbalances in agricultural development. Science 2009, 324, 1519–1520. [Google Scholar] [CrossRef] [PubMed]

- Chew, K.W.; Chia, S.R.; Yen, H.-W.; Nomanbhay, S.; Ho, Y.-C.; Show, P.L. Transformation of biomass waste into sustainable organic fertilizers. Sustainability 2019, 11, 2266. [Google Scholar] [CrossRef]

- Jiao, F.; Zhu, X.; Li, C.; Xie, H.; Li, H. Advancing biomass fermentation and composting for global sustainability: A bibliometric perspective (2019–2024). Discov. Sustain. 2025, 6, 667. [Google Scholar] [CrossRef]

- Manea, E.E.; Bumbac, C.; Dinu, L.R.; Bumbac, M.; Nicolescu, C.M. Composting as a sustainable solution for organic solid waste management: Current practices and potential improvements. Sustainability 2024, 16, 6329. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, L.; Li, Y.; Li, X.; Zhang, X.; Wang, X. Effects of compost application of green waste on soil properties: A meta-analysis. Sustainability 2024, 16, 8877. [Google Scholar] [CrossRef]

- Bohórquez-Sandoval, L.J.; García-Molano, J.F.; Pascual-Valero, J.A.; Ros-Muñoz, M. A comprehensive review on organic waste compost as an effective phosphorus source for sustainable agriculture. Int. J. Recycl. Org. Waste Agric. 2024, 13, 132441. [Google Scholar] [CrossRef]

- Svensson, A.; Almarstrand, M.; Axelsson, J.; Nilsson, M.; Timmermann, E.; Govindarajan, V. Valorising agricultural residues into pellets in a sustainable circular bioeconomy. Probl. Ekorozwoju/Probl. Sustain. Dev. 2024, 19, 272–278. [Google Scholar] [CrossRef]

- Ma, L.; Zhou, Y.; Wang, A.; Li, Q. A potential heavy metals detoxification system in composting: Biotic and abiotic synergy mediated by shell powder. Bioresour. Technol. 2023, 386, 129576. [Google Scholar] [CrossRef]

- Koziak, K.; Krasowska, M.; Piekut, J.; Obidziński, S.; Cwalina, P.; Kowczyk-Sadowy, M.; Kowalewska, O.E. Evaluation of the fertilising properties of composts containing herbal waste. Econ. Environ. 2025, 92, 907. [Google Scholar] [CrossRef]

- Gorzelany, J.; Zardzewiały, M.; Murawski, P.; Matłok, N. Analysis of selected quality features of wood pellets. Agric. Eng. 2020, 24, 5–12. [Google Scholar] [CrossRef]

- Williams, O.; Taylor, S.; Lester, E.; Kingman, S.; Giddings, D.; Eastwick, C. Applicability of mechanical tests for biomass pellet characterisation for bioenergy applications. Materials 2018, 11, 1329. [Google Scholar] [CrossRef] [PubMed]

- ISO 17225-2:2021; Solid Biofuels: Fuel Specifications and Classes—Part 2: Graded Wood Pellets. International Organization for Standardization (ISO): Geneva, Switzerland, 2021.

- Elniski, A.; Dongre, P.; Bujanovic, B.M. Lignin use in enhancing the properties of willow pellets. Forests 2023, 14, 2041. [Google Scholar] [CrossRef]

- Clavijo, L.; Zlatanovic, S.; Braun, G.; Bongards, M.; Dieste, A.; Barbe, S. Eucalyptus kraft lignin as an additive strongly enhances the mechanical resistance of tree-leaf pellets. Processes 2020, 8, 376. [Google Scholar] [CrossRef]

- Hettiarachchi, L.; Jayathillake, N.; Fernando, S.; Gunawardena, S. Effects of compost particle size, moisture content and binding agents on co-compost pellet properties. Int. J. Agric. Biol. Eng. 2019, 12, 184–191. [Google Scholar] [CrossRef]

- Butler, J.W.; Skrivan, W.; Lotfi, S. Identification of optimal binders for torrefied biomass pellets. Energies 2023, 16, 3390. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Ungureanu, N.; Vladut, V.; Voicu, G.; Dinca, M.-N.; Zabava, B.-S. Influence of biomass moisture content on pellet properties—Review. In Proceedings of the 17th International Scientific Conference “Engineering for Rural Development”, Jelgava, Latvia, 23–25 May 2018; pp. 1917–1924. [Google Scholar]

- Papandrea, S.F.; Giuffrè, A.M.; Sicari, V.; Piscopo, A. Pelletization of compost from different mixtures with the addition of exhausted extinguishing powders. Agronomy 2021, 11, 1357. [Google Scholar] [CrossRef]

- Ahn, B.J.; Chang, H.-S.; Lee, S.M.; Choi, D.H.; Cho, S.T.; Han, G.-S.; Yang, I. Effect of binders on the durability of wood pellets fabricated from larix kaemferi c. and liriodendron tulipifera l. sawdust. Renew. Energy 2014, 62, 18–23. [Google Scholar] [CrossRef]

- Peng, J.; Bi, X.T.; Lim, C.J.; Peng, H.; Kim, C.S.; Jia, D.; Zuo, H. Sawdust as an effective binder for making torrefied pellets. Appl. Energy 2015, 157, 491–498. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 17831-1:2015—Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 1: Pellets; ISO: Geneva, Switzerland, 2015; Available online: https://www.iso.org/standard/61616.html (accessed on 1 November 2025).

- Rancane, S.; Karklins, A.; Lazdina, D.; Berzins, P.; Bardule, A.; Butlers, A.; Lazdins, A. The evaluation of biomass yield and quality of phalaris arundinacea and festulolium fertilised with bio-energy waste products. Agron. Res. 2016, 14, 1342–1354. [Google Scholar]

- Filipek-Mazur, B.; Gondek, K. Fertilizer value of compost produced from green waste in kraków. Zesz. Probl. Post. Nauk Roln. 2003, 494, 113–121. (In Polish) [Google Scholar]

- Nilsson, D.; Bernesson, S.; Hansson, P.-A. Pellet production from agricultural raw materials—A systems study. Biomass Bioenergy 2011, 35, 679–689. [Google Scholar] [CrossRef]

- Larsen, S.U.; Lærke, P.E.; Jørgensen, U. Harvest of green willow biomass for feed—Effects of harvest time and frequency on yield, nutrient concentration, silage quality and regrowth. Acta Agric. Scand. Sect. B Soil Plant Sci. 2020, 70, 532–540. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Krzyżaniak, M.; Olba-Zięty, E. Properties of pellets from forest and agricultural biomass and their mixtures. Energies 2025, 18, 3137. [Google Scholar] [CrossRef]

- Bello, D.; Trasar-Cepeda, C.; Leirós, M.C.; Gil-Sotres, F. Effect of sawdust amendment on mineralization of organic nitrogen in a 2,4,5-trichlorophenol contaminated soil. J. Soil Sci. Plant Nutr. 2013, 13, 215–221. [Google Scholar] [CrossRef]

- Łabętowicz, J.; Rutkowska, B.; Ożarowski, G.; Szulc, W. Potential use of “dano” municipal waste compost in agriculture. Acta Agrophys. 2002, 70, 247–255. (In Polish) [Google Scholar]

- Pitman, R.M. Wood ash use in forestry—A review of the environmental impacts. Forestry 2006, 79, 563–588. [Google Scholar] [CrossRef]

- Buneviciene, K.; Drapanauskaite, D.; Mazeika, R.; Baltrusaitis, J. A mixture of green waste compost and biomass combustion ash for recycled nutrient delivery to soil. Agronomy 2021, 11, 641. [Google Scholar] [CrossRef]

- Rao, J.R.; Watabe, M.; Stewart, T.A.; Millar, B.C.; Moore, J.E. Pelleted organo-mineral fertilisers from composted pig slurry solids, animal wastes and spent mushroom compost for amenity grasslands. Waste Manag. 2007, 27, 1117–1128. [Google Scholar] [CrossRef]

- Heinsoo, K.; Hein, K.; Melts, I.; Holm, B.; Ivask, M. Reed canary grass yield and fuel quality in estonian farmers’ fields. Biomass Bioenergy 2011, 35, 617–625. [Google Scholar] [CrossRef]

- Al-Khatib, I.A.; Anayah, F.M.; Al-Sari, M.I.; Al-Madbouh, S.; Salahat, J.I.; Jararaa, B.Y.A. Assessing physiochemical characteristics of agricultural waste and ready compost at wadi al-far’a watershed of palestine. J. Environ. Public Health 2023, 2023, 6147506. [Google Scholar] [CrossRef] [PubMed]

- University of Minnesota. Green Waste Compost Analysis Report. Available online: https://conservancy.umn.edu/server/api/core/bitstreams/7b6f4ca4-85c7-4461-8b35-44a3db660814/content (accessed on 10 October 2025).

- Ujj, A.; Percsi, K.; Beres, A.; Aleksza, L.; Diaz, F.R.; Gyuricza, C.; Fogarassy, C. Analysis of quality of backyard compost and its potential utilization as a circular bio-waste source. Appl. Sci. 2021, 11, 4392. [Google Scholar] [CrossRef]

- Morales, J.; Martínez-Alcántara, B.; Bermejo, A.; Millos, J.; Legaz, F.; Quiñones, A. Effect of calcium fertilization on calcium uptake and its partitioning in citrus trees. Agronomy 2023, 13, 2971. [Google Scholar] [CrossRef]

- Katroschan, K.U.; Hirthe, G. Nitrogen supply by cut-and-carry biomass for vegetable crops and subsequent cereals. Nutr. Cycl. Agroecosyst. 2024, 129, 53–71. [Google Scholar] [CrossRef]

- Makádi, M.; Tomócsik, A.; Orosz, V. Digestate: A New Nutrient Source—Review. In Biogas; Kumar, S., Ed.; InTech: Rijeka, Croatia, 2012; Chapter 14. [Google Scholar]

- Olejarski, I. Utilization of logging residues for organic fertilization of post-agricultural soils. Postępy Tech. Leśnictwie 2005, 92, 20–24. (In Polish) [Google Scholar]

- Jourgholami, M.; Abari, M.E. Effectiveness of sawdust and straw mulching on postharvest runoff and soil erosion of a skid trail in a mixed forest. Ecol. Eng. 2017, 109, 15–24. [Google Scholar] [CrossRef]

- Rosa, E.; Sufardi, S.; Syafruddin, S.; Rusdi, M. Bioremediation of ex-mining soil with the biocompost in the incubation experiments. Appl. Environ. Soil Sci. 2023, 2023, 4129909. [Google Scholar] [CrossRef]

- Strenner, M.; Chmelíková, L.; Hülsbergen, K.-J. Compost fertilization in organic agriculture—A comparison of the impact on corn plants using field spectroscopy. Appl. Sci. 2023, 13, 3676. [Google Scholar] [CrossRef]

- Langsdorf, A.; Volkmar, M.; Holtmann, D.; Ulber, R. Material utilization of green waste: A review on potential valorization methods. Bioresour. Bioprocess. 2021, 8, 19. [Google Scholar] [CrossRef] [PubMed]

- Wieczorek, J. Chemical and biological properties of composts produced from municipal sewage sludge with sawdust supplement. Ecol. Chem. Eng. A 2012, 19, 897–904. [Google Scholar] [CrossRef]

- Szulc, W.; Rutkowska, B.; Stępień, W. Assessing the suitability of wood industry waste for fertilizer application. Zesz. Probl. Post. Nauk Rol. 2007, 518, 185–192. [Google Scholar]

- Vassilev, S.; Baxter, D.; Andersen, L.; Vassileva, C.; Morgan, T. An overview of the organic and inorganic phase composition of biomass. Fuel 2012, 94, 1–33. [Google Scholar] [CrossRef]

- Chávez-Rosales, J.S.; Pintor-Ibarra, L.F.; González-Ortega, N.; Orihuela-Equihua, R.; Ruiz-Aquino, F.; Luján-Álvarez, C.; Rutiaga-Quinones, J.G. Basic chemical composition of Pinus spp. sawdust from five regions of Mexico for bioenergetic purposes. BioResources 2021, 16, 816–824. [Google Scholar] [CrossRef]

- Bożym, M.; Dróżdż, N.; Siemiątkowski, G. Zawartość makroelementów i ich form przyswajalnych w kompostach produkowanych z odpadów zielonych. Prace ICiMB 2014, 18, 150–161. (In Polish) [Google Scholar]

- Cwalina, P.; Obidziński, S.; Sienkiewicz, A.; Kowczyk-Sadowy, M.; Piekut, J.; Bagińska, E.; Mazur, J. Production and quality assessment of fertilizer pellets from compost with sewage sludge ash (ssa) addition. Materials 2025, 18, 1145. [Google Scholar] [CrossRef] [PubMed]

- Maucieri, C.; Barco, A.; Borin, M. Compost as a substitute for mineral n fertilization? effects on crops, soil and n leaching. Agronomy 2019, 9, 193. [Google Scholar] [CrossRef]

- Sánchez, A. Special issue on “composting in the framework of a circular economy”. Processes 2023, 11, 1573. [Google Scholar] [CrossRef]

- Nworie, O.E.; Lin, C. Seasonal variation in tissue-borne heavy metal(loids) in herbaceous plants growing in contaminated soils developed from industrial wastes of industrial revolution age. Environ. Adv. 2021, 5, 100113. [Google Scholar] [CrossRef]

- Government of Poland. Regulation of the Minister of Agriculture and Rural Development of 18 June 2008 on the Implementation of Certain Provisions of the Act on Fertilizers and Fertilization. J. Laws Repub. Pol. 2008, Item 765. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20081190765 (accessed on 11 October 2025).

- European Parliament and Council. Regulation (EU) 2019/1009 of 5 June 2019 on the Making Available on the Market of EU Fertilising Products, Amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009, and Repealing Regulation (EC) No 2003/2003. Off. J. Eur. Union 2019, L170, 1–112. Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/?uri=CELEX%3A32019R1009 (accessed on 17 October 2025).

- Alloway, B.J. (Ed.) Heavy Metals in Soils: Trace Metals and Metalloids in Soils and Their Bioavailability; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Wang, X.; Sale, P.; Hunt, J.; Clark, G.; Wood, J.L.; Franks, A.E.; Reddy, P.; Jin, J.; Joseph, S.; Tang, C. Enhancing growth and transpiration efficiency of corn plants with compost addition and potential beneficial microbes under well-watered and water-stressed conditions. Plant Soil 2025, 515, 2475–2493. [Google Scholar] [CrossRef]

- Kamal, M.Z.U.; Sarker, U.; Roy, S.K.; Alam, M.S.; Azam, M.G.; Miah, M.Y.; Hossain, N.; Ercisli, S.; Alamri, S. Manure–biochar compost mitigates soil salinity stress in tomato plants by modulating the osmoregulatory mechanism, photosynthetic pigments, and ionic homeostasis. Sci. Rep. 2024, 14, 21929. [Google Scholar] [CrossRef] [PubMed]

- Hargreaves, J.C.; Adl, M.S.; Warman, P.R. A review of the use of composted municipal solid waste in agriculture. Agric. Ecosyst. Environ. 2008, 123, 1–14. [Google Scholar] [CrossRef]

- Ansar, A.; Du, J.; Javed, Q.; Adnan, M.; Javaid, I. Biodegradable waste in compost production: A review of its economic potential. Nitrogen 2025, 6, 24. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).