1. Introduction

Loess is a Quaternary yellow aeolian sediment. Due to its complex formation environment, it exhibits typical engineering deficiencies such as a loose structure, high porosity, significant compressibility, and insufficient mechanical strength. It is widely distributed in the Loess Plateau and arid and semi-arid regions of China. The Yili loess, a specific type distributed in the Yili River Valley of China, possesses not only common characteristics like a loose, porous structure, low structural strength, and susceptibility to disintegration upon wetting but also demonstrates notable strong collapsibility and high soluble salt content, attributable to its unique geographical, climatic conditions, and geological history [

1,

2,

3]. These properties pose numerous challenges in engineering applications, including foundation settlement, slope instability, and channel seepage, significantly constraining regional infrastructure development and economic growth [

4].

Current soil improvement methods primarily include physical reinforcement (e.g., compaction, reinforcement) and chemical stabilization (e.g., lime, cement solidification). For instance, Gao C et al. [

5] employed a vibrating probe compaction method to reinforce loess. Through laboratory and field tests evaluating its disintegration characteristics, they found that the disintegration rate of treated loess samples (0.2 %/s) decreased by 75.85% compared to untreated samples. Tang Fuchun et al. [

6] investigated the dynamic response characteristics of reinforced loess under different conditions in the Xining area, demonstrating that reducing reinforcement layer spacing and increasing the number of layers significantly enhanced the soil’s mechanical strength. Bao W et al. [

7] used lime as a stabilizing material for loess, exploring its mechanical strength properties and microstructural changes under varying temperatures and lime contents. The results indicated that lime effectively improved the compressive and shear strength of loess under both normal and elevated temperatures. Xuerui Yan et al. [

8] utilized Magnesium Oxysulfate (MOS) cement as a binding agent for loess stabilization, examining changes in bulk density, porosity, mineral structure, and microstructure. The porosity decreased from 40.97% in pure loess to 28.75% in samples with 13% MOS content, while the compressive strength increased to 7.9 MPa, indicating the effective improvement of MOS as a cementitious material for soil stabilization. However, traditional soil reinforcement methods suffer from drawbacks such as high energy consumption, environmental pollution, and insufficient long-term stability [

9,

10,

11]. Consequently, exploring a green, efficient, and sustainable soil improvement technology to enhance the mechanical properties of Yili loess is of significant importance.

As early as 2003, Nemati and Voordouw [

12] proposed using plant-derived free urease as a hydrolysis catalyst, a technique later termed “Enzyme-Induced Carbonate Precipitation (EICP)” by researchers. It was not until after 2010 that EICP technology began to be applied in soil improvement. Hideaki Yasuhara, Debendra Neupane, and others [

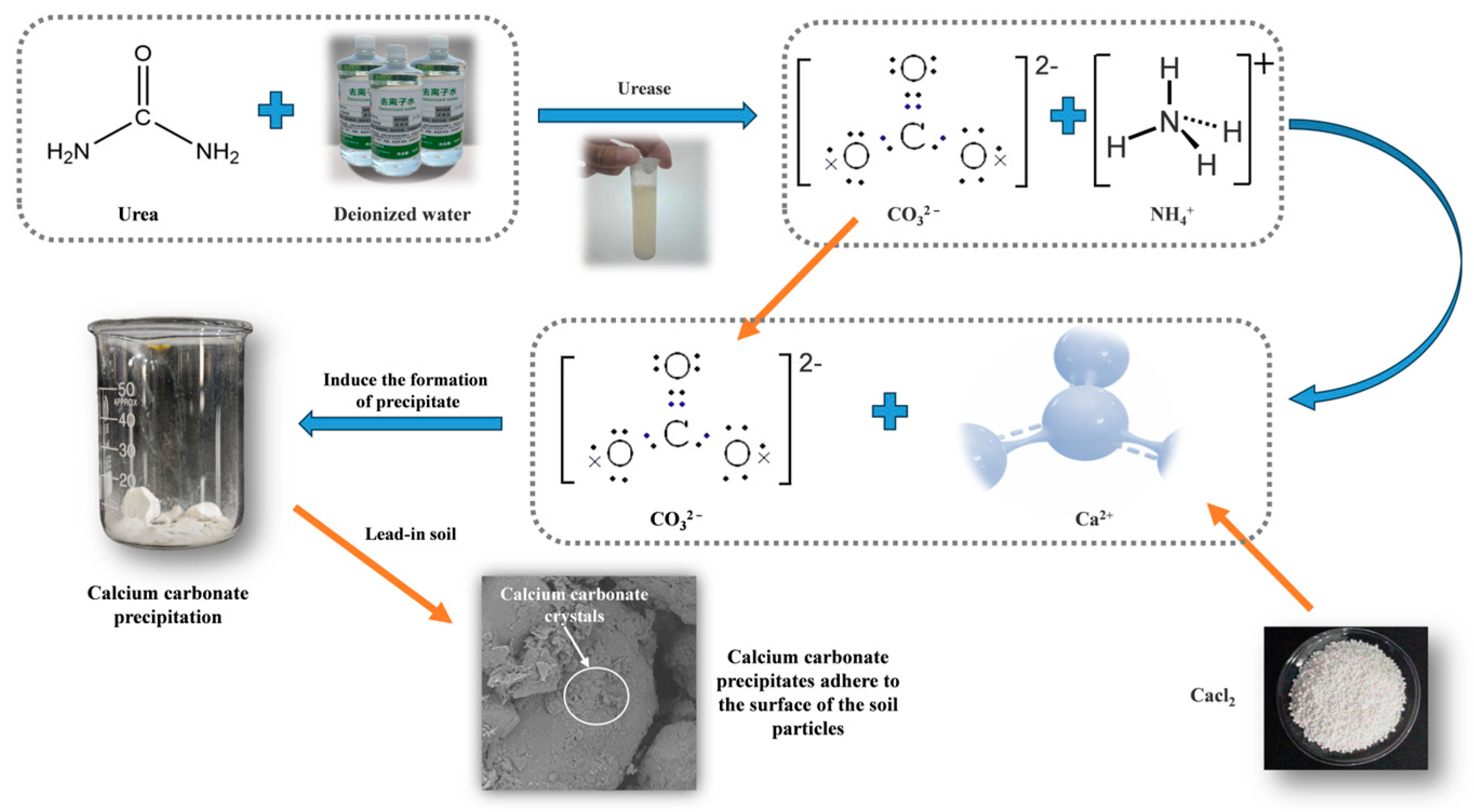

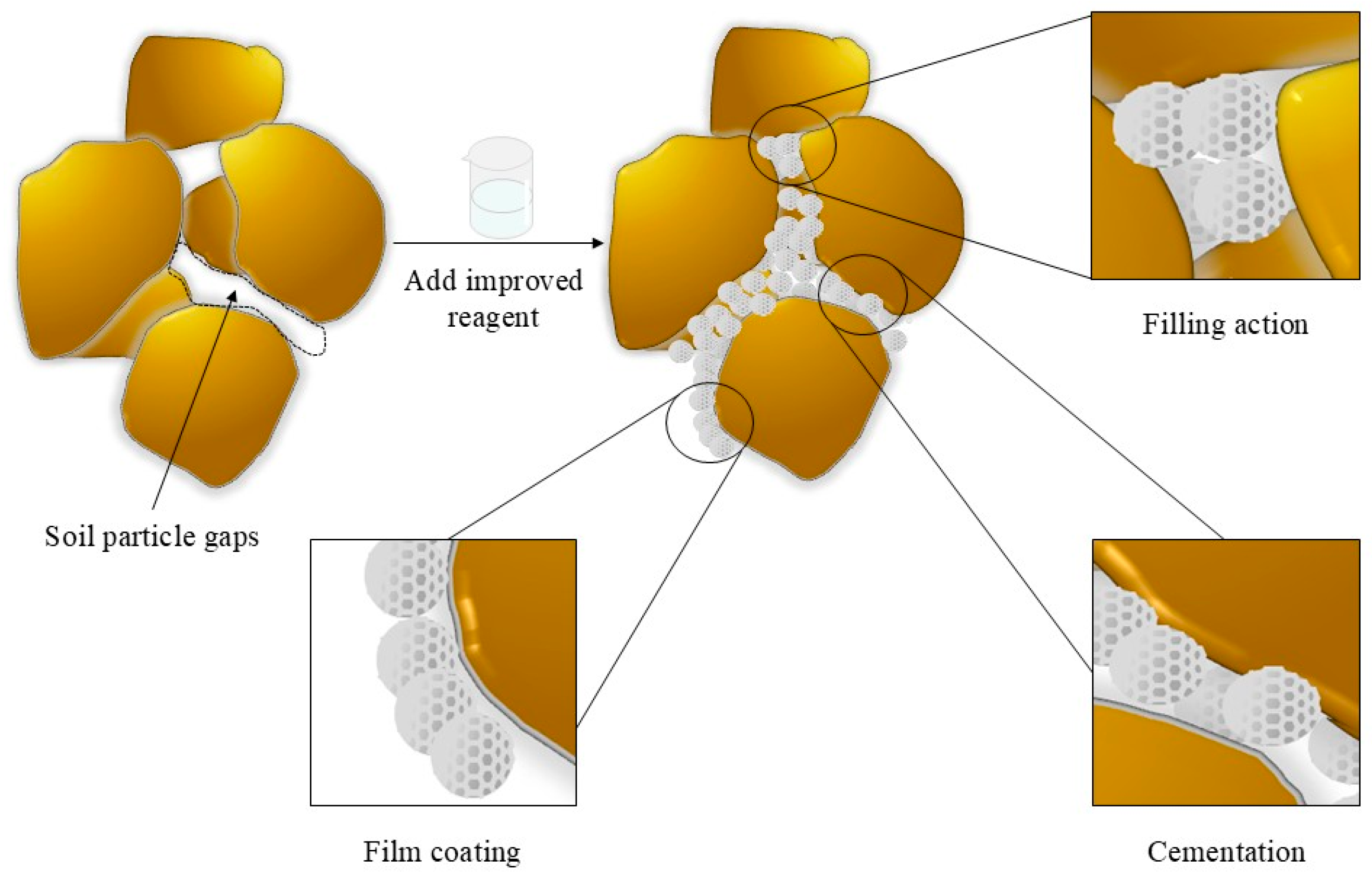

13] were among the first to apply EICP technology for sand improvement, investigating its effectiveness in enhancing soil mechanical strength and impermeability through numerical simulations and other means. As an emerging biomineralization technology, EICP primarily involves urease extracted from plants and their seeds catalyzing the hydrolysis of urea to produce carbonate ions. These ions then combine with introduced calcium ions to form calcium carbonate precipitates. These precipitates coat soil particle surfaces and fill the spaces between them, thereby enhancing the interparticle bonding force (

Figure 1) and consequently improving the soil’s mechanical properties and resistance to seepage [

14].

The chemical reactions involved in EICP are represented below:

Compared to Microbially Induced Carbonate Precipitation (MICP) technology, EICP does not rely on microbial growth and reproduction. It offers advantages such as simpler operation, faster reaction rates, environmental friendliness, and wider applicability. EICP demonstrates significant technical superiority, particularly in the improvement of fine-grained soils [

15,

16,

17,

18]. In recent years, EICP has also achieved notable results in areas such as sand solidification and dust control [

19,

20,

21,

22,

23]. However, research on the application of EICP technology for improving Yili loess is currently a theoretical void. Therefore, investigating the effectiveness and mechanisms of EICP technology for enhancing Yili loess is of great importance for disaster prevention and mitigation in the Yili region.

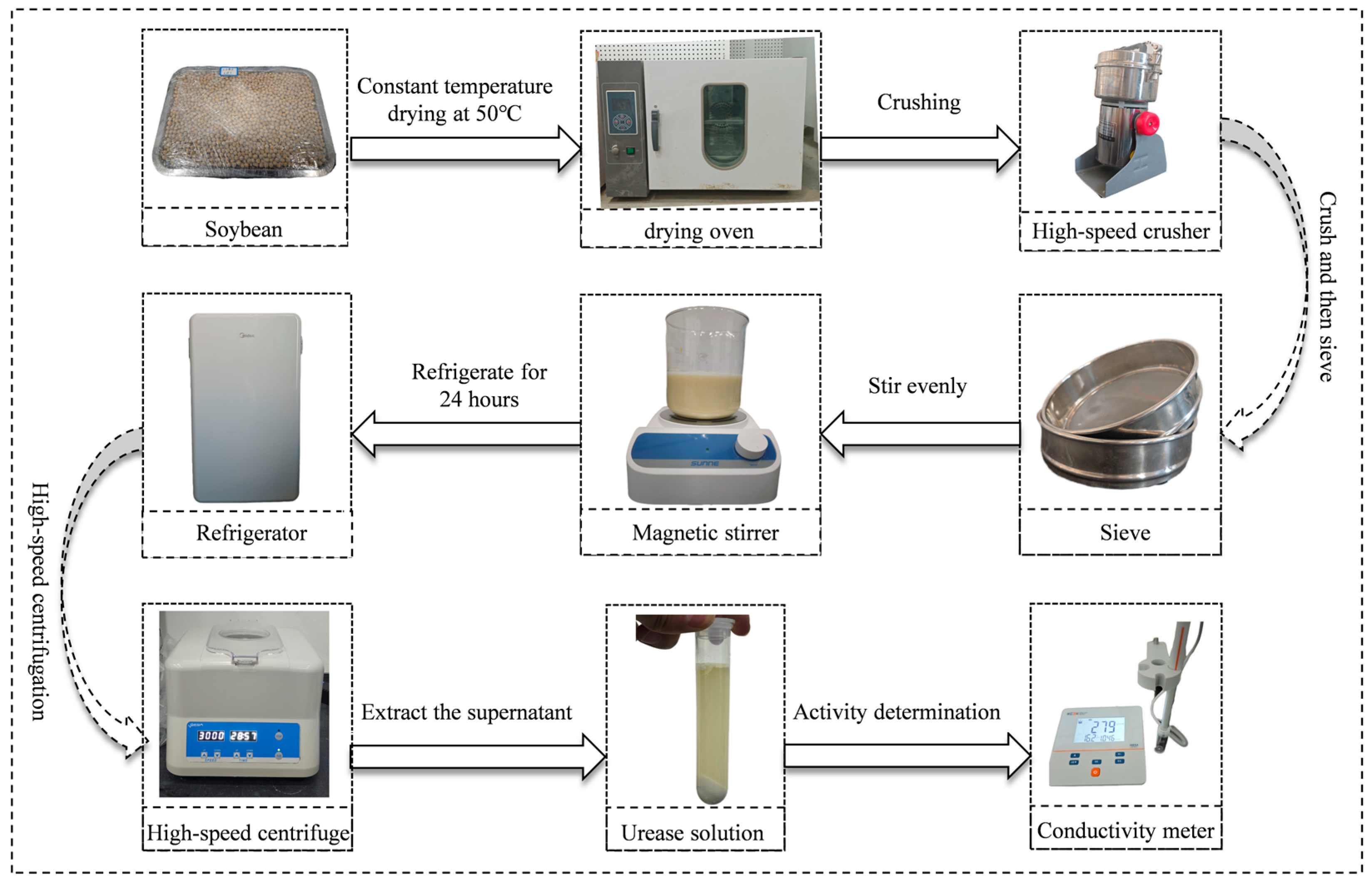

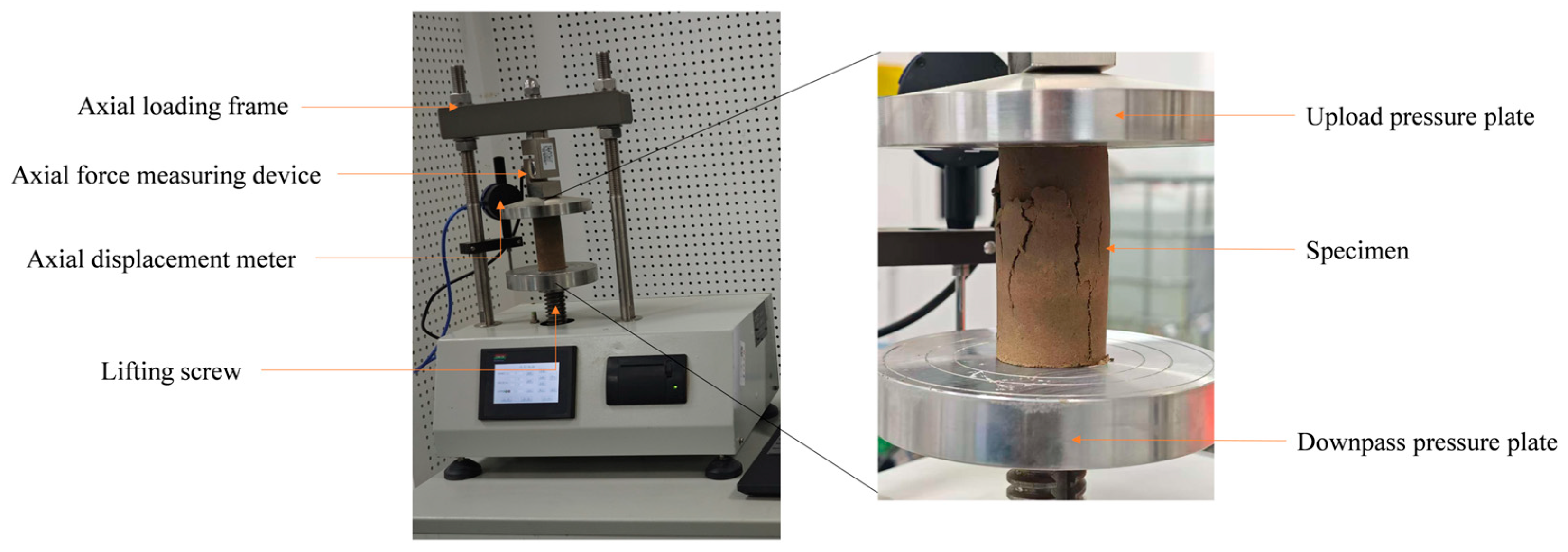

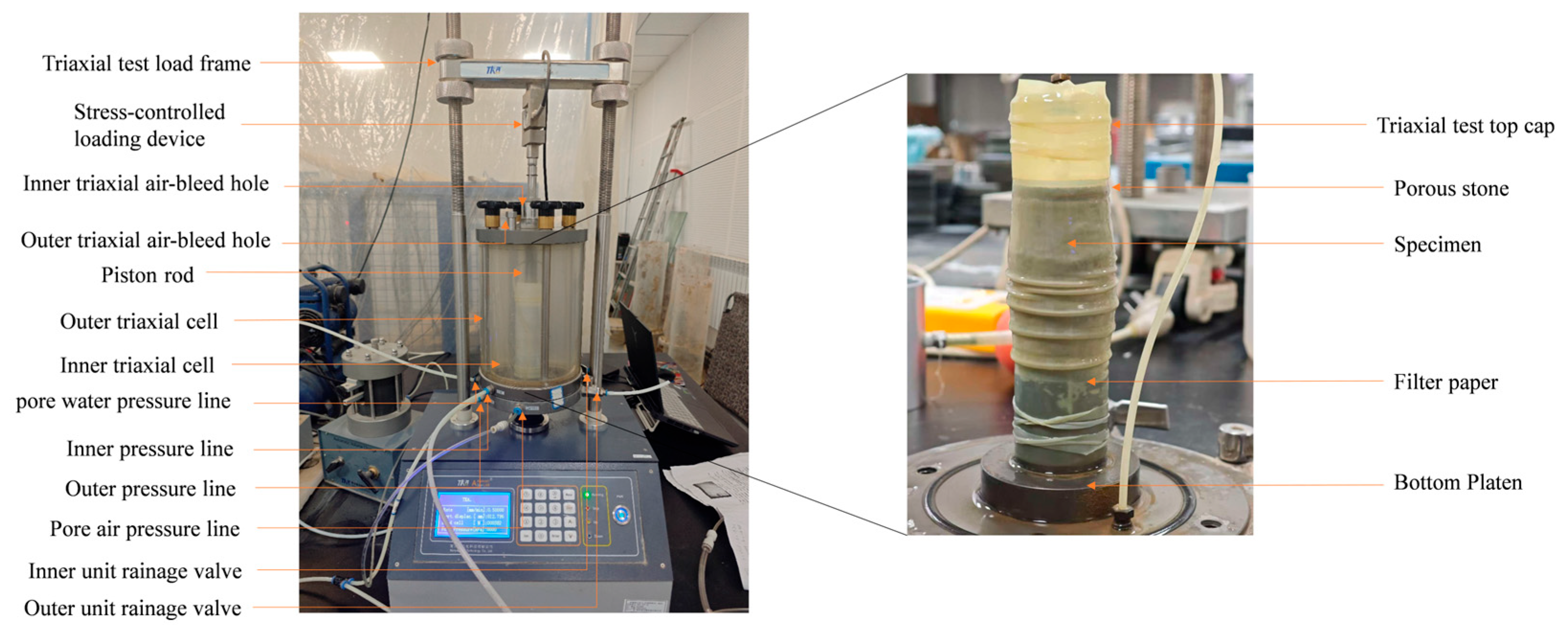

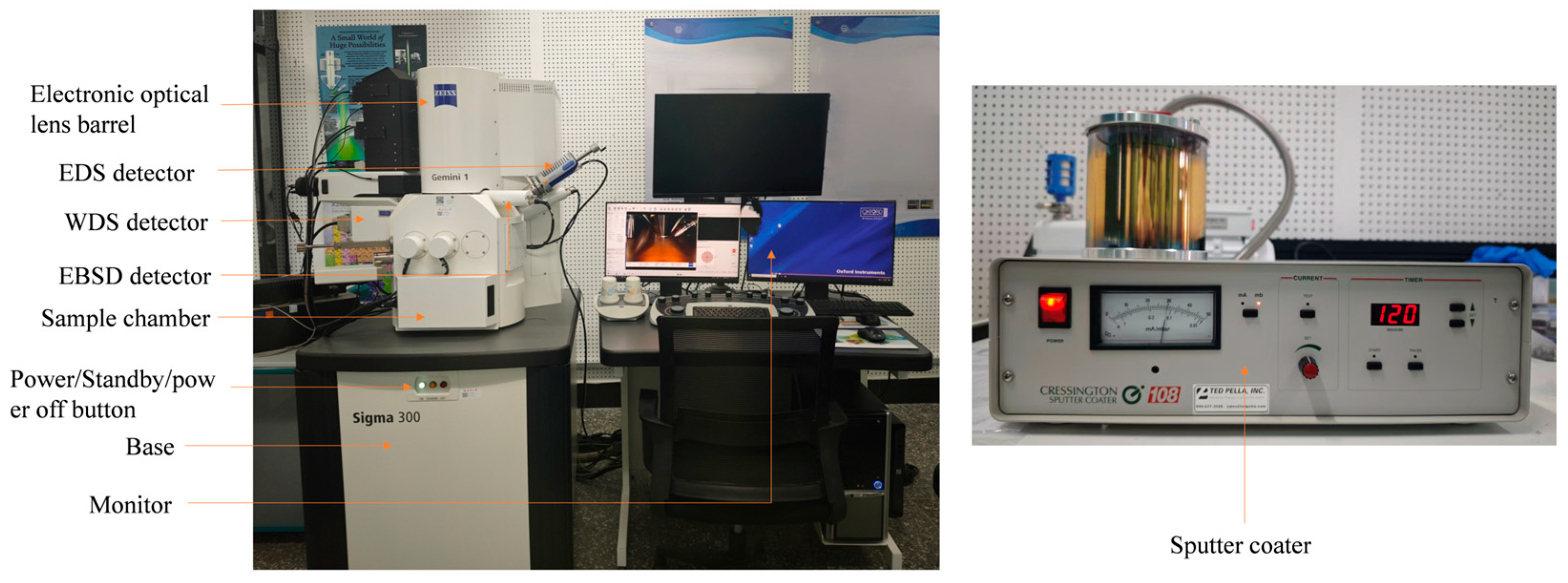

This study focuses on Yili loess as the research object and applies soybean-derived urease for Enzyme-Induced Carbonate Precipitation (EICP) to improve it. Through unconfined compressive strength tests, unconsolidated undrained triaxial shear tests, and scanning electron microscopy observations, the study aims to clarify the intrinsic relationships and mechanisms among urease catalytic efficiency, calcium carbonate precipitation, the evolution of the soil microstructure, and the enhancement of macroscopic mechanical properties. Consequently, it seeks to validate the effectiveness of EICP technology for improving Yili loess from a multi-scale perspective and to provide a theoretical basis for the engineering application of this technology in loess regions of Northwestern China.

4. Discussion

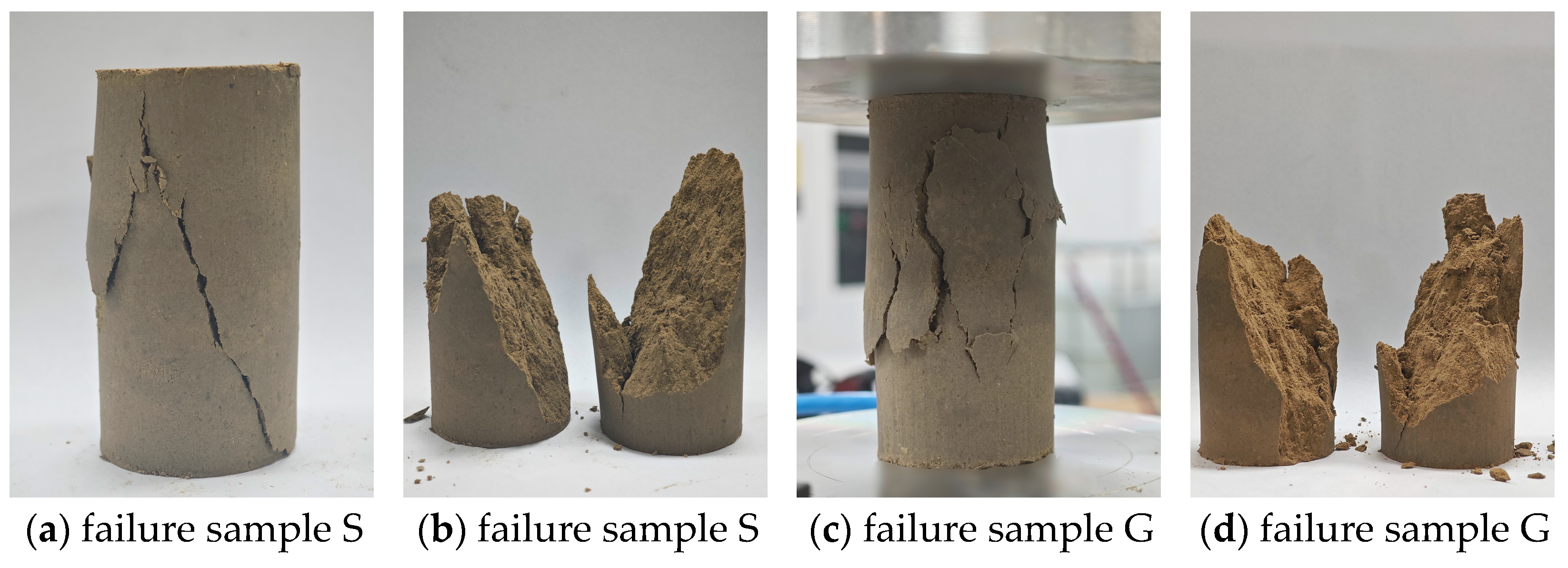

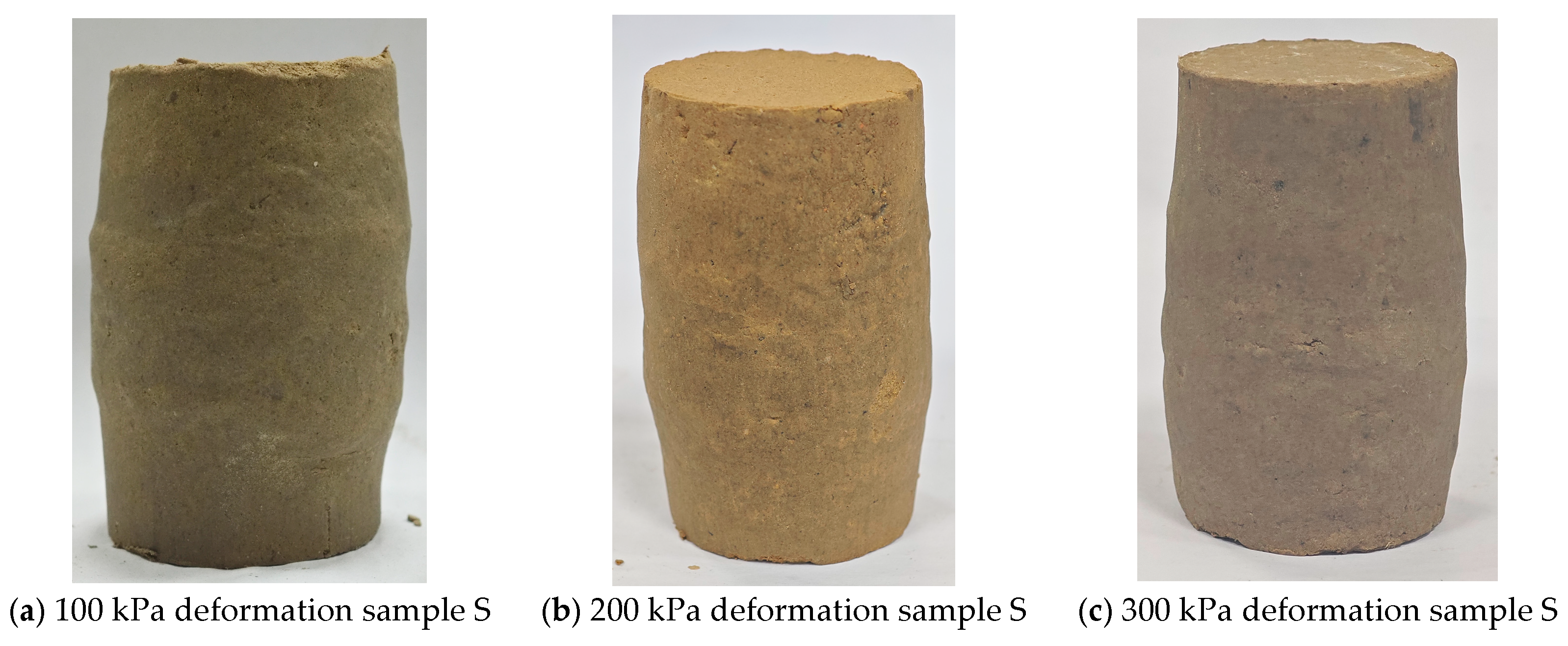

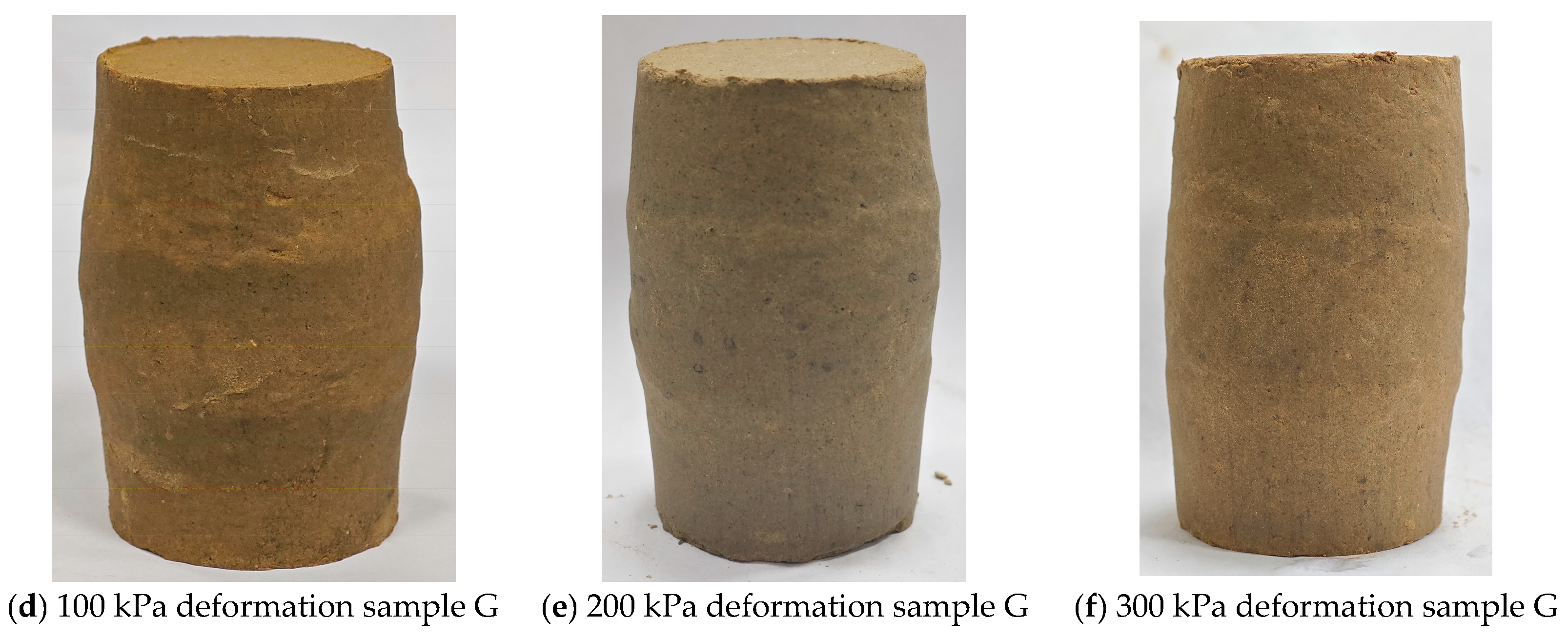

4.1. Cementing Mechanism and Failure Mode Transition of EICP-Improved Soils

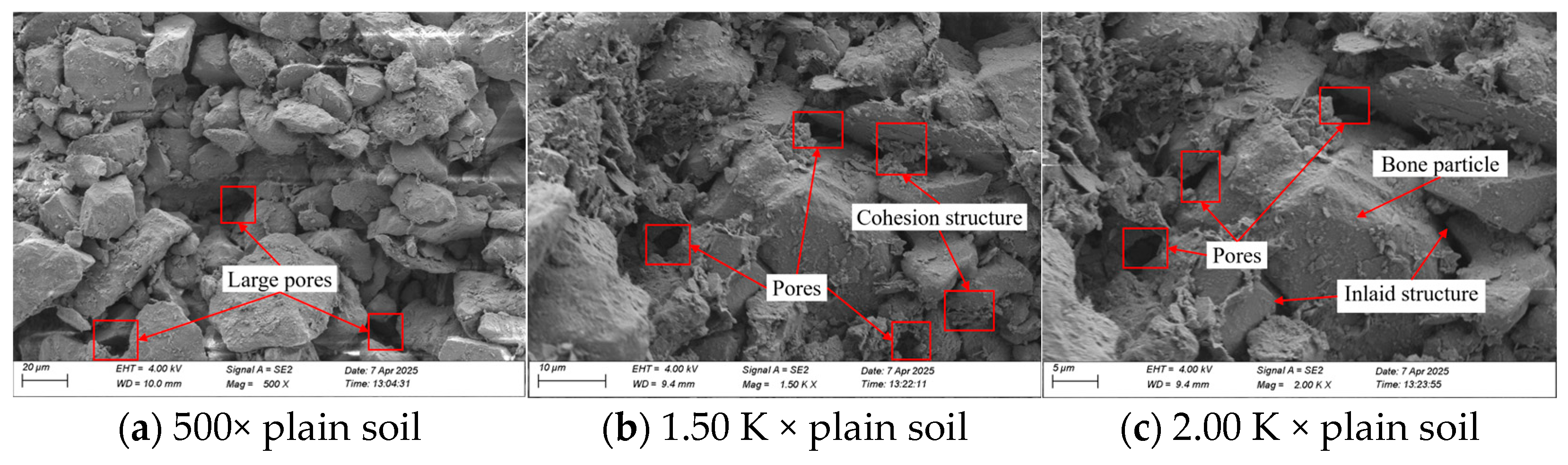

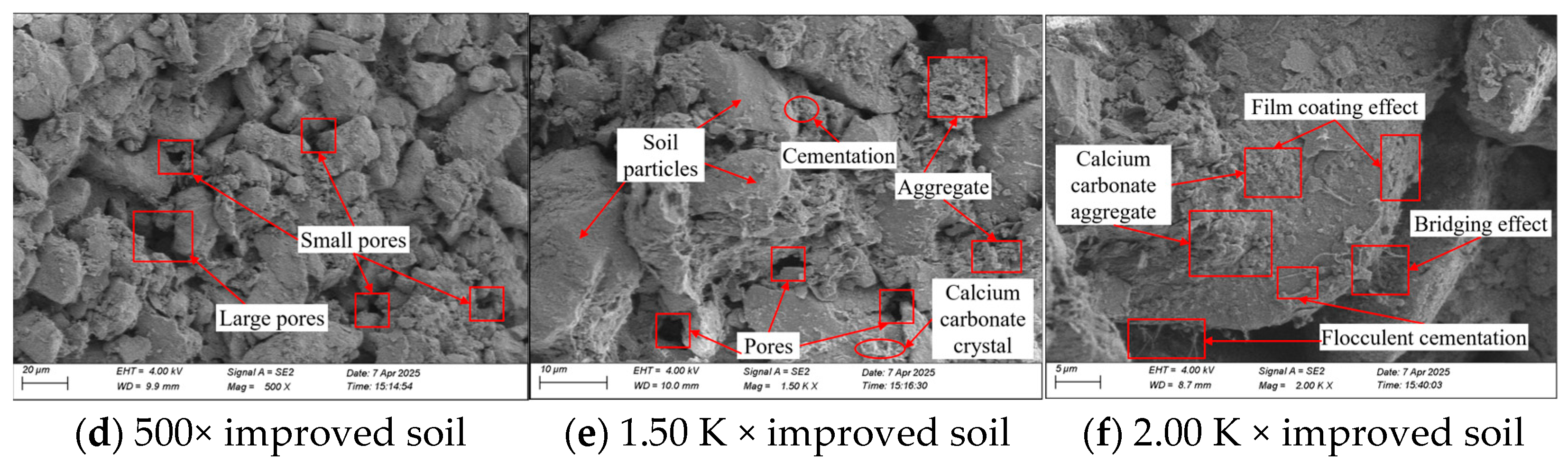

EICP induces the formation of CaCO

3 crystals in soils through biomineralization, filling pores between particles and cementing or coating them (

Figure 15), thereby improving the mechanical strength of the soils. The core mechanism lies in the dual effects exerted by CaCO

3 crystals on soil particles: First, the soils are coated by CaCO

3 crystals, resulting in smaller interparticle gaps and an optimized stress transfer network at the contact points; second, the interparticle friction and bonding are enhanced by cementation bonds. Such a spatial distribution pattern of the cementing effect had a profound impact on the macroscopic mechanical features of the materials.

The compressive strength test showed that the failure morphology of the improved soil samples was closely related to the three-dimensional distribution of cementation. The weakly cemented regions in the soil samples are spatially coupled to regions where main fissures are developed. The above finding corroborates the conclusion drawn by Arpajirakul et al. [

34] in MICP-improved clay and helps reveal the universal reinforcing mechanism of the biomineralization technologies. The loess treated with EICP exhibits a mixed failure mode: tension (at the beginning) and shear (at failure), which is due to the spatially uneven distribution of biological solidification generated between loess particles.

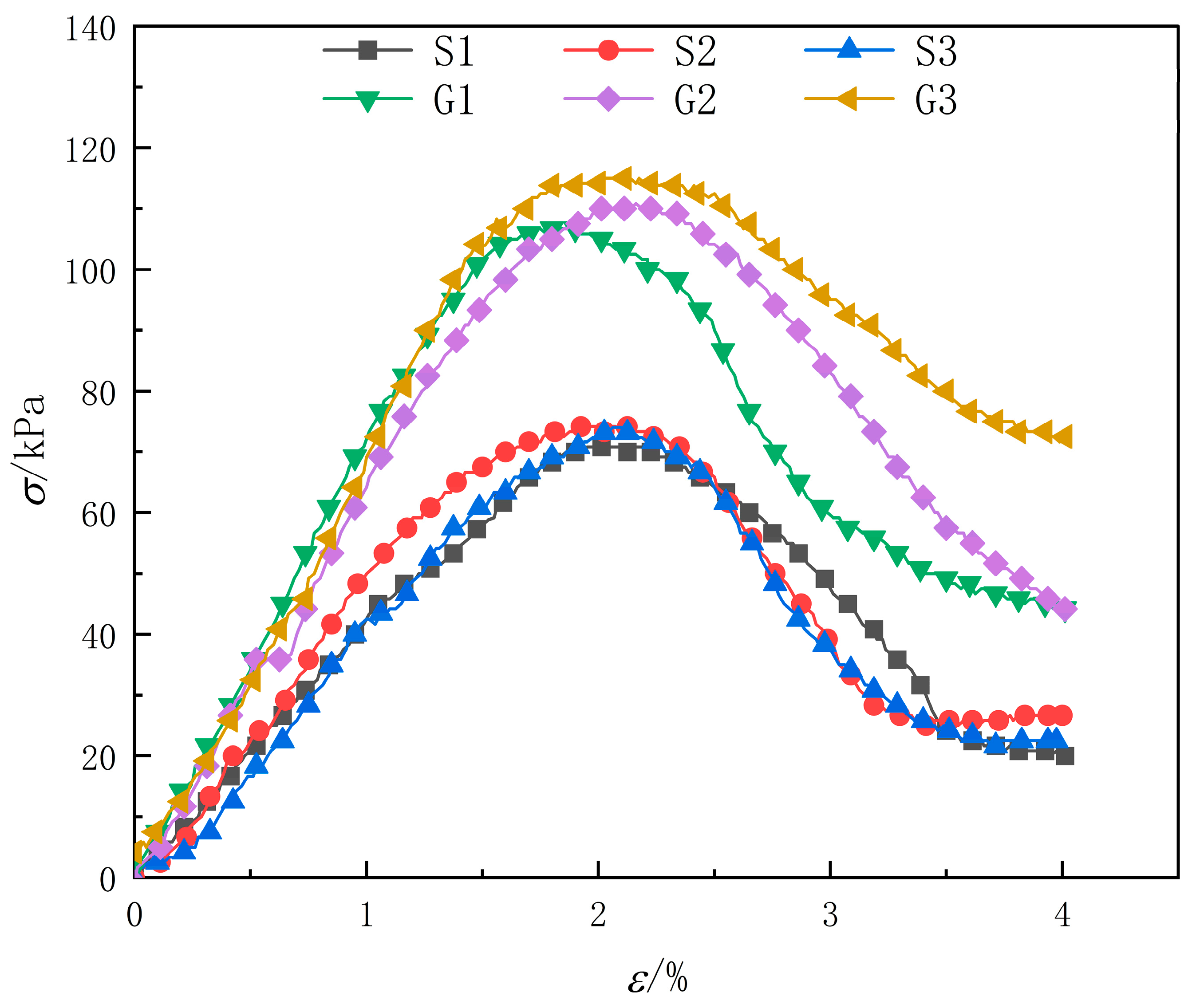

The aforementioned cementation mechanism directly governs the macroscopic mechanical response of the treated soil. The significant strength enhancement and alteration in failure mode observed in the unconfined compression tests are fundamentally attributed to the calcium carbonate cementation network effectively improving the soil’s integrity and modifying the internal stress transmission paths. Furthermore, the variation pattern of shear strength parameters revealed by the triaxial tests requires further examination based on the influence of cementation on interparticle friction and bonding characteristics.

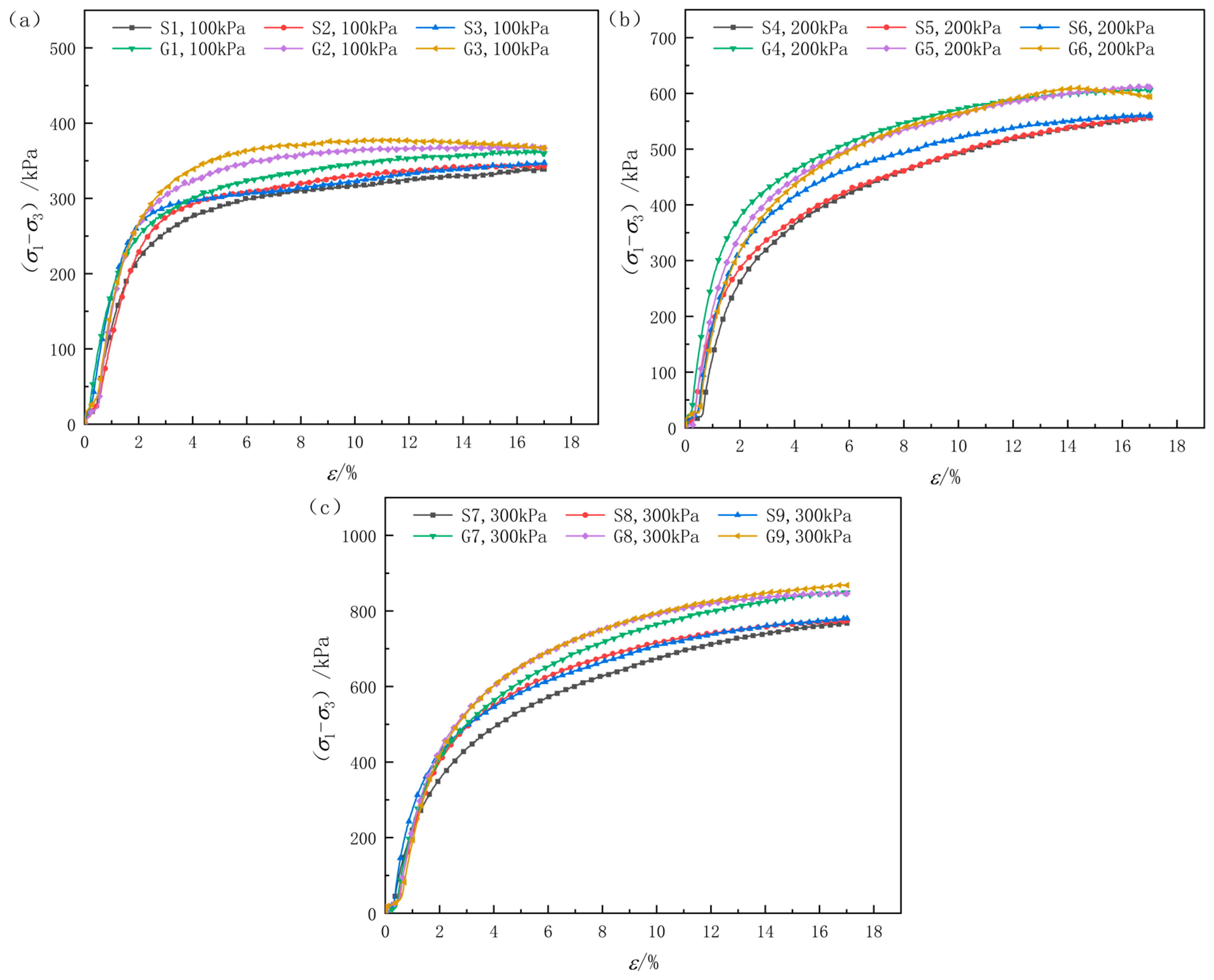

4.2. Analysis of the Differential Mechanism of Mechanical Strength Improvement of EICP-Improved Soils

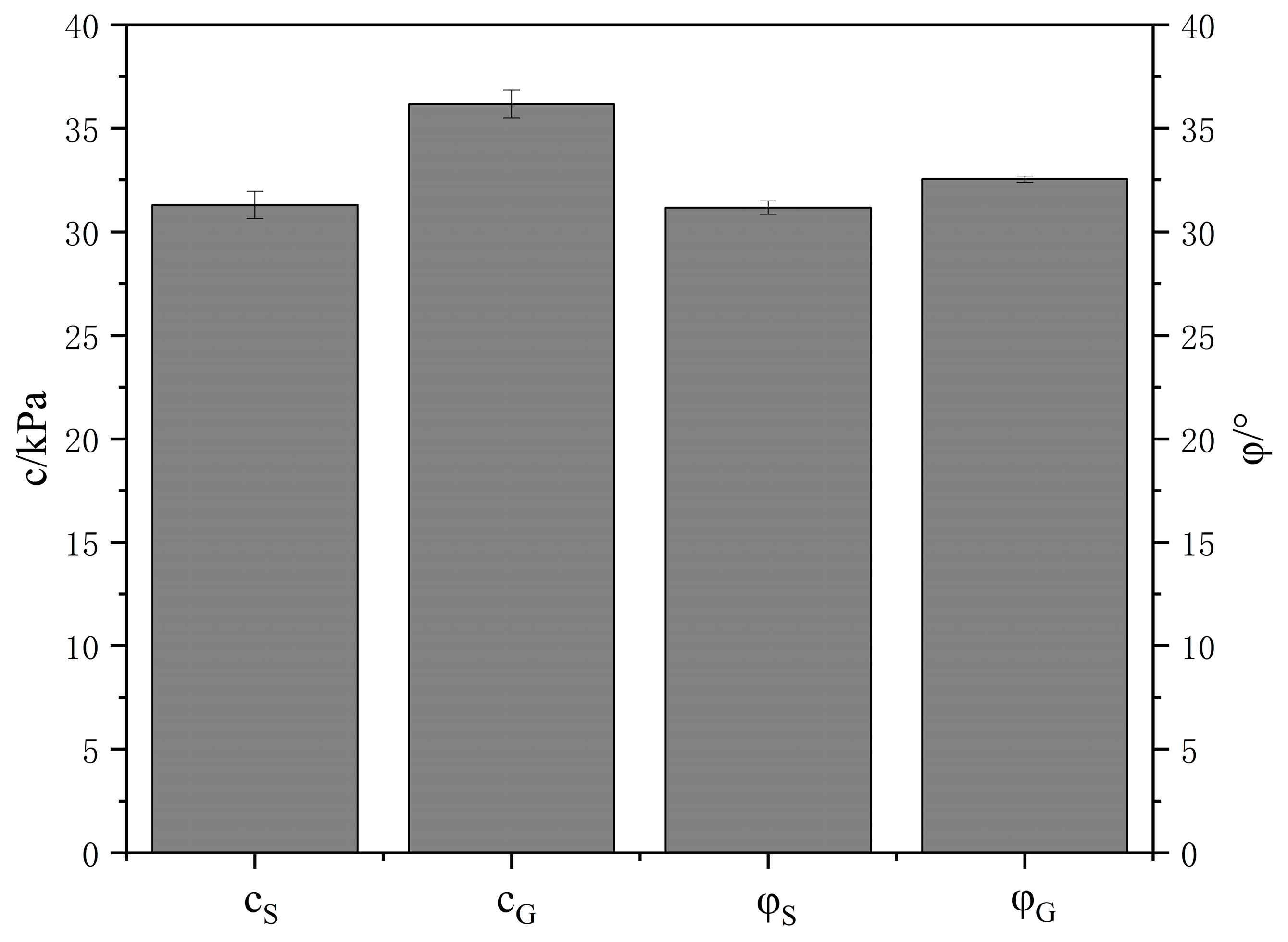

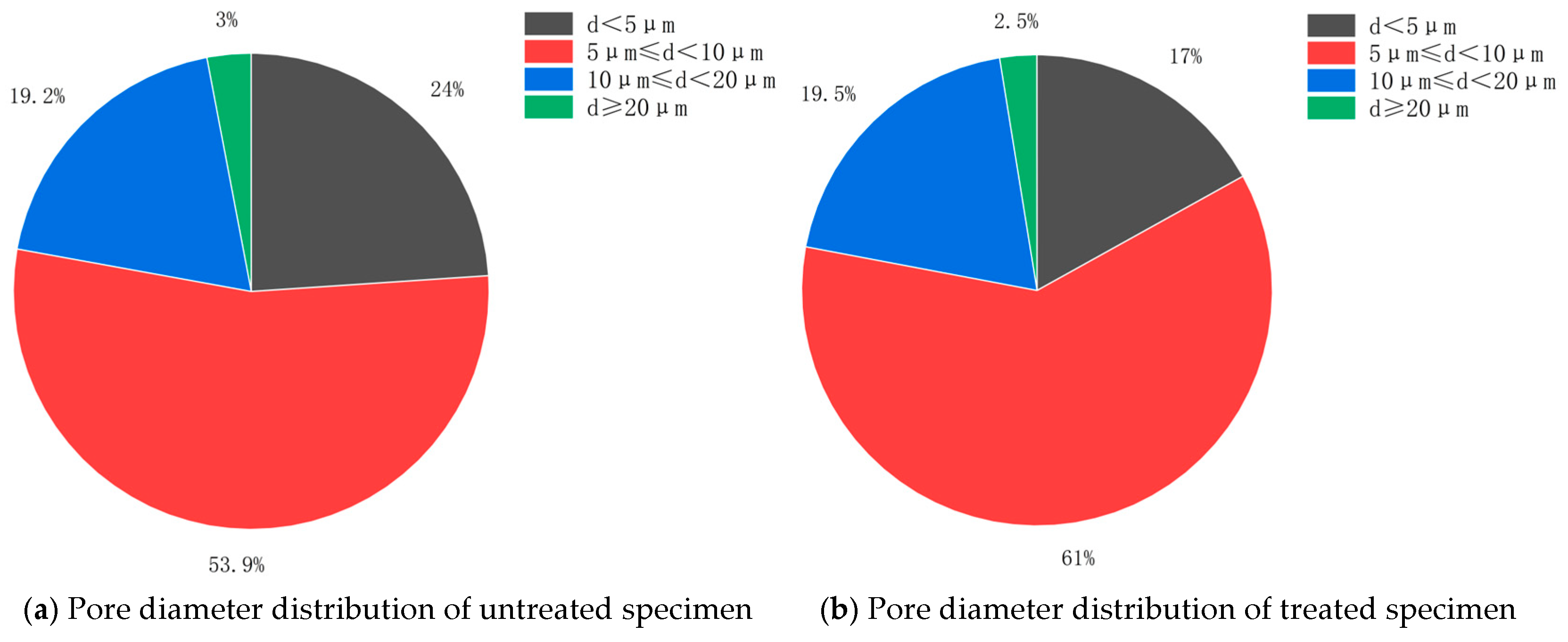

The differential effectiveness of EICP technology in improving the compressive versus shear strength of soil stems from the distinct roles and mechanisms of calcium carbonate cementation within the soil structure. The enhancement in compressive strength is primarily attributed to the spatial cementation network formed by calcium carbonate crystals, which comprehensively reinforces the soil structure and effectively bears and transmits compressive stresses. In contrast, shear strength relies more heavily on interparticle friction, interlocking, and bonding forces. Research indicates that the compressive strength of EICP-treated soil can reach 1.5 times that of untreated soil, whereas the improvement in shear strength is more limited. This suggests that the cementation layer formed by CaCO3, while coating particle surfaces, possesses relatively weak resistance to shear forces and cannot significantly enhance interparticle interlocking and frictional interactions. Consequently, the increases in shear strength parameters—cohesion (c) and internal friction angle (φ)—remain constrained.

Comparative analysis (

Table 6) reveals significant variations in the improvement effectiveness of EICP technology across different soil types, highlighting the controlling influence of the soil’s inherent structure and mineral composition on the biomineralization process. Regarding compressive strength, the improvement observed in this study for Yili loess (54.2% increase) surpasses that reported for Xi’an loess (26.6%) and Henan expansive soil (49.6%). This suggests that, although the soluble salts in Yili loess may adversely affect the purity of the cementitious products, its relatively high porosity and favorable permeability provide migration pathways and deposition space for the EICP reaction solution. This facilitates the formation of a widely distributed calcium carbonate cementation network, thereby effectively enhancing the overall structural resistance to compression.

However, the improvement pattern differs for shear strength parameters. The increase in cohesion for Yili loess achieved in this study (15.6%) is significantly lower than that for Henan expansive soil (37.8%) and Xi’an loess (26.0%). This phenomenon is likely related to the unique engineering geological characteristics of Yili loess. As mentioned previously, Yili loess is typically rich in soluble salts. These salts (e.g., sulfate, chloride ions) may compete with calcium ions, forming non-cementing competitive precipitates (such as gypsum), thereby reducing the purity and efficiency of the calcium carbonate available for effective cementation and resulting in a relatively limited cohesion enhancement.

Furthermore, the minor increase in the internal friction angle observed in this study (4.5%) is the lowest among all the compared cases, contrasting sharply with the significant improvements reported for Xi’an loess (30.1%) and Lanzhou loess (108%). This underscores a key distinction between the improvement mechanisms of EICP and MICP. MICP technology (as applied to Lanzhou loess) often utilizes microbial cells to form stronger cementation at particle contacts [

37]. This cementation mode effectively hinders particle rolling and sliding, leading to a substantial increase in the internal friction angle. In contrast, EICP technology, particularly in specific media like Yili loess, tends to generate calcium carbonate crystals that coat particle surfaces. Their primary role is to enhance bonding rather than reconfigure the interparticle arching structure, thus contributing less to the improvement of the internal friction angle. The notable increase in the internal friction angle in the Xi’an loess case might be attributed to its specific particle gradation and the particular penetration and nucleation patterns of the EICP solution within it, illustrating that even within EICP technology, the improvement effectiveness is highly dependent on the native soil properties.

Synthesizing the data from this study and the literature, the effectiveness of EICP technology in improving different soils (particularly the shear strength parameters) varies significantly, primarily controlled by the soil’s native structure and geochemical environment. For Yili loess, its high initial porosity provides favorable conditions for a notable increase in compressive strength. However, its potential soluble salt content might inhibit the formation of highly efficient cementitious products through competitive reactions with calcium ions, consequently limiting the extent of cohesion improvement. Therefore, prior to future engineering applications, preliminary determination of the pore structure and soluble salt content of the target soil is recommended.

4.3. EICP Optimization Strategy Oriented Towards Soil Homogenization and Shear Resistance Improvement

The EICP technique utilizes urease to induce the precipitation of calcium carbonate (CaCO3) within soil pores, generating intergranular cementation and coating effects that dramatically enhance the soil’s compressive strength. However, the improving effect for the shear resistance varies with soil type and cementing properties. The differentiation in improving effects for different soils testifies to the crucial influence of the soil’s primary texture, mineral composition, and distribution of nucleation sites on the performance of EICP. Further investigations are needed to reveal the influence patterns.

A review of existing studies reveals several major problems with EICP, including non-uniform distribution of cementation, a limited degree of shear strength improvement, varying compatibility with different soil types, and a shortage of nucleation sites. Pathways for optimizing cementation uniformity and controlling regional solidification include improving the permeation technique, regulating grouting parameters, and introducing nanomaterials to enhance dispersibility, thereby eliminating weakly cemented regions. To improve shear resistance, it is worthwhile exploring the combined use of EICP and compound modification, utilizing fibers and polymers to enhance interparticle occlusal friction or regulating the formative morphology of CaCO3 crystals to enhance interparticle anchoring. Meanwhile, we should intensify research on the compatibility of EICP with various soil types and develop a soil pore-cementation-strength system to achieve effective CaCO3 precipitation in diverse soils. Finally, mineral nucleating agents can be added to promote directional precipitation of CaCO3 crystals and increase the nucleation efficiency in interparticle gaps. In the future, we will focus on developing a control technique for cementation distribution and building a predictive model for the spatial configuration of cementation and mechanical performance of soils using in situ monitoring. The EICP parameters should be optimized based on pertinent findings. Efforts should be devoted to exploiting the biological sources of urease and the calcium sources from waste to promote green, low-carbon development and achieve an EICP technique capable of enhancing soil homogenization and shear resistance, compatible with diverse soil types.

5. Conclusions

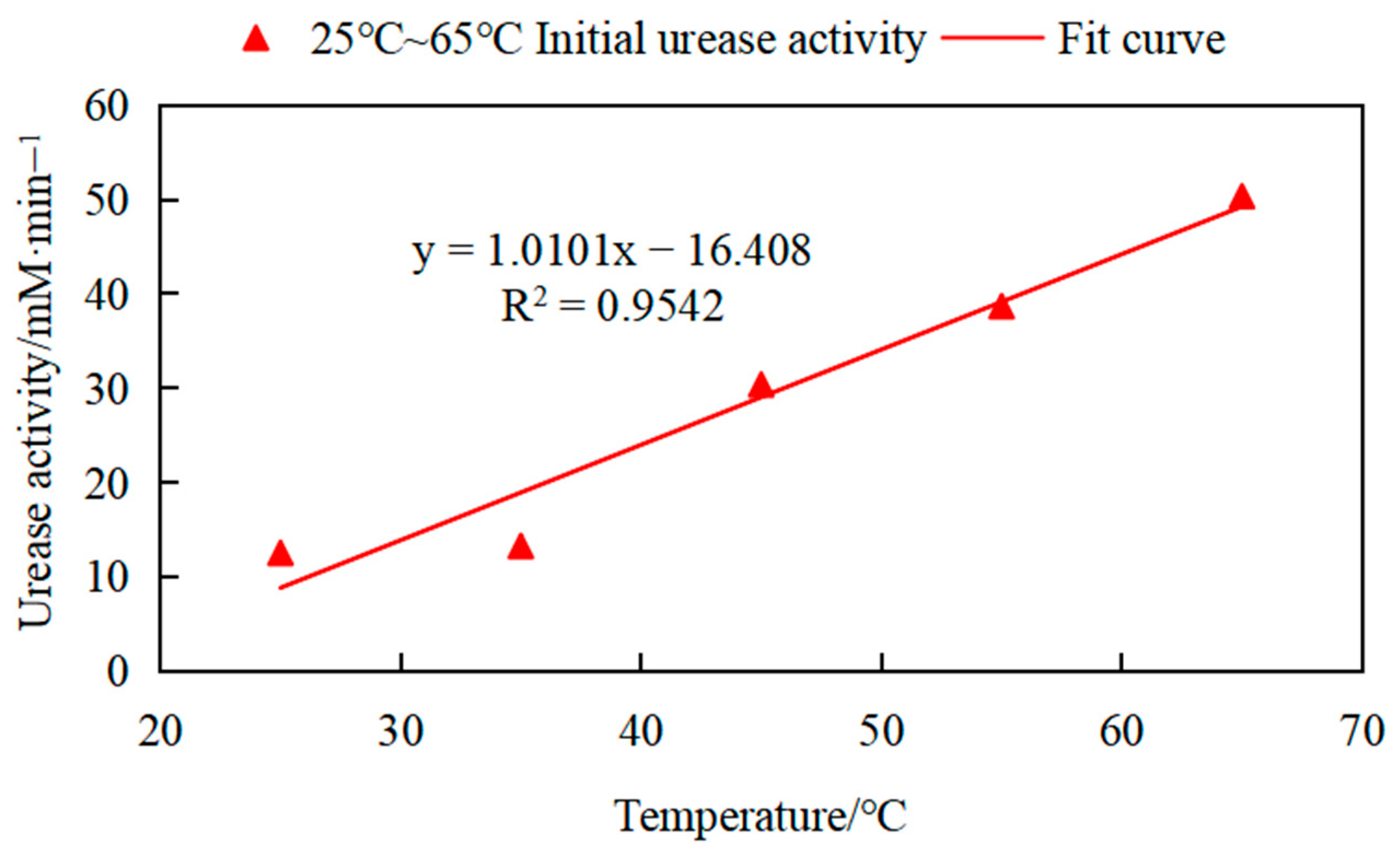

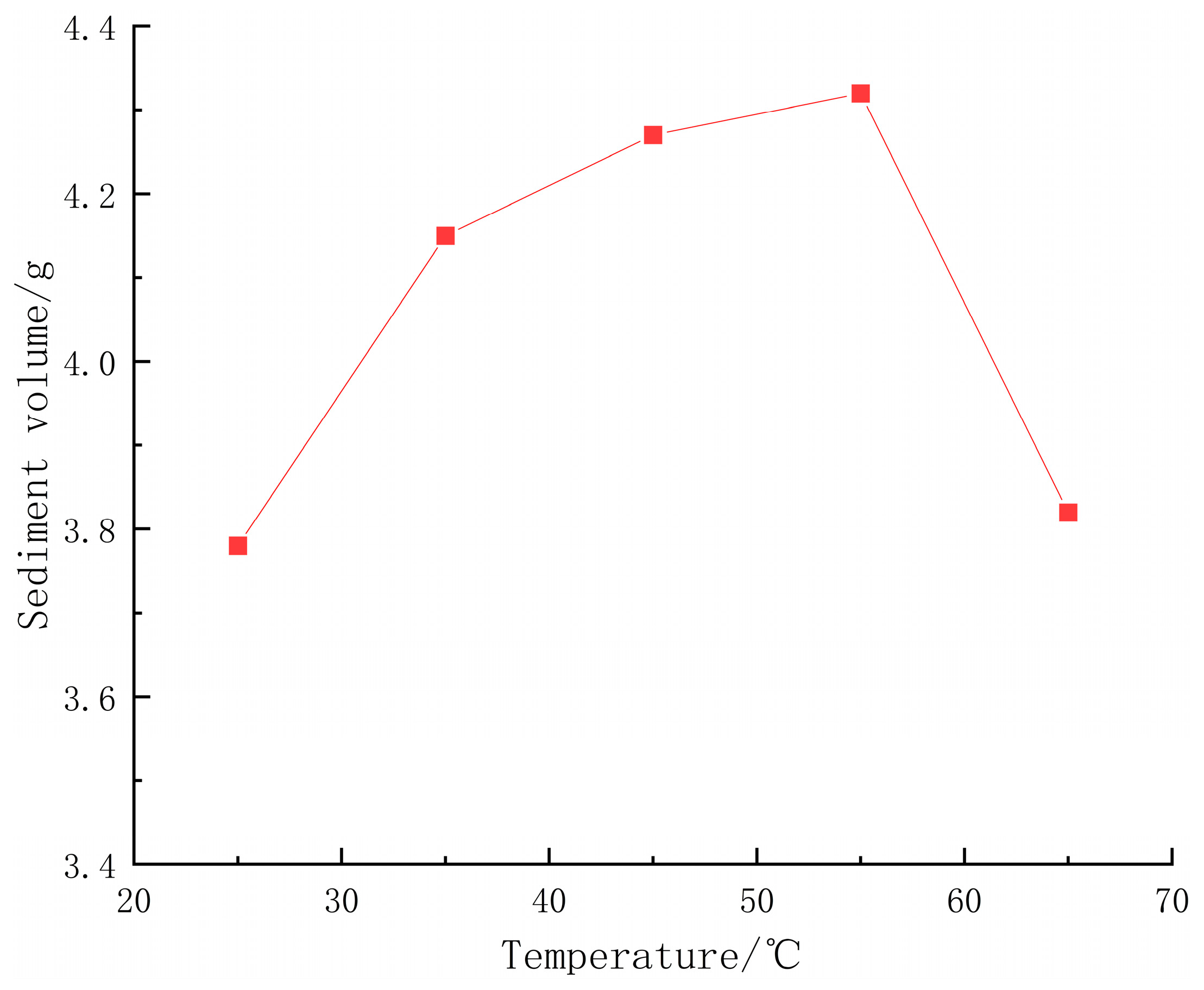

This study, through macro- and micro-scale experiments, elucidates the key mechanism of EICP technology for improving Yili loess: via the highly efficient catalysis of urease at 55 °C, an optimal yield of vaterite calcium carbonate crystals is generated. These crystals reshape the soil’s microstructure through cementation and filling effects, consequently significantly enhancing the macroscopic mechanical properties of Yili loess. The main conclusions are as follows:

(1) The optimal reaction temperature for EICP improvement of Yili loess was determined to be 55 °C. This finding provides a crucial parameter for developing on-site curing protocols. During summer in the Yili region, the natural environmental temperature can approach or reach this suitable range, significantly reducing the reliance on additional heating energy and enhancing the feasibility and economic viability of EICP technology application in Northwestern China.

(2) EICP technology effectively enhances the soil’s unconfined compressive strength (approximately 54%) and cohesion (approximately 16%), while also altering its failure mode. This indicates the technology’s potential for improving the shallow stability of loess slopes and possibly addressing uneven settlement of roadbeds. The modified mechanical behavior, exhibiting greater brittleness, provides guidance for assessing the long-term performance and failure warning signs of the reinforced soil.

(3) The study reveals the micro-mechanism of soil strengthening via EICP through “crystalline bridge” cementation and pore filling. This mechanism highlights that the successful application of EICP technology hinges on the effective transport and distribution of the reaction solution within the soil pores. Therefore, EICP technology demonstrates good applicability for soils possessing a similarly loose and porous structure, such as other aeolian loess deposits and silts.

(4) The improvement in the internal friction angle of the soil by EICP technology is limited. When treating engineering elements subjected to high shear stresses (e.g., steep slopes, foundation bearing layers), combining EICP technology with traditional methods like geosynthetic reinforcement should be considered to form a composite reinforcement technique that leverages complementary advantages. Future research should focus on developing localized urease sources with low environmental impact and optimizing grouting processes to enhance cementation uniformity, thereby facilitating the large-scale engineering application of this technology.