Environmental, Technical, and Circular Assessment of the Integration of Additive Manufacturing and Open-Loop Recycling of PET

Abstract

1. Introduction

Background: Life Cycle Assessment: Open-Loop Recycling

2. Materials and Methods

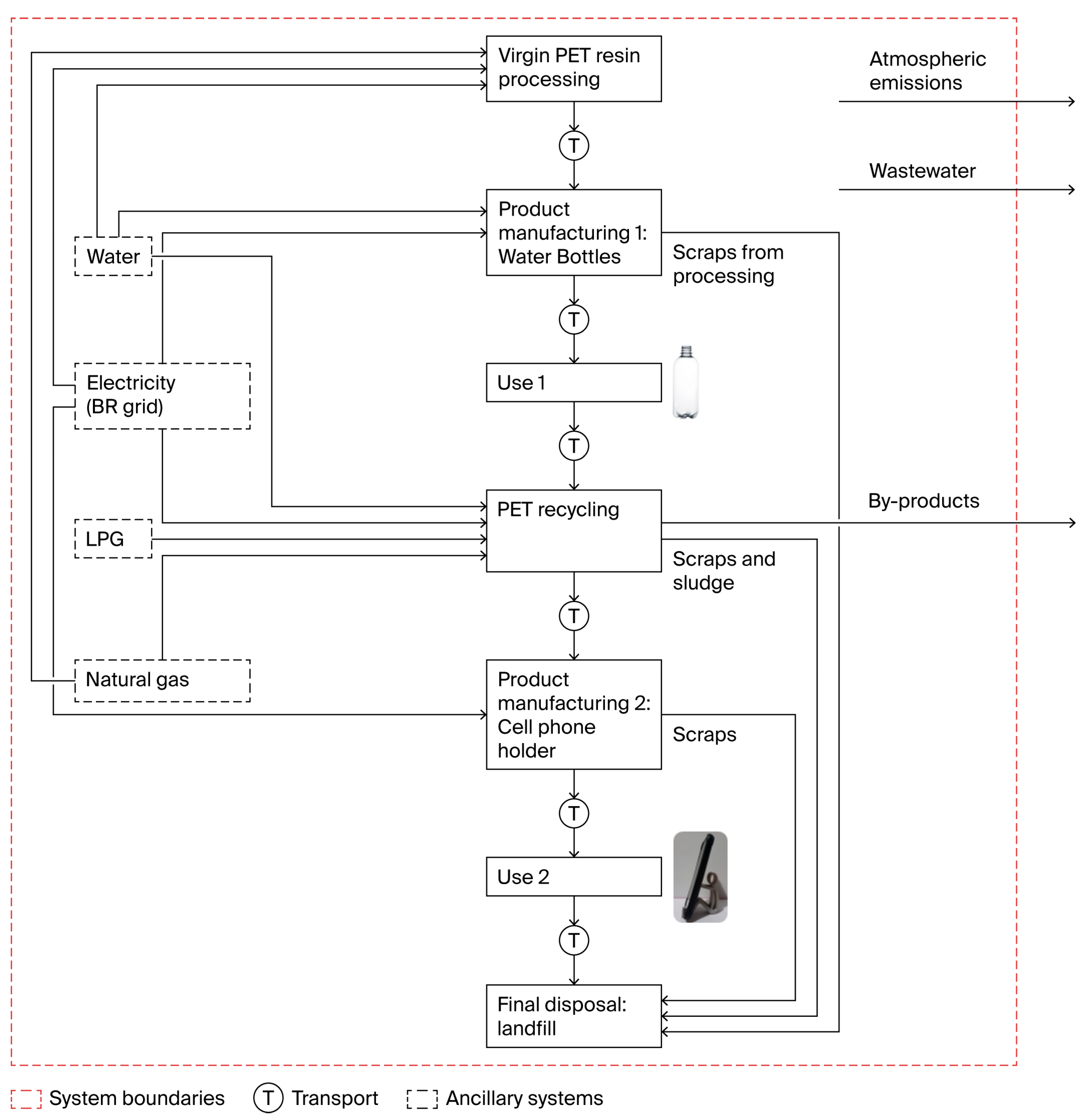

2.1. Specification of Production Routes for the PET Life Cycle Associated with an OLR Analysis

2.1.1. Virgin PET Resin Production

2.1.2. PET Bottle Manufacturing

2.1.3. Reverse Logistics and PET Recycling to Resin

2.1.4. Manufacturing a Cell Phone Holder Through 3D Printing

2.1.5. Use Phase

2.1.6. Final Disposal of the Cell Phone Holder

2.2. Analysis Dimensions: Technical Performance

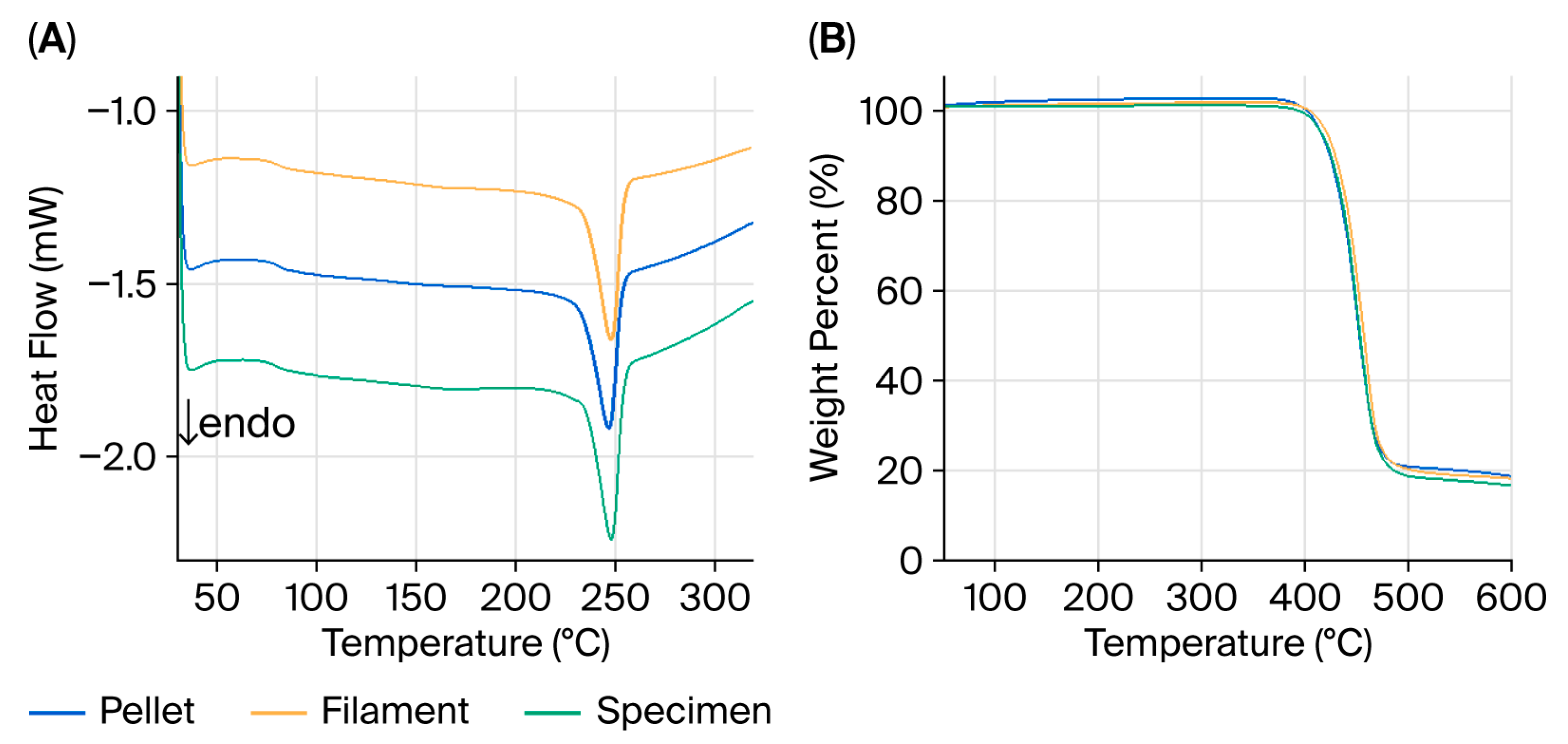

2.2.1. Thermal Characterization

- : area under the melting endotherm.

- : heat of fusion for a 100% crystalline sample (estimated to be 140 J/g for PET).

2.2.2. Rheological Characterization

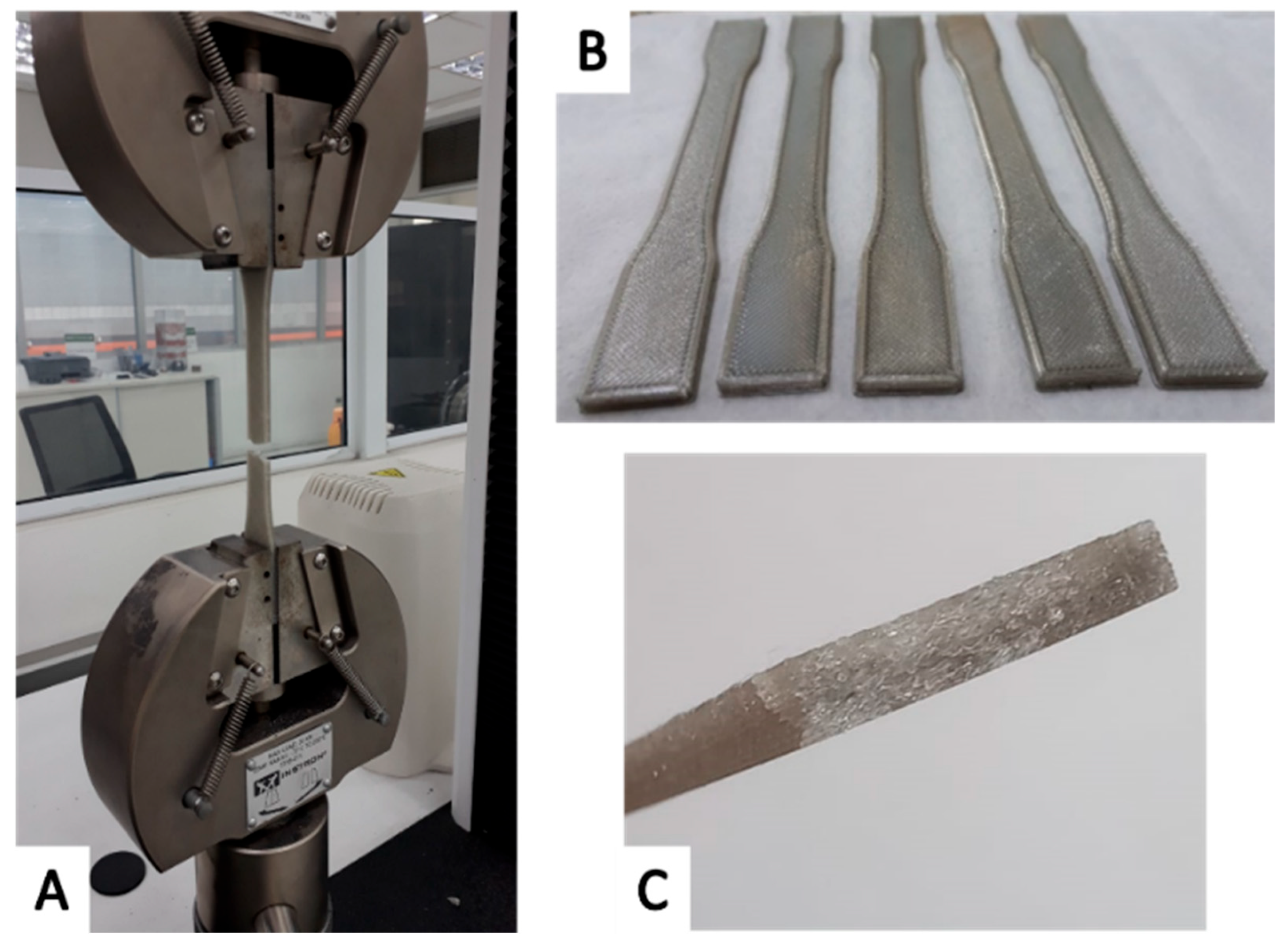

2.2.3. Mechanical Characterization

2.3. Analysis Dimensions: Environmental Performance Based on LCA Diagnosis

| Data | Sources | Comments |

|---|---|---|

| Virgin PET resin production | [48] | Adapted to Brazilian conditions |

| Grid electricity | [53,54] | Country-specific; Brazilian electricity mix (2020–2021): hydroelectric, 61%; natural gas, 11%; wind, 9.7%; biomass, 8.7%; coal, 3.1%; nuclear, 2.2%; oil and derivatives, 2.3%; solar, 2.0% |

| Natural gas (NG) production and combustion, LPG, fuel oil | [55,65,66,67] | Country-specific energy profiles; NG adaptations were conducted based on a model that considers Brazilian and Bolivian productions at a 72:26 ratio (offshore/onshore) |

| PET manufacturing bottles | [48,50] | Adapted to Brazilian conditions |

| Chemical production | [68] | Data and information on how these processes take place in Brazil were used to bring them closer to that reality, with changes in utility consumption (electricity, NG, and diesel) |

| Transportation | [52,55,69] Other distances obtained from PET recycled pellet producers | 7.5–16 lorry, EURO 4, for road transportation; country-specific procedural and technological requirements were considered for the diesel consumed during transportation |

| PET sorting and recycling | [70] Recycling processes from a recycled pellet PET producer | The sorting process was adapted to Brazilian conditions; site-specific recycling process (from 2020 and 2021) |

| Recycled PET filament manufacturing and cell phone holder production | Obtained from a pilot study conducted by a company | Site-specific (from 2020 and 2021) |

| Waste management: sanitary landfilling (4.0–8.0%) | [70] | Adapted to Brazilian conditions |

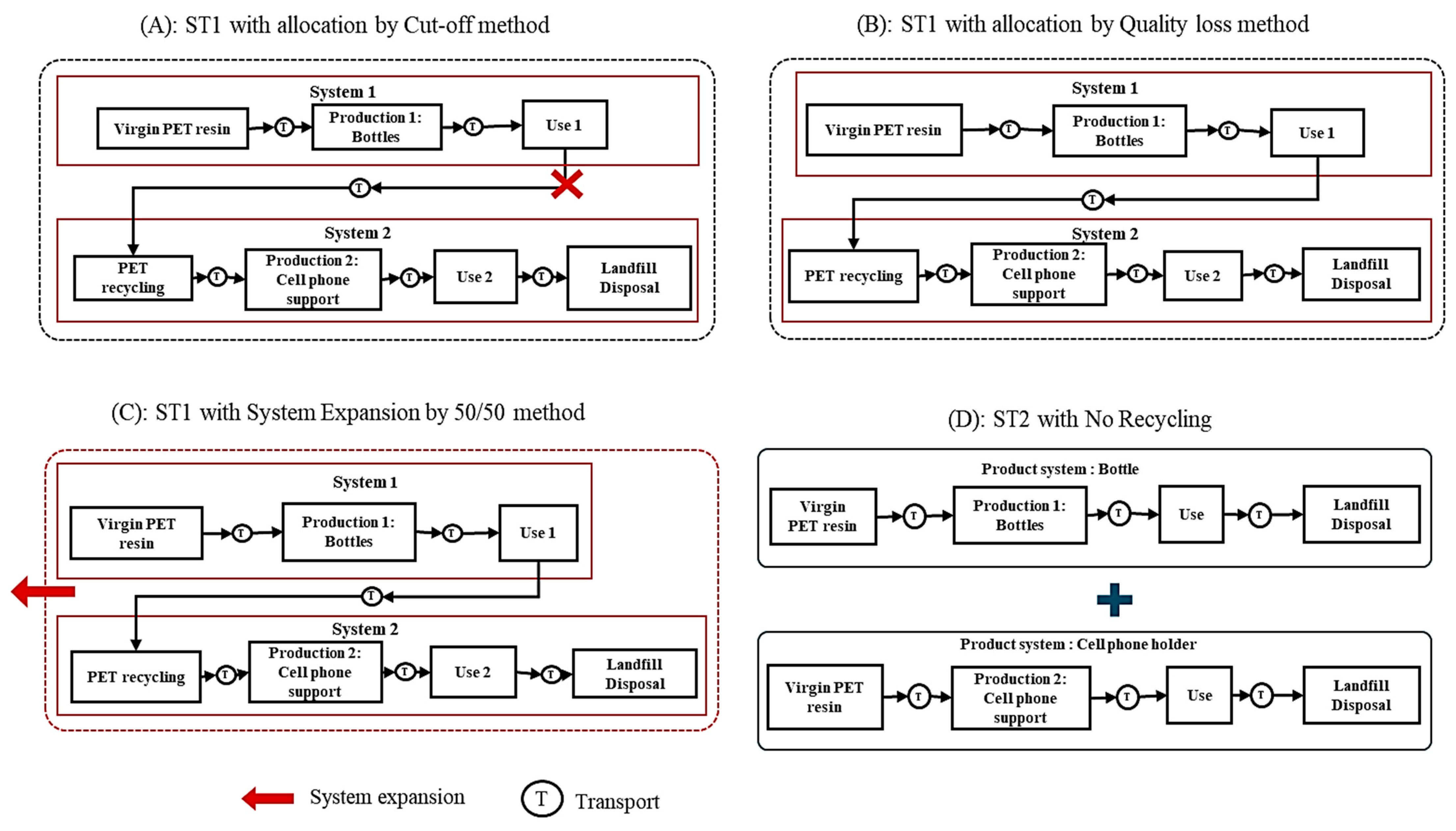

- Cut-Off method: The environmental performance of the cell phone holder was evaluated based on the collection of PET bottles used in its manufacturing (Figure 2A);

- Quality Loss method: The environmental performance of the cell phone holder was evaluated based on the production of the virgin PET resin used in the bottles (Figure 2B). According to this approach, environmental burdens occur during the common stages of systems ST1 and ST2 during the production of virgin PET resin, recycling, and final disposal. Intrinsic viscosity was chosen as the allocation criterion because it can simultaneously reflect the material’s melting point, crystallinity, and tensile strength. The (η) parameter is used to evaluate PET quality given its lower volatility and fewer uncertainties compared to economic criteria. The calculation of (η) is detailed in Section 3.1.2.

- 50/50 method: This method is a System Expansion option for addressing multifunctional situations in Consequential LCA. It equally allocates all environmental burdens between systems ST1 and ST2 (Figure 2C).

2.4. Analysis Dimensions: Circularity Performance—The MCI Index

3. Results

3.1. Technical Analyses

3.1.1. Thermal Analysis

3.1.2. Rheological Analysis

3.1.3. Mechanical Testing

3.2. Environmental Analysis

3.3. Circularity Analysis

4. Discussion

Limitations and Future Directions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CE | Circular economy |

| CLR | Closed-loop recycling |

| OLR | Open-loop recycling |

| LCA | Life Cycle Assessment |

| ALCA | Attributional Life Cycle Assessment |

| CLCA | Consequential Life Cycle Assessment |

| PET | Polyethylene terephthalate |

| AM | Additive manufacturing |

| FFF | Fused Filament Fabrication |

| B2B | Bottle-to-bottle |

| B2F | Bottle-to-fiber |

| GWP | Global Warming Potential |

| PED | Primary Energy Demand |

| WS | Water Scarcity |

| TAc | Terrestrial Acidification |

| MCI | Material Circularity Indicator |

| UNEA | United Nations Environment Assembly |

| UNEP | United Nations Environment Programme |

| DSC | Differential scanning calorimetry |

| TGA | Thermogravimetric analysis |

References

- MacLeod, M.; Arp, H.P.H.; Tekman, M.B.; Jahnke, A. The global threat from plastic pollution. Science 2021, 373, 61–65. [Google Scholar] [CrossRef]

- Kumar, R.; Verma, A.; Shome, A.; Sinha, R.; Sinha, S.; Jha, P.K.; Kumar, R.; Kumar, P.; Das, S.S.; Sharma, P.; et al. Impacts of plastic pollution on ecosystem services, sustainable development goals, and the need to focus on circular economy and policy interventions. Sustainability 2021, 13, 9963. [Google Scholar] [CrossRef]

- Statista Research Department. Average Weight of Polyethylene Terephthalate Bottles as of 2014, by Type (in Grams). Statista. 2014. Available online: https://www.statista.com/statistics/974035/average-weight-polyethylene-terephthalate-bottles-by-type/ (accessed on 20 June 2025).

- Gileno, L.A.; Turci, L.F.R. Life cycle assessment for PET-bottle recycling in Brazil: B2B and B2F routes. Clean. Environ. Syst. 2021, 3, 100057. [Google Scholar] [CrossRef]

- Korley, L.T.J.; Epps, T.H., III; Helms, B.A.; Ryan, A.J. Toward polymer upcycling-Adding value and tackling circularity. Science 2021, 373, 66–69. [Google Scholar] [CrossRef] [PubMed]

- Martin, E.J.P.; Oliveira, D.S.B.L.; Oliveira, L.S.B.L.; Bezerra, B.S. Life cycle comparative assessment of PET bottle waste management options: A case study for Bauru, Brazil. Waste Manag. 2021, 119, 226–234. [Google Scholar] [CrossRef]

- Bassi, S.A.; Tonini, D.; Ekvall, T.; Astrup, T.F. A life cycle assessment framework for large-scale changes in material circularity. Waste Manag. 2021, 135, 360–371. [Google Scholar] [CrossRef]

- UNEP. United Nations Environment Assembly of the United Nations Environment Programme: End Plastic Pollution: Towards an International Legally Binding Instrument. United Nations Environment Programme. 2022. Available online: https://digitallibrary.un.org/record/3999257?v=pdf (accessed on 2 March 2025).

- Ellen MacArthur Foundation. Circularity Indicators: An Approach to Measuring Circularity-Methodology. Ellen MacArthur Foundation. 2015. Available online: https://content.ellenmacarthurfoundation.org/m/5df196c8314ff61f/original/Circularity-Indicators-Project-Overview.pdf (accessed on 11 February 2025).

- Vadoudi, K.; Deckers, P.; Demuytere, C.; Askanian, H.; Verney, V. Comparing a material circularity indicator to life cycle assessment: The case of a three-layer plastic packaging. Sustain. Prod. Consum. 2022, 33, 820–830. [Google Scholar] [CrossRef]

- Lonca, G.; Lesage, P.; Majeau-Bettez, G.; Bernard, S.; Margni, M. Assessing scaling effects of circular economy strategies: A case study on plastic bottle closed-loop recycling in the USA PET market. Resour. Conserv. Recycl. 2020, 162, 105013. [Google Scholar] [CrossRef]

- Gracida-Alvarez, U.R.; Xu, H.; Benavides, P.T.; Wang, M.; Hawkins, T.R. Circular economy sustainability analysis framework for plastics: Application for poly(ethylene terephthalate) (PET). ACS Sustain. Chem. Eng. 2023, 11, 514–524. [Google Scholar] [CrossRef]

- Mobarak, H.; Islam, A.; Hossain, N.; Al Mahmud, Z.; Rayhan, T.; Nishi, N.J.; Chowdhury, M.A. Recent advances of additive manufacturing in implant fabrication-A review. Appl. Surf. Sci. Adv. 2023, 18, 100462. [Google Scholar] [CrossRef]

- Statista Research Department. Projected Global Additive Manufacturing Market Growth Between 2020 and 2026. Statista. 2022. Available online: https://www.statista.com/statistics/284863/additive-manufacturing-projected-global-market-size/ (accessed on 23 October 2024).

- Colorado, H.A.; Velásquez, E.I.G.; Monteiro, S.N. Sustainability of additive manufacturing: The circular economy of materials and environmental perspectives. J. Mater. Res. Technol. 2020, 9, 8221–8234. [Google Scholar] [CrossRef]

- Cruz-Sanchez, F.A.C.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Garcia, F.L.; Moris, V.A.d.S.; Nunes, A.O.; Silva, D.A.L. Environmental performance of additive manufacturing process-An overview. Rapid Prototyp. J. 2018, 24, 1166–1177. [Google Scholar] [CrossRef]

- Islam, A.; Mobarak, H.; Rimon, I.H.; Al Mahmud, Z.; Ghosh, J.; Ahmed, M.S.; Hossain, N. Additive manufacturing in polymer research: Advances, synthesis, and applications. Polym. Test. 2024, 132, 108364. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. On the environmental impacts of 3D printing technology. Appl. Mater. Today 2020, 20, 100689. [Google Scholar] [CrossRef]

- Saade, M.R.M.; Yahia, A.; Amor, B. How has LCA been applied to 3D printing? A systematic literature review and recommendations for future studies. J. Clean. Prod. 2020, 244, 118803. [Google Scholar] [CrossRef]

- Mikula, K.; Skrzypczak, D.; Izydorczyk, G.; Warchoł, J.; Moustakas, K.; Chojnacka, K.; Witek-Krowiak, A. 3D printing filament as a second life of waste plastic-A review. Environ. Sci. Pollut. Res. 2020, 28, 12321–12333. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, M.I.; Mohan, M.; Das, A.; Johnson, M.D.; Badwal, P.S.; McLean, D.; Gibson, I. A low carbon footprint approach to the reconstitution of plastics into 3D-printer filament for enhanced waste reduction. KnE Eng. 2017, 2, 234. [Google Scholar] [CrossRef]

- Bartolomei, S.S.; da Silva, F.L.F.; de Moura, E.A.B.; Wiebeck, H. Recycling expanded polystyrene with a biodegradable solvent to manufacture 3D printed prototypes and finishing materials for construction. J. Polym. Environ. 2022, 30, 3701–3717. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.T.; Khalid, M.; Yang, T.C.K.; Hung, S.T.; Huang, C.M. Physical characterization and pre-assessment of recycled high-density polyethylene as 3D printing material. J. Polym. Environ. 2017, 25, 136–145. [Google Scholar] [CrossRef]

- Gama, N.; Ferreira, A.; Barros-Timmons, A. 3D printed thermoplastic polyurethane filled with polyurethane foams residues. J. Polym. Environ. 2020, 28, 1560–1570. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life cycle analysis of distributed recycling of post-consumer high-density polyethylene for 3-D printing filament. J. Clean. Prod. 2014, 70, 90–96. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled polyethylene terephthalate as a new FFF feedstock material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- De Sá Teles, B.A.; Cunha, I.L.C.; da Silva Neto, M.L.; Wiebeck, H.; Valera, T.S.; de Souza, S.S.; Schmitt, A.F.O.; Oliveira, V.; Kulay, L. Effect of virgin PP substitution with recycled plastic caps in the manufacture of a product for the telephony sector. Recycling 2023, 8, 51. [Google Scholar] [CrossRef]

- Ügdüler, S.; Van Geem, K.M.; Denolf, R.; Roosen, M.; Mys, N.; Ragaert, K.; De Meester, S. Towards closed-loop recycling of multilayer and colored PET plastic waste by alkaline hydrolysis. Green Chem. 2020, 22, 5376–5394. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental Management-Life Cycle Assessment-Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Schrijvers, D.L.; Loubet, P.; Sonnemann, G. Developing a systematic framework for consistent allocation in LCA. Int. J. Life Cycle Assess. 2016, 21, 976–993. [Google Scholar] [CrossRef]

- Ligthart, T.N.; Ansems, T.M.M. Modeling of recycling in LCA. In Post-Consumer Waste Recycling and Optimal Production; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Geyer, R.; Kuczenski, B.; Zink, T.; Henderson, A. Common misconceptions about recycling. J. Ind. Ecol. 2015, 20, 1010–1017. [Google Scholar] [CrossRef]

- Kim, S.; Hwang, T.; Lee, K.M. Allocation for cascade recycling system. Int. J. Life Cycle Assess. 1997, 2, 217–222. [Google Scholar] [CrossRef]

- Ekvall, T.; Tillman, A.-M. Open-loop recycling: Criteria for allocation procedures. Int. J. Life Cycle Assess. 1997, 2, 155–162. [Google Scholar] [CrossRef]

- Ekvall, T.; Weidema, B.P. System boundaries and input data in consequential life cycle inventory analysis. Int. J. Life Cycle Assess. 2004, 9, 161–171. [Google Scholar] [CrossRef]

- Ekvall, T. A market-based approach to allocation at open-loop recycling. Resour. Conserv. Recycl. 2000, 29, 91–109. [Google Scholar] [CrossRef]

- Ekvall, T.; Björklund, A.; Sandin, G. Modeling Recycling in Life Cycle Assessment. Project Report 2020. Available online: https://www.researchgate.net/publication/344364006 (accessed on 5 February 2025).

- Klöpffer, W. Allocation rule for open-loop recycling in life cycle assessment—A review. Int. J. Life Cycle Assess. 1996, 1, 27–31. [Google Scholar] [CrossRef]

- Kousemaker, T.M.; Jonker, G.H.; Vakis, A. LCA practices of plastics and their recycling: A critical review. Appl. Sci. 2021, 11, 3305. [Google Scholar] [CrossRef]

- Vogdtländer, J.G.; Brezet, H.C.; Hendriks, C.E. Allocation in recycling systems. Int. J. Life Cycle Assess. 2001, 6, 344–355. [Google Scholar] [CrossRef]

- Nicholson, A.L.; Olivetti, E.A.; Gregory, J.R.; Field, F.R.; Kirchain, R.E. End-of-life LCA allocation methods: Open-loop recycling impacts on the robustness of material selection decisions. In Proceedings of the International Symposium on Sustainable Systems and Technology (ISSST 09), Tempe, AZ, USA, 18–20 May 2009. [Google Scholar]

- Chairat, S.; Gheewala, S.H. Life cycle assessment and circularity of polyethylene terephthalate bottles via closed and open loop recycling. Environ. Res. 2023, 236, 116788. [Google Scholar] [CrossRef]

- Baumann, H.; Tillman, A.-M. The Hitchhiker’s Guide to LCA: An Orientation in Life Cycle Assessment Methodology and Application; Studentlitteratur: Lund, Sweden, 2004. [Google Scholar]

- Bataineh, K.M. Life-cycle assessment of recycling post-consumer high-density polyethylene and polyethylene terephthalate. Adv. Civ. Eng. 2020, 2020, 8905431. [Google Scholar] [CrossRef]

- Williams, T.G.J.L.; Heidrich, O.; Sallis, P.J. A case study of the open-loop recycling of mixed plastic waste for use in a sports-field drainage system. Resour. Conserv. Recycl. 2010, 55, 118–228. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E.; Patel, M.K. Open-loop recycling: A LCA case study of PET bottle-to-fiber recycling. Resour. Conserv. Recycl. 2010, 55, 34–52. [Google Scholar] [CrossRef]

- Fröhlich, T. An Eco-Profile and Environmental Product Declaration of the European PET Manufacturers: Polyethylene Terephthalate (PET) (Bottle Grade). Plastics Europe Report. 2017. Available online: http://www.inference.org.uk/sustainable/LCA/elcd/external_docs/petb_31116f00-fabd-11da-974d-0800200c9a66.pdf (accessed on 17 March 2025).

- Romão, W.; Spinacé, M.A.S.; de Paoli, M.-A. Poli (tereftalato de etileno), PET: Uma revisão sobre os processos de síntese, mecanismos de degradação e sua reciclagem. Polímeros 2009, 19, 121–132. [Google Scholar] [CrossRef]

- Hischier, R. Life Cycle Inventories of Packaging and Graphical Papers; Ecoinvent Report No. 11; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Lopes, S.G.D.F.; dos Santos, A.T.S. Structure of the reverse chain: “Ways” of PET packing. Produção 2006, 16, 429–441. [Google Scholar]

- Paes, M.X.; de Medeiros, G.A.; Mancini, S.D.; Bortoleto, A.P.; de Oliveira, J.A.P.; Kulay, L. Municipal solid waste management: Integrated analysis of environmental and economic indicators based on life cycle assessment. J. Clean. Prod. 2020, 254, 119848. [Google Scholar] [CrossRef]

- Energy Research Company (EPE). Brazilian Energy Balance Year 2020; EPE: Brasília, Brazil, 2021. Available online: https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-601/topico-596/BEN2021.pdf (accessed on 8 August 2025).

- Energy Research Company (EPE). Brazilian Energy Balance Year 2021; EPE: Brasília, Brazil, 2022. Available online: https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-675/topico-638/BEN2022.pdf (accessed on 8 August 2025).

- Ministry of Mines and Energy (MME); Department of Natural Gas. Monthly Bulletin Monitoring the Natural Gas Industry December 2022; DNG: Brasília, Brazil, 2022. Available online: https://www.gov.br/mme/pt-br/assuntos/secretarias/petroleo-gas-natural-e-biocombustiveis/publicacoes-1/boletim-mensal-de-acompanhamento-da-industria-de-gas-natural/2022-2/12-boletim-de-acompanhamento-da-industria-de-gas-natural-dezembro-de-2022.pdf/view (accessed on 20 October 2025).

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- ABRELPE—Associação Brasileira de Empresas de Limpeza Pública e Resíduos Especiais. Panorama dos Resíduos Sólidos no Brasil; ABRELPE: São Paulo, Brazil, 2021; Available online: https://abrelpe.org.br/panorama-2021/ (accessed on 14 March 2025).

- Doka, G. Life Cycle Inventories of Waste Treatment Services; Ecoinvent Report No. 13; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2009. [Google Scholar]

- Paes, M.X.; Mancini, S.D.; de Medeiros, G.A.; Bortoleto, A.P.; Kulay, L. Life cycle assessment as a diagnostic and planning tool for waste management: A case study in a Brazilian municipality. J. Solid. Waste Technol. Manag. 2018, 44, 259–269. [Google Scholar] [CrossRef]

- Brandrup, J.; Immergut, E.H. Polymer Handbook, 3rd ed.; Wiley: New York, NY, USA, 1980. [Google Scholar]

- ASTM D4603-03; Standard Test Method for Determining Inherent Viscosity of Poly(Ethylene Terephthalate) (PET) by Glass Capillary Viscometer. ASTM International: West Conshohocken, PA, USA, 2003.

- Mancini, S.D.; Matos, I.G.; Almeida, R.F. Determinação da variação da viscosidade intrínseca do poli(tereftalato de etileno) de embalagens. Polímeros 2004, 14, 69–73. [Google Scholar] [CrossRef]

- IPCC. 2021: Climate Change 2021: The Physical Science Basis; Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V.P., Zhai, A., Pirani, S.L., Connors, C., Péan, S., Berger, N., Caud, Y., Chen, L., Goldfarb, M.I., Gomis, M., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2021; p. 2391. [Google Scholar] [CrossRef]

- Frischknecht, R.; Wyss, F.; Büsser Knöpfel, S.; Lützkendorf, T.; Balouktsi, M. Cumulative energy demand in LCA: The energy harvested approach. Int. J. Life Cycle Assess. 2015, 20, 957–969. [Google Scholar] [CrossRef]

- Faist, E.M.; Heck, T.; Jungbluth, N.; Tuchschmid, M. Erdgas. In Sachbilanzen von Energiesystemen; Dones, R., Ed.; Ecoinvent Report No. 6-V; Paul Scherrer Institut: Villigen, Switzerland, 2007. [Google Scholar]

- Jungbluth, N.; Chudacoff, M.; Dauriat, A.; Dinkel, F.; Doka, G.; Faist, E.M.; Gnausounou, E.; Kljun, N.; Schleiss, K.; Spielmann, M.; et al. Life Cycle Inventories of Bioenergy; Ecoinvent Report No. 17; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Sakamoto, H.; Maciel, M.; Cardoso, F.H.; Kulay, L. Energy and environmental contributions for future natural gas supply planning in Brazil. Energy Technol. 2019, 8, 1900976. [Google Scholar] [CrossRef]

- Althaus, H.J.; Chudacoff, M.; Hischier, R.; Jungbluth, N.; Osses, M.; Primas, A. Life Cycle Inventories of Chemicals; Ecoinvent Report No. 8, v2.0; EMPA Dübendorf, Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2009. [Google Scholar]

- Spielmann, M.; Dones, R.; Bauer, C. Life Cycle Inventories of Transport Services; Ecoinvent Report No. 14; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Haupt, M.; Käji, T.; Hellweg, S. Life cycle inventories of waste management processes. Data Brief. 2018, 19, 1441–1457. [Google Scholar] [CrossRef] [PubMed]

- Huijbregts, M.A.J. Life-Cycle Impact Assessment of Acidifying and Eutrophying Air Pollutants: Calculation of Equivalency Factors with RAINS-LCA; University of Amsterdam: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Azevedo, L.B.; van Zelm, R.; Hendriks, A.J.; Bobbink, R.; Huijbregts, M.A.J. Global assessment of the effects of terrestrial acidification on plant species richness. Environ. Pollut. 2013, 174, 10–15. [Google Scholar] [CrossRef]

- Boulay, A.M.; Bouchard, C.; Bulle, C.; Deschênes, L.; Margni, M. Categorizing water for LCA inventory. Int. J. Life Cycle Assess. 2011, 16, 639–651. [Google Scholar] [CrossRef]

- Karayilan, S.; Yilmaz, Ö.; Uysal, Ç.; Naneci, S. Prospective evaluation of circular economy practices within plastic packaging value chain through optimization of life cycle impacts and circularity. Resour. Conserv. Recycl. 2021, 173, 105691. [Google Scholar] [CrossRef]

- Gil Muñoz, V.; Muneta, L.M.; Carrasco-Gallego, R.; Marquez, J.d.J.; Hidalgo-Carvajal, D. Evaluation of the circularity of recycled PLA filaments for 3D printers. Appl. Sci. 2020, 10, 8967. [Google Scholar] [CrossRef]

- Berkowitz, S. Viscosity-molecular weight relationships for poly (ethylene terephthalate) in hexafluoroisopropanol-pentafluorophenol using SEC-LALLS. J. Appl. Polym. Sci. 1984, 29, 4353–4361. [Google Scholar] [CrossRef]

- Chacon, F.A.; Brouwer, M.T.; van Velzen, E.U.T. Effect of recycled content and rPET quality on the properties of PET bottles. Part I: Optical and mechanical properties. Packag. Technol. Sci. 2020, 33, 347–357. [Google Scholar] [CrossRef]

- Toth, L.; Slezák, E.; Bocz, K.; Ronkay, F. Progress in 3D Printing of Recycled PET. Addit. Manuf. 2024, 51, 102567. [Google Scholar] [CrossRef]

- Pinter, E.; Welle, F.; Mayrhofer, E.; Pechhacker, A.; Motloch, L.; Lahme, V.; Grant, A.; Tacker, M. Circularity study on PET bottle-to-bottle recycling. Sustainability 2021, 13, 7370. [Google Scholar] [CrossRef]

- Zander, N.E. Recycled polymer feedstocks for material extrusion additive manufacturing. In Polymer-Based Additive Manufacturing: Recent Developments; Seppala, J.E., Kotula, A.P., Sfronyder, C.R., Eds.; ACS Symposium Series, Vol. 1315; American Chemical Society: Washington, DC, USA, 2019; pp. 37–51. [Google Scholar] [CrossRef]

- Garcia, F.L.; Nunes, A.O.; Martins, M.G.; Belli, M.C.; Saavedra, Y.M.B.; Silva, D.A.L.; Moris, V.A.S. Comparative LCA of conventional manufacturing vs. additive manufacturing: The case of injection molding for recycled polymers. Int. J. Sustain. Eng. 2021, 14, 1604–1622. [Google Scholar] [CrossRef]

- BASF 3D PRINTING SOLUTIONS BV. Ultrafuse rPET Technical Data Sheet v3.2; BASF: Ludwigshafen, Germany, 2019; Available online: https://info.sculpteo.com/hubfs/Material%20documentation/Ultrafuse%20rPET/Ultrafuse_rPET_Technical_Data_Sheet_EN_v3.2.pdf (accessed on 4 August 2024).

- Tanguay, X.; Essoua, G.G.; Amor, B. Attributional and consequential life cycle assessments in a circular economy with the integration of a quality indicator: A case study of cascading wood products. J. Ind. Ecol. 2021, 25, 1462–1473. [Google Scholar] [CrossRef]

- Carvalho, K.M.; Alves, R.M.B.; Kulay, L. Environmental performance of alternative green polyol synthesis routes: A proposal for improvement. Processes 2021, 9, 1122. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Layer height | 0.30 mm |

| Infill pattern | Rectilinear: 45° and (−) 45° |

| Infill percentage | 30% |

| Bed temperature | 70 °C |

| Printing environment | 28 °C |

| Extruder temperature | 255–265 °C |

| Print speed | 80 mm/s |

| Filament diameter | 1.74 ± 0.50 mm |

| Sample | |||||||

|---|---|---|---|---|---|---|---|

| (J/g) | |||||||

| Pellet | 391 | 21.2 | 481 | 86.0 | 246 | 55.4 | 39.6 |

| Filament | 398 | 20.1 | 493 | 87.1 | 248 | 48.2 | 34.5 |

| Specimen | 395 | 18.8 | 491 | 87.7 | 248 | 50.1 | 35.8 |

| Sample | ||

|---|---|---|

| Pellet | 0.803 ± 0.002 | 23 467 |

| Filament | 0.667 ± 0.002 | 17 633 |

| Specimen | 0.622 ± 0.003 | 15 835 |

| Analysis | Tensile Strength at Yield | Elasticity Modulus | Elongation at Yield |

|---|---|---|---|

| (MPa) | (MPa) | (%) | |

| Samples | 37.7 ± 5.60 | 771 ± 29.4 | 7.64 ± 1.50 |

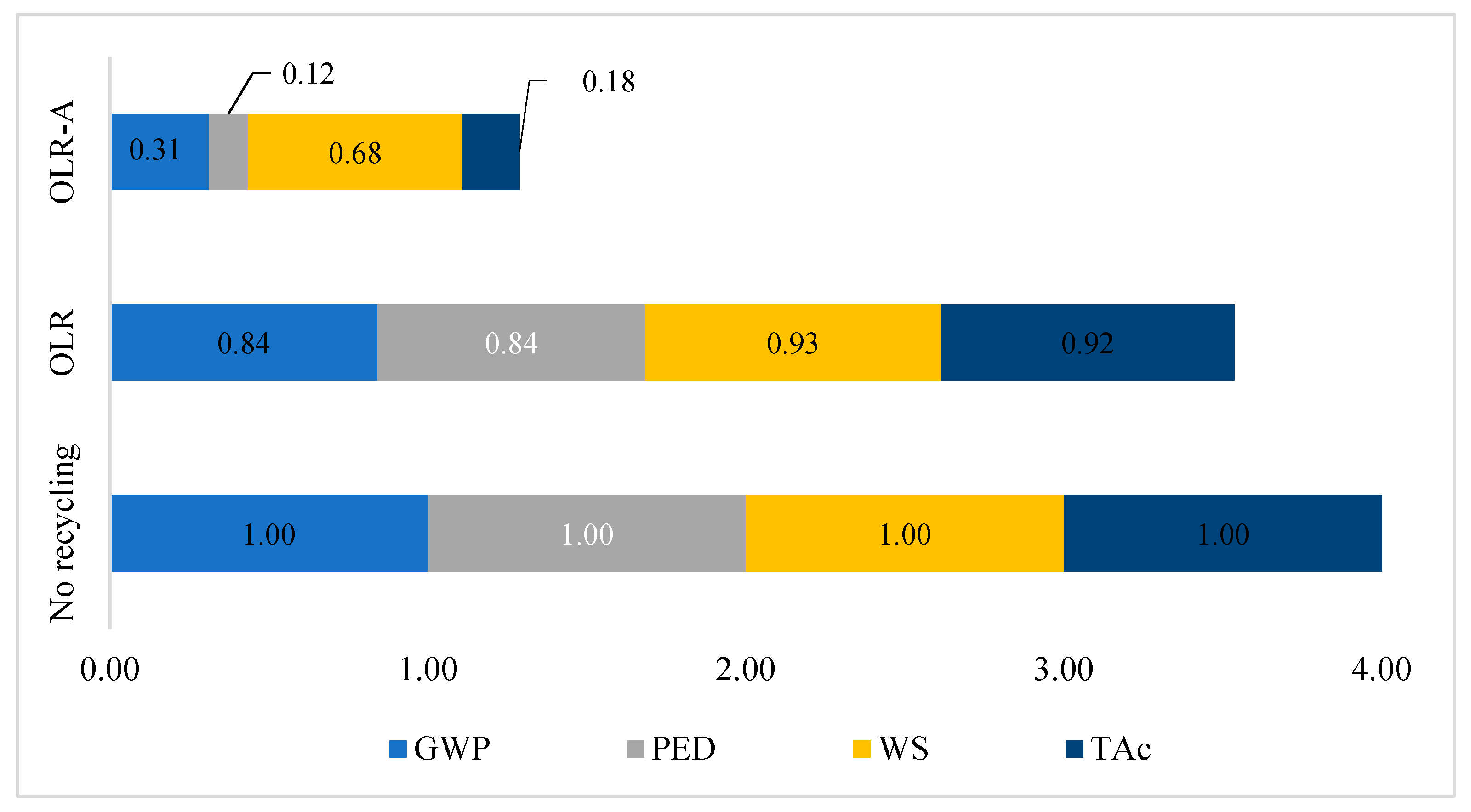

| Environmental Category | Unit (/FU) | No Recycling | OLR | ||

|---|---|---|---|---|---|

| Cell Phone Holder Production (ST2) | Total (ST1 + ST2) | Cut-Off (ST1A) | Quality Loss (ST1B) | ||

| GWP | g CO2 eq | 420 | 640 | 354 | 552 |

| PED | MJ | 16.3 | 23.6 | 13.7 | 20.5 |

| WS | L | 5.48 | 9.44 | 5.10 | 8.27 |

| TAc | g SO2 eq | 18.5 | 39.7 | 18.8 | 31.8 |

| – | 1.00 | 1.00 | 0.84 | 0.86 | |

| – | 1.00 | 1.00 | 0.84 | 0.87 | |

| – | 1.00 | 1.00 | 0.93 | 0.88 | |

| – | 1.00 | 1.00 | 1.02 | 0.80 | |

| – | 4.00 | 4.00 | 3.63 | 3.41 | |

| – | 1.00 | 1.00 | 0.91 | 0.85 | |

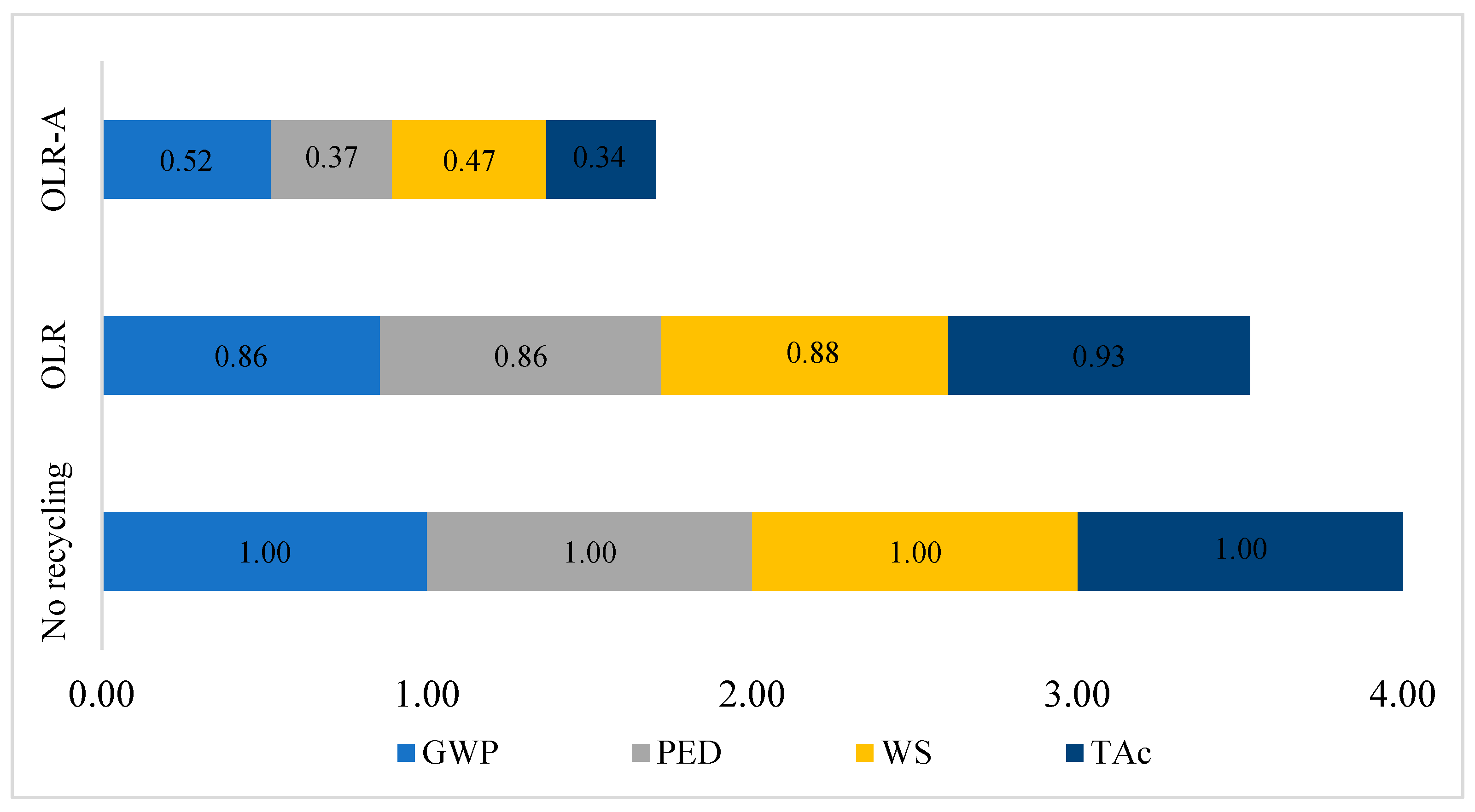

| Environmental Category | Unit (/FU) | No Recycling | OLR |

|---|---|---|---|

| Total (ST1 + ST2) | 50/50 (ST1C) | ||

| GWP | g CO2 eq | 656 | 562 |

| PED | MJ | 24.0 | 20.7 |

| WS | L | 11.2 | 9.92 |

| Tac | g SO2 eq | 2.81 | 2.61 |

| – | 1.00 | 0.86 | |

| – | 1.00 | 0.86 | |

| – | 1.00 | 0.88 | |

| – | 1.00 | 0.93 | |

| – | 4.00 | 3.53 | |

| – | 1.00 | 0.88 |

| Consumed Good | Equation | Values | |

|---|---|---|---|

| Bottles | (3) | ||

| Cell phone holder | (4) | ||

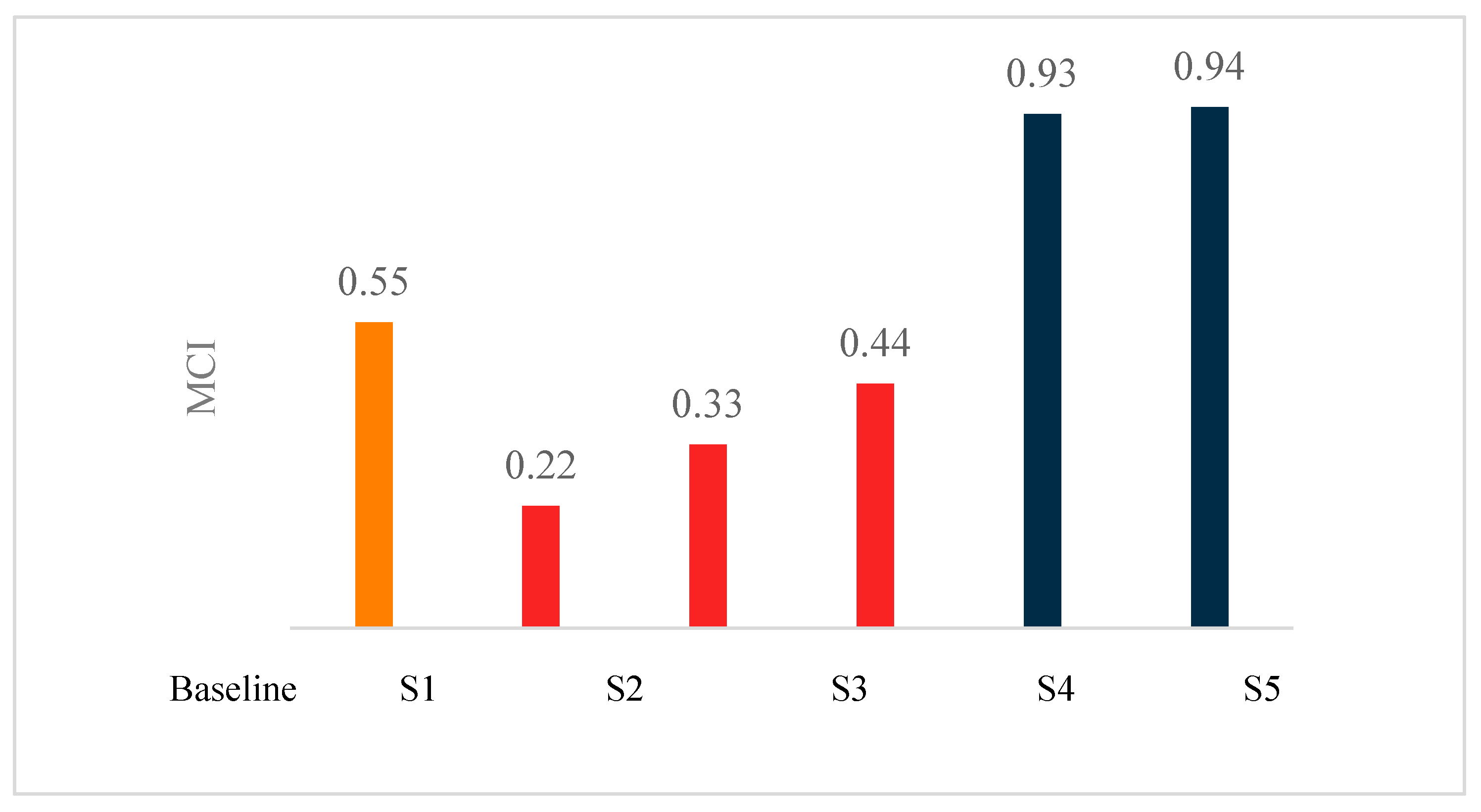

| Scenarios | Relative Amount of Virgin Material | Recycling Efficiency (End-of-Life Alternative) |

|---|---|---|

| (%) | (%) | |

| Baseline | 0.0 | 0.0 |

| S1 | 75 | 0.0 |

| S2 | 50 | 0.0 |

| S3 | 25 | 0.0 |

| S4 | 0.0 | 75 |

| S5 | 0.0 | 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teles, B.A.d.S.; Belli, M.C.; Barbosa Júnior, I.B.; Mancini, S.D.; Kulay, L. Environmental, Technical, and Circular Assessment of the Integration of Additive Manufacturing and Open-Loop Recycling of PET. Sustainability 2025, 17, 10068. https://doi.org/10.3390/su172210068

Teles BAdS, Belli MC, Barbosa Júnior IB, Mancini SD, Kulay L. Environmental, Technical, and Circular Assessment of the Integration of Additive Manufacturing and Open-Loop Recycling of PET. Sustainability. 2025; 17(22):10068. https://doi.org/10.3390/su172210068

Chicago/Turabian StyleTeles, Beatriz Arioli de Sá, Maria Cristina Belli, Irineu Bueno Barbosa Júnior, Sandro Donnini Mancini, and Luiz Kulay. 2025. "Environmental, Technical, and Circular Assessment of the Integration of Additive Manufacturing and Open-Loop Recycling of PET" Sustainability 17, no. 22: 10068. https://doi.org/10.3390/su172210068

APA StyleTeles, B. A. d. S., Belli, M. C., Barbosa Júnior, I. B., Mancini, S. D., & Kulay, L. (2025). Environmental, Technical, and Circular Assessment of the Integration of Additive Manufacturing and Open-Loop Recycling of PET. Sustainability, 17(22), 10068. https://doi.org/10.3390/su172210068