1. Introduction

China has experienced unprecedented economic growth during the past two decades; however, its energy consumption has released substantial CO

2 emissions that have possibly intensified climate change. According to McCarl [

1], the average world temperature will likely increase by more than 5 °C by the end of the century. Such a massive climate shift would also result in disastrous consequences, including rising sea levels, desertification, and an increased possibility of heat waves and hurricanes [

2], all degrading environmental quality and decreasing economic growth. Nevertheless, energy is also the key factor moving societal development forward, and countries are unlikely to keep growing without using energy. Thus, exploiting clean and sustainable energy sources is the only approach to secure the energy supply while maintaining social development [

3,

4].

Many countries and regions, such as the US, Japan, and the European Union, have made great efforts in renewable energy development since the beginning of the 21st century [

5,

6]. In recent years, China, the largest energy consumption country, has also pointed out that the development and employment of renewable energy would become its primary energy policy in the next five-year plan. The economy of southeastern China is prosperous. Guangdong, Fujian, and Zhejiang are the provinces that contribute more than 20% of the total GDP. However, their rapid economic growth indicates that these provinces consume the most fossil energy. Under the considerations of energy security and energy sustainability, the central government has forced these provinces to adjust their energy structure by increasing the share of renewable energy supply. Among all alternatives, bioresources have gained extraordinary attention.

Bioresources have been a key force stabilizing renewable energy production because they contain substantial organic matter that can quickly be converted into hydrogen energy [

7,

8,

9]. Kamshybayeva et al. [

10] show that rice paddies and hot springs have isolated nitrogen-fixing cyanobacterial strains that efficiently produce hydrogen energy. Kalantarifard et al. [

11] further identify that water splitting could be valuable for increasing renewable energy production under a specific catalyst process. The decomposition of bioresources also produces non-solid materials, such as biogas, which are beneficial for generating heat and electricity [

12]. For example, Kim et al. [

13] demonstrate that biogas utilization can improve operational efficiency and increase energy demand by enhancing the burner distribution ratio. However, the energy conversion ratio of biogas is sometimes unsatisfactory because it may decline when the reformer distribution ratio is low. Nevertheless, Sekar et al. [

14] indicate that when solid and non-solid bioresources are simultaneously employed, the internal combustion process is more efficient and greater biofuel production results.

The utilization of biogas is crucial because it is the primary output of livestock manure and agricultural residuals. During anaerobic digestion, organic sources release a substantial amount of methane (CH

4), which is considered a valuable energy source. Since livestock manure is constantly and stably distributed in many regions, anaerobic digestion is widely applied [

15]. Manure recycling and reuse have multiple benefits. Barragán-Escandón et al. [

16] point out that appropriate manure treatment can improve the environment and society. Chen et al. [

17] show that a manure plant with an 80-thousand-tons capacity can produce a benefit of up to USD 1.2 million annually. Generally, anaerobic digestion can be classified into mesophilic and thermophilic modules [

18]. Because mesophilic digestion is more robust with changes in operating parameters, it is widely deployed in many large biogas plants [

19,

20].

Nevertheless, robustness does not mean efficiency. Murillo-Roos et al. [

21] indicate that thermophilic digestion can efficiently degrade feedstocks and improve the output ratio. Still, Dalpaz et al. [

22] further argue that the thermophilic process consumes more energy to maintain the optimal fermenter temperature and stable operation. Biogas can be utilized not only for power generation but also for environmental protection [

23]. Pasternak [

24] shows that purifying and refining biogas can produce several value-added chemicals. Song et al. [

25] also point out that even the waste from anaerobic digestion can be a supplemental cropland fertilizer that can improve agricultural and environmental sustainability [

26]. Based on these considerations and the widely available manure resources in southeastern China, investigating the manure-based power potential could provide helpful information to improve regional energy security, adjust energy structures, and enhance energy sustainability [

15].

The study bridges the gap between economic growth, energy consumption, and environmental protection by comparing the development possibilities of alternative manure sources and processes. The fulfillment of this concern is crucial for two reasons. First, since bioenergy development involves long-term investment and the payback period is generally longer than 10 years [

27], it is necessary to determine whether a specific technique is economically feasible; otherwise, no investment can be made, and no economic and environmental gains can be achieved. Second, the analysis helps identify the capability of a regional renewable energy strategy under carbon neutrality. Thus, investigating the carbon offset potential of various manure utilization possibilities is crucial for China’s energy sustainability, social development, and environmental management.

Various manure applications exist, and each of them focuses on different aspects. For example, compositing is a general approach that converts manure into biofertilizer that improves crop yields. This method is a valuable technology; however, if we focus on the aspect of energy security, then compositing can only bring environmental benefits, not energy outputs. Thus, it is necessary to evaluate different manure application possibilities. The analysis of manure application aims to explore the potential of renewable energy and its emission offset consequences in southeastern China. Hog, cattle, sheep, and poultry manures are selected as the inputs because they are the primary livestock in this region, and thus, the biomass supply can be considered stable. The mesophilic and thermophilic processes are used to identify the differences between the production possibilities. This study applies a techno-economic analysis (TEA) and lifecycle assessment (LCA) to evaluate the economic and environmental components associated with the production routes. Given the specified system boundary, the LCA stage calculates the carbon footprints attached to transportation, the release of agricultural inputs, and the replacement of fossil energy. In contrast, the TEA stage evaluates the economic factors, such as energy sales, plant construction, and the value of biofertilizers.

Several contributions derive from the results. First, manure application should focus not only on energy potential but also on economic feasibility. While O-thong et al. [

28] and Zhang et al. [

29] investigated the financial and environmental effects of mesophilic and thermophilic anaerobic digestion, their results are incomparable because the study regions, feedstock types, and process methods were different. On the contrary, this study investigates the economic and environmental consequences of competitive anaerobic digestion methods in a properly defined region with the same biomass, making the comparisons more valid. Therefore, this study offers a more reasonable basis for the decision-makers to allocate capital and physical resources to optimize technology determination and improve regional renewable energy development. Second, studies have shown the energy output ratio of technologies; however, they have generally focused on the conversion efficiency rather than on the economic feasibility of a technology [

30,

31]. Thus, the results of this study provide an applicable basis for southeastern China to develop and apply the most capital-efficient manure strategies and make the overall renewable energy development effective.

2. Materials and Methods

2.1. Background to Anaerobic Digestion

Sakar et al. [

32] demonstrated that anaerobic digestion, which breaks down microorganisms, can effectively manage pollution and waste. During digestion, microorganisms play a key role in material decomposition. Still, Varjani et al. [

33] indicated that other factors, such as the pH level, nutrient environment, humidity, and temperature, also affect the reaction rate and output ratio. The primary output from anaerobic digestion is biogas and digestate [

34]; biogas contains various gases, such as methane (CH

4), hydrogen (H

2), carbon dioxide (CO

2), and nitrous oxide (N

2O), and digestate is known as the biogas residual that can be used as biofertilizer to increase crop yields [

26]. In addition, since methane is the primary feedstock that is collected and utilized to provide energy in many manure applications, this study will focus only on methane [

35].

Among all the impacting factors, temperature is crucial because it directly influences the output rates. Depending on the level of processing temperature, anaerobic digestion can be classified into mesophilic and thermophilic modes, of which the former requires a temperature between 30 and 40 °C. In contrast, the latter requires a temperature range between 40 and 60 °C. The higher the processing temperature, the more biogas output is expected due to active microorganism activities [

36].

Table 1 shows the biogas output of alternative biomasses and digestion processes. There is merit to discussing the data further. While a thermophilic process generally produces more biogas per ton of manure, it also requires more energy input to sustain the optimal temperature of a system [

37]. Thus, a mesophilic process that yields lower biogas does not necessarily mean that it is outperformed by the thermophilic mode. It is necessary to analyze the profitability of each process and biomass feedstock.

2.2. System Boundary

To complete the economic and environmental assessments of manure application, the system boundary should be carefully determined so that the influencing factors can be well estimated, and the insightful results are appropriately obtained. A techno-economic analysis (TEA) is widely used to evaluate the impacts of alternative economic components [

39], and a lifecycle analysis (LCA) is often used to estimate the environmental contributions of factors during their lifetime [

40]. For example, Kung et al. [

23] employed a TEA to analyze whether biochar application to cropland can increase farmers’ income, and to what extent agricultural sustainability can be achieved. Additionally, Zhang et al. [

20] adopted an LCA to estimate the emission consequences of a biogas-to-energy conversion system. Cao et al. [

3] combined a TEA and LCA to construct an optimal bioenergy development strategy. In this study, hog, sheep, cattle, and poultry manures are the primary feedstocks used to examine the mesophilic and thermophilic digestion processes. Thus, the system boundary is delineated in

Figure 1, which identifies the flow of the raw materials to the final use of outputs.

The system boundary indicates that anaerobic digestion applications may involve multiple stages. First, the manure resources must be classified, collected, and packed. Second, the transport and storage of the packed materials to the processing plant are involved. Subsequently, the factors involved in the construction and operation of the processing plant should be determined and estimated. The final stage is using biogas for bioenergy production or as agricultural amendments. For each stage, the economic and environmental factors should be identified and calculated, and they will be displayed in the following subsections. We convert the results into a ton of manure as a basis for comparison.

2.3. Manure Distribution

This study investigates the potential use of manure in southeastern China under two competing digestion systems, and we illustrate that the economic feasibility of the technology depends not only on the conversion ratio but also on the production costs. Since one of the most critical factors impacting the production costs is the acquisition cost of the raw materials [

23], the distribution of manure resources should be explicitly expressed to estimate the collection and transportation costs associated with manure recycling and reutilization.

Table 2 displays the results.

The data for

Table 2 can be found in

Table A6. Specifically, the data table contains three kinds of data. (1) The raw data for livestock and poultry was collected from the statistical yearbooks on the corresponding prefecture-level municipal government websites. The specific URLs are provided in

Appendix A. (2) The weight of manure is estimated based on the number of livestock. The lifecycle of marketed pigs is calculated as 350 kg of manure. That for breeding pigs is calculated as three times the weight of a pig. That for broilers and laying hens is computed as 0.1 kg per day, with a life span of 55 days. Beef cattle manure is calculated as an average of 10 kg per day, with a life span of 365 days. Dairy cow manure is calculated as 20 kg per day. Sheep manure is calculated as an average of 1.5 kg per day, with a life span of 180 days. (3) The table provides data for 57 cities across four southeastern provinces of China.

The specific cities in the study region and the data source are also identified. Fujian Province (9 cities) is divided into eastern Fujian, southern Fujian, and northern Fujian. Eastern Fujian includes Fuzhou, Ningde, and Putian; southern Fujian includes Xiamen, Quanzhou, and Zhangzhou; and northern Fujian includes Longyan, Sanming, and Nanping. Guangdong Province (21 cities) is divided into the Pearl River Delta, eastern Guangdong, western Guangdong, and northern Guangdong. The Pearl River Delta includes Guangzhou, Shenzhen, Foshan, Dongguan, Zhongshan, Zhuhai, Zhaoqing, Jiangmen, and Huizhou; eastern Guangdong includes Shantou, Chaozhou, Jieyang, and Shanwei; western Guangdong includes Zhanjiang, Maoming, Yangjiang, and Yunfu; and northern Guangdong includes Shaoguan, Qingyuan, Heyuan, and Meizhou. Zhejiang Province (11 cities) is divided into northern Zhejiang and southern Zhejiang. Northern Zhejiang includes Hangzhou, Jiaxing, Huzhou, Shaoxing, Ningbo, and Zhoushan; southern Zhejiang includes Wenzhou, Taizhou, Jinhua, Lishui, and Quzhou. Anhui Province (16 cities) is divided into northern Anhui, central Anhui, and southern Anhui. Northern Anhui includes Fuyang, Bozhou, Huaibei, Suzhou, and Bengbu; central Anhui includes Hefei, Lu’an, Huainan, and Chuzhou; and southern Anhui includes Xuancheng, Huangshan, Chizhou, Tongling, Wuhu, Anqing, and Ma’anshan.

2.4. Identification of Cost and Benefit Components

To determine the alternative digestion modes’ overall profitability and emission offset capability, it is necessary to classify the cost and benefit factors and estimate them with the appropriate analysis. The following sections show the definitions of energy output, the assumptions made for transportation, and the cost allocation of project investment.

2.4.1. Estimates of Biopower and Energy Sales

To evaluate the biopower production and subsequent economic and environmental factors, it is necessary to define the capacity of the manure processing plant. In this study, the digester capacity is assumed to be 100,000 tons per year, and this plant can preprocess the raw materials, digest the manures, separate the biogas and slurry, and convert the biogas into biopower [

39]. Based on Ji et al. [

41], the removal rate of chemical oxygen demand (COD) is approximately 85% and the gas yield is 2.23 m

3/day. Thus, we can estimate the city-level biopower production (

Powerijz) using Equation (1), shown below:

where

i stands for the types of manure resources,

j denotes the mode of anaerobic digestion, and

z identifies the city. The variable

biogasij is the net biogas production from the

ith manure under the

jth processing mode, which is expressed in cubic meters.

manureiz is the supply of

jth manure resource in city

z, and

Energy Coef shows the energy conversion rate of biogas to biopower, estimated at 2 kWh per m

3 of biogas [

35].

Nevertheless, a loss of methane is likely to occur during the production stage. For example, Scheutz and Fredenslund [

42] surveyed 23 biogas plants and showed that the methane loss rate generally ranges from 0.4% to 14.9%, and it is significantly higher in thermophilic processes. They also pointed out that, on average, the loss rate of methane for all the processing stages is around 7.5%. Following their study, this study will take off 7.5% from the biogas production, and the net biopower potential will be estimated based on 92.5% of the collected biogas.

2.4.2. Estimates of Production Profits

Production Costs

Their profitability must be carefully estimated to determine whether manure applications can be employed on a large scale. The cost components of manure recycling and reuse involve biomass collection and packing, transportation, storage and preprocessing, and anaerobic digestion [

43]. The China Ministry of Agriculture [

44] points out that the collection and compaction cost for a ton of manure is around USD 10, and the Institute of Agricultural Research [

35] shows that the collection and compaction cost for poultry manure is generally 10–20% higher. Thus, this study assumes that the per ton collection cost is USD 27 for hog, USD 25 for cattle and sheep, and USD 30 for poultry manure. The packing cost for mammals is USD 10 per ton, and it is USD 12 for poultry manure. Because manure is processed constantly and a substantial portion must be stored and preprocessed before it is eventually conveyed to an operating facility, the storage and the preprocessing costs must be determined. OYM logistics [

45] indicates that the storage cost for common manufacturers is generally between USD 6 and 20 per cubic meter. Since manure is considered an environmental waste, its storage cost is substantially higher. This study assumes it to be 15 USD/m

3.

Hauling efforts are required to convey manure to a processing facility. To investigate the transportation costs, we used French [

46] to estimate the hauling distance and hauling expenses, expressed as Equations (2) and (3). This approach assumes that square-grid roads surround the facility, and thus, the capacity of the processing plant and the distribution of biomass significantly affect the results.

In Equation (1), by multiplying by a factor of 1.6, the Hauling Distance is converted from miles to kilometers, and it shows the average kilometers between the collection sites and the facility; Demand is the capacity of the processing facility; Y identifies the per-hectare production of biomass; and den shows the distribution of the ranch. In Equation (2), b0 is the fixed loading expense irrelevant of the capacity, which is assumed to be USD 110 per truckload. b1 is the hauling cost, which includes the truck’s labor, fuel, and maintenance costs, which are about USD 2.5 per kilometer. Load is the truckload, commonly assumed to be 30 tons in China.

The costs of the processing plant should also be annualized. According to Aftab et al. [

47], the framework should include estimates, overhead, utility, labor, operation, and maintenance costs, and Tang [

48] illustrates how these factors can be calculated. Based on this method, the annualized facility per ton of manure can be determined, as shown in Equation (4).

where

Amortization is the total amount of facility costs to be allocated in each year;

Investment is the present value of assets, such as reactors and buildings; and

Salvage is the residual value of the facility at the end of its lifetime.

Useful life determines the facility’s service life, which is assumed to be 15 years in this study.

Equation (5) further identifies the process of converting energy production into revenues. Income is defined as USD/kWh; Biogas is the methane collected, with a unit of m3; Energy Conversion is the power conversion ratio per ton of manure, with a unit of kWh/m3, and Energy Price is the prevailing energy price, with a unit of USD/kWh. Additionally, the GWh used in this study is equivalent to 106 kWh.

Economic Gains

The gains from manure applications are two-fold. First, biopower and emission reduction can be sold to the market. We can estimate the energy sales revenues using the prevailing electricity price of 0.09 USD/kWh. The emission reduction value is somewhat arbitrary because the international emission price has been approximately USD 90–130 in the United States and the European Union in recent years [

49], but it is a mere USD 10–20 in China. Because China is an importing country and most of its products sold to the EU must satisfy international standards, we use the emission price listed on the European Climate Exchange to estimate the benefits of emission offset. Second, gains of biofertilizer (i.e., digestate) should be calculated. Biofertilizer blended with chemical fertilizers can improve soil fertility, reducing the seed needs, fertilizer use, and irrigation by approximately 17–36% [

50,

51,

52], and increasing crop yields by approximately 9% [

48]. Thus, the gains from agricultural systems due to biofertilizer application should be counted.

3. Results and Discussion

3.1. Results of Power Generation

Table 3 shows the biopower production under different anaerobic modes and feedstocks. Hog manure generally yields the most biopower in all regions because it is the primary livestock grown in China. Thus, hog manure can be a reliable input relative to other sources. Additionally, because the biogas produced from hog manure is close by, a 5% higher loss in the thermophilic mode would result in lower biopower. However, hog manure can be considered a special case since the significant difference in biogas production between the two processing modes is explored for the other manure sources. Therefore, energy production in the thermophilic mode is still higher for cattle, poultry, and sheep manure.

Poultry manure is another vital source that yields large amounts of biopower. In most regions of Fujian, Guangdong, Anhui, and the Pearl River Delta, the use of poultry manure can produce significant amounts of biopower. For example, in northern Fujian, recycled hog manure has a power potential of up to 508–515 GWh, and poultry manure can supply 432 to 516 GWh per year, depending on the anaerobic methods used. In Anhui province (which aggregates the northern, central, and southern regions), poultry manure can produce biopower of 952 GWh under a mesophilic system and 1137 GWh under a thermophilic system. Thus, poultry manure should be appropriately managed due to its excellent energy potential. If we only look at the net biopower production, cattle and sheep manure are relatively unattractive; nevertheless, a conclusion cannot be obtained based on this simple observation, and more issues should be considered.

By aggregating the results, hog manure can generate biopower ranging from 5599 to 5683 GWh; it is 653 to 1887 GWh for cattle, 2481 to 2963 GWh for poultry manure, and 1109 to 1536 GWh for sheep manure. The aggregate emission offset can also be substantial. If all manures are properly utilized, the net emission offset can be up to 12.07 million metric tons of CO2 equivalent. If the biopower can be sold at the prevailing market price, approximately USD 1086 million of energy sales can be expected.

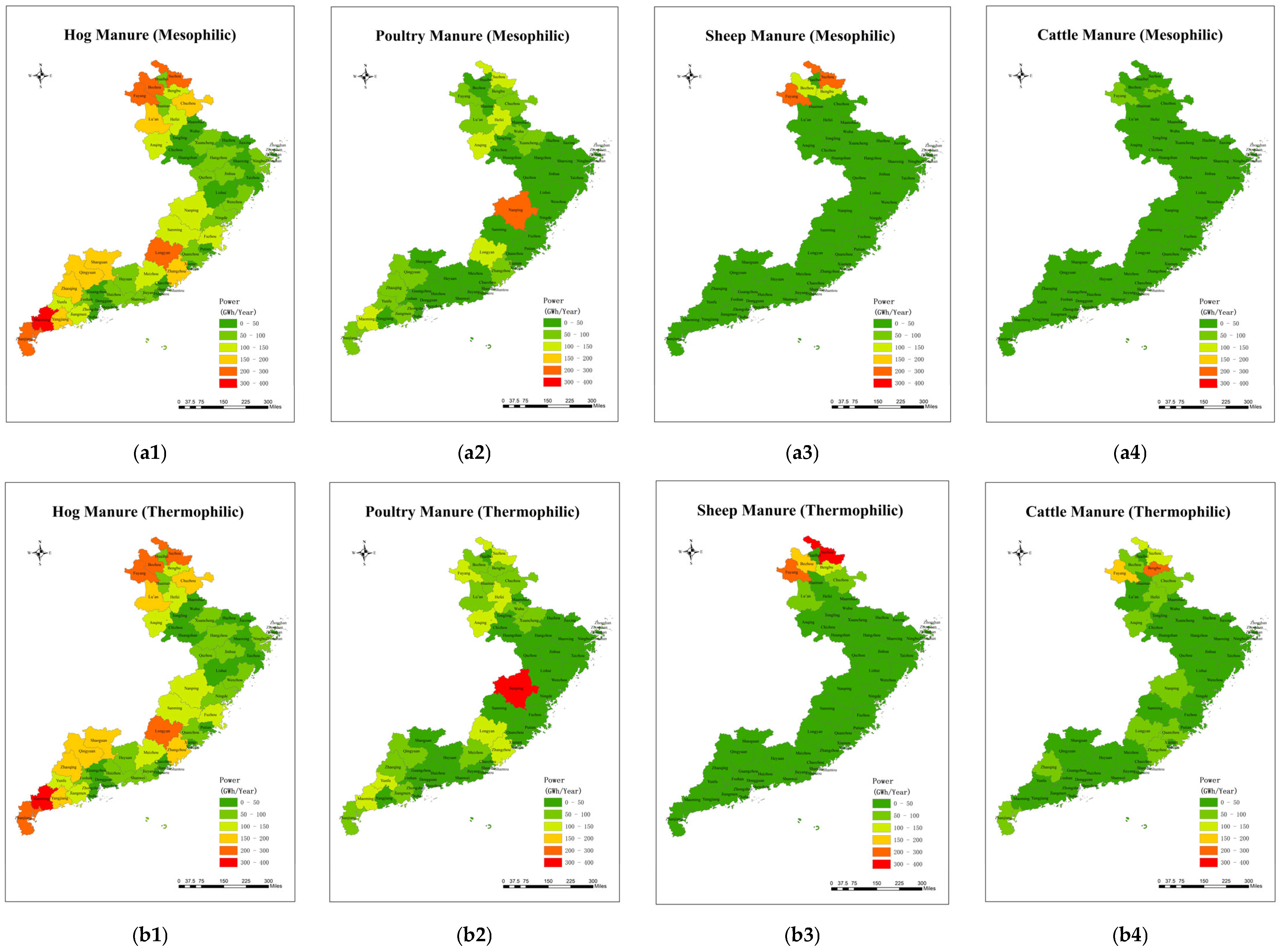

Table 3 shows the net biopower production of each region and demonstrates that hog and poultry manure are crucial for generating biopower.

Figure 2 illustrates the areas of biopower distribution, and provides efficient information regarding capital and input allocation. The results show that while hog and poultry manure are intensively distributed across the regions, cattle and sheep manure are generally distributed in Anhui province (i.e., the upper part of

Figure 2). This result is interesting because while the total biopower from sheep and cattle manure is less, it could be a valuable addition to regions where these manures are intensively distributed. A lower transportation and processing cost would be expected with a greater distribution density. Thus,

Figure 2 further points out that Anhui and central Fujian may still use sheep and cattle manure as production alternatives.

3.2. Economic Analysis Using Techno-Economic Analysis

3.2.1. Manure Collection, Compaction, and Hauling

The economics of manure applications are considered by a techno-economic analysis, in which all the benefits and costs associated with every production and processing stage are estimated appropriately. Based on the market price, this study assumes that the per-ton collection cost is USD 27 for hog, USD 25 for cattle and sheep, and USD 30 for poultry manure. Following the recommendations of Aftab et al. [

47] and the China Ministry of Agriculture [

44], the cost per ton of manure packing is USD 10 for hog, cattle, and sheep, and USD 12 for poultry manure due to the higher collection effort [

35].

Once the manure is correctly collected and packed, it is loaded onto a truck and transported to the storage plant. Thus, the transportation costs must be estimated. We can obtain the average hauling distance and hauling costs using Equations (2) and (3) and the manure distribution data in

Table 2.

Table 4 shows the results. Of all the manure resources, sheep manure has the lowest transportation distance and hauling costs because it is centrally distributed. Compared to sheep manure, poultry and cattle manures have a long hauling distance and high transportation cost, implying a divergent distribution. Such high costs decrease the profitability. Thus, even if we calculate the net biopower potential from the total manure supply, it is still uncertain whether these resources can be economically recycled and reused.

The results indicate that the transportation distance and cost can vary significantly. This is due to the distribution and availability of specific biomasses. If a biomass is concentratedly distributed within a small area, like sheep manure, then the average transportation distance is low and yields a low transportation cost.

3.2.2. Feedstock Storage and Pretreatment

A continuous and stable energy supply is key for a resource to be reliable. Thus, storage and preprocessing costs that guarantee the continuous operation of a facility should be considered. For most long-term projects, building a warehouse in an industrial park is relatively more cost-effective than renting one. This study suggests that investors construct a warehouse and then depreciate this investment. On average, the construction cost per m

2 is USD 143.6, and thus for a storage facility with 10,000 m

2 and 100,000 tons capacity, the estimated storage cost per ton of biomass is be USD 14.36. Chen et al. [

17] provide estimates for the manure pretreatment cost. Based on a 15-year useful life and a 5% discount rate, the annualized pretreatment cost per ton of manure is around USD 0.82.

3.2.3. Cost of Plant Construction and Operation

The next step is to calculate the plant’s construction and operation costs. Since the plant’s useful life is assumed to be 15 years, the discount rate is 5%, and the annual processing capacity is 100,000 tons, the plant’s annualized fixed cost is approximately USD 3.72 per ton of manure [

39]. The variable cost associated with the plant’s operation is another crucial component. Based on the reported Consumer Price Index report [

49], the operating cost per ton of manure is USD 5.6, among which the equipment maintenance cost is USD 3.36, the labor and management cost is USD 1.4, and the energy used to operate the reactors costs USD 0.84.

3.2.4. Cost of Power Generation

The per kWh electricity cost can be calculated along with the estimated costs and the total power potential, and are presented in

Table 3.

Table 5 shows the results. Since the biogas output and subsequent biopower production depend on the digestion modes, we separately present the unit cost for alternative processes. The results demonstrate that the source with the highest energy potential may not be the most economical choice. For example, hog manure has the most tremendous amount and is assumed to be the most helpful source in biopower production. Indeed, the cost per kWh from hog manure ranges from GHS 16.78 to GHS 18.89 under mesophilic mode and GHS 17.27 to GHS 18.93 under thermophilic mode. Such a high development cost makes manure-based biopower unattractive.

Nevertheless, the development cost does not indicate a negative net profit because we still need to incorporate the environmental benefits, such as cropland feedstock and emission trades, into account. Additionally, the thermophilic mode incurs a lower per kWh cost for other manure sources because they have higher biogas production under the thermophilic mode, even with an additional 5% loss of biogas collection. Since the facility is generally assumed to be operated under a specific technology and the transition between modes cannot be freely adjusted, a higher per kWh power cost would occur if the mesophilic mode were used.

Table 5 also indicates that under the current cost profile, anaerobic digestion may not be a good choice because the power supplier can generate more electricity but at a high cost. Nevertheless, the gains in biopower production come not only from energy sales but also from the agricultural feedback associated with digestate application and emission trades. Thus, a further investigation of these components should be conducted.

Table 5 shows the unit power cost, but how much the manure application contributes to the profits should also be explored to validate the feasibility of the technologies across provinces and cities.

Table 6 shows the results. Fujian and Anhui generally have higher energy sales because they produce more manure. Since the manure is unlikely to be transported across provinces due to the higher transportation costs, the manure is locally processed and thus increases the regional renewable energy supply and energy sales. We also show that poultry manure generates considerable revenues. However, because it incurs higher collection and packing costs, it is still considered a less cost-effective resource and should be used only after hog manure. Based on the economics, hog manure should first be used. Poultry and sheep manure should not be used independently because they generate the lowest amount of power and are not worth constructing a processing facility just for sheep manure. The results indicate that sheep and cattle manure should be used as

Appendix A to hog and poultry manure to maintain the routine operation of reactors. In general, if hog manure is processed under mesophilic systems, the benefits from selling it could be up to USD 533.16 million. A vast divergence occurs for cattle manure. Under a thermophilic system, it could yield up to USD 177 million in revenues, but it sharply decreases to USD 61.3 million under mesophilic modes. The results indicate that the system selection significantly affects the profitability of manure application.

3.2.5. Benefits of Digestate Application for Agriculture

Biogas is used to generate electricity, and the rest of the biomass residual, the digestate, can also have value. It can be hauled to the cropland and blended with chemical fertilizers to improve the soil quality and crop yields. Such applications involve two sorts of economic activities. The first activity is transportation, in which the digestate is loaded in the facility and hauled to the nearby cropland. The second activity is attached to the cost savings from fertilizer reduction [

53]. The hauling distance and hauling cost of digestate can be estimated using Equations (2) and (3), which are presented in

Table 7.

The biofertilizer’s hauling distance and costs vary significantly depending on the processing methods and distribution area. The biofertilizer produced by hog and poultry manure is much greater than that from cattle and sheep manure. Thus, they will incur higher hauling costs. For hog-manure-based biofertilizer, the transportation distance ranges from 6.55 to 116.98 km, with a hauling cost between USD 4.01 and 10.38 per ton of biofertilizer. This amount is significantly higher than that calculated by other studies, such as that by Kung et al. [

54], in which the per ton hauling cost of biofertilizer generally falls between USD 2.8 and 3.5. A higher initial loading cost and the longer distances in China may be the cause. However, in China the trucks also face a higher diesel price, which may further increase the hauling costs associated with manure application. Thus, comparing the hauling cost differences among different countries and regions may require a more detailed analysis. In this study, we follow the above calculation.

According to Hu et al. [

55], the cost of chemical fertilizer in China is approximately USD 185 per ha, and a 20% savings in fertilizer use will thus reduce the input costs by USD 37. We then assume that the price for blending and applying biofertilizer is USD 10 per ton. Therefore, depending on the residual production rate of manure, manure types, and processing strategies, the average savings in fertilizer will range from USD 27.7 to USD 43.5.

3.3. Greenhouse Gas Offset

In addition to a standard economic assessment of manure application, the environmental consequences, such as the emissions released during transportation and plant operation, emissions offset by biofertilizer, and fossil energy replacement, should be appropriately accounted for because the emissions have a value and can be traded in the emissions markets. Therefore, this study also incorporates a lifecycle analysis to estimate the emission effects during each production stage and then convert the net offset into a monetary value to reflect the overall profitability of China’s manure application.

3.3.1. Emissions from Manure Collection and Hauling

To collect and compact biomass materials, energy is consumed and CO

2 is emitted. It is estimated that 1.391 L of diesel and 0.355 L of gasoline are used to process a ton of manure [

56]. Using the EPA factor of fossil energy, the average CO

2 emissions released by biomass collection is 0.00457 tons. The transportation of biomass from the site to the plant also consumes diesel. According to

Table 4, the average fossil energy used by different manure sources varies. Since the per km energy use for a standard 30-ton truck is 0.38 L, we can calculate the emissions released during the transportation stage. Depending on the manure type, it is estimated to be 0.0023 to 0.0038 tons per ton.

3.3.2. Emissions from Plant Operation

The emissions from a plant’s operation is derived from the study of Kung et al. [

27]. For a 100,000-capacity digestion plant, the annual usage of natural gas ranges from 300 to 500 tons, depending on the processing alternatives. For example, compared to the mesophilic mode, a thermophilic system requires more energy to sustain the optimal temperature [

57]. Thus, the thermophilic mode uses more energy and releases more emissions. Using the emission factors reported for greenhouse gases, regulated emissions, and energy use in transportation (GREET), the approximate CO

2 emissions for a mesophilic system is 0.01 t CO

2e, and it is 0.021 t CO

2e for the thermophilic process.

3.3.3. Electricity Generation Offset

Biogas is used to produce biopower, which increases the domestic energy supply and reduces energy imports. Thus, a portion of fossil energy is replaced, and the total emissions from fossil energy can be decreased. The potential emissions reduction is calculated by multiplying the emission factors of fossil energy by the results from

Table 3. However, the net fossil offset from biopower differs among manure sources and processing strategies. The offset capability per ton of manure ranges from 0.042 to 0.0806 tons for hog and poultry manure. The offset ratio is generally between 0.0546 and 0.1622 tons for cattle and sheep manure. Nevertheless, while sheep and cattle manure have a higher offset ratio, the net emission offset from these sources is lower due to low material supply.

3.3.4. Reduction in Mineral Fertilizer Inputs

In southern China, rice is the most common crop, and thus, in this study, we assume the digestate is hauled back to the rice fields. During this application, two sources of emissions should be accounted for. The first component is the energy used in digestate transportation, and the second one is the emission offset from reduced fertilizer use.

One crucial emission component comes from fertilizer use. Since the application of digestate reduces the need for mineral fertilizers, its use would also decrease the total N

2O emissions from fertilizer use. Based on the agricultural data, the average amount of nitrogen fertilizer used for a hectare of rice paddy is approximately 69.65 kg of nitrogen (N), 111.44 kg of potassium (K), and 41.97 kg of phosphorus (P) [

58]. With an assumption of 15% fertilizer savings, the use of N fertilizer, P fertilizer, and K fertilizer would be 10.45 kg, 16.72 kg, and 6.29 kg, respectively. Using Equation (6), illustrated in the USEPA Draft Regulatory Impact Analysis [

59], the direct reduction in N

2O emissions per ton of manure is estimated to be 0.00146 t CO

2e for the mesophilic mode and 0.0014 t CO

2e under thermophilic systems.

where

NS is the nitrogen in synthetic N fertilizer and is equivalent to 99.86% of total N fertilizer.

NO is the nitrogen in organic N fertilizer and its composition is 0.14%.

VS is the fraction of synthetic N volatilized, and it is 10% based on the IPCC.

VO is a fraction of organic N volatilized, equal to 20% from the IPCC.

EfD is the N

2O emission factor, and it is estimated to be 1% from the IPCC.

The hauling emissions are calculated by multiplying the emission factor by the results of

Table 6. On average, the transportation emissions are between 0.0023 and 0.0038 tons per ton of digestate, depending on the processing modes and manure sources. In terms of emissions from fertilizer, the USEPA [

59] has demonstrated that fertilizer increases N

2O emissions. Thus, if the digestate can reduce fertilizer use, the total emissions from agricultural practice can also be reduced. Based on the emission factors of chemical fertilizers, a 20% reduction in fertilizer use would result in a reduction of 0.00101 to 0.00191 tons of CO

2e.

3.3.5. Net GHG Balance

The net emission consequences associated with manure application are presented in

Table 8. The net emission reduction per ton of manure is between 0.047 and 0.132 t CO

2e, depending on the type and digestion modes. The emission offset from the energy output is significantly higher than that from fertilizer reduction. In addition, since cattle manure has a greater energy conversion rate under the thermophilic mode, its net emission reduction is the highest. As of February 2023, the emission trade price listed on the European Climate Exchange is about USD 104 per ton of CO

2 [

58]. Thus, we can estimate the emission value associated with manure application, which is displayed in the bottom row of

Table 8. However, the emission price fluctuated frequently during 2024 and 2025, and thus, the emission price should be updated and forecasted before projects are actually undertaken.

3.4. Totality of Value

Table 9 totalizes the economic and environmental values of manure application. The results show that the input types and digestive modes significantly influence the profitability. The profit from the mesophilic mode is between USD 10.32 and USD 25.36, while that of thermophilic systems ranges from USD 8.36 to 34.3. The thermophilic process seems more profitable because it yields higher power, but it also incurs a lower net profit if poultry manure is utilized. Additionally, a mesophilic system generally brings more agronomic benefits. Thus, the lower bound of a mesophilic system is higher, but the thermophilic mode offers a higher upper bound of profits. Nevertheless, agricultural benefits sometimes involve greater uncertainty due to regional characteristics, such as temperature, rainfall, and soil quality; the benefits from a mesophilic system may stem from higher uncertainty.

The feedstock acquisition, transportation, and facility operation are the major cost components, while the energy sales and values attached to biofertilizer constitute the gains. The results show that digestate applications are more critical to the profitability and indicate that a variation in this factor could significantly influence the applicability of technologies. A slight decrease in the agronomic value could significantly impact a project’s profitability. Since the agronomic analysis did not consider the soil quality, precipitation, rainfall, or other regional characteristics, these estimates may deviate from reality, and a more detailed evaluation of agricultural systems should be conducted.

In addition, governments have provided several subsidies to maintain electricity prices; thus, energy sales are a relatively stable source of income. In general, the revenue from energy sales is approximately 18% to 30% of the total revenue, and it would have less impact on the overall profitability. While the extent of gains depends on the manure source and technology employed, this study shows how a techno-economic assessment can present a comprehensive manure application examination. This study explores the composition of income sources by analyzing the energy potential and the uses of anaerobic digestate. It identifies the impact factors of each component, thereby providing insightful economic information for the decision-makers and practitioners.

3.5. Sensitivity Analysis

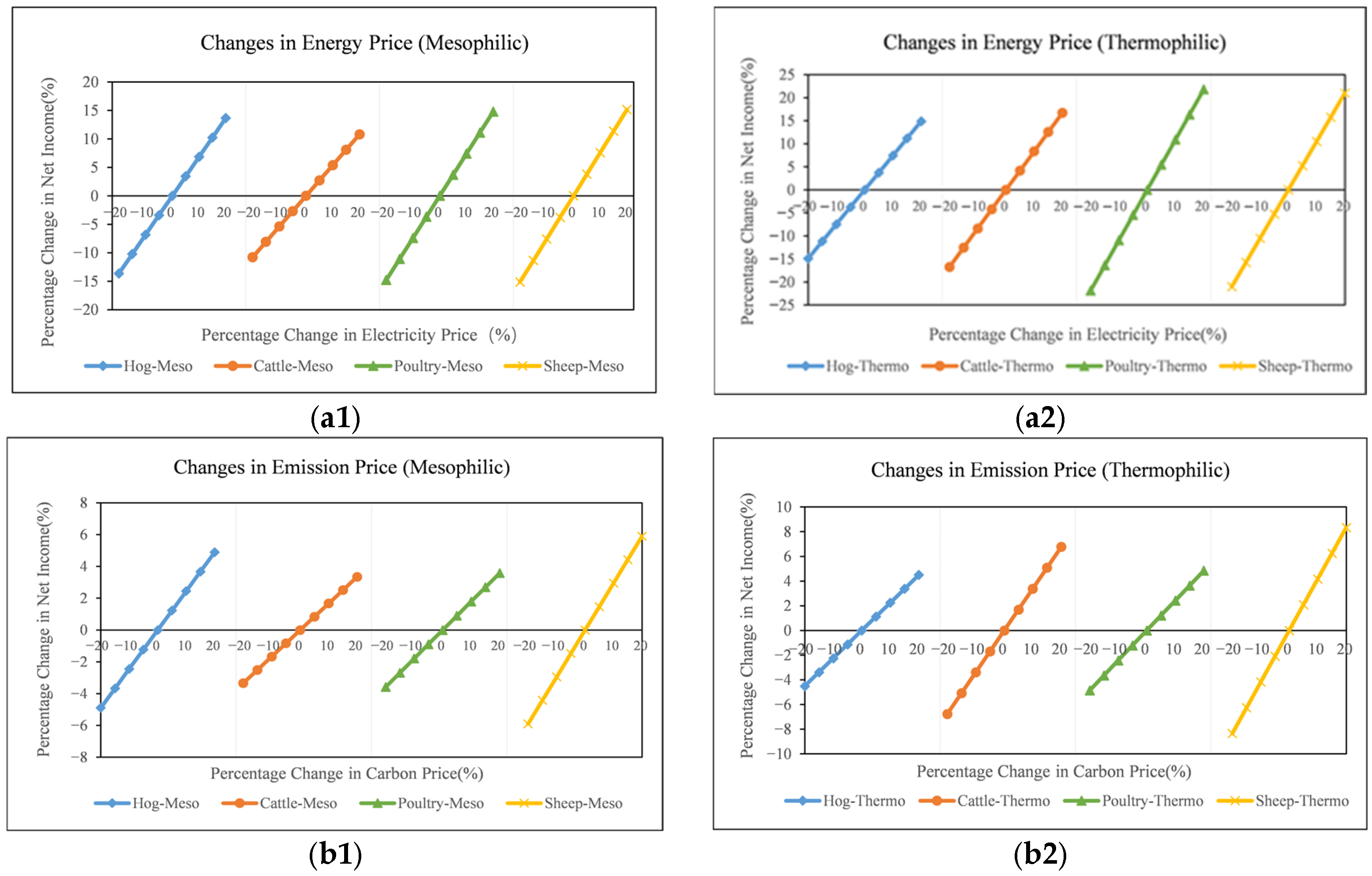

The study illustrates the economic and environmental effects of manure application in southern China. However, some uncertainties are continuously involved and we cannot treat the results deterministically. Instead, the risks associated with the development strategy should also be examined. In this section, we provide a sensitivity analysis to discover how changes in energy and emission prices alter profitability.

Figure 3 presents and compares the results of four sensitivity scenarios. Specifically, the scenarios contain 10% and 20% price increases and decreases in energy and emission prices. They indicate that profits are generally linearly related to price changes. However, the slopes can be different.

Figure 3(a1,a2) show that the changes in energy price have a steeper slope than that for emission price. The reason for this is because biopower is the most significant revenue source, and a slight change in the energy price could be substantial. The profit change due to an emission price change is relatively mild, but for sheep and cattle manure, for which the emission offset constitutes the significant revenue source, a greater change in the emission price would alter their profitability considerably.

3.6. Policy Implications

China has imported and utilized substantial fossil energy to sustain its development. However, such intensive energy use has also increased CO

2 emissions and intensified climate change. Thus, the Chinese government has promulgated multiple renewable energy programs to stimulate domestic clean energy production. Manure can be used for energy production, composting, and direct application to cropland. Studies [

60] have shown that the profit per ton of hog manure may reach USD 7 for composting, but the results may not be widely applicable due to regional characteristics and market conditions. This study evaluates how southern China may recycle manure for biopower production and examines whether an economically feasible possibility exists. Based on the analysis, the results provide several insightful and applicable policy recommendations to improve manure utilization.

(1)

Alleviation of financial risks. Regional governments have decided to convert manure into energy because it reduces the environmental pollution associated with manure treatments and increases bioenergy production, which is meaningful for carbon neutrality. However, the results show that not all manure sources can be used as energy sources due to high production costs. The production cost is the key factor impacting the profitability index, and it greatly influences producers’ financial risk, making some processing strategies not marketable. For example, USEPA [

59] points out that investors would choose not to expand the production scale unless they can reduce the investment and operating risks associated with projects. This implies that capital must be appropriately secured to achieve an efficient economic scale for a green project. If this is not the case, it will likely incur a loss to social welfare.

Green policies are sometimes helpful, but market mechanisms are generally used to determine production efficiency. One way to alleviate investors’ financial risk is to enlarge the green finance market so that investors can borrow at a lower rate, reducing the operating risks associated with a clean program. The Chinese government has set up some green financial policies to assist green industries and projects; however, the taxation standard is not fully determined, and this discourages lenders from investing in such projects. A clear standard that benefits capital lenders, such as a tax cut on the received interest payments from green finance markets, is necessary to improve large-scale manure reuse projects. However, in China, the green financing market is under-established; most firms can only borrow using high-cost loans rather than low-cost green funds. Further promotion of the green market is necessary.

(2)

Biomass selection and density distribution. The study explores the fact that biomass transportation costs are another crucial factor affecting profits. Instead of directly looking at the transportation costs, verifying the reasons for changing the costs is more critical. High transportation costs come with long hauling distances, primarily determining biomass distribution. Thus, the abundance of resources fundamentally affects transportation costs [

60]. This result implies that if a manure source is diversely distributed, this resource would eventually experience an increased hauling distance and subsequent hauling cost.

The results indicate that when planning for the goal of net biopower production, a local government should not simply take the total manure quantity as the usable value. Instead, an advanced investigation into the resource type and its distribution should be conducted to make its use efficient. This is not a big problem for most hog and cattle breeding, but the collection of poultry manure generally involves greater efforts. A possible approach to deal with such difficulties is to build many small digestive operators near poultry parks to reduce the biomass requirements for each plant and the total transportation distance. Another possible solution is to determine the plant’s location. For example, suppose the plant is in the center of a grid road. In that case, the average hauling distance from each breeding mill to the processing plant can be shortened, decreasing the hauling costs.

(3) Energy sales and emission trade. The government cares about the total renewable energy production to improve national energy security. However, this is not the concern of energy producers because, as a company, they should only care about whether such processes make a profit. Because the revenue sources of manure applications come from energy sales and emission trades, a successful manure reutilization program must ensure the realization of the energy output and emission offsets supplied by the producers.

In China, energy sales are not easy because the government manages all utilities. Thus, the most challenging issue for a small renewable power plant is not to generate power at a low cost, but to sell electricity to the nation-owned utility companies. If energy producers find it impossible to sell their electricity to the utility system, investments in these projects will be discouraged, and the renewable energy industry will eventually collapse. One way to deal with this concern is to contract a sellable quantity of biopower at a predetermined price, and firms can look at the price profile to determine their investments. Another issue related to profitability is the realization of emission values. The results indicate that a nontrivial portion of profits consists of emission offsets. The government should complete the current emission monitoring and trading system to allow small power suppliers to certify their offset contribution in the market. Otherwise, the economic scale of manure applications will decline.

4. Conclusions

Manure recycling and reutilization are crucial in environmental management, as well as in the renewable energy supply and agricultural sustainability. This study identifies the components related to manure development and explores the key factors affecting their profitability under the TEA and LCA frameworks. In this study, we establish three key findings.

First, while hog and poultry manure do not have the most significant energy conversion rates, the abundance of these resources significantly decreases the transportation efforts and improves the profitability. If all manures are properly utilized, the net emission offset can be up to 12.07 million metric tons of CO2 equivalent, with an aggregate energy revenue of approximately USD 1086 million annually. Second, while mesophilic digestion yields relatively less biopower, it also emits less CO2 and incurs a lower production cost during operation. For small energy producers who do not want to bear high investment risks, mesophilic processes are preferable thermophilic systems. Third, farmers can use digestate as a biofertilizer, improving agricultural sustainability. Our results indicate that manure applications can yield a profit ranging from USD 8.36 to USD 34.3, which is made by biofertilizer, whose benefit is roughly between USD 27.72 and USD 43.49. Digestate offers another possibility for energy suppliers to expand a revenue channel. However, it would be necessary to examine the exact price of the sellable digestate.

We also present some limitations of this study. First, the agricultural system is complex, and it is not likely that biofertilizer will always result in economic benefits. For example, precipitation patterns vary across regions, and digestate losses may occur. If heavy rainfall and runoffs arise, the loss rate could be significant; we must then discount and reevaluate the biofertilizer’s benefits and the agronomic effects. Second, the emission monitoring system in southern China is not well employed, and thus, the offset capacity from alternative manure processing technologies cannot be appropriately defined and determined. This would probably result in significant estimation errors of emission offset and understate the values attached to emission reduction.