A Framework for a Sustainable Adoption of Business Process Management

Abstract

1. Introduction

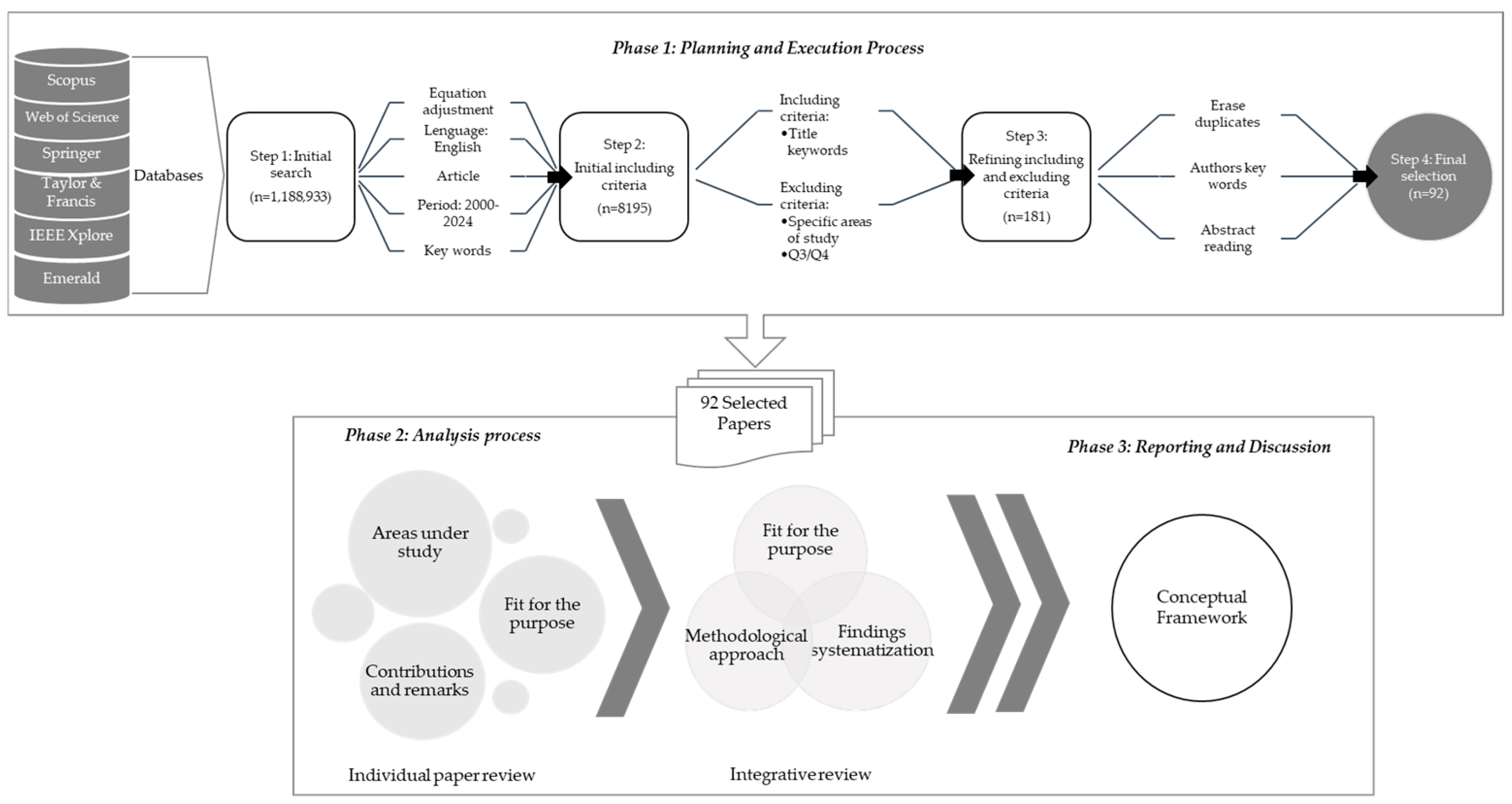

2. Methodology

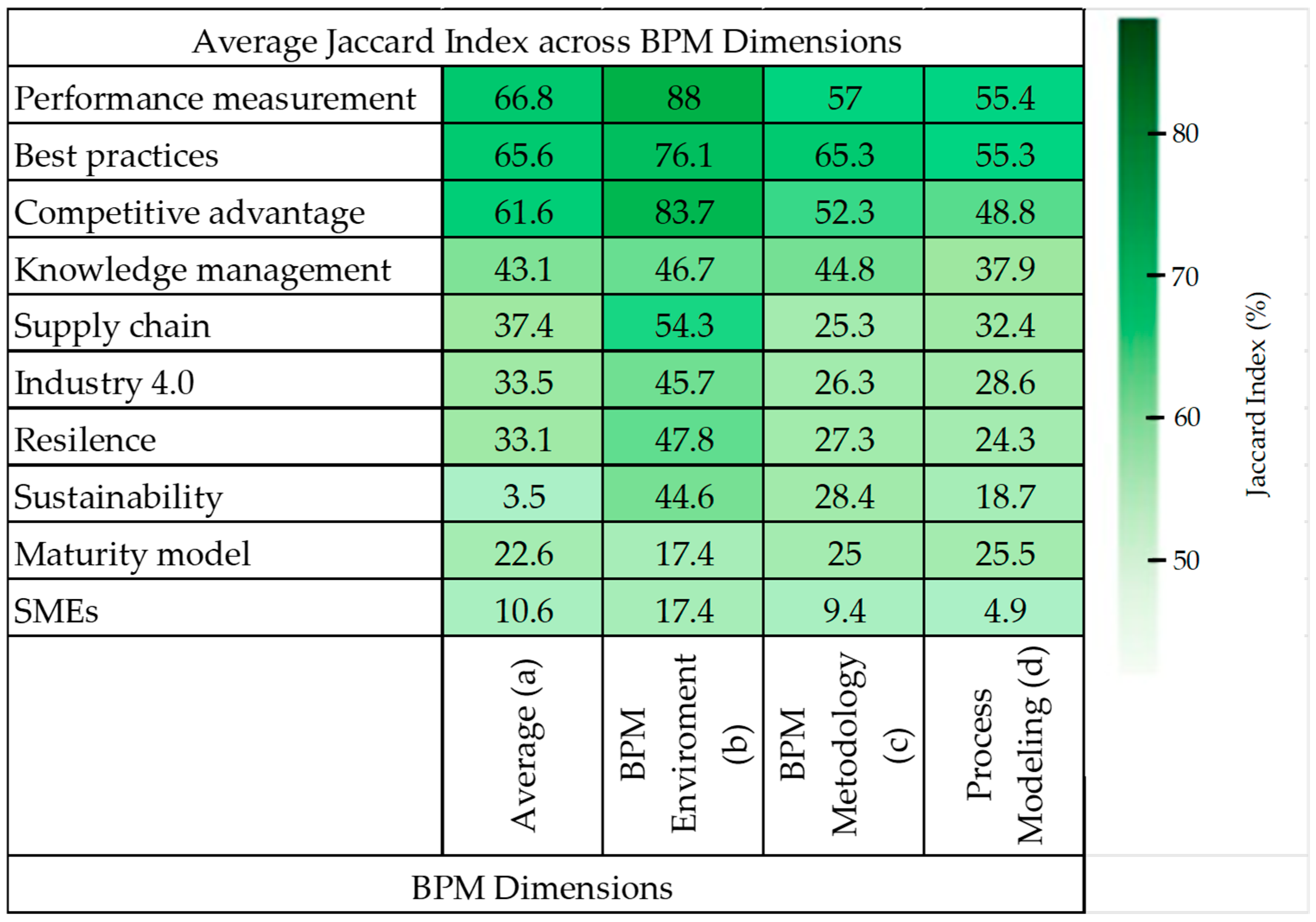

- Key concepts and definitions (RQ2).

- Knowledge domains, milestones and research trends (RQ3).

- The development of a conceptual framework (RQ1) that integrates adoption stages, sustainability, and technological evolution (RQ2 and RQ3).

2.1. Phase 1: Planning and Execution Process

2.2. Phase 2: Analysis Process

3. Results

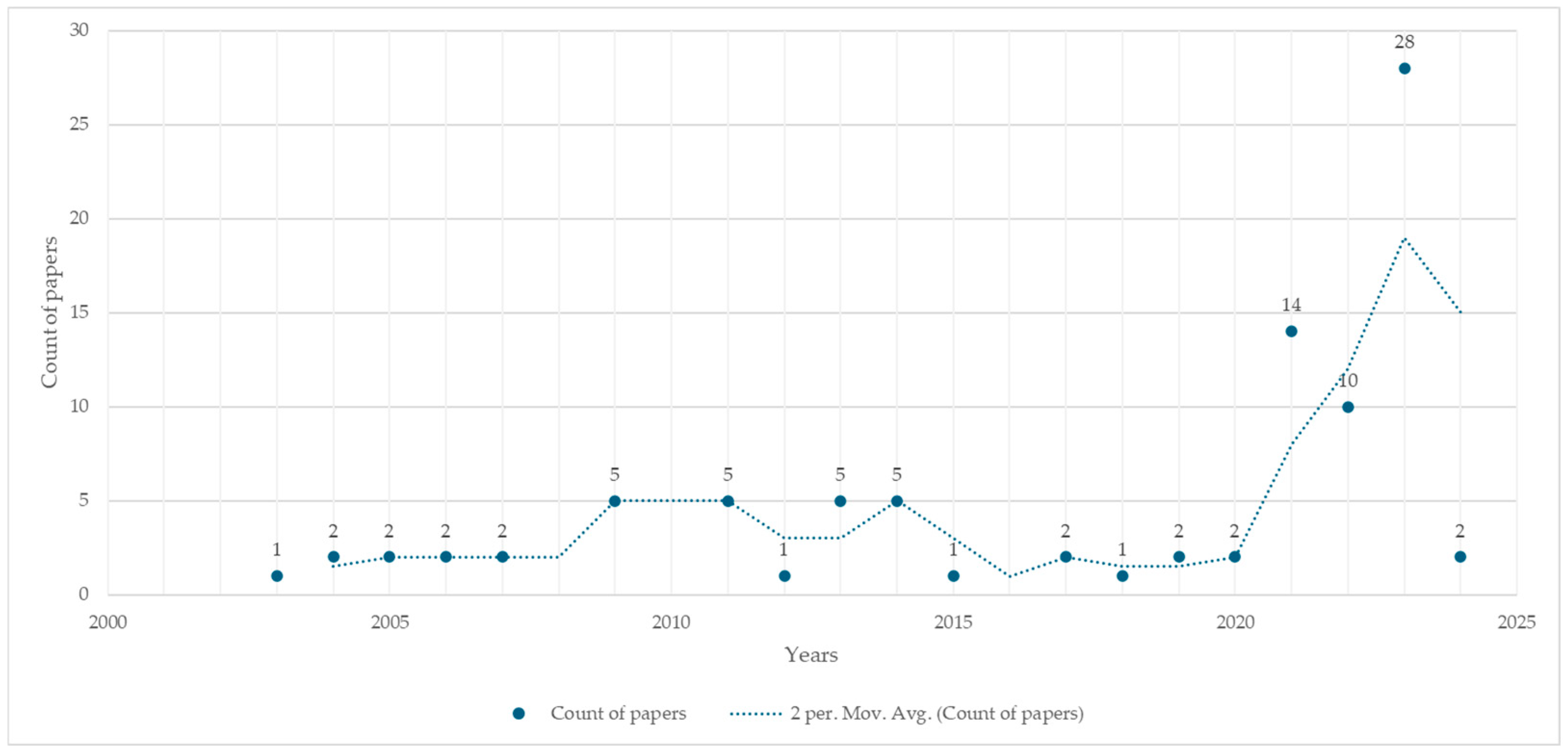

3.1. Characterization of Selected Publications

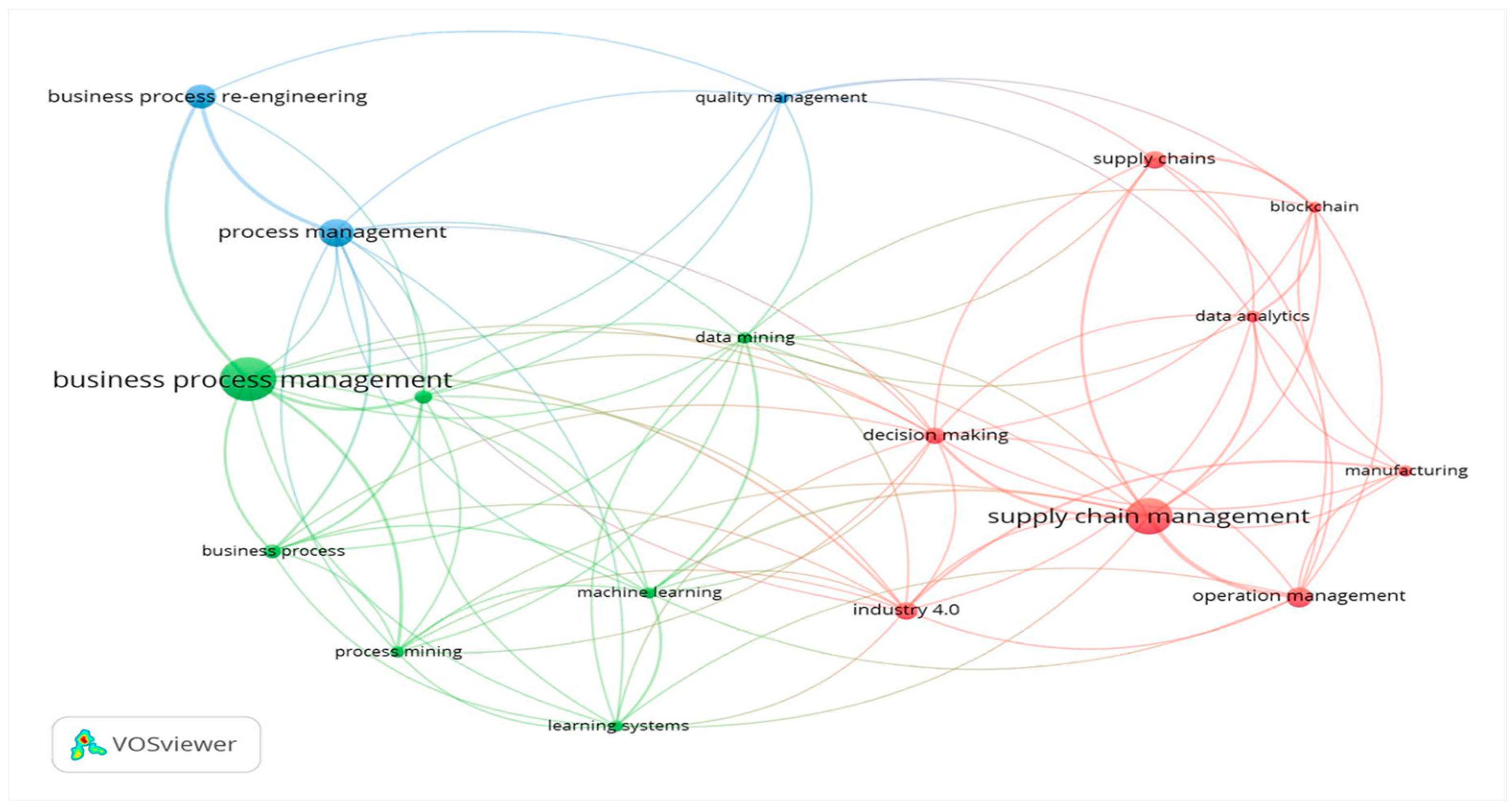

3.2. VOSviewer® Bibliometric Analysis

3.2.1. Business Process Management (BPM)

3.2.2. Supply Chain Management (SCM)

3.2.3. Operations Management

3.2.4. Industry 4.0

4. Discussion: Conceptualization, Relationships, and Research Gaps

4.1. Conceptualization

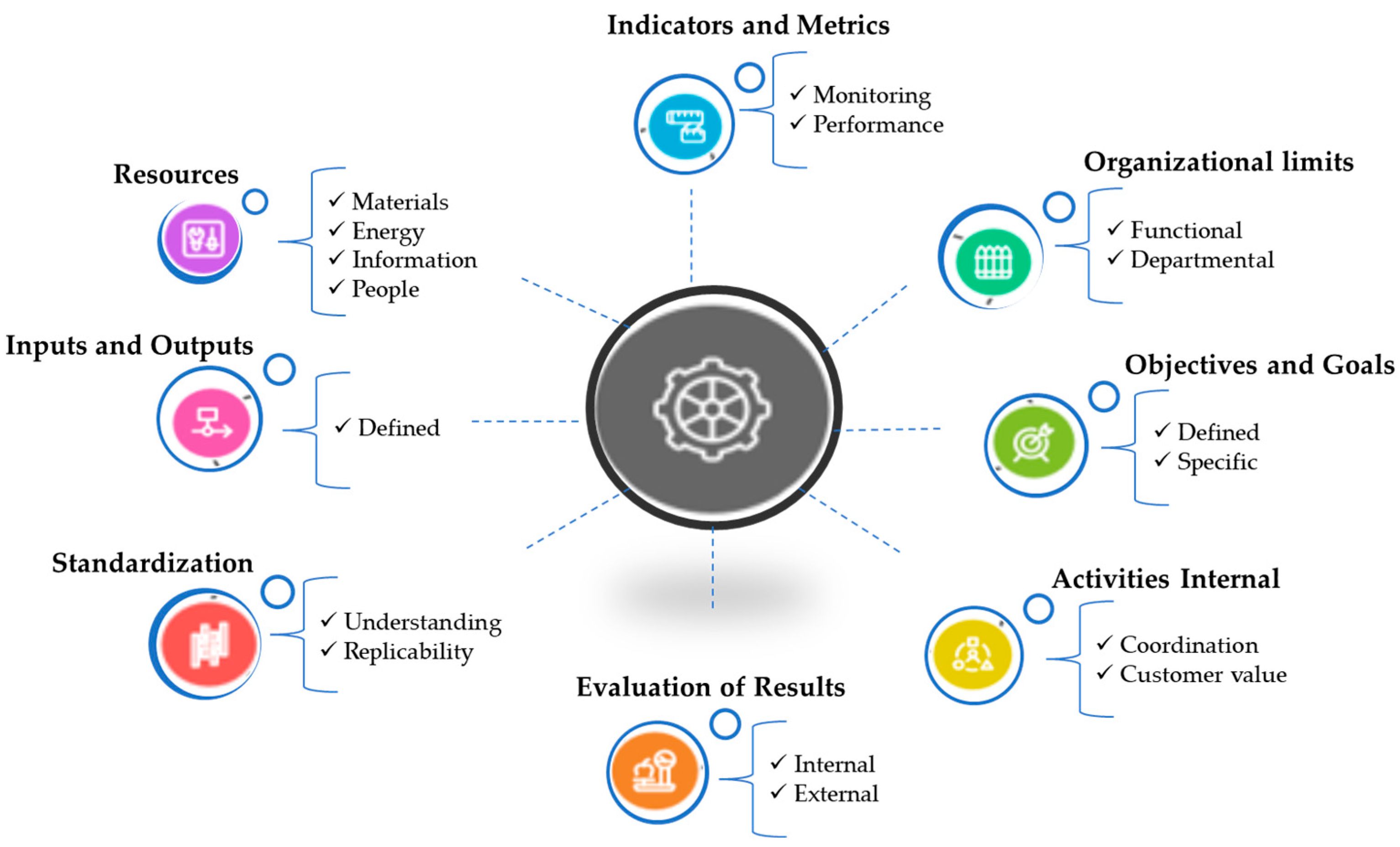

4.1.1. Business Process

4.1.2. Business Process Management (BPM)

4.2. Process Management Evolution

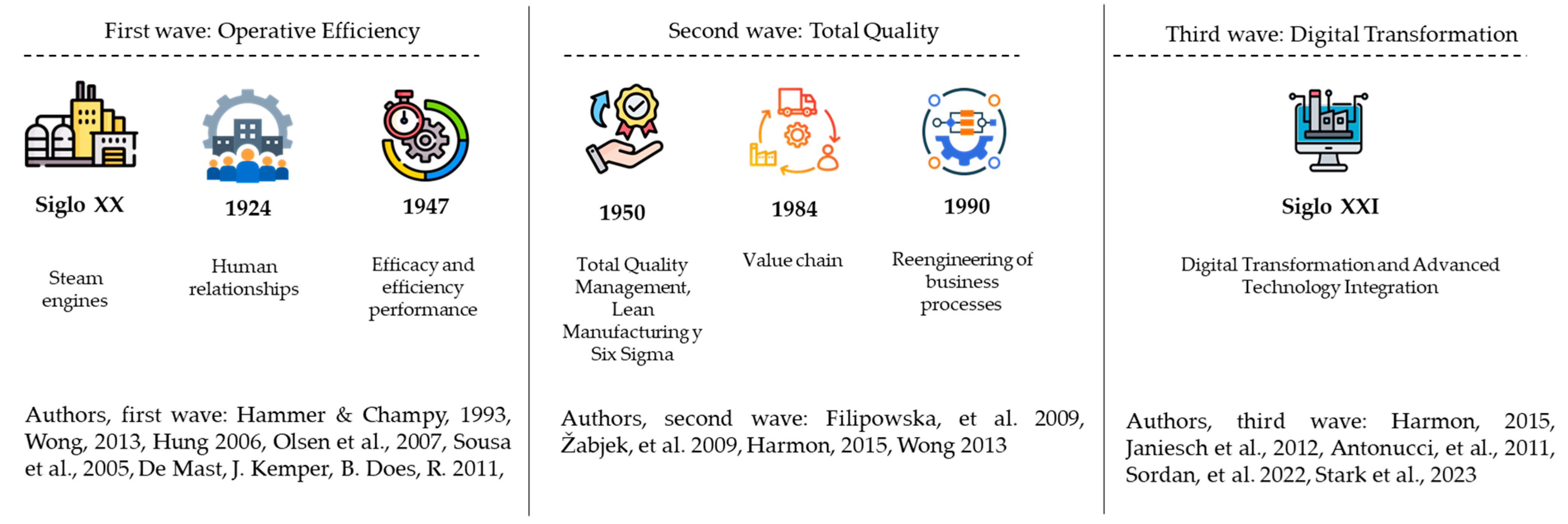

4.3. The Three Waves of BPM

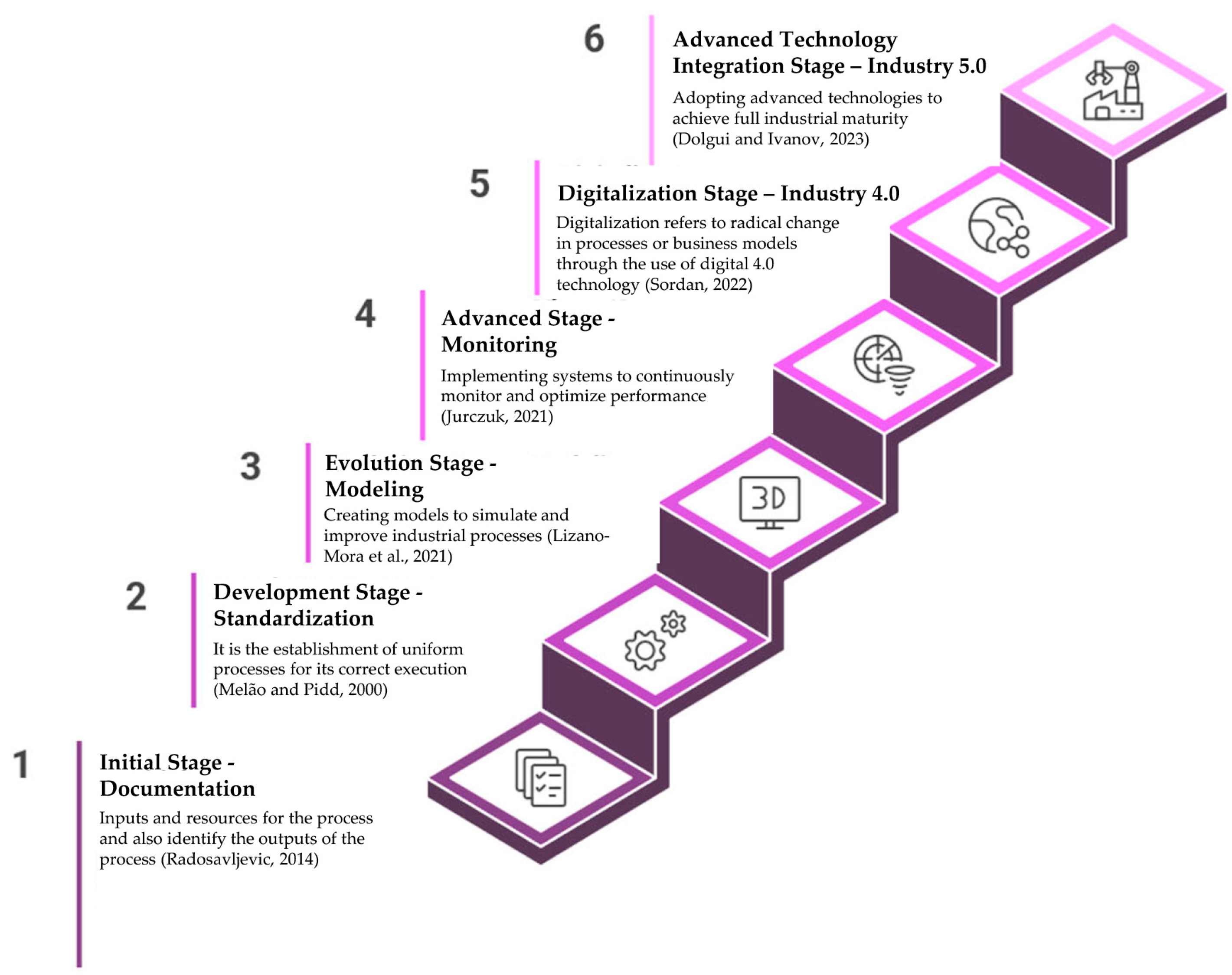

4.4. Stages of BPM Adoption in a Digital Era (Industry 4.0)

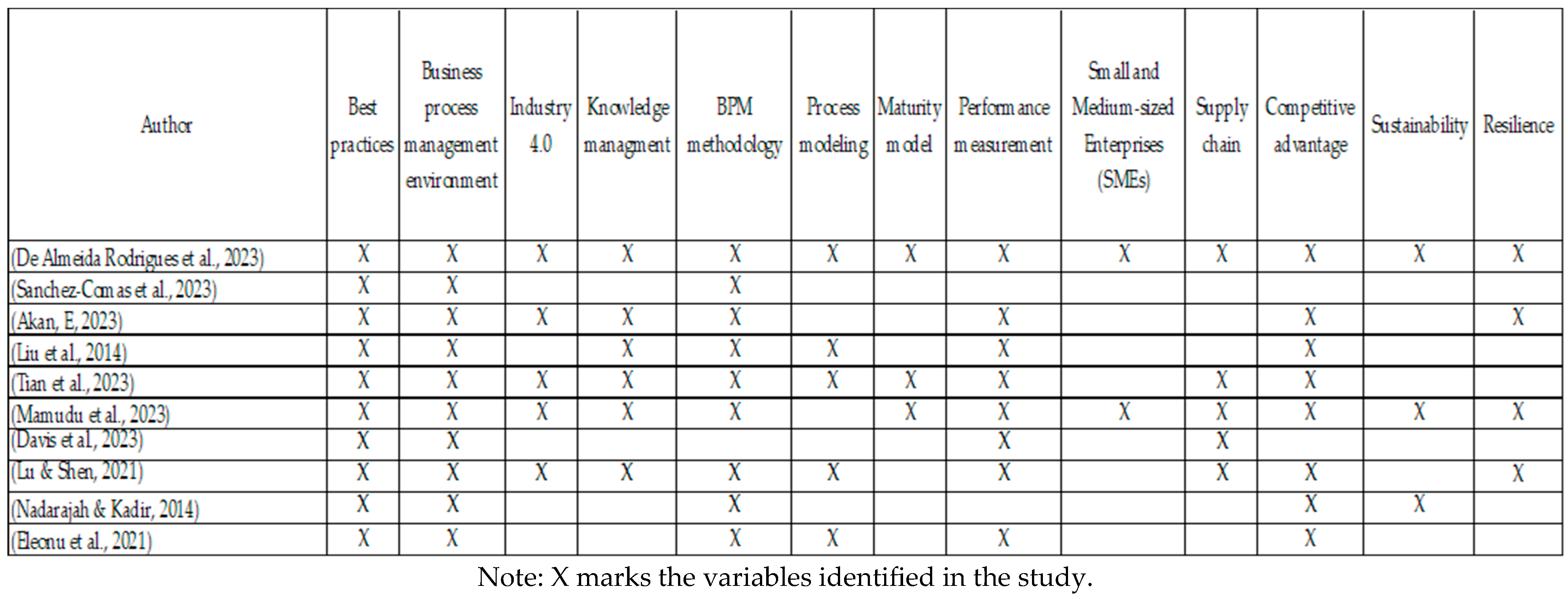

4.5. Identified Variables and Relationships

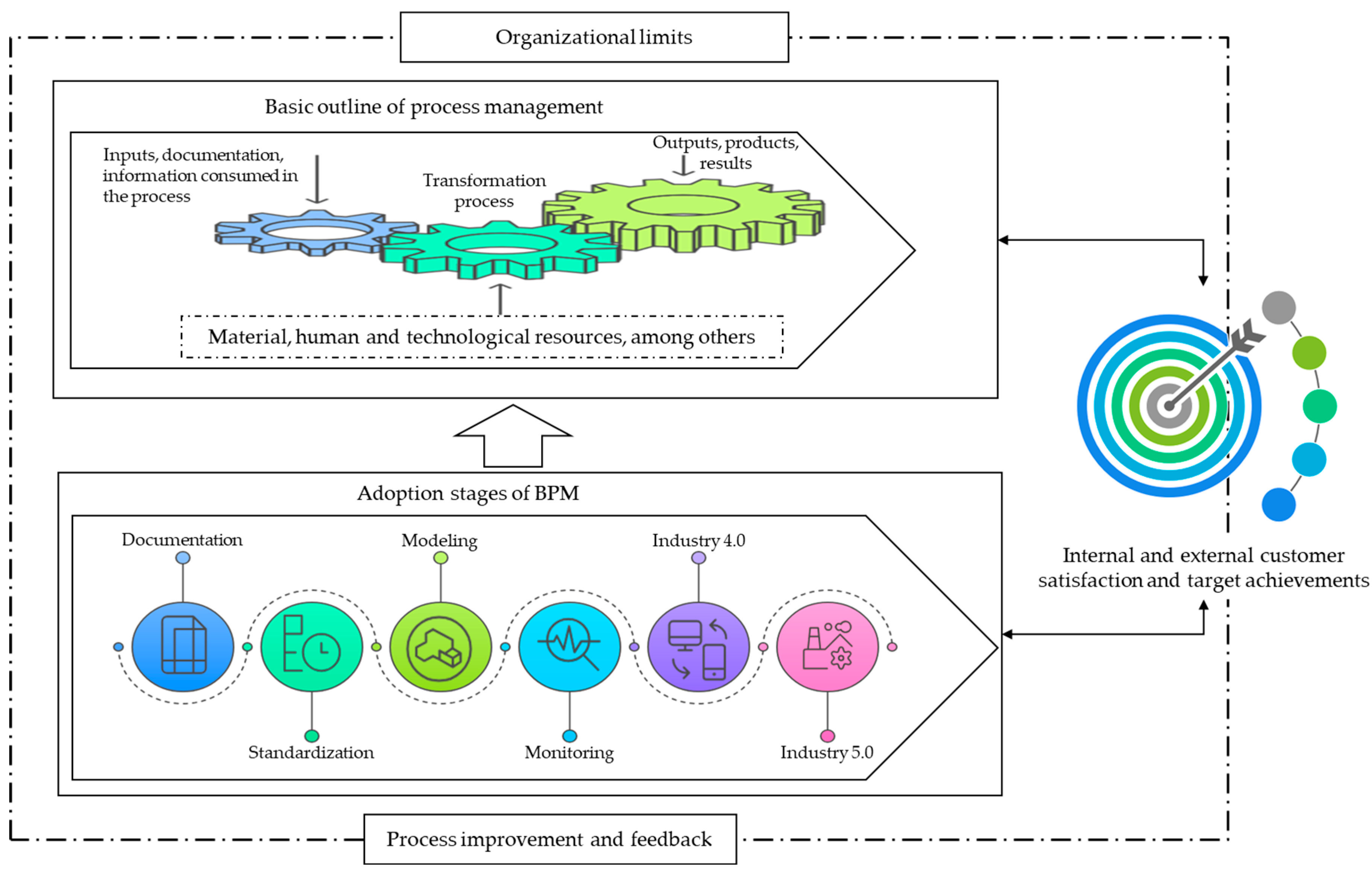

5. Conceptual Framework to Develop a BPM Environment

- Documentation involves defining and documenting the fundamental elements of a process, constituting the first step in understanding it.

- Standardization encompasses the establishment of guidelines under which a process must be executed to meet its objective.

- Modeling allows for visualizing process elements, simulating tasks and operations, and identifying opportunities for improvement.

- Monitoring measures the process using management indicators to demonstrate that it meets its objective. As sophisticated the monitoring system is, the more frequently and accurately it will provide feedback to the process, allowing for intervention if necessary.

- Finally, the most mature stage, which is the integration of processes with Industry 5.0 tools, which digitize and allow them to be managed in real time, also includes the coordination of BPM activities within the organization’s internal environment and outside of it, linking the organization to its business partners and customers, e.g., its supply chain partners.

6. Conclusions and Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BPM | Business process management |

| ICTs | Information and communication technologies |

| PEX | Process Excellence Network |

| RQ | Research questions |

| SCM | Supply chain management |

| RPA | Robotic process automation |

| TQM | Total quality management |

| AI | Artificial intelligence |

| IoT | Internet of things |

| MIS | Management information systems |

References

- Sardana, G.D. Evaluating the Business Performance of an SME: A Conceptual Framework. Int. J. Glob. Small Bus. 2009, 3, 137–159. [Google Scholar] [CrossRef]

- Filipowska, A.; Kaczmarek, M.; Kowalkiewicz, M.; Zhou, X.; Born, M. Procedure and Guidelines for Evaluation of BPM Methodologies. Bus. Process Manag. J. 2009, 15, 336–357. [Google Scholar] [CrossRef]

- Janssen, S.; Moeller, K.; Schlaefke, M. Using Performance Measures Conceptually in Innovation Control. J. Manag. Control 2011, 22, 107–128. [Google Scholar] [CrossRef]

- Calatayud, A.; Katz, R. Cadena de Suministro 4.0: Mejores Prácticas Internacionales y Hoja de Ruta Para América Latina; Inter-American Development Bank: Washington, DC, USA, 2019. [Google Scholar] [CrossRef]

- Christopher, M. The Agile Supply Chain: Competing in Volatile Markets. Ind. Mark. Manag. 2000, 29, 37–44. [Google Scholar] [CrossRef]

- Clegg, B. Business Process Orientated Holonic (PrOH) Modeling. Bus. Process Manag. J. 2006, 12, 410–432. [Google Scholar] [CrossRef]

- Gligor, D.M.; Holcomb, M.C. Understanding the Role of Logistics Capabilities in Achieving Supply Chain Agility: A Systematic Literature Review. Supply Chain Manag. Int. J. 2012, 17, 438–453. [Google Scholar] [CrossRef]

- Mentzer, J.T.; Keebler, J.S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining Supply Chain Management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Lummus, R.R.; Duclos, L.K.; Vokurka, R.J. Supply Chain Flexibility: Building a New Model. Glob. J. Flex. Syst. Manag. 2003, 4, 1–13. [Google Scholar]

- Cloutier, L.; Frayret, J.M.; D’Amours, S.; Espinasse, B.; Montreuil, B. A Commitment-Oriented Framework for Networked Manufacturing Co-Ordination. Int. J. Comput. Integr. Manuf. 2001, 14, 522–534. [Google Scholar] [CrossRef]

- Schmid, W.; Kern, E.M. Integration of Business Process Management and Knowledge Management: State of the Art, Current Research and Future Prospects. J. Bus. Econ. 2014, 84, 191–231. [Google Scholar] [CrossRef]

- Kozma, D.; Varga, P.; Larrinaga, F. Dynamic Multilevel Workflow Management Concept for Industrial IoT Systems. IEEE Trans. Autom. Sci. Eng. 2021, 18, 1354–1366. [Google Scholar] [CrossRef]

- Vom Brocke, J.; Mendling, J. Business Process Management Cases; vom Brocke, J., Mendling, J., Eds.; Management for Professionals; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-58306-8. [Google Scholar]

- Eleonu, H.C. Aggregate Metric Model for Evaluating Business Processes. Bus. Process Manag. J. 2021, 27, 388–414. [Google Scholar] [CrossRef]

- Surkova, E.V.; Mazhaiskii, Y.A. Management of Business Processes. Russ. Eng. Res. 2022, 42, 292–294. [Google Scholar] [CrossRef]

- Lizano-Mora, H.; Palos-Sanchez, P.R.; Aguayo-Camacho, M. The Evolution of Business Process Management: A Bibliometric Analysis. IEEE Access 2021, 9, 51088–51105. [Google Scholar] [CrossRef]

- Hariyani, D.; Mishra, S. Barriers to the Adoption of Integrated Sustainable-Green-Lean-Six Sigma-Agile Manufacturing System (ISGLSAMS): A Literature Review. Benchmarking Int. J. 2023, 30, 3590–3636. [Google Scholar] [CrossRef]

- United Nations Development Programme Goal 9: Industry, Inovation and Infrastructure. Available online: https://www.undp.org/sustainable-development-goals/industry-innovation-and-infrastructure (accessed on 2 July 2024).

- Li, J.; Li, Y.; Song, H.; Fan, C. Sustainable Value Creation from a Capability Perspective: How to Achieve Sustainable Product Design. J. Clean. Prod. 2021, 312, 127552. [Google Scholar] [CrossRef]

- Koblianska, I.; Varakin, D.; Pihul, O.; Somushkin, V.; Glukh, V. Review of Scientific Literature on BPM Concept in Social Sciences. Probl. Perspect. Manag. 2023, 21, 84–99. [Google Scholar] [CrossRef]

- Hopp, W.J.; Spearman, M.S. The Lenses of Lean: Visioning the Science and Practice of Efficiency. J. Oper. Manag. 2021, 67, 610–626. [Google Scholar] [CrossRef]

- Nadarajah, D.; Kadir, S.L.S.A. A Review of the Importance of Business Process Management in Achieving Sustainable Competitive Advantage. TQM J. 2014, 26, 522–531. [Google Scholar] [CrossRef]

- Process Excellence Network-PEX PEX Report 2024: Global State of Process Excellence. 2024. Available online: https://www.processexcellencenetwork.com/business-transformation/reports/pex-report-2024-global-state-process-excellence (accessed on 2 May 2025).

- Bureau-Johnson, S.; Hawkins, I.; Bishop, L. THE PEX REPORT Leadership and Technology Future of Leadership. 2018. Available online: https://www.processexcellencenetwork.com/innovation/articles/pex-network-annual-report (accessed on 2 May 2025).

- Sánchez, L.; Blanco, B. La Gestión Por Procesos. Un Campo Por Explorar. Dir. Y Organ. 2014, 54–71. [Google Scholar] [CrossRef]

- Meredith, J. Theory Building through Conceptual Methods. Int. J. Oper. Prod. Manag. 1993, 13, 3–11. [Google Scholar] [CrossRef]

- Barratt, M.; Choi, T.Y.; Li, M. Qualitative Case Studies in Operations Management: Trends, Research Outcomes, and Future Research Implications. J. Oper. Manag. 2011, 29, 329–342. [Google Scholar] [CrossRef]

- Duclos, L.K.; Vokurka, R.J.; Lummus, R.R. A Conceptual Model of Supply Chain Flexibility. Ind. Manag. Data Syst. 2003, 103, 446–456. [Google Scholar] [CrossRef]

- Corley, K.; Gioia, D. Building Theory about Theory Building: What Constitutes a Theoretical Contribution? Acad. Manag. Rev. 2011, 36, 12–32. [Google Scholar] [CrossRef]

- Snyder, H. Literature Review as a Research Methodology: An Overview and Guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Luft, J.A.; Jeong, S.; Idsardi, R.; Gardner, G. Literature Reviews, Theoretical Frameworks, and Conceptual Frameworks: An Introduction for New Biology Education Researchers. CBE—Life Sci. Educ. 2022, 21, rm33. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a Systematic Review. In The Sage Handbook of Organizational Research Methods; Buchanan, D.A., Bryman, A., Eds.; Sage Publications Ltd.: London, UK, 2009; pp. 671–689. ISBN 978-1-4129-3118-2. [Google Scholar]

- Kerr, J.; Coviello, N. Formation and Constitution of Effectual Networks: A Systematic Review and Synthesis. Int. J. Manag. Rev. 2019, 21, 370–397. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chaudhuri, R.; Vrontis, D.; Galati, A. Influence of Managerial Practices, Productivity, and Change Management Process on Organizational Innovation Capability of Small and Medium Businesses. Eur. Bus. Rev. 2023, 35, 839–859. [Google Scholar] [CrossRef]

- Ali, M.S.; Khan, S.; Miah, S.J. Understanding towards Interactions between Business Intelligence and SMEs: Learn from Each Other. J. Inf. Syst. Technol. Manag. 2017, 14, 151–168. [Google Scholar] [CrossRef]

- Wang, S.; Ghadge, A.; Aktas, E. Digital Transformation in Food Supply Chains: An Implementation Framework. Supply Chain. Manag. Int. J. 2024, 29, 328–350. [Google Scholar] [CrossRef]

- Stevenson, M.; Spring, M. Flexibility from a Supply Chain Perspective: Definition and Review. Int. J. Oper. Prod. Manag. 2007, 27, 685–713. [Google Scholar] [CrossRef]

- Jafari, H. Logistics Flexibility: A Systematic Review. Int. J. Product. Perform. Manag. 2015, 64, 947–970. [Google Scholar] [CrossRef]

- Mendoza-Silva, A. Innovation Capability: A Systematic Literature Review. Eur. J. Innov. Manag. 2020, 24, 707–734. [Google Scholar] [CrossRef]

- Patanakul, P.; Pinto, J.K. Examining the Roles of Government Policy on Innovation. J. High Technol. Manag. Res. 2014, 25, 97–107. [Google Scholar] [CrossRef]

- Novillo-Villegas, S.; Acosta-Vargas, P.; Cruz-Boada, C.; Garzon, M.; Marin-Dett, A.; Anzules-Falcones, W. Sustaining the Path for Innovation Capability from a Developing Country Perspective: A Conceptual Framework. Sustainability 2022, 14, 12807. [Google Scholar] [CrossRef]

- Piccarozzi, M.; Aquilani, B.; Gatti, C. Industry 4.0 in Management Studies: A Systematic Literature Review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Aguinis, H.; Ramani, R.S.; Alabduljader, N. Best-Practice Recommendations for Producers, Evaluators, and Users of Methodological Literature Reviews. Organ. Res. Methods 2023, 26, 46–76. [Google Scholar] [CrossRef]

- Viteri-Sanchez, C.; Novillo-Villegas, S.M.; Albuja, D.; Chantera, X.; Yánez, B.; Zurita, M.J. Semi-Structured Literature Review: Business Process Management. Mendeley Data 2025. [Google Scholar] [CrossRef]

- Scimago Institutions Ranking Scimago Journal & Country Rank. Available online: https://www.scimagojr.com/ (accessed on 2 May 2022).

- Correia, E.; Carvalho, H.; Azevedo, S.; Govindan, K. Maturity Models in Supply Chain Sustainability: A Systematic Literature Review. Sustainability 2017, 9, 64. [Google Scholar] [CrossRef]

- Hung, R.Y.-Y. Business Process Management as Competitive Advantage: A Review and Empirical Study. Total Qual. Manag. Bus. Excell. 2006, 17, 21–40. [Google Scholar] [CrossRef]

- Antonucci, Y.L.; Goeke, R.J. Identification of Appropriate Responsibilities and Positions for Business Process Management Success: Seeking a Valid and Reliable Framework. Bus. Process Manag. J. 2011, 17, 127–146. [Google Scholar] [CrossRef]

- Lin, M.; Lin, C.; Chang, Y.-S. The Impact of Using a Cloud Supply Chain on Organizational Performance. J. Bus. Ind. Mark. 2021, 36, 97–110. [Google Scholar] [CrossRef]

- Olsen, E.O.; Zhou, H.; Lee, D.M.S.; Ng, Y.E.; Chong, C.C.; Padunchwit, P. Performance Measurement System and Relationships with Performance Results: A Case Analysis of a Continuous Improvement Approach to PMS Design. Int. J. Product. Perform. Manag. 2007, 56, 559–582. [Google Scholar] [CrossRef]

- Akan, E. A Holistic Analysis of Maritime Logistics Process in Fuzzy Environment in Terms of Business Process Management. Bus. Process Manag. J. 2023, 29, 1116–1158. [Google Scholar] [CrossRef]

- Binci, D.; Belisari, S.; Appolloni, A. BPM and Change Management: An Ambidextrous Perspective. Bus. Process Manag. J. 2020, 26, 1–23. [Google Scholar] [CrossRef]

- de Almeida Rodrigues Gonçalves, J.C.; Baião, F.A.; Santoro, F.M.; Guizzardi, G. A Cognitive BPM Theory for Knowledge-Intensive Processes. Bus. Process Manag. J. 2023, 29, 465–488. [Google Scholar] [CrossRef]

- Harmon, P. The Scope and Evolution of Business Process Management. In Handbook on Business Process Management 1: Introduction, Methods, and Information Systems; Springer: Berlin/Heidelberg, Germany, 2015; pp. 37–80. ISBN 9783642451003. [Google Scholar]

- Centre for Science and Technology Studies-Leiden University VOSviewer-Visualizing Scientific Landscapes. Available online: https://www.vosviewer.com/ (accessed on 1 May 2024).

- Wang, J.; Cao, B.; Zheng, X.; Tan, D.; Fan, J. Detecting Difference Between Process Models Using Edge Network. IEEE Access 2019, 7, 142916–142925. [Google Scholar] [CrossRef]

- Akkaş, A.; Gaur, V. Reducing Food Waste: An Operations Management Research Agenda. Manuf. Serv. Oper. Manag. 2022, 24, 1261–1275. [Google Scholar] [CrossRef]

- Buh, B.; Kovačič, A.; ŠTemberger, M.I. Critical Success Factors for Different Stages of Business Process Management Adoption—A Case Study. Econ. Res. Istraz. 2015, 28, 243–258. [Google Scholar] [CrossRef]

- de Oliveira, G.G.; Caumo Vaz, G.; Antonio Andrade, M.; Iano, Y.; Ronchini Ximenes, L.; Arthur, R. System for PCB Defect Detection Using Visual Computing and Deep Learning for Production Optimization. IET Circuits Devices Syst. 2023, 2023, 6681526. [Google Scholar] [CrossRef]

- Dhiaf, M.M.; Atayah, O.F.; Nasrallah, N.; Frederico, G.F. Thirteen Years of Operations Management Research (OMR) Journal: A Bibliometric Analysis and Future Research Directions. Oper. Manag. Res. 2021, 14, 235–255. [Google Scholar] [CrossRef]

- Dolgui, A.; Ivanov, D. Metaverse Supply Chain and Operations Management. Int. J. Prod. Res. 2023, 61, 8179–8191. [Google Scholar] [CrossRef]

- Drofenik, J.; Pahor, B.; Kravanja, Z.; Pintaric, Z.N. Multi-Objective Scenario Optimization of the Food Supply Chain-Slovenian Case Study. Comput. Chem. Eng. 2023, 172, 108197. [Google Scholar] [CrossRef]

- Eikebrokk, T.R.; Iden, J.; Olsen, D.H.; Opdahl, A.L. Understanding the Determinants of Business Process Modelling in Organisations. Bus. Process Manag. J. 2011, 17, 639–662. [Google Scholar] [CrossRef]

- Fallah, F.; Azimi, P.; Sharifi, M. Designing a Multi-Objective Mathematical Model of a Perishable Supply Chain (PSC) in a State of Uncertainty. J. Model. Manag. 2023, 18, 1921–1949. [Google Scholar] [CrossRef]

- Flechsig, C.; Lohmer, J.; VOß, R.; Lasch, R. Business Process Maturity Model for Digital Transformation: An Action Design Research Study on the Integration of Information Technology. Int. J. Innov. Manag. 2022, 26, 2240012. [Google Scholar] [CrossRef]

- Hahn, G.J. Industry 4.0: A Supply Chain Innovation Perspective. Int. J. Prod. Res. 2020, 58, 1425–1441. [Google Scholar] [CrossRef]

- Gošnik, D.; Meško, M.; Stubelj, I. The Relationship between Leadership in BPM and Company Profitability. Adm. Sci. 2023, 13, 77. [Google Scholar] [CrossRef]

- Janiesch, C.; Matzner, M.; Müller, O. Beyond Process Monitoring: A Proof-of-Concept of Event-Driven Business Activity Management. Bus. Process Manag. J. 2012, 18, 625–643. [Google Scholar] [CrossRef]

- Kim, H.M.; Ramkaran, R. Best Practices in E-Business Process Management: Extending a Re-Engineering Framework. Bus. Process Manag. J. 2004, 10, 27–43. [Google Scholar] [CrossRef]

- Lee, J.Y.; Jiménez, A.; Devinney, T.M. Learning in SME Internationalization: A New Perspective on Learning From Success versus Failure. Manag. Int. Rev. 2020, 60, 485–513. [Google Scholar] [CrossRef]

- Liu, L.; Caldwell, B.S.; Wang, H.; Li, Y. A Knowledge-Centric CNC Machine Tool Design and Development Process Management Framework. Int. J. Prod. Res. 2014, 52, 6033–6051. [Google Scholar] [CrossRef]

- Maddah, N.; Roghanian, E. Data-Driven Performance Management of Business Units Using Process Mining and DEA: Case Study of an Iranian Chain Store. Int. J. Product. Perform. Manag. 2023, 72, 550–575. [Google Scholar] [CrossRef]

- De Mast, J.; Kemper, B.; Does, R.J.M.M.; Mandjes, M.; Van Der Bijl, Y. Process Improvement in Healthcare: Overall Resource Efficiency. Qual. Reliab. Eng. Int. 2011, 27, 1095–1106. [Google Scholar] [CrossRef]

- Melão, N.; Pidd, M. A Conceptual Framework for Understanding Business Processes and Business Process Modelling. Inf. Syst. J. 2000, 10, 105–129. [Google Scholar] [CrossRef]

- Mohammadi, S.; Farimani, N.M.; Farahi, M.M. Measuring Business Process Maturity: Is Hammer Model Validated in Practice? Int. J. Product. Qual. Manag. 2021, 32, 502–519. [Google Scholar] [CrossRef]

- Radosavljevic, M. Assessment of Process Management Maturity in Developing Countries Based on SAW Method. J. Bus. Econ. Manag. 2014, 15, 599–614. [Google Scholar] [CrossRef]

- Sanchez-Comas, A.; Troncoso-Palacio, A.; Arrieta-Barrios, T.; Vasquez-Osorio, L.E. A Framework for Best Organisational Practices, from Implementation to Certification in Quality Management Systems. Int. J. Product. Qual. Manag. 2023, 40, 453–468. [Google Scholar] [CrossRef]

- Soffer, P.; Wand, Y. On the Notion of Soft-Goals in Business Process Modeling. Bus. Process Manag. J. 2005, 11, 663–679. [Google Scholar] [CrossRef]

- Tiawon, H.; Supartha, I.W.G. Implementing a Business Strategy with Supply Chain Management in a Management System and Management Control to Improve the Performance of the Hotel Business. Uncertain Supply Chain Manag. 2021, 9, 687–695. [Google Scholar] [CrossRef]

- Wong, W.P. Business-Process Management: A Proposed Framework for Future Research. Total Qual. Manag. Bus. Excell. 2013, 24, 719–732. [Google Scholar] [CrossRef]

- Yang, L.; Huo, B.; Gu, M. The Impact of Information Sharing on Supply Chain Adaptability and Operational Performance. Int. J. Logist. Manag. 2022, 33, 590–619. [Google Scholar] [CrossRef]

- Zerbino, P.; Stefanini, A.; Aloini, D. Process Science in Action: A Literature Review on Process Mining in Business Management. Technol. Forecast. Soc. Change 2021, 172, 121021. [Google Scholar] [CrossRef]

- de Lima, E.P.; da Costa, S.E.G.; Angelis, J.J. Strategic Performance Measurement Systems: A Discussion about Their Roles. Meas. Bus. Excell. 2009, 13, 39–48. [Google Scholar] [CrossRef]

- Toorajipour, R.; Sohrabpour, V.; Nazarpour, A.; Oghazi, P.; Fischl, M. Artificial Intelligence in Supply Chain Management: A Systematic Literature Review. J. Bus. Res. 2021, 122, 502–517. [Google Scholar] [CrossRef]

- Mendonça, G.D.; Lima, O.F., Jr. Artificial Intelligence Applied to Supply Chain Operations Management: A Systematic Literature Review. Int. J. Logist. Syst. Manag. 2023, 45, 1–30. [Google Scholar] [CrossRef]

- Ali, Z. Investigating Information Processing Paradigm to Predict Performance in Emerging Firms: The Mediating Role of Technological Innovation. J. Bus. Ind. Mark. 2023, 38, 724–735. [Google Scholar] [CrossRef]

- Antonucci, Y.L.; Fortune, A.; Kirchmer, M. An Examination of Associations between Business Process Management Capabilities and the Benefits of Digitalization: All Capabilities Are Not Equal. Bus. Process Manag. J. 2021, 27, 124–144. [Google Scholar] [CrossRef]

- Bromley, M.; Cuthbertson, R.; Martinez, V.; Kennerley, M. Performance Management at EDF Energy: Ambition into Action. Meas. Bus. Excell. 2006, 10, 23–30. [Google Scholar] [CrossRef]

- Chiesa, V.; Frattini, F.; Lazzarotti, V.; Manzini, R. Performance Measurement of Research and Development Activities. Eur. J. Innov. Manag. 2009, 12, 25–61. [Google Scholar] [CrossRef]

- Handal, R. An Implementation Framework for Additive Manufacturing in Supply Chains. J. Oper. Supply Chain Manag. 2017, 10, 18–31. [Google Scholar] [CrossRef]

- Hernandez-Vivanco, A.; Bernardo, M. Management Systems and Productive Efficiency along the Certification Life-Cycle. Int. J. Prod. Econ. 2023, 266, 109028. [Google Scholar] [CrossRef]

- Kishore Kumar, A.; Aeri, M.; Grover, A.; Agarwal, J.; Kumar, P.; Raghu, T. Secured Supply Chain Management System for Fisheries through IoT. Meas. Sensors 2023, 25, 100632. [Google Scholar] [CrossRef]

- Lubi, R.; Alexandri, M.B.; Herawaty, T.; Tresna, P.W. The Effect of Entrepreneurial Leadership, Innovation Capacity, Workplace Performance on Business Process Management and Its Implication on Financial Governance in Small Medium Enterprises in Bandung City. Acad. Strateg. Manag. J. 2021, 20, 1–10. [Google Scholar]

- Mahata, G.C.; De, S.K.; Bhattacharya, K.; Maity, S. Three-Echelon Supply Chain Model in an Imperfect Production System with Inspection Error, Learning Effect, and Return Policy under Fuzzy Environment. Int. J. Syst. Sci. Oper. Logist. 2023, 10, 1962427. [Google Scholar] [CrossRef]

- Maiberger, T.W.; Sunmola, F.T. Effectiveness Factors of Food Safety Management Systems: A Systematic Literature Review. Br. Food J. 2023, 125, 2234–2256. [Google Scholar] [CrossRef]

- Mamo, T.; Montastruc, L.; Negny, S.; Dendena, L. Integreted Strategic and Tactical Optimization Planning of Biomass to Bioethanol Supply Chains Coupled with Operational Plan Using Vehicle Routing: A Case Study in Ethiopia. Comput. Chem. Eng. 2023, 172, 108186. [Google Scholar] [CrossRef]

- Mamudu, A.; Bandara, W.; Leemans, S.J.J.; Wynn, M.T. A Process Mining Impacts Framework. Bus. Process Manag. J. 2023, 29, 690–709. [Google Scholar] [CrossRef]

- Manenzhe, M.T.; Telukdarie, A.; Munsamy, M. Maintenance Work Management Process Model: Incorporating System Dynamics and 4IR Technologies. J. Qual. Maint. Eng. 2023, 29, 88–119. [Google Scholar] [CrossRef]

- Nakano, M.; Matsuyama, K. The Relationship between Internal Supply Chain Structure and Operational Performance: Survey Results from Japanese Manufacturers. Supply Chain Manag. 2022, 27, 469–484. [Google Scholar] [CrossRef]

- Sahoo, S. Process Quality Management and Operational Performance: Exploring the Role of Learning and Development Orientation. Int. J. Qual. Reliab. Manag. 2022, 39, 1190–1208. [Google Scholar] [CrossRef]

- Saiz, J.J.A.; Bas, A.O.; Rodríguez, R.R. Performance Measurement System for Enterprise Networks. Int. J. Product. Perform. Manag. 2007, 56, 305–334. [Google Scholar] [CrossRef]

- Sordan, J.E.; Oprime, P.; Pimenta, M.L.; Chiabert, P.; Lombardi, F. Industry 4.0: A Bibliometric Analysis in the Perspective of Operations Management. Oper. Supply Chain Manag. 2022, 15, 93–104. [Google Scholar] [CrossRef]

- Sousa, G.W.L.; Carpinetti, L.C.R.; Groesbeck, R.L.; Van Aken, E. Conceptual Design of Performance Measurement and Management Systems Using a Structured Engineering Approach. Int. J. Product. Perform. Manag. 2005, 54, 385–399. [Google Scholar] [CrossRef]

- Tangen, S. Performance Measurement: From Philosophy to Practice. Int. J. Product. Perform. Manag. 2004, 53, 726–737. [Google Scholar] [CrossRef]

- Tsang, Y.P.; Fan, Y.; Lee, C.K.M.; Lau, H.C.W. Blockchain Sharding for E-Commerce Supply Chain Performance Analytics towards Industry 5.0. Enterp. Inf. Syst. 2024, 18, 2311807. [Google Scholar] [CrossRef]

- Vernadat, F.B.; Shah, L.; Etienne, A.; Siadat, A. VR-PMS: A New Approach for Performance Measurement and Management of Industrial Systems. Int. J. Prod. Res. 2013, 51, 7420–7438. [Google Scholar] [CrossRef]

- Xu, X.; Lee, S.-D.; Kim, H.-S.; You, S.-S. Management and Optimisation of Chaotic Supply Chain System Using Adaptive Sliding Mode Control Algorithm. Int. J. Prod. Res. 2021, 59, 2571–2587. [Google Scholar] [CrossRef]

- Yu, W.; Wong, C.Y.; Chavez, R.; Jacobs, M.; Nittala, L. How Intellectual Capital Builds Supply Chain Resilience? Exploring Mediation and Interaction Effects from an Intellectual Capital Based View. Supply Chain Manag. Int. J. 2023, 28, 1060–1074. [Google Scholar] [CrossRef]

- Akpinar, H.; Ozer Caylan, D. Modeling Organizational Resilience in Maritime Business: An ISM and MICMAC Approach. Bus. Process Manag. J. 2023, 29, 597–629. [Google Scholar] [CrossRef]

- Jawahar, I.M.; Mohammed, Z.J. Process Management Self-Efficacy: Scale Development and Validation. J. Bus. Psychol. 2022, 37, 339–352. [Google Scholar] [CrossRef]

- Jurczuk, A. Barriers to Implementation of Business Process Governance Mechanisms. Eng. Manag. Prod. Serv. 2021, 13, 22–38. [Google Scholar] [CrossRef]

- Kuzmin, O.; Tsikalo, Y.; Komarnytska, H.; Terlecka, V. Modelling of Management Decisions in the Process of System Integration at Enterprises. Int. J. Serv. Econ. Manag. 2024, 15, 201–223. [Google Scholar] [CrossRef]

- Lu, M.; Shen, Z.-J.M. A Review of Robust Operations Management under Model Uncertainty. Prod. Oper. Manag. 2021, 30, 1927–1943. [Google Scholar] [CrossRef]

- Ng, S.C.H.; Ho, G.T.S.; Wu, C.H. Blockchain-IIoT-Big Data Aided Process Control and Quality Analytics. Int. J. Prod. Econ. 2023, 261, 108871. [Google Scholar] [CrossRef]

- Rizun, N.; Revina, A.; Meister, V.G. Assessing Business Process Complexity Based on Textual Data: Evidence from ITIL IT Ticket Processing. Bus. Process Manag. J. 2021, 27, 1966–1998. [Google Scholar] [CrossRef]

- Stark, A.; Ferm, K.; Hanson, R.; Johansson, M.; Khajavi, S.; Medbo, L.; Öhman, M.; Holmström, J. Hybrid Digital Manufacturing: Capturing the Value of Digitalization. J. Oper. Manag. 2023, 69, 890–910. [Google Scholar] [CrossRef]

- Cronemyr, P.; Danielsson, M. Process Management 1-2-3—A Maturity Model and Diagnostics Tool. Total Qual. Manag. Bus. Excell. 2013, 24, 933–944. [Google Scholar] [CrossRef]

- Tseng, C.H.; Chang, K.H.; Chen, H.W. Strategic Orientation, Environmental Innovation Capability, and Environmental Sustainability Performance: The Case of Taiwanese Suppliers. Sustainability 2019, 11, 1127. [Google Scholar] [CrossRef]

- Tian, X.; Pavur, R.; Han, H.; Zhang, L. A Machine Learning-Based Human Resources Recruitment System for Business Process Management: Using LSA, BERT and SVM. Bus. Process Manag. J. 2023, 29, 202–222. [Google Scholar] [CrossRef]

- Žabjek, D.; Kovačič, A.; Štemberger, M.I. The Influence of Business Process Management and Some Other CSFs on Successful ERP Implementation. Bus. Process Manag. J. 2009, 15, 588–608. [Google Scholar] [CrossRef]

- Nakandala, D.; Yang, R.; Lau, H.; Weerabahu, S. Industry 4.0 Technology Capabilities, Resilience and Incremental Innovation in Australian Manufacturing Firms: A Serial Mediation Model. Supply Chain Manag. Int. J. 2023, 28, 760–772. [Google Scholar] [CrossRef]

- Chou, Y.-C.; Chuang, H.H.-C.; Chou, P.; Oliva, R. Supervised Machine Learning for Theory Building and Testing: Opportunities in Operations Management. J. Oper. Manag. 2023, 69, 643–675. [Google Scholar] [CrossRef]

- Davis, A.M.; Flicker, B.; Hyndman, K.; Katok, E.; Keppler, S.; Leider, S.; Long, X.; Tong, J.D. A Replication Study of Operations Management Experiments in Management Science. Manag. Sci. 2023, 69, 4977–4991. [Google Scholar] [CrossRef]

- Shi, H.; Yang, C.; Jiang, X.; Su, C.; Li, P. Novel Two-Dimensional off-Policy Q-Learning Method for Output Feedback Optimal Tracking Control of Batch Process with Unknown Dynamics. J. Process Control 2022, 113, 29–41. [Google Scholar] [CrossRef]

- Rauniyar, K.; Wu, X.; Gupta, S.; Modgil, S.; Lopes de Sousa Jabbour, A.B. Risk Management of Supply Chains in the Digital Transformation Era: Contribution and Challenges of Blockchain Technology. Ind. Manag. Data Syst. 2023, 123, 253–277. [Google Scholar] [CrossRef]

- Wacker, J.G. A Definition of Theory: Research Guidelines for Different Theory-Building Research Methods in Operations Management. J. Oper. Manag. 1998, 16, 361–385. [Google Scholar] [CrossRef]

- ISO. Quality Management Systems-Requirements; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Janiesch, C.; Zschech, P.; Heinrich, K. Machine Learning and Deep Learning. Electron. Mark. 2021, 31, 685–695. [Google Scholar] [CrossRef]

- Akbaş, N.; Taner, B. Mary Parker Follett’s Footprints in the Management Principles of Today and the Future. Istanbul Manag. J. 2022, 93, 89–123. [Google Scholar] [CrossRef]

- Follett, M.P. Creative Experience; Longmans, Green and Company: New York, NY, USA, 1924. [Google Scholar]

- Simon, H.A. Rationality in Political Behavior. Political Psychol. 1995, 16, 45–61. [Google Scholar] [CrossRef]

- Weber, M. The Theory of Social and Economic Organization; Routledge: Oxford, UK, 1947. [Google Scholar]

- Clegg, S. Weber and Foucault: Social Theory for the Study of Organizations. Organ. Artic. 1994, 1, 149–178. [Google Scholar] [CrossRef]

- von Bertalanffy, L. An Outline of General System Theory. Br. J. Philos. Sci. 1950, 1, 134–165. [Google Scholar] [CrossRef]

- Kast, F.E.; Rosenzweig, J.E. General Systems Theory: Applications for Organization and Management. Acad. Manag. J. 1972, 11, 447–465. [Google Scholar] [CrossRef]

- Hammond, D. The Legacy of Ludwig von Bertalanffy and Its Relevance for Our Time. Syst. Res. Behav. Sci. 2019, 36, 301–307. [Google Scholar] [CrossRef]

- Drucker, P.F. “Management Scienc” and the Manager. Manag. Sci. 1955, 1, 115–126. [Google Scholar] [CrossRef]

- Hicks, H.G.; Goronzy, F. On Methodology in the Study of Management and Organization. Acad. Manag. J. 1967, 10, 371–384. [Google Scholar] [CrossRef]

- McGregor, D. The Human Side of Enterprise. In Readings in Managerial Psychology; Leavitt, H.J., Pondy, L.R., Boje, D.M., Eds.; University of Chicago Press: Chicago, IL, USA, 1980; pp. 310–321. ISBN 0226469875. [Google Scholar]

- Kirkhart, L.; White, O.F. The Future of Organization Development. Public Adm. Rev. 2014, 34, 129–140. [Google Scholar] [CrossRef]

- Fiedler, F.E. The Contingency Model: New Direction for Leadership Utilization. J. Contemp. Bus. 1974, 3, 65–79. [Google Scholar]

- Fiedler, F.E. The Contingency Model and the Dynamics of the Leadership Process. Adv. Exp. Soc. Psychol. 1978, 11, 59–112. [Google Scholar] [CrossRef]

- Fligstein, N. Alfred Chandler and the Sociology of Organizations. 2007. Available online: https://escholarship.org/uc/item/8bx511g9 (accessed on 1 June 2025).

- Chandler, A.D., Jr. Strategy and Structure: Chapters in the History of the American Industrial Enterprise, 2nd ed.; MIT Press: Cambridge, MA, USA, 1990. [Google Scholar]

- Porter, M.E. Competitive Strategy: Techniques for Analyzing Industries and Competitors; Free Press: New York, NY, USA, 1980; Volume 267. [Google Scholar]

- Porter, M.E. The Competitive Advantage of Nations; Free Press: New York, NY, USA, 1990. [Google Scholar]

- Porter, M.E. The Five Competitive Forces That Shape Strategy. Harv. Bus. Rev. 2008, 86, 78–93. [Google Scholar]

- de Mozota, B.B. Structuring Strategic Design Management: Michael Porter’s Value Chain. Des. Manag. J. (Former Ser.) 1998, 9, 26–31. [Google Scholar] [CrossRef]

- Hammer, M.; Champy, J. Reengineering the Corporation: A Manifesto for Business Revolution, 1st ed.; Harper Business: New York, NY, USA, 1993; ISBN 0887306403. [Google Scholar]

- Narain, R.; Yadav, R.C.; Sarkis, J.; Cordeiro, J.J. The Strategic Implications of Flexibility in Manufacturing Systems. Int. J. Agil. Manag. Syst. 2000, 2, 202–213. [Google Scholar] [CrossRef]

- Mohammed, I.R.; Shankar, R.; Banwet, D.K. Creating Flex-lean-agile Value Chain by Outsourcing. Bus. Process Manag. J. 2008, 14, 338–389. [Google Scholar] [CrossRef]

- Lee, H.L. The Triple-A Supply Chain. Harv. Bus. Rev. 2004, 82, 102–120. [Google Scholar]

- Clauss, T. Measuring Business Model Innovation: Conceptualization, Scale Development, and Proof of Performance. R&D Manag. 2017, 47, 385–403. [Google Scholar] [CrossRef]

- Zaltman, G.; Duncan, R.; Holbek, J. Innovations and Organizations; Wiley: New York, NY, USA, 1973. [Google Scholar]

- White, A.; Daniel, E.M.; Mohdzain, M. The Role of Emergent Information Technologies and Systems in Enabling Supply Chain Agility. Int. J. Inf. Manag. 2005, 25, 396–410. [Google Scholar] [CrossRef]

- Lu, N.; Zhou, W.; Dou, Z.W. Can Intelligent Manufacturing Empower Manufacturing?—An Empirical Study Considering Ambidextrous Capabilities. Ind. Manag. Data Syst. 2023, 123, 188–203. [Google Scholar] [CrossRef]

- Zhou, K.Z.; Wu, F. Technological Capability, Strategic Flexibility, and Product Innovation. Strateg. Manag. J. 2010, 31, 547–561. [Google Scholar] [CrossRef]

- Hong, P.C.; Hejazi, M.T.; Deng, X.; Jagani, S. Dynamic Market Complexity and Service Value Advantage: An Empirical Investigation of Business Process Management. Bus. Process Manag. J. 2022, 28, 983–1004. [Google Scholar] [CrossRef]

- Spencer, M.E. Weber on Legitimate Norms and Authority. Br. J. Sociol. 1970, 21, 123. [Google Scholar] [CrossRef]

- Moen, R. Foundation and History of the PDSA Cycle. Available online: https://deming.org/wp-content/uploads/2020/06/PDSA_History_Ron_Moen.pdf (accessed on 15 April 2025).

- von Bertalanffy, L. General System Theory. Main Currents in Modern Thought. Acad. Manag. J. 1955, 15, 407–426. [Google Scholar] [CrossRef]

- Viegas, R.A.; Costa, A.P.C.S. Assessing Business Process Orientation Using Multi-Criteria Decision-Making. Bus. Process Manag. J. 2023, 29, 352–368. [Google Scholar] [CrossRef]

- Tarhan, A.; Turetken, O.; Reijers, H.A. Business Process Maturity Models: A Systematic Literature Review. Inf. Softw. Technol. 2016, 75, 122–134. [Google Scholar] [CrossRef]

- Nousias, N.; Tsakalidis, G.; Vergidis, K. Not yet Another BPM Lifecycle: A Synthesis of Existing Approaches Using BPMN. Inf. Softw. Technol. 2024, 171, 107471. [Google Scholar] [CrossRef]

- Mosser, J.; Pellerin, R.; Bourgault, M.; Danjou, C.; Perrier, N. GRMI4.0: A Guide for Representing and Modeling Industry 4.0 Business Processes. Bus. Process Manag. J. 2022, 28, 1047–1070. [Google Scholar] [CrossRef]

- Weerabahu, W.M.S.K.; Samaranayake, P.; Nakandala, D.; Hurriyet, H. Digital Supply Chain Research Trends: A Systematic Review and a Maturity Model for Adoption. Benchmarking Int. J. 2023, 30, 3040–3066. [Google Scholar] [CrossRef]

- Bouchard, M.; Jousselme, A.L.; Doré, P.E. A Proof for the Positive Definiteness of the Jaccard Index Matrix. Int. J. Approx. Reason. 2013, 54, 615–626. [Google Scholar] [CrossRef]

- Arts, S.; Cassiman, B.; Gomez, J.C. Text Matching to Measure Patent Similarity. Strateg. Manag. J. 2018, 39, 62–84. [Google Scholar] [CrossRef]

- Fletcher, S.; Islam, M.Z. Comparing Sets of Patterns with the Jaccard Index. Australas. J. Inf. Syst. 2018, 22, 1–16. [Google Scholar] [CrossRef]

| No. | Cluster | Number of Papers | % | References |

|---|---|---|---|---|

| 1 | Business Process Management | 44 | 48 | [1,2,6,11,14,15,16,17,20,22,48,49,51,52,54,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85] |

| 2 | Supply Chain Management | 39 | 42 | [1,3,12,50,51,62,63,65,67,73,76,80,82,83,84,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109] |

| 3 | Process Management | 37 | 40 | [12,15,20,21,22,50,53,69,70,72,73,76,77,79,87,88,89,90,93,94,95,96,97,98,99,101,103,104,105,110,111,112,113,114,115,116,117] |

| 4 | Business Process Re-engineering | 26 | 28 | [1,6,11,16,22,48,52,54,55,59,70,72,74,75,77,78,86,88,94,100,107,111,118,119,120,121] |

| 5 | Industry 4.0 | 17 | 18 | [1,3,51,67,73,89,90,94,96,97,98,101,102,103,104,105,122] |

| 6 | Operation Management | 16 | 17 | [50,58,61,62,72,73,79,86,87,94,95,103,113,114,123,124] |

| 7 | Learning Systems | 14 | 15 | [12,60,63,71,78,84,92,93,96,104,120,123,125,126] |

| 8 | Machine Learning | 14 | 15 | [6,11,12,16,55,71,72,84,92,96,104,119,120,123] |

| 9 | Block Chain | 12 | 13 | [50,62,67,69,80,82,91,93,100,106,109,115] |

| 10 | Data Analytics | 11 | 12 | [49,62,67,69,73,76,83,86,106,115,116] |

| 11 | Decision Making | 10 | 11 | [6,76,79,95,99,103,113,114,118,122] |

| 12 | Resource Management | 8 | 9 | [1,49,70,72,75,81,91,98] |

| 13 | Business Process | 8 | 9 | [14,51,58,61,62,63,71,82] |

| 14 | Data Mining | 8 | 9 | [73,77,83,98,99,103,115,120] |

| 15 | Inventory Control | 5 | 5 | [3,62,65,97,124] |

| 16 | Sustainable Development | 5 | 5 | [1,17,22,92,114] |

| 17 | Multi-objective Optimization | 5 | 5 | [60,63,69,97,114] |

| Definition | Theoretical Approach | Reference |

|---|---|---|

| A business process is a collection of activities that takes one or more kinds of input and creates an output that is of value to the customer. A business process has a goal and is affected by events occurring in the external world or in other processes. | Maturity Models Assessment | [76] |

| A business process is a complete and dynamically coordinated set of logically related activities or tasks that must be performed to deliver value to customers or meet other strategic objectives. | Management Theory | [81] |

| A business process emphasizes how work is performed rather than describing products or services that are a result of a process. | Management Theory | [81] |

| Consistent and predictable results are achieved more effectively and efficiently when activities are understood and managed as interrelated processes that function as a coherent system. | Governance Process | [112] |

| A process establishes an internal framework of standards intended to engage and motivate employees to deliver products and services that meet customer requirements within business expectations. | Complex systems | [69] |

| A business process is an approach that aims to improve the performance and flexibility of organizations through their management. | Management Theory | [15] |

| A business process is a management discipline that identifies and governs an organization’s business processes. The goal of its application is continuous improvement. | Value chain | [73] |

| Year | Administrative Theory or Technique | References | Connection with Process Management |

|---|---|---|---|

| 1924 | Human Relations Theory | [130,131] |

|

| |||

| |||

| 1947 | Behavioral Theory | [132] |

|

| |||

| 1950 | Structuralist Theory | [133,134] |

|

| |||

| 1951 | Systems Theory | [135,136,137] |

|

| |||

| 1954 | Neoclassical Theory | [138,139] |

|

| 1962 | Organizational Management | [140,141] |

|

| 1972 | Contingency Theory | [142,143,144,145] |

|

| |||

| |||

| |||

| 1980 | Porter’s Value Chain | [146,147,148,149] |

|

| 1994 | Business Process Reengineering and Improvement | [70,150] |

|

| 2010 | Orientation towards Innovation and Agility | [22,151,152,153,154,155] |

|

| |||

| |||

| 2020 | Integration with Emerging Technologies | [53,156,157,158,159] |

|

| Features | First Wave: Operative Efficiency (1900) | Second Wave: Total Quality (1950) | Third Wave: Digital Transformation (2000) |

|---|---|---|---|

| Focus | Steam engines improved efficiency in industry, while human relations were key to optimizing work performance. | Total Quality Management, Lean Manufacturing and Six Sigma systems improve efficiency and reduce errors in the value chain, while process reengineering transforms operations to optimize results. | Digital transformation and the integration of advanced technology improve efficiency and effectiveness in the process, facilitating adaptation to change and innovation. |

| Key Technologies and Methods | Steam engines, industrial machinery | Quality management methods (e.g., quality circles, benchmarking) and the emergence of management systems such as ISO standards. | Big Data, artificial intelligence (AI), RPA, Cloud, internet of things (IoT), Blockchain |

| Process Management | Focus on optimizing machinery and enhancing production efficiency. | Radical redesign, Total Quality Management (TQM), and Statistical Control (Six Sigma) | Agility, automation, real-time data analysis, flexibility |

| Organizational Impact | Increased production capacity, but limitations in quality and working conditions. | Improved quality, more customer-oriented processes, and greater employee engagement. | Business agility and flexibility, data-driven decision-making, and global reach. |

| Scope | Automotive industry, energy management, chemical and mechanical industry, mass consumption industry | Manufacturing industry: application of ISO 9001 standard. Chemical and Pharmaceutical industry: application of TQM and statistical control (Six Sigma) | Education industry: application of digitalization tools Financial industry: application of Big Data and AI |

| References | [16,53,55,71,92] | [22,74,77,78] | [20,66,77,80,106] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Viteri-Sánchez, C.; Novillo-Villegas, S. A Framework for a Sustainable Adoption of Business Process Management. Sustainability 2025, 17, 9827. https://doi.org/10.3390/su17219827

Viteri-Sánchez C, Novillo-Villegas S. A Framework for a Sustainable Adoption of Business Process Management. Sustainability. 2025; 17(21):9827. https://doi.org/10.3390/su17219827

Chicago/Turabian StyleViteri-Sánchez, Cristina, and Sylvia Novillo-Villegas. 2025. "A Framework for a Sustainable Adoption of Business Process Management" Sustainability 17, no. 21: 9827. https://doi.org/10.3390/su17219827

APA StyleViteri-Sánchez, C., & Novillo-Villegas, S. (2025). A Framework for a Sustainable Adoption of Business Process Management. Sustainability, 17(21), 9827. https://doi.org/10.3390/su17219827