Material Flow Analysis of Wood Resources: A Review of Current Practices in EU and Switzerland

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Definition of System Boundaries and Research Purposes

- A—Methodological Development and Standardization of MFA

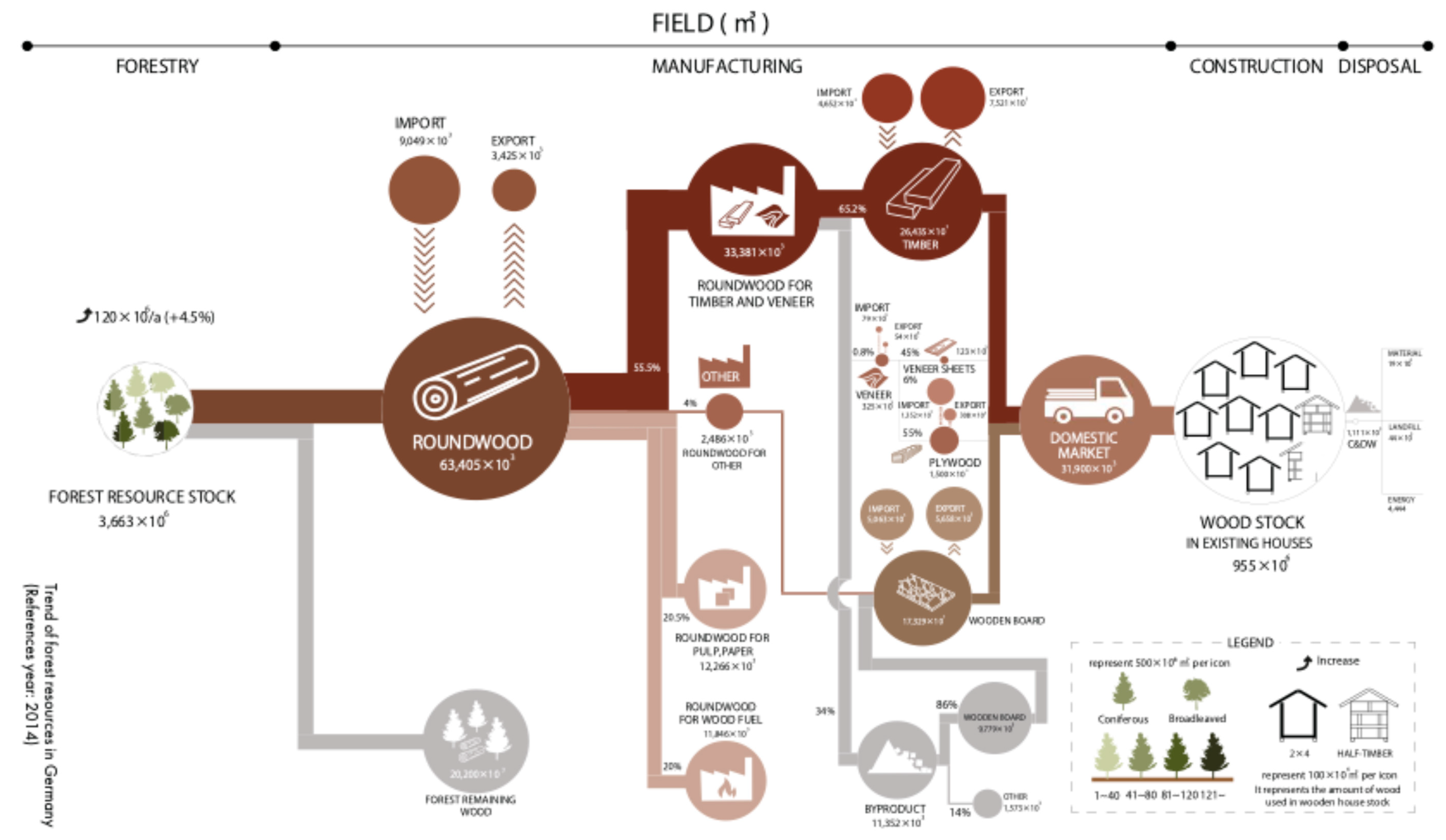

- B—National and Regional Wood Flow Analyses

- C—Climate Change Mitigation and Carbon Accounting

- D—Resource Efficiency, Circularity, and Cascading Use

- E—Policy Support, Strategic Planning, and Socioeconomic Implications

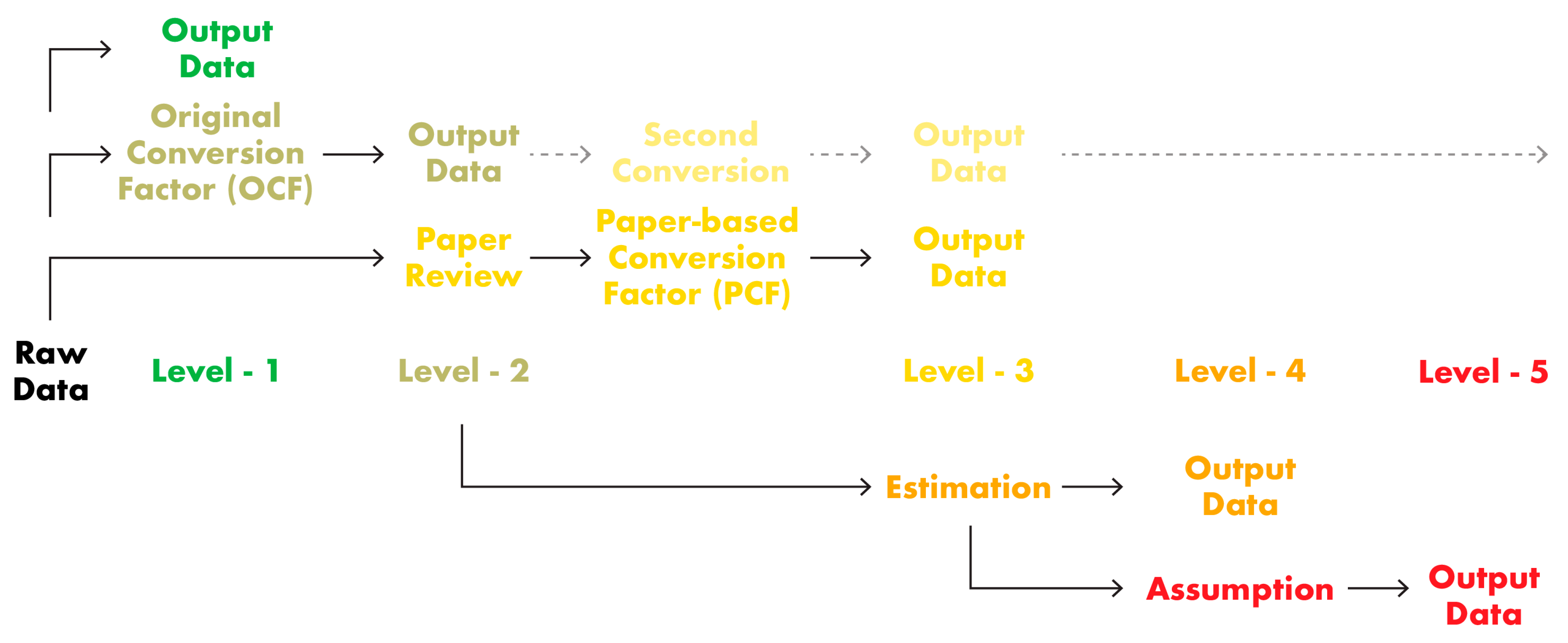

3.2. Data Processing

3.3. Outputs and Applications

3.4. Recommendations and Future Work

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| EU | European Union |

| MFA | Material Flow Analysis |

| STREAMS | Statistical Research of the Analysis of Material Streams |

| LCA | Life Cycle Assessment |

| FOR | Forestry |

| MAN | Manufacturing |

| BLD | Building |

| EOL | End-of-Life |

| FAO | Food and Agriculture Organization of the United Nations |

| DM | Dry matter |

| SWE | Solid wood equivalent |

| RWE | Roundwood equivalent |

| OCF | Original conversion factor |

| PCF | Paper-based conversion factor |

References

- European Commission: Directorate-General for Research and Innovation. A Sustainable Bioeconomy for Europe—Strengthening the Connection Between Economy, Society and the Environment—Updated Bioeconomy Strategy; Publications Office of the European Union: Luxembourg, 2018. [CrossRef]

- European Commission: Directorate-General for Communication. The European Green Deal—Delivering the EU’s 2030 Climate Targets; Publications Office of the European Union: Luxembourg, 2023. [CrossRef]

- Brunner, P.H.; Rechberger, H. Practical Handbook of Material Flow Analysis, 1st ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Buchanan, A.H.; Levine, S.B. Wood-based building materials and atmospheric carbon emissions. Environ. Sci. Policy 1999, 2, 427–437. [Google Scholar] [CrossRef]

- Joosten, L.A.J.; Hekkert, M.P.; Worrell, E.; Turkenburg, W.C. STREAMS: A new method for analysing material flows through society. Resour. Conserv. Recycl. 1999, 27, 249–266. [Google Scholar] [CrossRef]

- Marques, A.; Cunha, J.; De Meyer, A.; Navare, K. Contribution Towards a Comprehensive Methodology for Wood-Based Biomass Material Flow Analysis in a Circular Economy Setting. Forests 2020, 11, 106. [Google Scholar] [CrossRef]

- Džubur, N.; Sunanta, O.; Laner, D. A Fuzzy Set-Based Approach to Data Reconciliation in Material Flow Modeling. Appl. Math. Model. 2017, 43, 464–480. [Google Scholar] [CrossRef]

- Džubur, N.; Laner, D. Evaluation of Modeling Approaches to Determine End-of-Life Flows Associated with Buildings: A Viennese Case Study on Wood and Contaminants. J. Ind. Ecol. 2018, 22, 1156–1169. [Google Scholar] [CrossRef]

- Kalcher, J.; Praxmarer, G.; Teischinger, A. Quantification of Future Availabilities of Recovered Wood from Austrian Residential Buildings. Resour. Conserv. Recycl. 2017, 123, 143–152. [Google Scholar] [CrossRef]

- Kalt, G. Biomass Streams in Austria: Drawing a Complete Picture of Biogenic Material Flows within the National Economy. Resour. Conserv. Recycl. 2015, 95, 100–111. [Google Scholar] [CrossRef]

- Bergeron, F.C. Assessment of the Coherence of the Swiss Waste Wood Management. Resour. Conserv. Recycl. 2014, 91, 62–70. [Google Scholar] [CrossRef]

- Bergeron, F.C. Energy and Climate Impact Assessment of Waste Wood Recovery in Switzerland. Biomass Bioenergy 2016, 94, 245–257. [Google Scholar] [CrossRef]

- Mehr, J.; Vadenbo, C.; Steubing, B.; Hellweg, S. Environmentally Optimal Wood Use in Switzerland—Investigating the Relevance of Material Cascades. Resour. Conserv. Recycl. 2018, 131, 181–191. [Google Scholar] [CrossRef]

- Suter, F.; Steubing, B.; Hellweg, S. Life Cycle Impacts and Benefits of Wood along the Value Chain: The Case of Switzerland. J. Ind. Ecol. 2017, 21, 874–886. [Google Scholar] [CrossRef]

- Jasinevičius, G.; Lindner, M.; Cienciala, E.; Tykkyläinen, M. Carbon Accounting in Harvested Wood Products: Assessment Using Material Flow Analysis Resulting in Larger Pools Compared to the IPCC Default Method. J. Ind. Ecol. 2018, 22, 121–131. [Google Scholar] [CrossRef]

- Bösch, M.; Jochem, D.; Weimar, H.; Dieter, M. Physical Input–Output Accounting of the Wood and Paper Flow in Germany. Resour. Conserv. Recycl. 2015, 94, 99–109. [Google Scholar] [CrossRef]

- Cote, M.; Poganietz, W.-R.; Schebek, L. Anthropogenic Carbon Stock Dynamics of Pulp and Paper Products in Germany. J. Ind. Ecol. 2015, 19, 366–379. [Google Scholar] [CrossRef]

- Egenolf, V.; Vita, G.; Distelkamp, M.; Schier, F.; Hüfner, R.; Bringezu, S. The Timber Footprint of the German Bioeconomy—State of the Art and Past Development. Sustainability 2021, 13, 3878. [Google Scholar] [CrossRef]

- Jochem, D.; Weimar, H.; Bösch, M.; Mantau, U.; Dieter, M. Estimation of Wood Removals and Fellings in Germany: A Calculation Approach Based on the Amount of Used Roundwood. Eur. J. For. Res. 2015, 134, 869–888. [Google Scholar] [CrossRef]

- Knauf, M. An Analysis of Wood Market Balance Modeling in Germany. For. Policy Econ. 2015, 50, 319–326. [Google Scholar] [CrossRef]

- Knauf, M. The Wood Market Balance as a Tool for Calculating Wood Use’s Climate Change Mitigation Effect—An Example for Germany. For. Policy Econ. 2016, 66, 18–21. [Google Scholar] [CrossRef]

- Schweinle, J.; Geng, N.; Iost, S.; Weimar, H.; Jochem, D. Monitoring Sustainability Effects of the Bioeconomy: A Material Flow Based Approach Using the Example of Softwood Lumber and Its Core Product Epal 1 Pallet. Sustainability 2020, 12, 2444. [Google Scholar] [CrossRef]

- Szarka, N.; Haufe, H.; Lange, N.; Schier, F.; Weimar, H.; Banse, M.; Sturm, V.; Dammer, L.; Piotrowski, S.; Thrän, D. Biomass Flow in Bioeconomy: Overview for Germany. Renew. Sustain. Energy Rev. 2021, 150, 111449. [Google Scholar] [CrossRef]

- Szichta, P.; Risse, M.; Weber-Blaschke, G.; Richter, K. Potentials for wood cascading: A model for the prediction of the recovery of timber in Germany. Resour. Conserv. Recycl. 2022, 178, 106101. [Google Scholar] [CrossRef]

- Taskhiri, M.S.; Garbs, M.; Geldermann, J. Sustainable logistics network for wood flow considering cascade utilisation. J. Clean. Prod. 2016, 110, 25–39. [Google Scholar] [CrossRef]

- Wang, R.; Haller, P. Dynamic material flow analysis of wood in Germany from 1991 to 2020. Resour. Conserv. Recycl. 2024, 201, 107339. [Google Scholar] [CrossRef]

- Brownell, H.; Iliev, B.E.; Bentsen, N.S. How much wood do we use and how do we use it? Estimating Danish wood flows, circularity, and cascading using national material flow accounts. J. Clean. Prod. 2023, 423, 138720. [Google Scholar] [CrossRef]

- Hassan, M.K.; Villa, A.; Kuittinen, S.; Jänis, J.; Pappinen, A. An assessment of side-stream generation from Finnish forest industry. J. Mater. Cycles Waste Manag. 2019, 21, 265–280. [Google Scholar] [CrossRef]

- Nasiri, B.; Piccardo, C.; Hughes, M. Estimating the material stock in wooden residential houses in Finland. Waste Manag. 2021, 135, 318–326. [Google Scholar] [CrossRef]

- Layton, R.J.; Horta Arduin, R.; Yazdeen, H.; Pommier, R.; Sonnemann, G. Material Flow Analysis to Evaluate Supply Chain Evolution and Management: An Example Focused on Maritime Pine in the Landes de Gascogne Forest, France. Sustainability 2021, 13, 4378. [Google Scholar] [CrossRef]

- Lenglet, J.; Courtonne, J.-Y.; Caurla, S. Material flow analysis of the forest-wood supply chain: A consequential approach for log export policies in France. J. Clean. Prod. 2017, 165, 1296–1305. [Google Scholar] [CrossRef]

- Polgár, A. Carbon footprint and sustainability assessment of wood utilisation in Hungary. Environ. Dev. Sustain. 2024, 26, 24495–24519. [Google Scholar] [CrossRef]

- Donlan, J.; Skog, K.E.; Byrne, K.A. Carbon storage in harvested wood products for Ireland 1961–2009. Biomass Bioenergy 2012, 46, 731–738. [Google Scholar] [CrossRef]

- Hekkert, M.P.; Joosten, L.A.J.; Worrell, E. Analysis of the paper and wood flow in The Netherlands. Resour. Conserv. Recycl. 2000, 30, 29–48. [Google Scholar] [CrossRef]

- Gonçalves, M.; Freire, F.; Garcia, R. Material flow analysis of forest biomass in Portugal to support a circular bioeconomy. Resour. Conserv. Recycl. 2021, 169, 105507. [Google Scholar] [CrossRef]

- Piškur, M.; Krajnc, N. Roundwood flow analysis in Slovenia. Croj. J. For. Eng. 2007, 28, 39–46. [Google Scholar]

- Gejdoš, M.; Danihelová, Z. Valuation and timber market in the Slovak Republic. Procedia Econ. Financ. 2015, 34, 697–703. [Google Scholar] [CrossRef]

- Parobek, J.; Paluš, H.; Kaputa, V.; Šupín, M. Modelling of wood and wood products flow in the Slovak Republic. In A European Wood Processing Strategy: Future Resources Matching Products and Innovations; COST Action E44 Conference; COST Association: Ghent, Belgium, 2008; pp. 93–99. Available online: https://www.researchgate.net/publication/285288571_Modelling_of_wood_and_wood_products_flow_in_the_Slovak_Republic (accessed on 25 April 2024).

- Parobek, J.; Paluš, H.; Kaputa, V.; Šupín, M. Analysis of wood flows in Slovakia. BioResources 2014, 9, 6453–6462. [Google Scholar] [CrossRef]

- Parobek, J.; Paluš, H. Material flows in primary wood processing in Slovakia. Acta Logist. 2016, 3, 1–5. [Google Scholar] [CrossRef]

- Bais-Moleman, A.; Sikkema, R.; Vis, M.; Reumerman, P.; Theurl, M.; Erb, K.-H. Assessing wood use efficiency and greenhouse gas emissions of wood product cascading in the European Union. J. Clean. Prod. 2018, 172, 3942–3954. [Google Scholar] [CrossRef]

- Mantau, U.; Saal, U.; Steierer, F.; Verkerk, H.; Lindner, M.; Anttila, P.; Asikainen, A.; Oldenburger, J.; Leek, N.; Eggers, J.; et al. Real Potential for Changes in Growth and Use of EU Forests; Final Report; EUwood: Hamburg, Germany, 2010; 160p, Available online: https://www.probos.nl/images/pdf/rapporten/Rap2010_Real_potential_for_changes_in_growth_and_use_of_EU_forests.pdf (accessed on 18 March 2024).

- Mantau, U. Wood Flows in Europe (EU 27); Project Report; INFRO e.K.: Celle, Germany, 2012; 24p, Available online: https://www.researchgate.net/publication/291034739_Wood_flows_in_Europe_EU_27 (accessed on 24 May 2023).

- Mantau, U. Wood flow analysis: Quantification of resource potentials, cascades and carbon effects. Biomass Bioenergy 2015, 79, 28–38. [Google Scholar] [CrossRef]

- Pilli, R.; Fiorese, G.; Grassi, G. EU mitigation potential of harvested wood products. Carbon Balance Manag. 2015, 10, 6. [Google Scholar] [CrossRef] [PubMed]

- Saal, U.; Iost, S.; Weimar, H. Supply of wood processing residues—A basic calculation approach and its application on the example of wood packaging. Trees For. People 2022, 7, 100199. [Google Scholar] [CrossRef]

- Sikkema, R.; Styles, D.; Jonsson, R.; Tobin, B.; Byrne, K.A. A market inventory of construction wood for residential building in Europe—In the light of the Green Deal and new circular economy ambitions. Sustain. Cities Soc. 2023, 90, 104370. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Available online: http://www.fao.org (accessed on 14 July 2025).

- Food and Agriculture Organization of the United Nations. FAO Yearbook of Forest Products 2020; FAO: Rome, Italy, 2020. Available online: https://openknowledge.fao.org/items/6fdc429f-1d35-428d-bcde-326070d6d3ad (accessed on 16 January 2024).

- Wang, H.; Takano, A.; Tamura, K. An attempt to create the holistic flow chart of forest resources. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 042039. [Google Scholar] [CrossRef]

| No. | Title | Year | Country | First Author |

|---|---|---|---|---|

| 1 | A fuzzy set-based approach to data reconciliation in material flow modeling [7] | 2017 | AT | Džubur |

| 2 | Evaluation of modeling approaches to determine end-of-life flows associated with buildings: A Viennese case study on wood and contaminants [8] | 2018 | AT | Džubur |

| 3 | Quantification of future availabilities of recovered wood from Austrian residential buildings [9] | 2017 | AT | Kalcher |

| 4 | Biomass streams in Austria: Drawing a complete picture of biogenic material flows within the national economy [10] | 2015 | AT | Kalt |

| 5 | Assessment of the coherence of the Swiss waste wood management [11] | 2014 | CH | Bergeron |

| 6 | Energy and climate impact assessment of waste wood recovery in Switzerland [12] | 2016 | CH | Bergeron |

| 7 | Environmentally optimal wood use in Switzerland—Investigating the relevance of material cascades [13] | 2018 | CH | Mehr |

| 8 | Life cycle impacts and benefits of wood along the value chain [14] | 2017 | CH | Suter |

| 9 | Carbon accounting in harvested wood products: Assessment using material flow analysis resulting in larger pools compared to the IPCC default method [15] | 2018 | CZ | Jasinevičius |

| 10 | Physical input-output accounting of the wood and paper flow in Germany [16] | 2015 | DE | Bösch |

| 11 | Anthropogenic carbon stock dynamics of pulp and paper products in Germany [17] | 2015 | DE | Cote |

| 12 | The timber footprint of the German bioeconomy—State of the art and past development [18] | 2021 | DE | Egenolf |

| 13 | Estimation of wood removals and fellings in Germany: A calculation approach based on the amount of used roundwood [19] | 2015 | DE | Jochem |

| 14 | An analysis of wood market balance modeling in Germany [20] | 2015 | DE | Knauf |

| 15 | The wood market balance as a tool for calculating wood use’s climate change mitigation effect—An example for Germany [21] | 2016 | DE | Knauf |

| 16 | Monitoring sustainability effects of the bioeconomy: A material flow based approach using the example of softwood lumber and its core product epal 1 pallet [22] | 2020 | DE | Schweinle |

| 17 | Biomass flow in bioeconomy: Overview for Germany [23] | 2021 | DE | Szarka |

| 18 | Potentials for wood cascading: A model for the prediction of the recovery of timber in Germany [24] | 2022 | DE | Szichta |

| 19 | Sustainable logistics network for wood flow considering cascade utilisation [25] | 2016 | DE | Taskhiri |

| 20 | Dynamic material flow analysis of wood in Germany from 1991 to 2020 [26] | 2024 | DE | Wang |

| 21 | How much wood do we use and how do we use it? Estimating Danish wood flows, circularity, and cascading using national material flow accounts [27] | 2023 | DK | Brownnell |

| 22 | An assessment of side-stream generation from Finnish forest industry [28] | 2019 | FI | Hassan |

| 23 | Estimating the material stock in wooden residential houses in Finland [29] | 2021 | FI | Nasiri |

| 24 | Material flow analysis to evaluate supply chain evolution and management: An example focused on maritime pine in the Landes de Gascogne forest, France [30] | 2021 | FR | Layton |

| 25 | Material flow analysis of the forest-wood supply chain: A consequential approach for log export policies in France [31] | 2017 | FR | Lenglet |

| 26 | Carbon footprint and sustainability assessment of wood utilisation in Hungary [32] | 2024 | HU | Polgár |

| 27 | Carbon storage in harvested wood products for Ireland 1961–2009 [33] | 2012 | IE | Donlan |

| 28 | Analysis of the paper and wood flow in The Netherlands [34] | 2000 | NT | Hekkert |

| 29 | Material flow analysis of forest biomass in Portugal to support a circular bioeconomy [35] | 2021 | PT | Gonçalves |

| 30 | Contribution towards a comprehensive methodology for wood-based biomass material flow analysis in a circular economy setting [6] | 2020 | PT | Marques |

| 31 | Roundwood flow analysis in Slovenia [36] | 2007 | SI | Piškur |

| 32 | Valuation and timber market in the Slovak Republic [37] | 2015 | SK | Gejdoš |

| 33 | Modelling of wood and wood products flow in the Slovak Republic [38] | 2008 | SK | Parobek |

| 34 | Analysis of Wood Flows in Slovakia [39] | 2014 | SK | Parobek |

| 35 | Material flows in primary wood processing in Slovakia [40] | 2016 | SK | Parobek |

| 36 | Assessing wood use efficiency and greenhouse gas emissions of wood product cascading in the European Union [41] | 2018 | EU | Bais-Moleman |

| 37 | EUwood—Real potential for changes in growth and use of EU forests. Final report [42] | 2010 | EU | Mantau |

| 38 | Wood flows in Europe [43] | 2012 | EU | Mantau |

| 39 | Wood flow analysis: Quantification of resource potentials, cascades and carbon effects [44] | 2015 | EU | Mantau |

| 40 | EU mitigation potential of harvested wood products [45] | 2015 | EU | Pilli |

| 41 | Supply of wood processing residues—A basic calculation approach and its application on the example of wood packaging [46] | 2022 | EU | Saal |

| 42 | A market inventory of construction wood for residential building in Europe: In the light of the Green Deal and new circular economy ambitions [47] | 2023 | EU | Sikkema |

| Evaluation Criterion | Purpose | Specific Aspects Analyzed |

|---|---|---|

| Geographical and temporal coverage | Understand spatial and historical scope of studies | Countries or regions covered, temporal range |

| System boundaries | Clarify purposes and completeness of material flow systems | Inclusion of forest resources, processing stages, product use, end-of-life |

| Data sources and quality | Assess transparency, reliability, and comparability of data | Data sources, unit consistency, conversion factors, estimation methods, treatment of gaps |

| Flow representation techniques | Evaluate clarity and comprehensiveness | Use of diagrams, flow charts, tables; level of detail and consistency in visualization |

| Treatment of uncertainty | Identify methodological validity and transparency | Presence of sensitivity analysis, handling of uncertainties, documentation of assumptions, reconciliation steps |

| No. | I | II | III | IV | Type | No. | I | II | III | IV | Type |

|---|---|---|---|---|---|---|---|---|---|---|---|

| FOR | MAN | BLD | EOL | FOR | MAN | BLD | EOL | ||||

| 1 | ● | ● | ● | ● | A | 22 | ○ | ● | ○ | ● | D |

| 2 | ○ | ○ | ● | ○ | C | 23 | ○ | ○ | ● | ○ | D |

| 3 | ○ | ○ | ● | ○ | B | 24 | ○ | ● | ○ | ○ | B |

| 4 | ● | ● | ○ | ● | B | 25 | ● | ● | ○ | ● | E |

| 5 | ● | ● | ● | ● | D | 26 | ● | ● | ○ | ○ | C |

| 6 | ● | ● | ● | ● | C | 27 | ● | ● | ● | ● | C |

| 7 | ● | ● | ● | ● | D | 28 | ○ | ● | ● | ● | A |

| 8 | ● | ● | ● | ○ | E | 29 | ○ | ● | ○ | ● | B |

| 9 | ● | ● | ● | ● | C | 30 | ● | ● | ○ | ● | A |

| 10 | ● | ● | ● | ● | A | 31 | ● | ● | ○ | ● | E |

| 11 | ○ | ● | ○ | ● | A | 32 | ○ | ● | ○ | ○ | D |

| 12 | ● | ● | ○ | ○ | D | 33 | ○ | ● | ○ | ● | E |

| 13 | ● | ● | ○ | ○ | A | 34 | ○ | ● | ○ | ● | B |

| 14 | ● | ● | ○ | ● | A | 35 | ○ | ● | ○ | ● | B |

| 15 | ● | ● | ○ | ● | C | 36 | ● | ● | ○ | ● | D |

| 16 | ● | ● | ○ | ● | D | 37 | ● | ● | ○ | ● | E |

| 17 | ● | ● | ○ | ○ | D | 38 | ● | ● | ○ | ● | B |

| 18 | ● | ● | ● | ● | B | 39 | ● | ● | ○ | ● | A |

| 19 | ● | ● | ● | ● | D | 40 | ○ | ● | ○ | ○ | C |

| 20 | ● | ● | ○ | ● | B | 41 | ○ | ● | ○ | ● | A |

| 21 | ● | ● | ● | ● | B | 42 | ○ | ● | ● | ○ | E |

| No. | Symbol | Name | Type | No. | Symbol | Name | Type |

|---|---|---|---|---|---|---|---|

| 1 | t/t dry matter | tonnes of dry wood/matter | mass | 22 | m3 | cubic meter | volume |

| 2 | t | metric ton = tonne | mass | 23 | m3 | cubic meter | volume |

| 3 | m3 | cubic meter | volume | 24 | m3 [f] | wood fiber equivalent | volume |

| 4 | Mtdry | million tonnes of dry mass | mass | 25 | m3 [f] | wood fiber equivalent | volume |

| 5 | Mt | megatonnes | mass | 26 | m3 | cubic meter | volume |

| 6 | m3 | cubic meter | volume | 27 | m3 | cubic meter | volume |

| 7 | m3 | cubic meter | volume | 28 | kt | kilotonne | mass |

| 8 | m3 solid wood | cubic meter solid wood equivalent | volume | 29 | m3 (f) | cubic meter of wood fiber equivalent | volume |

| 9 | m3 | cubic meter | volume | 30 | kt | kilotonne | mass |

| 10 | m3 (f) | cubic meter of wood fiber equivalent | volume | 31 | m3 | cubic meter | volume |

| 11 | Mt | million metric tonnes | mass | 32 | m3 | cubic meter | volume |

| 12 | m3 | cubic meter | volume | 33 | m3 | cubic meter | volume |

| 13 | m3 | cubic meter | volume | 34 | m3 | cubic meter | volume |

| 14 | Mm3 | million cubic meters | volume | 35 | m3 | cubic meter | volume |

| 15 | Mm3 | million cubic meters | volume | 36 | t | tonne wet weight woody raw material | mass |

| 16 | t | metric ton = tonne | mass | 37 | m3 rwe | roundwood equivalent | volume |

| 17 | tDM | tonnes of dry matter | mass | 38 | m3 swe | solid wood equivalent | volume |

| 18 | m3 SWE | volume of solid wood equivalents | volume | 39 | m3 swe | solid wood equivalent | volume |

| 19 | m3 | cubic meter | volume | 40 | m3 | cubic meter | volume |

| 20 | SWE | solid wood equivalent | volume | 41 | m3 [f] | wood fiber equivalent | volume |

| 21 | m3 SWE | cubic meter solid wood equivalent | volume | 42 | m3 | cubic meter | volume |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Takano, A.; Winter, S. Material Flow Analysis of Wood Resources: A Review of Current Practices in EU and Switzerland. Sustainability 2025, 17, 9808. https://doi.org/10.3390/su17219808

Wang H, Takano A, Winter S. Material Flow Analysis of Wood Resources: A Review of Current Practices in EU and Switzerland. Sustainability. 2025; 17(21):9808. https://doi.org/10.3390/su17219808

Chicago/Turabian StyleWang, Hongjun, Atsushi Takano, and Stefan Winter. 2025. "Material Flow Analysis of Wood Resources: A Review of Current Practices in EU and Switzerland" Sustainability 17, no. 21: 9808. https://doi.org/10.3390/su17219808

APA StyleWang, H., Takano, A., & Winter, S. (2025). Material Flow Analysis of Wood Resources: A Review of Current Practices in EU and Switzerland. Sustainability, 17(21), 9808. https://doi.org/10.3390/su17219808