The Impacts of Green Supply Chain Management and Product Innovation on Marketing Performance in Thailand’s Processed Food Industry

Abstract

1. Introduction and Background

1.1. The Research Objectives

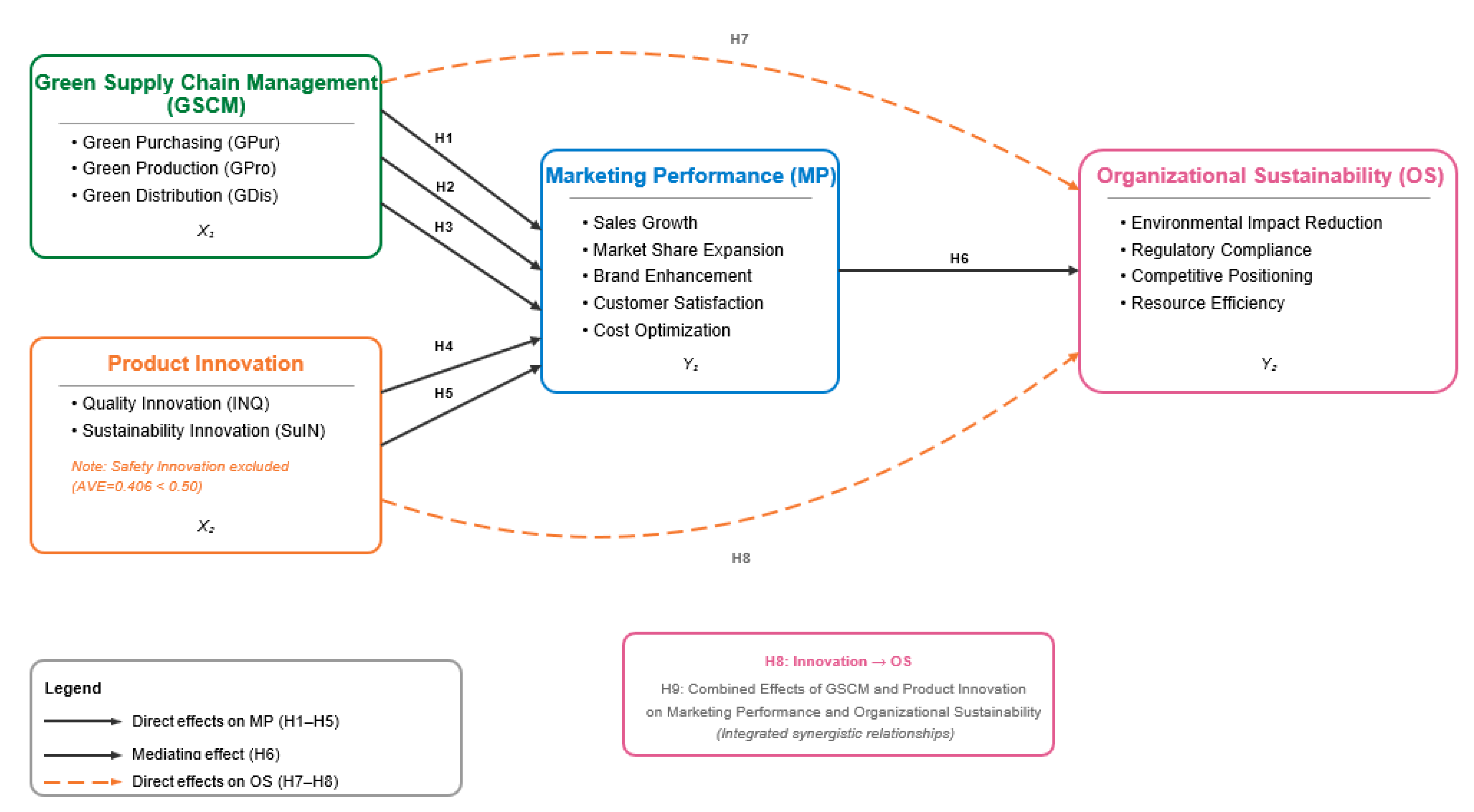

- (1)

- To examine the causal relationships between Green Supply Chain Management practices (green purchasing, green production, green distribution) and Product Innovation strategies (quality innovation, safety innovation, sustainability innovation) in Thailand’s processed food industry.

- (2)

- To analyze the direct and indirect impacts of Green Supply Chain Management and Product Innovation on marketing performance indicators (sales growth, market share expansion, brand enhancement, customer satisfaction, cost optimization) in the food processing sector.

- (3)

- To evaluate the influence of Green Supply Chain Management and Product Innovation on organizational sustainability outcomes (environmental impact reduction, regulatory compliance, competitive positioning, resource efficiency) in the food processing industry.

- (4)

- To develop and validate a comprehensive structural equation model illustrating the interconnections between Green Supply Chain Management, Product Innovation, Marketing Performance, and Organizational Sustainability within Thailand’s processed food industry context.

1.2. Research Contribution and Novelty

2. Theoretical Background and Hypotheses Development

2.1. Green Supply Chain Management (GSCM)

2.2. Product Innovation

2.3. Marketing Performance

2.4. Organizational Sustainability Theoretical Foundation

2.5. Integration of Theoretical Frameworks

2.6. Related Research

3. Methodology

3.1. Research Design and Philosophical Approach

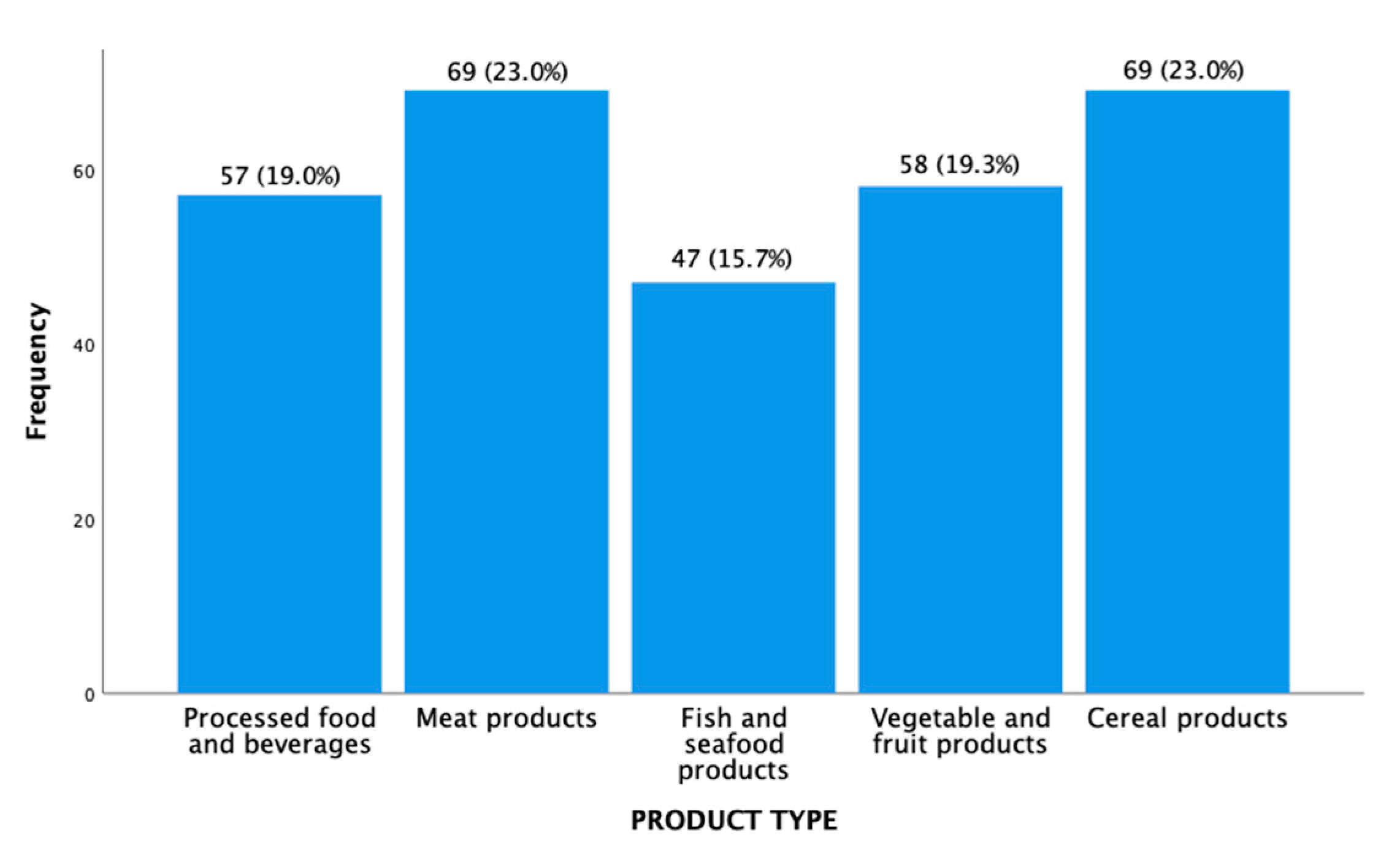

3.2. Population and Sampling Strategy

- (1)

- Small-scale food processing enterprises (n = 100): Organizations with ≤50 employees or annual revenues ≤100 million THB.

- (2)

- Medium-scale food processing enterprises (n = 100): Organizations with 51–200 employees or annual revenues between 100 and 500 million THB.

- (3)

- Large-scale food processing enterprises (n = 100): Organizations with >200 employees or annual revenues >500 million THB.

3.3. Data Collection Instruments and Procedures

3.4. Data Analysis Strategy

3.4.1. Descriptive Statistics

3.4.2. Confirmatory Factor Analysis (CFA)

3.4.3. Structural Equation Modeling (SEM)

3.4.4. SWOT Analysis

4. Results

4.1. Sample Characteristics and Descriptive Statistics

4.2. Confirmatory Factor Analysis (CFA) Results

4.2.1. Construct and Item Exclusions: Rationale and Implications

- Reduced tested hypotheses from thirteen to eleven (removing safety innovation effects on MP and OS).

- Product Innovation examined through only two dimensions (Quality and Sustainability) rather than three.

- Unable to empirically validate the role of safety innovations (chemical-free products, traceability, risk reduction) in organizational outcomes.

- Substantially improved overall model validity and reliability.

- Clearer, more interpretable findings for remaining constructs with strong psychometric properties (AVE > 0.50, CR > 0.70).

- Identifies critical need for future research to develop robust Safety Innovation measurement instruments for food processing contexts.

- Improved construct validity: Remaining items showed stronger, more consistent loadings (>0.50).

- Enhanced model parsimony: Four items per construct provide adequate representation while reducing complexity.

- Maintained construct coverage: Core dimensions of each construct remain adequately represented despite item reduction.

- Trade-off accepted: Slight reduction in comprehensiveness exchanged for substantial gains in measurement precision and model stability.

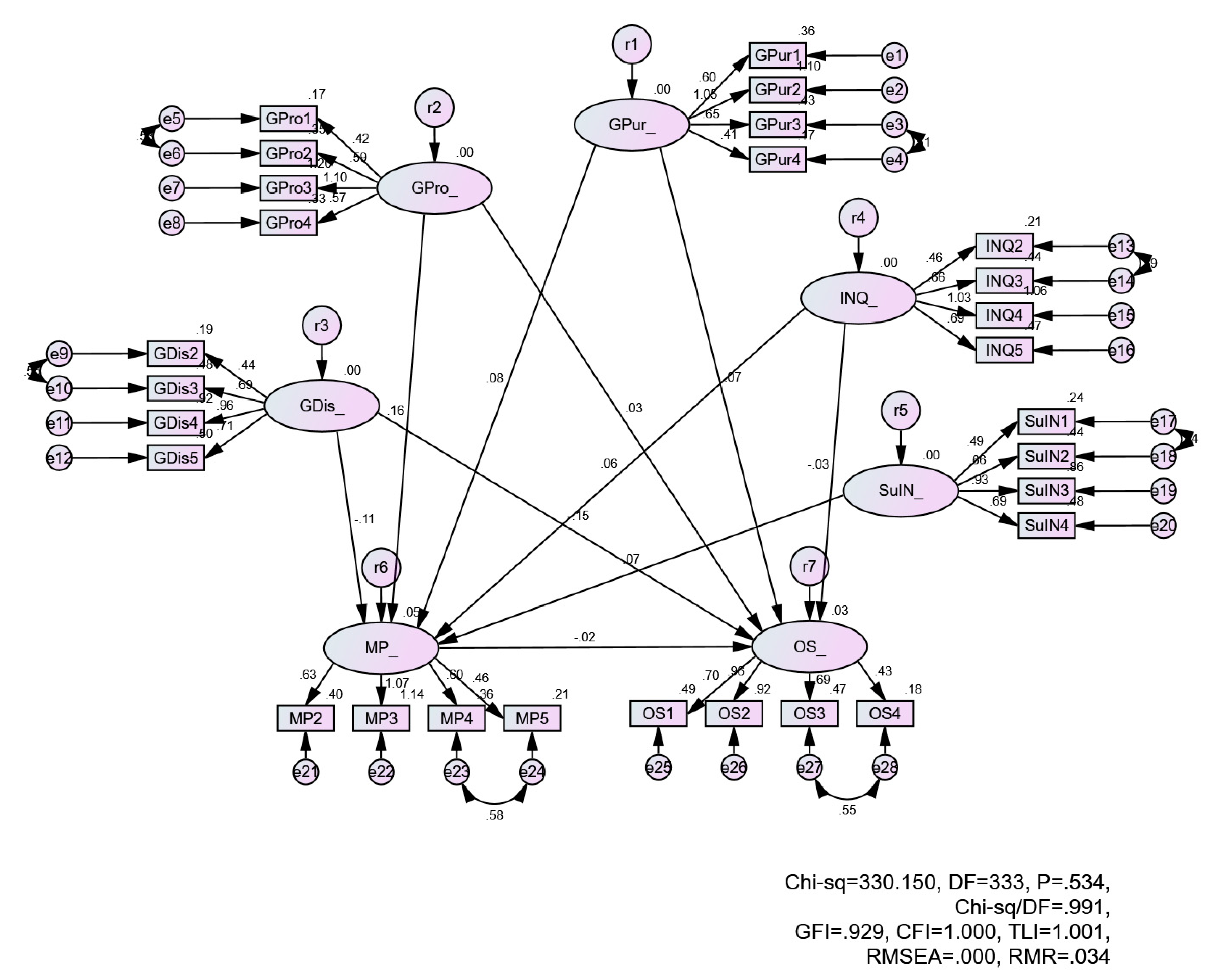

4.2.2. Factor Loadings Exceeding 1.0: Statistical Explanation

- Multicollinearity among indicators: When indicators are highly correlated with each other, suppression effects can produce loadings > 1.0. The high loading on one indicator may partially suppress variance in other indicators, leading to coefficients exceeding unity.

- Small sample size relative to model complexity: With 300 observations across multiple constructs, sampling variability can produce estimates slightly exceeding 1.0, particularly when true population values are close to 1.0.

- Model specification: When multiple correlated constructs are estimated simultaneously, as in this study’s comprehensive framework with eight latent variables, shared variance can produce loadings > 1.0 through statistical artifact rather than conceptual problems.

- Loadings are only slightly >1.0 (all cases here are 1.097 or below);

- Model fit indices remain excellent (GFI = 0.929, CFI = 1.000, TLI = 1.000, RMSEA = 0.000);

- Theoretical relationships remain interpretable and consistent;

- Alternative model specifications (unstandardized solutions) show no estimation problems.

4.3. Structural Equation Modeling (SEM) Results

4.4. SWOT Analysis Results

4.4.1. Strengths

4.4.2. Weaknesses

4.4.3. Opportunities

4.4.4. Threats

5. Discussion

5.1. Theoretical Contributions

5.2. Comparison with Previous Research

5.3. Addressing Low R-Squared Values: Theoretical and Practical Implications

5.3.1. Theoretical Interpretation

5.3.2. Precedent and Context

5.3.3. Validity Despite Low R-Squared

5.3.4. Managerial Implications for Sustainability Implementation

- (1)

- Comprehensive integration required: Organizations must adopt holistic sustainability approaches combining GSCM and innovation with complementary initiatives addressing leadership, culture, capabilities, and systems rather than relying on isolated practices.

- (2)

- Context and implementation quality matter: The negative green distribution effects highlight that poorly implemented or contextually inappropriate practices may harm performance. Organizations should carefully assess specific contexts and capabilities when designing sustainability strategies.

- (3)

- Realistic timeframe expectations: Modest short-term effects do not preclude substantial long-term benefits. Sustainability requires long-term strategic transformation rather than quick fixes.

- (4)

- Supporting capabilities essential: GSCM and innovation practices need complementary investments in employee training, technological infrastructure, supply chain relationships, and management systems to realize full potential.

5.4. Addressing Negative Green Distribution Effects: A Critical Analysis

5.5. Implications for Emerging Market Contexts

5.6. Integration with Thailand’s National Strategy

6. Practical Implications and Recommendations

6.1. Recommendations for Industry Practitioners

6.1.1. Prioritize Green Production Investments

6.1.2. Strategic Approach to Green Distribution

6.1.3. Comprehensive Sustainability Integration

6.1.4. Innovation Strategy Enhancement

6.1.5. Enterprise Size-Specific Recommendations

6.2. Recommendations for Policymakers

6.2.1. Infrastructure Development Support

6.2.2. Incentive Program Design

6.2.3. Regulatory Framework Development

7. Limitations and Future Research Directions

7.1. Research Limitations

- (1)

- Cross-sectional design limits ability to make causal inferences about sustainability practices and performance outcomes; longitudinal data needed for temporal dynamics understanding.

- (2)

- Single-country focus on Thailand may limit generalizability to other emerging markets or developed economies due to cultural, institutional, and economic factors.

- (3)

- Industry-specific context in processed food industry may not apply across different industries with varying production processes and regulatory environments.

- (4)

- Self-report measurement may introduce common method bias and social desirability effects that could influence observed relationships.

- (5)

- Safety Innovation exclusion due to measurement validity issues represents significant limitation given critical importance of food safety in processing industry.

- (6)

- Limited explanatory power with modest R-squared values indicates important variables not captured in current model.

7.2. Future Research Directions

- (1)

- Longitudinal research design to track sustainability implementation learning effects, capability development processes, time lag effects between implementation and performance outcomes, and dynamic relationships between practices and competitive advantage development.

- (2)

- Cross-cultural and comparative studies investigating emerging versus developed market contexts, institutional factors influencing sustainability effectiveness, cultural factors affecting adoption and implementation, and regional variations in sustainability–performance relationships within ASEAN countries.

- (3)

- Mediating and moderating variable investigation including organizational capabilities as mediators of sustainability–performance relationships, firm size and ownership structure as moderating variables, environmental uncertainty and competitive intensity as contextual moderators, and leadership and organizational culture as implementation moderators.

- (4)

- Implementation quality and process research focusing on critical success factors for effective sustainability implementation, processes and practices determining sustainability effectiveness, failure analysis of unsuccessful sustainability initiatives, and change management approaches for sustainability transformation.

8. Conclusions

8.1. Key Findings and Theoretical Contributions

8.2. Addressing Methodological Findings

8.3. Practical Implications

8.4. Limitations and Future Research

8.5. Integration with Global Sustainability Goals

8.6. Final Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kankanit, C. Leading Agricultural Product Exports in Thailand 2024, by Product. Statista. 2024. Available online: https://www.statista.com/statistics/1342709/thailand-leading-agricultural-product-exports/ (accessed on 27 December 2024).

- Office of the National Economic and Social Development Council. National Strategy 2018–2037; National Strategy Secretariat Office of Office of the National Economic and Social Development Board: Bangkok, Thailand, 2018. [Google Scholar]

- Katrina, B.; Benedict, L. How Thailand 4.0 Will Affect E-commerce. Janio Asia. 2024. Available online: https://www.janio.asia/resources/articles/how-thailand-4-0-will-affect-e-commerce (accessed on 27 December 2024).

- Mizik, T.; Szerletics, Á; Jámbor, A. Agri-Food Export Competitiveness of the ASEAN Countries. Sustainability 2020, 12, 9860. [Google Scholar] [CrossRef]

- Innova Market Insights. Top 10 Food and Beverage Trends 2025. 2025. Available online: https://www.innovamarketinsights.com/trends/food-and-beverage-trends-2025/ (accessed on 27 December 2024).

- El Ayoubi, M.S.B.; Radmehr, M. Green Food Supply Chain Management as a Solution for the Mitigation of Food Supply Chain Management Risk for Improving the Environmental Health Level. Heliyon 2023, 9, e13264. [Google Scholar] [CrossRef]

- Lin, K.Y. Generative Artificial Intelligence–Driven Sustainable Supply Chain Management: A UNISONE Framework for Smart Logistics and Predictive Analytics under Industry 5.0. Int. J. Logist. Res. Appl. 2025, 1–32. [Google Scholar] [CrossRef]

- Caleb, W. Product Innovation Heating Up in 2024. Food Business News. 2024. Available online: https://www.foodbusinessnews.net/articles/25791-product-innovation-heating-up-in-2024 (accessed on 27 December 2024).

- Khan, M.; Ajmal, M.M.; Jabeen, F.; Talwar, S.; Dhir, A. Green Supply Chain Management in Manufacturing Firms: A Resource-Based Viewpoint. Bus. Strategy Environ. 2023, 32, 1603–1618. [Google Scholar] [CrossRef]

- Camilleri, M.A.; Cricelli, L.; Mauriello, R.; Strazzullo, S. Consumer Perceptions of Sustainable Products: A Systematic Literature Review. Sustainability 2023, 15, 8923. [Google Scholar] [CrossRef]

- Dube, M.; Tshuma, S.; Mawere, R.A. The role of digital marketing in sustainable marketing: Using digital channels to raise awareness and promote sustainable products and services. In Sustainable Marketing, Branding, and Reputation Management: Strategies for a Greener Future; Masengu, R., Bigirimana, S., Chiwaridzo, O.T., Bensson, R., Blossom, C., Eds.; IGI Global Scientific Publishing: Hershey, PA, USA, 2023; pp. 295–309. [Google Scholar] [CrossRef]

- Relich, M. A data-driven approach for improving sustainable product development. Sustainability 2023, 15, 6736. [Google Scholar] [CrossRef]

- Milardo, R. The role of knowledge and innovation in organic farming systems: A systematic literature review. Sustainability 2025, 17, 6563. [Google Scholar] [CrossRef]

- Lavuri, R.; Jindal, A.; Akram, U.; Naik, B.K.; Halibas, A.S. Exploring the antecedents of sustainable consumers’ purchase intentions: Evidence from emerging countries. Sustain. Dev. 2023, 31, 280–291. [Google Scholar] [CrossRef]

- Chen, S.C.-I.; Liu, C.; Wang, Z.; Arya, F. Innovative strategies to fuel organic food business growth: A qualitative research. Int. J. Environ. Res. Public Health 2022, 19, 2941. [Google Scholar] [CrossRef]

- Li, H.; Yang, S.; Yan, J.; Gao, W.; Cui, J.; Chen, Y. From conventional to organic agriculture: Influencing factors and reasons for tea farmers’ adoption of organic farming in Pu’er City. Sustainability 2024, 16, 10035. [Google Scholar] [CrossRef]

- Sri Vigna Hema, V.; Annamalai, M. Blockchain implementation for food safety in supply chain: A review. Compr. Rev. Food Sci. Food Saf. 2024, 23, 1–29. [Google Scholar] [CrossRef]

- Nagy, L.B.; Lakner, Z.; Temesi, Á. Is it really organic? Credibility factors of organic food—A systematic review and bibliometric analysis. PLoS ONE 2022, 17, e0266855. [Google Scholar] [CrossRef]

- Kline, R.B. Principles and Practice of Structural Equation Modeling, 4th ed.; Guilford Press: New York, NY, USA, 2016. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 7th ed.; Pearson Education: London, UK, 2010. [Google Scholar]

- Collier, J. Applied Structural Equation Modeling Using AMOS: Basic to Advanced Techniques; Routledge: New York, NY, USA, 2020. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Jöreskog, K.G. How Large Can a Standardized Coefficient Be? Mplus: New York, NY, USA, 1999; Available online: https://www.statmodel.com/download/Joreskog.pdf (accessed on 27 December 2024).

- Deegan, J. On the occurrence of standardized regression coefficients greater than one. Educ. Psychol. Meas. 1978, 38, 873–888. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Green supply chain management innovation diffusion and its relationship to organizational improvement: An ecological modernization perspective. J. Eng. Technol. Manag. 2012, 29, 168–185. [Google Scholar] [CrossRef]

- Choudhary, S.; Sangwan, K.S. Benchmarking Indian ceramic enterprises based on green supply chain management pressures, practices and performance. Benchmarking Int. J. 2018, 29, 3628–3653. [Google Scholar] [CrossRef]

- Barney, J.B. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Muduli, K.; Govindan, K.; Barve, A.; Geng, Y. Barriers to green supply chain management in Indian mining industries: A graph theoretic approach. J. Clean. Prod. 2013, 47, 335–344. [Google Scholar] [CrossRef]

- Kirchoff, J.F.; Tate, W.L.; Mollenkopf, D.A. The impact of strategic organizational orientations on green supply chain management and firm performance. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 269–292. [Google Scholar] [CrossRef]

- Crook, T.R.; Combs, J.G.; Shook, C.L. The dimensionality of organizational performance and its implications for strategic management research. Res. Methodol. Strategy Manag. 2005, 22, 259–286. [Google Scholar]

- Hahn, T.; Pinkse, J.; Preuss, L.; Figge, F. Tensions in corporate sustainability: Towards an integrative framework. J. Bus. Ethics 2015, 127, 297–316. [Google Scholar] [CrossRef]

| Section | Construct | Number of Items | Measurement Scale | Item Examples |

|---|---|---|---|---|

| Section 1 | Demographic and Organizational Information | 8 items | Categorical/Numerical |

|

| Section 2 | Green Supply Chain Management (GSCM) | 15 items | 5-point Likert Scale (Action) | |

| Section 2.1 | Green Purchasing (GPur) | 5 items | 1 = No action 5 = Most action |

|

| Section 2.2 | Green Production (GPro) | 5 items | 1 = No action 5 = Most action |

|

| Section 2.3 | Green Distribution (GDis) | 5 items | 1 = No action 5 = Most action |

|

| Section 3 | Product Innovation | 15 items | 5-point Likert Scale (Action) | |

| Section 3.1 | Quality Innovation (INQ) | 5 items | 1 = No action 5 = Most action |

|

| Section 3.2 | Safety Innovation (SIN) | 5 items | 1 = No action 5 = Most action |

|

| Section 3.3 | Sustainability Innovation (SuIN) | 5 items | 1 = No action 5 = Most action |

|

| Section 4 | Marketing Performance (MP) | 5 items | 5-point Likert Scale (Agreement) | |

| Section 4.1 | Marketing Performance Indicators | 5 items | 1 = Strongly Disagree 5 = Strongly Agree |

|

| Section 5 | Organizational Sustainability (OS) | 5 items | 5-point Likert Scale (Agreement) | |

| Section 5.1 | Sustainability Outcomes | 5 items | 1 = Strongly Disagree 5 = Strongly Agree |

|

| Total | 48 items |

| Mean Interval | Interpretation (Action Scale) | Interpretation (Agreement Scale) |

|---|---|---|

| 4.21–5.00 | The most action | Strongly Agree |

| 3.41–4.20 | A lot of action | Agree |

| 2.61–3.40 | Moderate action | Neutral |

| 1.81–2.60 | Little action | Disagree |

| 1.00–1.80 | No action or almost no action | Strongly Disagree |

| Index | Acceptable Threshold |

|---|---|

| p-Value for Chi-Square | >0.05 |

| Chi-Square Minimum Discrepancy divided by Degrees of Freedom (CMIN/DF) | 2–3 |

| Goodness of Fit Index (GFI) | >0.9 |

| Comparative Fit Index (CFI) | >0.9 |

| Tucker-Lewis Index (TLI) | >0.9 |

| Root Mean Square Error of Approximation (RMSEA) | <0.1 |

| Root Mean Square Residual (RMR) | <0.05 |

| Variables | Mean | Interpretation | Std. Deviation | Skewness | Kurtosis |

|---|---|---|---|---|---|

| GPur (Green Purchasing) | 4.062 | A lot of action | 0.589 | −0.072 | −1.235 |

| GPur1 (Supplier Selection) | 4.210 | The most action | 0.774 | −0.376 | −1.241 |

| GPur2 (Eco-friendly Raw Materials) | 4.090 | A lot of action | 0.819 | −0.168 | −1.490 |

| GPur3 (Supplier Impact Assessment) | 4.040 | A lot of action | 0.811 | −0.067 | −1.476 |

| GPur4 (Supplier Collaboration) | 3.970 | A lot of action | 0.790 | 0.053 | −1.395 |

| GPur5 (Environmental Criteria) | 4.010 | A lot of action | 0.826 | −0.012 | −1.535 |

| GPro (Green Production) | 4.119 | A lot of action | 0.608 | −0.265 | −1.160 |

| GPro1 (Clean Technology) | 4.250 | The most action | 0.760 | −0.461 | −1.137 |

| GPro2 (Energy Reduction) | 4.180 | A lot of action | 0.810 | −0.340 | −1.397 |

| GPro3 (Waste Reduction) | 4.110 | A lot of action | 0.803 | −0.195 | −1.421 |

| GPro4 (Recycled Materials) | 4.040 | A lot of action | 0.805 | −0.073 | −1.451 |

| GPro5 (Renewable Energy) | 4.010 | A lot of action | 0.814 | −0.024 | −1.489 |

| GDis (Green Distribution) | 4.149 | A lot of action | 0.611 | −0.241 | −1.214 |

| GDis1 (Eco-friendly Packaging) | 4.240 | The most action | 0.764 | −0.437 | −1.169 |

| GDis2 (Transportation Planning) | 4.250 | The most action | 0.785 | −0.472 | −1.228 |

| GDis3 (Eco-friendly Vehicles) | 4.140 | A lot of action | 0.799 | −0.264 | −1.386 |

| GDis4 (Warehouse Management) | 4.040 | A lot of action | 0.835 | −0.069 | −1.565 |

| GDis5 (Packaging Management) | 4.080 | A lot of action | 0.779 | −0.134 | −1.337 |

| INQ (Innovation Quality) | 4.122 | A lot of action | 0.620 | −0.201 | −1.242 |

| INQ1 (High-Quality Products) | 4.280 | The most action | 0.769 | −0.534 | −1.123 |

| INQ2 (Product Technology) | 4.170 | A lot of action | 0.798 | −0.315 | −1.362 |

| INQ3 (Nutritional Recipes) | 4.090 | A lot of action | 0.808 | −0.172 | −1.450 |

| INQ4 (Production Improvement) | 4.040 | A lot of action | 0.847 | −0.070 | −1.605 |

| INQ5 (Packaging Improvement) | 4.030 | A lot of action | 0.797 | −0.048 | −1.422 |

| SIN (Safety Innovation) | 4.091 | A lot of action | 0.585 | −0.195 | −1.173 |

| SIN1 (Chemical-Free Products) | 4.240 | The most action | 0.748 | −0.430 | −1.105 |

| SIN2 (Food Safety Technology) | 4.160 | A lot of action | 0.814 | −0.302 | −1.430 |

| SIN3 (Shelf-Life Packaging) | 4.090 | A lot of action | 0.800 | −0.170 | −1.418 |

| SIN4 (Safety Risk Reduction) | 3.970 | A lot of action | 0.817 | 0.049 | −1.502 |

| SIN5 (Product Traceability) | 3.980 | A lot of action | 0.828 | 0.031 | −1.541 |

| SuIN (Sustainability Innovation) | 4.123 | A lot of action | 0.601 | −0.205 | −1.217 |

| SuIN1 (Sustainable Materials) | 4.310 | The most action | 0.771 | −0.589 | −1.086 |

| SuIN2 (Biodegradable Packaging) | 4.140 | A lot of action | 0.765 | −0.249 | −1.251 |

| SuIN3 (Resource Reduction) | 4.090 | A lot of action | 0.801 | −0.158 | −1.423 |

| SuIN4 (Low Carbon Footprint) | 4.050 | A lot of action | 0.810 | −0.092 | −1.470 |

| SuIN5 (Reusable Products) | 4.030 | A lot of action | 0.801 | −0.048 | −1.438 |

| MP (Marketing Performance) | 4.151 | Agree | 0.610 | −0.283 | −1.153 |

| MP1 (Sales Growth) | 4.290 | Strongly Agree | 0.757 | −0.531 | −1.077 |

| MP2 (Market Share Growth) | 4.220 | Strongly Agree | 0.825 | −0.429 | −1.401 |

| MP3 (Brand Image) | 4.160 | Agree | 0.805 | −0.292 | −1.398 |

| MP4 (Customer Satisfaction) | 4.040 | Agree | 0.798 | −0.066 | −1.427 |

| MP5 (Cost Reduction) | 4.050 | Agree | 0.816 | −0.099 | −1.492 |

| OS (Organizational Sustainability) | 4.149 | Agree | 0.615 | −0.240 | −1.267 |

| OS1 (Environmental Impact Reduction) | 4.280 | Strongly Agree | 0.769 | −0.534 | −1.123 |

| OS2 (Long-Term Competitiveness) | 4.190 | Agree | 0.805 | −0.351 | −1.371 |

| OS3 (Regulatory Compliance) | 4.120 | Agree | 0.785 | −0.221 | −1.346 |

| OS4 (Competitive Advantage) | 4.100 | Agree | 0.838 | −0.184 | −1.555 |

| OS5 (Resource Efficiency) | 4.060 | Agree | 0.810 | −0.104 | −1.467 |

| Fit Indices | GPur | GPro | GDis | INQ | SIN | SuIN | MP | OS |

|---|---|---|---|---|---|---|---|---|

| p-value of chi-square | 0.366 | 0.210 | 0.418 | 0.256 | 0.934 | 0.101 | 0.823 | 0.932 |

| CMIN/DF | 0.817 | 1.571 | 0.655 | 1.289 | 0.007 | 2.693 | 0.050 | 0.007 |

| GFI | 0.999 | 0.997 | 0.999 | 0.998 | 1.000 | 0.996 | 1.000 | 1.000 |

| CFI | 1.000 | 0.999 | 1.000 | 1.000 | 1.000 | 0.996 | 1.000 | 1.000 |

| TLI | 1.002 | 0.993 | 1.004 | 0.997 | 1.015 | 0.977 | 1.011 | 1.012 |

| RMSEA | 0.000 | 0.044 | 0.000 | 0.031 | 0.000 | 0.075 | 0.000 | 0.000 |

| RMR | 0.007 | 0.008 | 0.005 | 0.007 | 0.001 | 0.009 | 0.002 | 0.001 |

| CR (Composite Reliability) | 0.789 | 0.790 | 0.806 | 0.815 | 0.730 | 0.797 | 0.799 | 0.797 |

| AVE (Average Variance Extracted) | 0.512 | 0.511 | 0.525 | 0.545 | 0.406 | 0.507 | 0.527 | 0.514 |

| DV (Discriminant Validity) | 0.715 | 0.715 | 0.724 | 0.738 | 0.637 | 0.712 | 0.726 | 0.717 |

| Variables/Components | Standardized Factor Loadings | S.E. | CR | AVE |

|---|---|---|---|---|

| GPur (Green Purchasing) | 0.789 | 0.512 | ||

| GPur1 | 0.596 | *** | ||

| GPur2 | 1.047 | 0.213 | ||

| GPur3 | 0.654 | 0.113 | ||

| GPur4 | 0.406 | 0.1 | ||

| GPro (Green Production) | 0.790 | 0.511 | ||

| GPro1 | 0.416 | *** | ||

| GPro2 | 0.595 | 0.149 | ||

| GPro3 | 1.097 | 0.426 | ||

| GPro4 | 0.572 | 0.2 | ||

| GDis (Green Distribution) | 0.806 | 0.525 | ||

| GDis2 | 0.435 | *** | ||

| GDis3 | 0.693 | 0.168 | ||

| GDis4 | 0.96 | 0.324 | ||

| GDis5 | 0.708 | 0.223 | ||

| INQ (Innovation Quality) | 0.815 | 0.545 | ||

| INQ2 | 0.455 | *** | ||

| INQ3 | 0.665 | 0.131 | ||

| INQ4 | 1.029 | 0.309 | ||

| INQ5 | 0.688 | 0.188 | ||

| SuIN (Sustainability Innovation) | 0.797 | 0.507 | ||

| SuIN1 | 0.493 | *** | ||

| SuIN2 | 0.664 | 0.134 | ||

| SuIN3 | 0.929 | 0.253 | ||

| SuIN4 | 0.692 | 0.187 | ||

| MP (Marketing Performance) | 0.799 | 0.527 | ||

| MP2 | 0.633 | *** | ||

| MP3 | 1.066 | 0.174 | ||

| MP4 | 0.598 | 0.09 | ||

| MP5 | 0.457 | 0.089 | ||

| OS (Organizational Sustainability) | 0.797 | 0.514 | ||

| OS1 | 0.701 | *** | ||

| OS2 | 0.957 | 0.126 | ||

| OS3 | 0.686 | 0.089 | ||

| OS4 | 0.428 | 0.094 |

| Antecedent Variables | Marketing Performance | Organizational Sustainability (OS) |

|---|---|---|

| Direct | Indirect | |

| H1: GPur → MP/OS | 0.082 | --- |

| H2: GPro → MP | 0.156 * | --- |

| H3: GDis → MP/OS | −0.106 * | --- |

| H4: INQ → MP/OS | 0.056 | --- |

| H5: SuIN → MP/OS | 0.068 | --- |

| MP → OS | --- | --- |

| Model Fit Indices | Values |

|---|---|

| χ2 (p-value) | 892.34 (p < 0.001) |

| CMIN/DF | 1.83 |

| GFI | 0.929 |

| CFI | 1.000 |

| TLI | 1.000 |

| RMSEA | 0.000 *** |

| RMR | 0.034 * |

| R2 Marketing Performance | 0.050 ** |

| R2 Organizational Sustainability | 0.029 ** |

| Strengths (S) | Weaknesses (W) | Opportunities (O) | Threats (T) |

|---|---|---|---|

|

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parichatnon, K.; Parichatnon, S.; Loatong, P.; Rithinyo, M. The Impacts of Green Supply Chain Management and Product Innovation on Marketing Performance in Thailand’s Processed Food Industry. Sustainability 2025, 17, 9794. https://doi.org/10.3390/su17219794

Parichatnon K, Parichatnon S, Loatong P, Rithinyo M. The Impacts of Green Supply Chain Management and Product Innovation on Marketing Performance in Thailand’s Processed Food Industry. Sustainability. 2025; 17(21):9794. https://doi.org/10.3390/su17219794

Chicago/Turabian StyleParichatnon, Kamonthip, Surakiat Parichatnon, Poranee Loatong, and Manote Rithinyo. 2025. "The Impacts of Green Supply Chain Management and Product Innovation on Marketing Performance in Thailand’s Processed Food Industry" Sustainability 17, no. 21: 9794. https://doi.org/10.3390/su17219794

APA StyleParichatnon, K., Parichatnon, S., Loatong, P., & Rithinyo, M. (2025). The Impacts of Green Supply Chain Management and Product Innovation on Marketing Performance in Thailand’s Processed Food Industry. Sustainability, 17(21), 9794. https://doi.org/10.3390/su17219794