Analyzing Determinants of Aircraft Used Serviceable Material’s Value Using Fuzzy Analytic Hierarchy Process

Abstract

1. Introduction

2. Literature Review

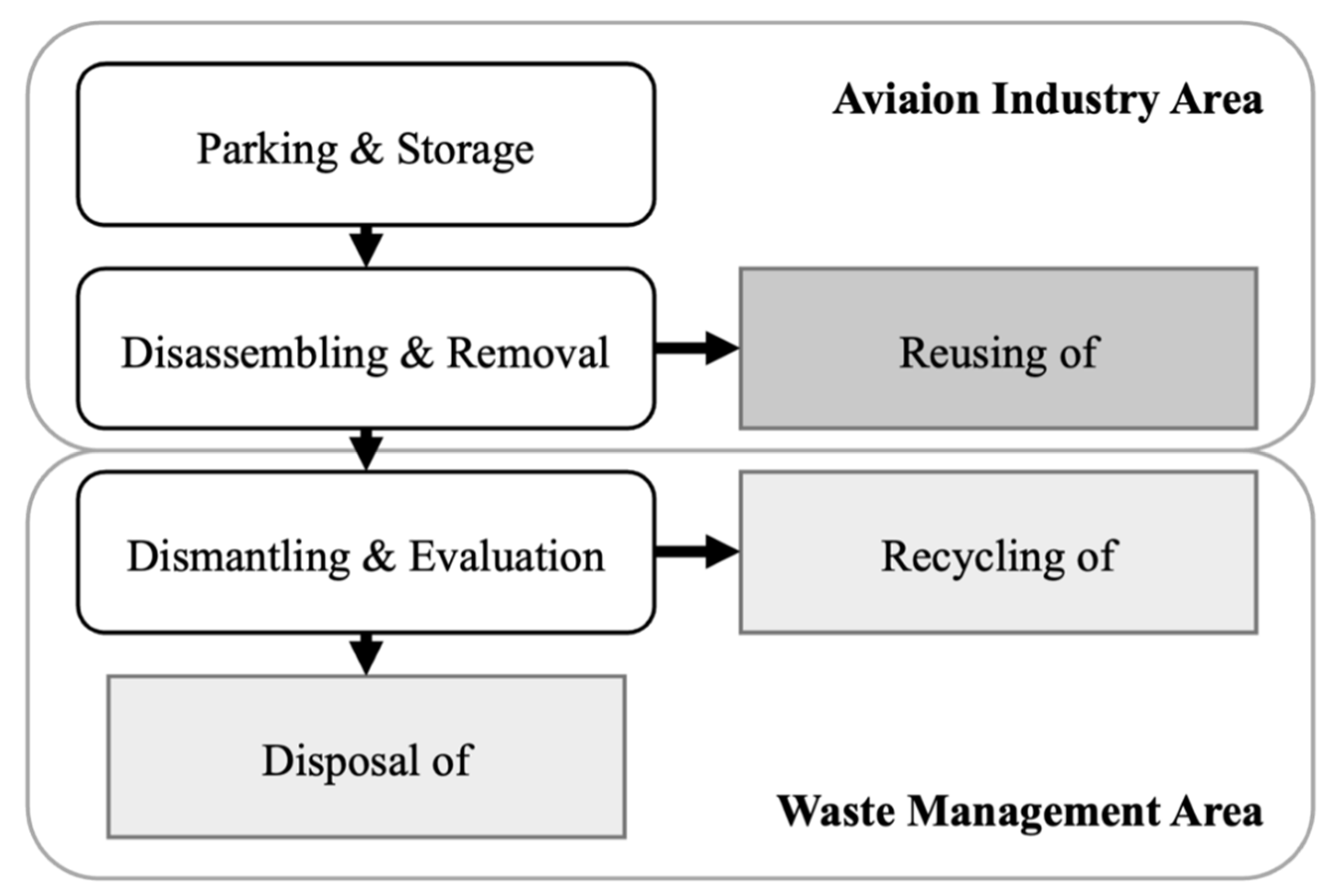

2.1. Circular Economy in the Aviation Industry

2.2. USM in Practice

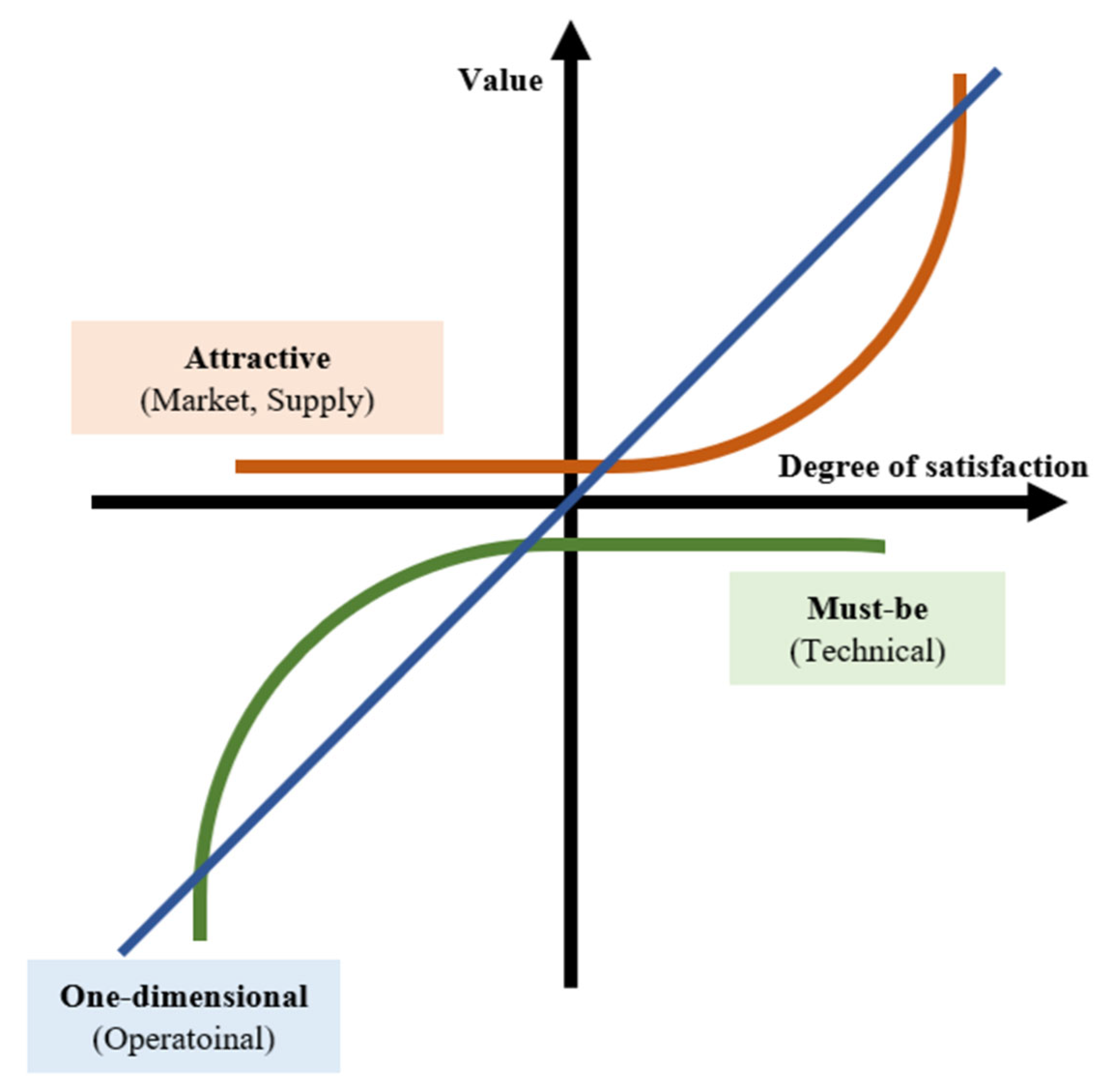

2.3. Factors Influencing USM’s Value

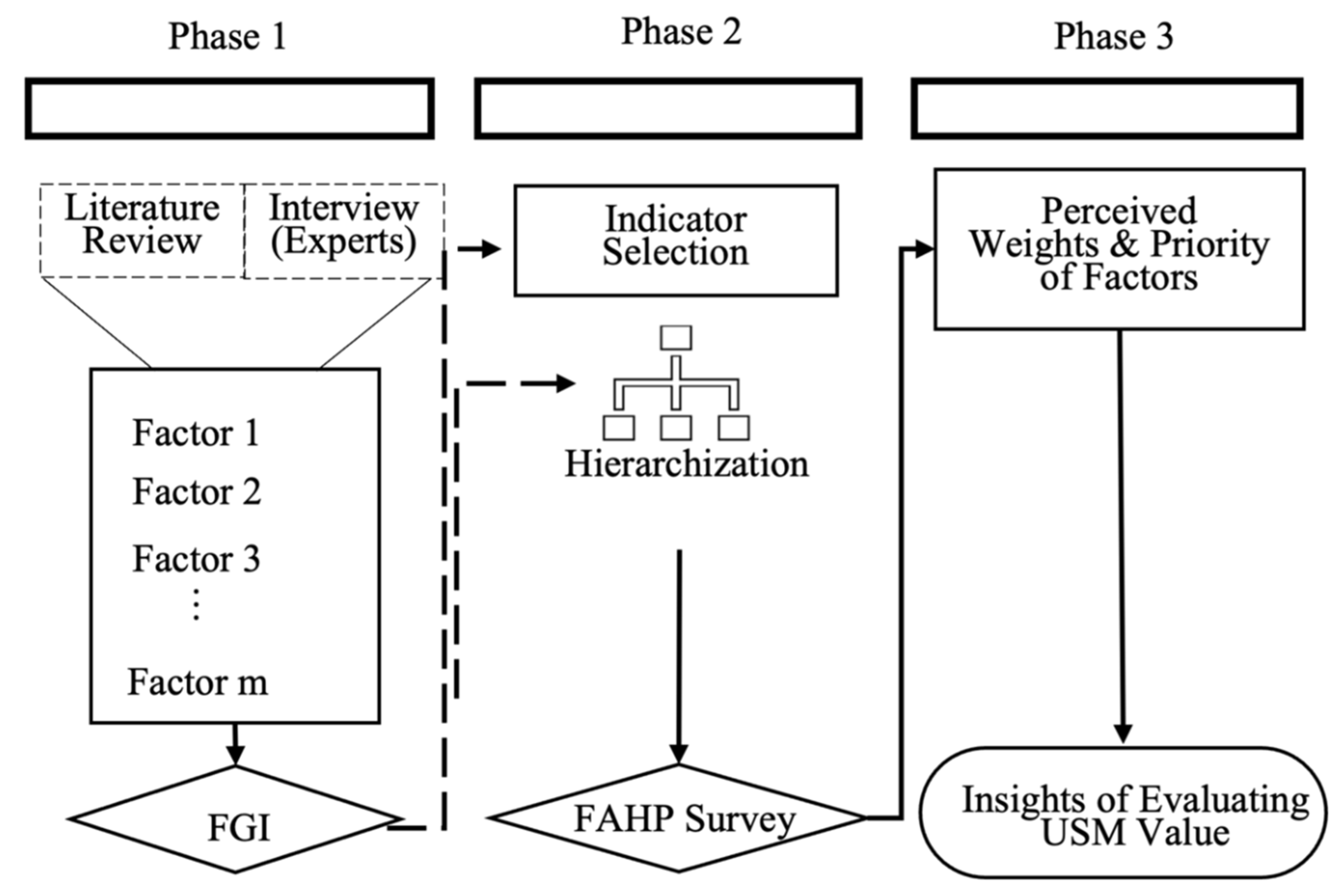

3. Methodology

3.1. Research Framework

3.2. Fuzzy Analytical Hierarchy Process (FAHP)

- (1)

- There exists such that

- (2)

- For any , is a closed interval.

3.3. Data Collection

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. FAHP Survey

- 1.

- Age① 20–29 ② 30–39 ③ 40–49 ④ 50–59 ⑤ Over 60

- 2.

- Work Experience① Less than 5 years ② 5–9 years ③ 10–14 years ④ 15–19 years ⑤ Over 20 years

- 3.

- Work Place① Airline ② Approved Maintenance Organization ③ Others ( )

| Evaluation scales | Linguistic terms |

| ① | Equally important |

| ③ | Moderately important |

| ⑤ | Important |

| ⑦ | Very important |

| ⑨ | Absolutely important |

| ② ④ ⑥ ⑧ | Intermediate value |

- (1)

- Please compare the importance of each category considering their impact on the USM value.

- 1.

- Technical Category (T)Category related to manufacturers and national requirements for airworthiness.

- 2.

- Operational Category (O)Category related to the operating environment, standards and reliability.

- 3.

- Market Category (M)Category related to characteristics of USM Market

- 4.

- Supply Category

| Assessment | Poor←Medium→Good | Assessment | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | O |

| T | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | M |

| T | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | S |

| O | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | M |

| O | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | S |

| M | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | S |

- (2)

- Please compare the importance of each factor considering their impact on the USM value.

Appendix A.1. Technical Category (T)

- Maintenance Requirements (T1)

- 2.

- Airworthiness Directive Status (T2)

- 3.

- Maintenance Status (T3)

- 4.

- Aircraft Eligibility (T4)

| Assessment | Poor←Medium→Good | Assessment | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T1 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | T2 |

| T1 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | T3 |

| T1 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | T4 |

| T2 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | T3 |

| T2 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | T4 |

| T3 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | T4 |

- (3)

- Please compare the importance of each factor considering their impact on the USM value.

Appendix A.2. Operational Category (O)

- Former Operator (O1)

- 2.

- Former Aviation Authority (O2)

- 3.

- Traceability (O3)

- 4.

- Accident/Incident Status (O4)

| Assessment | Poor←Medium→Good | Assessment | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O1 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | O2 |

| O1 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | O3 |

| O1 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | O4 |

| O2 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | O3 |

| O2 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | O4 |

| O3 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | O4 |

- (4)

- Please compare the importance of each factor considering their impact on the USM value.

Appendix A.3. Market Category (M)

- New Part Value (M1)

- 2.

- Market Liquidity (M2)

- 3.

- Trade Difficulty (M3)

- 4.

- Indirect Cost (M4)

| Assessment | Poor←Medium→Good | Assessment | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | M2 |

| M1 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | M3 |

| M1 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | M4 |

| M2 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | M3 |

| M2 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | M4 |

| M3 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | M4 |

- (5).

- Please compare the importance of each factor considering their impact on the USM value.

Appendix A.4. Supply Category

- Passenger Demand (S1)

- 2.

- Fuel Price (S2)

- 3.

- Aircraft Age (S3)

- 4.

- Environmental Regulation (S4)

| Assessment | Poor←Medium→Good | Assessment | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | S2 |

| S1 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | S3 |

| S1 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | S4 |

| S2 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | S3 |

| S2 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | S4 |

| S3 | ⑨ | ⑧ | ⑦ | ⑥ | ⑤ | ④ | ③ | ② | ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | ⑧ | ⑨ | S4 |

References

- Oliver Wyman. How Used Aircraft Parts Can Help DoD Improve Mission Readiness; Oliver Wyman: New York, NY, USA, 2022. [Google Scholar]

- McFadden, M.; Worrells, D.S. Global outsourcing of aircraft maintenance. J. Aviat. Technol. Eng. 2012, 1, 63–73. [Google Scholar] [CrossRef]

- Olaganathan, R.; Miller, M.; Mrusek, B.M. Managing safety risks in airline maintenance outsourcing. Int. J. Aviat. Aeronaut. Aerosp. 2020, 7, 1–21. [Google Scholar] [CrossRef]

- Nam, S.; Song, W.K.; Yoon, H. An maintenance, repair, and overhaul (MRO) safety oversight system analysis: A case in Korea. J. Air Transp. Manag. 2023, 107, 102349. [Google Scholar] [CrossRef]

- Prentice, B.; DiNota, A.; Costanza, D.; Reagan, I.; Franzoni, C.; Stelle, M. Global Fleet and MRO Market Forecast 2022–2032; Oliver Wyman: New York, NY, USA, 2022. [Google Scholar]

- IATA. Best Industry Practices for Aircraft Decommissioning (BIPAD), 1st ed.; IATA: Montreal, QC, Canada, 2018. [Google Scholar]

- IATA. MRO SmartHub; IATA: Montreal, QC, Canada, 2022; Available online: https://www.iata.org/en/services/statistics/safety-data/mro-smarthub/ (accessed on 30 November 2022).

- IATA. The Impact of the COVID-19 Crisis on the Used Serviceable Materials Market; IATA: Montreal, QC, Canada, 2021; Available online: https://www.iata.org/en/publications/newsletters/iata-knowledge-hub/the-impact-of-the-covid-19-crisis-on-the-used-serviceable-materials-market/ (accessed on 30 November 2022).

- ICAO. Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA); ICAO: Montreal, QC, Canada, 2018; Volume IV, Annex 16. [Google Scholar]

- Roskam, J. Airplane Cost Estimation: Design, Development, Manufacturing and Operating; part VIII; University of Kansas: Lawrence, KS, USA, 1989. [Google Scholar]

- Hammad, A.W.A.; Rey, D.; Bu-Qammaz, A.; Grzybowska, H.; Akbarnezhad, A. Mathematical optimization in enhancing the sustainability of aircraft trajectory: A review. Int. J. Sustain. Transp. 2020, 14, 413–436. [Google Scholar] [CrossRef]

- Cui, Q.; Li, Y. CNG2020 strategy and airline efficiency: A network epsilon-based measure with managerial disposability. Int. J. Sustain. Transp. 2018, 12, 313–323. [Google Scholar] [CrossRef]

- Khalifa, R.; Alherbawi, M.; Bicer, Y.; Al-Ansari, T. Fueling Circularity: A Thorough Review of Circular Practices in the Aviation Sector with Sustainable Fuel Solutions. Resour. Conserv. Recycl. Adv. 2024, 23, 200223. [Google Scholar] [CrossRef]

- Airbus. Process for Advanced Management of End-of-Life Aircraft (PAMELA). 2008. Available online: https://webgate.ec.europa.eu/life/publicWebsite/project/LIFE05-ENV-F-000059/process-for-advanced-management-of-end-of-life-of-aircraft (accessed on 30 November 2022).

- ICAO. Environmental Report. 2019. Available online: https://www.icao.int/sites/default/files/sp-files/environmental-protection/Documents/EnvironmentReport-2010/ICAO-ENV-Report2019-F1-WEB-1.pdf (accessed on 30 November 2022).

- ICAO. Environmental Report. 2025. Available online: https://www.icao.int/sites/default/files/environmental-protection/Documents/EnvironmentalReports/2025/ICAO-EnvReport-2025.pdf (accessed on 29 September 2025).

- Santos, A.C.J.; Cavalcante, C.A.V.; Ribeiro, L.F.A. The use of second-hand items based on delay time modelling. Process Saf. Environ. Prot. 2021, 146, 118–125. [Google Scholar] [CrossRef]

- Yeh, R.H.; Lo, H.C.; Yu, R.Y. A study of maintenance policies for second-hand products. Comput. Ind. Eng. 2011, 60, 438–444. [Google Scholar] [CrossRef]

- Lo, H.C.; Yu, R.Y. A study of quality management strategy for reused products. Reliab. Eng. Syst. Saf. 2013, 119, 172–177. [Google Scholar] [CrossRef]

- ICAO. Environmental Report. 2022. Available online: https://www.icao.int/icao-environmental-report-2022 (accessed on 21 June 2023).

- IATA. Used Serviceable Materials (USM): Impact of the COVID Crisis on Market Dynamics; IATA: Montreal, QC, Canada, 2020. [Google Scholar]

- Jain, K.P.; Pruyn, J.F.J.; Hopman, J.J. Quantitative assessment of material composition of end-of-life ships using onboard documentation. Resour. Conserv. Recycl. 2016, 107, 1–9. [Google Scholar] [CrossRef]

- Ferrão, P.; Nazareth, P.; Amaral, J. Strategies for meeting EU end-of-life vehicle reuse/recovery targets. J. Ind. Ecol. 2008, 10, 77–93. [Google Scholar] [CrossRef]

- Asmatulu, E.; Overcash, M.; Twomey, J. Recycling of aircraft: State of the art in 2011. J. Ind. Eng. 2013, 960581. [Google Scholar] [CrossRef]

- Mascle, C.; Baptiste, P.; Beuve, D.S.; Camelot, A. Process for advanced management and technologies of aircraft EOL. Procedia CIRP 2015, 26, 299–304. [Google Scholar] [CrossRef]

- Zhao, X.; Verhagen, W.J.C.; Curran, R. Disposal and recycle economic assessment for aircraft and engine end of life solution evaluation. Appl. Sci. 2020, 10, 522. [Google Scholar] [CrossRef]

- Sabaghi, M.; Cai, Y.; Mascle, C.; Baptiste, P. Sustainability assessment of dismantling strategies for end-of-life aircraft recycling. Resour. Conserv. Recycl. 2015, 102, 163–169. [Google Scholar] [CrossRef]

- Jang, Y.C.; Choi, K.; Jeong, J.H.; Kim, H.; Kim, J.G. Recycling and Material-Flow Analysis of End-of-Life Vehicles towards Resource Circulation in South Korea. Sustainability 2022, 14, 1270. [Google Scholar] [CrossRef]

- Silva, R.F.; Kaewunruen, S. Recycling of rolling stocks. Environments 2017, 4, 39. [Google Scholar] [CrossRef]

- Martinez-Laserna, E.; Gandiaga, I.; Sarasketa-Zabala, E.; Badeda, J.; Stroe, D.I.; Swierczynski, M.; Goikoetxea, A. Battery second life: Hype, hope or reality? A critical review of the state of the art. Renew. Sustain. Energy Rev. 2018, 93, 701–718. [Google Scholar] [CrossRef]

- Kotak, Y.; Marchante Fernández, C.; Canals Casals, L.; Kotak, B.S.; Koch, D.; Geisbauer, C.; Trilla, L.; Gómez-Núñez, A.; Schweiger, H.G. End of electric vehicle batteries: Reuse vs. recycle. Energies 2021, 14, 2217. [Google Scholar] [CrossRef]

- Wangsupphaphol, A.; Chaitusaney, S.; Salem, M. A techno-economic assessment of a second-life battery and photovoltaics hybrid power source for sustainable electric vehicle home charging. Sustainability 2023, 15, 5866. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; Pang, B.; Sun, B.; Kokko, A. Second use value of China’s new energy vehicle battery: A view based on multi-scenario simulation. Sustainability 2020, 12, 341. [Google Scholar] [CrossRef]

- Neubauer, J.; Pesaran, A.; Williams, B.; Ferry, M.; Eyer, J. A Techno-Economic Analysis of PEV Battery Second Use: Repurposed-Battery Selling Price and Commercial and Industrial End-User Value; SAE Technical Paper 2012-01-0349; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Bowler, M. Battery Second Use: A Framework for Evaluating the Combination of Two Value Chains. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2014. [Google Scholar]

- Haram, M.H.S.M.; Lee, J.W.; Ramasamy, G.; Ngu, E.E.; Thiagarajah, S.P.; Lee, Y.H. Feasibility of utilising second life EV batteries: Applications, lifespan, economics, environmental impact, assessment, and challenges. Alex. Eng. J. 2021, 60, 4517–4536. [Google Scholar] [CrossRef]

- Winans, K.; Kendall, A.; Deng, H. The history and current applications of the circular economy concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Rodrigues Dias, V.M.; Jugend, D.; de Camargo Fiorini, P.; Razzino, C.d.A.; Paula Pinheiro, M.A. Possibilities for applying the circular economy in the aerospace industry: Practices, opportunities and challenges. J. Air. Transp. Manag. 2022, 102, 102227. [Google Scholar] [CrossRef]

- Keivanpour, S.; Ait Kadi, D.; Mascle, C. End-of-life aircraft treatment in the context of sustainable development, lean management, and global business. Int. J. Sustain. Transp. 2017, 11, 357–380. [Google Scholar] [CrossRef]

- Aircraft Fleet Recycling Association. Best Management Practices (BMP). Available online: https://afraassociation.org/AFRA_BMP (accessed on 28 September 2025).

- Oliver Wyman. Update: Impact of COVID-19 on Commercial MRO; Oliver Wyman: New York, NY, USA, 2020. [Google Scholar]

- KPMG. Circularity in Flight: The Aviation Industry and the Circular Economy. 2024. Available online: https://assets.kpmg.com/content/dam/kpmgsites/ie/pdf/insights/aviation/ie-aviation-circular-economy-tl.pdf.coredownload.inline.pdf (accessed on 28 September 2025).

- Ackert, S. The Relationship between an Aircraft’s Value and Its Maintenance Status. 2011. Available online: https://www.aircraftmonitor.com/uploads/1/5/9/9/15993320/the_relationship_between_an_aicrafts_value__its_maintenance_status___v1.pdf (accessed on 30 November 2022).

- Vasigh, B.; Azadian, F. Aircraft Valuation in Volatile Market Conditions; Springer: London, UK, 2022. [Google Scholar] [CrossRef]

- Boeing. Used Serviceable Materials. 2022. Available online: https://services.boeing.com/parts/parts-kits-and-packages/used-serviceable-materials (accessed on 30 November 2022).

- Schlesinger, C.; Grimme, W. Forecast of aircraft retirement probabilities using neural networks. Transp. Res. Proc. 2020, 56, 1–9. [Google Scholar] [CrossRef]

- Dray, L. An analysis of the impact of aircraft lifecycles on aviation emissions mitigation policies. J. Air Transp. Mana. 2013, 28, 62–69. [Google Scholar] [CrossRef]

- Ozgur Catak, F. Fuzzy analytic hierarchy based DBMS selection in Turkish national identity card management project. Int. J. Inf. Sci. Tech. 2012, 2, 29–38. [Google Scholar] [CrossRef]

- Dožić, S. Multi-criteria decision making methods: Application in the aviation industry. J. Air. Transp. Manag 2019, 79, 101683. [Google Scholar] [CrossRef]

- Chang, D.-Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Kiracı, K.; Akan, E. Aircraft selection by applying AHP and TOPSIS in interval type-2 fuzzy sets. J. Air Transp. Manag. 2020, 89, 101924. [Google Scholar] [CrossRef]

- Alves, C.J.P.; da Silva, E.J.; Müller, C.; Borille, G.M.R.; Guterres, M.X.; Arraut, E.M.; Peres, M.S.; dos Santos, R.J. Towards an objective decision-making framework for regional airport site selection. J. Air Transp. Manag. 2020, 89, 101888. [Google Scholar] [CrossRef]

- Dožić, S.; Lutovac, T.; Kalić, M. Fuzzy AHP approach to passenger aircraft type selection. J. Air Transp. Manag. 2018, 68, 165–175. [Google Scholar] [CrossRef]

- Catak, F.O. Fuzzy AHP. MATLAB Central File Exchange. 2023. Available online: https://www.mathworks.com/matlabcentral/fileexchange/33406-fuzzy-ahp (accessed on 21 June 2023).

- Kano, N.; Seraku, N.; Takahashi, F.; Shin-Ichi, T. Attractive quality and must-be quality. J. Jpn. Soc. Qual. Control 1984, 14, 147–156. [Google Scholar]

- ICAO. Airworthiness of Aircraft; ICAO, Ed.; International Civil Aviation Organization: Montreal, QC, Canada, 2018; Annex 8. [Google Scholar]

- ICAO. Operation of Aircraf; ICAO, Ed.; International Civil Aviation Organization: Montreal, QC, Canada, 2018; Annex 6. [Google Scholar]

- IATA. Best Practices for Component Maintenance Cost Management, 2nd ed.; International Air Traffic Association: Montreal, QC, Canada, 2015. [Google Scholar]

- IATA. Guidance Material and Best Practices for Alternate Parts (PMA) and Approved (Non-OEM) Repairs (DER); International Air Traffic Association: Montreal, QC, Canada, 2015. [Google Scholar]

- IATA. Guidance Material and Best Practices for Life-Limited Parts (LLPs) Traceability; International Air Traffic Association: Montreal, QC, Canada, 2020. [Google Scholar]

- IATA. Airline Disclosure Guide—Aircraft Acquisition Cost and Depreciation Purpose of Airline Disclosure Guides; International Air Traffic Association: Montreal, QC, Canada, 2016. [Google Scholar]

- ICAO. Assuring Compliance with International Oversight Obligations Without Duplication, Shared Surveillance of Approved Maintenance Organizations; International Civil Aviation Organization: Montreal, QC, Canada, 2015. [Google Scholar]

- ICAO. Collaborative Approaches Among Member States for Global Recognition Related to Approved Maintenance Organizations (AMOs); International Civil Aviation Organization: Montreal, QC, Canada, 2019. [Google Scholar]

- ICAO. Application of Circular Economy in Aviation; ICAO: Montreal, QC, Canada, 2022; Available online: https://www.icao.int/environmental-protection/Pages/CircularEconomy.aspx (accessed on 4 December 2022).

| Category of Factors | Factors | Description | References | |

|---|---|---|---|---|

| Technical (T) | T1 | Maintenance Requirements | Compliance with manufacturer maintenance manuals and mandatory programs, showing whether inspections and repairs have been properly performed | [6,43,44] |

| T2 | Airworthiness Directive Status | Regulatory directives issued to correct safety issues; compliance confirms the part is free from unresolved safety concerns | [6] | |

| T3 | Maintenance Status | Recorded results of work performed by operators or approved maintenance organizations, reflecting the current technical condition of the part | [6,43,44] | |

| T4 | Aircraft Eligibility | Certification of whether a part can be legally and technically installed on different aircraft types, indicating its applicability | [6,44] | |

| Operational (O) | O1 | Former Operator | Information on the previous owner or airline, which signals operational environment and management practices | [6,40] |

| O2 | Former Aviation Authority | Oversight history from the national or supranational authority that previously regulated the aircraft, affecting reliability of compliance | [21,40] | |

| O3 | Traceability | Documentation proving the complete lifecycle history of the part, ensuring authenticity and regulatory acceptance | [6,21,40,43,44] | |

| O4 | Accident/ Incident Status | Records of involvement in accidents or incidents; parts may remain usable but require additional verification and certification | [6,40,44] | |

| Market (M) | M1 | New Part Value | Price of an equivalent new part from the OEM, often serving as the baseline reference for USM valuation | [1,42] |

| M2 | Market Liquidity | The ease with which a part can be bought or sold, reflecting supply–demand balance and inventory turnover | [6] | |

| M3 | Trade Difficulty | Practical barriers to transactions, including market accessibility and platform availability for buyers and sellers | [21,45] | |

| M4 | Indirect Cost | Extra expenses such as shipping, tariffs, and handling fees, which influence the final cost of transactions | [6,7,44] | |

| Supply (S) | S1 | Passenger Demand | Overall air transport demand that drives fleet utilization and retirement | [6,41,46,47] |

| S2 | Fuel Price | Global jet fuel price, influencing airline operating costs and decisions on fleet replacement or retirement | [6,46,47] | |

| S3 | Aircraft Age | The elapsed time since manufacture | [6,46,47] | |

| S4 | Environmental Regulation | National or international policies requiring eco-friendly operations or retirements | [6,47] | |

| Linguistic Scale | Triangular Fuzzy Scale | Triangular Fuzzy Reciprocal Scale |

|---|---|---|

| Just Equal | (1,1,1) | (1,1,1) |

| Equally Important | (1/2,1,3/2) | (2/3,1,2) |

| Weakly Important | (1,3/2,2) | (1/2,2/3,1) |

| Strongly Important | (3/2,2,5/2) | (2/5,1/2,2/3) |

| Very strongly important | (2,5/2,3) | (1/3,2/5,1/2) |

| Absolutely more important | (5/2,3,7/2) | (2/7,1/3,2/5) |

| Characteristics | Observations | Frequency | |

|---|---|---|---|

| Work Experience | Less than 5 | 35 | 33.7% |

| 5–9 | 9 | 8.7% | |

| 10–14 | 5 | 4.8% | |

| 15–19 | 8 | 7.7% | |

| Over 20 | 47 | 45.2% | |

| Workplace | Airline | 58 | 53.8% |

| Approved Maintenance Organization | 21 | 20.2% | |

| Others | 25 | 26.0% | |

| Age | 20–29 | 18 | 17.3% |

| 30–39 | 29 | 27.9% | |

| 40–49 | 18 | 17.3% | |

| 50–59 | 34 | 32.7% | |

| Over 60 | 5 | 4.8% |

| Global Categories | Priority | Rank | |||||

| Global Category | T | O | M | S | |||

| T | (1, 1, 1) | (3/2, 2, 5/2) | (3/2, 2, 5/2) | (3/2, 2, 5/2) | 51.96% | 1 | |

| O | (2/5, 1/2, 2/3) | (1, 1, 1) | (1, 3/2, 2) | (1, 3/2, 2) | 27.64% | 2 | |

| M | (2/5, 1/2, 2/3) | (1/2, 2/3, 1) | (1, 1, 1) | (2/3, 1, 3/2) | 10.20% | 3 | |

| S | (2/5, 1/2, 2/3) | (1/2, 2/3, 1) | (3/2, 1, 2/3) | (1, 1, 1) | 10.20% | 3 | |

| Technical Category (T) | Priority | Rank | |||||

| Technical Category (T) | T1 | T2 | T3 | T4 | |||

| T1 | (1, 1, 1) | (2/3, 1, 3/2) | (1, 3/2, 2) | (1, 3/2, 2) | 32.03% | 2 | |

| T2 | (3/2, 1, 2/3) | (1, 1, 1) | (3/2, 2, 5/2) | (3/2, 2, 5/2) | 38.86% | 1 | |

| T3 | (1/2, 2/3, 1) | (2/5, 1/2, 2/3) | (1, 1, 1) | (1, 3/2, 2) | 19.43% | 3 | |

| T4 | (1/2, 2/3, 1) | (2/5, 1/2, 2/3) | (1/2, 2/3, 1) | (1, 1, 1) | 9.68% | 4 | |

| Operational Category (O) | Priority | Rank | |||||

| Operational Category (O) | O1 | O2 | O3 | O4 | |||

| O1 | (1, 1, 1) | (2/3, 1, 3/2) | (1/2, 3/4, 1) | (2/3, 1, 3/2) | 23.02% | 3 | |

| O2 | (3/2, 1, 2/3) | (1, 1, 1) | (2/3, 1, 3/2) | (2/3, 1, 3/2) | 24.88% | 2 | |

| O3 | (1, 4/3, 2) | (3/2, 1, 2/3) | (1, 1, 1) | (1, 3/2, 2) | 29.45% | 1 | |

| O4 | (3/2, 1, 2/3) | (3/2, 1, 2/3) | (1/2, 2/3, 1) | (1, 1, 1) | 22.64% | 4 | |

| Market Category (M) | Priority | Rank | |||||

| Market Category (M) | M1 | M2 | M3 | S | |||

| M1 | (1, 1, 1) | (2/3, 1, 3/2) | (1, 3/2, 2) | (1, 3/2, 2) | 30.21% | 1 | |

| M2 | (3/2, 1, 2/3) | (1, 1, 1) | (2/3, 1, 3/2) | (2/3, 1, 3/2) | 24.77% | 2 | |

| M3 | (1/2, 2/3, 1) | (3/2, 1, 2/3) | (1, 1, 1) | (2/3, 1, 3/2) | 22.51% | 3 | |

| M4 | (1/2, 2/3, 1) | (3/2, 1, 2/3) | (3/2, 1, 2/3) | (1, 1, 1) | 22.51% | 3 | |

| Supply Category (S) | Priority | Rank | |||||

| Supply Category (S) | S1 | S2 | S3 | S4 | |||

| S1 | (1, 1, 1) | (3/2, 2, 5/2) | (2/3, 1, 3/2) | (1, 3/2, 2) | 33.57% | 1 | |

| S2 | (2/5, 1/2, 2/3) | (1, 1, 1) | (2/3, 1, 3/2) | (2/3, 1, 3/2) | 20.07% | 3 | |

| S3 | (3/2, 1, 2/3) | (3/2, 1, 2/3) | (1, 1, 1) | (2/3, 1, 3/2) | 24.52% | 2 | |

| S4 | (1/2, 2/3, 1) | (3/2, 1, 2/3) | (3/2, 1, 2/3) | (1, 1, 1) | 21.83% | 4 | |

| Category of Factors | Priority | Rank | Factors | Global Priority | Global Rank | |

|---|---|---|---|---|---|---|

| Technical (T) | 51.96% | 1 | T1 | Maintenance Requirements | 16.64% | 2 |

| T2 | Airworthiness Directive Status | 20.19% | 1 | |||

| T3 | Maintenance Status | 10.10% | 3 | |||

| T4 | Aircraft Eligibility | 5.03% | 8 | |||

| Operational (O) | 27.64% | 2 | O1 | Former Operator | 6.36% | 6 |

| O2 | Former Aviation Authority | 6.88% | 5 | |||

| O3 | Traceability | 8.14% | 4 | |||

| O4 | Accident/Incident Status | 6.26% | 7 | |||

| Market (M) | 10.2% | 3 | M1 | New Part Value | 3.08% | 10 |

| M2 | Market Liquidity | 2.53% | 11 | |||

| M3 | Trade Difficulty | 2.29% | 13 | |||

| M4 | Indirect Cost | 2.29% | 13 | |||

| Supply (S) | 10.2% | 3 | S1 | Passenger Demand | 3.42% | 9 |

| S2 | Fuel Price | 2.05% | 16 | |||

| S3 | Aircraft Age | 2.50% | 12 | |||

| S4 | Environmental Regulation | 2.23% | 15 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, J.; Nam, S.; Song, W.-K. Analyzing Determinants of Aircraft Used Serviceable Material’s Value Using Fuzzy Analytic Hierarchy Process. Sustainability 2025, 17, 9666. https://doi.org/10.3390/su17219666

Cho J, Nam S, Song W-K. Analyzing Determinants of Aircraft Used Serviceable Material’s Value Using Fuzzy Analytic Hierarchy Process. Sustainability. 2025; 17(21):9666. https://doi.org/10.3390/su17219666

Chicago/Turabian StyleCho, Jaehyun, Seungju Nam, and Woon-Kyung Song. 2025. "Analyzing Determinants of Aircraft Used Serviceable Material’s Value Using Fuzzy Analytic Hierarchy Process" Sustainability 17, no. 21: 9666. https://doi.org/10.3390/su17219666

APA StyleCho, J., Nam, S., & Song, W.-K. (2025). Analyzing Determinants of Aircraft Used Serviceable Material’s Value Using Fuzzy Analytic Hierarchy Process. Sustainability, 17(21), 9666. https://doi.org/10.3390/su17219666