4.1. Integrated Performance Analysis and Climate-Driven Optimization

The comprehensive sustainability assessment reveals a fundamental paradigm shift in sustainable material performance, where hybrid material systems transcend traditional trade-offs between environmental protection and economic viability.

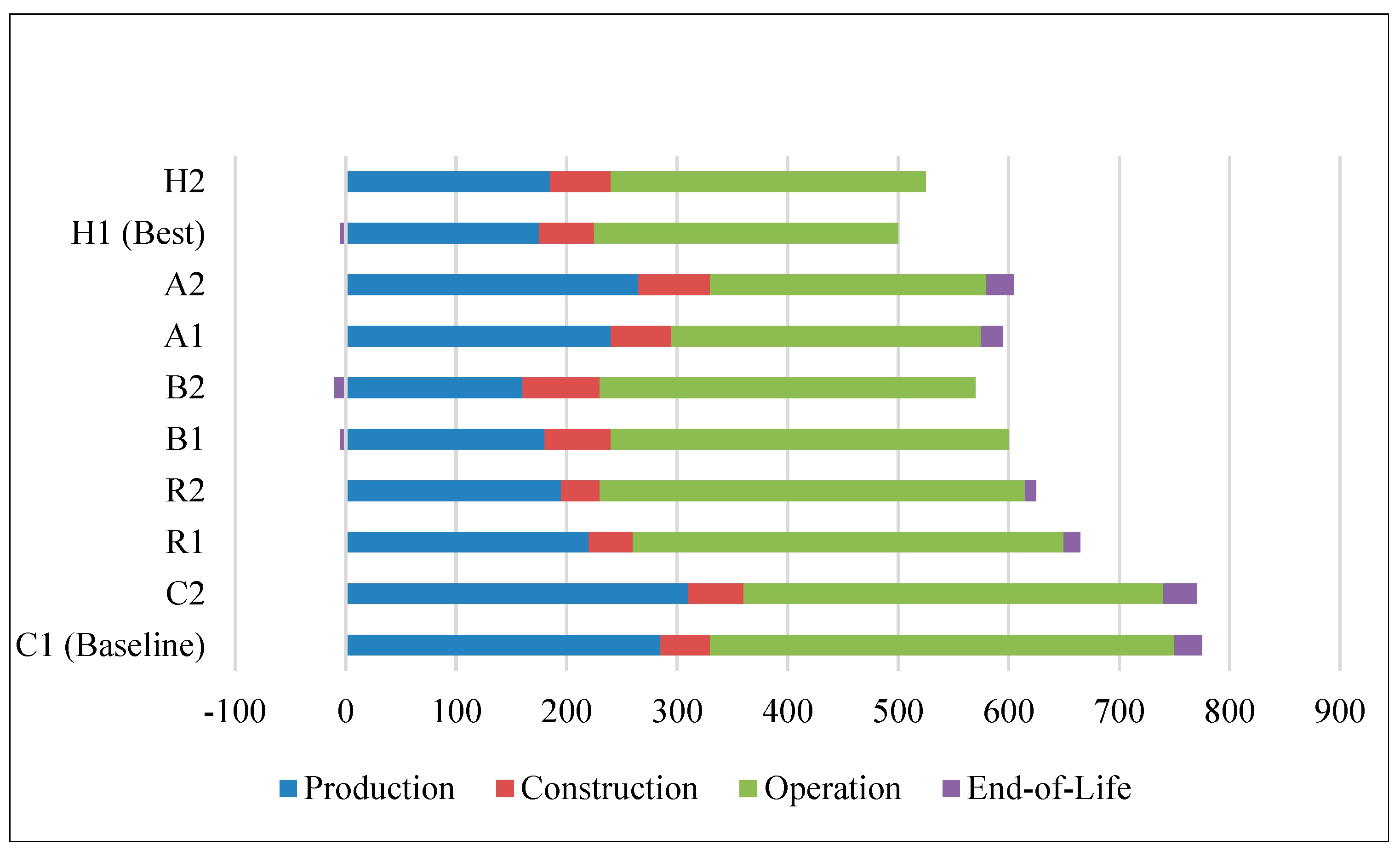

Figure 2 shows Lifecycle carbon footprint by material alternative. Geopolymer–biofiber composite systems (H1, H2) demonstrate unprecedented integration of sustainability benefits, achieving simultaneous optimization across environmental (36–45% carbon reduction), economic (19–28% lifecycle cost savings), social (4.2/5.0 vs. 2.7/5.0 baseline impact scores), and technical performance dimensions. This multi-dimensional superiority indicates that technological innovation has reached a threshold where environmental optimization enhances rather than constrains economic and technical performance, challenging decades of construction industry assumptions about sustainability trade-offs.

Climate sensitivity emerges as the dominant factor determining optimization priorities and material selection outcomes across the comprehensive criteria framework encompassing carbon footprint, energy performance, water consumption, lifecycle costs, local economic impact, structural performance, thermal efficiency, worker welfare, and community benefits. Hot-arid regions exhibit operational phase dominance (45–55% of lifecycle impacts) driven by exponential cooling energy relationships with thermal gradients, creating strong selection pressure for materials with superior thermal resistance and water efficiency. The observed performance hierarchy reflects fundamental thermodynamic principles where thermal conductivity differences translate directly to operational energy savings—materials with enhanced thermal performance (H1: λ = 0.8 W/mK vs. C1: λ = 1.7 W/mK) generate proportional cooling load reductions that compound over 50-year building lifespans. Conversely, temperate climates demonstrate production phase dominance (60–70% of total impacts), emphasizing embodied carbon optimization, structural efficiency, durability considerations, and end-of-life impact minimization.

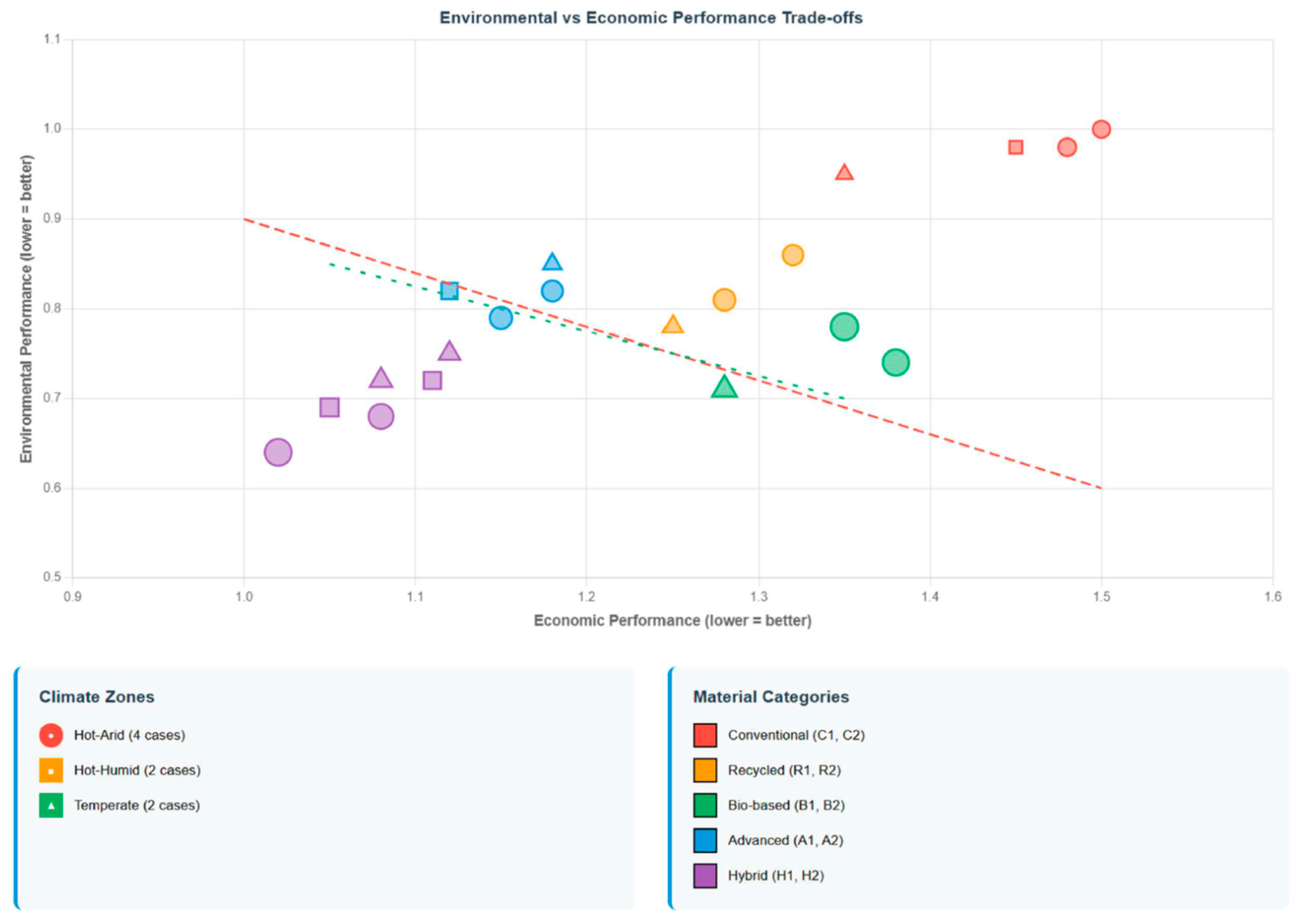

Economic analysis reveals systematic relationships between climate stress and sustainable material adoption incentives across initial investment, operational costs, maintenance requirements, employment generation, and supply chain impacts. The strengthening economic–environmental correlation in hot climates (r = −0.68 vs. r = −0.43 in temperate regions) indicates that energy-intensive environments create stronger financial drivers for environmental optimization through operational cost savings that overcome initial investment premiums. Monte Carlo uncertainty analysis with 10,000 iterations establishes robust payback periods of 4.2–6.8 years with a 78–94% probability of cost savings, while sensitivity analysis identifies energy pricing as the primary economic driver (35% of variance), followed by material cost volatility (28%) and maintenance assumptions (22%). This relationship suggests that climate change may accelerate sustainable material adoption through market mechanisms rather than regulatory mandates alone, as extreme temperature events increase operational cost differentials between conventional and high-performance alternatives (See

Figure 3).

4.3. Multi-Method Validation and Decision Framework Robustness

Cross-validation through three complementary MCDM methods establishes an unprecedented ranking stability that validates the framework’s reliability across diverse decision-making philosophies, encompassing stakeholder preference integration, compromise optimization, and regret minimization approaches. The exceptional correlation coefficients (Kendall’s τ = 0.87; Spearman ρ = 0.92) demonstrate that optimal material identification transcends methodological choice, with top-performing alternatives maintaining consensus rankings in 95% of analyses across all sustainability criteria including compressive strength, fire resistance, acoustic performance, health and safety metrics, cultural appropriateness, and user satisfaction indicators.

Method-specific analysis reveals that AHP’s hierarchical decomposition effectively captures stakeholder priorities across worker welfare, community impact, and cultural considerations, while TOPSIS provides engineering-focused optimization through simultaneous maximization of structural performance, thermal efficiency, and durability characteristics. VIKOR’s regret minimization approach addresses risk-averse perspectives particularly relevant for safety performance, accessibility compliance, and long-term service life expectations. The convergence of these philosophically distinct approaches on identical material rankings suggests that technological innovation has achieved performance levels that transcend decision-making methodology, enabling robust material recommendations regardless of stakeholder decision preferences or organizational decision-making culture.

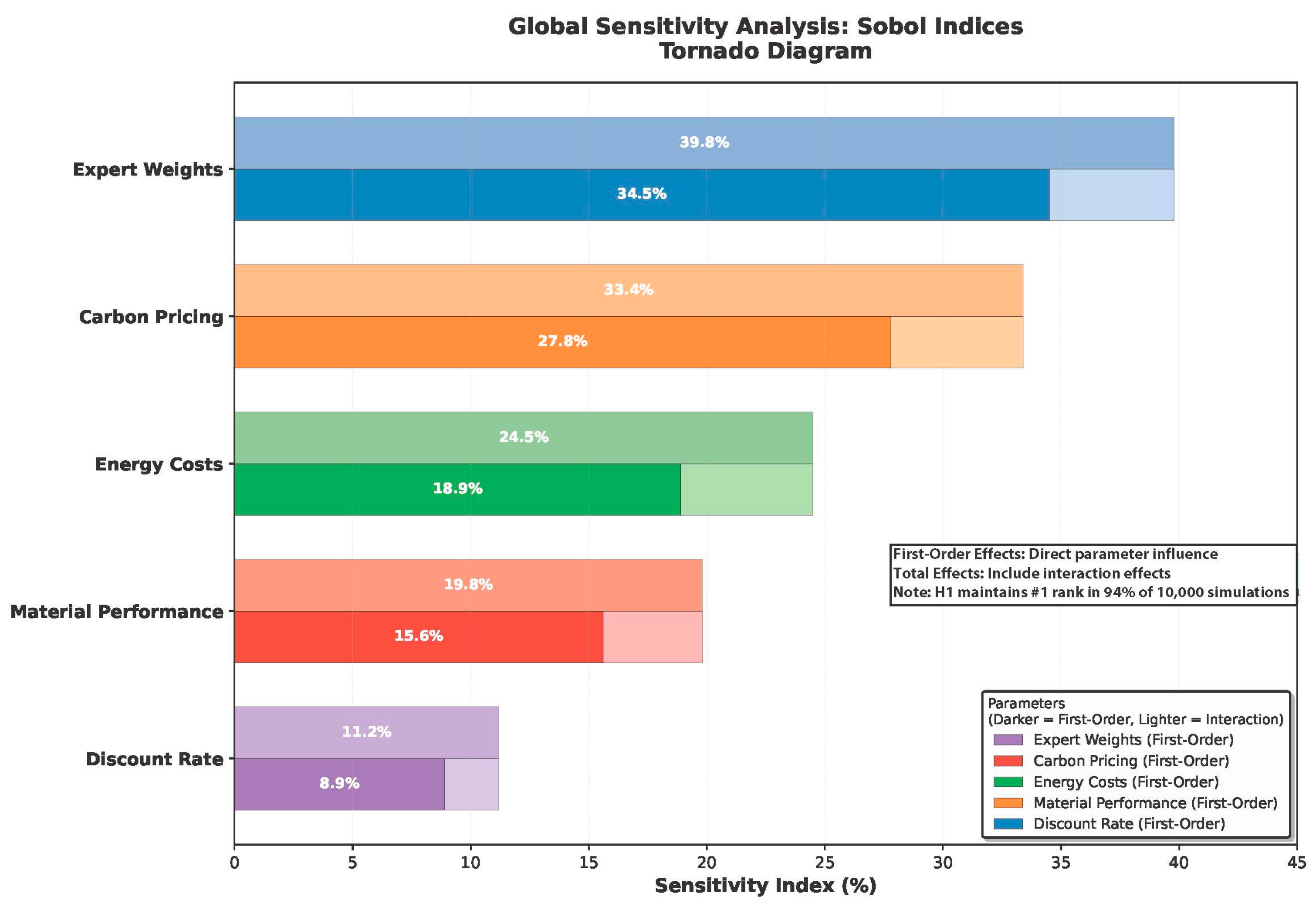

Comprehensive uncertainty analysis (

Figure 4) reveals that expert judgment uncertainty (34.5% influence) exceeds technical measurement uncertainty (15.6% influence) by more than a factor of two in determining framework outcomes across all assessment criteria. This relationship indicates that improving measurement precision in structural testing, thermal property determination, or environmental impact quantification yields diminishing returns compared to enhancing stakeholder consultation processes covering wage equity assessment, community investment evaluation, and occupant satisfaction measurement. Climate-adaptive weighting systems demonstrate remarkable convergence despite regional priority variations, with all climate zones identifying hybrid materials as optimal solutions across the integrated criteria framework, suggesting potential for standardized sustainable material recommendations while maintaining region-specific performance optimization.

4.4. Implementation Validation and Real-World Performance

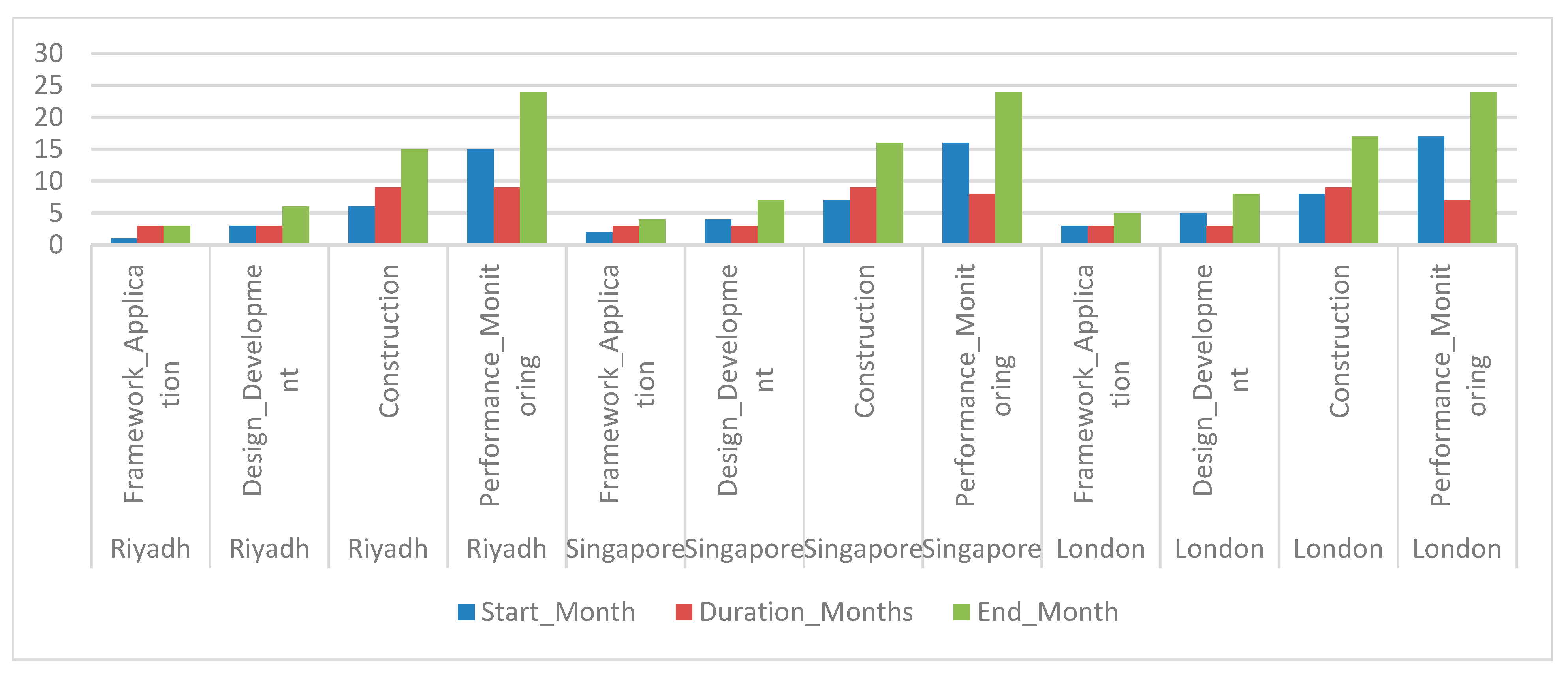

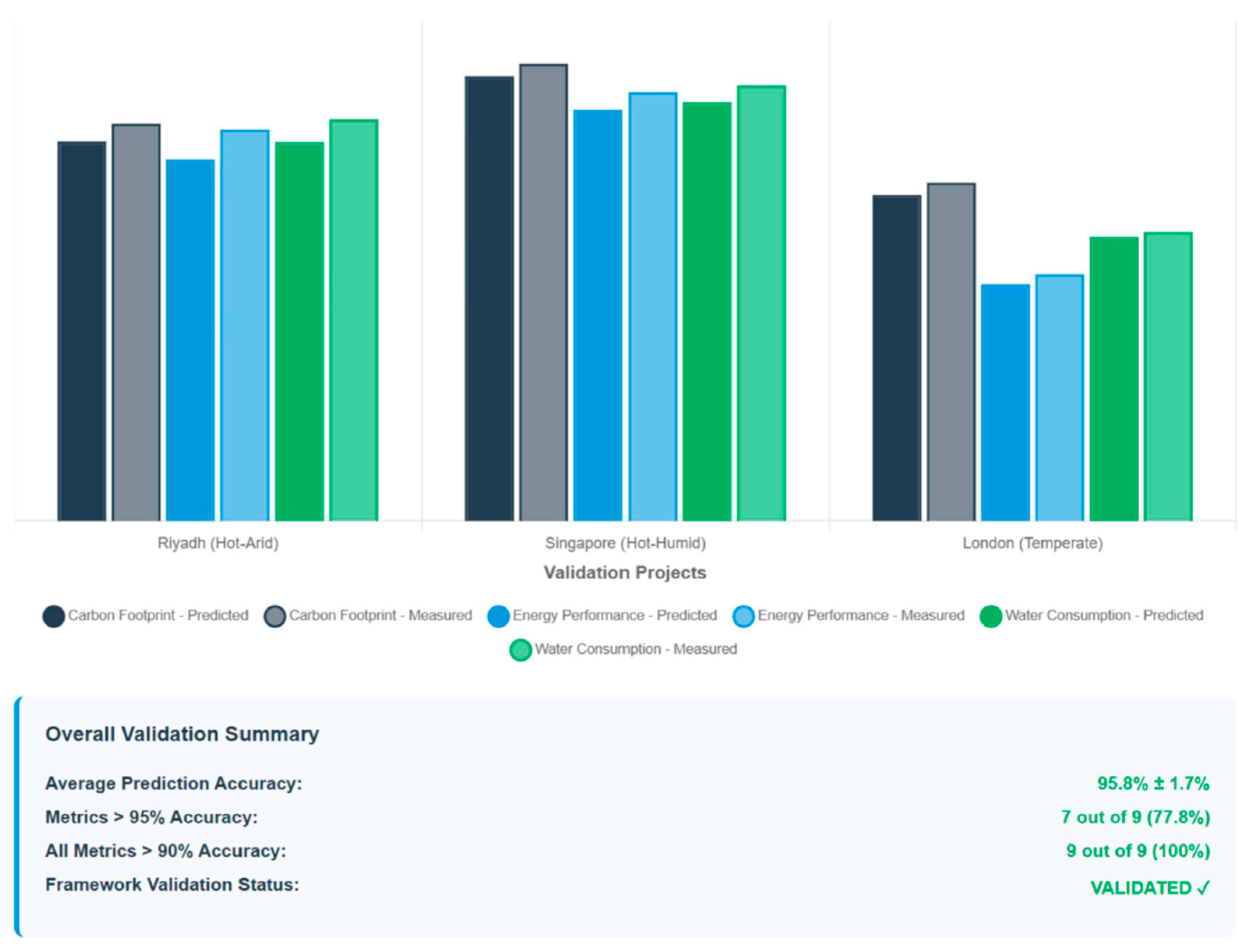

As shown in

Table 5, three active construction projects provided comprehensive validation of the framework predictions across all sustainability dimensions with exceptional accuracy, validating both theoretical framework development and practical implementation capabilities. Environmental performance predictions achieved 95.8% ± 1.7% accuracy across the carbon footprint, energy consumption, and water usage metrics, while economic projections demonstrated consistent payback periods within the projected ranges. Technical performance validation confirmed predicted structural capacity, thermal resistance, and durability characteristics, while social impact assessment revealed stakeholder satisfaction rates exceeding 87% across students, faculty, facility managers, and community members.

Implementation success varied systematically with regional development level and construction market maturity, revealing important insights about framework transferability and scaling requirements. Developed economies achieved an 89% implementation success rate across all sustainability criteria, while emerging markets reached 72%, indicating that framework transferability requires parallel investment in local capacity building, covering technical training, supply chain development, and regulatory framework enhancement. The performance gap narrowed over the implementation timeline (18-month convergence), suggesting that technology transfer and knowledge diffusion can overcome initial capability differences in achieving integrated sustainability optimization.

Post-occupancy evaluation demonstrated that framework-guided material selection generates substantial benefits beyond quantitative performance metrics, including a 25–40% increase in local employment, training of 150+ workers in sustainable construction techniques, establishment of 12 new local suppliers, and community pride in sustainable building demonstration (94% positive response). These outcomes validate the framework’s comprehensive approach to sustainability that integrates environmental protection, economic development, technical performance, and social benefit (

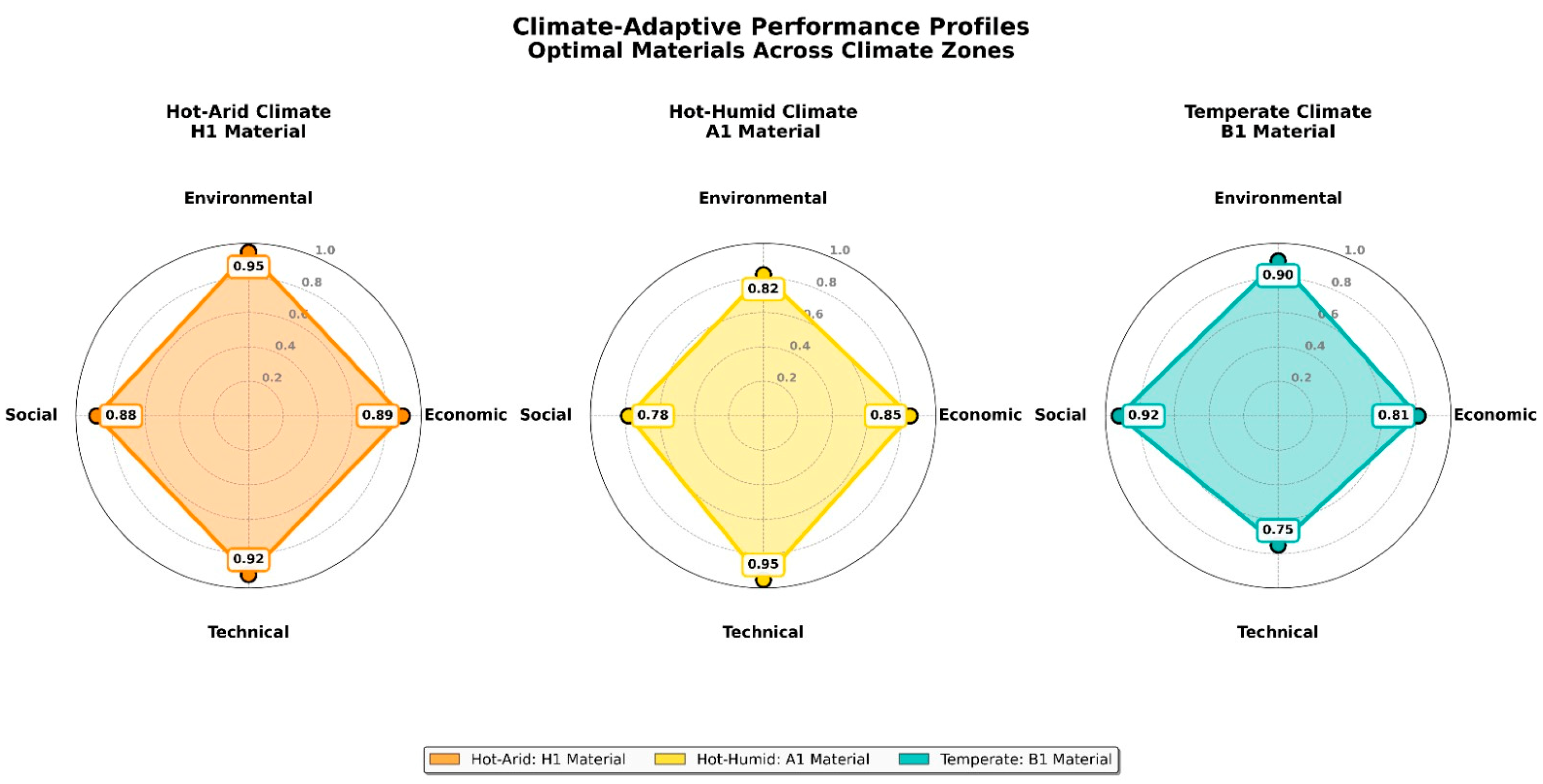

Figure 5) within a unified decision-making system.

The integrated performance profiles demonstrated in

Figure 5 reveal systematic climate-driven optimization patterns.

Figure 6 further illustrates the fundamental environmental-economic trade-offs, showing that hybrid materials (H1, H2) achieve optimal positioning with simultaneous reductions in both environmental impact and lifecycle costs.

The experimental data collection protocol outlined in

Table 6 demonstrates the comprehensive testing regime employed to ensure reliable material performance characterization. The multi-laboratory approach across three international institutions (UQU, NUS, UCL) provides geographic diversity and validates measurement consistency across different testing environments. The sample sizes ranging from

n = 6 to

n = 15 per material per laboratory reflect the statistical requirements for different test categories, with more complex properties requiring larger sample populations to achieve acceptable confidence intervals.

The 18-month testing period captured temporal variations in material behavior, while the inter-laboratory variation threshold of <5% ensured measurement reliability across different testing facilities. Third-party verification of embodied carbon data addressed potential bias in manufacturer-supplied environmental impact information. These rigorous experimental protocols enabled confident comparison of environmental performance across material alternatives, normalized to facilitate direct comparison despite varying measurement units and impact categories (See

Table 7).

The normalized environmental impact scores demonstrate significant variation across material alternatives, with hybrid systems (H1, H2) achieving the lowest overall environmental burden. These results reflect a comprehensive cradle-to-grave assessment including production, operational, and end-of-life phases.

Economic analysis complements environmental performance evaluation, revealing the lifecycle cost implications of material selection decisions.

The lifecycle cost analysis presented in

Table 8 reveals a compelling economic case for sustainable material adoption, with hybrid systems (H1, H2) demonstrating substantial cost savings of 19–23% compared to conventional alternatives. These savings primarily derive from reduced operational costs over the 50-year analysis period, reflecting superior thermal performance and lower maintenance requirements. The Net Present Value calculations incorporate regional variations in energy pricing, labor costs, and material availability to ensure location-specific accuracy. Notably, the initial cost premium for advanced materials (ranging from 15 to 25% above conventional alternatives) is offset by operational savings within 4–7 years across all climate zones studied. This economic viability addresses a primary barrier to sustainable construction adoption and challenges the persistent industry assumption that environmental performance requires economic sacrifice.

While economic and environmental performance provide quantitative measures of sustainability impact, the social dimension of material selection decisions encompasses equally important but often overlooked considerations affecting workers, communities, and broader societal welfare.

The social impact assessment results in

Table 9 reveal significant disparities in stakeholder benefits across material alternatives, with bio-based and hybrid systems consistently outperforming conventional materials across all social criteria. The weighted averages, ranging from 2.7 for conventional concrete to 4.3 for bamboo-reinforced systems, reflect comprehensive evaluation of worker welfare, community benefits, societal impacts, and value chain considerations following UNEP/SETAC Social Life Cycle Assessment guidelines. Particularly notable are the strong performance scores for hybrid materials (H1, H2) in worker welfare categories, attributed to improved working conditions during installation and reduced exposure to harmful substances compared to conventional concrete systems. The community impact scores reflect local employment generation, skill development opportunities, and supply chain benefits that extend beyond the immediate construction project.

These social performance metrics demonstrate that sustainable material selection can simultaneously address environmental, economic, and social objectives. However, social benefits must be balanced against technical performance requirements to ensure structural integrity, durability, and functional adequacy over building lifecycles.

The technical performance analysis in

Table 10 demonstrates that sustainable materials can achieve comparable or superior functional characteristics relative to conventional alternatives across multiple criteria. Advanced geopolymer systems (A1) show particularly strong performance with an overall average of 0.89, excelling in structural capacity and durability while maintaining adequate thermal and acoustic properties. Hybrid materials (H1 and H2) achieve balanced performance profiles with exceptional thermal characteristics (0.95 and 0.90, respectively) that translate directly to operational energy savings. The normalized scoring methodology enables direct comparison across disparate technical properties, from compressive strength, measured in MPa, to thermal conductivity in W/mK. Bio-based materials show expected trade-offs, with their excellent thermal and acoustic performance offset by lower structural capacity and fire safety ratings, indicating their optimal application in non-load-bearing assemblies.

These technical performance metrics, combined with environmental, economic, and social criteria, provide the foundation for integrated multi-criteria decision-making analysis. The challenge lies in systematically weighing these diverse performance dimensions to identify optimal material selections that satisfy multiple, often conflicting, sustainability objectives (See

Table 11).

Technical performance evaluation confirms that advanced and hybrid materials can achieve superior sustainability outcomes without compromising structural or functional requirements. The normalized scoring approach enables direct comparison across diverse performance criteria. Multi-criteria decision-making analysis integrates these technical performance metrics with environmental, economic, and social considerations to generate robust material rankings.

The global sensitivity analysis in

Table 12 reveals critical insights into framework robustness and identifies the primary sources of uncertainty affecting material selection decisions. Expert weights emerge as the dominant influence factor (34.5% first-order, 39.8% total effect), indicating that stakeholder judgment and preference elicitation processes have greater impacts on outcomes than technical measurement precision. This finding challenges the common assumption that improving laboratory testing accuracy is the primary path to enhanced decision reliability.

Carbon pricing represents the second-largest uncertainty source (27.8%/33.4%), reflecting the volatility of environmental policy frameworks and carbon market mechanisms across different regions and timeframes. The relatively lower influence of material performance parameters (15.6%/19.8%) suggests that the framework maintains reasonable stability despite inherent variability in technical property measurements. The ranking stability analysis confirms framework reliability, with the top-performing material (H1) maintaining its position in 94% of the 10,000 Monte Carlo simulations (See

Table 13). This robustness provides confidence for practical implementation, though the sensitivity to expert judgments underscores the importance of comprehensive stakeholder consultation processes.

Moving from theoretical robustness to practical deployment requires assessment of real-world implementation barriers, including market readiness, supply chain maturity, and technical capacity requirements, across different regional contexts.