1. Introduction

The industrial sector poses a significant challenge in terms of environmental pollution and management in all countries owing to its utilization and processing of various chemical substances [

1]. To prevent industrial pollution, the European Union introduced the Integrated Pollution Prevention and Control (IPPC) Directive in 1996 [

2], which mandates the application of best available techniques (BATs) [

3], and has enforced integrated permitting systems. In 2010, this directive was revised and strengthened into the Industrial Emissions Directive (IED) [

4], which continued to contribute to environmental improvements within the industrial sector.

One of the key aspects of integrated permitting systems is the effective removal of pollutants via BATs. BATs are applied across various industrial sectors to promote pollutant management, cost reduction via facility modifications, efficient resource use, and enhanced operational efficiency via energy savings [

5,

6,

7,

8,

9]. Furthermore, BAT use has gradually expanded to realize ecosystem stability restoration [

10] and greenhouse gas reduction associated with climate change [

11].

The Integrated Environmental Management System (IEMS), which originated in the UK (1990) and Germany (1996), has since been adopted by numerous countries, including Korea and Vietnam. The number of countries adopting this system has continued to increase. The UK and Korea are among the nations that have participated in the Organization for Economic Co-operation and Development (OECD) BAT expert group. This expert group has been in operation since 2015, with participation of over 40 countries and organizations and more than 155 experts. Through the OECD-BAT project (2016–2024), these nations share information and support the implementation of integrated permitting systems in various countries [

12].

In Korea, an IEMS has been implemented since 2017 [

13,

14]. This system currently targets 1603 facilities across 19 high-emission industries, such as power generation and semiconductor manufacturing. These facilities are categorized as first or second class based on their contribution to air or water pollution according to the following thresholds: for air pollution, emission outlets releasing a combined annual total of 20 t or more of dust, SOx, and NOx; for water pollution, outlets discharging 700 m

3 or more of wastewater per day.

Individual countries operate their IEMSs based on their unique national conditions. Thus, IEMS implementation and operational status differ across countries. In some nations such as EU member states, BATs are mandated in IEDs. However, in other countries such as Korea, BAT applications are voluntarily. In addition, BAT reference documents have not been developed by each country operating an IEMS. Moreover, countries such as Korea and EU member states that have more experience in IEMS operations have achieved a level of operational stability within their systems, whereas countries such as Vietnam and India are still in the early stages of implementation.

Despite differences in system maturity and design, integrated permitting is expected to positively affect site-level environmental management. For example, in the EU, system implementation is estimated to reduce administrative costs by €110 million to €260 million annually across 52,000 permitted facilities [

15]. Additionally, in sectors such as textiles and metal surface treatments, reductions were achieved in water use (30–90%), auxiliary materials (30–50%), and energy use (15–25%) (based on data from 2001 to 2006) [

16]. In the UK, particulate matter and heavy metal pollution, such as lead and SOx, and waste generation decreased (20%), and waste reuse increased (50%) [

15]. The number of environmental incidents in the UK industry also decreased considerably from 884 in 2000 to 464 in 2006 [

15].

Other benefits have also been documented: in the UK, collaboration and technical support between regulatory bodies and pig farming establishments yielded tangible benefits [

17]; in Finland, environmental performance improvements in the pulp and paper industry were observed over 5 years [

18]; and in Ireland, pollution reduction of up to 40% was reported for the pharmaceutical sector [

19]. In Korea, after adopting an integrated permit system, major air pollutants, such as SOx and NOx, were reduced by approximately 44–69% and water pollutants, such as TN and TP, were reduced by approximately 69–92% (as of 2022) [

20]. Moreover, the system has stimulated substantial investments in environmental facilities, amounting to 17.4 trillion KRW [

21].

In developed countries that have successfully implemented IEMSs, the system can be enhanced by addressing internationally recognized challenges. For example, the EU is in the process of developing IED 2.0 [

22], which will minimize the use and emissions of hazardous chemicals, support the transition to a circular economy, accelerate industrial decarbonization, and promote innovative technology adoption [

22]. Moreover, the scope of the IED will be expanded to cover metal mining, battery manufacturing, and intensive livestock farming and the establishment of a BAT for waste landfill operations [

22]. Furthermore, new tools are being developed to enforce the substitution of hazardous substances and integrate environmental management systems [

22].

Korea is in the process of developing an IEMS 2.0, which will be introduced in 2025. This system aims to address the shortcomings of the current system and integrate innovative and forward-looking components. IEMS 2.0 seeks to enhance media-integrated management, introduce a specialist technical review committee, provide post-management through environmental management specialized companies, introduce a smart integrated environmental management system that utilizes artificial intelligence and the Internet of Things, and promote information disclosure system efficiency [

23].

This study analyzes the effectiveness and practical implications of Korea’s Integrated Environmental Permit System (IEPS) and investigates the associated policy design and technological implementation. Moreover, it combines conceptual analysis with limited empirical evidence drawn from multiple industrial cases. Ultimately, in this study, we advocate for IEMS implementation experience sharing and collaboration in the development of advanced systems. Furthermore, we sought beneficial processes based on Korea’s experience of operating its IEMS that could help support other countries seeking to improve their own IEMS. These proposals may be adopted directly or adapted according to the unique circumstances of a given country.

2. Materials and Methods

2.1. E-Permit

The necessity, application scope, and prospective benefits of the e-permit system are presented based on Korea’s 8-year operational history with the Korean Integrated Environment Permitting System (K-IEPS) since its inception in 2017.

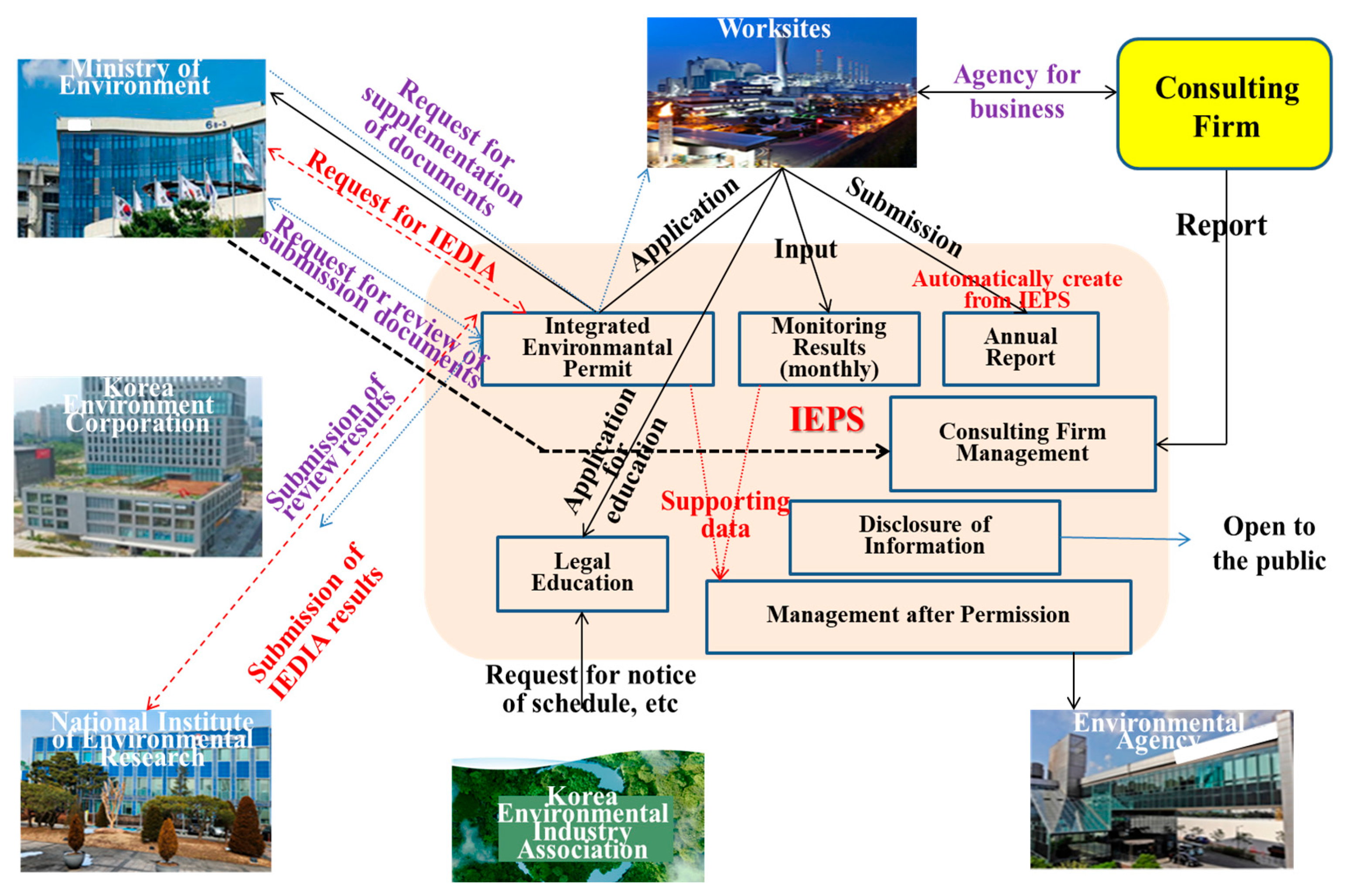

The K-IEPS issues new permits, modifies existing permits, provides change notifications, reviews permits, and assists in application document preparation. For post-permit management, the system inputs monthly monitoring data, prepares and submits annual reports, provides facility start-up notifications, reports pollution inspections, issues corrective orders and administrative sanctions, calculates pollutant discharge charges, and reports regular ad hoc inspections by the local environmental office.

Additionally, the IEPS manages public disclosure of environmental information, including annual reports, permit review results, and four essential datasets, namely (i) fuel and water usage information, (ii) types and locations of pollutant-emitting facilities, (iii) permitted emission standards and historical emission data from the past 5 years, and (iv) emergency response plans for environmental accidents. It also processes applications for site environmental managers, registrations for mandatory environmental training, performance evaluations of delegated permitting agencies, and documentation of administrative enforcement actions.

Furthermore, the IEPS facilitated BAT reference document preparation by supporting the collection of monitoring data necessary to determine BAT-associated emission levels (BAT-AELs) and tracking the application status of BATs at the facility level.

2.2. Automation of BAT-AEL Calculation

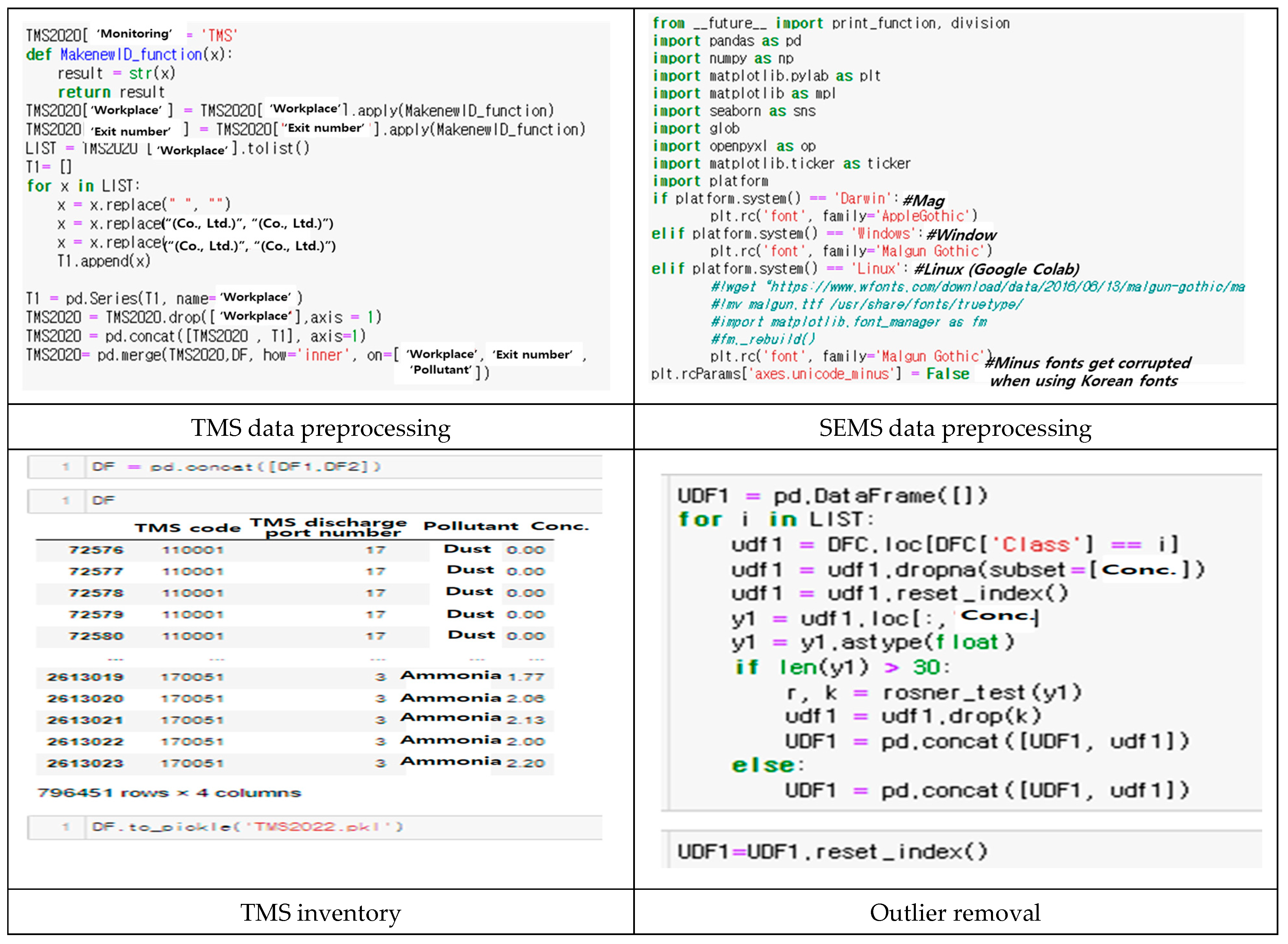

BAT-AEL calculation automation was implemented in Python (v. 3.12.7). Nationally certified monitoring data from the past 3 years (2020–2022) were used as input data, including the tele-monitoring system (TMS), stack emission management system (SEMS), water tele-monitoring system (WTMS), and water emission management system (WEMS).

From each monitoring dataset, the essential fields required for the BAT-AEL calculation were extracted, including industry type, facility name, pollutant, emission outlet number, concentration, and units. After extracting these key parameters, the data were matched across datasets to create a unified dataset.

Outliers were identified and removed using the Rosner simulation method [

24,

25]. Subsequently, the cleaned datasets were merged again, and descriptive statistics were calculated. Based on these statistics, BAT-AEL values were determined and summarized using pivot tables.

3. Results and Discussion

3.1. Efficient Integrated Environmental Permit Management by the E-Permit System

Establishing an e-permit system is essential to effectively implement an IEPS. The E-permit system is useful [

26,

27,

28] not only during the permitting phase but is also crucial for post-permit site management. This enables the integrated management of permit conditions, pollution monitoring compliance, and pollution prevention measures. Since the introduction of the permit system in 2017, Korea has operated an e-permit system, known as the K-IEPS [

29].

The greatest advantage of implementing an e-permit system is its convenience. Previously, for business establishments, people had to physically visit the permitting authority to submit documents and provide related details to the designated officer. Furthermore, monitoring the status of permit processing was difficult without directly contacting the authorities. However, with the implementation of the e-permit system, all application documents can now be submitted online, and document supplementation can be performed electronically. Applicants can also track the progress of their permits in real time via the system. Although the permitting process typically takes approximately 5 months in the EU, 7 months in Germany, and 4 to 24 months in the UK [

30], the K-IEPS has reduced the minimum review period to 2–23 days, depending on the industrial sector, although the statutory permit period remains 35 days. When there are few facilities or the industry is simple, the permit review period is relatively short, whereas when there are numerous facilities and the industry is complex, such as in the chemical and semiconductor sectors, the permit review period is considerably long.

The e-permit system also ensures secure and long-term storage of permit documents. Many business establishments have been in operation for decades, making it difficult to store paper documents over long periods. The large volume of documents, such as facility blueprints, and the risks of misplacement owing to office relocations or the gradual degradation of physical records over time pose major challenges. By contrast, through the use of an e-permit system, documents can be managed within a digital database or as electronic files, minimizing the risk of loss or damage. In the early stages of Korea’s system implementation, business establishments had to recreate permit documents because of loss or damage.

Moreover, the e-permit system is effective not only during the permitting process but also for environmental management after permit issuance. It allows authorities to verify whether a facility complies with permit conditions, conduct pollution monitoring as required, and properly implement preventive and corrective measures.

In Korea, after receiving a permit, facilities are required to input monthly post-permit compliance data into the IEPS, along with relevant supporting documents. The supervisory authority (in Korea, the regional environmental office) can then monitor whether the facility is fulfilling its post-permit responsibilities in accordance with regulations. Through this approach, the system leverages big data collected through the IEPS for continuous compliance monitoring. If the authority determines that a facility is not managing its post-permit obligations properly, it can conduct an on-site inspection and take legal action, if necessary.

The e-permit system also helps prevent the submission of false or manipulated data. Because facilities must submit supporting documents along with their operational and monitoring data, inconsistencies can be identified through cross-checking. In addition, links with other relevant systems allow error tracking and data validation.

As demonstrated by Korea’s operation of the IEPS, there are various advantages in adopting an e-permit system (

Table 1). However, except Korea, no other country currently implementing an IEPS has adopted such an e-permit framework.

The IEPS operates on continuous environmental data transmitted from industrial sites; therefore, robust governance and data protection are essential. Data access is managed via a three-tier structure: operators can view only their own monitoring data, regulators can access aggregated datasets for compliance and policy review, and administrators maintain read-only access under strict audit logging.

All transactions within the IEPS are time-stamped and stored in an immutable audit trail to prevent tampering. Data exchanges among related systems (TMS, SEMS, and WEMS) occur via encrypted and authenticated channels, minimizing inconsistencies and unauthorized manipulation. When anomalies such as sensor errors or missing data are detected, the system issues alerts and temporarily flags the records for verification before regulatory evaluation.

Data ownership remains with the facility, whereas stewardship and verification responsibilities lie with the permitting authority, ensuring both accountability and privacy. Key risks—such as data falsification, privacy breaches, system mismatches, and cybersecurity threats—are mitigated via encryption, access control, and continuous monitoring. This governance framework strengthens transparency and reliability, supporting the IEPS as a secure and sustainable environmental management platform.

Each country may adopt different approaches based on information infrastructure variations. For countries seeking to establish a permit system similar to Korea’s IEPS, integrated permitting processes must be automated for efficient system operation. In the case of Korea, approximately 2 years were required to establish the IEPS. Conversely, in countries where information infrastructure is underdeveloped, it is necessary to establish a long-term plan and gradually implement a permit automation system. Specifically, in the first stage, an initial model for permit application, submission, and review should be developed; in the second stage, a monitoring system should be established for post-permit environmental management; and in the third stage, a system should be implemented to continuously verify compliance with permit standards and conditions.

Figure 1 introduces the IEPS homepage and system menu in Korea [

29], and

Figure 2 illustrates the workflow in the processing of permits and post-permit tasks handled via the IEPS.

3.2. Package Management of Industries in Related Sectors and with Value Chain Relationships

Each country determines the industries that are subject to integrated environmental management based on various principles. Industries with high pollutant emissions and emitting pollutants of current concern and sectors requiring enhanced pollution control are typically considered. For example, the EU operates an IEPS across 30 industry sectors, including large combustion plants [

31]. In Korea, the system covers 19 industries, including the top 18 sectors in terms of the emissions of major air and water pollutants (such as BOD and dust), as well as the cement industry, which has become a growing environmental concern. The list of target industries is subject to change based on the ongoing evaluations of emission trends and industrial advancements.

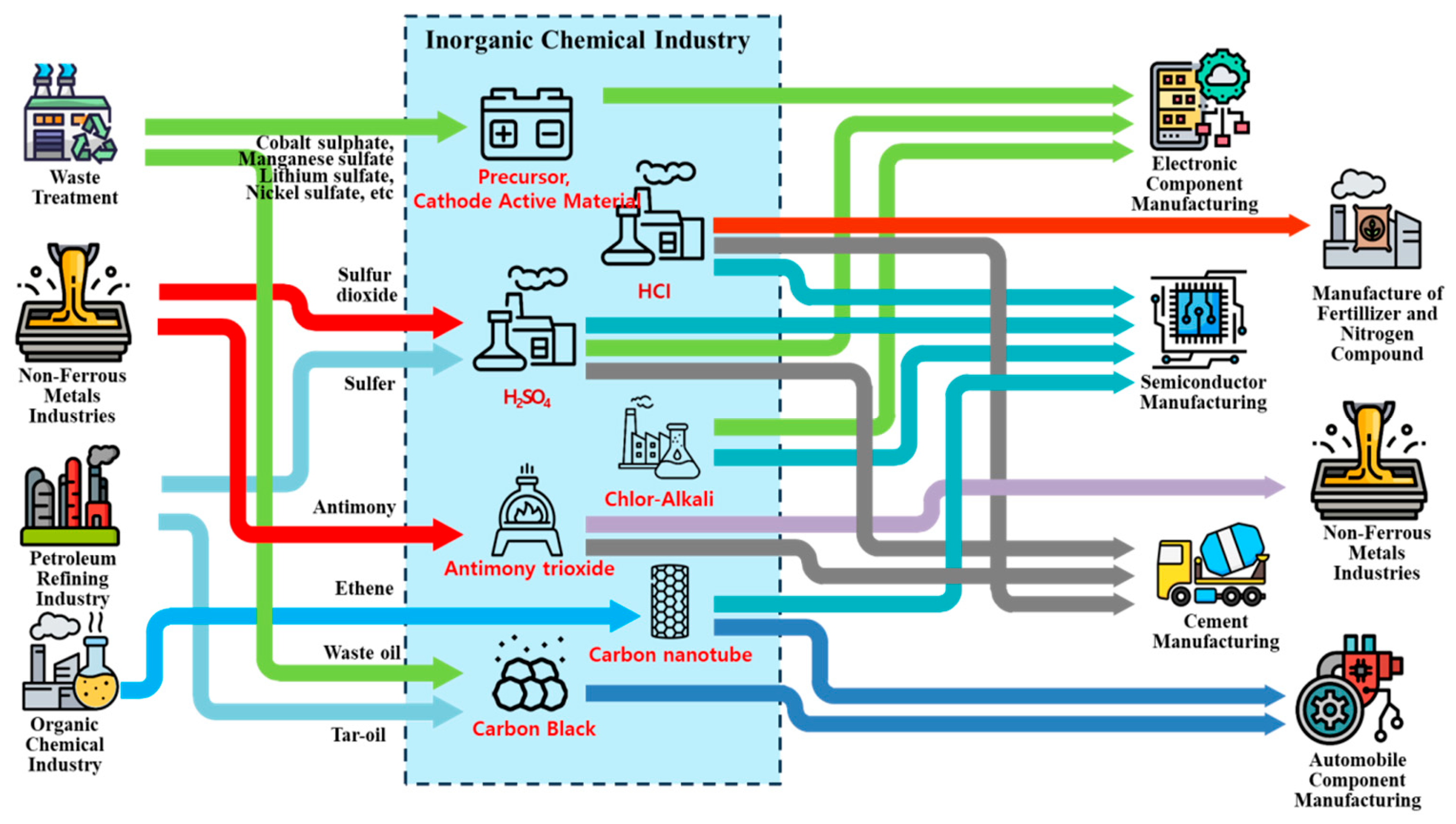

These target industries are typically interconnected with other sectors through the procurement or distribution of raw materials and intermediate products, establishing interconnected or value-chain relationships.

Figure 3 shows examples of industries that are either linked or engaged in a value chain relationship with Korea’s inorganic chemical sector, a regulated target of integrated permission. Managing such industries collectively rather than individually is expected to yield more effective environmental outcomes [

32].

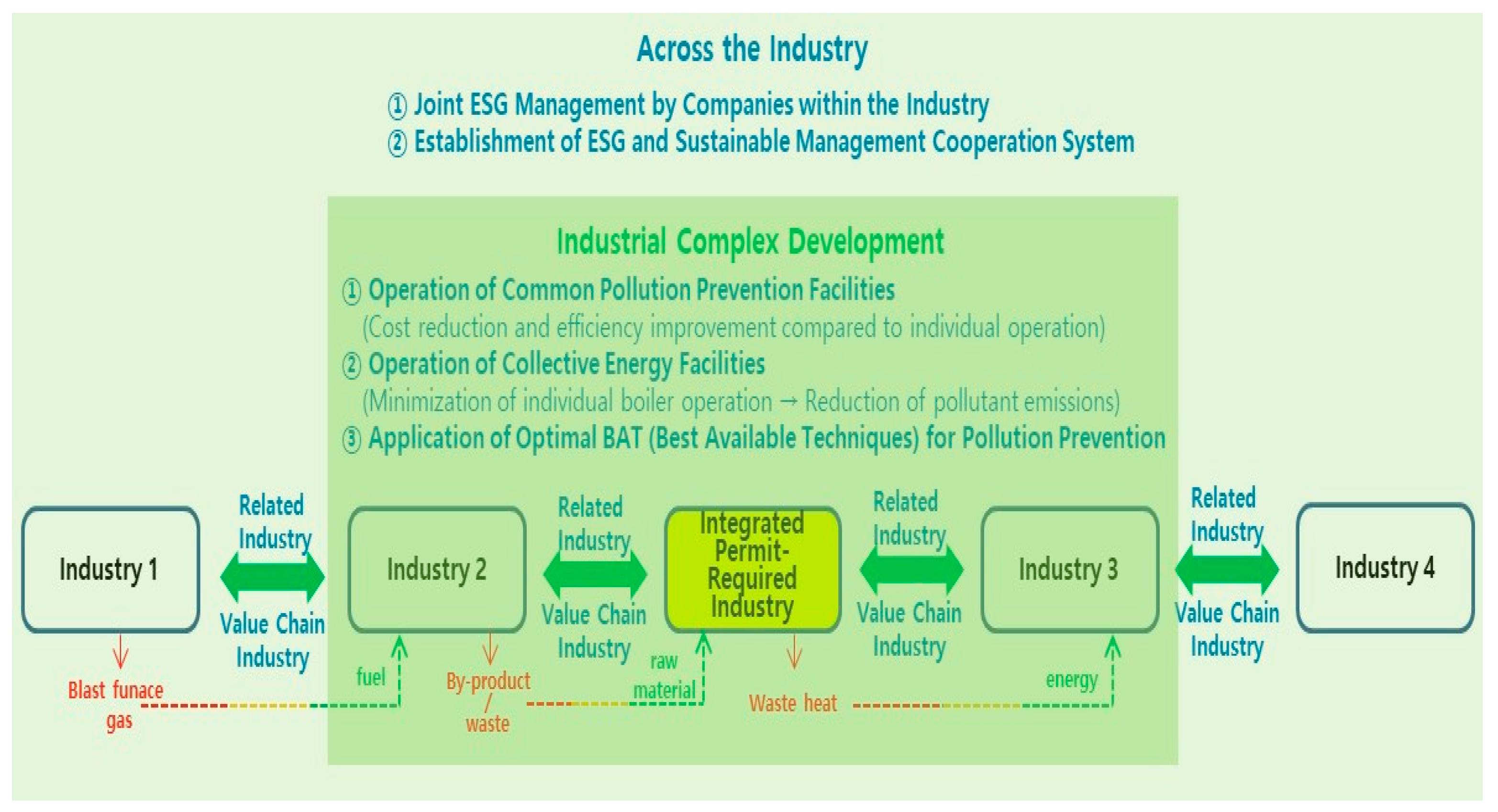

While separately managing each industry is important, integrating related and value chain-linked industries as packages offers numerous benefits (

Figure 4). For example, byproducts or waste from one industry can serve as raw materials for another, reducing pollutant emissions and cutting costs. Coal ash from power plants can be reused as a raw material in cement manufacturing, whereas slag from the steel industry can be used for cement, aggregates, or road paving. Byproduct gases from petrochemical industries or steelworks can be used as fuels in other sectors or for combined in-house heat and power generation. Waste heat from industrial processes can be used as an energy source to enhance energy efficiency and contribute to the mitigation of global warming and greenhouse gas emissions. This type of package management also promotes resource recycling and strengthens the circular economy [

33,

34,

35].

If these related industries are co-located in industrial complexes, they can jointly handle pollutant treatment. For example, operating a shared wastewater treatment facility can reduce costs and improve efficiency compared with operating individual facilities. In South Korea, textile dyeing factories form industrial complexes and operate a joint wastewater treatment facility instead of treating the generated dye wastewater individually. Similarly, centralized energy systems such as combined heat and power plants can reduce the need for individual boilers and contribute to cost savings and pollution reduction.

Such integrated management facilitates collaboration across industries, maximizes pollution reduction, improves productivity, and reduces energy and water consumption. These efforts can lead to joint Environmental, Social, and Governance initiatives and the establishment of sustainable management frameworks. Additional synergies may include enhanced market responsiveness, better supply–demand balancing of products, improved global competitiveness, and strong responses to international trade barriers.

If all related and value-chain-linked industries were subject to the integrated permit system, pollution control would be effective. However, even if they are not, establishing collaborative and integrated management frameworks among them could yield substantial synergy and environmental benefits.

However, countries that have implemented the integrated permitting system, including South Korea, do not yet apply it to all industrial sectors. Therefore, at this stage, it is difficult to manage all industrial sectors that are interconnected or are a part of a value chain as a single package. As an alternative approach to managing related industries as a package, it is necessary to first conduct effective pollution management by limiting the scope to facilities subject to integrated permits and to establish a system that enables the management of related industries outside integrated facilities in conjunction with life cycle assessment (LCA) and greenhouse gas management, including emissions calculations (Scopes 1–3).

3.3. Balloon Effect and Site-Specific BAT Selection

Many countries that operate IEPS, such as EU members and Korea, develop BAT reference documents to guide permitting. These reference documents are periodically revised to reflect industry changes and incorporate newly identified BATs.

Each country determines its own BATs based on its own selection criteria. The EU considers cross-media environmental impacts when selecting BATs, whereas Korea evaluates environmental effectiveness, technical feasibility, applicability, and economic viability based on the operational guidelines for the development of BAT reference document [

36]. Among these factors, environmental performance and economic efficiency are important.

Although the BATs selected under current procedures are effective in reducing specific pollutants, it is also necessary to examine whether they inadvertently increase pollution in other media or processes within the facility. Such unintended side effects are referred to as the “balloon effect” (

Figure 5). If the balloon effect is identified during the application of a BAT candidate, further consideration is required to determine whether it should be adopted as a BAT.

The EU’s IPPC reference documents call for the evaluation of “economics and cross-media effects” during BAT selection. However, the balloon effect discussed herein is more narrowly focused and site-specific than the broader interpretation of cross-media effects in EU documents.

In the IPPC approach, the evaluation of cross-media effects involves the consideration of seven environmental impact categories: human toxicity, global warming, aquatic toxicity, acidification, eutrophication, ozone depletion, and photochemical ozone creation [

37]. This evaluation framework addresses broad national and global issues, making the assessment complex, uncertain, and difficult to apply at the site level. Furthermore, facility operators may question whether they should be held accountable for addressing global-scale effects in the absence of corresponding legal obligations.

However, businesses tend to focus on the impacts confined within the boundaries of their own facilities. They are primarily concerned with whether a candidate BAT can meet the permit conditions, whether it is efficient and easy to maintain, and whether it might cause unintended issues, such as increased pollution in another part of the facility, which is the classic balloon effect. For example, applying a certain BAT to reduce one air pollutant may unintentionally increase the emissions of another, generate more wastewater, or produce more solid waste.

By focusing on BAT evaluations within a narrow scope, site-specific concerns, particularly the balloon effect, become more practical and relevant to facility operators. This narrow approach simplifies the assessment compared to the EU’s broader cross-media analysis. BATs that cause an overall increase in pollutants within a facility, particularly at the level of concern, are less desirable and should, therefore, be avoided.

However, from the facility’s perspective, it may be necessary to adopt a BAT with some degree of balloon effect [

38,

39], particularly if the resulting emissions do not exceed permit thresholds and the technique remains cost-effective. However, permitting authorities may be reluctant to accept techniques such as BAT, given their responsibility for broader environmental protection and pollutant control at the national level.

Table 2 compares the EU’s cross-media approach to Korea’s balloon-effect-focused approach. The emphasis placed on each factor varies depending on whether the country mandates the use of BATs. Countries with mandatory BAT systems must consider both facility-level efficiency and national-level environmental protection, whereas countries that do not require BAT adoption, such as Korea, may leave the final decision to facility operators.

The balloon effect resulting from the implementation of BAT has recently become a growing concern in industrial workplaces. Therefore, research on the balloon effect is necessary, along with the establishment of evaluation criteria and specification of evaluation indicators. Furthermore, effective management strategies are essential for addressing both the narrowly defined balloon effect within workplaces and the broader cross-media effects recognized by organizations such as the EU. This is because the balloon effect and the cross-media effect are not separate phenomena but are closely interconnected. Whether these effects are limited to workplaces or encompass a broader national and global scope is an urgent question.

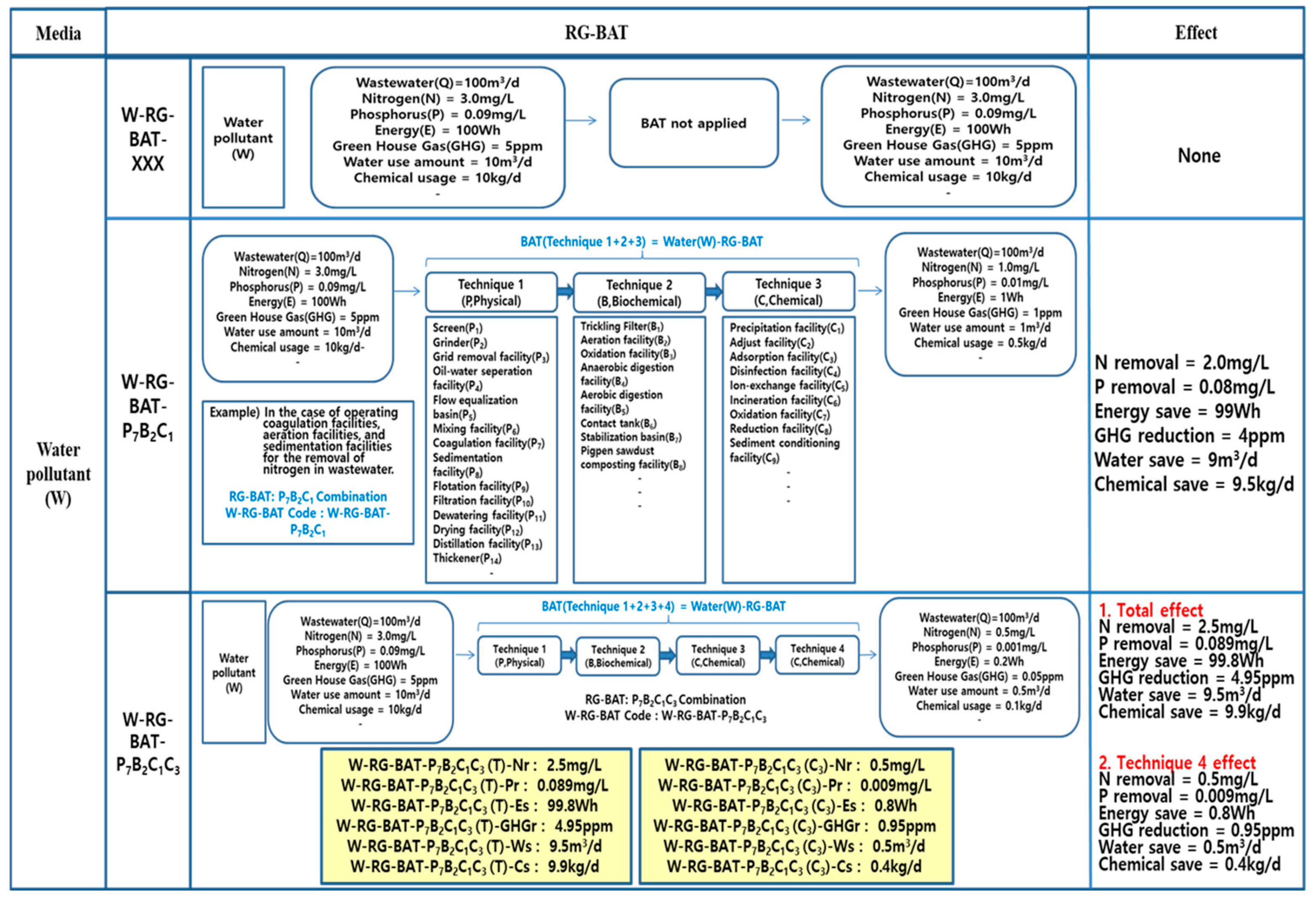

3.4. BAT-AEL Calculation Automation

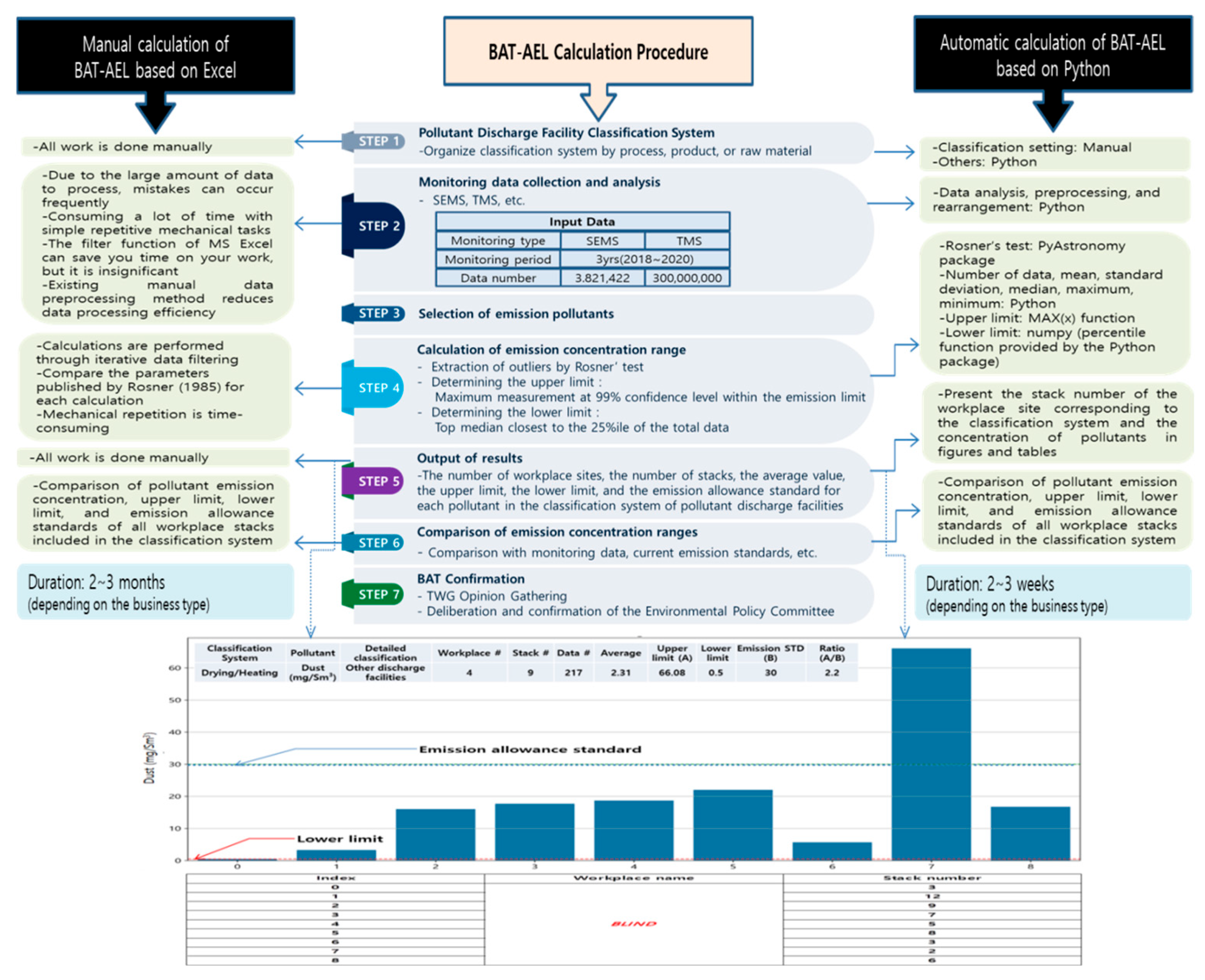

To calculate the BAT-AEL, it is essential to classify facilities based on various continuous monitoring data [

40,

41] and the specific characteristics of each industry’s processes or products. This task is time-consuming and repetitive. In addition, the large amount of data involved increases the likelihood of human error during manual processing. Nevertheless, most countries that operate IEMS rely on manual methods for BAT-AEL calculations. Therefore, there is a growing need to establish automated systems to improve efficiency.

From 2017 to 2023, Korea manually calculated BAT-AELs using Excel. The data used in this process included intermittent self-measurement data (e.g., quarterly, biannual, or annual), SEMS data monitored monthly (approximately one million data points annually), and TMS data, which consisted of real-time measurements averaged over 5 or 30 min intervals across 3 years (approximately 300 million data points). These monitoring datasets are categorized by process or product type and reorganized according to classification standards that reflect the timing of the enforcement of legal emission standards. Because of the volume and complexity of these tasks, calculating the BAT-AELs for each industry typically requires 2–3 months. When converted into administrative costs, this is estimated to result in savings of approximately $2.6 million.

However, in countries that implement an integrated permitting system, it may not be necessary to consider Korea’s calculation method, depending on the procedures used to determine BAT-AEL and the factors considered. If the method for calculating BAT-AEL is simple and the process straightforward, a passive approach could be applied. Therefore, because institutional differences may exist among countries in calculating BAT-AEL, the choice of methodology to apply may remain optional.

Starting in 2024, Python was introduced to automate the BAT-AEL calculation process, and it has considerably reduced the time required to approximately 3 weeks from 3 months.

Figure 6 illustrates the BAT-AEL calculation procedure, along with a comparison between the Excel-based manual and Python-based automated methods. An example of Python coding for BAT-AEL calculation is presented in

Figure 7.

One of the most time-consuming steps is to establish a classification system for emission sources and standardize various monitoring data formats (Step 1). This classification must reflect the industry’s nature using factors such as manufacturing processes, product categories, and unit operations. Legal revisions that tighten emission limits must also be considered, as facilities typically reduce emissions after such enforcement.

Once the classification system was established, the relevant monitoring data were collected, categorized, and analyzed (Step 2). This step involves handling large datasets and performing repetitive mechanical tasks, resulting in considerable labor and time costs.

In Step 4, the emission ranges were calculated by removing outliers from the dataset and determining the median and 99% confidence interval maximum values. The emission limit was referenced to calculate the 99th percentile of the maximum value to establish the upper BAT-AEL bound. For the lower bound, the 25th percentile of the dataset was calculated, and the highest median value among the individual emission outlets was selected.

Outlier detection was conducted using Rosner’s Generalized Extreme Studentized Deviate test to identify extreme values in the emission dataset. The significance level (α) for outlier detection was set at 0.05, corresponding to a 95% confidence level. In some cases, a more conservative threshold (α = 0.01, 99% confidence) can be applied; therefore, for stricter detection, α = 0.01 was selected in this study. The maximum number of potential outliers (k) was defined prior to testing and limited to 10% of the dataset size (n), following standard statistical guidance.

Before applying the Rosner’s test, the raw emission data were grouped by process type, emission source, and measurement method to ensure comparability and maintain homogeneity within each group. Specifically, the data matching and grouping followed these rules: (1) datasets were classified by identical process categories (e.g., kiln, boiler, incinerator); (2) only measurements obtained using the same analytical units and methods were combined; and (3) when applicable, temporal variations such as seasonal or annual averages were considered. The Rosner test was then applied independently within each matched dataset, with the maximum number of potential outliers (k) set to 10% of the total data points (n) and the significance level (α) fixed at 0.01. This procedure ensured consistent and unbiased outlier detection across comparable process conditions within the BAT-AEL derivation framework.

After defining the emission range, Step 5 involved generating visual graphs and tables showing the pollutant concentrations at all emission outlets for all facilities within the classification group. If performed in Excel, this requires the time-consuming manual preparation of tables and visual representations.

Owing to the repetitive nature and large amount of data in steps 1–5, automation using Python or similar tools is considerably more efficient. Although classification schemes may vary by industry, the BAT-AEL calculation process, types of monitoring data used, and evaluation criteria are consistent across sectors. Thus, automation can be easily standardized and scaled using stepwise programming.

In Step 6, the calculated data are shared with the facilities for review, and feedback is collected to confirm the accuracy. Inputs are also gathered from the technical working group. If no objections are raised, the proposed upper and lower BAT-AEL values are finalized.

Finally, in Step 7, the confirmed BAT-AELs are submitted to the Central Environmental Policy Council for formal approval. If important objections are not raised during deliberation, then the values are officially adopted.

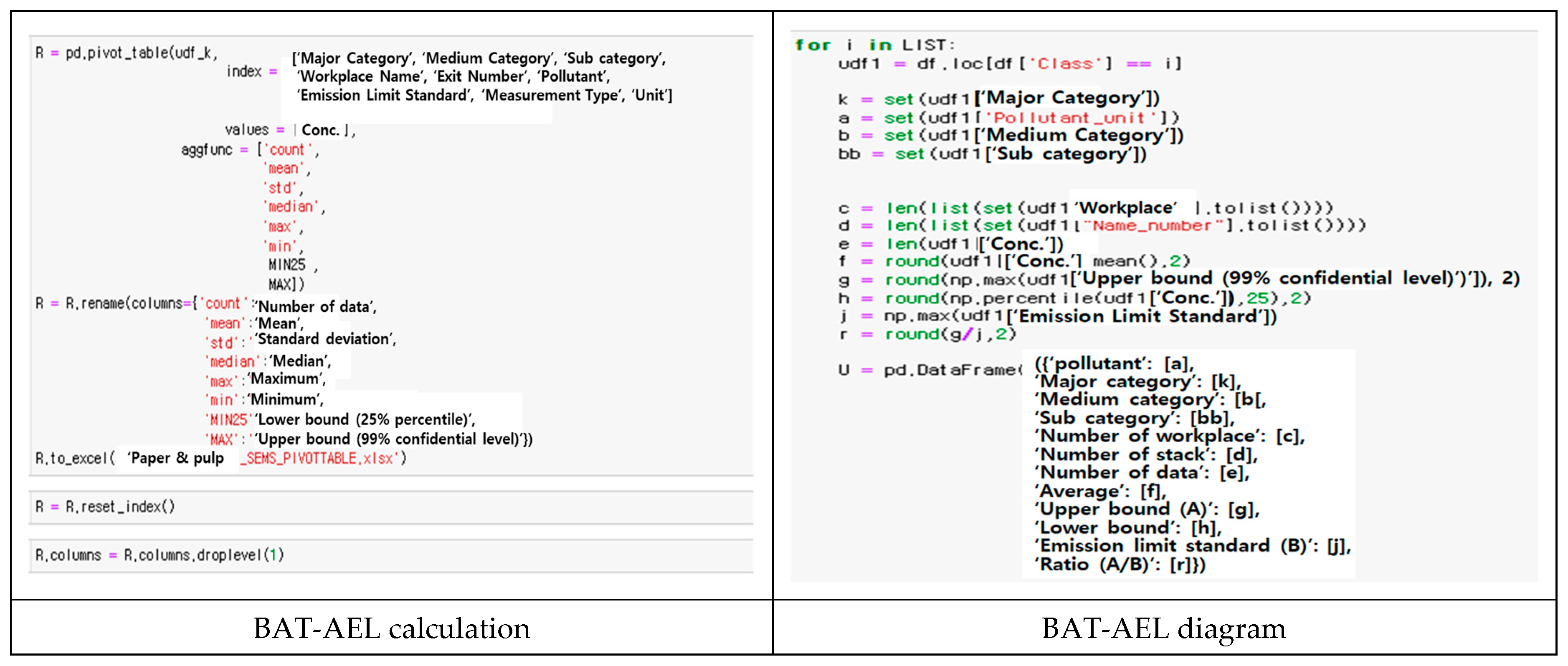

3.5. ReGreen-BAT Diagram

When a single pollution control technology or unit technique is applied, it is relatively easy to determine whether the technique qualifies as a BAT and to assess the level of pollutant reduction achieved. In other words, if the single treatment technology or unit technique applied at the workplace is included in the BAT list of the BAT reference document, it can be considered as BAT. However, it is uncommon for industries to rely solely on a single technique. Most facilities manage pollutants using a combination of multiple techniques.

Additional techniques are typically implemented before or after existing technique to comply with increasingly strict emission limits or achieve further pollutant reduction. Therefore, it must be possible to determine whether the technique composed of combinations corresponds to BAT. Furthermore, because most facilities measure pollutant concentrations only at the inflow and final discharge points, it is difficult to assess the additional reduction achieved by each supplementary BAT.

Thus, it is necessary for BAT reference documents to present combinations of BATs, referred to as BAT combinations, and associated pollutant reduction levels. If the BAT reference documents do not provide such information, it becomes difficult for new facilities to determine the combinations of control techniques that are most effective in treating specific pollutants at the desired concentrations.

Despite this need, most BAT reference documents across countries focus on individual techniques rather than combinations. Furthermore, environmental management in integrated permit facilities should include not only pollutant reduction but also additional aspects such as energy conservation, greenhouse gas reduction, and water conservation, which are core elements of the green transition.

To address this issue, it has been proposed that BAT reference documents include a ReGreen-BAT (RG-BAT) diagram for each BAT or BAT combination. This diagram codes and manages environmental performance indicators, including pollutant reduction levels, energy savings, water use reduction, and greenhouse gas emission mitigation.

The availability of such RG-BAT diagrams would facilitate environmental performance evaluations of each BAT combination, as shown in the example in

Figure 8. Furthermore, these diagrams provide facilities with comprehensive information to select appropriate BATs by integrating pollution control with broader environmental and sustainability considerations.

In

Figure 8, which presents an example from the water quality field, the RG-BAT diagram code is arranged in the order of the water treatment process flow. The code W-RG-BAT-P

7B

2C

1C

3(T or C

3)-N

r (or P

r, E

s, GHG

r, W

s, C

s) indicates that the ReGreen-BAT (W-RG-BAT) in the water quality field was applied and involves four combined processes (P

7B

2C

1C

3) executed in the order P

7 → B

2 → C

1 → C

3. Here, P

7 denotes coagulation among physical methods; B

2 denotes aeration among biochemical methods; C

1 denotes precipitation among chemical methods; and C

3 denotes adsorption among chemical methods. In addition, T represents the overall BAT removal efficiency of the P

7B

2C

1C

3 combination, whereas C

3 represents the removal efficiency of the final C

3 stage within that combination. N

r, P

r, E

s, GHG

r, W

s, and C

s represent nitrogen removal rate, phosphorus removal rate, energy savings, greenhouse gas reduction, water savings, and chemical consumption reduction, respectively.

Figure 8 provides a simple conceptual example to clarify the process. This type of analytical process is highly complex and requires sufficient workplace data to perform the analysis. In some cases, it may be difficult to conduct the analysis because such data are not monitored at the workplace. Currently, additional research is underway to determine whether this conceptual analysis is feasible for certain industries. If the research yields meaningful results, the findings will be published in a paper.

4. Limitations and Future Work

Despite the practical and conceptual contributions of this study, some limitations remain that offer directions for future research.

This study primarily focuses on a qualitative and descriptive analysis of Korea’s experience in implementing the IEPS. Quantitative validation of its effects—such as reductions in permit review time, improvements in BAT-AEL automation efficiency, and associated economic or environmental benefits—remains limited. Future studies should conduct time-series or regression analyses using sector-specific datasets to quantify these impacts, including uncertainty ranges and inter-sectoral variability.

Although the balloon effect has been conceptually introduced as a site-specific issue under integrated permits, empirical case studies are still lacking. Future research should include quantitative assessments of cross-media impacts (e.g., increased sludge generation because of SOx scrubber installation) to develop definite indicators and decision-support tools for policymakers.

The value chain-based package management concept is promising but has yet to be empirically demonstrated. Future studies should incorporate LCAs, material-flow analyses, and performance indicators (e.g., energy savings, resource efficiency, avoided GHG emissions) to verify the concept’s feasibility via pilot applications in selected industrial sectors.

The proposed RG-BAT framework remains conceptual and lacks empirical validation. Future work should define coding parameters, construct sector-specific codebooks, and conduct inter-rater reliability tests among engineers to assess its practical applicability and decision-making accuracy within IEPS operations.

The findings are largely derived from Korea’s institutional experience, which may limit their generalizability to other regions. Future research should explore adaptation pathways for developing countries by considering their legal, institutional, and data infrastructure differences and should verify the applicability of the proposed IEPS framework using international collaborative studies.

5. Conclusions

Korea’s IEPS, which includes an e-permit system, has improved the convenience of the permitting process, facilitated big data management at the facility level, and effectively linked pre- and post-permit data for comprehensive environmental management.

Countries implementing IEPSs are encouraged to actively adopt e-permit systems to enhance administrative efficiency and enable broader applications across environmental management tasks.

Integrating related and value-chain linked industries with the permit system’s primary target industries can generate various synergistic effects. These include pollution reduction, increased productivity through inter-industry collaboration, energy and water savings, and the promotion of circular economy principles.

When selecting BATs, it is crucial to consider not only macro-level environmental effects but also narrow-scope, site-specific factors that are of immense concern to facility operators. This includes a thorough assessment of the balloon effect, in which a reduction in one pollutant can cause an unintended increase in another. Evaluating BATs from a site-centered perspective leads to the selection of practical and acceptable techniques.

Calculating BAT-AELs is inherently data-intensive and involves repetitive tasks, making it time-consuming when performed manually. Automating the BAT-AEL calculation process using standardized systems can greatly reduce the time required and improve overall work efficiency.

If BATs or BAT combinations can be coded and managed using RG-BAT codes, it would enable better visualization of the environmental performance of the combined techniques. Such an approach not only helps identify the most effective BATs but also allows the integration of additional environmental management factors, such as energy and water conservation. This would provide facilities with more comprehensive guidance for selecting the most suitable BATs or BAT combinations.

The contents of this paper are based on experience accumulated over approximately 10 years of implementing the IEMS in Korea. These data will promote effective system operations in countries currently implementing or preparing to implement an IEMS. The suggestions made in this paper will be analyzed based on the results applied in Korea, and additional papers are planned to be submitted in the future.