Studies on the Valorization of Aluminum Production Residues into Bituminous Materials at Different Scales: A Review

Abstract

1. Introduction

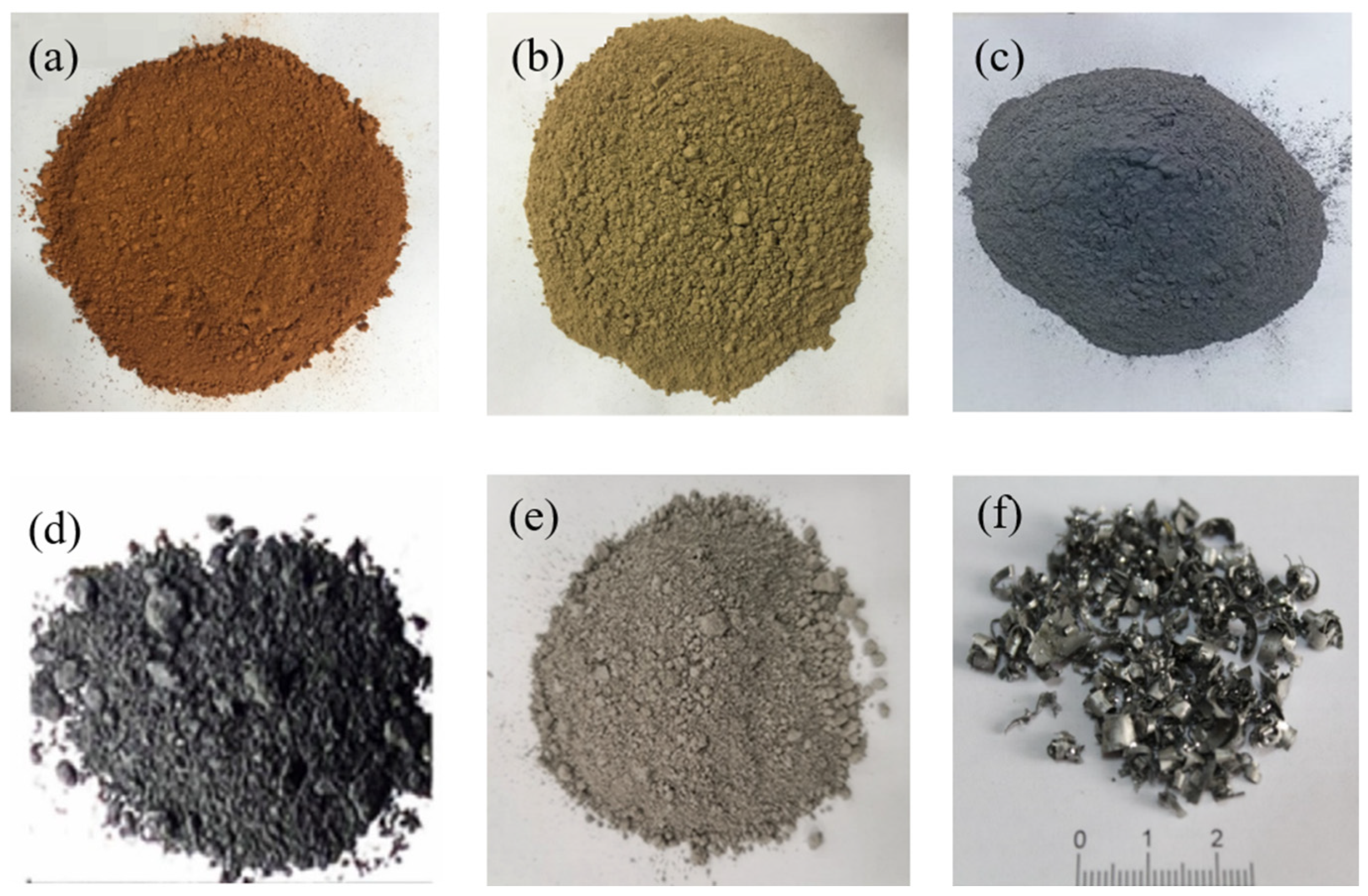

1.1. Red Mud

1.2. Aluminum Dross

1.3. Spent Pot Lining Residues

1.4. Secondary Aluminum Waste

2. Physicochemical and Mineralogical Properties of Various Aluminum Production Residues

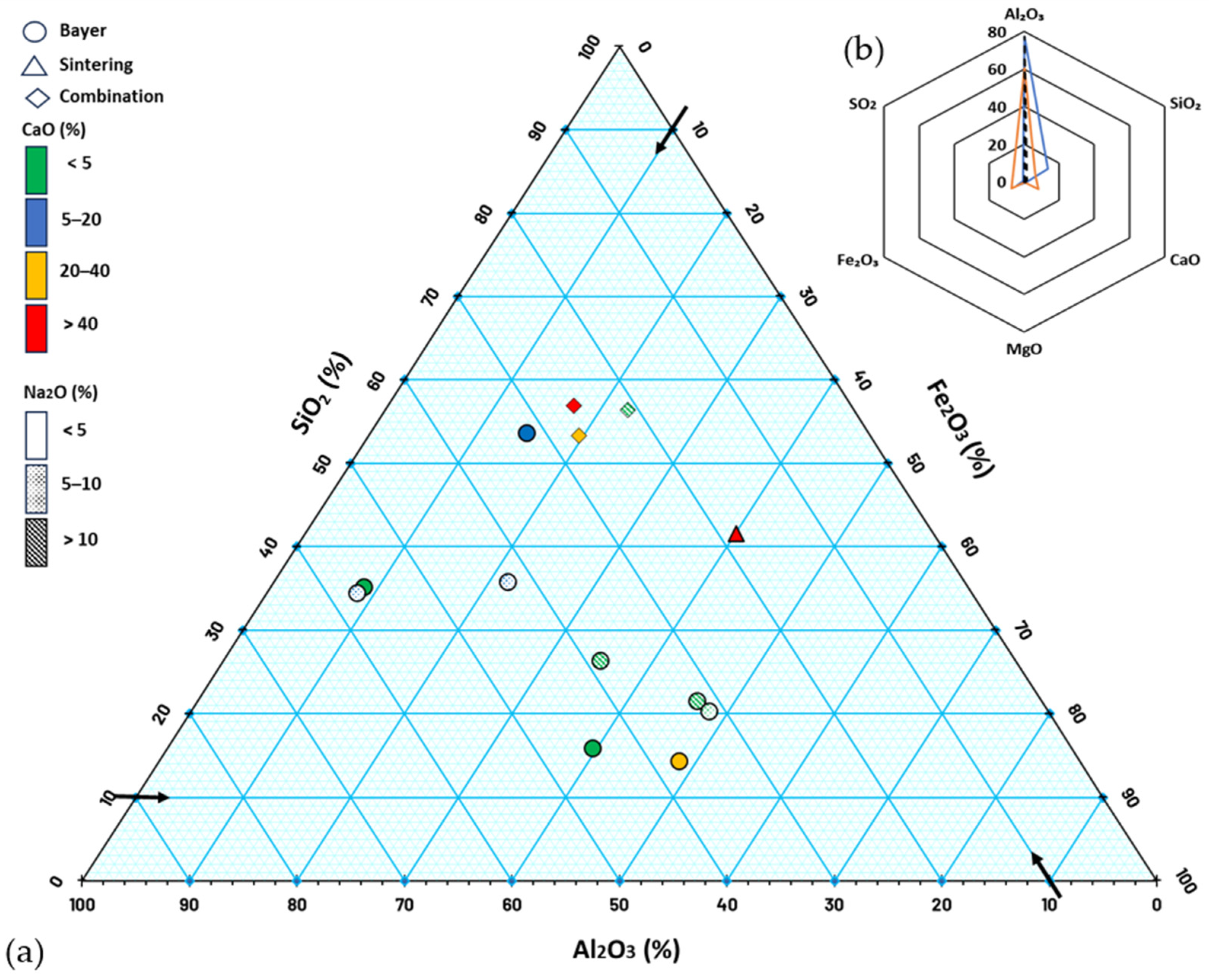

2.1. Chemical Composition of APRs

2.2. Mineralogical Properties

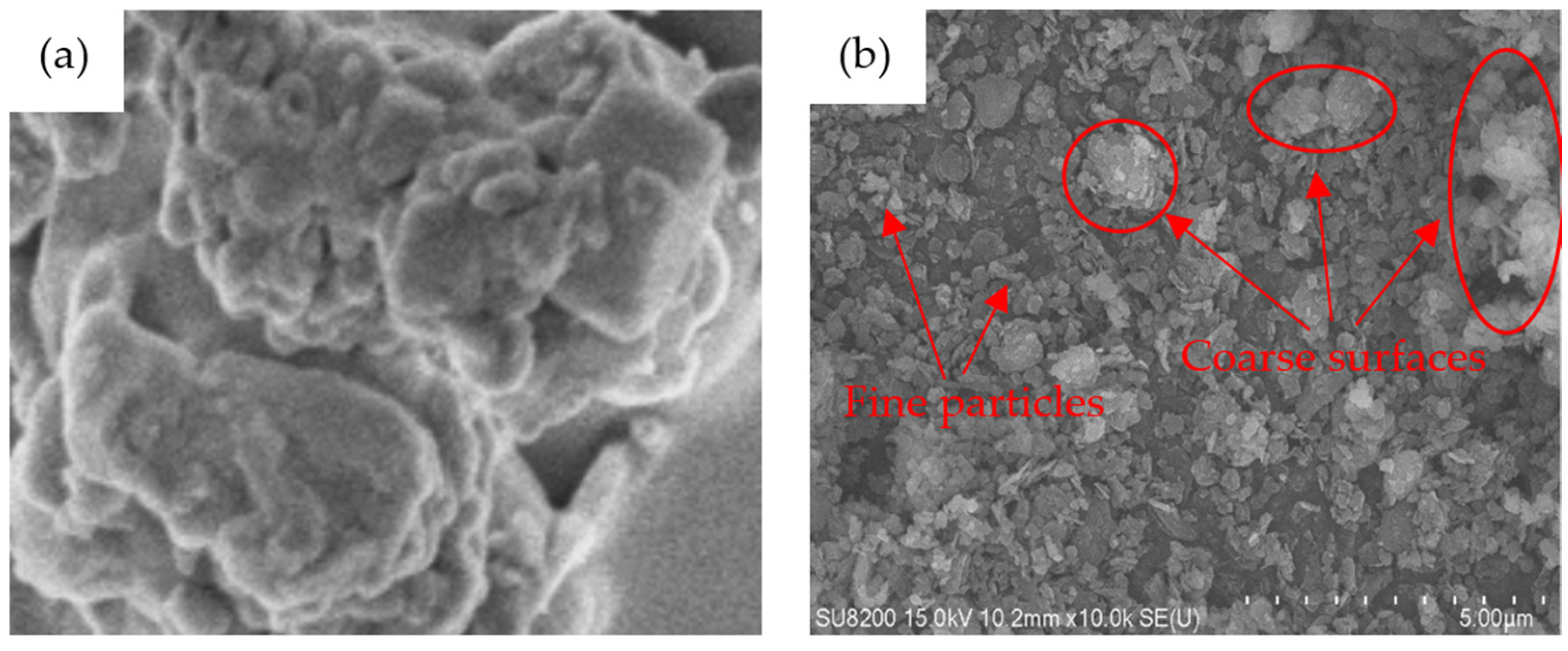

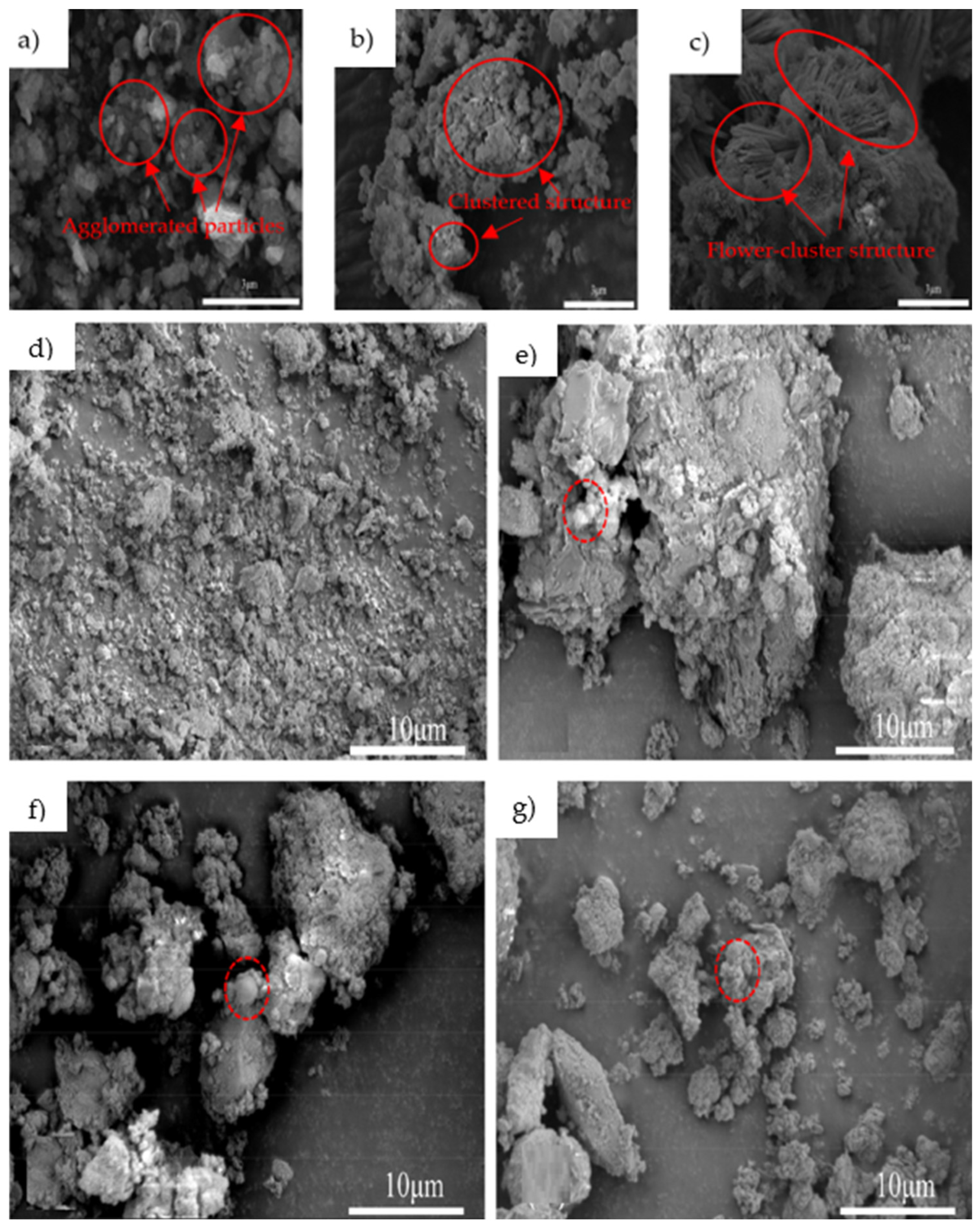

2.3. Microstructural Assessment

| APR Type | Specific Gravity (g/cm3) | Average Particle Size, d50 (μm) | Specific Surface Area, SSA (m2/g) | Rigden Void, RV (vol%) | Hydrophilic Coefficient, η | pH Range |

|---|---|---|---|---|---|---|

| RM | 3.10 [108,114], 3.50 [115], 2.60 [94], 2.97 [90], 2.80 [116], 2.55, 2.85 [91] | 4.50 [108], 3.33 [114], 2.75 [115], 6.50 [94], 7.20 [116] | 12.10 [117], 8.30 [116], 30.99, 35.41 [91] | 44.05 [114], 47.90 [94], 44.80 [116] | 0.85 [108], 0.47 [94], 0.70 [96], 0.62 [97] | 9.98 [108], 9.18 [114], 10.25 [109], 11.00 [115], 12.40 [116], 9.90, 10.00 [91] |

| AD | 2.90 [110], 2.79 [118] | 24.96 [110], 15.62 [119] | 1.03 [110], 1.26 [119] | 45.70 [110] | 0.67 [110] | - |

3. Valorization of APRs in Asphalt Binders (Microscale): Additive Applications

3.1. Use of RM as an Additive

3.2. Utilization of Other APRs as Modifiers

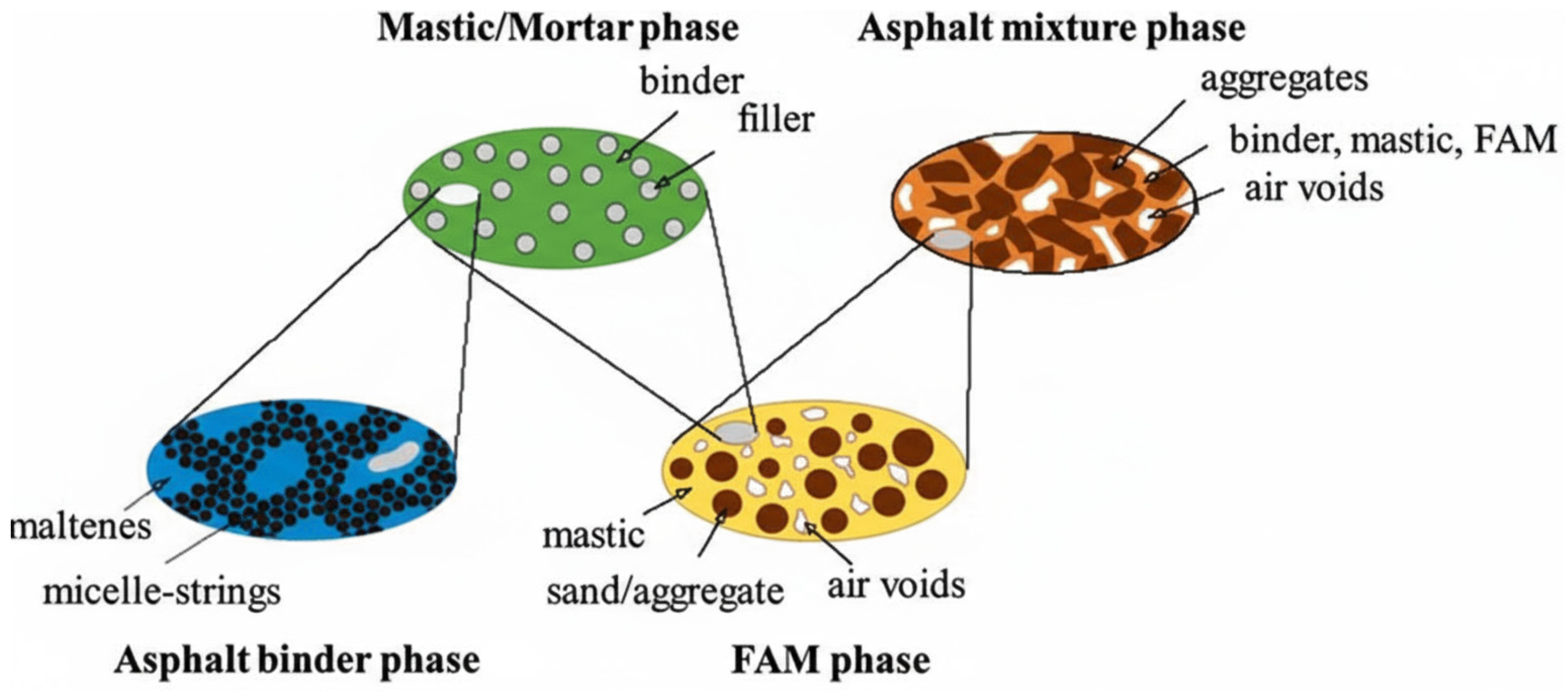

4. Studies on Asphalt Mastic (Mesoscale) and Binder–Filler Interactions

4.1. Conventional Physical Properties

4.2. Rotational Viscosity

4.3. Linear Viscoelastic Properties

4.4. Permanent Deformation (Rutting) Resistance

4.5. Fatigue Resistance

4.6. Resistance to Low-Temperature Cracking

4.7. Aging Resistance

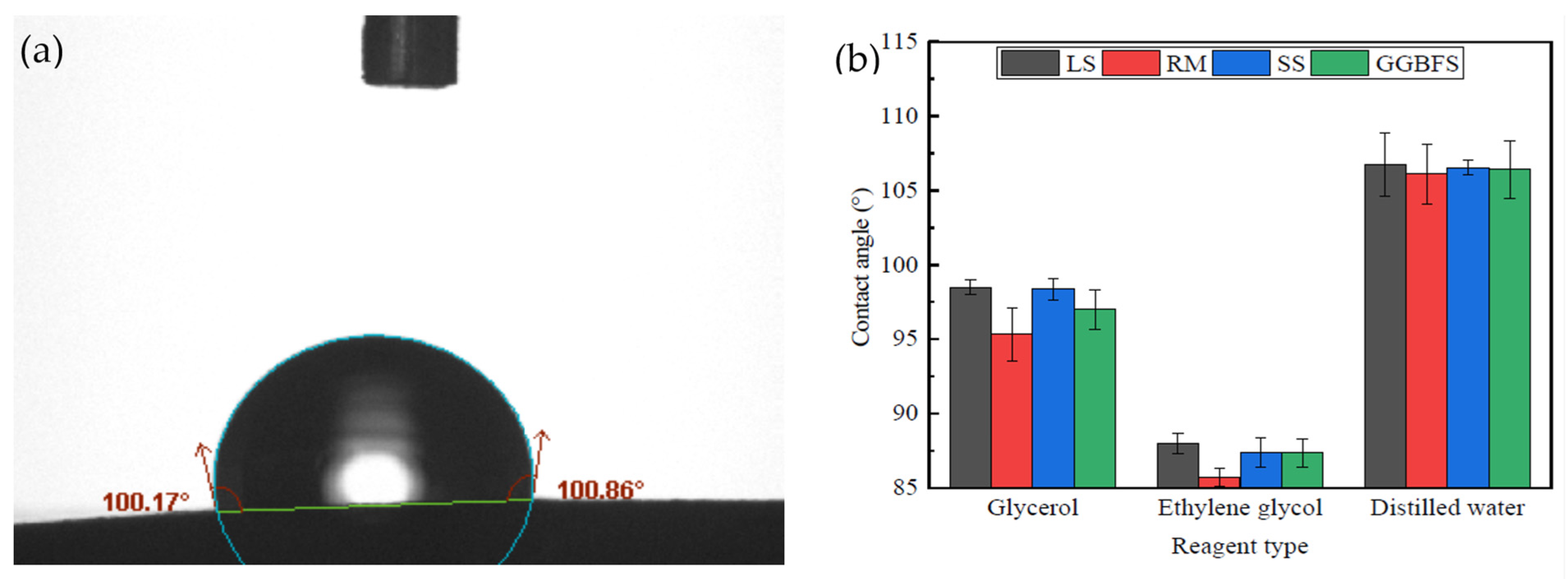

4.8. Bonding, Wettability, and Moisture Susceptibility

5. Valorization of APRs in Asphalt Mixtures (Macroscale)

5.1. Studies on RM Hot Mix Asphalt Samples

5.1.1. Volumetric Properties

5.1.2. Strength and Flow Measurement

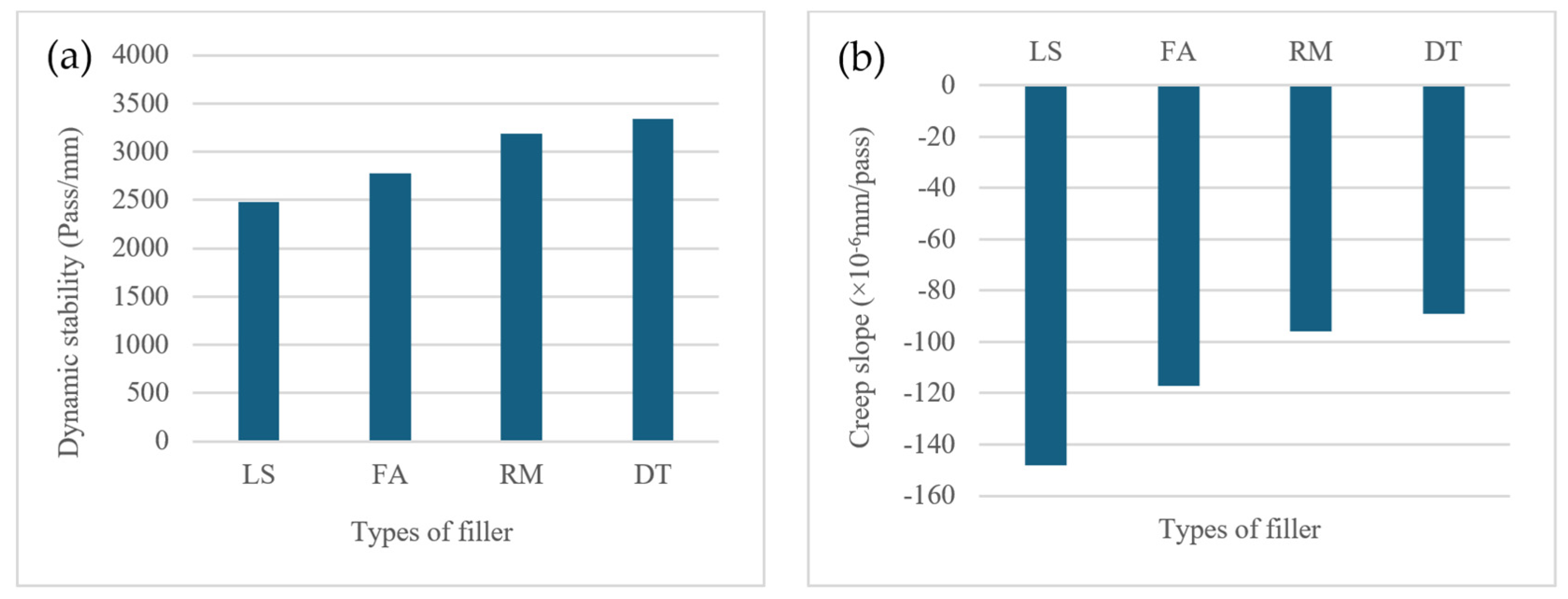

5.1.3. Permanent Deformation Resistance

5.1.4. Moisture Susceptibility

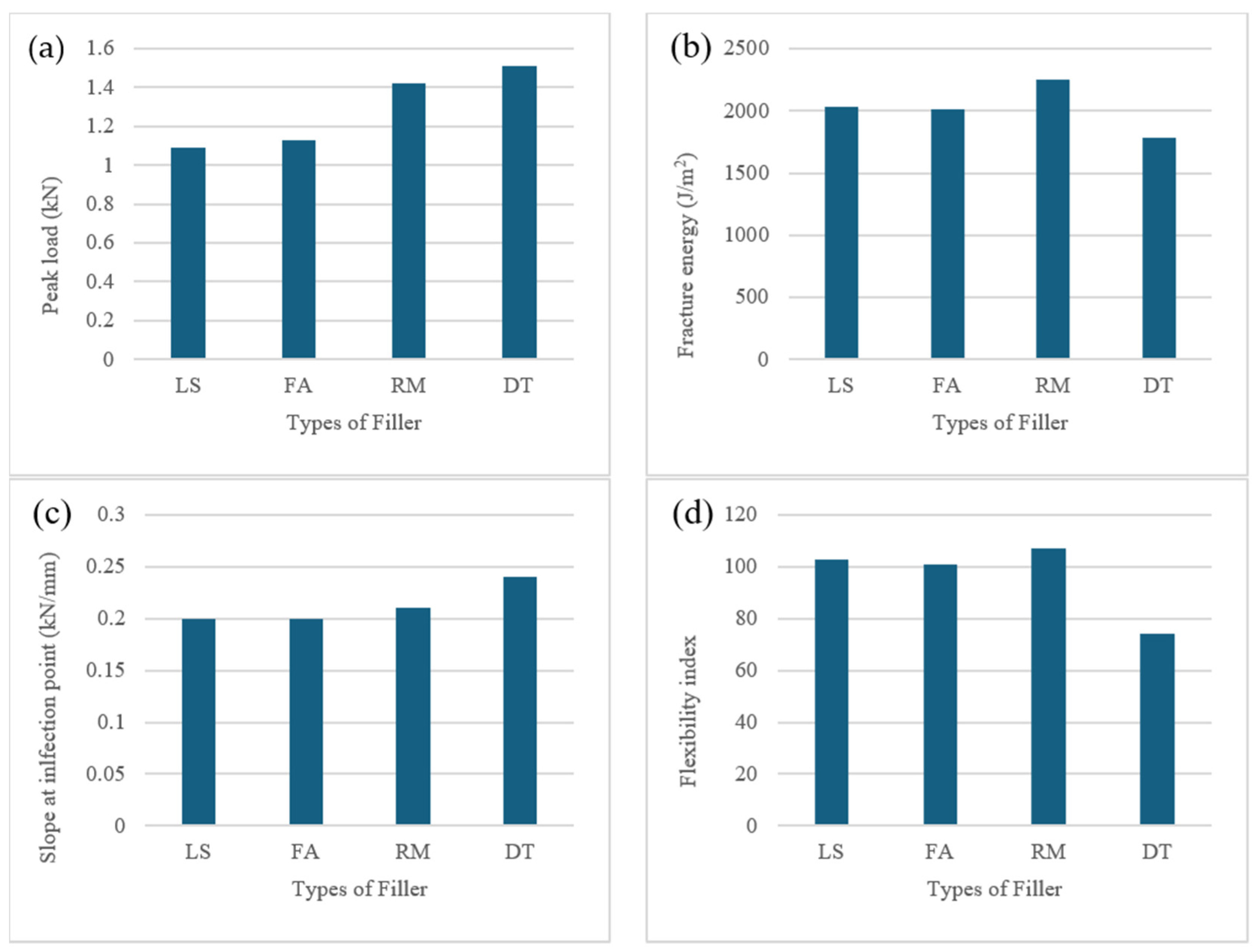

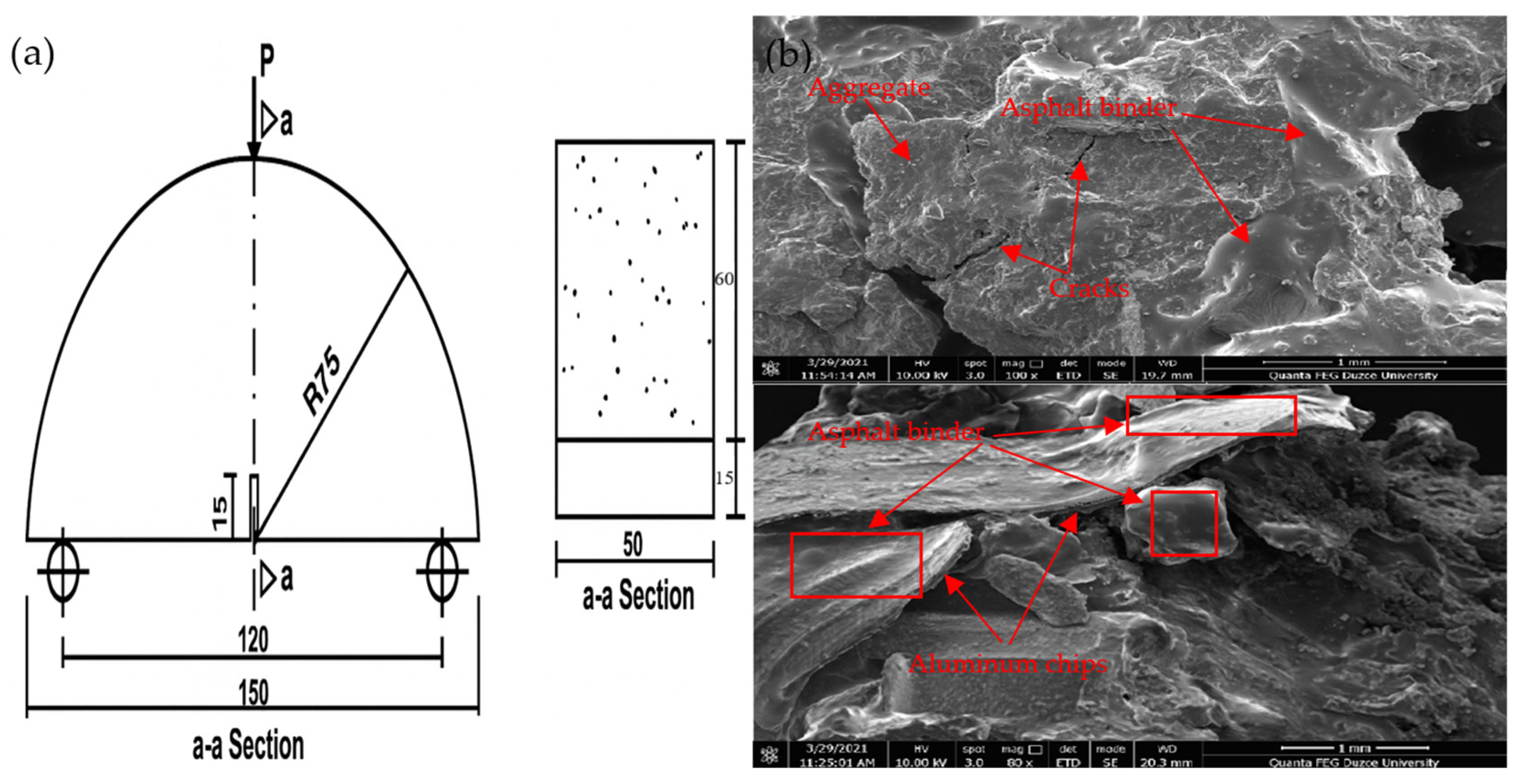

5.1.5. Tensile Strength and Cracking Resistance at Intermediate Temperatures

5.1.6. Adhesion and Bonding

5.1.7. Raveling Resistance

5.1.8. Aging Resistance

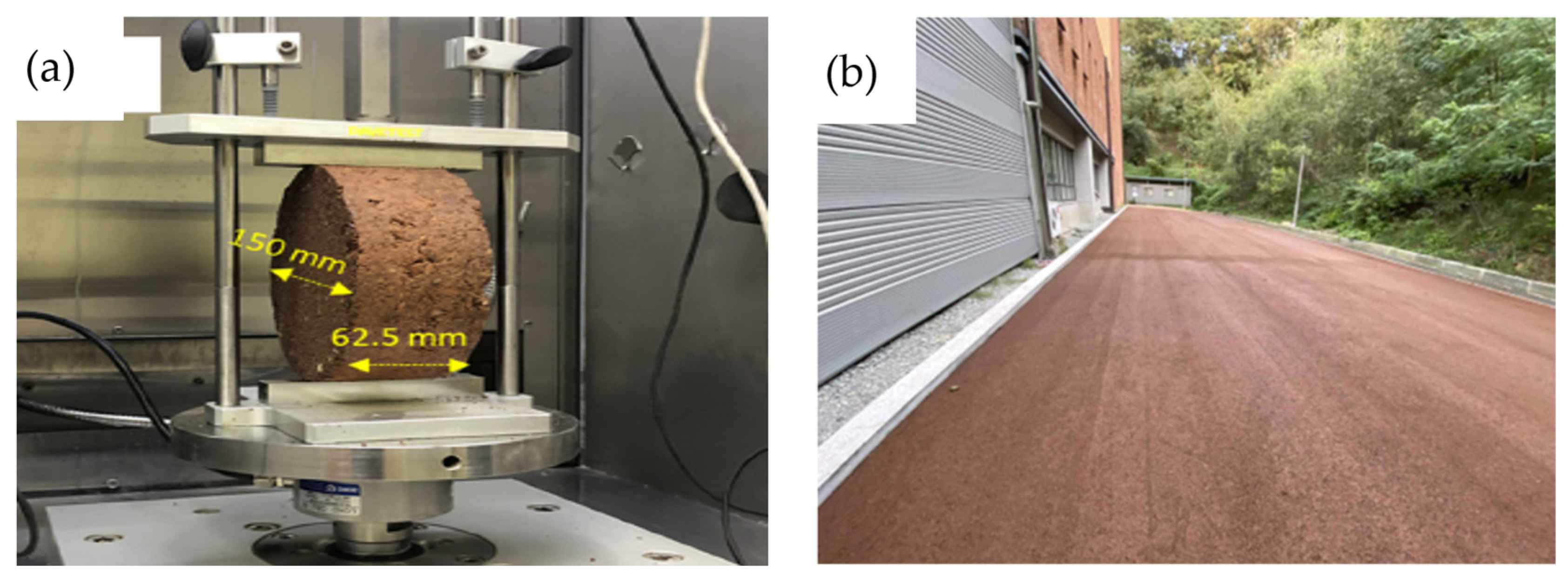

5.1.9. Valorization of RM in Alternative Asphalt Mixture Types

5.1.10. Environmental Aspects of RM Valorization

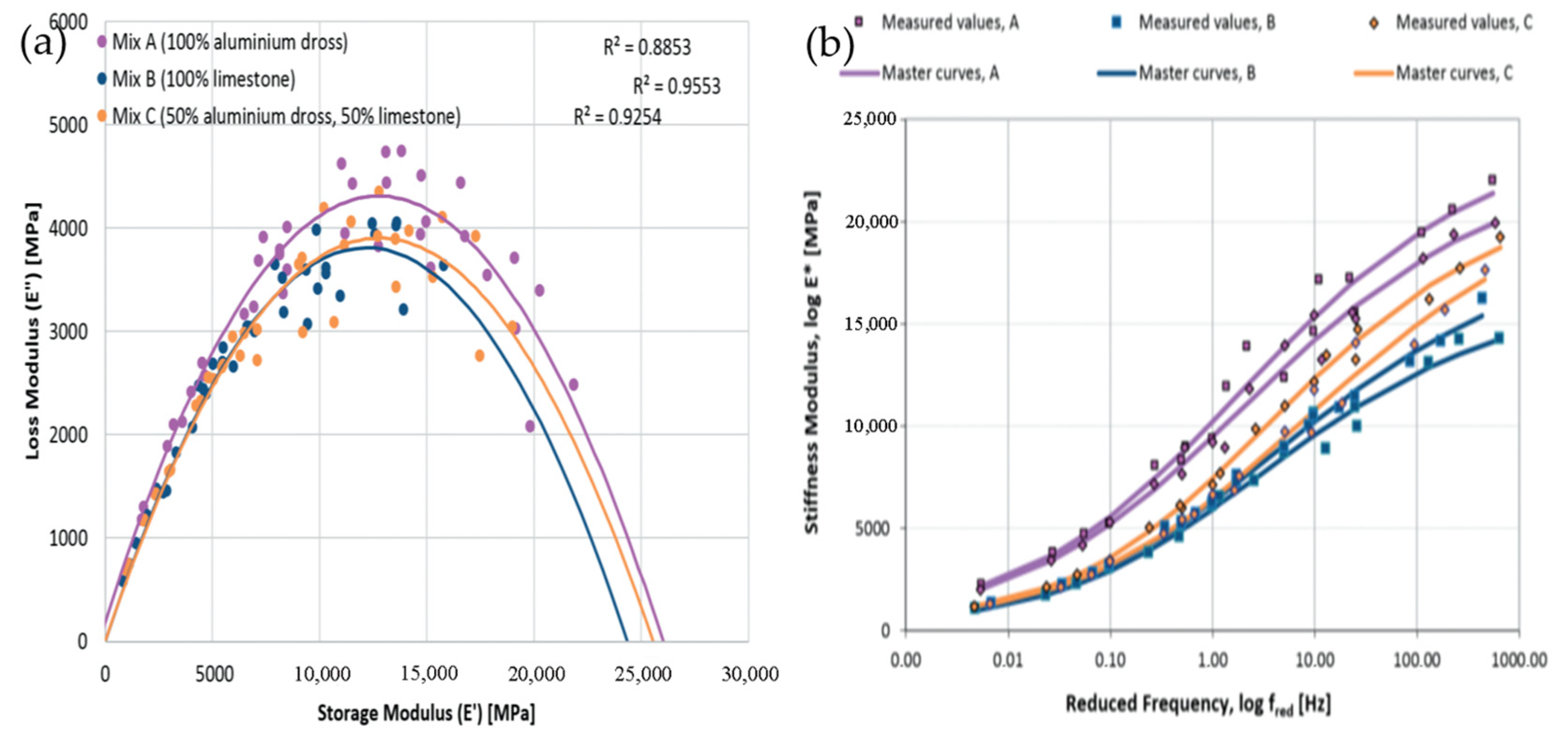

5.2. Utilization of Aluminum Dross in HMA

5.3. Incorporation of Aluminum Shavings in HMA

6. Challenges and Recommendations for Future Work

- Investigate the linkage between the physicochemical properties of APRs and the rheological and mechanical performance of bituminous materials using advanced analytical tools, such as machine learning. This will help in developing robust characterization protocols and classification systems for APRs and standardizing their application in mix design, construction, and quality assessment.

- Explore advanced surface modification techniques to enhance APR–asphalt binder compatibility, focusing on scalable, eco-friendly approaches that are feasible for large-scale applications.

- Study the incorporation of APRs at the FAM scale as a more precise approach compared to the mastic phase to simulate the performance of large-scale asphalt mixtures.

- Assess the feasibility of incorporating APRs into various asphalt mixture types—such as CMA and WMA—to achieve a more sustainable approach.

- Focus on the use of APRs in road pavements for cold regions by designing comprehensive experimental testing protocols tailored to these environmental conditions.

- Conduct life cycle assessments and life cycle cost analyses to evaluate the environmental and economic viability of APRs in large-scale industrial applications.

7. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hasan, A.; Hasan, U.; Whyte, A.; Al Jassmi, H. Lifecycle analysis of recycled asphalt pavements: Case study scenario analyses of an urban highway section. CivilEng 2022, 3, 242–262. [Google Scholar] [CrossRef]

- Ahmed, W.; Lu, G.; Ng, S.T.; Liu, G. Innovative valorization of solid waste materials for production of sustainable low-carbon pavement: A systematic review and scientometric analysis. Case Stud. Constr. Mater. 2025, 22, e04541. [Google Scholar] [CrossRef]

- Tsakoumaki, M.; Plati, C. A critical overview of using reclaimed asphalt pavement (RAP) in road pavement construction. Infrastructures 2024, 9, 128. [Google Scholar] [CrossRef]

- Fanijo, E.O.; Kolawole, J.T.; Babafemi, A.J.; Liu, J. A comprehensive review on the use of recycled concrete aggregate for pavement construction: Properties, performance, and sustainability. Clean. Mater. 2023, 9, 100199. [Google Scholar] [CrossRef]

- Zeleke, Y.S.; Tsegaye, D.B. Investigating the Effect of Crumb Rubber Using as an Aggregate in the Hot Mix Asphalt Mixture Properties. In Sustainable Development Research in Green Infrastructure, Water Resources, Manufacturing, and Process Engineering: Advancements of Science and Technology; Springer Nature: Cham, Switzerland, 2025; pp. 429–450. [Google Scholar]

- Russo, F.; Veropalumbo, R.; Pontoni, L.; Oreto, C.; Biancardo, S.A.; Viscione, N.; Pirozzi, F.; Race, M. Sustainable asphalt mastics made up recycling waste as filler. J. Environ. Manag. 2022, 301, 113826. [Google Scholar] [CrossRef] [PubMed]

- Nassar, A.I.; Mohammed, M.K.; Thom, N.; Parry, T. Characterisation of high-performance cold bitumen emulsion mixtures for surface courses. Int. J. Pavement Eng. 2018, 19, 509–518. [Google Scholar] [CrossRef]

- Al-Hdabi, A. Laboratory investigation on the properties of asphalt concrete mixture with Rice Husk Ash as filler. Constr. Build. Mater. 2016, 126, 544–551. [Google Scholar] [CrossRef]

- Arabani, M.; Tahami, S.A.; Taghipoor, M. Laboratory investigation of hot mix asphalt containing waste materials. Road Mater. Pavement Des. 2017, 18, 713–729. [Google Scholar] [CrossRef]

- Kütük-Sert, T.; Kütük, S. Physical and Marshall properties of borogypsum used as filler aggregate in asphalt concrete. J. Mater. Civil. Eng. 2013, 25, 266–273. [Google Scholar] [CrossRef]

- Nie, Q.; Hu, W.; Ai, T.; Huang, B.; Shu, X.; He, Q. Strength properties of geopolymers derived from original and desulfurized red mud cured at ambient temperature. Constr. Build. Mater. 2016, 125, 905–911. [Google Scholar] [CrossRef]

- Kumar, B.R.; Ramakrishna, G. Performance evaluation of red mud as a construction material—A review. Mater. Today Proc. 2023, 84, 263–278. [Google Scholar]

- Brunori, C.; Cremisini, C.; Massanisso, P.; Pinto, V.; Torricelli, L. Reuse of a treated red mud bauxite waste: Studies on environmental compatibility. J. Hazard. Mater. 2005, 117, 55–63. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Yao, Z.; Wang, K.; Wang, F.; Jiang, H.; Liang, M.; Wei, J.; Airey, G. Sustainable utilization of bauxite residue (Red. Mud) as a road material in pavements: A critical review. Constr. Build. Mater. 2021, 270, 121419. [Google Scholar] [CrossRef]

- Harmaji, A.; Jafari, R.; Simard, G. Valorization of residue from aluminum industries: A review. Materials 2024, 17, 5152. [Google Scholar] [CrossRef]

- Reddy, P.S.; Reddy, N.G.; Serjun, V.Z.; Mohanty, B.; Das, S.K.; Reddy, K.R.; Rao, B.H. Properties and assessment of applications of red mud (bauxite residue): Current status and research needs. Waste Biomass Valorization 2021, 12, 1185–1217. [Google Scholar] [CrossRef]

- Sun, C.; Chen, J.; Tian, K.; Peng, D.; Liao, X.; Wu, X. Geochemical characteristics and toxic elements in alumina refining wastes and leachates from management facilities. Int. J. Environ. Res. Public Health 2019, 16, 1297. [Google Scholar] [CrossRef]

- Bánvölgyi, G.; Huan, T.M.; Director, F. De-watering, disposal and utilization of red mud: State of the art and emerging technologies. TRAVAUX 2010, 35, 431–443. [Google Scholar]

- Evans, K. The history, challenges, and new developments in the management and use of bauxite residue. J. Sustain. Metall. 2016, 2, 316–331. [Google Scholar] [CrossRef]

- Wang, L.; Hu, G.; Lyu, F.; Yue, T.; Tang, H.; Han, H.; Yang, Y.; Liu, R.; Sun, W. Application of red mud in wastewater treatment. Minerals 2019, 9, 281. [Google Scholar] [CrossRef]

- Hua, Y.; Heal, K.V.; Friesl-Hanl, W. The use of red mud as an immobiliser for metal/metalloid-contaminated soil: A review. J. Hazard. Mater. 2017, 325, 17–30. [Google Scholar] [CrossRef]

- Mukiza, E.; Zhang, L.; Liu, X.; Zhang, N. Utilization of red mud in road base and subgrade materials: A review. Resour. Conserv. Recycl. 2019, 141, 187–199. [Google Scholar] [CrossRef]

- Deelwal, K.; Dharavath, K.; Kulshreshtha, M. Evaluation of characteristic properties of red mud for possible use as a geotechnical material in civil construction. Int. J. Adv. Eng. Technol. 2014, 7, 1053. [Google Scholar]

- Molineux, C.J.; Newport, D.J.; Ayati, B.; Wang, C.; Connop, S.P.; Green, J.E. Bauxite residue (red mud) as a pulverised fuel ash substitute in the manufacture of lightweight aggregate. J. Clean. Prod. 2016, 112, 401–408. [Google Scholar] [CrossRef]

- Xu, Y.T.; Yang, B.; Liu, X.M.; Gao, S.; Li, D.S.; Mukiza, E.; Li, H.J. Investigation of the medium calcium based non-burnt brick made by red mud and fly ash: Durability and hydration characteristics. Int. J. Miner. Metall. Mater. 2019, 26, 983–991. [Google Scholar] [CrossRef]

- Liu, T.; Li, X.; Guan, L.; Liu, P.; Wu, T.; Li, Z.; Lu, A. Low-cost and environment-friendly ceramic foams made from lead–zinc mine tailings and red mud: Foaming mechanism, physical, mechanical and chemical properties. Ceram. Int. 2016, 42, 1733–1739. [Google Scholar] [CrossRef]

- Sglavo, V.M.; Maurina, S.; Conci, A.; Salviati, A.; Carturan, G.; Cocco, G. Bauxite ‘red mud’in the ceramic industry. Part. 2: Production of clay-based ceramics. J. Eur. Ceram. Soc. 2000, 20, 245–252. [Google Scholar] [CrossRef]

- Tang, W.C.; Wang, Z.; Liu, Y.; Cui, H.Z. Influence of red mud on fresh and hardened properties of self-compacting concrete. Constr. Build. Mater. 2018, 178, 288–300. [Google Scholar] [CrossRef]

- Ghalehnovi, M.; Roshan, N.; Hakak, E.; Shamsabadi, E.A.; De Brito, J. Effect of red mud (bauxite residue) as cement replacement on the properties of self-compacting concrete incorporating various fillers. J. Clean. Prod. 2019, 240, 118213. [Google Scholar] [CrossRef]

- Singh, V.; Bano, S.; Chauhan, V.B.; Pal, P.; Kumar, A.; Srivastava, J.B. Red mud as a sustainable road construction material: An. experimental investigation. Constr. Build. Mater. 2024, 411, 134549. [Google Scholar] [CrossRef]

- Mudgal, M.; Singh, A.; Chouhan, R.K.; Acharya, A.; Srivastava, A.K. Fly. ash red mud geopolymer with improved mechanical strength. Clean. Eng. Technol. 2021, 4, 100215. [Google Scholar] [CrossRef]

- Li, Y.; Min, X.; Ke, Y.; Liu, D.; Tang, C. Preparation of red mud-based geopolymer materials from MSWI fly ash and red mud by mechanical activation. Waste Manag. 2019, 83, 202–208. [Google Scholar] [CrossRef]

- Sun, Z.; Tang, Q.; Xakalashe, B.S.; Fan, X.; Gan, M.; Chen, X.; Ji, Z.; Huang, X.; Friedrich, B. Mechanical and environmental characteristics of red mud geopolymers. Constr. Build. Mater. 2022, 321, 125564. [Google Scholar] [CrossRef]

- Harmaji, A.; Jafari, R.; Simard, G. Durable bauxite-residue geopolymers: Enhancing scaling resistance with fly ash and waste glass powder. Constr. Build. Mater. 2025, 491, 142661. [Google Scholar] [CrossRef]

- Sahoo, S.; Mohanty, C. Construction of road sub-base by using industrial waste. Int. J. Eng. Res. Dev. 2016, 3, 20–26. [Google Scholar]

- Singh, K.; Pandey, R.K.; Mishra, C.S.; Rai, A.K.; Bind, Y.K. Analysis on utilization of cement kiln dust stabilized red mud for road construction. Int. J. Civil. Eng. Technol. 2014, 5, 56–61. [Google Scholar]

- Satayanarayana, P.V.V.; Naidu, G.; Adiseshu, S.; Rao, C. Characterization of lime stabilized red mud mix for feasibility in road construction. Int. J. Eng. Res. Dev. 2012, 3, 20–26. [Google Scholar]

- Liu, X.M.; Tang, B.W.; Yin, H.F.; Emile, M. Durability and environmental performance of Bayer. red mud-coal gangue-based road base material. Chin. J. Eng. 2018, 40, 438–445. [Google Scholar]

- Wong, T.L.X.; Hasan, M.R.M.; Peng, L.C. Recent development, utilization, treatment and performance of solid wastes additives in asphaltic concrete worldwide: A review. J. Traffic Transp. Eng. 2022, 9, 693–724. [Google Scholar]

- Wilson, S. Residues from Aluminium Dross Recycling in Cement; Citeseer: University Park, PA, USA, 2007. [Google Scholar]

- Hwang, J. Recovery of metals from aluminum dross and saltcake. J. Miner. Mater. Charact. Eng. 2006, 5, 47. [Google Scholar] [CrossRef]

- Muñoz Perez, S.P.; Garcia Chumacero, J.M.; Charca Mamani, S.; Villena Zapata, L.I. Influence of the secondary aluminum chip on the physical and mechanical properties of concrete. Innov. Infrastruct. Solut. 2023, 8, 45. [Google Scholar]

- Mahinroosta, M.; Allahverdi, A. Hazardous aluminum dross characterization and recycling strategies: A critical review. J. Environ. Manag. 2018, 223, 452–468. [Google Scholar] [CrossRef]

- Udvardi, B.; Géber, R.; Kocserha, I. Examination of the utilization of aluminum dross in road construction. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Hiroshima, Japan, 26–28 March 2019; IOP Publishing: Bristol, UK. [Google Scholar]

- Busari, A.; Joseph, F.; Ajayi, S.; Alayande, T.; Nwachukwu, J.; Agbama, D. Index properties of aluminum dross modified pavement geo-material. J. Phys. Conf. Series. 2019, 1378, 022102. [Google Scholar] [CrossRef]

- Lou, B.; Shen, H.; Liu, B.; Liu, J.; Zhang, S. Recycling secondary aluminum dross to make building materials: A review. Constr. Build. Mater. 2023, 409, 133989. [Google Scholar] [CrossRef]

- Ewais, E.M.; Besisa, N.H. Tailoring of magnesium aluminum titanate based ceramics from aluminum dross. Mater. Des. 2018, 141, 110–119. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, J.; Shen, H.; Zhang, J.; Li, W.; Zhang, X.; Liu, J.; Liu, B.; Zhang, S. Synthesis of porous glass ceramics with hierarchical and interconnected pores from secondary aluminum dross and waste glass. Ceram. Int. 2022, 48, 34364–34373. [Google Scholar] [CrossRef]

- Ni, H.; Wu, W.; Lv, S.; Wang, X.; Tang, W. Formulation of non-fired bricks made from secondary aluminum ash. Coatings 2021, 12, 2. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Li, S.Z.; Wang, L.L.; Li, M.K.; Huang, K.P.; Wu, W.; Liu, J.; Yi, X.M. Preparation of Aluminum Dross Microporous Bricks and the Pore Formation Mechanisms. JOM 2023, 75, 4701–4713. [Google Scholar] [CrossRef]

- Parra-Molina, D.; Rojas-Manzano, M.A.; Gómez-Gómez, A.; Muñoz-Vélez, M.F.; Maury-Ramírez, A. Mechanical Performance of Mortars with Partial. Replacement of Cement by Aluminum Dross: Inactivation and Particle Size. Sustainability 2023, 15, 14224. [Google Scholar] [CrossRef]

- Elinwa, A.U.; Mbadike, E. The use of aluminum waste for concrete production. J. Asian Archit. Build. Eng. 2011, 10, 217–220. [Google Scholar] [CrossRef]

- Javali, S.; Chandrashekar, A.R.; Naganna, S.R.; Manu, D.S.; Hiremath, P.; Preethi, H.G.; Vinod Kumar, N. Eco-concrete for sustainability: Utilizing aluminium dross and iron slag as partial replacement materials. Clean Technol. Environ. Policy 2017, 19, 2291–2304. [Google Scholar] [CrossRef]

- Reddy, M.S.; Neeraja, D. Mechanical and durability aspects of concrete incorporating secondary aluminium slag. Resour.-Effic. Technol. 2016, 2, 225–232. [Google Scholar]

- Busari, A.A.; Akinwumi, I.I.; Awoyera, P.O.; Olofinnade, O.M.; Tenebe, T.I.; Nwanchukwu, J.C. Stabilization effect of aluminum dross on tropical lateritic soil. Int. J. Eng. Res. Afr. 2018, 39, 86–96. [Google Scholar] [CrossRef]

- Zhou, L.; Yao, Z.; Sun, K.; Tian, Z.; Li, J.; Zhong, Q. Methodological Review of Methods and Technology for Utilization of Spent Carbon Cathode in Aluminum Electrolysis. Energies 2024, 17, 4866. [Google Scholar] [CrossRef]

- Tu, H.; Li, X.; Muhammad, Y.; Jin, X.; Lin, H.; Pei, R.; Zhao, Z.; Li, J. Feasibility of reuse of modified electrolytic aluminium spent refractory material in asphalt and assessment of its environmental stability. J. Clean. Prod. 2023, 389, 136072. [Google Scholar] [CrossRef]

- Birry, L.; Poirier, S. The LCL&L process: A sustainable solution for the treatment and recycling of spent pot lining. Light Met. 2020, 2020, 1237–1242. [Google Scholar]

- Zhao, X.; Ma, L. Hazardous waste treatment for spent pot liner. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Kolaka, Indonesia, 7–9 February 2018; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Choubisa, S.L.; Choubisa, D. Status of industrial fluoride pollution and its diverse adverse health effects in man and domestic animals in India. Environ. Sci. Pollut. Res. 2016, 23, 7244–7254. [Google Scholar] [CrossRef]

- Lisbona, D.F.; Somerfield, C.; Steel, K.M. Leaching of spent pot-lining with aluminum anodizing wastewaters: Fluoride extraction and thermodynamic modeling of aqueous speciation. Ind. Eng. Chem. Res. 2012, 51, 8366–8377. [Google Scholar] [CrossRef]

- Nunez, P. Sustainable spent pot line management guidance. Light Met. 2020, 2020, 1225–1230. [Google Scholar]

- Camara, N.; Ouellet-Plamondon, C. Scenarios to Valorize Treated Spent Pot Lining in Cement and Concrete. In Proceedings of the Canadian Society of Civil Engineering Annual Conference, Niagara Falls, ON, Canada, 26–29 May 2021; Springer: Singapore, 2021. [Google Scholar]

- Wallace, G. Production of secondary aluminium. Fundam. Alum. Metallurgy 2011, 70–82. [Google Scholar]

- Aleksić, J.; Vargas, D.B. Aluminium Demand Will Rise 40% by 2030, Here’s How to Make It Sustainable. World Economic Forum. Available online: https://www.weforum.org/agenda/2023/11/aluminium-demand-how-to-make-it-sustainable/ (accessed on 28 November 2023).

- Elsayed, M.; Abd-Allah, S.R.; Said, M.; El-Azim, A.A. Structural performance of recycled coarse aggregate concrete beams containing waste glass powder and waste aluminum fibers. Case Stud. Constr. Mater. 2023, 18, e01751. [Google Scholar] [CrossRef]

- Ofuyatan, O.M.; Ivoke, A.A.; Olowofoyeku, A.M.; Adesina, A.; Oluwafemi, J. Effect of waste aluminium shavings on the bond characteristics of laterized concrete. Adv. Mater. Res. 2019, 8, 25–36. [Google Scholar]

- Yusuf, M.O. Performance of aluminium shaving waste and silica fume blended mortar. Mag. Civil Eng. 2023, 122, 100–112. [Google Scholar]

- Filazi, A.; Yilmazel, R.; Pul, M. The Effect of Material Ratios on Technical Properties in Fly Ash and Blast Furnace Slag Based Aluminum Chip Reinforced Geopolymer Mortars. Int. Conf. Pioneer Innov. Stud. 2023, 1, 344–350. [Google Scholar] [CrossRef]

- Gulmez, N. Roles of aluminium shavings and calcite on engineering properties of cement-based composites. J. Clean. Prod. 2020, 277, 124104. [Google Scholar] [CrossRef]

- Ahmed, L.S.A.; Mahmood, L.O.T. Influence of Mineral fibers Properties on the performance of Hot Mix Asphalt for the Surface Layer of Pavement. Department of Civil Engineering, Faculty of Engineering, Koya University, Erbil, Iraq. Int. J. Eng. Trends Technol. 2015, 26, 145–151. [Google Scholar] [CrossRef]

- Lackner, R.; Spiegl, M.; Blab, R.; Eberhardsteiner, J. Is low-temperature creep of asphalt mastic independent of filler shape and mineralogy?—Arguments from multiscale analysis. J. Mater. Civil. Eng. 2005, 17, 485–491. [Google Scholar] [CrossRef]

- Salehfard, R.; Behbahani, H.; Dalmazzo, D.; Santagata, E. Effect of colloidal instability on the rheological and fatigue properties of asphalt binders. Constr. Build. Mater. 2021, 281, 122563. [Google Scholar] [CrossRef]

- Salehfard, R.; Yeganeh, S.; Dalmazzo, D.; Underwood, B.S.; Santagata, E. Linking chemical structure to the linear and nonlinear properties of asphalt binders. Transp. Res. Rec. 2024, 2678, 1483–1495. [Google Scholar] [CrossRef]

- EN 12697–2 (2015); Bituminous Mixtures-Test Methods-Part 2: Determination of Particle Size Distribution. European Committee for Standardization: Brussels, Belgium, 2015.

- Wang, D.; Cannone Falchetto, A.; Zhang, F.; Riccardi, C.; Sun, Y. Fabrication and characterization of multiphase bituminous materials for cold region pavements. J. Infrastruct. Preserv. Resil. 2023, 4, 22. [Google Scholar] [CrossRef]

- Behbahani, H.; Salehfard, R. A review of studies on asphalt fine aggregate matrix. Arab. J. Sci. Eng. 2021, 46, 10289–10312. [Google Scholar] [CrossRef]

- Arabani, M.; Mirabdolazimi, S. Experimental investigation of the fatigue behaviour of asphalt concrete mixtures containing waste iron powder. Mater. Sci. Eng. A 2011, 528, 3866–3870. [Google Scholar] [CrossRef]

- Ullah, S.; Yang, C.; Cao, L.; Wang, P.; Chai, Q.; Li, Y.; Wang, L.; Dong, Z.; Lushinga, N.; Zhang, B. Material design and performance improvement of conductive asphalt concrete incorporating carbon fiber and iron tailings. Constr. Build. Mater. 2021, 303, 124446. [Google Scholar] [CrossRef]

- He, Y.; Zeng, Q.; Liu, Y.; Liu, P.; Zeng, Y.; Xu, Z.; Liu, Q. Evaluation of the Composite Mechanism of Nano-Fe2O3/Asphalt Based on Molecular Simulation and Experiments. Materials 2021, 14, 3425. [Google Scholar] [CrossRef] [PubMed]

- Sherre, T.K.; Liao, M.-C. Characteristics of recycled mineral fillers and their effects on the mechanical properties of hot-mix asphalt when used as limestone filler replacements. J. Mater. Civil Eng. 2022, 34, 04021395. [Google Scholar] [CrossRef]

- Zhu, S.; Kong, L.; Peng, Y.; Chen, Y.; Zhao, T.; Jian, O.; Zhao, P.; Sheng, X.; Li, Z. Mechanisms of interface electrostatic potential induced asphalt-aggregate adhesion. Constr. Build. Mater. 2024, 438, 137255. [Google Scholar] [CrossRef]

- Du, Z.; Zhu, X. Molecular dynamics simulation to investigate the adhesion and diffusion of asphalt binder on aggregate surfaces. Transp. Res. Rec. 2019, 2673, 500–512. [Google Scholar] [CrossRef]

- Yao, L.; Gao, W.; Ma, X.; Fu, H. Properties analysis of asphalt binders containing Bayer. red mud. Materials 2020, 13, 1122. [Google Scholar] [CrossRef]

- Padhan, A.; Paul, B. Unlocking the potential of red mud: Advanced strategies for economic optimization and sustainable recovery of critical minerals. J. Environ. Manag. 2025, 389, 126040. [Google Scholar] [CrossRef]

- Shen, H.; Liu, B.; Ekberg, C.; Zhang, S. Harmless disposal and resource utilization for secondary aluminum dross: A review. Sci. Total Environ. 2021, 760, 143968. [Google Scholar] [CrossRef]

- Mintsis, M.Y.; Galevsky, G.V.; Rudneva, V.V.; Galevsky, S.G. Formation and emission of sulfur dioxide in aluminum production. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bangkok, Thailand, 24–26 February 2018; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Meng, Y.; Huang, J.; Lai, J.; Li, Y.; Pan, Z.; Lu, T. Feasibility and synergies of aluminum electrolysis spent refractory material and graphene oxide for rubber modified asphalt mixture. Constr. Build. Mater. 2025, 481, 141647. [Google Scholar] [CrossRef]

- Li, X.; Ren, D.; Fan, S.; Lin, Z.; Meng, F.; Wu, H.; Li, J. Synthesis of gel crosslinked composite material from spent cathode carbon blocks and its application in modified asphalt binders. J. Clean. Prod. 2024, 434, 140253. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H.; Zhang, Y.; Wang, D.; Harvey, J.; Wang, H. Performance enhancement of porous asphalt pavement using red mud as alternative filler. Constr. Build. Mater. 2018, 160, 707–713. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, S.; Yao, Z.; Wu, S.; Jiang, H.; Liang, M.; Qiao, Y. Environmental aspects and pavement properties of red mud waste as the replacement of mineral filler in asphalt mixture. Constr. Build. Mater. 2018, 180, 605–613. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H.; Abdelhady, A.; Mo, D.; Yang, B.; Harvey, J. Optimum filler–bitumen ratio of asphalt mortar considering self-healing property. J. Mater. Civil Eng. 2019, 31, 04019166. [Google Scholar] [CrossRef]

- Lima, M.S.S.; Thives, L.P. Mechanical feasibility of using red mud as filler in asphalt mixtures to improve permanent deformation. Transportes 2020, 28, 1–13. [Google Scholar] [CrossRef]

- Tian, Y.; Sun, L.; Li, H.; Zhang, H.; Harvey, J.; Yang, B.; Zhu, Y.; Yu, B.; Fu, K. Laboratory investigation on effects of solid waste filler on mechanical properties of porous asphalt mixture. Constr. Build. Mater. 2021, 279, 122436. [Google Scholar] [CrossRef]

- Ou, L.; Zhu, H.; Chen, R.; Su, C.; Yang, X. Effect of industrial solid waste as fillers on the rheology and surface free energy of asphalt mastic. Materials 2024, 17, 1125. [Google Scholar] [CrossRef]

- Wu, D.; Yin, Y.; Fu, T.; Liu, F. Simulation study on basic road performance and modification mechanism of red mud modified asphalt mixture. Sci. Eng. Compos. Mater. 2024, 31, 20240003. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, C.; Li, P.; Liang, M.; Jiang, H.; Yao, Z. Experimental study on rheological properties and moisture susceptibility of asphalt mastic containing red mud waste as a filler substitute. Constr. Build. Mater. 2019, 211, 159–166. [Google Scholar] [CrossRef]

- Liu, W.; Chen, X.; Li, W.; Yu, Y.; Yan, K. Environmental assessment, management and utilization of red mud in China. J. Clean. Prod. 2014, 84, 606–610. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, Y.; Lin, C. Chemistry and mineralogy of red mud and its utilization in Zhengzhou Alumina Refinery. Light Met. 2007, 10, 18–21. [Google Scholar]

- Nan, X.L.; Zhang, T.A.; Liu, Y.; Dou, Z.H.; Zhao, Q.Y. Main categories of red mud and its environmental impacts. Chin. J. Process Eng. 2009, 9, 459–464. [Google Scholar]

- Busari, A.A.; Adeboje, A.; Modupe, A.E.; Fadugba, G.O.; Loto, R.T.; Abatan, G.O. Assessment of the engineering properties of modified Asphalt using Aluminium dross as a filler. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Suzhou, China, 17–19 March 2021; IOP Publishing: Bristol, UK, 2021. [Google Scholar]

- Ugla, S.K.; Ismael, M.Q. Evaluating the moisture susceptibility of asphalt mixtures containing RCA and modified by waste alumina. Civil. Eng. J. 2023, 9, 250–262. [Google Scholar]

- Ozerkan, N.; Maki, O.; Anayeh, M.; Tangen, S.; M Abdullah, A. The effect of aluminium dross on mechanical and corrosion properties of concrete. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 9912–9922. [Google Scholar]

- Kang, S.-P.; Kwon, S.-J. Effects of red mud and alkali-activated slag cement on efflorescence in cement mortar. Constr. Build. Mater. 2017, 133, 459–467. [Google Scholar] [CrossRef]

- Zhang, J.; Li, P.; Liang, M.; Jiang, H.; Yao, Z.; Zhang, X.; Yu, S. Utilization of red mud as an alternative mineral filler in asphalt mastics to replace natural limestone powder. Constr. Build. Mater. 2020, 237, 117821. [Google Scholar] [CrossRef]

- Hu, S.; Wang, D.; Hou, D.; Zhao, W.; Li, X.; Qu, T.; Zhu, Q. Research on the preparation parameters and basic properties of premelted calcium aluminate slag prepared from secondary aluminum dross. Materials 2021, 14, 5855. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Performance evaluation of bauxite residue modified asphalt concrete mixes. Eur. J. Environ. Civil. Eng. 2022, 26, 978–994. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Application of waste materials as fillers in bituminous mixes. Waste Manag. 2018, 78, 417–425. [Google Scholar] [CrossRef]

- Lima, M.S.; Thives, L.P. Evaluation of red mud as filler in Brazilian dense graded asphalt mixtures. Constr. Build. Mater. 2020, 260, 119894. [Google Scholar] [CrossRef]

- Soós, Z.; Géber, R.; Tóth, C.; Igazvölgyi, Z.; Udvardi, B. Utilization of aluminium dross as asphalt filler. Építőanyag J. Silic. Based Compos. Mater. 2017, 69, 89–93. [Google Scholar] [CrossRef]

- Shishehboran, M.; Ziari, H.; Korayem, A.H.; Hajiloo, M. Environmental and mechanical impacts of waste incinerated acidic sludge ash as filler in hot mix asphalt. Case Stud. Constr. Mater. 2021, 14, e00504. [Google Scholar] [CrossRef]

- Cui, Y.; Si, C.; Li, S.; Jia, Y.; Guo, B. Iron tailings as mineral fillers and their effect on the fatigue performance of asphalt mastic. Materials 2024, 17, 2927. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Kumar, S. Development of paving blocks from synergistic use of red mud and fly ash using geopolymerization. Constr. Build. Mater. 2013, 38, 865–871. [Google Scholar] [CrossRef]

- Choudhary, R.; Kumar, A.; Rahman, G. Rheological and mechanical properties of bauxite residue as hot mix asphalt filler. Int. J. Pavement Res. Technol. 2019, 12, 623–631. [Google Scholar] [CrossRef]

- Phan, T.M.; Kang, S.P.; Vo, H.V.; Park, D.W. Evaluation on performances of cold asphalt mixture containing recycled waste glass and red mud. Case Stud. Constr. Mater. 2024, 20, e03194. [Google Scholar] [CrossRef]

- Lima, M.S.S.; Thives, L.P.; Haritonovs, V.; Gschösser, F. The influence of alternative fillers on the adhesive properties of mastics fabricated with red mud. Materials 2020, 13, 484. [Google Scholar] [CrossRef]

- Rashidian, S.; Hosseini, S.A.; Korandeh, M.E. Investigation of red mud effects on microsurfacing asphalt performance: Quality enhancement and industrial waste reduction. Constr. Build. Mater. 2025, 483, 141798. [Google Scholar] [CrossRef]

- Ergezer, F.; Terzi, S. Investigation into the deicing efficiency and self-healing capability of asphalt mixtures with aluminum dross powder and steel fiber. Road Mater. Pavement Des. 2025, 26, 1–21. [Google Scholar] [CrossRef]

- Udvardi, B.; Géber, R.; Kocserha, I. Investigation of aluminum dross as a potential asphalt filler. Int. J. Eng. Manag. Sci. 2019, 4, 445–451. [Google Scholar] [CrossRef]

- Xu, F.; Zhao, Y.; Li, K. Using. waste plastics as asphalt modifier: A review. Materials 2021, 15, 110. [Google Scholar] [CrossRef]

- Ling, T.; Lu, Y.; Zhang, Z.; Li, C.; Oeser, M. Value-added application of waste rubber and waste plastic in asphalt binder as a multifunctional additive. Materials 2019, 12, 1280. [Google Scholar] [CrossRef]

- Elahi, Z.; Mohd Jakarni, F.; Muniandy, R.; Hassim, S.; Ab Razak, M.S.; Ansari, A.H.; Ben Zair, M.M. Waste cooking oil as a sustainable bio modifier for asphalt modification: A review. Sustainability 2021, 13, 11506. [Google Scholar] [CrossRef]

- Zhang, R.; You, Z.; Ji, J.; Shi, Q.; Suo, Z. A review of characteristics of bio-oils and their utilization as additives of asphalts. Molecules 2021, 26, 5049. [Google Scholar] [CrossRef] [PubMed]

- Tao, F.; Hui-ming, B. Molecular simulation study on modification mechanism of red mud modified asphalt. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Pekanbaru, Indonesia, 25–26 July 2017; IOP Publishing: Bristol, UK, 2017. [Google Scholar]

- Fu, T.; Wei, J.; Bao, H.; Liang, J. Multiscale study on the modification mechanism of red mud modified asphalt. Adv. Mater. Sci. Eng. 2020, 2020, 2150215. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, Z.; Wang, X.; Guo, H.; Ji, X.; Liu, J. Utilization of calcium carbide slag as alternative filler in asphalt mastic: Filler characteristics, rheological and adhesion properties. J. Clean. Prod. 2022, 380, 134980. [Google Scholar] [CrossRef]

- Qin, Y.; Xie, K.; Meng, Y.; Fu, T.; Fang, G.; Luo, X.; Wang, Q. Feasibility and environmental assessment of reusing aluminum tailing slurry in Asphalt. Constr. Build. Mater. 2024, 411, 134737. [Google Scholar] [CrossRef]

- Yue, H.; Zeng, Z.; Chen, M.; Xiao, J.; Bi, Y.; Zhang, H.; Ding, T.; Zhang, J. The Impacts of Red. Mud on Road Performance and Aging Resistance of Asphalt Mixture. J. Test. Eval. 2024, 52, 2451–2467. [Google Scholar] [CrossRef]

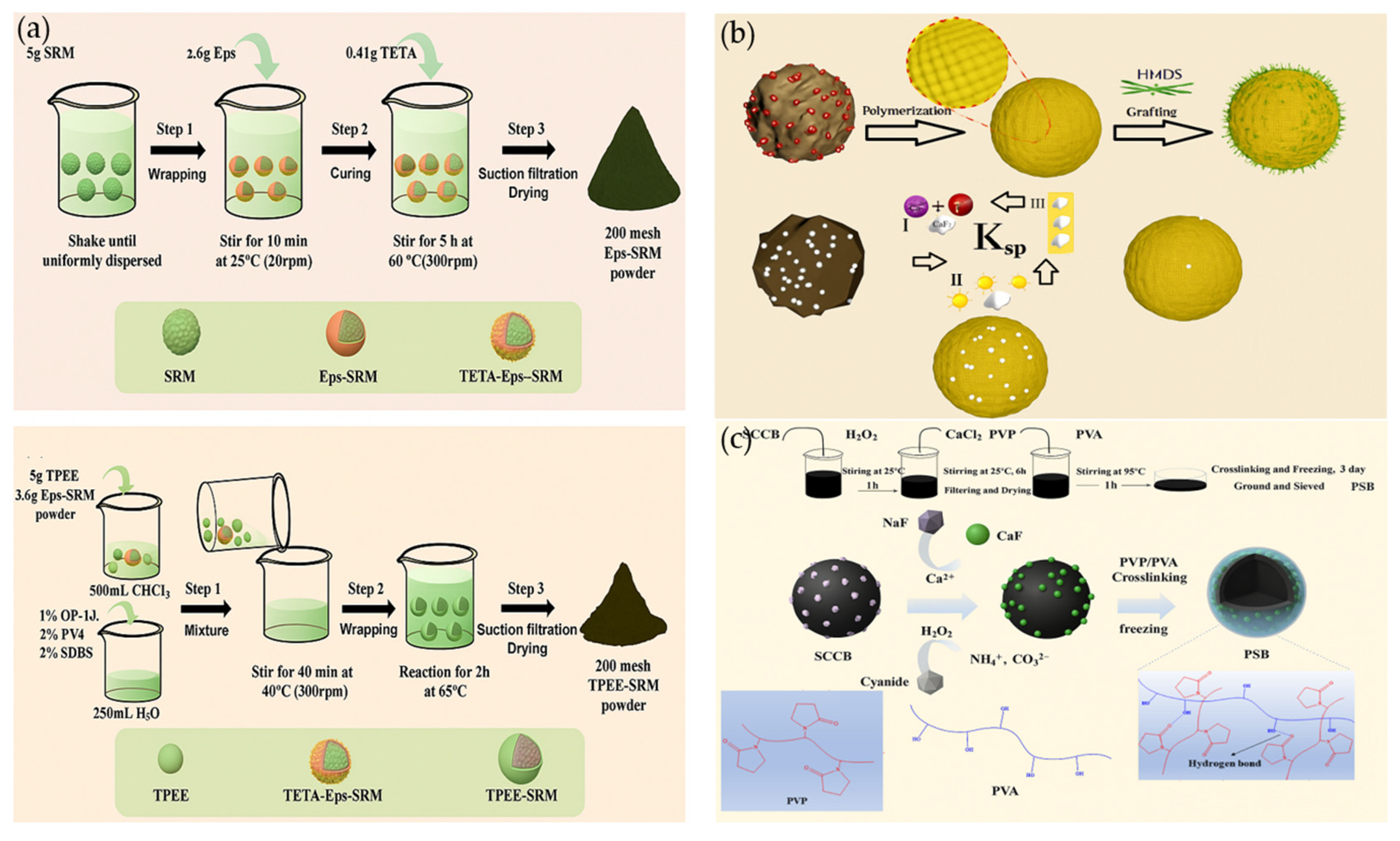

- Xiao, J.; Zhang, J.; Zhang, H.; Bi, Y.; Yue, H.; Xu, R. Preparation and characterization of organic red mud and its application in asphalt modification. Constr. Build. Mater. 2023, 367, 130269. [Google Scholar] [CrossRef]

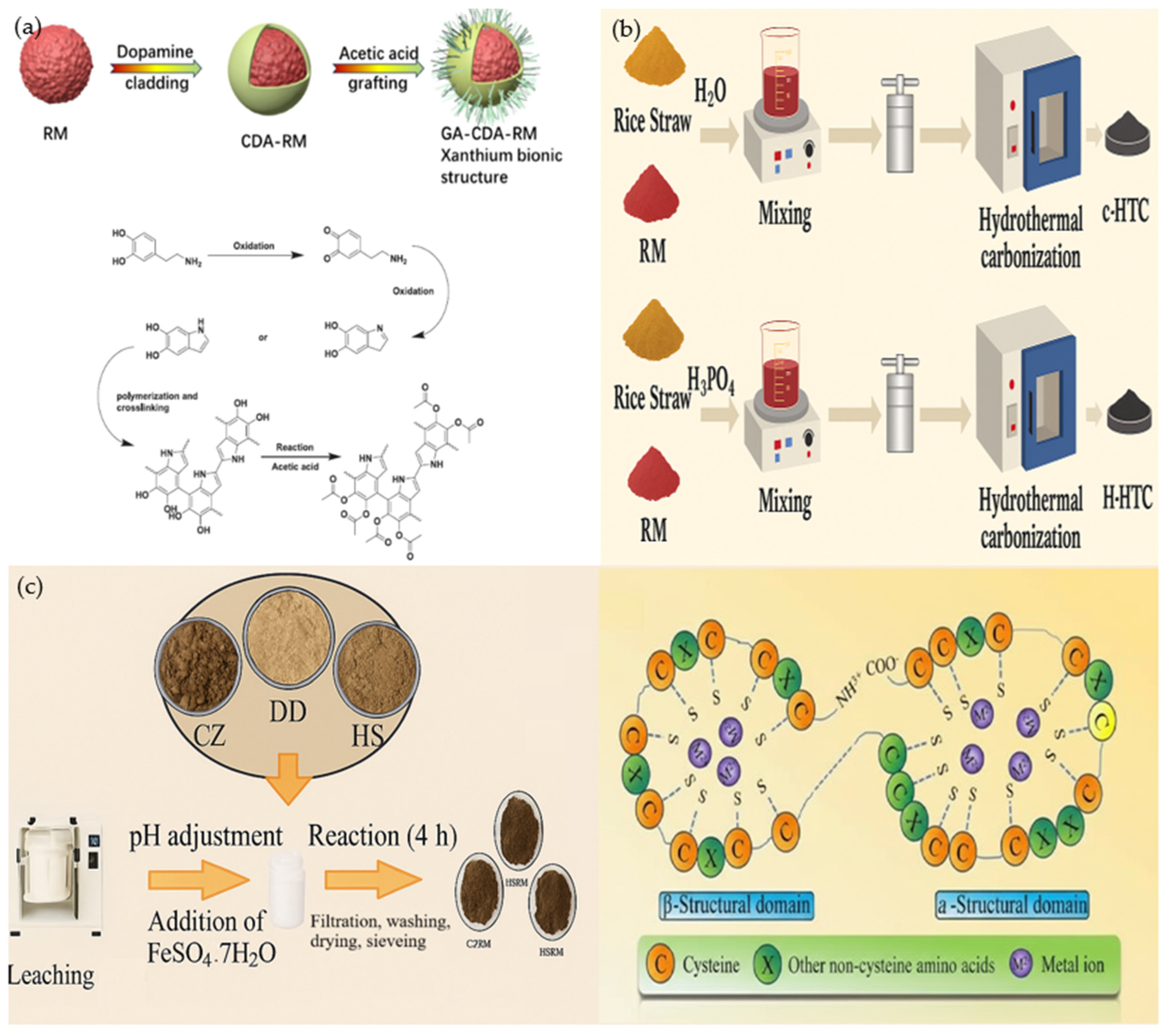

- Han, F.; Li, C.; Luo, Y.; Lv, Y.; Tan, D.; Zhao, Z.; Li, J. Study on Properties of Siberian Cocklebur Bionic Harmless Red Mud Modified Asphalt. J. Appl. Polym. Sci. 2025, e57179. [Google Scholar] [CrossRef]

- Lee, H.; Dellatore, S.M.; Miller, W.M.; Messersmith, P.B. Mussel-inspired surface chemistry for multifunctional coatings. Science 2007, 318, 426–430. [Google Scholar] [CrossRef]

- Ren, D.; Jiang, H.; Fan, S.; Song, L.; Luo, Y.; Lai, F.; Pei, R.; Yang, Q.; Li, J. Polydopamine-modified black phosphorus/microcapsule composite material used to enhance the solar thermal conversion and self-healing performance of SBS modified asphalt. J. Appl. Polym. Sci. 2025, 142, e56316. [Google Scholar] [CrossRef]

- Li, C.; Guo, J.; Wu, Y.; Chen, J.; Bai, X.; Zou, H.; Li, J.; Li, J. Synthesis of flower cluster structure from red mud and rice straw through co-hydrothermal carbonization for modified asphalt applications. Constr. Build. Mater. 2025, 471, 140745. [Google Scholar] [CrossRef]

- Li, J.; Han, F.; Lv, Y.; Wei, X.; Deng, S.; Liu, Y. Research on the harmless treatment of RM with MTs in plant oil residue and its anti-aging in asphalt. Constr. Build. Mater. 2025, 483, 141797. [Google Scholar] [CrossRef]

- Fan, S.; Tu, H.; Muhammad, Y.; Ren, D.; Lai, F.; Yang, Q.; Zhao, Z.; Li, J. Resource utilization of emulsion evaporation modified aluminum industrial refractory waste in the preparation of composite modified asphalt. J. Appl. Polym. Sci. 2024, 141, e56092. [Google Scholar] [CrossRef]

- Li, J.; Tu, H.; Li, X.; Chen, Y.; Zhou, T.; Li, Z.; Zhao, Z.; Liu, Y. Resourceful modification mechanism of modified electrolytic aluminum spent refractory material and its long-term safety performance assessment. Constr. Build. Mater. 2024, 418, 135254. [Google Scholar] [CrossRef]

- ASTM D5/D5M–20; Standard Test Method for Penetration of Bituminous Materials. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM D36/D36M-14; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM: West Conshohocken, PA, USA, 2014.

- ASTM D113-17; Standard Test Method for Ductility of Asphalt Materials. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D4402/D4402M-15; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM D2872-22; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D6521-22; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). ASTM: West Conshohocken, PA, USA, 2022.

- AASHTO T 315-22; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO T350-19; Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- AASHTO TP 101-14; Standard Method of Test for Estimating Damage Tolerance of Asphalt Binders Using the Linear Amplitude Sweep. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014.

- AASHTO T313-22; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- ASTM D6732-02; Standard Test Method for Determining the Failure Properties of Asphalt Binder in Direct Tension. ASTM: West Conshohocken, PA, USA, 2002.

- AASHTO TP-91; Standard Method of Test for Determining Asphalt Binder Bond Strength by Means of the Asphalt Bond Strength (ABS) Test. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2011.

- Zhang, J.; Li, P.; Wang, K.; Ma, C.; Liang, M.; Jiang, H.; Yao, K.; Su, C.; Yao, Z. Adhesive behavior and pavement performance of asphalt mixtures incorporating red mud as a filler substitute. Constr. Build. Mater. 2021, 298, 123855. [Google Scholar] [CrossRef]

- Chaudhary, M.; Saboo, N.; Gupta, A. Introduction of a new parameter to quantify the fatigue damage in asphalt mastics and asphalt binder. Coatings 2021, 11, 828. [Google Scholar] [CrossRef]

- Chaudhary, M.; Saboo, N.; Gupta, A.; Steineder, M.; Hofko, B. Effect of analysis procedure and sample geometry on the fatigue life results of asphalt mastics from linear amplitude sweep test. Mech. Time-Depend. Mater. 2023, 27, 1097–1121. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Zhang, H.; Zhang, X.; Guo, B.; Yu, B.; Tian, Y. Experimental study on the aging behavior of modified asphalt with different types of fine solid wastes under different aging conditions. Constr. Build. Mater. 2021, 291, 123308. [Google Scholar] [CrossRef]

- Xing, Z.; Hébert, R.; Beaucour, A.L.; Ledésert, B.; Noumowé, A. Influence of chemical and mineralogical composition of concrete aggregates on their behaviour at elevated temperature. Mater. Struct. 2014, 47, 1921–1940. [Google Scholar] [CrossRef]

- Chaudhary, M.; Saboo, N.; Gupta, A.; Hofko, B.; Steineder, M. Assessing the effect of fillers on LVE properties of asphalt mastics at intermediate temperatures. Mater. Struct. 2020, 53, 96. [Google Scholar] [CrossRef]

- Chaudhary, M.; Saboo, N.; Gupta, A.; Miljković, M. Contribution of mineral filler to the fatigue damage behaviour of bituminous mastic. Constr. Build. Mater. 2022, 334, 127120. [Google Scholar] [CrossRef]

- ASTM D6927-15; Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM D6931-12; Standard Test Method for Indirect Tensile (IDT) Strength of Bituminous Mixtures. ASTM: West Conshohocken, PA, USA, 2012.

- AASHTO TP124-16; Standard Method of Test for Determining the Fracture Potential of Asphalt Mixtures Using Semicircular Bend Geometry (SCB) at Intermediate Temperature. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2016.

- ASTM D8225-19; Standard Test Method for Determination of Cracking Tolerance Index of Asphalt Mixture Using the Indirect Tensile Cracking Test at Intermediate Temperature. ASTM: West Conshohocken, PA, USA, 2019.

- AASHTO T 324-11; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Hot Mix Asphalt (HMA). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2011.

- AFNOR NF P 98-250-2; Essais Relatifs Aux Chaussées: Préparation des Mélanges Hydrocarbonés—Partie 2: Compactage des plaques. AFNOR Éditions: Paris, France, 1997.

- ASTM D1075-11; Standard Test Method for Effect of Water on Compressive Strength of Compacted Bituminous Mixtures. ASTM: West Conshohocken, PA, USA, 2011.

- AASHTO T 283-14; Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014.

- ASTM D3625-12; Standard Test Method for Effect of Water on Bituminous-Coated Aggregate Using Boiling Water. ASTM: West Conshohocken, PA, USA, 2012.

- AASHTO TP 108-14; Standard Method of Test for Determining the Abrasion Loss of Asphalt Mixture Specimens (Cantabro Test). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014.

- Choudhary, J.; Kumar, B.; Gupta, A. Effect of filler on the bitumen-aggregate adhesion in asphalt mix. Int. J. Pavement Eng. 2020, 21, 1482–1490. [Google Scholar] [CrossRef]

- Asphalt Institute. Mix Design Methods for Asphalt Concrete and Other Hot-Mix Types: Manual Series No. 2 (MS-2), 6th ed.; Asphalt Institute: Lexington, KY, USA, 1997. [Google Scholar]

- Zoorob, S.; Suparma, L. Laboratory design and investigation of the properties of continuously graded Asphaltic concrete containing recycled plastics aggregate replacement (Plastiphalt). Cem. Concr. Compos. 2000, 22, 233–242. [Google Scholar] [CrossRef]

- Modarres, A.; Bengar, P.A. Investigating the indirect tensile stiffness, toughness and fatigue life of hot mix asphalt containing copper slag powder. Int. J. Pavement Eng. 2019, 20, 977–985. [Google Scholar] [CrossRef]

- Lima, M.; Thives, L.P.; Haritonovs, V. Rutting performance of bituminous mixtures composed with red mud. In Bearing Capacity of Roads, Railways and Airfields; CRC Press: Boca Raton, FL, USA, 2017; pp. 349–355. [Google Scholar]

- Pasandín, A.; Pérez, I. The influence of the mineral filler on the adhesion between aggregates and bitumen. Int. J. Adhes. Adhes. 2015, 58, 53–58. [Google Scholar] [CrossRef]

- Shanchun, F.; Dongdong, W.; Hongyan, S. Study on Water Damage Resistance of Red Mud Mineral Powder Asphalt Mixture. Multipurp. Util. Miner. Resour. Kuangchan Zonghe Liyong 2022, 43, 25–30, 36. [Google Scholar]

- Tarrer, A. The Effect of the Physical and Chemical Characteristics of the Aggregate on Bonding; Strategic Highway Research Program (SHRP): Washington, DC, USA, 1991. [Google Scholar]

- Kandhal, P.S.; Chakraborty, S. Effect of asphalt film thickness on short-and long-term aging of asphalt paving mixtures. Transp. Res. Rec. 1996, 1535, 83–90. [Google Scholar] [CrossRef]

- Antunes, M.; Conceição, F.; Navarro, G. Caracterização da lama vermelha brasileira (resíduo do refino da bauxita) e avaliação de suas propriedades para futuras aplicações. Int. Workshop Adv. Clean. Prod. 2011, 3, 10. [Google Scholar]

- Collazo, A.; Fernández, D.; Izquierdo, M.; Nóvoa, X.R.; Pérez, C. Evaluation of red mud as surface treatment for carbon steel prior painting. Progress. Org. Coat. 2005, 52, 351–358. [Google Scholar] [CrossRef]

- Nunn, R.F. Advances in red mud dewatering and disposal technologies. Light Met. Warrendale 1998, 107–114. [Google Scholar]

- Lima, F. Utilização da Lama Vermelha e do Resíduo Caulinítico na Produção de Pigmento Pozolânico Para Argamassas e Concretos de Cimento Portland; UFPA: Belém, PA, Brazil, 2006. [Google Scholar]

- Lima, M.S.S.; Hajibabaei, M.; Thives, L.P.; Haritonovs, V.; Buttgereit, A.; Queiroz, C.; Gschösser, F. Environmental potentials of asphalt mixtures fabricated with red mud and fly ash. Road Mater. Pavement Des. 2021, 22 (Suppl. S1), S690–S701. [Google Scholar] [CrossRef]

- Li, H.; Liu, J.; Zhang, H.; Harvey, J. Investigation on the effect of fine solid wastes on the runoff purification performance of porous asphalt mixture. J. Environ. Manag. 2021, 300, 113612. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Li, H.; Sun, L.; Zhang, H.; Xie, N.; Tian, Y.; Jia, M.; Fu, K.; Yu, B.; Zhu, Y. Leachate risks of fine solid wastes in porous asphalt pavement and runoff purification effects of diatomite filler. J. Clean. Prod. 2021, 297, 126623. [Google Scholar] [CrossRef]

- Modarres, A.; Ramyar, H.; Ayar, P. Effect of cement kiln dust on the low-temperature durability and fatigue life of hot mix asphalt. Cold Reg. Sci. Technol. 2015, 110, 59–66. [Google Scholar] [CrossRef]

- Busari, A.; Snyman, J.; Kupolati, W.; Ndambuki, J.; Sadiku, E.; Loto, R.; Sagay, A. Data on the engineering properties of aluminum dross as a filler in asphalt. Data Brief. 2020, 31, 105934. [Google Scholar] [CrossRef]

- Ugla, S.K.; Ismael, M.Q. Evaluating the moisture susceptibility of asphalt mixtures containing aluminum dross as a filler. J. Eng. 2024, 30, 190–206. [Google Scholar] [CrossRef]

- Yinfei, D.; Jiacheng, W.; Jiaqi, C. Cooling asphalt pavement by increasing thermal conductivity of steel fiber asphalt mixture. Sol. Energy 2021, 217, 308–316. [Google Scholar] [CrossRef]

- Serin, S.; Emiroğlu, M.; Gönül, V.E. Investigation of the fracture energy of hot mixtures asphalt incorporating metallic wastes via semi-circular bending test. Constr. Build. Mater. 2021, 300, 124006. [Google Scholar] [CrossRef]

- Al-Obaidi, M.K.; Abed, A.H. Appraisal of asphalt mixtures’ cracking resistance modified with waste aluminum scrap powder (wasp) at intermediate temperatures. In Proceedings of the E3S Web of Conferences, Semarang, Indonesia, 8–9 August 2023; EDP Sciences: London, UK, 2023. [Google Scholar]

- Atakan, M.; Yıldız, K. Self-healing potential of porous asphalt concrete containing different aggregates and metal wastes through microwave heating. Politek. Derg. 2022, 25, 623–631. [Google Scholar] [CrossRef]

- Pamulapati, Y.; Elseifi, M.A.; Cooper, S.B., III; Mohammad, L.N.; Elbagalati, O. Evaluation of self-healing of asphalt concrete through induction heating and metallic fibers. Constr. Build. Mater. 2017, 146, 66–75. [Google Scholar] [CrossRef]

- Bastidas-Martínez, J.G.; Rondón-Quintana, H.A.; Mojica-Herrera, L.F. Behavior of a hot-mix asphalt with aluminum shavings. Constr. Build. Mater. 2025, 474, 140905. [Google Scholar] [CrossRef]

| SRM | Ref. | |||||

|---|---|---|---|---|---|---|

| CaO | SiO2 | MgO | Al2O3 | Fe2O3 | MnO | |

| 54.3 | 0.82 | 0.62 | 0.52 | 0.16 | 0.15 | [88] |

| SCCB | ||||||

| C | NaF | Fe2O3 | CaO | SO3 | K2O | [89] |

| 79.6 | 9.23 | 3.00 | 2.03 | 1.64 | 1.12 | |

| Property | Test and Simulation Methods | Standard Code |

|---|---|---|

| Penetration | Needle penetration | ASTM D5 [137] |

| Softening point | Ring and ball | ASTM D36 [138] |

| Ductility | Elongation | ASTM D113 [139] |

| Viscosity | Rotational viscosity | ASTM D4402 [140] |

| Short-term aging | Rolling thin-film oven test | ASTM D2872 [141] |

| Long-term aging | Pressure aging vessel | ASTM D6521 [142] |

| Linear viscoelastic behavior | Frequency and temperature sweep tests | AASHTO T315 [143] |

| Permanent deformation resistance and elastic behavior | Multiple stress creep recovery test | AASHTO T350 [144] |

| Fatigue resistance | Linear amplitude sweep test | AASHTO TP 101 [145] |

| Low temperature stiffness | Bending beam rheometer | AASHTO T313 [146] |

| Cracking resistance at low temperature | Direct tension test | ASTM D6732-02 [147] |

| Adhesion and bonding performance | Binder bond strength | AASHTO TP-91 [148] |

| Ref. | Filler Type | F–B Ratios | Physicochemical and Microstructural Assessment | Rheological Characterization |

|---|---|---|---|---|

| [114] | RM and stone dust (SD) | 0.6, 0.9, 1.2, and 1.5 (w/w) | ✓ RM consisted of rounded, agglomerated particles with a rough texture, whereas SD contained flaky, irregularly shaped particles. ✓ RM was significantly finer than SD and exhibited higher specific gravity and Rigden voids. | ✓ G* was comparable for both fillers, but the SD mastic was stiffer, at a F–B ratio of 1.5. ✓ SD mastics had a lower phase angle, indicating higher elasticity compared to RM mastics. ✓ SD mastics had lower Jnr values, at 3.2 kPa (Jnr 3.2), suggesting higher stiffness than RM mastics. ✓ At lower F–B ratios, SD mastics had a higher recovery. However, at an F–B ratio of 1.5, RM mastics exhibited greater recovery due to a faster increase in recovery with the F–B ratio. |

| [154] | RM, marble dust (MD), limestone (LS), granite (GR), basalt (BA), and quartz (QZ) | 0.5, 1, and 1.5 (w/w) | ✓ RM exhibited the lowest fineness modulus, the highest Rigden value (RV), and the highest filler grain coefficient, indicating a well-graded and fine particle distribution. | ✓ The RM asphalt mastic exhibited the highest G*LVE of all the samples. |

| [151] | RM and LS | 0.5, 1, and 1.5 (w/w) | ✓ Compared to LS, RM showed higher specific gravity and RV but a lower fineness modulus. | ✓ There was no consistent superiority between RM and LS fillers in terms of fatigue life, as performance varied depending on test conditions, analysis methods, and filler-to-binder ratios. ✓ The pseudo-strain energy method consistently produced the highest fatigue life estimates for both RM and LS asphalt mastics, followed by dissipated energy and R-based approaches. ✓ Hyperbolic geometry proved more effective in capturing fatigue damage in asphalt mastics for both types of fillers. |

| [150] | RM and conventional filler | 10%, 20%, and 30% (v/v) | ✓ Increased RM content resulted in greater fatigue damage. ✓ The newly proposed fatigue parameter (F) proved to be an effective indicator of fatigue damage in both asphalt mastics and binders. | |

| [155] | RM, LS, and MD | 10%, 20%, and 30% (v/v) | ✓ RM was much finer, with approximately 40% of RM particles smaller than 10 μm, compared to ~12% for the other fillers. | ✓ Mastics containing 30% RM filler were excessively stiff and required more time for homogenization, unlike the other mixes. ✓ RM showed the most significant sensitivity of the G* and Glover–Rowe parameters to changes in filler volume fraction. ✓ The fine, porous structure of RM and its strong binder interaction significantly influenced fatigue damage evolution, whereas MD and LS fillers had more moderate effects, with temperature being a more dominant factor in their performance. ✓ The strong contribution of RM was linked to its intensive interaction with asphalt binder, with a critical threshold observed at a 20% volume fraction, likely due to particle interlocking. |

| [116] | RM, LS, dolomite, and fly ash (FA) | 20% and 40% (v/v) | ✓ RM exhibited the highest surface area, RV, and pH among the fillers. | ✓ RM asphalt mastics demonstrated excellent adhesion to aggregates. Mastics containing 40% RM achieved the required minimum aggregate coverage (≥85%) in the boiling water stripping test without the need for any chemical adhesion improver, indicating robust adhesive properties. ✓ The wettability test results showed that mastics with RM had favorable contact angles, indicating good affinity between the mastics and water, which is important for durability in wet conditions. |

| [95] | RM, LS, steel slag (SS), and ground granulated blast-furnace slag (GGBFS) | 1 (w/w) | ✓ RM showed a denser microstructure than the other fillers, with fine, agglomerated particles. | ✓ RM asphalt mastic exhibited the lowest G* and the highest phase angle. ✓ RM asphalt mastic showed better fatigue performance than LS asphalt mastic. ✓ Unlike SS, RM showed the lowest recovery and the highest Jnr, indicating the poorest resistance to rutting. |

| [152] | RM, LS, FA, and diatomite (DT) | 33% (v/v) | ✓ The RV values of RM and DT were significantly higher than those of LS and FA, indicating a more porous structure. | ✓ RM asphalt mastic retained its low-temperature flexibility better than LS mastic after prolonged aging. ✓ The stress sensitivity of the RM asphalt mastic in the fatigue test was higher than that of LS or FA mastics, due to differences in the effect of physical hardening caused by the porous structure of RM. ✓ In unaged samples, RM asphalt mastic exhibited a higher percentage of recovery than LS mastic. |

| [84] | RM and LS | 0.3, 0.6, 0.9, 1.2, 1.5, 1.8, and 2.1 (w/w) | ✓ Incorporating and increasing the amount of RM led to a rise in rotational viscosity, G*, rutting index, and creep stiffness, all of which increased further with a higher F–B ratio. ✓ Increasing the substitution of LS with RM increased creep stiffness (S), while the rate of change in stiffness (m-value) decreased. | |

| [90] | LS and RM | 0.3, 0.6, and 0.9 (w/w) | ✓ Based on the rutting index, the high-temperature performance of RM was superior to that of LM, especially when the F–B ratio was at least 0.6. ✓ Incorporating RM increased percentage recovery and decreased Jnr, indicating improved elasticity and resistance to permanent deformation. ✓ Increasing the F–B ratio reduced low-temperature cracking, and RM did not consistently outperform LS in low-temperature performance. | |

| [91] | Conventional filler, Sintering RM, and Bayer RM | 1 (w/w) | ✓ Sintering RM contained more aggregated particles than Bayer RM, despite their similar particle sizes. The pore volume of RM was more than five times greater than that of conventional mineral filler. | ✓ Sintering RM more effectively enhanced G* and rutting resistance. It also improved elastic recovery, unlike Bayer RM, which had a minimal effect. |

| [97] | RM, LS, hydrated lime (HL), and FA | 1 (w/w) | ✓ RM had smaller, rougher, and more porous particles than LS, with fine, near-spherical particles prone to agglomeration, affecting asphalt binder absorption and asphalt mastic rheology. | ✓ The viscosity of RM asphalt mastic was over four times higher than that of LS mastic. ✓ The fatigue parameter (G*sin δ) of RM mastic showed the highest values, especially at low frequencies. |

| [92] | RM, LS, FA, and DT | 0.11, 0.22, 0.33, 0.44, and 0.55 (v/v) | ✓ Larger RV in fillers such as DT and RM increased asphalt absorption and particle friction, leading to higher viscosity and lower Jnr 3.2 than LS and FA asphalt mastics. | |

| [105] | RM and LS | 1 (w/w) | ✓ RM consisted of near-spherical, fine particles with coarse, edgeless surfaces, which tended to agglomerate into larger clusters. | ✓ RM improved the elastic recovery of asphalt mastic but negatively affected cracking and fatigue resistance, which could be mitigated by adding white mud. ✓ RM significantly increased the viscosity of mastic, and adding HL amplified this effect, while white mud slightly reduced it. |

| [88] | SRM | 0%, 50%, and 100% (v/v) | ✓ Both SRM and graphene oxide (GO) featured wrinkled and grooved surfaces that effectively adsorbed free asphalt without undergoing any chemical reaction with it. | ✓ The synergistic effect of GO as an asphalt modifier and SRM as a filler improved asphalt mastic stiffness, reduced permanent deformation, and lowered stress sensitivity, mainly due to the CaO and Al2O3 content in SRM and the surface structure of GO. |

| Property | Test | Standard Code |

|---|---|---|

| Strength and flow | Marshall stability and flow test | ASTM D6927 [156] |

| Tensile strength | Indirect tensile strength test | ASTM D6931-12 [157] |

| Cracking resistance | Semicircular bend test | AASHTO TP124-16 [158] |

| Indirect tensile asphalt cracking test | ASTM D8225 [159] | |

| Rutting resistance | Hamburg wheel tracking test | AASHTO T 324–11 [160] |

| French wheel tracker test | NF P 98-250-2 [161] | |

| Moisture resistance | Moisture susceptibility test | ASTM D1075-11 [162] |

| AASHTO T283 [163] | ||

| Adhesion and bonding | Boiling water test | ASTM D3625-12 [164] |

| Raveling resistance | Cantabro abrasion loss test | AASHTO TP108-14 [165] |

| Reference Filler | Gradation Type | Type of Asphalt Binder | Effect of RM | Ref. | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OBC% | Stability and Flow | Rutting Resistance | Tensile Strength and Cracking Resistance | Moisture Susceptibility | Adhesion | Raveling Resistance | Aging Resistance | ||||

| OPC | Dense-graded | 60–70 penetration grade | - | ↑ | ↑ | ↑ | ↓ | ↓ | [108] | ||

| SD | Dense-graded | VG-30 | ↓ | ↑ | ↑ | [114] | |||||

| SD | Dense-graded | VG-30 | ↑ | ↑ | ↑ | ↑ | ↑ | ↓ | ↓ | [107] | |

| SD | Dense-graded | VG-30 | ↑ | ↓ | [166] | ||||||

| SD | Dense-graded | PG 64-22 | ↑ | ↑ | [109] | ||||||

| LS | Dense-graded | 60–80 penetration grade | ↑ | ↓ | [149] | ||||||

| LS | Open-graded | SBS asphalt (PG 76-22) | ↑ | ↑ | ↑ | ↑ | [90] | ||||

| LS | Open-graded | SBS asphalt (PG 82-28) | ↑ | ↑ | ↓ | ↑ | ↑ | [94] | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salehfard, R.; Jafari, R. Studies on the Valorization of Aluminum Production Residues into Bituminous Materials at Different Scales: A Review. Sustainability 2025, 17, 9634. https://doi.org/10.3390/su17219634

Salehfard R, Jafari R. Studies on the Valorization of Aluminum Production Residues into Bituminous Materials at Different Scales: A Review. Sustainability. 2025; 17(21):9634. https://doi.org/10.3390/su17219634

Chicago/Turabian StyleSalehfard, Reza, and Reza Jafari. 2025. "Studies on the Valorization of Aluminum Production Residues into Bituminous Materials at Different Scales: A Review" Sustainability 17, no. 21: 9634. https://doi.org/10.3390/su17219634

APA StyleSalehfard, R., & Jafari, R. (2025). Studies on the Valorization of Aluminum Production Residues into Bituminous Materials at Different Scales: A Review. Sustainability, 17(21), 9634. https://doi.org/10.3390/su17219634