Advancements and Challenges in Coatings for Wind Turbine Blade Raindrop Erosion: A Comprehensive Review of Mechanisms, Materials and Testing

Abstract

1. Introduction

2. Mechanisms of Raindrop Erosion

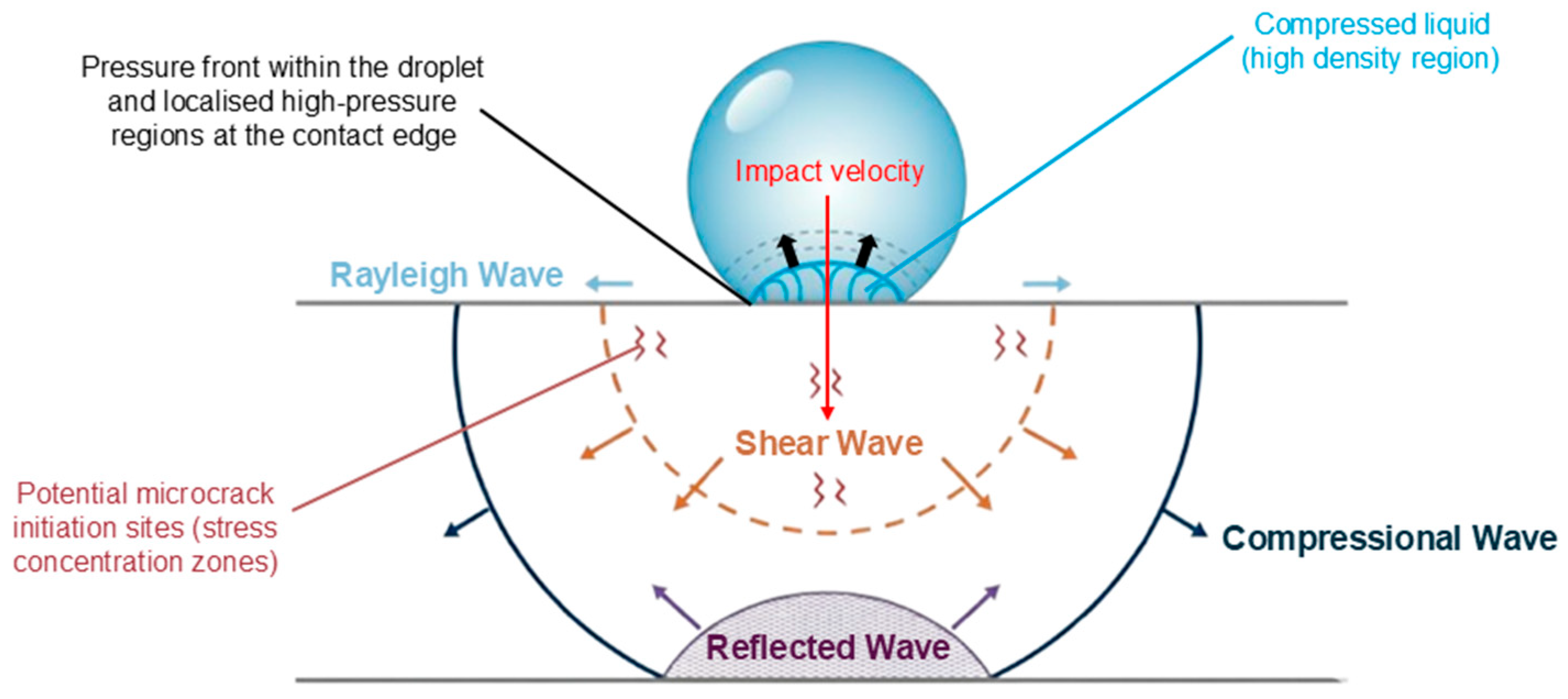

2.1. Physics of Droplet Impact and Stress Wave Propagation

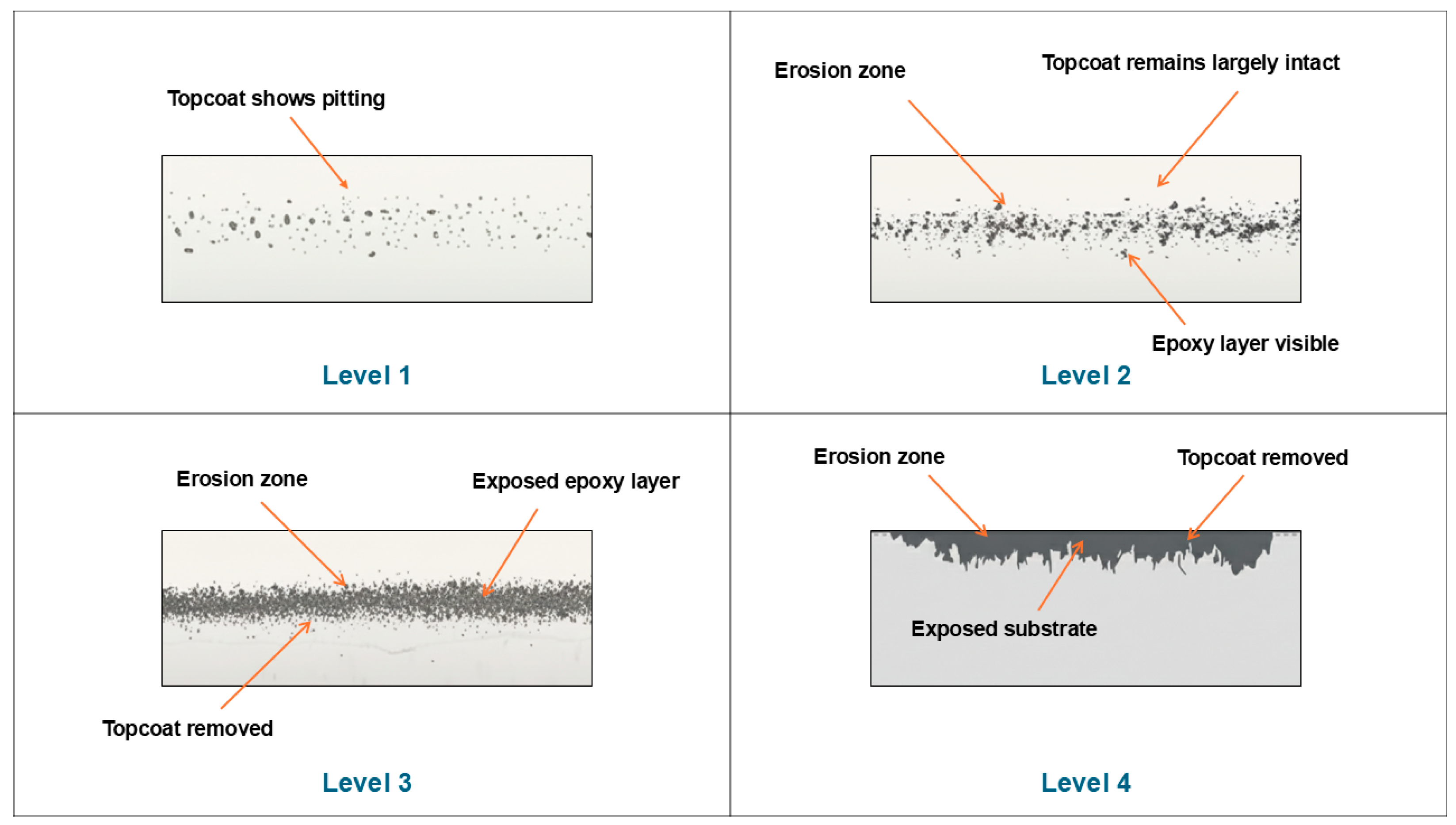

2.2. Material Response: Surface Fatigue, Delamination and Failure Modes

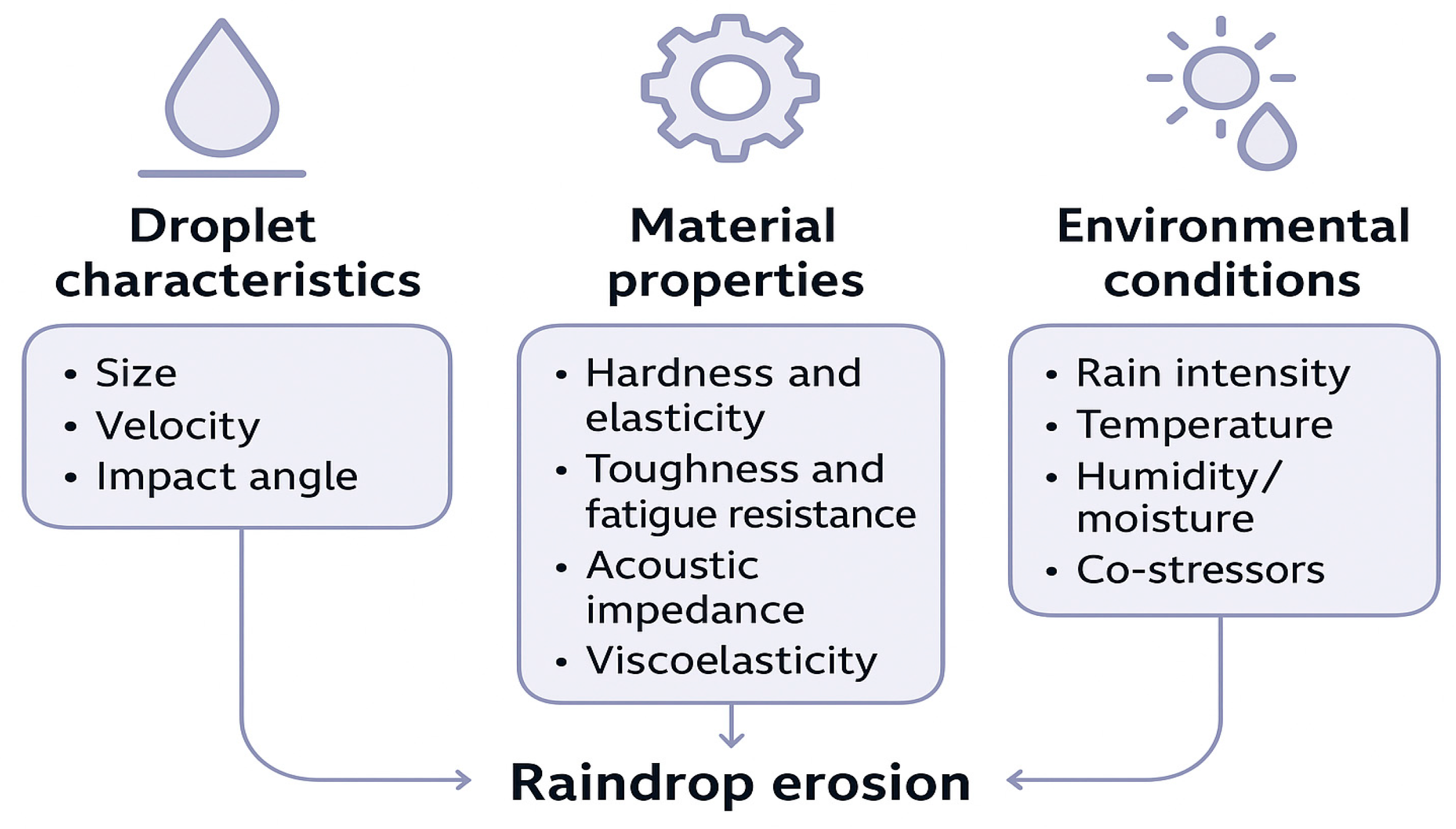

2.3. Influencing Factors: Droplet Characteristics, Impact Velocity, Environmental Conditions

2.3.1. Droplet Characteristics

2.3.2. Material Properties

2.3.3. Environmental Conditions

2.4. Mechanical and Operational Implications

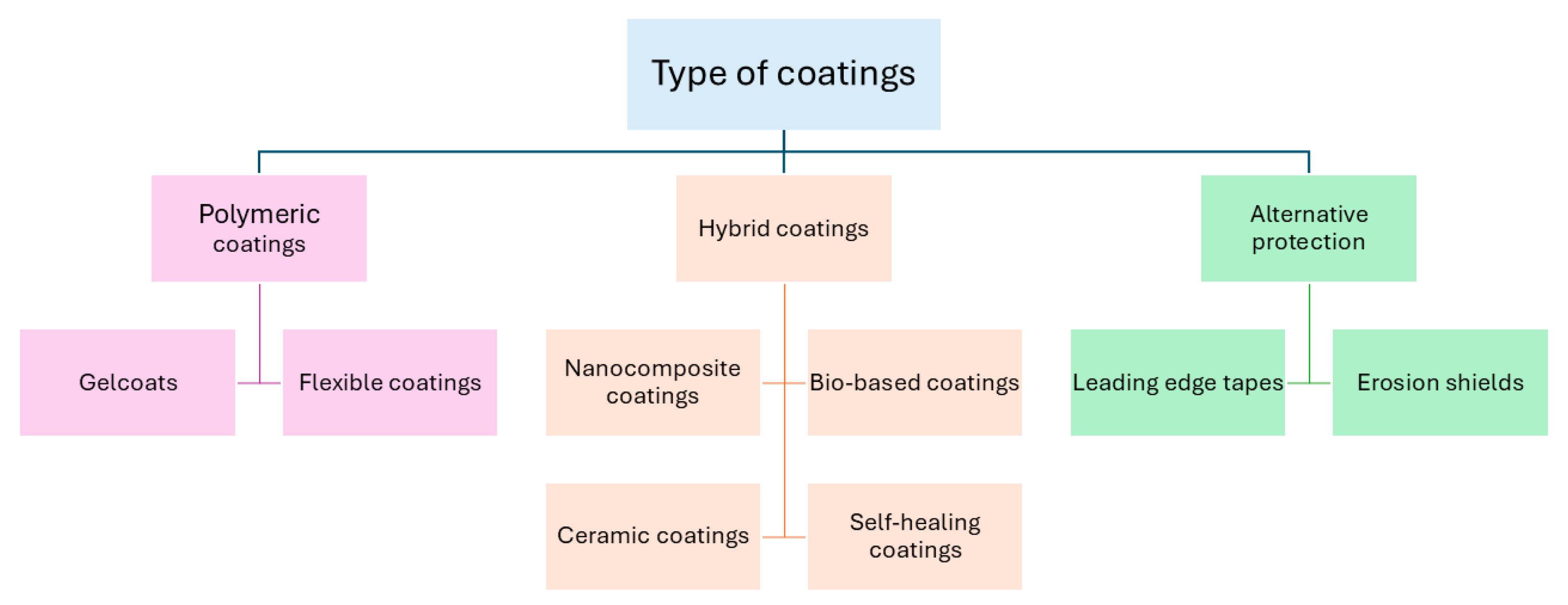

3. Protective Coating Technologies for Wind Turbine Blades

3.1. Requirements for Anti-Erosion Coatings

3.2. Conventional Coating Materials

3.3. Emerging Coating Technologies and Advanced Materials

3.3.1. Nanocomposite Coatings

3.3.2. Bio-Based Coatings

3.3.3. Ceramic Coatings

3.3.4. Self-Healing Coatings

3.4. Coating Application Methods

4. Experimental Testing Methodologies for Raindrop Erosion

4.1. Laboratory Testing Methods

4.1.1. Whirling Arm Rain Erosion Test

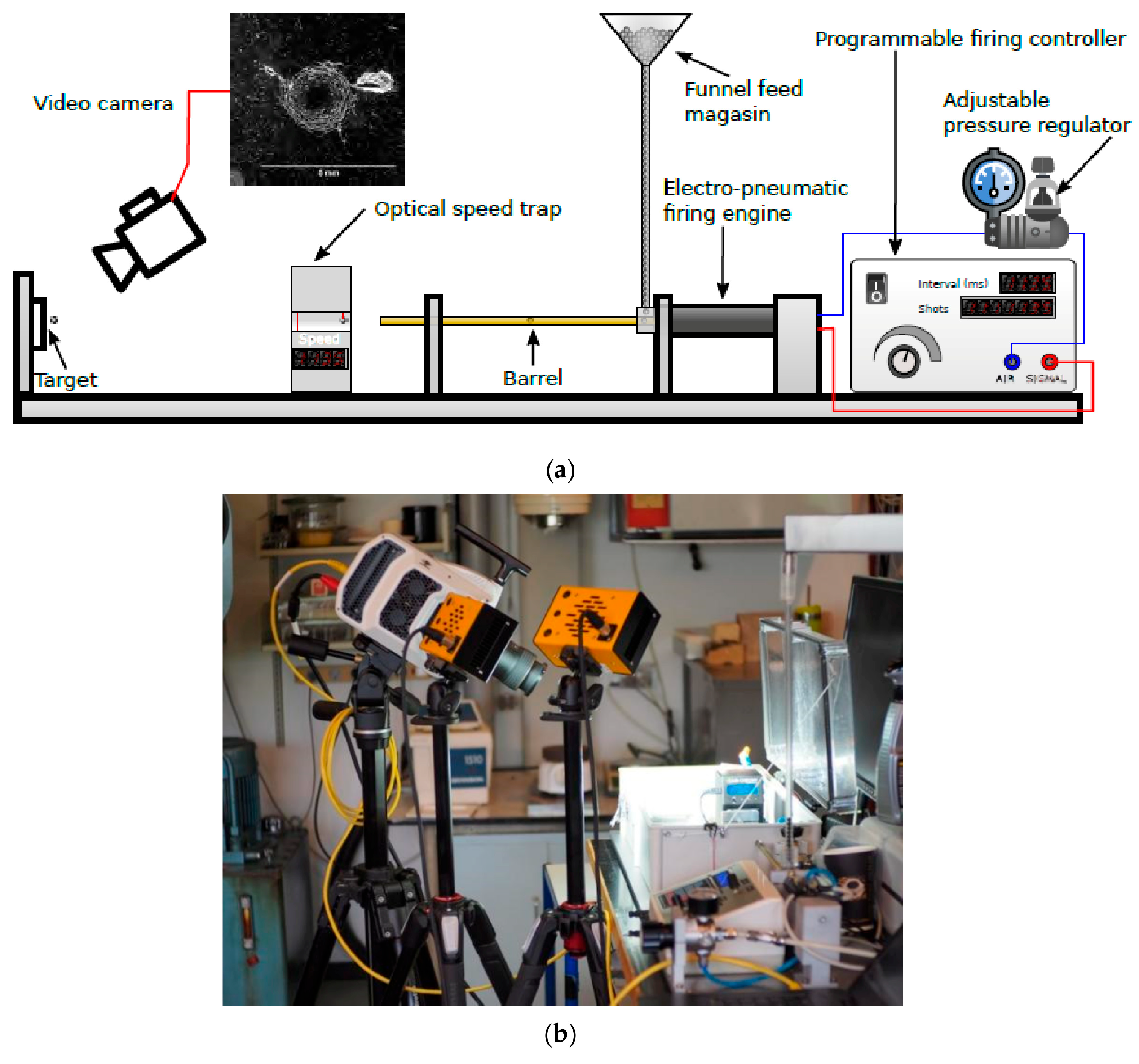

4.1.2. Single Point Impact Fatigue Tester

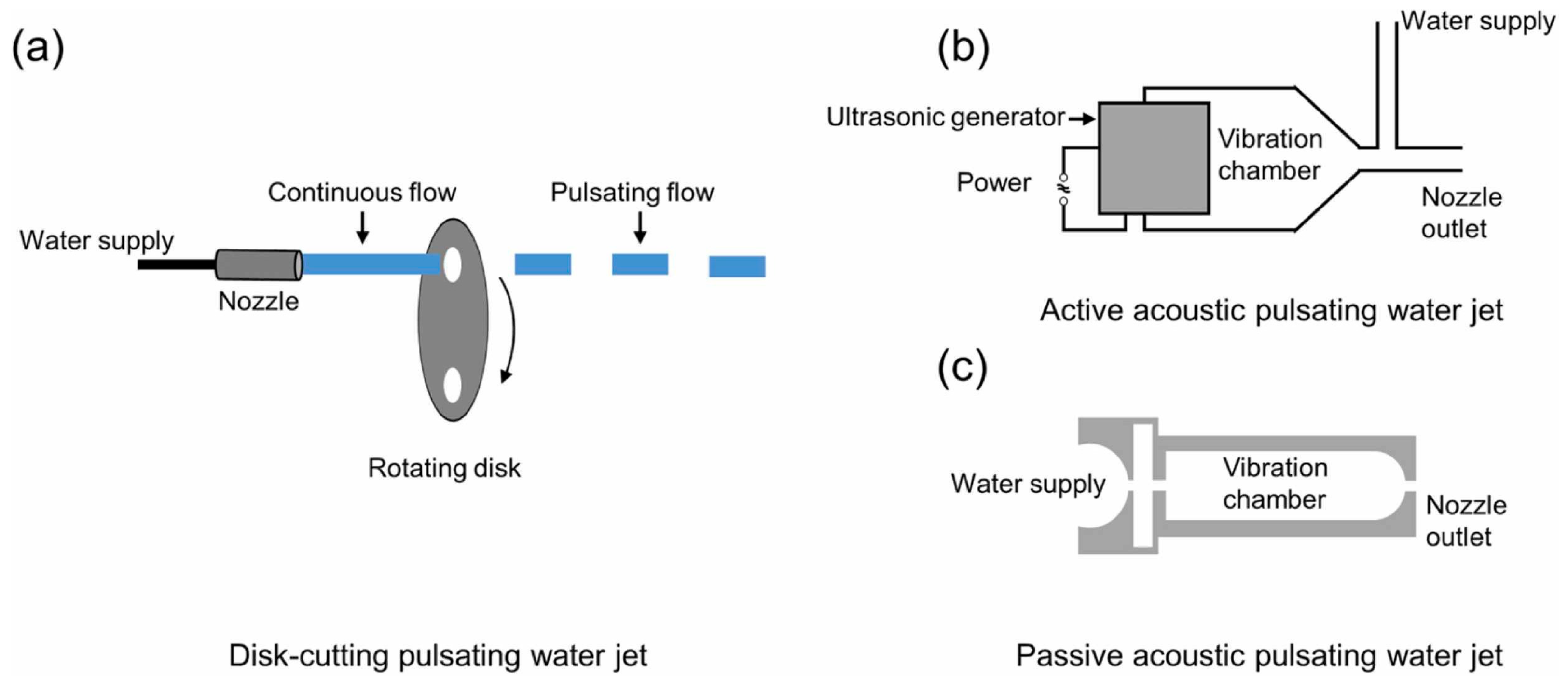

4.1.3. Water Jet Impingement

4.2. Characterisation Techniques for Erosion Damage

4.2.1. Surface Microstructure Characterisation

4.2.2. Microstructure Characterisation Through Thickness

4.3. Correlation Between Laboratory and Field Testing

4.3.1. Parameter Comparison

4.3.2. Performance Metrics Alignment

4.3.3. Validation Studies and Case Evidence

4.3.4. Protocol Modifications to Improve Correlation

5. Summary and Future Outlook

5.1. Summary

5.2. Future Outlook

- Developed erosion-testing parameters including impact velocity, droplet size, frequency, and environmental coupling to establish benchmark reference conditions. Energy- or impulse-equivalent mapping between whirling arm RET, SPFIT, and water jet setups will enable direct cross-validation and model calibration.

- Integrate UV radiation, humidity, temperature cycling, and saline or acidic media into erosion experiments. Coupled weather-erosion chambers will reveal how ageing process interacts with impact fatigue to determine service lifetimes.

- Investigate how impact repetition rate and viscoelastic recovery govern damage accumulation. Developing variable-frequency or pulsed-rain setups would help reproduce the intermittent impact characteristics observed in real field conditions, bridging the gap with constant high-frequency laboratory-based testing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Backwell, B.; Clarke, E.; Ladwa, R.; Mullin, S.; Jayasurya, F.; Hutchinson, M.; Qiao, L.; Williams, R.; Han, W.; Liang, W.; et al. Global Wind Report 2025; Clean: Lisbon, Portugal, 2025. [Google Scholar]

- IRENA; COP28 Presidency; COP29 Presidency; Global Renewables Alliance (GRA); Ministry of Energy of the Republic of Azerbaijan (MoEA); Government of Brazil. Delivering on the UAE Consensus: Tracking Progress Toward Tripling Renewable Energy Capacity and Doubling Energy Efficiency by 2030; IRENA: Abu Dhabi, United Arab Emirates, 2024.

- Johnson, N.; Bortolotti, P.; Dykes, K.; Barter, G.; Moriarty, P.; Carron, S.; Wendt, F.; Veers, P.; Paquette, J.; Kelly, C.; et al. Investigation of Innovative Rotor Concepts for the Big Adaptive Rotor Project; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2019.

- Chaviaropoulos, P.K.; Beurskens, J.; Voutsinas, S.G.; Beurskens, H.J.M. Moving towards Large(r) Rotors-Is That a Good Idea? In Proceedings of the European Wind Energy Conference & Exhibition (EWEC) 2013, Vienna, Austria, 4–7 February 2013. [Google Scholar]

- Salas, J. Planet’s Largest Wind Turbine Record Broken Again at 26-MW. Available online: https://newatlas.com/energy/world-record-offshore-wind-turbine-dongfang-26-mw/ (accessed on 19 June 2025).

- Vestas Wind Systems A/S V236-15.0 MWTM. Available online: https://www.vestas.com/en/energy-solutions/offshore-wind-turbines/V236-15MW (accessed on 19 June 2025).

- Pugh, K.; Rasool, G.; Stack, M.M. Some Thoughts on Mapping Tribological Issues of Wind Turbine Blades Due to Effects of Onshore and Offshore Raindrop Erosion. J. Bio Tribo-Corros. 2018, 4, 50. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for Wind Turbine Blades: An Overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef] [PubMed]

- Blade|Energy|MARKETS|Carbon Fiber Composite Materials|TORAY. Available online: https://www.cf-composites.toray/markets/energy/blade/ (accessed on 3 July 2025).

- Jamieson, P. 7.2 High Speed Rotor. In Innovation in Wind Turbine Design, 2nd ed.; Wiley: Chichester, UK, 2018; Available online: https://app-knovel-com.proxy.lib.strath.ac.uk/kn/resources/kt011UIC32/kpIWTDE002/pdf?b-toc-cid=kpIWTDE002&b-toc-root-slug=innovation-in-wind-turbine&b-toc-title=Innovation%20in%20Wind%20Turbine%20Design%20%282nd%20Edition%29&b-toc-url-slug=introduction&kpromoter=marc (accessed on 19 June 2025).

- Ning, A.; Dykes, K. Understanding the Benefits and Limitations of Increasing Maximum Rotor Tip Speed for Utility-Scale Wind Turbines. J. Phys. Conf. Ser. 2014, 524, 012087. [Google Scholar] [CrossRef]

- Herring, R.; Dyer, K.; Martin, F.; Ward, C. The Increasing Importance of Leading Edge Erosion and a Review of Existing Protection Solutions. Renew. Sustain. Energy Rev. 2019, 115, 109382. [Google Scholar] [CrossRef]

- Keegan, M.H.; Nash, D.H.; Stack, M.M. On Erosion Issues Associated with the Leading Edge of Wind Turbine Blades. J. Phys. D Appl. Phys. 2013, 46, 383001. [Google Scholar] [CrossRef]

- RE News Anholt Grapples with Blade Fix-Renewable Energy News. Available online: https://renews.biz/33085/anholt-grapples-with-blade-fix/ (accessed on 20 June 2025).

- RE News London Array Braced for Blade Fix—Renewable Energy News. Available online: https://renews.biz/32801/london-array-braced-for-blade-fix/ (accessed on 20 June 2025).

- Durakovic, A. Siemens Gamesa and Ziton Sign West of Duddon Sands Blade Upgrade Contract|Offshore Wind. Available online: https://www.offshorewind.biz/2019/05/16/siemens-gamesa-and-ziton-sign-west-of-duddon-sands-blade-upgrade-contract/ (accessed on 20 June 2025).

- Jonsson, R. Characterisation and Validation of a Pulsating Jet Erosion Test 2007:279 CIV. Master’s Thesis, Luleå University of Technology, Luleå, Sweden, 2007. [Google Scholar]

- Zhou, W.; Zhang, D.; Yang, M. Effects of Surface Curvature on Rain Erosion of Wind Turbine Blades under High-Velocity Impact. Heliyon 2024, 10, e40761. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, N.; Chen, X.; Xu, T.; Hui, S.; Zhang, D. Analysis of Water Drop Erosion on Turbine Blades Based on a Nonlinear Liquid–Solid Impact Model. Int. J. Impact Eng. 2009, 36, 1156–1171. [Google Scholar] [CrossRef]

- Ibrahim, M.E.; Medraj, M. Water Droplet Erosion of Wind Turbine Blades: Mechanics, Testing, Modeling and Future Perspectives. Materials 2019, 13, 157. [Google Scholar] [CrossRef] [PubMed]

- Cortés, E.; Sánchez, F.; O’Carroll, A.; Madramany, B.; Hardiman, M.; Young, T.M. On the Material Characterisation of Wind Turbine Blade Coatings: The Effect of Interphase Coating–Laminate Adhesion on Rain Erosion Performance. Materials 2017, 10, 1146. [Google Scholar] [CrossRef] [PubMed]

- Ansari, M.; Sánchez, F.; Doménech-Ballester, L.; Young, T. Evaluation of Offshore Wind Turbine Leading Edge Protection Coating Failure Mode under Rain Erosion. Procedia Struct. Integr. 2024, 52, 122–132. [Google Scholar] [CrossRef]

- Zhang, S. Accelerated Rain Erosion of Wind Turbine Blade Coatings. Ph.D. Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2014. [Google Scholar]

- Keegan, M.H.; Nash, D.H.; Stack, M.M. Modelling Rain Drop Impact of Offshore Wind Turbine Blades. In Proceedings of the ASME Turbo Expo, Copenhagen, Denmark, 11–15 June 2012; Volume 6, pp. 887–898. [Google Scholar] [CrossRef]

- O’Carroll, A.; Hardiman, M.; Tobin, E.F.; Young, T.M. Correlation of the Rain Erosion Performance of Polymers to Mechanical and Surface Properties Measured Using Nanoindentation. Wear 2018, 412–413, 38–48. [Google Scholar] [CrossRef]

- Wind Power Lab What Is Leading Edge Erosion?—Wind Power LAB. Available online: https://windpowerlab.com/what-is-leading-edge-erosion/ (accessed on 20 July 2025).

- Verma, A.S.; Castro, S.G.; Jiang, Z.; Hu, W.; Teuwen, J.J. Leading Edge Erosion of Wind Turbine Blades: Effects of Blade Surface Curvature on Rain Droplet Impingement Kinematics. J. Phys. Conf. Ser. 2020, 1618, 052003. [Google Scholar] [CrossRef]

- Fujisawa, N.; Aihara, A. Rain Erosion Mechanism on a Leading-Edge Half Cylinder. Wear 2023, 532–533, 205103. [Google Scholar] [CrossRef]

- Slot, H.M.; Gelinck, E.R.M.; Rentrop, C.; Van der Heide, E. Leading Edge Erosion of Coated Wind Turbine Blades: Review of Coating Life Models. Renew. Energy 2015, 80, 837–848. [Google Scholar] [CrossRef]

- Chen, J.; Wang, J.; Ni, A. A Review on Rain Erosion Protection of Wind Turbine Blades. J. Coat. Technol. Res. 2019, 16, 15–24. [Google Scholar] [CrossRef]

- Rain Erosion Testing’s NEW Analysis Methodology—Wind Power LAB. Available online: https://windpowerlab.com/rain-erosion-testing/ (accessed on 5 August 2025).

- Eisenberg, D.; Laustsen, S.; Stege, J. Wind Turbine Blade Coating Leading Edge Rain Erosion Model: Development and Validation. Wind Energy 2018, 21, 942–951. [Google Scholar] [CrossRef]

- Pryor, S.C.; Barthelmie, R.J.; Cadence, J.; Dellwik, E.; Hasager, C.B.; Kral, S.T.; Reuder, J.; Rodgers, M.; Veraart, M. Atmospheric Drivers of Wind Turbine Blade Leading Edge Erosion: Review and Recommendations for Future Research. Energies 2022, 15, 8553. [Google Scholar] [CrossRef]

- Caboni, M.; Schwarz, A.E.; Slot, H.; van der Mijle Meijer, H. Estimating Microplastic Emissions from Offshore Wind Turbine Blades in the Dutch North Sea. Wind Energy Sci. 2025, 10, 1123–1136. [Google Scholar] [CrossRef]

- Fujisawa, N. Review: Fundamentals of Liquid Droplet Impingement and Rain Erosion of Wind Turbine Blade. Next Energy 2025, 8, 100262. [Google Scholar] [CrossRef]

- Rasool, G.; Larios, M.P.; Stack, M.M. Impact Angle and Exposure Time Effects on Raindrop Erosion of Fibre Reinforced Polymer Composites: Application to Offshore Wind Turbine Conditions. Tribol. Trans. 2020; in press. Available online: https://pure.strath.ac.uk/ws/portalfiles/portal/89373624/Rasool_Stack_TT_2019_Impactangle_and_exposure_time_effects_on_raindrop_erosion.pdf (accessed on 15 September 2025).

- Tempelis, A.; Mishnaevsky, L., Jr. Coating Material Loss and Surface Roughening Due to Leading Edge Erosion of Wind Turbine Blades: Probabilistic Analysis. Wear 2025, 566, 205755. [Google Scholar] [CrossRef]

- Barfknecht, N.; Von Terzi, D. Drop-Size-Dependent Effects in Leading-Edge Rain Erosion and Their Impact on Erosion-Safe Mode Operation. Wind Energy Sci. 2025, 10, 315–346. [Google Scholar] [CrossRef]

- Pryor, S.C.; Coburn, J.J.; Barthelmie, R.J. Spatiotemporal Variability in Wind Turbine Blade Leading Edge Erosion. Energies 2025, 18, 425. [Google Scholar] [CrossRef]

- Dashtkar, A.; Hadavinia, H.; Sahinkaya, M.N.; Williams, N.A.; Vahid, S.; Ismail, F.; Turner, M. Rain Erosion-Resistant Coatings for Wind Turbine Blades: A Review. Polym. Polym. Compos. 2019, 27, 443–475. [Google Scholar] [CrossRef]

- Groucott, S.; Pugh, K.; Zekos, I.; Stack, M.M. A Study of Raindrop Impacts on a Wind Turbine Material: Velocity and Impact Angle Effects on Erosion MAPS at Various Exposure Times. Lubricants 2021, 9, 60. [Google Scholar] [CrossRef]

- Keegan, M.H.; Nash, D.; Stack, M. Numerical Modelling of Hailstone Impact on the Leading Edge of a Wind Turbine Blade. In Proceedings of the EWEA Annual Wind Energy Event 2013, Vienna, Austria, 4 February 2013. [Google Scholar]

- Fang, W.Z.; Zhu, F.Q.; Shen, F.; Chai, D.; Tao, W.Q. Freezing Behaviors of Impacting Water Droplets on Cold Inclined Surfaces. Appl. Therm. Eng. 2023, 219, 119562. [Google Scholar] [CrossRef]

- Mishnaevsky, L. Toolbox for Optimizing Anti-Erosion Protective Coatings of Wind Turbine Blades: Overview of Mechanisms and Technical Solutions. Wind Energy 2019, 22, 1636–1653. [Google Scholar] [CrossRef]

- Domenech, L.; Renau, J.; Šakalyte, A.; Sánchez, F. Top Coating Anti-Erosion Performance Analysis in Wind Turbine Blades Depending on Relative Acoustic Impedance. Part 1: Modelling Approach. Coatings 2020, 10, 685. [Google Scholar] [CrossRef]

- TNO. TNO Research Leads to Better Damage Prediction for Offshore Wind Turbine Blades. Available online: https://www.tno.nl/en/newsroom/2025/03/damage-prediction-wind-turbine-blades/ (accessed on 14 August 2025).

- Godfrey, M.; Siederer, O.; Zekonyte, J.; Barbaros, I.; Wood, R. The Effect of Temperature on the Erosion of Polyurethane Coatings for Wind Turbine Leading Edge Protection. Wear 2021, 476, 203720. [Google Scholar] [CrossRef]

- Momber, A.W.; Irmer, M.; Glück, N. Effects of Accelerated Low-Temperature Ageing on the Performance of Polymeric Coating Systems on Offshore Steel Structures. Cold Reg. Sci. Technol. 2017, 140, 39–53. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Tempelis, A.; Kuthe, N.; Mahajan, P. Recent Developments in the Protection of Wind Turbine Blades against Leading Edge Erosion: Materials Solutions and Predictive Modelling. Renew. Energy 2023, 215, 118966. [Google Scholar] [CrossRef]

- Rasool, G.; Middleto, A.C.; Stack, M.M. Mapping Raindrop Erosion of GFRP Composite Wind Turbine Blade Materials: Perspectives on Degradation Effects in Offshore and Acid Rain Environmental Conditions. J. Tribol. 2020, 142, 061701. [Google Scholar] [CrossRef]

- Bouhelal, A.; Hamlaoui, M.N.; Smaili, A. Impact of Surface Roughness on the Aerodynamic Efficiency of Wind Turbines: A New CFD-Based Correlation. J. Appl. Fluid Mech. 2025, 18, 438–449. [Google Scholar] [CrossRef]

- Wang, H.; Chen, B. Investigation on Unsteady Aerodynamic Noise of Leading Edge Erosion for Wind Turbine Blade. Ocean Eng. 2025, 341, 122744. [Google Scholar] [CrossRef]

- Biazar, D.; Afzalian, A. The Impact of Blade Surface Roughness on Wind Turbine Efficiency: A Monte Carlo Method Approach. Energy Sci. Eng. 2025, 13, 2022–2030. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Hasager, C.B.; Bak, C.; Tilg, A.M.; Bech, J.I.; Doagou Rad, S.; Fæster, S. Leading Edge Erosion of Wind Turbine Blades: Understanding, Prevention and Protection. Renew. Energy 2021, 169, 953–969. [Google Scholar] [CrossRef]

- IEA Wind Task 11. Erosion of Wind Turbine Blades. In Proceedings of the Technical Expert Meeting #98, Roskilde, Denmark, 6–7 February 2020. [Google Scholar]

- Alizadeh, A.; Bahadur, V.; Shang, W.; Zhu, Y.; Buckley, D.; Dhinojwala, A.; Sohal, M. Influence of Substrate Elasticity on Droplet Impact Dynamics. Langmuir 2013, 29, 4520–4524. [Google Scholar] [CrossRef] [PubMed]

- Elege Energy Importance of Wind Turbine Blade Protection—Elege New Energy Manufacturer. Available online: https://energy-elege.com/wind-turbine-blade-protection/ (accessed on 16 August 2025).

- Doagou-Rad, S.; Mishnaevsky, L. Rain Erosion of Wind Turbine Blades: Computational Analysis of Parameters Controlling the Surface Degradation. Meccanica 2020, 55, 725–743. [Google Scholar] [CrossRef]

- Incorez Oxazolidines in Polyurethane Coatings for Wind Turbines|Incorez. Available online: https://www.incorez.com/en/case-studies/coatings/heavy-duty-protective/oxazolidines-in-polyurethane-coatings-for-wind-turbines.html (accessed on 16 August 2025).

- Alajmi, A.F.; Ramulu, M. The Effectiveness of Graphene and Polyurethane Multilayer Coating on Minimizing the Leading-Edge Erosion of Wind Turbine Blades. Results Eng. 2025, 26, 104804. [Google Scholar] [CrossRef]

- Martínez, F.J.; Canales, M.; Bielsa, J.M.; Jiménez, M.A. Relationship between Wear Rate and Mechanical Fatigue in Sliding TPU–Metal Contacts. Wear 2010, 268, 388–398. [Google Scholar] [CrossRef]

- Nixon-Pearson, O.; Greaves, P.; Mamalis, D.; Stevenson, L. Cornwall Flow Accelerator WP4 Innovation in Low Carbon Design and Manufacturability–Wind Turbine Blades Design and Manufacturing, Current State-of-the Art Literature Review; ORE Catapult: Scotland, UK, 2022. [Google Scholar]

- Pathak, S.M.; Kumar, V.P.; Bonu, V.; Mishnaevsky, L.; Lakshmi, R.V.; Bera, P.; Barshilia, H.C. Enhancing Wind Turbine Blade Protection: Solid Particle Erosion Resistant Ceramic Oxides-Reinforced Epoxy Coatings. Renew. Energy 2025, 238, 121681. [Google Scholar] [CrossRef]

- Ashrafizadeh, H.; Mertiny, P.; McDonald, A. Evaluation of the Effect of Temperature on Mechanical Properties and Wear Resistance of Polyurethane Elastomers. Wear 2016, 368–369, 26–38. [Google Scholar] [CrossRef]

- Ramakrishnan, T.; Raja Karthikeyan, K.; Tamilselvan, V.; Sivakumar, S.; Gangodkar, D.; Radha, H.R.; Narain Singh, A.; Asrat Waji, Y. Study of Various Epoxy-Based Surface Coating Techniques for Anticorrosion Properties. Adv. Mater. Sci. Eng. 2022, 2022, 5285919. [Google Scholar] [CrossRef]

- Varganici, C.D.; Rosu, L.; Rosu, D.; Rosca, I.; Ignat, M.E.; Ignat, L. Surface Degradation of DGEBA Epoxy Resins Cured with Structurally Different Amine Hardeners: Effects of UV Radiation. Polymers 2024, 16, 67. [Google Scholar] [CrossRef] [PubMed]

- Garg, A.C.; Mai, Y.W. Failure Mechanisms in Toughened Epoxy Resins—A Review. Compos. Sci. Technol. 1988, 31, 179–223. [Google Scholar] [CrossRef]

- Baig, M.M.A.; Samad, M.A. Epoxy\Epoxy Composite\Epoxy Hybrid Composite Coatings for Tribological Applications—A Review. Polymers 2021, 13, 179. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, N.; Huang, M.; Gao, G.; Liu, S.; Liu, C. Polyurethane-Based Nanocomposite Film with Thermal Deicing Capability and Anti-Erosion for Wind Turbine Blades Protection in Extreme Environments. J. Mater. Chem. A Mater. 2023, 11, 23844–23853. [Google Scholar] [CrossRef]

- He, Z.; Xie, H.; Jamil, M.I.; Li, T.; Zhang, Q. Electro-/Photo-Thermal Promoted Anti-Icing Materials: A New Strategy Combined with Passive Anti-Icing and Active De-Icing. Adv. Mater. Interfaces 2022, 9, 2200275. [Google Scholar] [CrossRef]

- Johansen, N.F.J.; Mishnaevsky, L.; Dashtkar, A.; Williams, N.A.; Fæster, S.; Silvello, A.; Cano, I.G.; Hadavinia, H. Nanoengineered Graphene-Reinforced Coating for Leading Edge Protection of Wind Turbine Blades. Coatings 2021, 11, 1104. [Google Scholar] [CrossRef]

- Ibrahim, S.H.; El-Tayeb, N.S.M. Effect of Nano-Silica/Alumina Hybrid Coating on Erosion Resistance of Glass Fibre-Reinforced Polymer for the Application of Wind Turbine Blades. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 2013–2031. [Google Scholar] [CrossRef]

- Pathak, S.M.; Kumar, V.P.; Bonu, V.; Mishnaevsky, L.; Lakshmi, R.V.; Bera, P.; Barshilia, H.C. Development of Cellulose-Reinforced Polyurethane Coatings: A Novel Eco-Friendly Approach for Wind Turbine Blade Protection. Energies 2023, 16, 1730. [Google Scholar] [CrossRef]

- SpecialChem. MCG’s Bio-Based PU Coatings to Be Used for Wind Turbine Blade Protection. Available online: https://www.specialchem.com/coatings/news/mcg-biobased-pu-coatings-wind-turbine-blade-protection-000234059 (accessed on 18 August 2025).

- Ceramic Coatings–Applications in Engineering; Shi, F., Ed.; InTech: Rijeka, Croatia, 2012; ISBN 978-953-51-0083-6. [Google Scholar]

- Keller, M.W.; Hampton, K.; McLaury, B. Self-Healing of Erosion Damage in a Polymer Coating. Wear 2013, 307, 218–225. [Google Scholar] [CrossRef]

- Kinsley, P.; Porteous, S.; Jones, S.; Subramanian, P.; Campo, O.; Dyer, K. Limitations of Standard Rain Erosion Tests for Wind Turbine Leading Edge Protection Evaluation. Wind 2025, 5, 3. [Google Scholar] [CrossRef]

- Bartolomé, L.; Teuwen, J. Prospective Challenges in the Experimentation of the Rain Erosion on the Leading Edge of Wind Turbine Blades. Wind Energy 2019, 22, 140–151. [Google Scholar] [CrossRef]

- Siddons, C.; Macleod, C.; Yang, L.; Stack, M. An Experimental Approach to Analysing Rain Droplet Impingement on Wind Turbine Blade Materials. In Proceedings of the EWEA 2015 Annual Event, Paris, France, 17–20 November 2015. [Google Scholar]

- Tobin, E.F.; Young, T.M.; Raps, D. Evaluation and Correlation of Inter-Laboratory Results from a Rain Erosion Test Campaign. In Proceedings of the 28th Congress of the International Council of the Aeronautical Sciences 2012, ICAS 2012, Brisbane, Australia, 23–28 September 2012; Volume 6, pp. 4957–4966. [Google Scholar]

- Mackie, C.; Boyce, D.; Nash, D. Characterisation of a Whirling Arm Erosion Test Rig; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Wu, Z. Use of a Pulsating Water Jet for Accelerated Rain Erosion of Wind Turbine Blade Coatings. Ph.D. Thesis, University of Denmark, Kongens Lyngby, Denmark, 2023. [Google Scholar]

- Hammitt, F.G.; Lafferty, J.F.; Cheesewright, R.; Pitek, M.T.; Kemppainen, D.J.; Mitchel, T.M. Laboratory Scale Devices for Rain Erosion Simulation; American Institute of Aeronautics and Astronautics (AIAA): Reston, VA, USA, 1967. [Google Scholar]

- Bech, J.I.; Johansen, N.F.J.; Madsen, M.B.; Hannesdóttir, Á.; Hasager, C.B. Experimental Study on the Effect of Drop Size in Rain Erosion Test and on Lifetime Prediction of Wind Turbine Blades. Renew. Energy 2022, 197, 776–789. [Google Scholar] [CrossRef]

- Fraisse, A.; Bech, J.I.; Borum, K.K.; Fedorov, V.; Frost-Jensen Johansen, N.; McGugan, M.; Mishnaevsky, L.; Kusano, Y. Impact Fatigue Damage of Coated Glass Fibre Reinforced Polymer Laminate. Renew. Energy 2018, 126, 1102–1112. [Google Scholar] [CrossRef]

- Wu, Z.; Azizaddini, N.; Weinell, C.E.; Dam-Johansen, K.; Kiil, S. Characterization of a Pulsating Water Jet for Rain Erosion Testing of Blade Coatings: Flow Visualization, Pressure Investigation, and Damage Analysis. Mater. Today Commun. 2024, 40, 109898. [Google Scholar] [CrossRef]

- ASTM G73-10; Standard Test Method for Liquid Impingement Erosion Using Rotating Apparatus (G73-10). ASTM International: West Conshohocken, PA, USA, 2010.

- DNV-RP-0171; Testing of Rotor Blade Erosion Protection Systems. DNV: Høvik, Norway, 2018.

- Zhang, S.; Dam-Johansen, K.; Bernad, P.L.; Kiil, S. Rain Erosion of Wind Turbine Blade Coatings Using Discrete Water Jets: Effects of Water Cushioning, Substrate Geometry, Impact Distance, and Coating Properties. Wear 2015, 328–329, 140–148. [Google Scholar] [CrossRef]

- Finnegan, W.; Bech, J.I.; Hasager, C.B.; Tobin, E.; Dyer, K.; Johansen, N.F.-J.; Katsivalis, I.; López, F.S.; Hamerton, I.; Blattert, H.; et al. Review on Available Technologies for Laboratory Erosion Testing; Technical Report; Technical University of Denmark (DTU): Kongens Lyngby, Denmark, 2022; Available online: https://iea-wind.org/wp-content/uploads/2022/12/IEA-WT46-WP4.1-report-Review-on-available-technologies-for-laboratory-erosion-testing.pdf (accessed on 19 August 2025).

- Pugh, K.; Nash, J.W.; Reaburn, G.; Stack, M.M. On Analytical Tools for Assessing the Raindrop Erosion of Wind Turbine Blades. Renew. Sustain. Energy Rev. 2021, 137, 110611. [Google Scholar] [CrossRef]

- Tobin, E.F.; Rohr, O.; Raps, D.; Willemse, W.; Norman, P.; Young, T.M. Surface Topography Parameters as a Correlation Factor for Liquid Droplet Erosion Test Facilities. Wear 2015, 328–329, 318–328. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, L.; Liu, Y.; Ren, J.; Hu, H. An Experimental Study of Rain Erosion Effects on a Hydro-/Ice-Phobic Coating Pertinent to Unmanned-Arial-System (UAS) Inflight Icing Mitigation. Cold Reg. Sci. Technol. 2021, 181, 103196. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Fæster, S.; Mikkelsen, L.P.; Kusano, Y.; Bech, J.I. Micromechanisms of Leading Edge Erosion of Wind Turbine Blades: X-Ray Tomography Analysis and Computational Studies. Wind Energy 2020, 23, 547–562. [Google Scholar] [CrossRef]

- Garcea, S.C.; Wang, Y.; Withers, P.J. X-Ray Computed Tomography of Polymer Composites. Compos. Sci. Technol. 2018, 156, 305–319. [Google Scholar] [CrossRef]

- Hasager, C.; Mishnaevsky, L.; Bak, C.; Bech, J.I.; Faester, S.; Johansen, N.F. How Can We Combat Leading-Edge Erosion on Wind Turbine Blades? DTU Wind Energy: Roskilde, Denmark, 2021; pp. 134–142. [Google Scholar] [CrossRef]

- Valeur, B.; Ario, M.; Berberan-Santos, N. A Brief History of Fluorescence and Phosphorescence before the Emergence of Quantum Theory. J. Chem. Educ. 2011, 88, 731–738. [Google Scholar] [CrossRef]

- Olawale, D.O.; Dickens, T.; Sullivan, W.G.; Okoli, O.I.; Sobanjo, J.O.; Wang, B. Progress in Triboluminescence-Based Smart Optical Sensor System. J. Lumin. 2011, 131, 1407–1418. [Google Scholar] [CrossRef]

- Pugh, K.; Rasool, G.; Stack, M.M. Raindrop Erosion of Composite Materials: Some Views on the Effect of Bending Stress on Erosion Mechanisms. J. Bio Tribo-Corros. 2019, 5, 45. [Google Scholar] [CrossRef]

- Eisenberg, D.; Laustsen, S.; Stege, J. Leading Edge Protection Lifetime Prediction Model Creation and Validation. In Proceedings of the WindEurope Summit 2016: Conference Poster Presentation, Hamburg, Germany, 27–29 September 2016; Wind Europe: Hamburg, Germany, 2016; Volume 17. [Google Scholar]

- Caboni, M.; van Dalum, G. Developing an Atlas of Rain-Induced Leading Edge Erosion for Wind Turbine Blades in the Dutch North Sea. Wind Energy Sci. 2024, 10, 1887–1906. [Google Scholar] [CrossRef]

- Mishnaevsky, L. Root Causes and Mechanisms of Failure of Wind Turbine Blades: Overview. Materials 2022, 15, 2959. [Google Scholar] [CrossRef]

- Hoksbergen, N.; Akkerman, R.; Baran, I. The Springer Model for Lifetime Prediction of Wind Turbine Blade Leading Edge Protection Systems: A Review and Sensitivity Study. Materials 2022, 15, 1170. [Google Scholar] [CrossRef]

- Herring, R.; Domenech, L.; Renau, J.; Šakalytė, A.; Ward, C.; Dyer, K.; Sánchez, F. Assessment of a Wind Turbine Blade Erosion Lifetime Prediction Model with Industrial Protection Materials and Testing Methods. Coatings 2021, 11, 767. [Google Scholar] [CrossRef]

- Johansen, N.F.J. Test Methods for Evaluating Rain Erosion Performance of Wind Turbine Blade Leading Edge Protection Systems. Ph.D. Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2020. [Google Scholar]

| Category | Parameter | Typical Range/Test Conditions | Outcome of the Study |

|---|---|---|---|

| Droplet Characteristics | Droplet size | 0.76 mm, 1.90 mm, 2.38 mm, and 3.50 mm [38] | Larger droplets produced greater erosion due to higher impact velocity. Inclusion of drop-size effects shifts the 50% cumulative damage contribution from <1.26 mm to <2 mm, highlighting the strong influence of droplet size distribution on erosion behaviour [38]. |

| Impact velocity | 20–60 m/s [7]; 40–60 m/s [41] | ||

| Impact angle | 15–90° [7,41] | At lower angles (~15°), erosion was dominated by shear-induced cutting; at higher angles (~90°), surface deformation increased with less mass loss. Maximum mass loss occurred at 60° under pure water impacts [7,41]. | |

| Freezing rain | Droplet temperature: 22 °C; substrate: −45 °C to −25 °C [43] | Freezing behaviour was governed by surface angle (α) and temperature difference (ΔT). Fixed angles (30°) produced rounded ice shapes, while steeper angles (45–60°) generated cusped geometries that increased aerodynamic loss and coating stress. Rapid freezing caused cracking from volume expansion, and greater subcooling enhanced adhesion and rivulet slenderness. Lower temperatures reduce droplet spreading due to higher viscosity, altering initial erosion and adhesion behaviour [43]. | |

| Material properties | Hardness | PMMA-C: 0.30 GPa; PMMA-E: 0.28 GPa; PET: 0.16 GPa; PC: 0.18 GPa; PE: 0.07 GPa; PP: 0.05 GPa [25] | Lower indentation hardness improved rain erosion resistance; softer materials endured longer before reaching steady mass loss. A negative correlation was observed between hardness and erosion resistance [25]. |

| Elasticity/toughness | — | Improved erosion durability was linked to lower stiffness, which enhanced shockwave dissipation and delayed crack propagation. A critical surface roughness threshold was required before significant mass removal occurred [25]. | |

| Acoustic impedance | — | Lower indentation storage modulus (E′) increased erosion resistance logarithmically. Reduced elastic modulus minimised acoustic impedance mismatch with water, enabling better energy absorption [25]. | |

| Viscoelastic behaviour | — | High short-term (elastic) recovery correlated with improved durability, whereas long-term viscoelastic recovery had little effect under high impact frequency. A lower spring component was beneficial [25]. | |

| Environmental conditions | Temperature | Ambient (25 °C) and cold (−30 °C) [47] | Erosion rate was significantly higher at −30 °C than at 25 °C. Cold tests revealed a more ductile erosion mechanism with increased pitting and abrasion of the PU layer and cracking in the underlying PE layer. Nanoindentation showed a higher plasticity index (PI) and lower H/Er ratio at reduced temperature, suggesting coatings with lower temperature sensitivity provide better erosion resistance [47]. |

| Co-stressors (e.g., humidity, UV radiation, acid rain) | Rainwater solutions: deionized water (pH 7); artificial acid rain (pH 4); saltwater (pH 8.1) [50] UV radiation: UV-A 340 lamp; UV exposure: 4 h (60 ± 3 °C); condensation: 4 h (50 ± 3 °C); salt spray pH value: 6.7–7.2 [48] |

|

| Coating Type | Nanofiller/Composite System | Base Matrix | Application/Method | Key Findings | Ref. |

|---|---|---|---|---|---|

| Nanocomposite | GNP (graphene nanoplatelets), Hybrid GNP + Silica (PU + GNP + SG) | PU | In situ polymerisation; SPIFT testing |

| [71] |

| CNTs (carbon nanotubes) + GNP (sandwich film) | TPU | Spray-hot pressing |

| [69] | |

| CNTs, Graphene | Silica | Sol–gel technique |

| [40] | |

| Nano-silica + Nano-alumina hybrid | PU on GFRP | Spray method; air-jet erosion tests |

| [72] | |

| Bio-based | Nanocellulose reinforcement (fibres, fibrils) | PU | Computational modelling + experimental validation |

| [49] |

| CMP (cellulose microparticles), CMF (cellulose microfibres) | Water-based PU | Spray method; air-jet erosion tests |

| [73] | |

| Ceramic | Al2O3, ZrO2, CeO2 nanoparticles | Epoxy resin | Spray method; erosion tests at 30°, 60°, 90° |

| [63] |

| Self-healing | Dual microcapsules (vinyl-functionalized PDMS resin + platinum catalyst), PDMS copolymer initiator | PDMS resin | Mixed capsules in PDMS, applied to aluminium substrate; erosion tests with sand at ~88 m/s (30°) |

| [76] |

| Epoxy: hexamethylene diisocyanate (HDI) | Epoxy resin | Mixed capsules in epoxy, applied to aluminium substrate erosion tests with sand at ~88 m/s (90°) |

| [76] |

| Flow Zone | Standoff Distance (mm) | Flow Structure (Image Visualisation) | Pressure Investigation (Impact Zone) |

|---|---|---|---|

| Zone 1 | 0–45 | Continuous flow | High-frequency high-pressure impact (0–30 mm) |

| Zone 2 | 45–75 | Pulsating flow | High-frequency middle-pressure impact (30–90 mm) |

| Zone 3 | Beyond 75 | Expanding flow | Low-frequency low-pressure impact (Beyond 90 mm) |

| Equipment | Advantages | Disadvantages |

|---|---|---|

| Whirling Arm Rain Erosion Test |

|

|

| Single Point Impact Fatigue Tester |

|

|

| Water Jet Impingement |

|

|

| Test Method | Ref. | Key Parameters | Material/Coating | Measured Outcome | Key Findings/Trends |

|---|---|---|---|---|---|

| Whirling arm rain erosion test | [7,41,50,99] | Impact velocity 20–60 m/s, media: pure water, salt water (3.5% NaCl); acid rain (pH 4), applied bending stress (in selected tests), exposure time/cycle 219–864 km | G10/GFRE composite laminates | Mass change %, erosion map, SEM/EDX and, optical microscopy | Erosion rate increased with impact velocity and most severe at 45–60°. Applied bending stress accelerated degradation and produced a ductile–brittle crossover zone with surface impact circular deformation. Acidic rain caused highest mass loss and cracking; salt water led to mass gain from absorption. Early cycles (<432 km) dominated total loss before stabilising. Fibre exposure, pitting, and blistering were identified as primary damage modes. |

| [84] | Impact velocity 90–150 m/s, mean droplet diameter 0.76–3.50 mm | PU topcoat on GF epoxy |

|

| |

| [37] | Impact velocity 100–125 m/s, constant droplet diameter 2.4 mm, rain intensity 5 mm/h; 10 mm/h; 20 mm/h, | PU |

|

| |

| Single Point Impact Fatigue Tester (SPFIT) | [85] | Impact velocity 123–165 m/s; 6 mm rubber ball | GFRP laminates coated with epoxy-based gelcoat |

|

|

| [71] | Impact velocity 150 and 173 m/s; 6 mm nitrile rubber ball | PU, PU + Graphene (GNP), PU + GNP + Sol–gel (SG) |

|

| |

| Water jet impingement | [86] | Flow velocity 99–143 m/s, operating pressure 100–200 bar, standoff 30–110 mm, impact frequency ≈ 7500 impacts/s | Epoxy-primed PU |

|

|

| [89] | Flat and curved panels, standoff 50–100 mm, nozzle diameter 1.0–10 mm, operating pressure 150 bar, jet velocity 167 m/s, air blowing ON/OFF | PU topcoats: Coating A—polyester polyol + flexibilised isocyanate trimer, Coating B—polyester polyol + standard isocyanate trimer |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

A. Yusof, N.A.W.; Algaddaime, T.F.; Stack, M.M. Advancements and Challenges in Coatings for Wind Turbine Blade Raindrop Erosion: A Comprehensive Review of Mechanisms, Materials and Testing. Sustainability 2025, 17, 9611. https://doi.org/10.3390/su17219611

A. Yusof NAW, Algaddaime TF, Stack MM. Advancements and Challenges in Coatings for Wind Turbine Blade Raindrop Erosion: A Comprehensive Review of Mechanisms, Materials and Testing. Sustainability. 2025; 17(21):9611. https://doi.org/10.3390/su17219611

Chicago/Turabian StyleA. Yusof, Nur Ain Wahidah, Talal F. Algaddaime, and Margaret M. Stack. 2025. "Advancements and Challenges in Coatings for Wind Turbine Blade Raindrop Erosion: A Comprehensive Review of Mechanisms, Materials and Testing" Sustainability 17, no. 21: 9611. https://doi.org/10.3390/su17219611

APA StyleA. Yusof, N. A. W., Algaddaime, T. F., & Stack, M. M. (2025). Advancements and Challenges in Coatings for Wind Turbine Blade Raindrop Erosion: A Comprehensive Review of Mechanisms, Materials and Testing. Sustainability, 17(21), 9611. https://doi.org/10.3390/su17219611