Abstract

This paper examines how organizations and regions integrate digital transformation with environmental sustainability (“twin transition”). Based on 43 semi-structured expert interviews across 27 countries, we identify five empirically grounded insights. First, adoption is propelled by competitive pressure, external shocks, and rising regulatory and stakeholder demands. Second, success depends on internal capabilities—clear leadership vision and workforce skills—together with supportive regional innovation ecosystems. Third, deliberate technological synergies—especially digital twins for lifecycle optimization, Artificial Intelligence (AI)/analytics and Internet of Things (IoT) for monitoring, and blockchain for traceability—enable measurable gains in resource efficiency and environmental performance. Fourth, integration strengthens eco-innovation capacity, resilience to disruption, competitive positioning, and regional innovation dynamics. Fifth, persistent barriers remain; organizational silos, key performance indicators (KPIs) misalignment, rebound effects from digital infrastructures, and uneven regional capabilities. By linking enabling conditions, integration mechanisms, and barriers, the study advances theory and offers actionable guidance for managers and policymakers on realizing the twin transition, using descriptive counts to indicate salience within a purposive expert sample rather than to draw statistical inferences.

1. Introduction

The concept of a “twin transition,” referring to the simultaneous pursuit of digital transformation and environmental sustainability, has emerged prominently within recent innovation and policy agendas. It encapsulates the integration of digital innovations, such as AI, the IoT, big data analytics, and blockchain technologies, with sustainability initiatives aimed at achieving climate neutrality, resource efficiency, and long-term ecological resilience [1,2,3]. While initially promoted within European policy frameworks [4,5,6,7], the twin transition has recently attracted significant scholarly attention, becoming increasingly relevant for firms and regions seeking enhanced competitiveness and resilience [1,2,3]. However, integrating digital transformation with sustainability is inherently complex. Digital technologies can enable cleaner production processes, facilitate circular economy practices, and promote eco-innovation. Yet, they can also be resource-intensive, potentially offsetting environmental benefits through increased energy demand or material usage. Thus, digital transformation presents both opportunities and challenges—effectively serving as a “double-edged sword” in sustainability transition [1,2,8].

Academic debates surrounding the twin transition have generated substantial theoretical and policy interest. Early theoretical contributions have primarily focused on the potential of digital technologies to improve environmental outcomes through cleaner processes, efficient resource use, and improved sustainability management [9,10,11,12]. Yet, as Industry 4.0 technologies—AI, IoT, robotics, and digital twins—gain prominence, the complexity of their environmental implications demands deeper exploration [13,14]. Empirical evidence on how firms practically integrate these digital technologies into sustainability initiatives remains fragmented and limited, producing inconsistent findings across different organizational and regional contexts [3,15,16].

Recent studies have begun to clarify some aspects of this integration, highlighting instances where digital technologies significantly promote eco-innovation and circular practices [1,3]. Other studies emphasize regional contexts where digital and green innovations jointly enhance sustainability outcomes [16]. However, much of this empirical research is quantitatively oriented or based on broadly defined case studies, offering limited insights into detailed mechanisms, enabling conditions, and specific barriers to successful integration. Consequently, existing scholarship still provides limited empirical clarity regarding how digital transformation is effectively aligned with sustainability at both organizational and regional levels. In contrast to previous qualitative research that primarily offers generalized insights, this study provides detailed empirical evidence about specific organizational processes, regional conditions, and practical barriers influencing the successful integration of digital transformation and sustainability.

To address these significant empirical gaps, this study adopts an exploratory qualitative approach focused on the practical mechanisms and conditions that facilitate successful integration of digital transformation and sustainability. Drawing on rich empirical data collected through 43 semi-structured expert interviews across 27 countries, the study seeks to provide detailed empirical insights, moving beyond existing generalized and quantitative assessments prevalent in the current literature. In particular, this study seeks to answer the following overarching research question: “How do organizations concretely integrate digital transformation with sustainability strategies, and what key enabling factors, mechanisms, and barriers shape the success of this integration?”

Addressing this comprehensive research question, the study makes three specific original empirical contributions. First, it identifies concrete integration mechanisms through which digital technologies practically support sustainability outcomes at both organizational and regional levels, thus providing detailed empirical evidence beyond general conceptual frameworks. Second, it systematically highlights critical internal organizational capabilities (e.g., leadership clarity, workforce competencies) and external regional conditions (e.g., innovation ecosystems, institutional support) that significantly influence effective digital-sustainability integration. Third, it analyzes persistent implementation barriers—including internal organizational silos, rebound effects from digitalization, KPI misalignment, and regional disparities—that have often been under-explored in existing qualitative studies.

The remainder of this paper proceeds as follows: Section 2 offers a literature review. Section 3 describes the qualitative research methodology in detail. Section 4 presents the main findings. Section 5 discusses these findings in relation to existing literature. Finally, Section 6 provides concluding remarks, noting limitations of the research and outlining avenues for future research.

2. Literature Review

One significant strand of literature examines digital transformation as driven by Industry 4.0 technologies and their impacts on innovation and industrial performance. Originating from discussions at the 2011 Hanover Fair, Industry 4.0 emphasizes integrating advanced digital tools—AI, IoT, big data analytics, cloud computing, robotics, and additive manufacturing—into production processes to create adaptive, intelligent industrial environments [17,18,19]. These cyber-physical systems enable real-time data sharing, improved efficiency, strategic agility, and innovation capacity [1,20,21,22,23]. Research shows that effective adoption of digital technologies lowers barriers to eco-innovation, enhances resource efficiency, and significantly improves overall organizational performance [3,16,24,25,26]. However, capturing these benefits necessitates substantial investments in skills development, infrastructure enhancement, and robust collaborative ecosystems [3,16]. Moreover, researchers underscore the critical role of digital skills in harnessing the full potential of Industry 4.0 technologies, aligning digital performance indicators with environmental goals [1,16]. The emerging paradigm of Industry 5.0 further reinforces this alignment by emphasizing human-centric values and sustainability principles alongside technological advancements, framing digital innovation as an enabler of sustainability transitions [27,28,29,30,31].

Another distinct strand of research centers on sustainability transitions and eco-innovation strategies in industrial systems. Driven by global imperatives—such as climate change, resource circularity, and the United Nations Sustainable Development Goals (UN, 2015)—sustainability transitions involve systemic transformations toward low-carbon, circular, and environmentally sustainable economic models [2,3,4,32]. Sustainable innovation entails comprehensive redesign of products, processes, and business models, integrating recycling, energy efficiency, and green manufacturing to minimize ecological harm and align with regulatory expectations and market demands [6,33,34,35]. Previous studies indicate that firms proactively investing in sustainability initiatives significantly enhance their eco-innovation capacity, gain market advantages, and respond effectively to regulatory and stakeholder demands [16,36]. Integrating sustainability strategies with digital and lean manufacturing practices improves operational efficiency, eco-efficiency, and environmental performance [37,38]. Consequently, sustainability is increasingly viewed not as a constraint but as a strategic opportunity for innovation, competitiveness, and market differentiation, aligning sustainability objectives with broader industrial transformation agendas [2,30].

A third body of scholarship examines the integration of digital and sustainability transitions, exploring their synergies, inherent tensions, and enabling conditions. This convergence, referred to as the twin transition, has emerged as a cornerstone of European industrial strategy and scholarly discourse, emphasizing simultaneous advancement in digital transformation and environmental sustainability [1,4,6,30,39,40,41]. Scholars increasingly advocate viewing digitalization and sustainability not as parallel or sequential processes but as mutually reinforcing and complementary trajectories [1,3,24,42]. Technological innovations—including AI, IoT, big data, digital twins, and blockchain—function as sustainability enablers by enhancing energy efficiency, reducing emissions, supporting circular economy practices, and improving supply chain transparency [1,3,16,25,42]. Evidence demonstrates substantial synergies when digital and sustainability transitions are integrated, enhancing innovation capacity, environmental performance, and organizational competitiveness [3,24,43,44]. However, significant barriers persist, notably rebound effects from increased energy and resource demands of digital technologies, internal organizational silos, misalignment of performance metrics, and regional disparities in innovation capabilities [2,41,45]. Ref. [46] cautions that without careful governance, digitalization may inadvertently amplify rather than mitigate environmental challenges. Addressing these barriers requires integrated governance, cross-sector coordination, strategic leadership, targeted investments, and aligned policy interventions [30,39,47]. The literature emphasizes employing integrated strategies that incorporate technology, policy, and organizational change to optimally leverage the twin transition, ensuring digital advancements meaningfully contribute to climate objectives and equitable, inclusive development [7,41,45,47].

Despite considerable scholarly attention across these research strands, clear empirical gaps remain. Most current research comprises conceptual discussions, generalized quantitative assessments, or broadly scoped case studies. However, there is limited detailed qualitative empirical insight into precisely how organizations operationally integrate digital transformation strategies with sustainability objectives. Little empirical clarity exists regarding specific integration mechanisms, internal organizational capabilities (such as workforce skills, leadership strategies, innovation culture), and external regional conditions (innovation ecosystems, institutional support, regional infrastructure) essential to successful integration. Additionally, existing studies provide minimal insight into how organizations practically manage persistent implementation barriers—such as KPIs misalignment, internal silos, rebound effects, and regional disparities. Addressing these empirical gaps, this study provides qualitative evidence derived from semi-structured expert interviews across diverse international contexts, clarifying the nuanced organizational practices, enabling conditions, and practical barriers organizations face in integrating digital transformation effectively with sustainability.

3. Methodology

3.1. Research Design and Approach

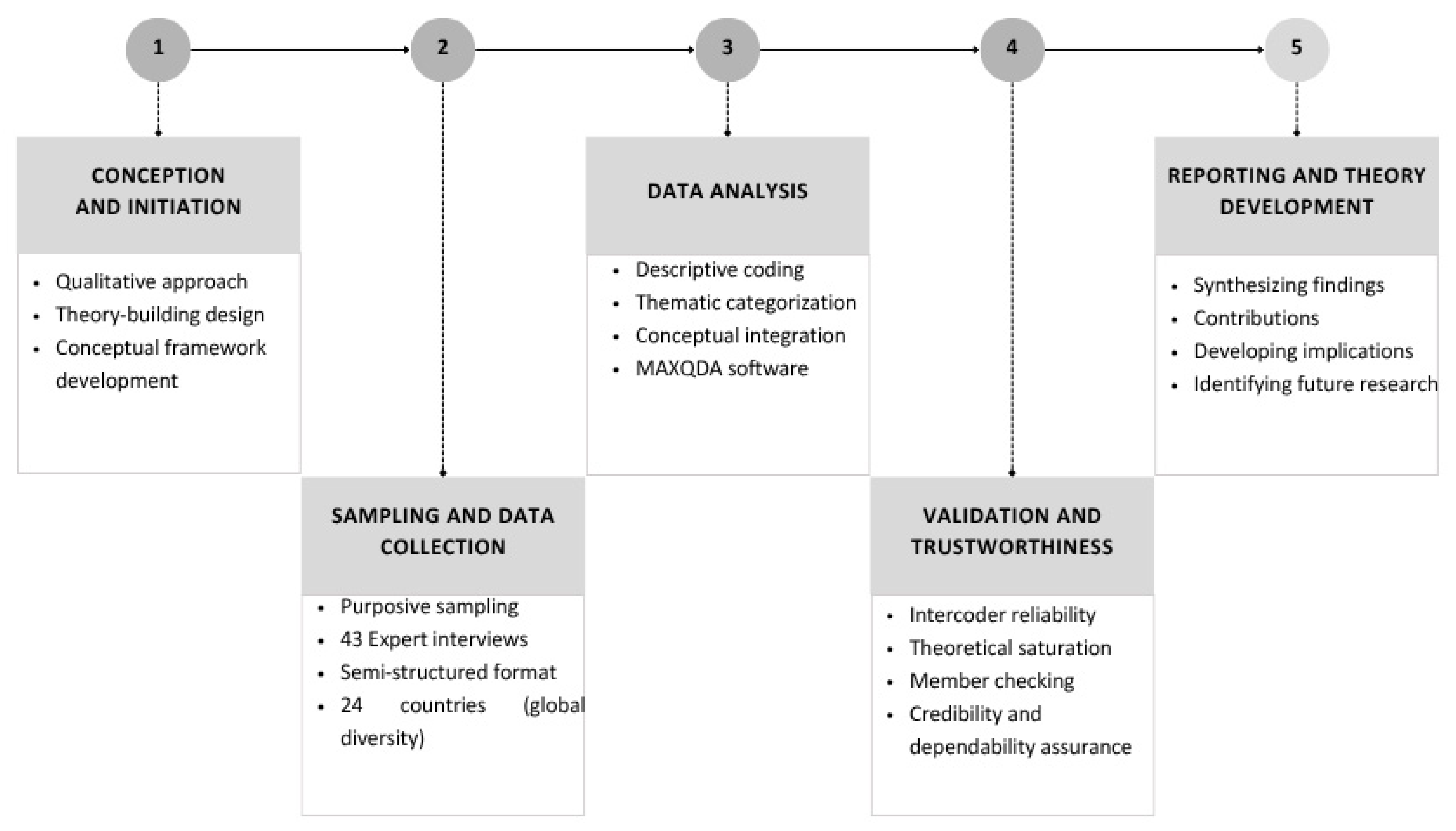

This study adopts an exploratory qualitative approach to investigate the integration mechanisms linking digital transformation and sustainability transitions—commonly referred to as the “twin transition.” Given the emerging nature of this research area and the fragmented state of existing theoretical frameworks [1,3], an inductive, theory-building research design was deemed appropriate. The study aims to identify and systematically analyze critical enabling factors, integration mechanisms, outcomes, and barriers associated with the simultaneous pursuit of digital transformation and sustainability. The research approach follows structured methodological steps as outlined in Figure 1.

Figure 1.

Methodological steps (Source: Authors).

3.2. Sampling and Participant Selection

The study employed purposive sampling to ensure participants possessed relevant expertise and practical experiences directly linked to the conceptual framework guiding this research. Participant selection was guided by three criteria: (1) in-depth experience with Industry 4.0 technologies; (2) extensive knowledge of managerial challenges related to environmental issues; and (3) clear expertise in understanding the potential sustainability impacts of digital technologies. These criteria ensured that interviewees had both theoretical and applied knowledge, enhancing the rigor and relevance of the qualitative data. A detailed profile of the interview sample is summarized in Table 1 and the profile of participants is shown in Appendix (Table A1).

Table 1.

Sample profile and interview coverage.

The study involved 43 expert participants with balanced representation between academic researchers and industry practitioners, including senior consultants and executives actively involved in digital-sustainability initiatives. The participants represented 27 countries—Argentina, Australia, Austria, Brazil, Cameroon, China, Croatia, France, Germany, Greece, Hungary, India, Italy, Japan, Kenya, Malaysia, Mexico, Morocco, Saudi Arabia, Serbia, South Korea, Spain, Sweden, Switzerland, Tunisia, the United Arab Emirates, and the United States—ensuring broad international representation and diverse perspectives. Participant recruitment commenced at the Smart Factory Summit held in Switzerland in June 2024, followed by further recruitment through professional networks and referrals, continuing until theoretical saturation was reached [48].

Because recruitment began at a smart-manufacturing summit and continued via professional networks, the sample may over-represent digitally advanced sectors and regions. We therefore frame our results as analytic generalization from information-rich expert cases rather than population estimates. To avoid overstating prevalence, we do not weight interviews and refrain from frequency claims across sectors or regions.

3.3. Data Collection Procedure

Given the exploratory characteristic of the research, the primary method for data collection involved semi-structured expert interviews. Although a general thematic script guided each interview, maintaining consistency with the research objectives, the precise formulation and sequencing of interview questions varied organically, adapting dynamically to participants’ responses and the natural flow of discussion. This flexible approach allowed researchers to explore specific topics raised by participants more deeply, facilitating rich qualitative insights reflecting the diverse professional experiences and contexts represented within the sample. Interviews were conducted between June and September 2024, initially face-to-face at the Smart Factory Summit, and subsequently via online video conferencing. The interviews ranged from 40 to 80 min, systematically covering themes such as digital transformation drivers, sustainability imperatives, integration mechanisms, organizational and regional conditions, innovation outcomes, and barriers encountered during implementation.

At the outset of each interview, ethical considerations were addressed with each participant. Given the qualitative, exploratory, and anonymous nature of this research, verbal informed consent was obtained rather than written consent. Participants were thoroughly briefed about the study’s objectives, methodological approach, potential implications, and the measures taken to ensure confidentiality and anonymity. Specifically, participants were informed that their participation was voluntary, and that they could withdraw at any point without any repercussions. This procedure aligned with standard practices in qualitative research, particularly for expert interviews where identifiable information is not collected or disclosed. Participants’ anonymity was meticulously protected throughout the research process. Personal names, identifiable details, or specific information that could potentially compromise anonymity were systematically excluded from the data and manuscript. Data collected from the interviews have been aggregated and reported strictly in a manner ensuring that individual respondents cannot be identified.

All interviews were digitally recorded with participants’ permission and subsequently transcribed verbatim to ensure accuracy, completeness, and detailed documentation of data. Approximately 40 h of recorded material were collected, providing substantial qualitative data for rigorous analysis.

3.4. Data Analysis

The qualitative data were analyzed using a structured thematic approach guided by the conceptual framework. Adhering to the recommendations of established guidelines [48,49], the analysis placed significant emphasis on the coherent presentation of participant quotations and their integration with emerging theoretical insights [50]. This methodological approach ensured that findings were systematically linked to theoretical constructs, thereby creating a clear narrative that enhanced both the rigor and transparency of the analysis. The analytical process entailed a structured thematic approach comprising three sequential stages: (1) descriptive coding; (2) thematic categorization; and (3) conceptual integration aligned with the predefined conceptual framework dimensions. In the initial phase of the study, descriptive coding was utilized to systematically identify specific practices, experiences, and expert perceptions expressed by participants regarding digital transformation enablers, sustainability drivers, integration mechanisms, innovation outcomes, and implementation barriers. This preliminary coding remained closely linked to the conceptual categories within the guiding framework.

In the subsequent analytical stage, these descriptive codes were methodically organized into coherent thematic categories that reflected the fundamental elements of the conceptual framework. For instance, insights concerning digital instruments utilized for the optimization of resources, including AI-driven predictive maintenance and IoT-based energy administration, were grouped under the rubric of “digital as enabler of sustainability.” In a similar vein, statements pertaining to leadership roles, internal skill-building, and regional innovation ecosystems were aggregated into themes related to “organizational and regional capabilities” The third analytical stage entailed the conceptual integration of these themes into aggregate dimensions derived from the study’s conceptual framework. This methodological approach enabled a straightforward and unambiguous correlation between empirical findings and theoretical constructs. These measures—along with reaching data saturation [48]—strengthen the credibility, dependability, and overall validity of the qualitative findings. Participants provided verbal informed consent for the use of anonymized quotations in publications; all identifying details were removed.

Interview data were managed and analyzed using MAXQDA 24 https://www.maxqda.com/ software, which facilitated systematic coding, thematic categorization, and visualization of results. Initial descriptive coding was conducted to identify patterns, followed by thematic categorization aligned with the conceptual framework. This study reports interview-level coverage (n/43; %) for all codes and mechanism → outcome co-occurrence (interviews where both appear). Two researchers double coded ~20% of transcripts (≈9/43) and reconciled discrepancies by discussion before finalizing the codebook. The unit of analysis is the interview; counts indicate salience in this corpus and are not used for statistical inference or causal interpretation (see Appendix B).

3.5. Validity, Reliability, and Trustworthiness

Several methodological procedures were implemented to enhance the validity, reliability, and trustworthiness of the qualitative findings [51]. Purposive sampling ensured that participant selection aligned with the study’s theoretical and practical requirements, mitigating biases related to narrow perspectives or homogeneous samples. Structured thematic analysis provided a transparent, theoretically coherent analytical process, reducing subjectivity. Reliability was further strengthened through intercoder reliability procedures, involving independent parallel coding followed by collaborative consensus-building discussions. Member checking procedures—sharing preliminary findings with selected participants—provided additional assurance regarding the accuracy, credibility, and representativeness of the results obtained. We acknowledge potential selection bias toward advanced settings and limit claims to analytical generalization.

3.6. Conceptual Framework

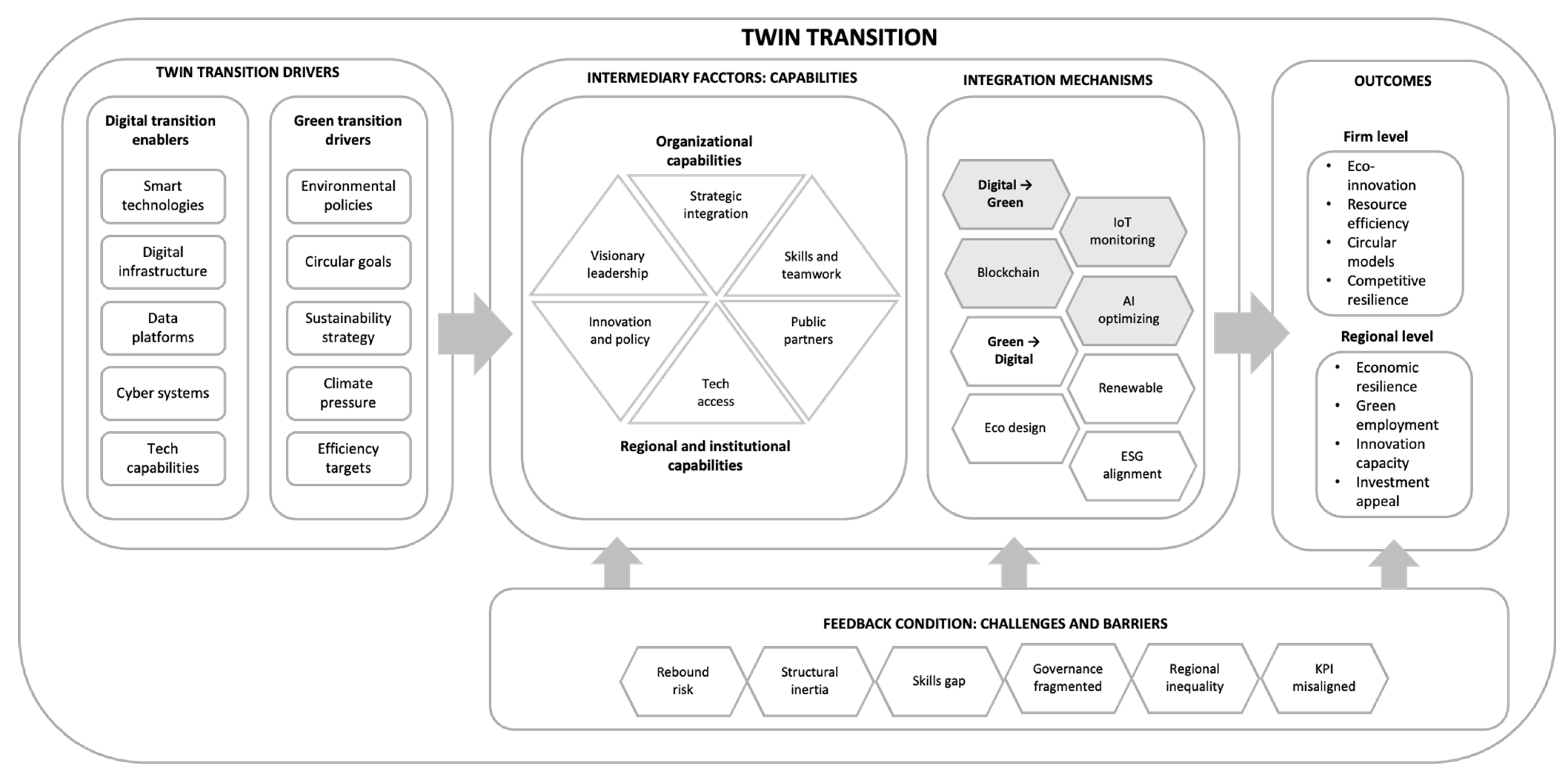

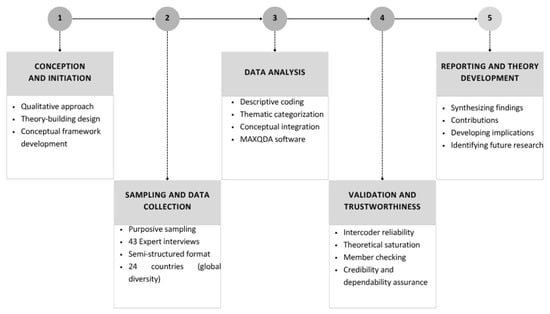

The conceptual approach is consistent with the guidelines for rigorous conceptual research [52] and is appropriate given the emerging nature of Industry 4.0 phenomena [11,20,21,22,31]. The conceptual framework (Figure 2) guided the entire methodological process, facilitating structured data collection and rigorous qualitative analysis. It conceptualizes the twin transition as a dynamic integrative process driven by digital enablers—such as smart technologies, data analytics platforms, and digital twins—and sustainability imperatives, including environmental regulations, circular economy practices, and stakeholder expectations. Central to the framework are organizational capabilities, including leadership, innovation policies, and workforce competencies, and regional institutional conditions, such as innovation ecosystems and public–private partnerships, that facilitate effective integration of digital technologies with sustainability objectives. Integration mechanisms highlighted within the framework include digital twins, IoT-based monitoring, blockchain transparency, and strategic alignment of digital initiatives with environmental, social, and governance (ESG) objectives. The framework acknowledges persistent barriers, such as internal organizational silos, rebound effects from resource-intensive digital technologies, fragmented governance structures, and regional disparities in innovation capacity, underscoring the need for integrated policy responses and aligned KPIs.

Figure 2.

Conceptual framework (Source: Authors).

4. Results

4.1. Drivers and Enabling Factors of the Twin Transition

Interviews show that the twin transition is driven mainly by competitiveness pressures and the need for operational resilience. Adopting advanced digital technologies—such as AI, IoT, robotics, cloud computing, and big data analytics—is essential for effectively responding to competitive pressures and operational challenges, especially in regions with higher labor costs. Highlighting this competitive imperative, one expert specifically noted: “We need to automate, we need to digitize so that we compete better against countries where the labor force is cheaper”. This directly illustrates how organizations view digitalization as more than mere technological upgrading, considering it a strategic necessity for achieving sustained competitiveness, productivity gains, and operational efficiency.

Additionally, the COVID-19 pandemic and subsequent global supply-chain disruptions acted as significant accelerators for digital technology adoption. Respondents underscored how these unprecedented crises exposed vulnerabilities in traditional manufacturing practices and prompted organizations to rapidly embrace digital solutions as essential tools for continuity and resilience. One interviewee explained: “COVID was positive from the perspective of increasing digitalization because it forced companies to adapt rapidly… previously hesitant firms now realized, ‘We need to do something’”. This highlights how external shocks served as catalysts for accelerated digital adoption, reshaping organizational strategies and underscoring digital technologies as foundational for sustained adaptability and resilience.

Another critical driver identified through our empirical analysis was the escalating importance of sustainability imperatives, including stringent environmental regulations, climate targets, and heightened stakeholder expectations. These imperatives increasingly shape firms’ digital strategies and technology adoption patterns. Digital technologies such as IoT sensors for emissions monitoring, blockchain applications for traceability, and AI-driven analytics for environmental management have become central to regulatory compliance and transparency. Reflecting this imperative, one respondent noted: “Sustainability has become critical because new regulations are forcing small- and medium-sized enterprises (SMEs) in the supply chain of large firms to report their emissions. They are now compelled to implement digital tools for compliance purposes”. This demonstrates how regulatory pressures and stakeholder expectations are directly influencing organizational decisions to integrate digital technologies with sustainability performance and environmental outcomes.

Finally, our findings emphasize that organizations increasingly recognize digital transformation and sustainability as mutually reinforcing and interconnected strategies, rather than separate initiatives. Investments in digital technologies are no longer evaluated solely on operational efficiency or cost reduction, but on their contribution to sustainability goals, such as reducing energy consumption, emissions, and waste. Capturing this strategic integration, one expert emphasized: “Companies must understand that digital transformation and sustainability are interconnected, and they need to invest in both simultaneously if they want to stay competitive”. This integrated strategic perspective represents a significant reorientation, aligning technological advancement with ecological sustainability. Moreover, the findings underscore key enabling factors—such as clear organizational leadership, targeted workforce development, robust innovation ecosystems, and supportive regional institutional contexts—as essential for successfully navigating and realizing the comprehensive benefits of the twin transition.

4.2. Organizational and Regional Factors Shaping Twin Transition Success

Interview findings highlight that robust internal organizational capabilities, particularly leadership commitment and strategic clarity, significantly shape the successful integration of digital transformation and sustainability initiatives. Respondents frequently underscored the critical role of leadership in articulating a vision that connects digital and sustainability objectives. Effective leaders not only set strategic direction but also mobilize necessary internal resources and overcome organizational silos. As one expert specifically emphasized: “The leader must be convinced by digitalization and innovation; otherwise, there is no hope of changing the mindset of the organization”. This highlights leadership as not merely symbolic but crucial for ensuring internal alignment, enabling effective implementation of combined digital-sustainability strategies.

Another critical internal capability identified by respondents involves workforce competencies and skills alignment. Firms often struggle with a mismatch between existing employee skills and those required for integrating advanced digital technologies into sustainability projects. Interviewees consistently highlighted that gaps in specialized skills—such as those needed for IoT integration, AI analytics, and sustainability management—represent significant barriers limiting successful digital-sustainability integration. One interviewee addressed this challenge, stating: “We can have excellent digital skills, but without the sustainability know-how, we cannot properly align our digital tools with environmental goals”. This underscores the necessity of not only advanced digital competencies but also their integration with sustainability-specific skills for achieving comprehensive twin-transition outcomes.

Furthermore, our findings reveal that external regional conditions influence the effectiveness of twin-transition strategies. Interviewees frequently emphasized the importance of robust regional innovation ecosystems—characterized by close collaboration among industry, academia, research institutions, and public entities—as essential for lowering barriers and accelerating innovation diffusion, particularly among SMEs. Regional clusters, innovation hubs, shared technological infrastructures, and demonstration centers emerged as critical elements supporting digital adoption and sustainability integration. Reflecting on this regional dynamic, one expert explained: “SMEs often hesitate because of high costs and uncertainty; regional ecosystems offering collaborative platforms and shared technology resources significantly lower these barriers, making ambitious projects possible”. This highlights how supportive regional ecosystems play an instrumental role in fostering organizational confidence and enabling effective digital-sustainability transitions.

Regional context shapes the twin transition via three channels: (i) institutional depth and infrastructure, (ii) global value-chain compliance exposure, and (iii) energy-mix constraints. In peripheral/rural regions, the binding constraints are infrastructural and integrative—connectivity, interoperability, and brownfield ERP/operational technology (OT) integration—slowing diffusion despite strong intent. Among developing-country suppliers tied to regulated buyers, Scope 3/Digital Product Passport (DPP) compliance acts as the immediate adoption trigger; the bottlenecks are upfront cost and skills, not willingness. In fossil-heavy grids, digital rollouts risk rebound unless paired with renewable procurement and device circularity. Table A3 in appendix synthesizes these contrasts and anchors them in the evidence base with representative quotations.

Respondents consistently indicated the critical importance of regional institutional frameworks, policy environments, and supportive public governance structures as enabling factors for successful twin transitions. Firms operating within regions characterized by coherent institutional support, targeted subsidies, incentives, and structured public–private partnerships benefit from accelerated and sustained integration of digital and sustainability initiatives. Conversely, respondents described fragmented institutional contexts and insufficient regional support as significant impediments to effective implementation. One interviewee emphasized: “Public institutions providing partial funding or subsidies significantly reduce uncertainties and encourage adoption among smaller enterprises”. Thus, the findings indicate that comprehensive organizational capabilities, combined with favorable regional contexts and supportive institutional frameworks, constitute critical determinants shaping the overall success and strategic effectiveness of the twin transition.

4.3. Effective Integration Mechanisms Through Technological Synergies and Strategic Alignment

Empirical findings from our interviews indicate that effective integration between digital transformation and sustainability is contingent upon strategically leveraging synergies inherent in advanced Industry 4.0 technologies. Respondents consistently emphasized that technologies such as AI, the IoT, blockchain, digital twins, robotics, and big data analytics are increasingly deployed not merely for productivity improvements, but specifically for enhancing sustainability outcomes. For instance, firms have leveraged AI-driven predictive analytics and IoT-based monitoring systems to optimize resource utilization, reduce energy consumption, and decrease waste generation. One interviewee specifically highlighted: “AI helps us optimize energy use, detect inefficiencies quickly, and significantly reduce our environmental footprint. It’s central to how we achieve both economic efficiency and sustainability”. This demonstrates how digital technologies directly enable improved sustainability performance through targeted environmental optimization.

A particular example of these synergies emerged from the adoption of digital twins in manufacturing processes. Interviewees described digital twins as sophisticated virtual replicas allowing comprehensive simulations and lifecycle analyses without the resource-intensive demands of physical prototypes. This digital simulation approach not only accelerates innovation cycles but reduces physical resource use, emissions, and waste throughout the product lifecycle. A respondent articulated this: “Imagine simulating an entire product lifecycle without a single physical prototype—testing new biomaterials, zero-carbon processes digitally, and then launching only proven, sustainable solutions. That’s what digital twins enable us to do”. This capability underscores how digital twins function as critical tools enabling sustainability objectives, significantly reducing the environmental impact of innovation processes.

Across the 43 interviews, the most frequently mentioned integration mechanisms were AI & analytics (43/43; 100.0%), digital twins/simulation (43/43; 100.0%), IoT & monitoring (34/43; 79.1%), blockchain & traceability (29/43; 67.4%), and additive/3D printing (25/43; 58.1%) (Table 2). These figures are consistent with the drivers emphasized by participants—competitive pressure/cost and regulation & stakeholder pressure—and with the capabilities most often cited—workforce skills/training, cross-functional integration, and regional ecosystem/policy support (Table 2).

Table 2.

Theme prevalence across 43 interviews (respondent coverage).

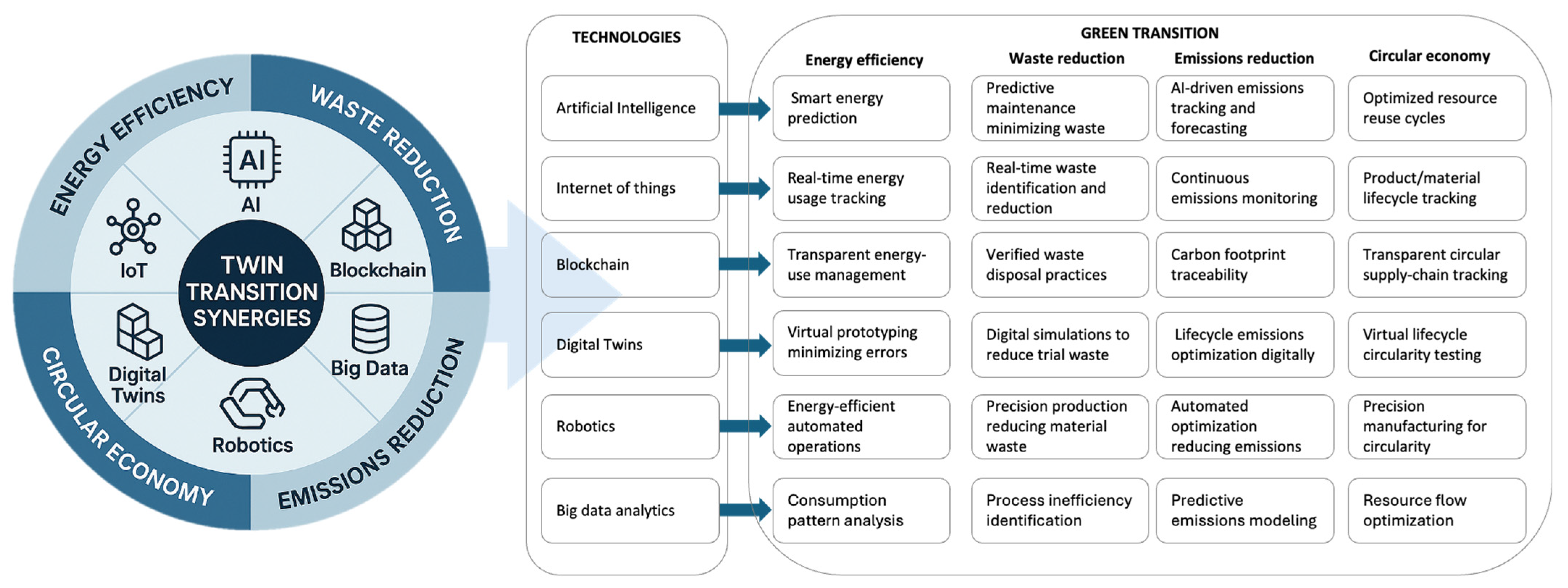

Co-occurrence analysis indicates frequent co-mentions between specific mechanisms and the outcome “Eco-innovation/environmental performance”. In interviews, AI & analytics co-occur with the outcome in 39/43 (90.7%), digital twins/simulation in 38/43 (88.4%), IoT & monitoring in 31/43 (72.1%), blockchain & traceability in 17/43 (39.6%), and additive/3D printing in 14/43 (32.5%) (Table 3). Because the outcome itself appears in 39/43 interviews, these mechanisms are regularly co-mentioned: AI 39/39, digital twins 38/39, IoT 31/39, blockchain 17/39, and additive/3D printing 14/39. These are descriptive patterns of salience rather than statistical associations. These quantitative patterns structure and reinforce the qualitative pathways discussed above and are visualized in Figure 3 (synergy matrix). Operational definitions, inclusion/exclusion rules, and representative interview excerpts for all codes are provided in (Table A2).

Table 3.

Mechanism → Outcome co-occurrence (interviews with both mentioned).

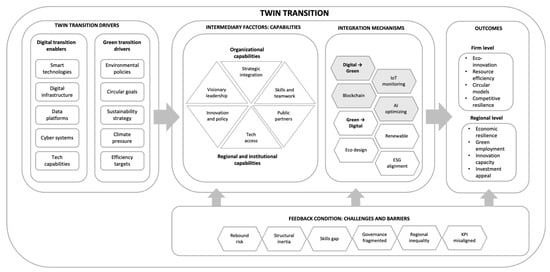

Figure 3.

Technology–sustainability synergy matrix (Source: Authors).

These findings are visually summarized in Figure 3, which provides a comprehensive illustration of specific strategic synergies between key Industry 4.0 digital technologies and targeted sustainability outcomes: energy efficiency, waste reduction, emissions reduction, and circular economy implementation. The matrix in Figure 3 highlights practical applications and associated benefits of each technology, demonstrating how firms and regions strategically leverage these digital tools to achieve sustainability objectives. For example, blockchain technologies facilitate robust supply-chain transparency, thereby supporting circular economy practices and emissions reduction through verifiable resource flows. Similarly, big data analytics enable predictive modeling for consumption patterns and emissions management, crucial for proactive sustainability initiatives. This strategic alignment underscores how digital transformation pathways are directly integrated with sustainability goals, resulting in substantial environmental benefits and operational efficiencies.

Moreover, our interviews highlighted that successful integration relies on strategic alignment between digital investments and sustainability considerations. Respondents indicated that sustainability goals increasingly guide firms’ digital investment decisions. This shift is evident in practices such as establishing data centers powered by renewable energy, initiating product development guided by eco-design principles, and deploying IoT-based monitoring for sustainability compliance. One expert summarized this strategic reorientation: “Our investment decisions in digital technology now incorporate sustainability criteria. We evaluate digital projects not just for efficiency or productivity, but also their environmental contribution”. However, respondents also emphasized that the strength and effectiveness of these integration mechanisms are influenced by internal organizational alignment and external regional support structures. Firms characterized by strong internal collaboration across sustainability, operations, and IT departments reported more successful integration outcomes. Conversely, organizations facing internal silos and fragmented decision-making reported weaker synergies and missed opportunities. Additionally, supportive regional innovation ecosystems and coherent institutional frameworks significantly amplify the effectiveness of digital-sustainability integration. Therefore, achieving optimal integration requires not only leveraging technological synergies but also aligning internal organizational structures and benefiting from conducive regional innovation contexts.

4.4. Innovation Outcomes Enhancing Environmental Performance and Competitive Advantage

Interview findings reveal that effectively integrating digital transformation with sustainability strategies yields substantial innovation outcomes within firms, particularly by enhancing their eco-innovation capabilities. Organizations consistently reported improvements in resource efficiency, waste reduction, and adoption of circular economy practices, facilitated through integrated digital-sustainability approaches. One interviewee succinctly articulated this integration outcome, stating: “Implementing Industry 4.0 allows us not only to achieve higher productivity but also to significantly reduce waste generation and optimize resource utilization in ways previously not possible”. Firms deploying IoT solutions and advanced analytics specifically highlighted tangible gains in environmental performance, enabling them to meet stringent regulatory standards and capitalize on growing market demand for environmentally sustainable products and services.

Furthermore, respondents emphasized that successful twin-transition integration significantly enhances firms’ competitive positioning, particularly by fostering resilience and adaptability to market disruptions and regulatory shifts. The use of digital tools such as AI-driven predictive analytics and blockchain-enabled traceability systems was reported to markedly improve companies’ forecasting accuracy, supply-chain responsiveness, and regulatory compliance. Reflecting on the role of digital tools in enabling competitive advantage, one expert remarked: “Thanks to advanced analytics, we can better predict disruptions, trace products accurately, and swiftly adapt to regulatory changes. This capability makes us far more agile and resilient than competitors who have not integrated digital and sustainability strategies”. This indicates that digital-sustainability integration is perceived not merely as beneficial for environmental outcomes, but as strategically essential for maintaining and enhancing long-term competitive advantage in increasingly volatile market environments.

Moreover, our analysis indicates that the benefits of twin transition extend well beyond individual firms, significantly enhancing regional innovation capacities and broader economic resilience. Experts frequently highlighted that regions successfully integrating digital and sustainability innovations experience strengthened innovation ecosystems, increased spillover effects, and improved workforce competencies, subsequently attracting environmentally oriented investments. One respondent specifically highlighted this regional effect: “Regions that actively support twin transitions see clear benefits—more skilled jobs in digital analytics, sustainability management, and advanced manufacturing, alongside stronger innovation networks and clusters”. Such regional ecosystems act as hubs for knowledge exchange, collaborative innovation, and skill upgrading, amplifying regional competitiveness and innovation capabilities.

Additionally, respondents emphasized that regions embracing twin transitions are better positioned for sustained economic diversification and reduced vulnerability to environmental and market disruptions. Robust regional digital and green innovation networks were described as crucial for facilitating efficient diffusion of sustainable innovations, particularly benefiting SMEs that face higher barriers to technology adoption. One interviewee explained this dynamic: “Having strong regional support and innovation networks helps SMEs overcome technological adoption barriers. As a result, the entire region becomes more resilient, less dependent on unsustainable industries, and better able to attract new sustainable investments”. Consequently, regions demonstrating successful integration between digital transformation and sustainability initiatives are perceived as having enhanced long-term growth prospects and competitive resilience, rooted in strategically aligned digital and environmental innovation practices.

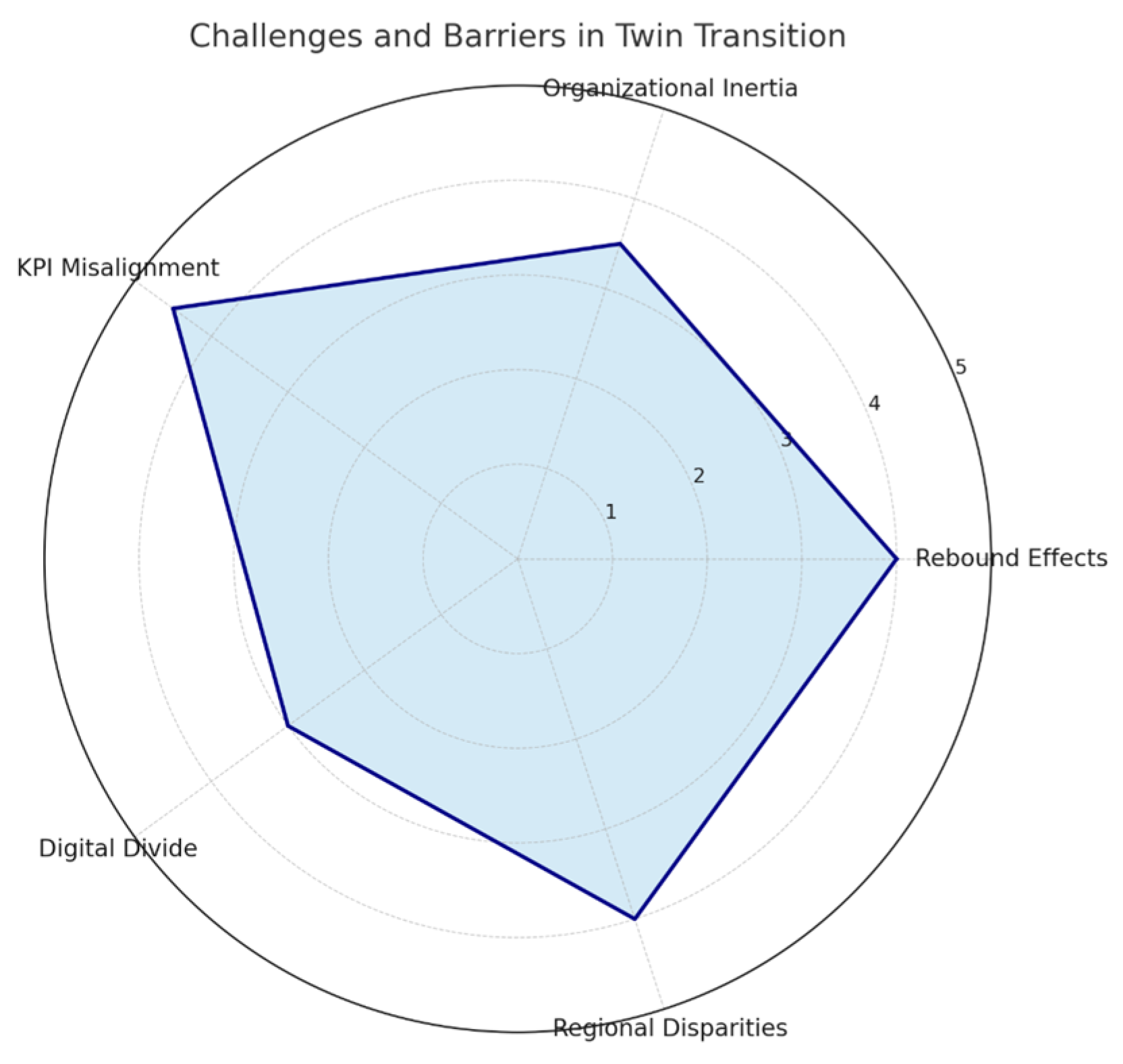

4.5. Persistent Barriers and Challenges in Implementing the Twin Transition

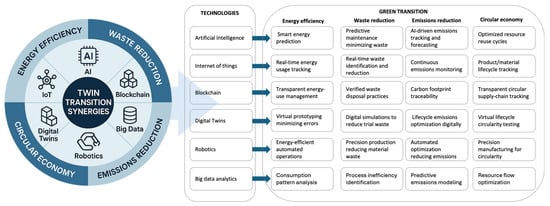

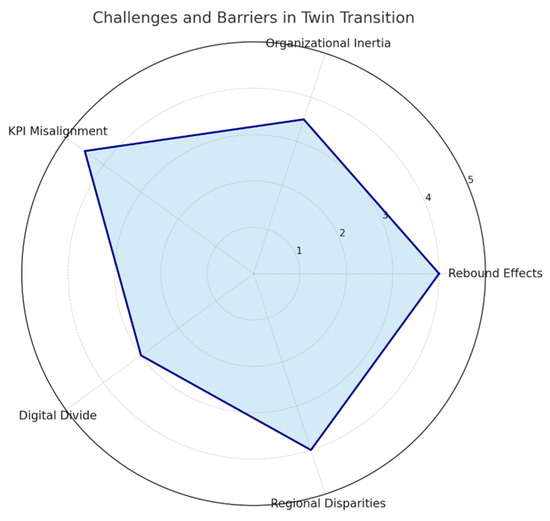

Despite the clear innovation potential and competitive advantages associated with integrating digital and sustainability strategies, our empirical findings highlight several persistent internal and external barriers that significantly challenge the effective implementation of the twin transition (Figure 4). Internally, organizational inertia and compartmentalized structures constitute substantial impediments. Interviewees frequently identified rigid departmental silos separating digital transformation and sustainability teams as key obstacles preventing cohesive strategic integration. One respondent highlighted this barrier, noting: “A big issue we see is internal silos—digital and sustainability teams don’t always talk to each other. It creates confusion, duplicated efforts, and missed opportunities”. Such internal fragmentation often leads firms to implement digital technologies without consideration of sustainability outcomes, limiting potential synergies and reducing overall strategic effectiveness.

Figure 4.

Challenges and barriers in twin transition (Source: Authors).

A further internal challenge identified is the misalignment of KPIs. Respondents consistently pointed to difficulties in aligning digital transformation objectives with sustainability performance metrics. Traditional organizational measurement systems, often focused predominantly on economic performance or standalone sustainability indicators, fail to capture fully the integrated value created by combining digital and environmental initiatives. One expert emphasized: “Our current KPIs don’t adequately measure the synergy between digital and sustainability efforts. This lack of integrated metrics makes it difficult for us to justify investments and track strategic success”. Such misalignment hampers organizational efforts to strategically manage and evaluate twin-transition initiatives, reducing transparency and effectiveness of integrated strategies.

In response to the KPI misalignment identified by interviewees, this paper distills a pragmatic protocol that links digital mechanisms to sustainability outcomes and specifies how to measure them. The protocol prioritizes mechanism→outcome pairs with strongest empirical co-occurrence (Table 3) and operationalizes them as auditable KPIs (Table 4). Managers begin by scoping goals, mapping mechanisms to outcomes, defining formulas and data sources, and then attaching these KPIs to project stage-gates to prevent “digital without environmental value.”

Table 4.

Integrated KPI library linking digital mechanisms to sustainability outcomes.

Another barrier identified through our interviews was the rebound effect associated with digital technologies. While digitalization generally enhances operational efficiency and supports sustainability objectives, respondents expressed concerns that the proliferation of digital infrastructure—such as data centers, IoT devices, blockchain systems, and big data platforms—may paradoxically increase overall energy consumption and resource demands, potentially undermining sustainability gains if not adequately managed. One respondent articulated this concern: “If digitalization is not matched with renewable energy sources and strong recycling practices, it may end up creating more environmental problems than it solves”. This indicates a substantial risk that, without intentional strategic alignment of digital infrastructure with sustainability goals such as renewable energy use and circular economy practices, digital initiatives may inadvertently exacerbate environmental challenges rather than resolving them.

Externally, pronounced regional disparities represent another significant barrier complicating effective twin-transition implementation. Interviewees consistently highlighted that regions differ considerably in digital infrastructure, innovation capabilities, institutional frameworks, and support mechanisms. These disparities favor regions already well-equipped with strong innovation ecosystems and robust public–private collaboration structures, while peripheral or less-developed regions face disproportionately greater challenges and slower progress. One expert illustrated this challenge: “There is a clear innovation gap. Well-developed urban regions benefit from strong support and innovation ecosystems, but smaller, peripheral regions lack these, severely limiting their ability to adopt digital and sustainability innovations”. Such disparities in regional contexts create uneven conditions for firms, reinforcing innovation gaps and potentially exacerbating broader economic disparities, thus posing clear challenges for equitable and widespread implementation of twin-transition strategies.

5. Discussion

This research contributes to existing scholarship by providing detailed empirical evidence on the critical drivers and enabling factors underpinning successful integration of digital transformation and sustainability—the “twin transition.” While earlier studies have broadly highlighted the strategic importance of digital technologies, such as AI, IoT, robotics, and big data analytics, as catalysts for innovation and competitiveness [1,3,23], this study provides novel empirical insights revealing how competitive pressures and external shocks like COVID-19 significantly accelerate digital adoption. This aligns with [16,23], who also recognized that external disruptions catalyze digital innovation, yet our findings extend existing understanding by highlighting the critical role of leadership clarity and strategic commitment in rapidly achieving digital-sustainability integration.

Furthermore, our research highlights surprising findings regarding internal organizational challenges, particularly the misalignment of KPIs and internal compartmentalization, which have previously received insufficient empirical attention. While prior literature broadly acknowledged these barriers conceptually [2,3,45], our detailed interviews reveal how firms experience these challenges practically, limiting effective integration outcomes. Notably, the recognition by respondents that traditional organizational measurement systems inadequately capture the integrated value of digital-sustainability synergies provides clear novel insights, challenging conventional assumptions and highlighting the urgent need for integrated performance metrics aligned with strategic sustainability objectives.

Another surprising empirical insight emerged around the rebound effects of digitalization, corroborating concerns raised in previous conceptual and quantitative analyses [2,16,41]. Rebound effects, regional disparities, organizational inertia [53], and the digital divide [54], emphasize the complexity and multi-dimensional nature of successfully executing integrated digital-sustainability strategies. Respondents highlighted that without pairing digital infrastructure investments with renewable energy sources, digital transformation may paradoxically exacerbate environmental challenges rather than resolving them. This finding underscores a critical tension previously identified conceptually but inadequately explored empirically, providing clear evidence that strategies addressing energy and resource impacts must accompany digital-sustainability initiatives to ensure genuine sustainability outcomes.

Supported by prior research, our findings also confirmed the critical importance of regional innovation ecosystems, supportive institutional frameworks, and public–private partnerships as decisive external enabling conditions for effective twin-transition implementation. These findings align with regional studies by [54], which similarly identified regional disparities and supportive contexts as critical determinants of digital-sustainability integration success. However, our study extends this understanding by demonstrating empirically how regional contexts interact with internal organizational capabilities, determining effectiveness and strategic alignment of integrated innovation initiatives. The clear evidence of regional innovation gaps provided by our interviews emphasizes the need for targeted regional policy interventions aimed at reducing innovation disparities and enabling widespread twin-transition adoption.

Finally, our research contributes novel empirical insights into the mechanisms through which digital technologies support sustainability objectives. Specifically, the detailed empirical evidence gathered highlights digital twins, blockchain-based traceability, IoT-based monitoring, and AI-driven analytics as instrumental in achieving substantial environmental performance improvements and operational efficiencies. These empirical insights substantiate prior conceptual arguments by [1,30,55], but advance understanding by demonstrating how strategic alignment guides technology investment decisions and innovation strategies. This strategic shift, identified through detailed empirical evidence, redefines innovation priorities, aligning technological advancement with ecological sustainability, thus providing clear novel insights relevant for both managerial practice and policy formulation related to facilitating effective digital-sustainability integration in organizational and regional contexts.

6. Conclusions, Implications, Limitations and Future Research

6.1. Conclusions

This paper analyzes the twin transition, highlighting the strategic integration of digital transformation and sustainability as a pathway for fostering innovation and sustainable growth. Drawing on empirical insights from 43 expert interviews, the study presents five key findings. First, the twin transition effectively combines advanced digital technologies—including AI, the IoT, robotics, and big data analytics—with sustainability objectives, redefining innovation priorities towards environmental outcomes. Second, internal organizational capabilities such as strategic leadership clarity and workforce competencies, coupled with external regional conditions like robust innovation ecosystems and effective partnerships, significantly influence successful implementation. Third, strategically leveraging technological synergies, notably digital twins for lifecycle optimization and blockchain for enhanced transparency, results in substantial improvements in resource efficiency and environmental performance. Fourth, the effective integration of digital and sustainability strategies yields notable organizational and regional benefits, including enhanced eco-innovation, competitive resilience, and strengthened regional economic stability. Finally, persistent challenges—such as organizational fragmentation, digital rebound effects, and pronounced regional disparities—continue to hinder effective implementation, underscoring the need for coordinated organizational strategies, integrated KPIs, and supportive collaborative ecosystems to overcome these barriers.

6.2. Theoretical Implications

This study enhances theoretical insights into the twin transition by providing a detailed empirical analysis of how digital transformation and sustainability initiatives intersect to generate innovation outcomes. First, it clarifies the symbiotic relationship between digital technologies and sustainability, demonstrating that Industry 4.0 innovations inherently serve dual purposes—enhancing efficiency and supporting environmental objectives. Second, the findings advance innovation theory by highlighting internal organizational capabilities, notably strategic leadership clarity and workforce competencies, as critical enablers of effective twin-transition integration. Third, the research expands theoretical frameworks by incorporating regional contextual conditions—including innovation ecosystems and institutional support—illustrating their direct influence on firm-level outcomes and broader regional innovation dynamics. Fourth, by detailing technological synergies, specifically digital twins and blockchain-enabled transparency solutions, the study contributes novel theoretical insights into how strategic technological alignment facilitates environmental sustainability. Finally, the identification of significant barriers, such as rebound effects from digitalization, organizational fragmentation, and pronounced regional disparities, enriches transition theory by acknowledging the multi-level constraints that organizations and regions encounter. Together, these contributions reinforce a holistic and integrative theoretical understanding of innovation transitions.

6.3. Policy and Managerial Implications

This study offers significant implications for policymakers and managers seeking to adeptly navigate the dual transition of concurrently driving digitalization and sustainability transformations. Figure 5 presents a strategic roadmap offering clear guidance for policymakers and managers to sequentially implement integrated digital-sustainability strategies, thereby facilitating sustainable innovation and strengthening organizational resilience and regional competitiveness.

Figure 5.

Roadmap for twin transition (Source: Authors).

A design protocol for integrated digital–sustainability key performance indicators (DS-KPIs): Drawing on the interview evidence and the mechanism → outcome links (Table 2 and Table 3), this paper proposes a seven-step protocol: (1) Scope and materiality—fix the system boundary (site/business unit [BU]/company), functional unit (e.g., per unit, per euro of revenue), and material topics (energy, emissions, waste, circularity). (2) Map mechanisms to outcomes—use Table 2 to select high-leverage pairs (e.g., artificial intelligence [AI]→energy/emissions; digital twins → waste). (3) Select KPIs with a clear taxonomy—for each pair, choose 1–2 outcome key performance indicators (e.g., kilograms of carbon-dioxide equivalent per unit [kg CO2e/unit]) and one enabler/process KPI (e.g., sensor coverage %). (4) Define formulas & boundaries—state numerator and denominator, normalization, Greenhouse Gas (GHG) Protocol scopes and units, and list exclusions. (5) Data architecture and quality—name source systems (Internet of Things [IoT]; energy-management system [EMS]; enterprise resource planning [ERP]; product lifecycle management [PLM]; life-cycle assessment [LCA]), reporting cadence, and data-quality thresholds (completeness, timeliness). (6) Baselines & targets—set a 12-month baseline and science- or policy-aligned targets, documenting attribution to the digital intervention. (7) Governance & assurance—attach KPIs to project stage-gates, assign a RACI matrix (Responsible, Accountable, Consulted, Informed), audit quarterly, and review rebound metrics (information-technology energy [IT energy], electronic waste [e-waste]). We operationalize this protocol in Table 4, which provides an illustrative DS-KPI roster by mechanism → outcome with definitions, formulas/units, boundaries, data sources, and governance fields.

From a policy perspective, governments and regional authorities must develop integrated frameworks that concurrently incentivize digital and sustainable innovations. It is imperative for policies to transcend the confines of isolated digital or environmental agendas, evolving into strategies that are meticulously designed to capitalize on the synergies inherent in these domains. In practice, this could entail the introduction of joint incentives, such as subsidies or tax relief, for digital technologies aimed at enhancing environmental performance. Examples of such technologies include AI-based resource optimization and blockchain-based carbon traceability solutions. Furthermore, policies that fortify regional innovation ecosystems through targeted infrastructure investments, public–private partnerships, and knowledge-sharing platforms are imperative. The existence of such supportive ecosystems will help mitigate regional disparities and accelerate the broad diffusion of integrated digital-sustainability innovations, particularly benefiting SMEs that often lack the resources to independently pursue ambitious twin-transition projects.

The findings underscore the critical importance of internal strategic clarity and robust cross-functional collaboration for managers in achieving twin-transition objectives. It is incumbent upon organizational leaders to articulate and systematically their vision for integrated digital sustainability and to align strategic investments with sustainability goals. This strategic alignment can be operationalized through the adoption of integrated KPIs that concurrently measure digital performance and sustainability impacts. The adoption of these KPIs would provide clear metrics for evaluating progress and justifying investments. Furthermore, it is imperative for managers to prioritize initiatives that foster combined digital and sustainability competencies within the workforce. This will enhance an organization’s capacity to leverage Industry 4.0 technologies effectively for achieving sustainability outcomes. Finally, it is imperative for managers to exercise vigilance regarding potential rebound effects and proactively incorporate sustainability measures within digital transformation strategies. This may entail prioritizing the procurement of renewable energy for digital infrastructures and enforcing robust recycling and reuse practices for digital devices. By proactively overseeing these intricate interrelations, enterprises can optimize the synergies between digital transformation and sustainability, thereby fortifying their competitive edge and long-term resilience in the face of evolving regulatory and market dynamics.

6.4. Limitations and Future Research

Notwithstanding its theoretical and managerial contributions, this study has limitations. The qualitative expert-interview design and purposive sampling limit statistical generalizability; interviews were not stratified or weighted, and key-informant/self-report bias is possible despite anonymization and member checking. Reported counts are descriptive rather than causal; mechanism→outcome links structure the findings but do not identify effects. The design is cross-sectional, restricting temporal inference. Regional contrasts in Table A3 are a cross-case synthesis rather than matched comparative case studies and should be interpreted as analytic generalization, not population estimates. The DS-KPI protocol and Table 4 are illustrative design guidance, not a validated metric set. Finally, we do not quantify rebound effects (IT energy, embodied materials, e-waste) with metered/LCA data.

These boundaries suggest a clear agenda for future work: (i) quantitative validation of mechanism→outcome links using firm-level microdata (surveys linked to operational/EMS/LCA telemetry) and quasi-experimental designs around digital rollouts or regulatory shocks; (ii) longitudinal panels to track how capabilities, governance, KPIs, and outcomes co-evolve; (iii) matched comparative cases to deepen regional heterogeneity (developed vs. developing, urban vs. rural, cluster vs. peripheral), integrating multi-level governance; (iv) DS-KPI protocol trials—sector-specific piloting, reliability/assurance testing, and boundary-condition checks (energy mix, firm size, GVC position); and (v) rebound quantification that couples metered IT/OT energy and asset lifecycles with carbon-aware operations and circular device management. Together, these steps would extend the qualitative insights offered here into robust, generalizable evidence for managers and policymakers.

Funding

This research received no external funding.

Institutional Review Board Statement

Ethical review and approval were waived for this study. Under France’s Public Health Code, Article R1121-1, research requiring review by a Comité de protection des personnes (CPP) is limited to studies organized on humans for the development of biological or medical knowledge.

Informed Consent Statement

Verbal informed consent was obtained from all participants. Interviews were recorded with permission, then transcribed and anonymized before analysis; no directly identifying personal data were retained in the study dataset.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The author declares no conflicts of interest.

Appendix A

Table A1.

Profile of participants.

Table A1.

Profile of participants.

| Participant | Type | Country | Participant | Type | Country | Participant | Type | Country |

|---|---|---|---|---|---|---|---|---|

| 1 | Researcher | Croatia | 16 | Practitioner | Morocco | 31 | Researcher | Hungary |

| 2 | Researcher | Germany | 17 | Practitioner | Kenya | 32 | Researcher | Switzerland |

| 3 | Researcher and Consultant | Mexico | 18 | Practitioner | Morocco | 33 | Researcher | Serbia |

| 4 | Practitioner | France | 19 | Consultant | Brazil | 34 | Researcher | Italy |

| 5 | Practitioner | Tunisia | 20 | Consultant | Brazil | 35 | Researcher | Argentina |

| 6 | Practitioner | Malaysia | 21 | Practitioner | Germany | 36 | Researcher | Argentina |

| 7 | Practitioner | Malaysia | 22 | Consultant and Practitioner | Cameroon | 37 | Researcher | United Arab Emirates |

| 8 | Consultant and Practitioner | Saudi Arabia | 23 | Practitioner | India | 38 | Researcher | Spain |

| 9 | Practitioner | Switzerland | 24 | Practitioner | Switzerland | 39 | Researcher | Japan |

| 10 | Practitioner | Switzerland | 25 | Consultant and Practitioner | Switzerland | 40 | Researcher | Australia |

| 11 | Practitioner | Switzerland | 26 | Researcher | United States | 41 | Practitioner | India |

| 12 | Consultant | Brazil | 27 | Researcher | Sweden | 42 | Researcher | China |

| 13 | Researcher | South Korea | 28 | Researcher | Brazil | 43 | Practitioner | Austria |

| 14 | Practitioner | Greece | 29 | Researcher | Brazil | |||

| 15 | Practitioner | Switzerland | 30 | Researcher | Germany |

Appendix B. Codebook (Families, Second-Order Codes, Criteria, and Excerpts)

Purpose. The codebook operationalizes the constructs used in Section 4.1, Section 4.2, Section 4.3, Section 4.4 and Section 4.5. Each entry lists a concise definition, inclusion/exclusion guidance, example indicators (terms/phrases), and a short, anonymized excerpt.

Table A2.

Codebook used in the analysis.

Table A2.

Codebook used in the analysis.

| Family | Second-Order Code | Definition | Include/Exclude (Decision Rule) | Typical Indicators | Representative Excerpt * |

|---|---|---|---|---|---|

| Drivers | Competitive pressure/cost | Market or cost imperatives motivating digital + green adoption | Include: productivity, unit cost, competitiveness; Exclude: generic “innovation is good” | compete, productivity, cost, efficiency | “We need to automate; we need to digitize so that we compete better against countries where the labor force is cheaper.” |

| External shocks/disruptions | Adoption accelerated by crisis or supply shocks | Include: COVID-19, shortages; Exclude: long-run macro trends | COVID, disruption, supply chain | “COVID was positive from the perspective of increasing digitalization because it forced companies to adapt rapidly… previously hesitant firms now realized, ‘We need to do something.’” | |

| Regulation & stakeholder pressure | Compliance/ESG and customer demands shaping adoption | Include: reporting, standards, scope-3; Exclude: internal policy only | ESG reporting, compliance, standard | “Sustainability has become critical because new regulations are forcing SMEs… to report their emissions… compelled to implement digital tools for compliance.” | |

| Capabilities (org./regional) | Leadership & vision | Executive commitment linking digital and sustainability | Include: strategy/vision; Exclude: ad hoc enthusiasm | leadership, vision, strategy | “The leader must be convinced by digitalization and innovation; otherwise, there is no hope of changing the mindset of the organization.” |

| Workforce skills & training | Skills to execute integration | Include: reskill/upskill; Exclude: generic talent shortage | training, skills, competence | “We can have excellent digital skills, but without the sustainability know-how, we cannot properly align our digital tools with environmental goals.” | |

| Cross-functional integration | IT/OT–sustainability coordination and anti-silo work | Include: joint teams, shared OKRs; Exclude: single team wins | cross-functional, alignment | “A big issue we see is internal silos—digital and sustainability teams don’t always talk to each other. It creates confusion, duplicated efforts, and missed opportunities.” | |

| Regional ecosystems & policy support | Clusters, testbeds, subsidies, PPPs | Include: shared infra, grants; Exclude: single-firm funding only | ecosystem, subsidy, testbed | “Public institutions providing partial funding or subsidies significantly reduce uncertainties and encourage adoption among smaller enterprises.” | |

| Integration mechanisms | AI & analytics | Optimization/forecasting directly tied to sustainability | Include: energy/waste/emissions optimization; Exclude: purely commercial analytics | predictive, optimization, analytics | “AI helps us optimize energy use, detect inefficiencies quickly, and significantly reduce our environmental footprint. It’s central to how we achieve both economic efficiency and sustainability.” |

| IoT & monitoring | Sensorization enabling real-time sustainability metrics | Include: energy/emissions/waste monitoring; Exclude: telemetry without sustainability linkage | sensor, monitoring, IoT | “…had sensors on their paper cutters that would actually measure the torque on the blades that were cutting paper.” | |

| Digital twins/simulation | Virtualization to test low-impact designs and processes | Include: lifecycle/process twins; Exclude: 2D CAD only | digital twin, simulation | “Imagine simulating an entire product lifecycle without a single physical prototype—testing new biomaterials, zero-carbon processes digitally, and then launching only proven, sustainable solutions. That’s what digital twins enable us to do.” | |

| Blockchain & traceability | Ledger-based transparency for circularity/compliance | Include: material passports, scope-3 trace; Exclude: crypto use without traceability | Traceab *, material passport, blockchain | “…you need to maintain the digital product passport for four owners over 50 years.” | |

| Additive/3D printing | AM reducing waste/material; on-demand fabrication | Include: scrap reduction, light-weighting; Exclude: prototyping without sustainability link | 3D printing, additive | “You print on demand.” | |

| Outcomes (granular) | Energy efficiency/intensity | kWh per unit, load curves, energy savings | Include: kWh/unit, PUE; Exclude: vague “savings” | energy, kWh, efficiency | “…how much energy we are using per piece, so we can really calculate the footprint of one particular product.” |

| Waste reduction/scrap/yield | Material scrap, defect rates, FPY | Include: scrap %, FPY; Exclude: quality mentions without waste | scrap, waste, yield | “Waste can be reduced by 60%.” | |

| Emissions management/CO2 | GHG/CO2 intensity or absolute emissions | Include: CO2/unit, scopes; Exclude: non-quantified green claims | CO2, emission, GHG | “…identified around 300 million data points to connect to in order to fulfill scope one, two and three.” | |

| Circularity & traceability | Reuse, returns, passports, reverse logistics | Include: material IDs, take-back; Exclude: generic “recycling is good” | Circular *, passport, traceab * | “…you can give them a second life later on, if you can recycle or remanufacture or refurbish or repurpose them.” | |

| Outcomes | Eco-innovation/environmental performance | Aggregate environmental performance gains | Include: cleaner processes, eco-innovation; Exclude: commercial benefits only | eco-innovation, environmental | “Implementing Industry 4.0 allows us not only to achieve higher productivity but also to significantly reduce waste generation and optimize resource utilization in ways previously not possible.” |

| Competitive advantage/market | Market performance/resilience outcomes | Include: agility, lead-time, compliance agility; Exclude: cost alone | advantage, lead time, delivery | “Thanks to advanced analytics, we can better predict disruptions, trace products accurately, and swiftly adapt to regulatory changes. This capability makes us far more agile and resilient than competitors who have not integrated digital and sustainability strategies.” | |

| Barriers | Organizational silos/inertia | Fragmented governance obstructing integration | Include: siloed teams; Exclude: culture in general | silo, fragment, inertia | “A big issue we see is internal silos—digital and sustainability teams don’t always talk to each other. It creates confusion, duplicated efforts, and missed opportunities.” |

| KPI misalignment | Metrics fail to capture digital–sustainability synergy | Include: missing eco-KPIs in digital projects; Exclude: cost KPIs alone | KPI, indicator, measure | “Our current KPIs don’t adequately measure the synergy between digital and sustainability efforts. This lack of integrated metrics makes it difficult for us to justify investments and track strategic success.” | |

| Rebound/energy & resource burden | Digital loads increase energy/material impacts | Include: compute, e-waste; Exclude: cost-only mentions | data center, compute, e-waste | “If digitalization is not matched with renewable energy sources and strong recycling practices, it may end up creating more environmental problems than it solves.” | |

| Cost & investment constraints | Capex/ROI hurdles | Include: budgets, payback; Exclude: macro price trends | capex, budget, payback | “…any single technology is tremendously cost still for SMEs, and even for large companies.” | |

| Infrastructure/integration gaps | Connectivity, legacy systems, ERP integration | Include: broadband gaps, brownfield integration; Exclude: hiring problems | connectivity, legacy, ERP | “…firstly, invest on the connectivity, real data collection, interoperability, where to store data, industrial networks—many technologies should be integrated.” |

* Excerpts are verbatim from the anonymized interview transcripts. Alignment notes. Leadership & vision is coded and discussed in Section 4.2 but not tabulated in Table 2 for brevity. Table 2 reports only two barrier codes (Cost & investment constraints; Infrastructure/integration gaps); the full barrier set appears here for completeness.

Table A3.

Regional contexts and twin-transition contrasts (evidence-based synthesis).

Table A3.

Regional contexts and twin-transition contrasts (evidence-based synthesis).

| Regional Context (Examples) | Institutional & Infrastructure Conditions | Adoption Drivers (Dominant Triggers) | Binding Constraints (Primary Barriers) | Typical Integration Pattern (Mechanisms & Scope) | Representative Quote | Policy/Managerial Levers (Actionable) |

|---|---|---|---|---|---|---|

| Advanced urban innovation clusters | Dense university–industry links, DIHs/testbeds, grants/subsidies, high-quality connectivity, strong integrator/vendor base | Competitive pressure; ESG leadership; customer transparency demands | KPI misalignment; IT–sustainability silos; change-management frictions | Full-stack AI+IoT at plant scale; digital twins for lifecycle/process; blockchain/DPP for scope-3; renewable-powered data infra | “Public institutions providing partial funding or subsidies significantly reduce uncertainties and encourage adoption among smaller enterprises.” | Tie co-funding to integrated KPIs; cross-functional OKRs; DPP sandboxes; workforce up/re-skilling programs |

| Peripheral/rural industrial regions (brownfield sites) | Patchy broadband; legacy OT/ERP; few DIHs/shared labs | Cost and yield pressure; energy-efficiency mandates; buyer requests for basic telemetry | Connectivity gaps; interoperability with legacy; CAPEX and skills shortages | IoT metering & energy dashboards first; targeted AI on bottlenecks; pilot digital twins on single lines; traceability for priority SKUs | “…firstly, invest on the connectivity, real data collection, interoperability, where to store data, industrial networks—many technologies should be integrated.” | Backbone connectivity & edge gateways; vendor-neutral interoperability standards; SME innovation vouchers; shared regional testbeds |

| Developing-country suppliers in global value chains (GVCs) | Uneven digital infra; thin support programs; limited concessional finance | Scope-3/DPP compliance to keep export access; OEM audits; market entry | Up-front cost; skills & tooling; standards uncertainty; vendor lock-in risk | Traceability-first (blockchain/DPP) plus basic IoT monitoring; cloud reporting; AI added later for quality/energy | “Sustainability has become critical because new regulations are forcing SMEs… to report their emissions… [they are] compelled to implement digital tools for compliance.” | Buyer–supplier co-investment; concessional loans/guarantees; templated data models; regional competence centers for compliance |

| Fossil-heavy grids/energy-constrained contexts | Coal/gas-biased grids; DC power/water limits; weak e-waste systems | Efficiency/cost focus; rising scrutiny on energy and carbon | Rebound risk from compute/IoT; high energy intensity; device lifecycle impacts | Edge AI & demand response; compute budgets/model efficiency; virtual-first twins; device circularity & take-back | “If digitalization is not matched with renewable energy sources and strong recycling practices, it may end up creating more environmental problems than it solves.” | Green PPAs/RECs; low-power architectures; heat-recovery at sites; device repair/reuse mandates; e-waste stewardship |

Notes (abbreviations): AI = Artificial Intelligence; IoT = Internet of Things; DIH = Digital Innovation Hub; KPI = Key Performance Indicator; IT = Information Technology; ESG = Environmental, Social & Governance; DPP = Digital Product Passport; Scope-3 = value-chain emissions under the GHG Protocol; OT = Operational Technology; ERP = Enterprise Resource Planning; CAPEX = Capital Expenditure; SKU = Stock-Keeping Unit; SME = Small and Medium-sized Enterprise; GVC = Global Value Chain; OEM = Original Equipment Manufacturer; DC = Data Center; OKR = Objectives and Key Results; PPA = Power Purchase Agreement; REC = Renewable Energy Certificate.

References

- Aiello, F.; Cozzucoli, P.C.; Mannarino, L.; Pupo, V. Bayesian insights on digitalization and environmental sustainability practices: Towards the twin transition in the EU. Bus. Strategy Environ. 2024, 34, 417–432. [Google Scholar] [CrossRef]

- Gao, X. The EU’s Twin Transitions towards Sustainability and Digital Leadership: A Coherent or Fragmented Policy Field? Reg. Stud. 2025, 59, 2360053. [Google Scholar] [CrossRef]

- Montresor, S.; Vezzani, A. Digital Technologies and Eco-Innovation: Evidence of the Twin Transition from Italian Firms. Ind. Innov. 2023, 30, 766–800. [Google Scholar] [CrossRef]

- European Commission. A New Industrial Strategy for Europe; COM/2020/102 Final; European Commission: Brussels, Belgium, 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52020DC0102 (accessed on 21 July 2025).

- European Commission. ‘Fit for 55’: Delivering the EU’s 2030 Climate Target on the Way to Climate Neutrality; COM/2021/550 Final; European Commission: Brussels, Belgium, 2021. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52021DC0550 (accessed on 21 July 2025).